Page 1

gyM

sy...

Instruction Manual

PC 300

Waterproof Hand-held pH/Conductivity/TDS/Temperature Meter

Technolo

adeEa

35631-00

68X248908

Rev3 01/04

Page 2

Page 3

Preface

This manual serves to explain the use of the Waterproof PC 300 hand-held meter. It functions in

two ways, firstly as a step by step guide to help you to operate the meter. Secondly, it serves as a

handy reference guide. It is written to cover as many anticipated applications of the Waterproof PC

300 hand-held meter as possible. If there are doubts in the use of the PC 300, please do not

hesitate to contact the nearest Eutech Instruments/ Oakton Instruments Authorized Distributor.

Eutech Instruments/ Oakton Instruments cannot accept any responsibility for damage or

malfunction to the meter caused by improper use of the instrument.

The information presented in this manual is subject to change without notice as improvements are

made, and does not represent a commitment on the part of Eutech Instruments Pte Ltd/ Oakton

Instruments.

Copyright © Feb 2000 All rights reserved.

Eutech Instruments Pte Ltd/ Oakton Instruments

Rev3 01/04

Page 4

TABLE OF CONTENTS

1 INTRODUCTION 1

2 DISPLAY AND KEYPAD FUNCTIONS 2

2.1 Display 2

2.2 Keypad 3

3 PREPARATION 4

3.1 Inserting the Batteries 4

3.2 Probe Information 5

4 CALIBRATION 7

4.1 Important Information on Meter Calibration 7

4.2 Preparing the Meter for Calibration 8

4.3 pH Calibration 8

4.4 Conductivity Calibration 11

4.5 TDS Calibration 14

4.6 Calibration with Conductivity Standard and TDS factor 15

4.7 Temperature Calibration 16

5 MEASUREMENT 18

5.1 Taking pH Measurements 18

5.2 Taking Conductivity or TDS Measurement 22

6 HOLD FUNCTION 28

7 ADVANCED SETUP FUNCTIONS 29

7.1 Advanced SETUP Mode Overview 31

7.2 P1.0: Viewing previous pH calibration data 34

7.3 P2.0: Viewing pH electrode data 35

7.4 P3.0: pH Measurement configuration 36

7.5 P4.0: Resetting to factory default settin g s (pH ) 40

7.6 P5.0: Viewing Previous Conductivity Calibration data 41

7.7 P6.0: Viewing Conductivity Probe Data 42

7.8 P7.0: Conductivity or TDS Measurement Configuration 43

7.9 P8.0 Temperature 47

8 PROBE CARE AND MAINTENANCE 50

8.1 pH Electrode care 50

8.2 Conductivity Electrode 52

9 TROUBLE SHOOTING GUIDE 53

10 ERROR MESSAGES 54

11 SPECIFICATIONS 55

12 ACCESSORIES 56

