Evend SOLID AS 6x6, SOLID AS 6x8, SOLID AS 6x10, SOLID AS 6x12 Service Manual

EBA Sp. z o.o.

ul. Popiełuszki 86

38-401 Krosno, PL

evend@evend.com.pl

www.evend.com.pl

tel. +48 13 436 19 61

Service

Manual

Spring Operated Automatic Vending Machine

SOLID

AS 6x6

AS 6x8

AS 6x10

AS 6x12

VENDING MACHINE

Evend is a brand of Polish

vending machines produced by

EBA Sp.z o.o. a company with

long tradition of industrial

production, strong position on

the Polish and international

market and a company that

promotes the development and

innovative technology.

VENDING MACHINE

Dear Customer

Thank you for purchasing our spring operated automatic vending machine and congratulations

on a good choice. This service manual allows you to become familiarized with the operation,

start-up and proper maintenance of the machine. The information contained concerns

particular functions and a method of their use. You should carefully read the following

recommendations and warnings, before starting installation.

VENDING MACHINE

VENDING MACHINE

Table of contents

VENDING MACHINE

5

1. Information ...................................................................................................................... 7

1.1. Equipment .................................................................................................................. 7

1.2. Specifications ............................................................................................................. 7

1.3. External structure of automatic machine ..................................................................... 8

1.4. Internal structure of automatic machine ...................................................................... 8

1.5. Assembly .................................................................................................................... 9

1.6. Power supply. Electric box. ........................................................................................10

1.7. Display.......................................................................................................................12

1.8. Drawers .....................................................................................................................13

1.9. Springs ......................................................................................................................14

1.10. Gear motors.............................................................................................................16

1.11. Payment device ................................................................................................ .......17

1.12. Maintenance and cleaning operations. Hygiene .......................................................17

1.13. Transport .................................................................................................................18

1.14. Additional equipment ...............................................................................................18

2. Main board. Automatic machine configuration ............................................................19

2.1. Main board ................................................................................................................19

2.2.1. Main board components .....................................................................................19

2.2.2. Main board connector with pin description ..........................................................20

2.3. Main board menu .......................................................................................................21

2.3.1. Prices .................................................................................................................22

2.3.2. Statistics .............................................................................................................23

2.3.3. Automatic machine setting ..................................................................................23

2.3.5. Accessories ........................................................................................................25

2.3.6. Communication ...................................................................................................26

2.3.7. Test ....................................................................................................................27

2.3.8. Failures ...............................................................................................................28

3. Refrigerating unit ...........................................................................................................29

3.1. Refrigerating unit construction ...................................................................................29

3.2. Refrigerating unit disassembly procedure ..................................................................29

3.3. PJEZS0H000 temperature controller .........................................................................31

3.3.1. Controller's front panel ........................................................................................31

3.3.2. Controller's back panel ........................................................................................32

3.3.3. Functions of controller .........................................................................................32

3.4. Automatic machine refrigeration unit cautions............................................................33

4. Environment protection .................................................................................................34

5. Warranty ..........................................................................................................................35

VENDING MACHINE

6

Information

VENDING MACHINE

7

1. Information

1.1. Equipment

The spring-operated automatic vending

machine is the equipment used for the

automatic sell of the packed products in

controlled temperature. The drink and snack

type products can be stored in it.

The automatic machine is built of three

chambers. Refrigerating unit is placed in the

first, the products in the second and a control

block in the third one.

The products are visible through a double, low

emission glazing. A purchase of the product can

be made by means of a keyboard and a

payment device. All operations are clearly

visible on a graphical display. The purchased

product can be collected from a product release

pocket. Distribution servos are controlled by a

main board with a microprocessor. It enables

programming and modification of the automatic

machine performance.

