Page 1

Open this leaflet for calibration/testing/maintenance

instructions.

Changing Batteries

1. Open battery

compartment

lid (with

attached

lanyard loop).

2. Remove old

batteries;

replace

with fresh

ones. Note

polarity as

shown in battery compartment. See Diagram 1.

3. Recalibrate after battery change.

INC

+

+

DEC

Diagram 1

Warranty

Eutech Instruments warrants its meter free from

manufacturing defects for 2 years and electrode

module for 6 months. If r epair, adjustment or

replacement is necessary and has not been the result

of abuse or misuse within the time period, please

return the tester – freight prepaid – and correction

will be made without charge. Out of warranty products

will be repaired on a charge basis.

Return Of Items

Authorization must be obtained from Eutech’s

distributor before returning items for any reason.

When applying for authorization, please include

information regarding the reason the item(s) are to

be returned.

Note: We reserve the right to make improvements in

design, construction and appearance of products

without notice. Prices are subject to change without

notice.

• Waterproof & Floats

• Replaceable Electrode

• Auto-off

• Automatic Temperature

Compensation (ATC)

Page 2

Waterproof ECScan High Instructions

Before You Begin

Remove electrode cap. Soak electrode for a few

minutes in alcohol to remove oils.

Calibration

Tester is factory calibrated. However, to ensure

accuracy, calibrate conductivity on a regular basis.

Select a calibration standard appropriate for the

ECScan High tester (between 2.00 mS and

19.90 mS). It is best to select a standard close

to the test solution value.

1. Open battery compar tment lid (end with

lanyard loop).

2. Orientate the battery compar tment as

shown in Diagram 1.

3. Rinse electrode in deionized water, then

rinse it in calibration standard, then dip it

into a container of calibration standard.

4. Switch unit on (ON/OFF key). Wait

several minutes for display to stabilize.

5. Press the INC or DEC key to adjust

reading to match the calibration

standard value.

6. After 3 seconds without a key press,

the display flashes 3 times, then

shows ‘ENT’. The tester accepts

calibration value; returns to

measurement mode.

7. Replace battery cap.

Conductivity Testing

1. Remove electrode cap. Switch unit on (ON/OFF

key).

2. Dip electrode into test solution. Make sure sensor

is fully covered.

3. Wait for reading to stabilize (Automatic

Temperature Compensation corrects for

temperature changes). Note reading.

4. Press ON/OFF to turn off tester. Replace electrode

cap. Note: Tester automatically shuts off after

8.5 minutes of non-use.

HOLD Function

Press HOLD key to freeze display. Press HOLD again

to release.

Tester Maintenance

• To improve performance, clean the electrode

by rinsing them in alcohol for 10 to 15 minutes.

• Replace all batteries if low battery indicator

appears, or if readings are faint or unstable.

• If you experience drift, periodically let electrode

fully dry.

When you need a new electrode, see “Electrode

Replacement” on insert in back of box.

Self-Diagnostic MessagesSelf-Diagnostic Messages

Self-Diagnostic Messages

Self-Diagnostic MessagesSelf-Diagnostic Messages

bAt Weak batteries–replace with fresh ones specified

by manufacturer .

Err Wrong keypress.

Or, Ur Over range/Under range signal, or electrode

is not in contact with solution, or electrode is failing.

---- Calibration mode activated but not performed.

68X247755 11/00 Rev 0

Page 3

Open this leaflet for calibration/testing/maintenance

instructions.

Changing Batteries

1. Open battery

compartment

lid (with

attached

lanyard loop).

2. Remove old

batteries;

replace with

fresh ones.

Note polarity

as shown in

battery compartment. See Diagram 1.

3. Recalibrate after battery change.

INC

+

+

DEC

Diagram 1

Warranty

Eutech Instruments warrants its meter free from

manufacturing defects for 2 years and electrode

module for 6 months. If repair, adjustment or

replacement is necessary and has not been the result

of abuse or misuse within the time period, please

return the tester – freight prepaid – and correction

will be made without charge. Out of warranty products

will be repaired on a charge basis.

Return Of Items

Authorization must be obtained from Eutech’s

distributor before returning items for any reason.

When applying for authorization, please include

information regarding the reason the item(s) are to

be returned.

Note: We reserve the right to make improvements in

design, construction and appearance of products

without notice. Prices are subject to change without

notice.

• Waterproof & Floats

• Replaceable Electrode

• Auto-off

• Automatic Temperature

Compensation (ATC)

Page 4

Waterproof ECScan Low Instructions

Before You Begin

Remove electrode cap. Soak electrode for a few

minutes in alcohol to remove oils.

Calibration

Tester is factory calibrated. However, to ensure

accuracy, calibrate conductivity on a regular basis.

Select a calibration standard appropriate for the

ECScan Low tester (between 200 µS and

1990 µS). It is best to select a standard close

to the test solution value.

1. Open battery compar tment lid (end with

lanyard loop).

2. Orientate the battery compar tment as

shown in Diagram 1.

3. Rinse electrode in deionized water, then

rinse it in calibration standard, then dip it

into a container of calibration standard.

4. Switch unit on (ON/OFF key). Wait

several minutes for display to stabilize.

5. Press the INC or DEC key to adjust

reading to match the calibration

standard value.

6. After 3 seconds without a key

press, the display flashes 3 times,

then shows ‘ENT’. The tester accepts

calibration value; returns to

measurement mode.

7. Replace battery cap.

Conductivity Testing

1. Remove electrode cap. Switch unit on (ON/OFF

key).

2. Dip electrode into test solution. Make sure

sensor is fully covered.