13 ADDENDUM 1: CONDUCTIVITY TO TDS CONVERSION FACTORS 58

14 ADDENDUM 2: CALCULATING TDS CONVERSION FACTORS 59

15 ADDENDUM 3: CALCULATING TEMPERATURE COEFFICIENTS 60

16 ADDENDUM 4: METER FACTORY DEFAULT SETTINGS 62

17 ADDENDUM 5: SELECTING USA OR NIST BUFFER SET IN P3.3 63

18 WARRANTY 64

19 RETURN OF ITEMS 65

Page 5

Instruction Manual PC 300

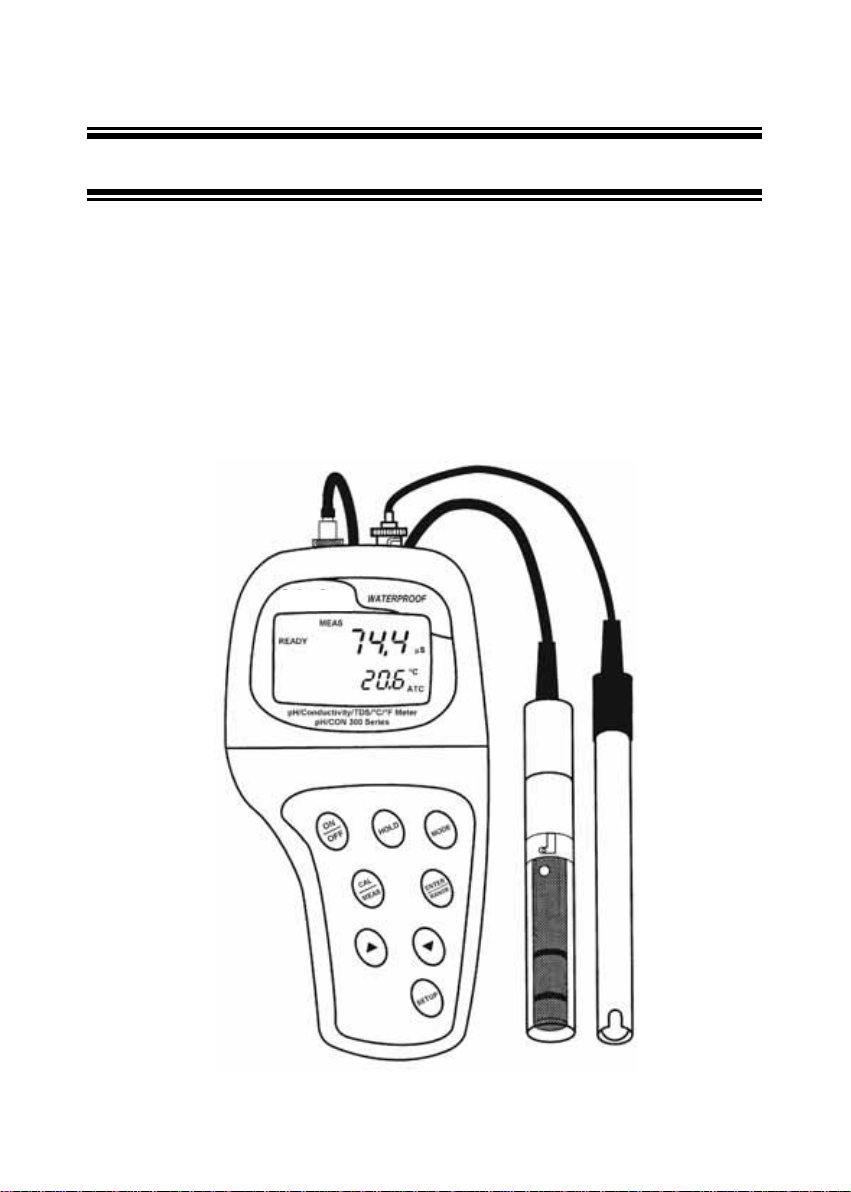

1 INTRODUCTION

Thank you for selecting the PC300 waterproof portable meter. This meter is a microprocessorbased instrument that is designed to be handy capable of allowing one-hand operation. It is

capable of measuring pH, Conductivity, TDS and Temperature. It is completely

WATERPROOF --- and it FLOATS!

This meter has many user-friendly features ---- all of which are completely access ible through

the water-resistant membrane keypad. Your meter includes a conductivity electrode (cell

constant K = 1.0) with built-in temperature sensor (Order Code: EC-CONSEN91W/ 35608-50),

pH electrode (EC-FE72522-01B/ 35641-51) and batteries. Please read this manual thoroughl y

before operating your meter.

Figure 1: PC 300 meter

1

Page 6

Instruction Manual PC 300

2 DISPLAY AND KEYPAD FUNCTIONS

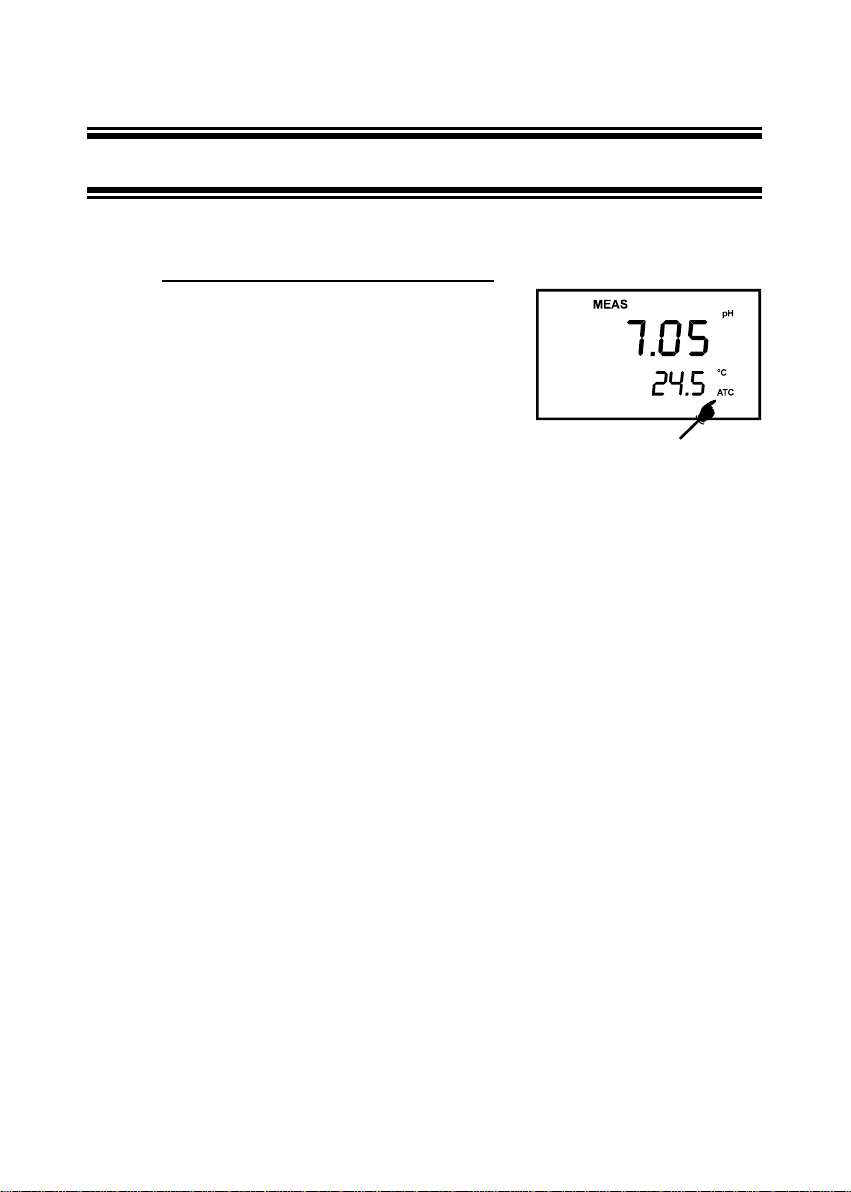

2.1 Display

The LCD has a primary and secondary display.

• The primary display shows the measured pH, conductivity or TDS.

• The secondary display shows the measured temperature.

The display also shows error messages, keypad functions and program functions.

See Figure 2.

Figure 2: Full LCD Screen

1. SETup mode indicator 8. micro-siemens indicator 15. Low battery indicator

2. MEASurement mode

indicator

3. CALibration indicator 10. parts per million indicator 17. Calibration solution

4. mV indicator 11. Temperature indicator 18. Cell constant indicator

5. % indicator 12. pH indicator 19. ON / OFF indicator

6. pH measurement indicator 13. Automa tic Temperature

7. milli-Siemens indicator 14. ERRor indicator 21. READY indicator

9. parts per thousand indicator 16. Probe indicator

indicator

20. HOLD indicator

Compensation indicator

2

Page 7

Instruction Manual PC 300

2.2 Keypad

The large membrane keypad makes the instrument easy to use. Each button, when pressed,

has a corresponding graphic indicator on the LCD. See Figure 1. Some buttons have several

functions depending on its mode of operation.