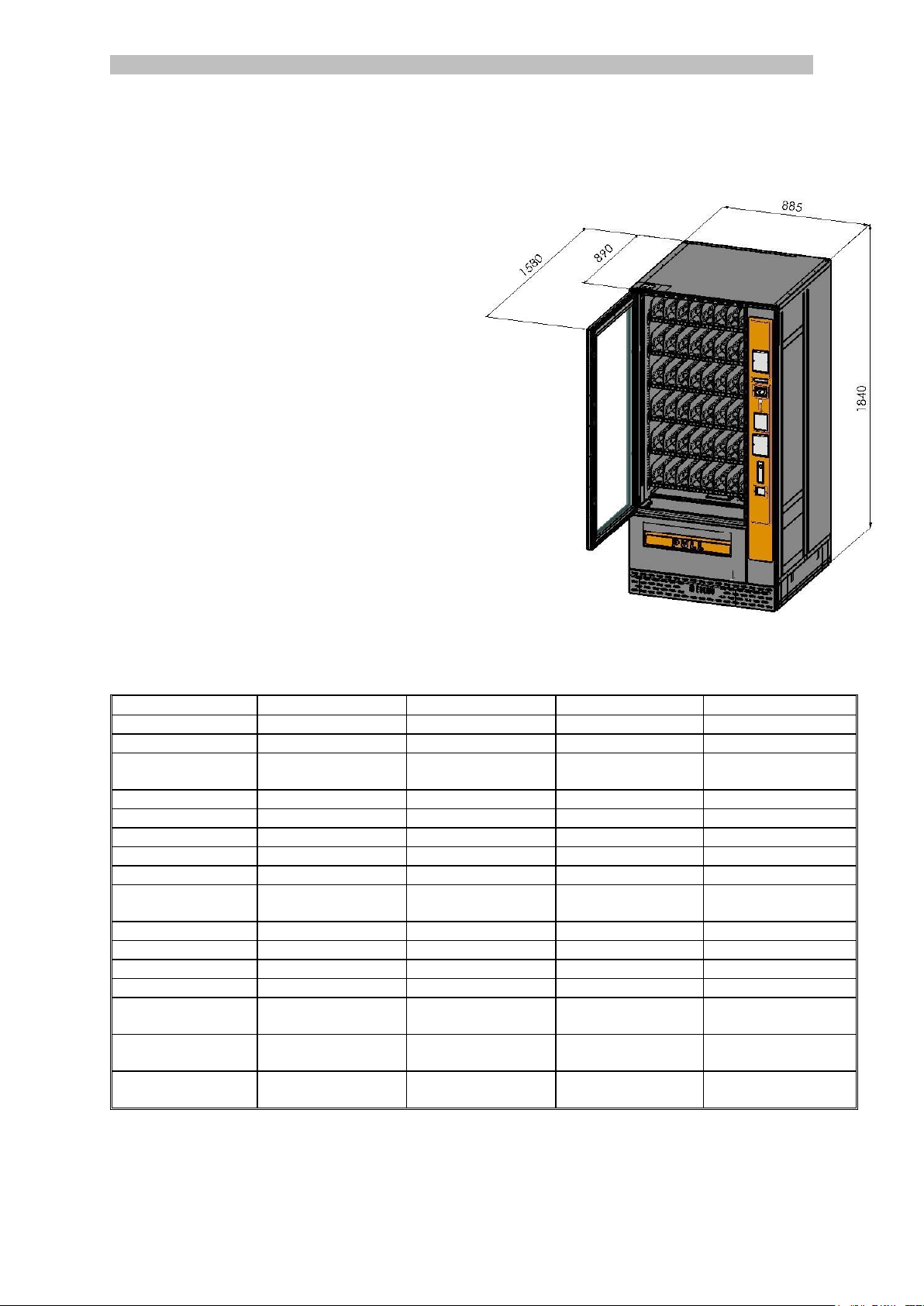

Fig.1 Spring-operated automatic

machine AS6x8 with parameters

1.2. Specifications

AS6x6

AS6x8

AS6x10

AS 6x12

Height

1840mm

1840mm

1840mm

1840mm

Width

737mm

885mm

1032mm

1185mm

Depth / ( with

doors opened)

890mm /

(1430mm)

890mm /

(1580mm)