3. Wait for reading to stabilize (Automatic

Temperature Compensation corrects for

temperature changes). Note reading.

4. Press ON/OFF to turn off tester. Replace

electrode cap. Note: Tester automatically

shuts off after 8.5 minutes of non-use.

HOLD Function

Press HOLD key to freeze display. Press HOLD again

to release.

Tester Maintenance

••

• To improve performance, clean the electrode

••

by rinsing them in alcohol for 10 to 15 minutes.

• Replace all batteries if low battery indicator

appears, or if readings are faint or unstable.

• If you experience drift, periodically let electrode

fully dry.

When you need a new electrode, see “Electrode

Replacement” on insert in back of box.

Self-Diagnostic MessagesSelf-Diagnostic Messages

Self-Diagnostic Messages

Self-Diagnostic MessagesSelf-Diagnostic Messages

bAt Weak batteries–replace with fresh ones

specified by manufacturer.

Err Wrong keypress.

Or, Ur Over range/Under range signal, or electrode

is not in contact with solution, or electrode is failing.

---- Calibration mode activated but not performed.

68X247754 11/00 Rev 0

Page 5

Twist-off

Battery

Compartment

Lanyard

connection

Replaceable

Sensor

• Push-button calibration

• Fast, stable, repeatable readings

• Available through authorized distributors

SPECIFICATIONS

Tester TDScan TDScan ECScan ECScan

Range 0 to 0 to 0 to 0 to

Resolution 10 0.10 10 0.10

Accuracy ±1% Full Scale

TDS factor 0.4 to 1.0 selectable Calibration 200 to 2 .00 to 200 to 2.00 to

Standard 1990 10.00 1990 19.90

Range ppm ppt µS/cm mS/cm

Calibration 1 point (calibration range is ±30%

ATC 0 to 50 °C

Temp 2% per °C

Coefficient

Operating 0 to 50 °C

Temp

Power Four X 1.5V

Battery (Type: A76, LR 44 or V136A);

Dimension; Tester: 16.5 cm x 3.8 cm; 90 g

Weight Boxed: 22 cm x6 cm x 5 cm; 170 g

Low High Low High

1990 10.00 1990 19.90

ppm ppt µS/cm mS/cm

ppm ppt µS/cm mS/cm

of factory default parameter)

> 140 hrs continuous use

Manufactured By:

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah Crescent,

#04-14/24, Singapore 139949

Tel: (65)778 6876 Fax: (65)773 0836

E-Mail: marketing@eutechinst.com

Web-Site: http://www.eutechinst.com

Made in Singapore

68X247828 11/00 Rev 0

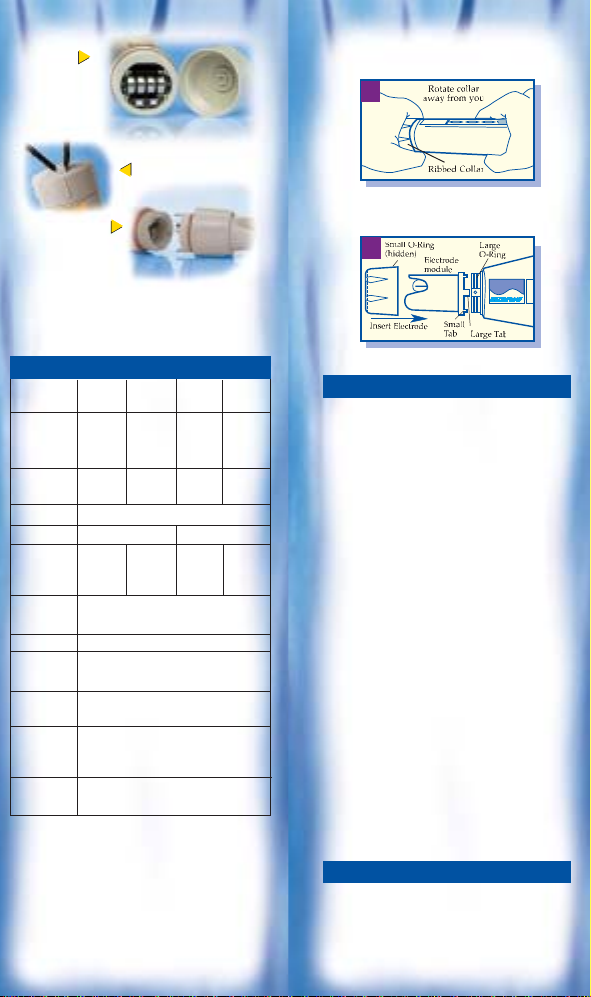

REMOVE THE OLD ELECTRODE

(Picture A)

A

(Picture B)

REPLACE THE ELECTRODE

B

Electrode Replacement

You can replace the electrode module

at the fraction of the cost of a new

tester. When the tester fails to calibrate

or gives fluctuating readings in

calibration standards, you need to

change the electrode.

1. With dry hands, grip the ribbed tester

collar with electrode facing you. Twist

the collar counter clockwise (see picture

A). Save the ribbed tester collar and

O-ring for later use.

2. Pull the old electrode module away from

the tester.

3. Align the four tabs on the new module

so that they match the four slots on the

tester (see picture B).

4. Gently push the module onto the slots

to sit it in position. Push the smaller

O-ring fully onto the new electrode

module. Push the collar over the module

and thread it into place by firmly twisting

clockwise.

Applications

Water quality testing • water and

Wastewater treatment • hydroponics

• pools • boilers • factories • ecology

studies • and more!

Loading...

Loading...