Key Function

ON/OFF Powers on and shuts off the meter. When you switch on the meter, the meter starts up

HOLD Freezes the measured reading. To activate, press HOLD while in measurement mode.

MODE Selects the measurement parameter. Press MODE to toggle between pH or TDS or

CAL/MEAS Toggles between Calibration and Measurement mode.

ENTER /

RANGE

/ In Calibration mode:

SETUP Takes you into the SETUP mode. This mode lets you customize meter preference and

in the mode that you last switched off from. For example, if you shut the meter off in

conductivity measurement mode, the meter will be in conductivity measurement mode

when you switch the meter on.

To release, press HOLD again.

conductivity measurement mode.

1. If you are in pH measurement mode, press CAL/MEAS to enter pH calibration

mode.

2. If you are in conductivity measurement mode, press CAL/MEAS to enter

conductivity calibration mode.

3. If you are in TDS measurement mode, press CAL/MEAS to enter TDS

measurement calibration mode.

While in SETUP sub-menu, pressing CAL/MEAS once takes you out to the SETUP

main menu and pressing CAL/MEAS second time takes you directly into the

measurement mode.

ENTER function: Press to confirm values in Calibration mode and to confirm selections

in SETUP mode.

RANGE function (for conductivity &TDS measurements only): Press to enter manual

ranging function. The MEAS indicator blinks while in manual ranging function.

During conductivity and TDS calibration, press to scroll through calibration values.

In SETUP mode:

Press to scroll through the setup subgroup programs.

defaults, view calibration, electrode offset data, adjust for temperature coefficient and

normalization temperature.

3

Page 8

Instruction Manual PC 300

3 PREPARATION

3.1 Inse rting the Batteries

Four AAA batteries are included with your meter.

1. Use a Philips screwdriver to remove the two screws holding the battery cover.

See Figure 3 below.

2. Remove battery cover to expose batteries.

3. Insert batteries. Follow the diagram inside the cover for correct polarity.

4. Replace the battery cover into its original position using the two screws removed earlier.

Figure 3 - Back panel of meter showing meter compartment

4

Page 9

Instruction Manual PC 300

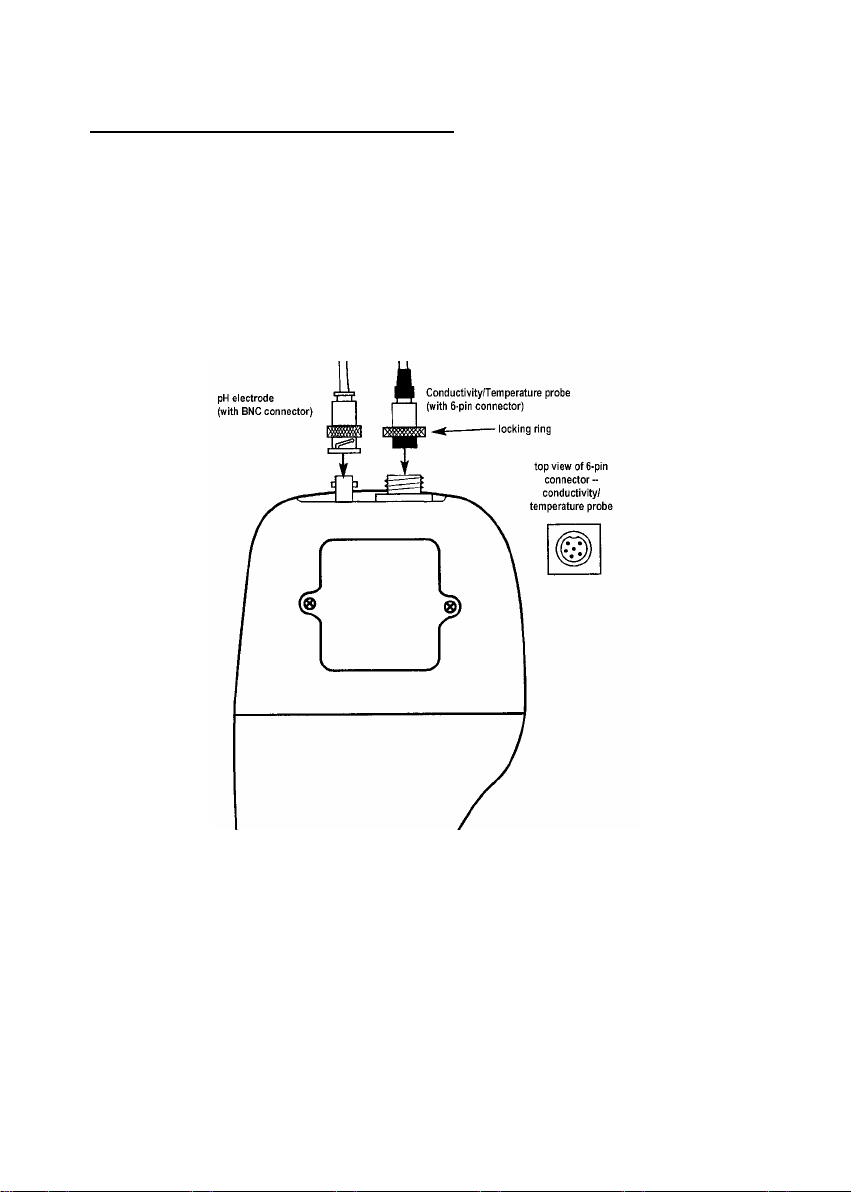

3.2 Probe Information

Your meter includes two probes:

• pH electrode with BNC connector.

• conductivity/temperature probe with a notched 6-pin connector

The temperature sensing element built into the conductivity probe will als o c omp ensa te

for pH readings as long as both probes are in your solution at the same time.