890mm /

(1727mm)

890mm / (1865mm)

Weight

290 kg

320 kg

350 kg

390 kg

Supply

230 V

230 V

230 V

230 V

Frequency

50 Hz

50 Hz

50 Hz

50 Hz

Power

400 W

600 W

600 W

600 W

Ambient temp.

from +9° to +26°C

from +9° to +26°C

from +9° to +26°C

from +9° to +26°C

Max. Relative

humidity

60%

60%

60%

60%

Payments system

MDB

MDB

MDB

MDB

Coolant

Refrigerating unit

Refrigerating unit

Refrigerating unit

Refrigerating unit

Defrosting

Automatic, Manual

Automatic, Manual

Automatic, Manual

Automatic, Manual

Refrigerant

R507

R507

R507

R507

Max. drawer

number

6 6 6

6

Numer of springs

30 single,

3 double

40 single,

4 double

50 single,

5 double

60 single,

6 double

Operating

temperature

od +7°C do +20°C

od +7°C do +20°C

od +7°C do +20°C

od +7°C do +20°C

Information

VENDING MACHINE

8

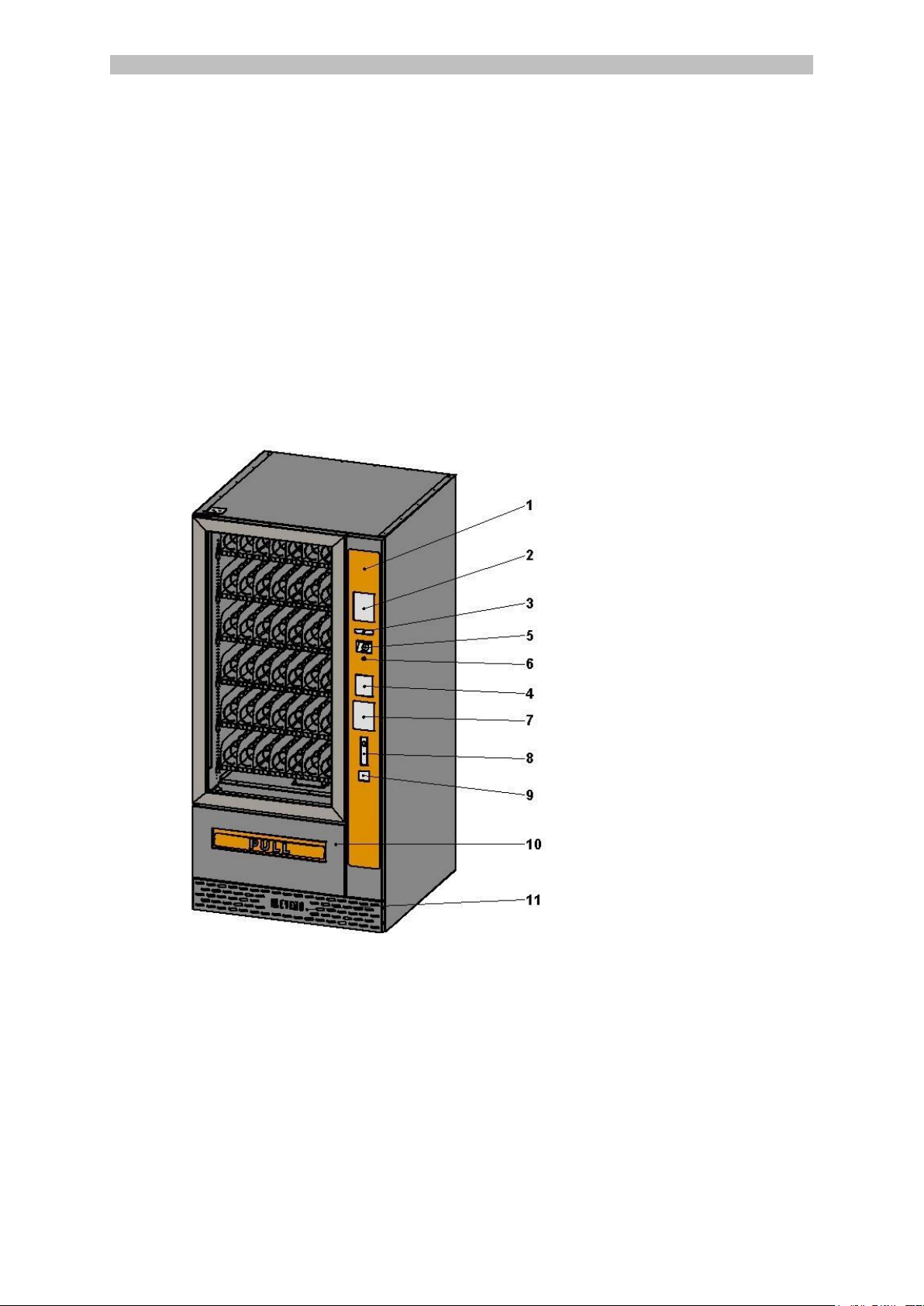

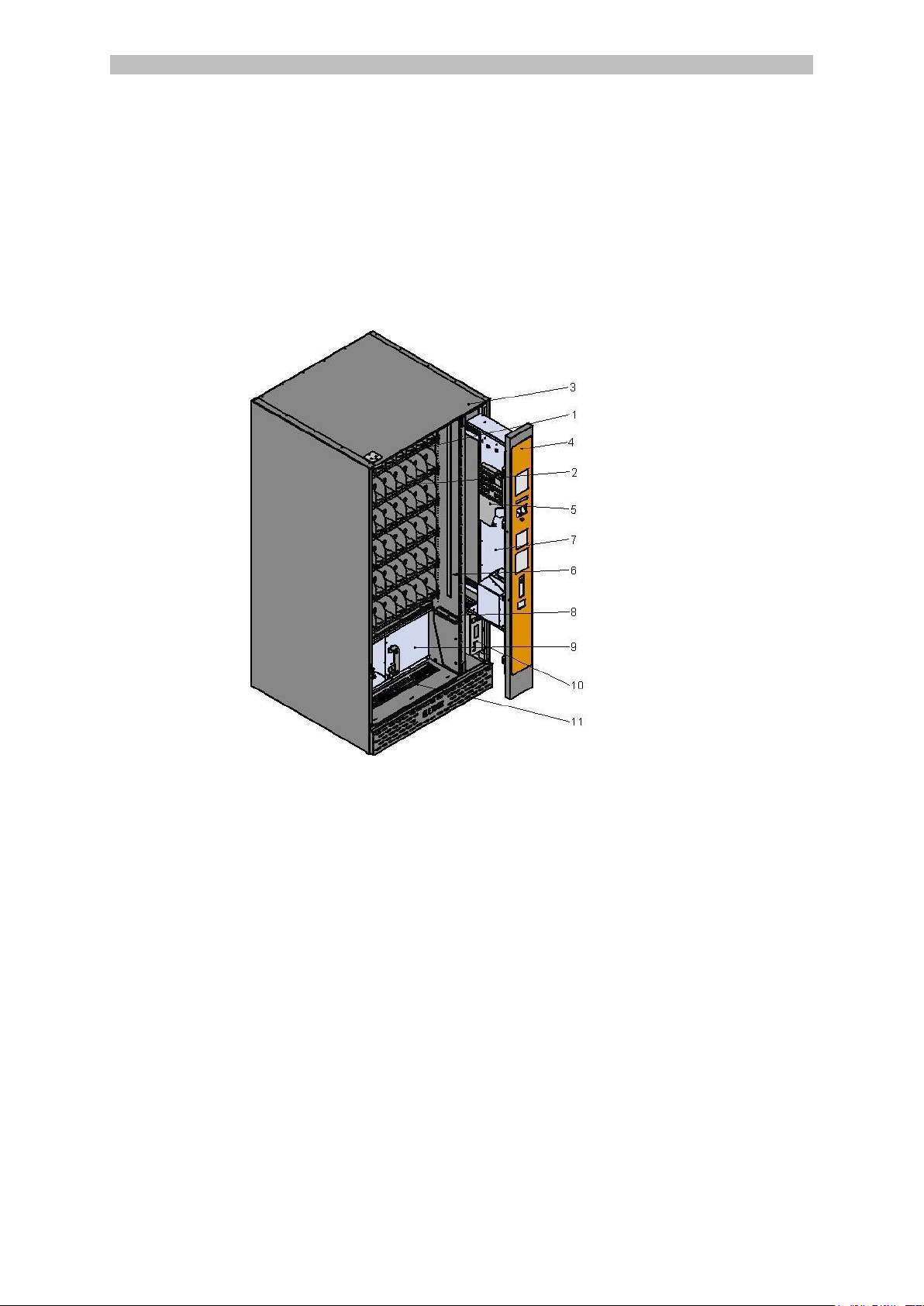

1.3. External structure of automatic machine

1. Loudspeaker with motion sensor /optional/.

2. Banknotes accepter /optional/.

3. LCD display.

4. Numeric keyboard – used by customers to select a product and by an operator for the

automatic machine servicing and programming.

5. Coin intake.

6. Withdrawal button – pressing the button results in a return of the thrown in coins from

a coin mechanism before purchase of goods /the function depends on the coin

mechanism setting.

7. Proximity card reader. RFID.

8. Lock – used to open and close main doors and control panel.

9. Coin return – receipt of a change and not accepted coins.

10. Product collection pocket – receipt of the purchased goods.

11. Front grill.

Fig.2 External structure of automatic machine

1.4. Internal structure of automatic machine

1. Spring operated drawers – used for storage and sell of products.

2. Product number and price display /optional/.

3. Hotspot Wi-Fi. /optional/.

4. Sense & Talk. Speaking system. Lighting change /optional/.

5. Main board with microprocessor - enables programming and modification of the

automatic machine performance.

6. LED lighting . /optional LED RGB/.

7. Mains connector - /optional/.

Information

VENDING MACHINE

9

8. Payment device – used to make payments.

9. Photocell – used for product release detection.

10. Refrigerating unit – responsible for proper temperature maintenance in the product

chamber.

11. Electric box with thermoregulator. The thermoregulator is a programmable controller

enabling direct control of the refrigerating unit.