If you want to use a “3-in1” pH probe with a built-in temperature element, or if you want to use

a separate temperature probe, you will need to disconnect the conductivity probe to allow for

connection of the separate temperature sensor.

You can use any standard pH electrode with a BNC connector with this meter. Conductivity

probes, “3-in-1” pH electrodes with a built-in temperature element, and temperature probes

require a notched 6-pin connector (see Figure 4). For replacement probes, see the

“Accessories” section.

NOTE: Keep connector dry and clean. Do not touch connector with soiled hands.

To connect the pH electrode:

1. Slide the BNC connector of the probe over the BNC connector socket on the meter.

Make sure the slots of the connector are in line with the posts of the socket. Rotate and

push the connector clockwise until it locks.

2. To remove electrode, push and rotate the connector anti-clockwise. While holding onto

the metal part of the connector, pull it away from the meter.

CAUTION: Do not pull on the probe cord or the probe wires might disconnect.

5

Page 10

Instruction Manual PC 300

To connect the conductivity/temperature probe:

1. Line up the notch and 6 pins on the probe connector with the holes in the connector

located on the top of the meter. Push down and screw the metal sleeve to lock the probe

connector into place. See Figure 4.

2. To remove probe, unscrew the metal sleeve and slide up the probe connector. While

holding onto metal sleeve, pull probe away from the meter.

NOTE: Follow the same directions to connect an optional separate temperature element.

CAUTION: Do not pull on the probe cord or the probe wires might disconnect.

Figure 4: Connecting pH and conductivity/temperature probes

6

Page 11

Instruction Manual PC 300

4 CALIBRATION

4.1 Important Information on Meter Calibration

When you re-calibrate your meter, old calibration points are replaced on a “point-by-point”

basis in pH, and on a “range-by-range” basis in conductivity.

For example:

• pH:

• Conductivity:

• TDS:

To view current calibration points:

• pH: Program P1.0 in the SETUP section

• Conductivity & TDS: Program P5.0 in the SETUP section

if you previously calibrated your meter at pH 4.01, 7.00, and 10.01, and

you re-calibrate at pH 7.00, the meter retains the old calibration data at pH

4.01 and pH 10.01.

If you previously calibrated your conductivity meter at 1413 µS

in the 0 to 1999 µS range and you re-calibrate at 1500 µS (which is also in the

0 to 1999 µS), the meter will replace the old calibration data (1413 µS) in that

range. The meter will retain all calibration data in other ranges.

If you previously calibrated your conductivity meter at 300 ppm in the 0

to 999 ppm range and you re-calibrate at 500 ppm (which is also in the 0 to

999 ppm), the meter will replace the old calibration data (300 ppm) in that

range. The meter will retain all calibration data in other ranges.

To completely re-calibrate your meter, or when you use a replacement probe, it is best to

delete the old calibration data by re-setting the meter.

To reset the meter to its factory defaults:

• pH: Program P4.0 in the SETUP section

• Conductivity & TDS: Program P9.0 in the SETUP section

NOTE: Re-setting the meter will set meter to factory defaults. Conductivity and pH must be

reset separately.

For directions on how to calibrate your meter:

• See section 4.3 for pH calibration.

• See section 4.4 for conductivity calibration.

• See section 4.4 for TDS calibration.

• See section 4.5 for Temperature calibration.

7

Page 12

Instruction Manual PC 300

4.2 Prep aring the Meter for Calib ration

Before starting calibration, make sure you are in the correct measurement mode. When you

switch on the meter, the meter starts up in the measurement mode you shut it off in. For

example, if you shut the meter off in pH measurement mode, the meter will come back into pH

measurement mode when you switch the meter on.

4.3 pH Calibration

NOTE: We recommend that you perform at least 2-point calibration using standard

buffers that bracket (one above and one below) the expected sample range.

Preparing for pH calibration

This meter is capable of up to 5-point pH calibration to ensure accuracy across the entire pH

range of the meter. Select from the following buffer options:

• pH 1.68, 4.01, 7.00, 10.01 and 12.45 (USA)

• pH 1.68, 4.01, 6.86, 9.18, 12.45 (NIST)

The meter automatically recognizes and calibrates to these standard buffer values, which

makes pH calibration faster and easier.

Be sure to remove the protective electrode storage bottle or ru bber cap of t he electrode

before calibration or measurement. If the electrode has been s tored dry, wet the electrode

in tap water for 10 minutes before calibrating or taking readings to saturate the pH electrode

surface and minimize drift.

Wash your electrode in de-ionized water after use, and store in electrode storage solution. If

storage solution is not available, use pH 4.01 or 7.00 buffer solution.

Do not reuse buffer solutions after calibration. Contaminants in the solution can affect the

calibration and eventually the accuracy of the measurements. See Section on Accessories for

information on our high-quality pH buffer solutions.

8

Page 13

Instruction Manual PC 300

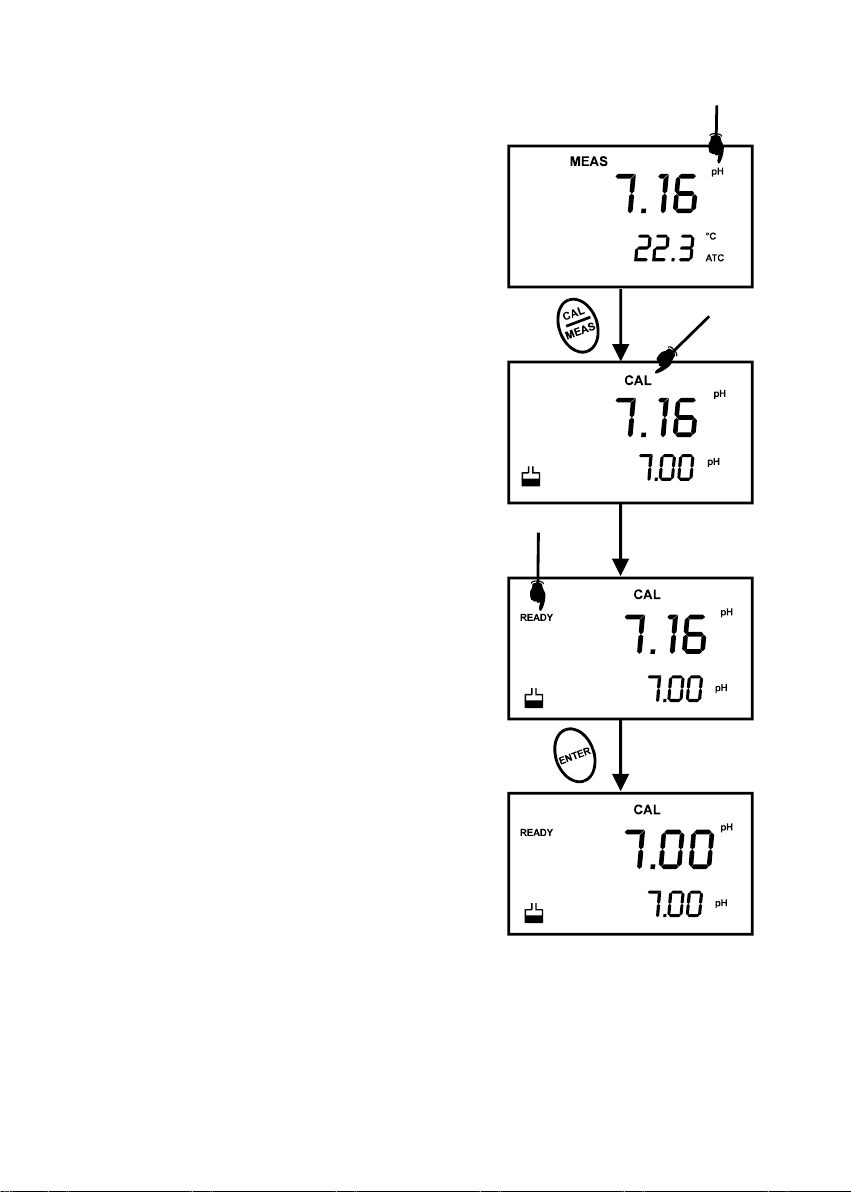

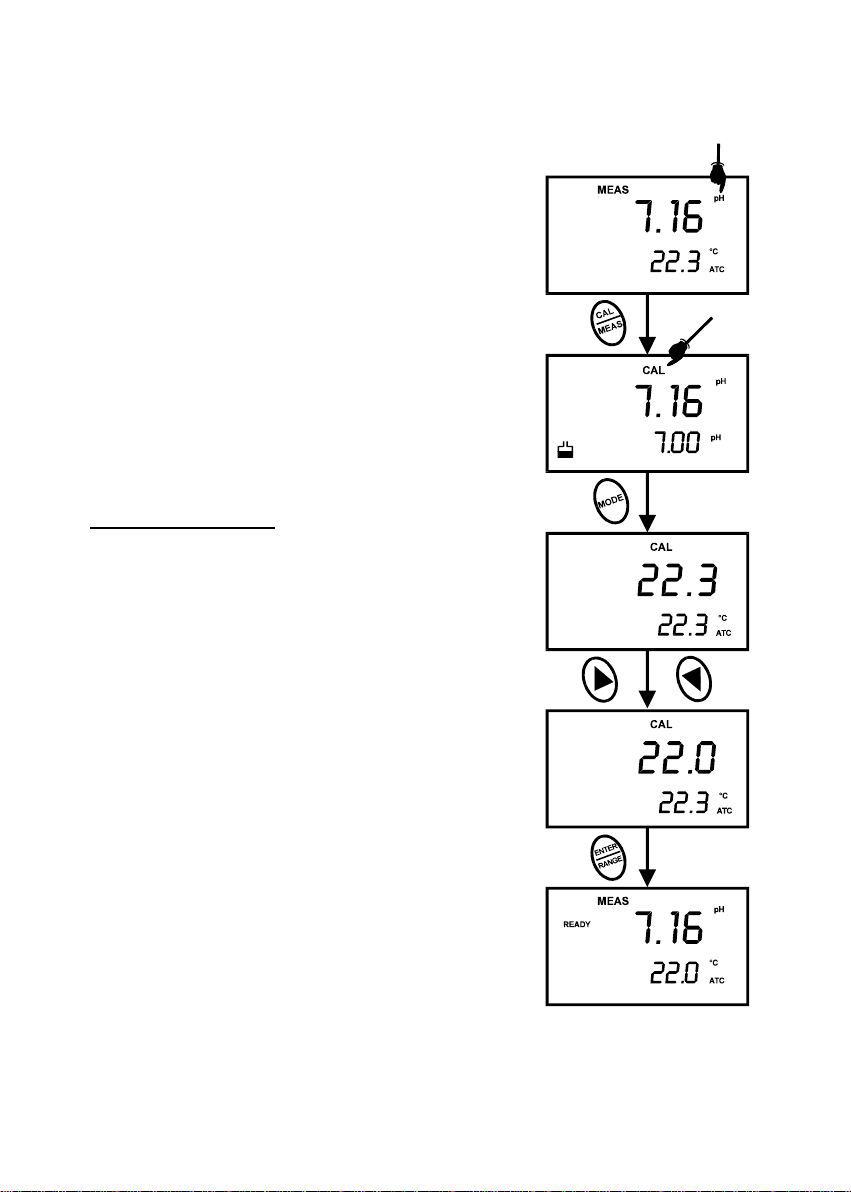

To Calibrate pH:

1. If necessary, press the MODE key to select pH

mode. The pH indicator appears in the upper right

hand corner of the display.

2. Rinse the prob e thoroughly with de-ionized water

or a rinse solution. Do not wipe the probe; this

causes a build-up of electrostatic charge on the

glass surface.