12. Refrigerating unit filter.

Fig.3 Internal structure of automatic

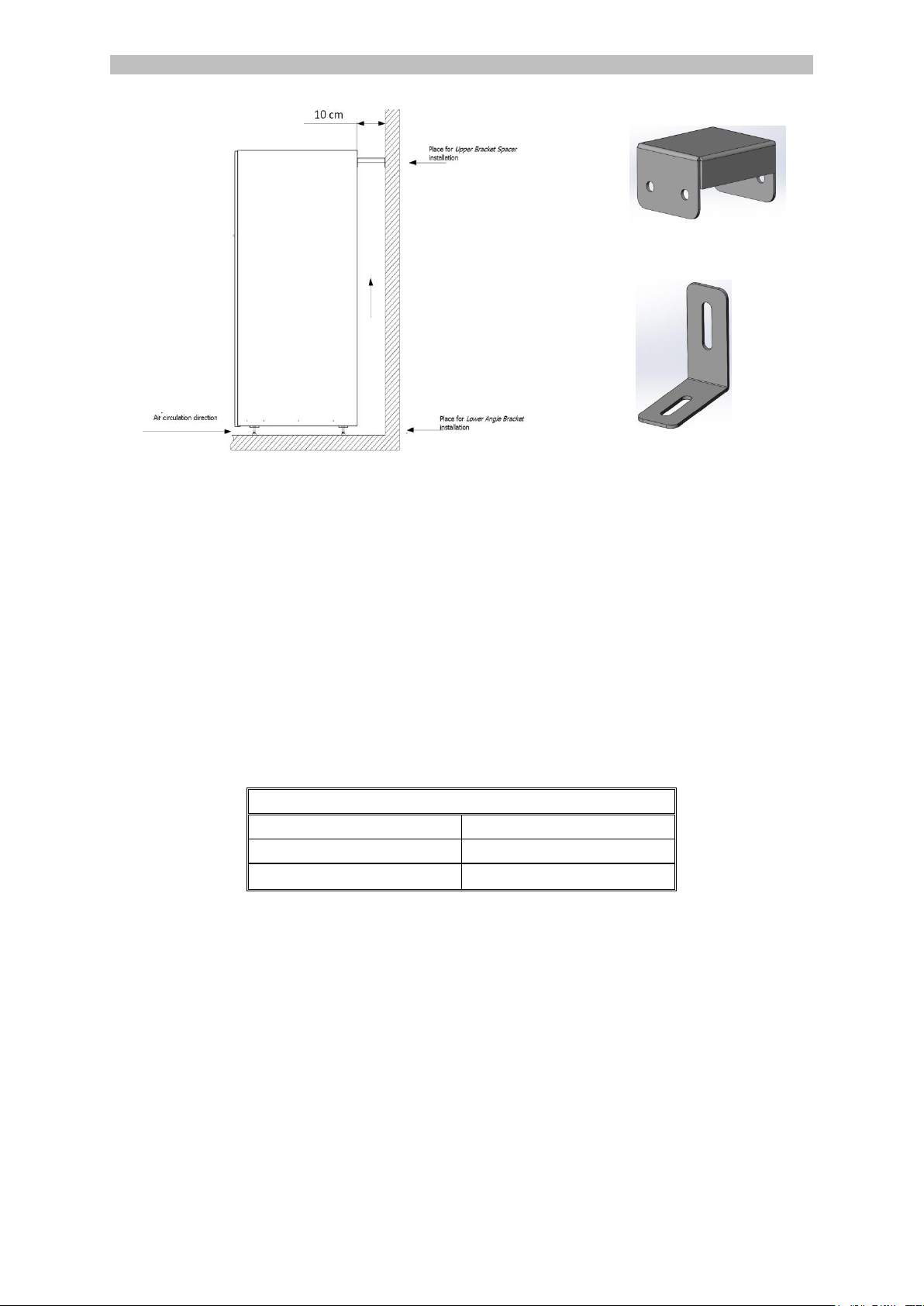

1.5. Assembly

The automatic machine is designed for indoor operation. The automatic machine must not be

installed near intensive heat sources or water sprinklers. Before the installation make sure that

the front glass is not subject to a direct effect of the sun’s rays. The machine operates properly

in the temperature range from 9°C to 26°C and the humidity not exceeding 60%.

In order to ensure a proper circulation, areas of air change shall be left free (front and back of

the machine) (Fig.4). A distance between the machine and a wall shall not be less than 10 cm.

It is recommended to apply the Upper Bracket Spacer (Fig.5). Where necessary the automatic

machine can be fixed to a substrate with the Lower Angle Bracket (Fig.6),delivered with the

machine, screwed into the machine feet.

Information

VENDING MACHINE

10

Fig.5 Upper Bracket Spacer

Fig.4 Proper machine installation Fig.6 Lower Angle Bracket

The machine should be properly levelled. The lower machine feet should be used for that. The

real machine dimensions (door opened, easy access) should be taken into consideration in

planning distributor layout.