3. Dip the probe into the calibration buffer. The end of

the probe must be completely immersed into the

sample. Stir the probe gently to create a

homogeneous sample.

NOTE: The temperature element is in the conductivity

cell. For temperature compensated readings, dip

the conductivity cell into the calibration buffer as

well.

4. Press CAL/MEAS to enter pH calibration mode.

The CAL indicator will be shown. The primary

display will show the measured reading while the

smaller secondary display will indicate the pH

standard buffer solution.

5. Wait for the measured pH value to stabilize. See

Figure 5.

9

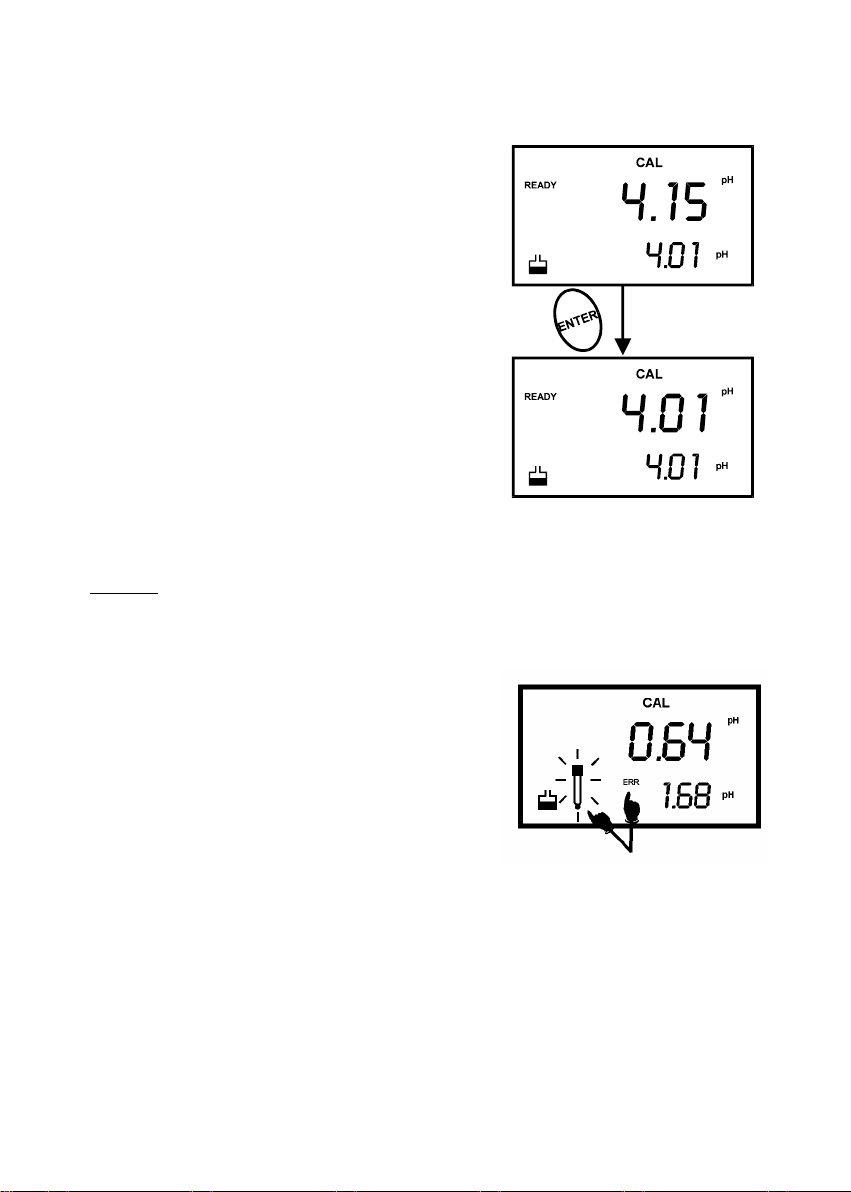

Figure 5 - pH Calibration

Page 14

Instruction Manual PC 300

6. Press ENTER to confirm calibration. The meter is

now calibrated to the current buffer. The lower

display scrolls through the remaining buffer options.

• If you are performing multi-point calibration, go

to step 7.

• If you are performing one-point calibration, go

to step 9.

7. Rinse the electro de with de-ionized water or in rinse

solution, and place it in the next pH buffer.

8. Follow steps 5 to 8 for additional calibration points.

See Figure 6.

9. When calibration is complete, press CAL/MEAS to

return to pH measurement mode.

Figure 6 - Next point calibration for

pH 4.01

NOTES:

To exit from pH calibration mode without

confirming calibration, DO NOT press ENTER in

step 6. Press CAL/MEAS instead.

If the selected buffer value is not within ±1.0 pH from

the measured pH value: the electrode and buffer icon

blink and the ERR annunciator appears in the lower left

corner of the display. See Figure 7.

To limit the number of pH buffer values available during

calibration, see SETUP section P3.2.

10

Figure 7 - Err message and

electrode icon will appear if

incorrect buffer are used

Page 15

Instruction Manual PC 300

4.4 Conductivity Calibration

The PC 300 meter has five measuring ranges. You can calibrate one point in each of the

measuring ranges (up to five points). If you are measuring values in more than one range,

make sure to calibrate each of the ranges you are measuring. All new calibration data will

over-ride existing stored calibration data for each measuring range you calibrate.

• If you are measuring in ranges near to or greater than 20 mS (10 ppt), or

near to or lower than 100 µS (50 ppm), calibrate the meter at least once

a week to get specified ±1% F.S. accuracy.

• If you are measuring in the mid ranges and you washed the probe in

deionized water and stored it dry, calibrate the meter at least once a

month.

• If you take measurements at extreme temperatures, calibrate the meter

at least once a week.

Preparing for conductivity calibration

For best results, select a standard value close to the sample value you are measuring.

Alternatively use a calibration solution value that is approximately 2/3 the full-scale value of

the measurement range you plan to use. For example, in the 0 to 1999 µS conducti vity range,

use a 1413 µS solution for calibration.

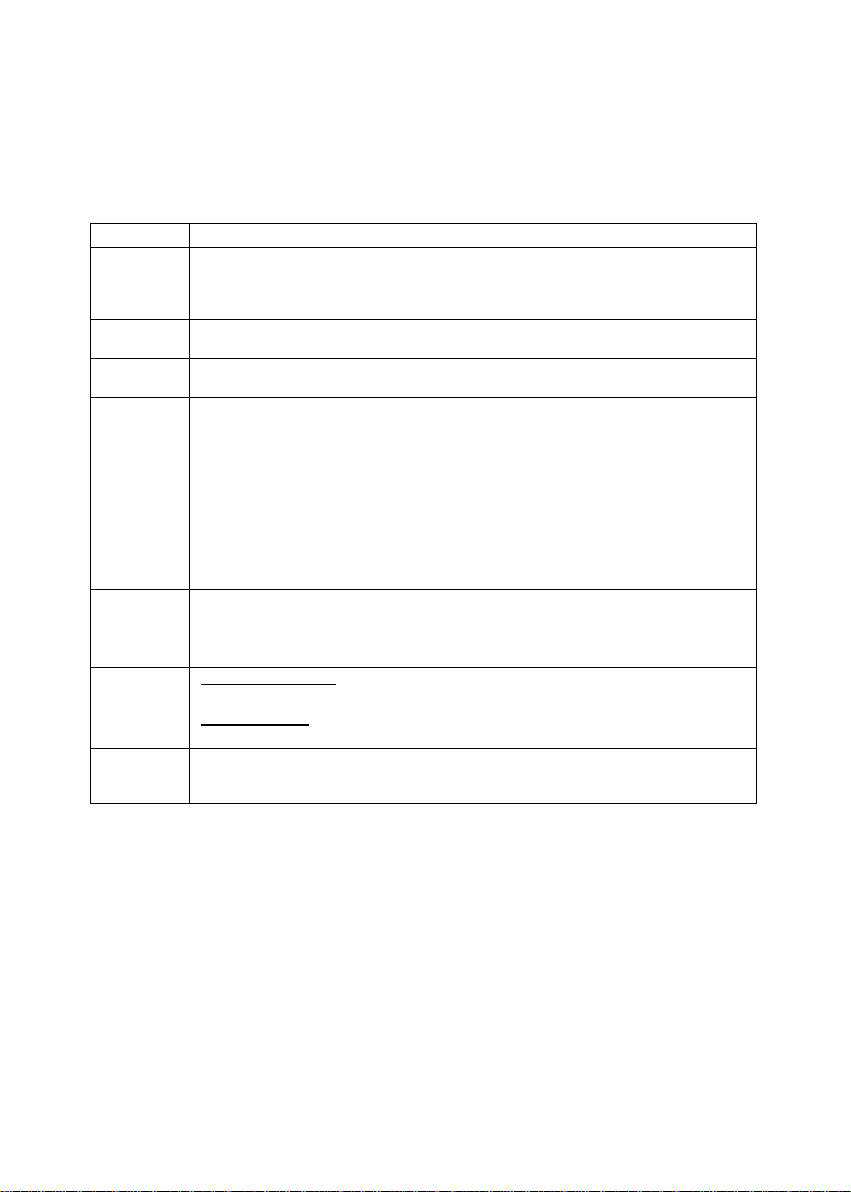

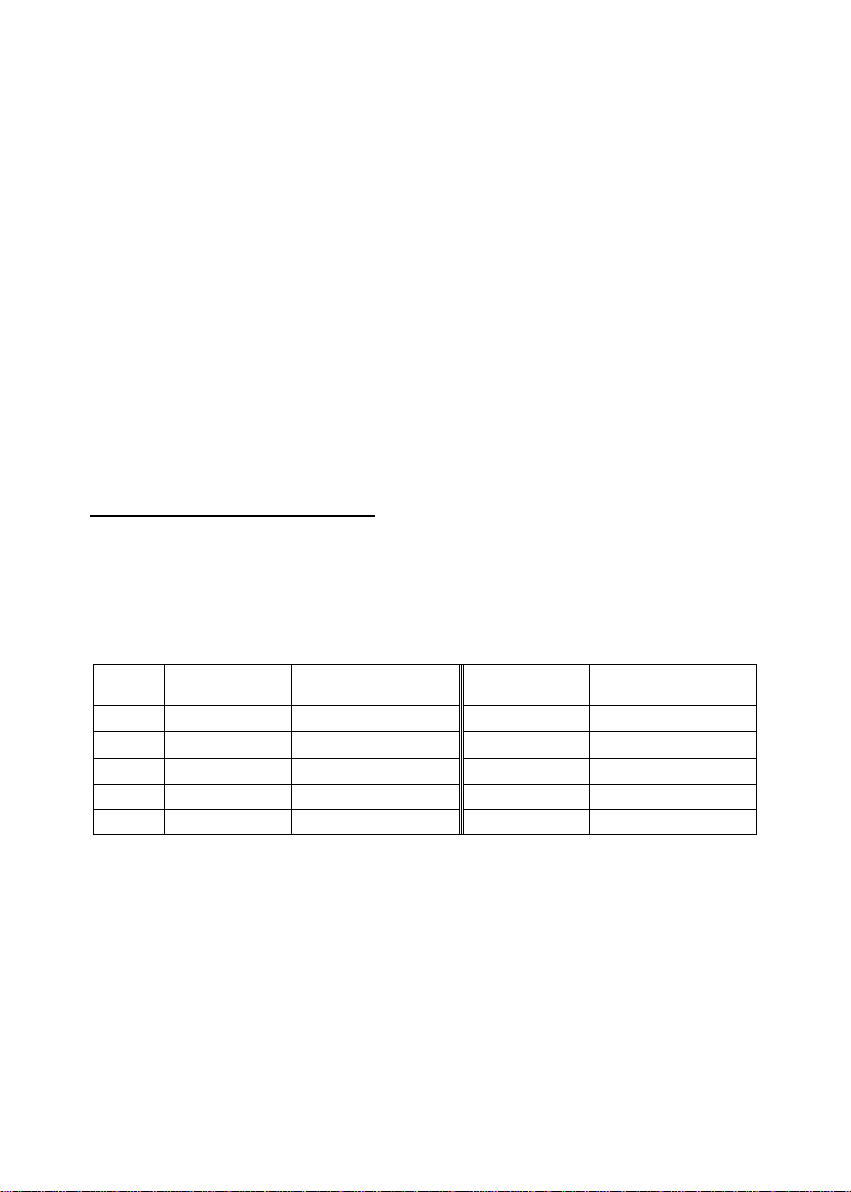

Table 1 - Range Indicator and its corresponding ranges

Range

indicator

r 1

r 2

r 3

r 4 0.00 Æ 19.99 mS 6.00 to 17.00 mS 1.00 Æ 9.99 ppt 3.00 to 8.50 ppt

r 5 0.0 Æ 199.9 mS 60.0 to 170.0 mS 10.0 Æ 200 ppt 30.0 to 170 ppt

Conductivity

Range

0.00 Æ 19.99 µS 6.00 to 17.00 µS

0.0 Æ 199.9 µS 60.0 to 170.0 µS

0 Æ 1999 µS 600 to 1700 µS

Recommended Calibration

Solution Range

TDS Range Recommended Calibration

Solution Range

0.00 Æ 9.99 ppm 3.00 to 8.50 ppm

10.0 Æ 99.9 ppm 30.0 to 85.0 ppm

100 Æ 999 ppm 300 to 850 ppm

Temperature Coefficient: These meters are factory set to a temperature coefficient of 2.1 %

per °C. For most applications this will provide good results. See Program P8.1 in