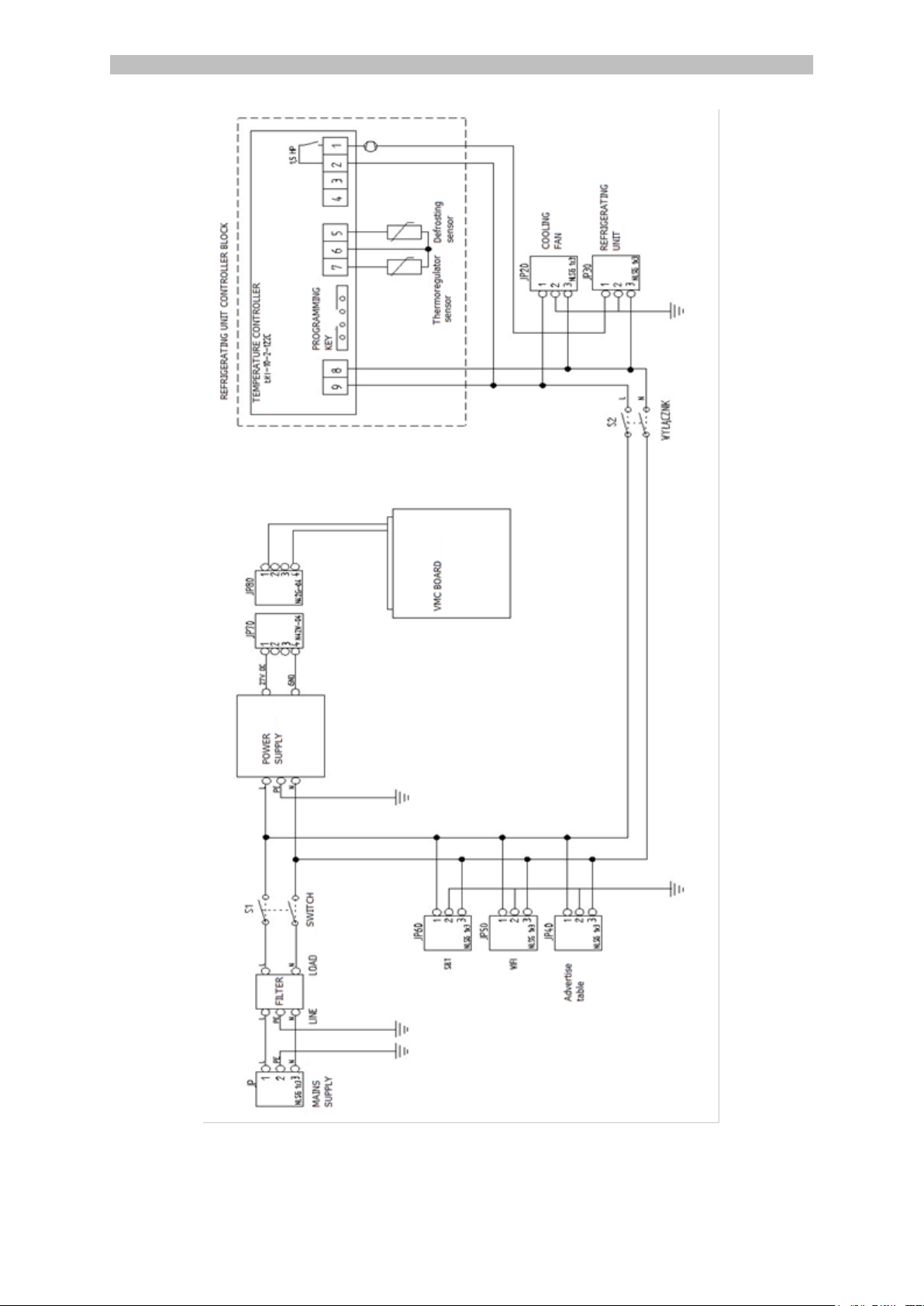

1.6. Power supply. Electric box.

The machine is supplied with the electric cable with plug for connection to 230V power network.

Before making the electricity connection we need to ensure that the socket the machine will

be connected to meets the standard requirements as well as verify the grounding integrity. An

annual verification is strictly recommended.

The supply connections inside the machine shall not be modified.

Supply indications

Brown

Phase

Blue

Neutral

Green-yellow

Protective

Power consumption:

The measurement was performed at the ambient temperature maximum 30°C, the refrigerating

chamber temperature 10°C , the temperature of loaded products (with the machine empty)

less than the ambient temperature. The power consumption for one day (24 hours) is 6kWh

( for AS 6x8).

Information

VENDING MACHINE

11

Fig.7 Block diagram of the automatic machine supply

Loading...

Loading...