Section 7.9 to set the temperature coefficient to different value. See Addendum 3,

“Calculating Temperature Coefficients” to determine the appropriate temperature

coefficient for your solution.

Normalization Temperature: The factory default value for normalization temperature is 25

°C. If you need to normalize to a value other than 25 °C, see Program P8.2 in Section

7.9.

11

Page 16

Instruction Manual PC 300

Do not reuse calibration solutions after calibration. Contaminants in the solution can affect the

calibration, and eventually the accuracy of the measurements. Use fresh calibration solution

each time you calibrate your meter.

All new calibration data will over-ride existing stored calibration data for each measuring range

calibrated.

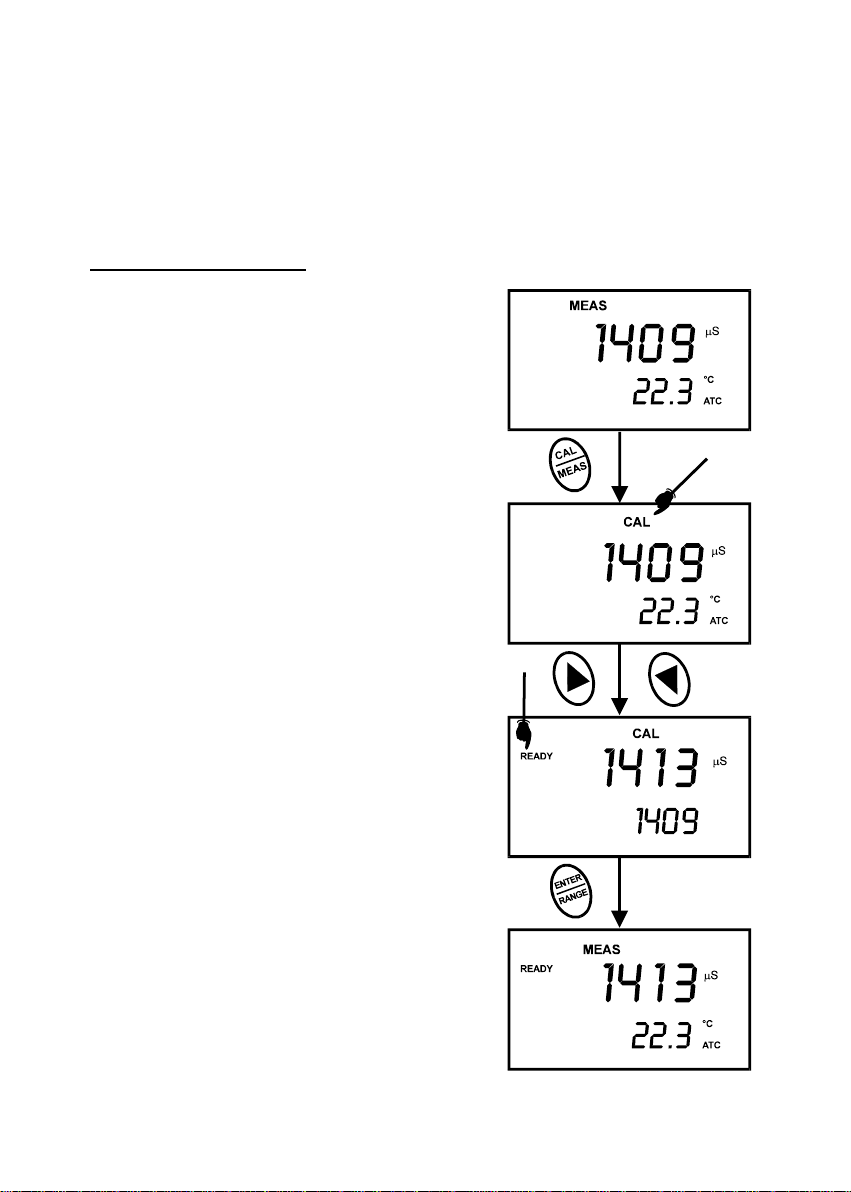

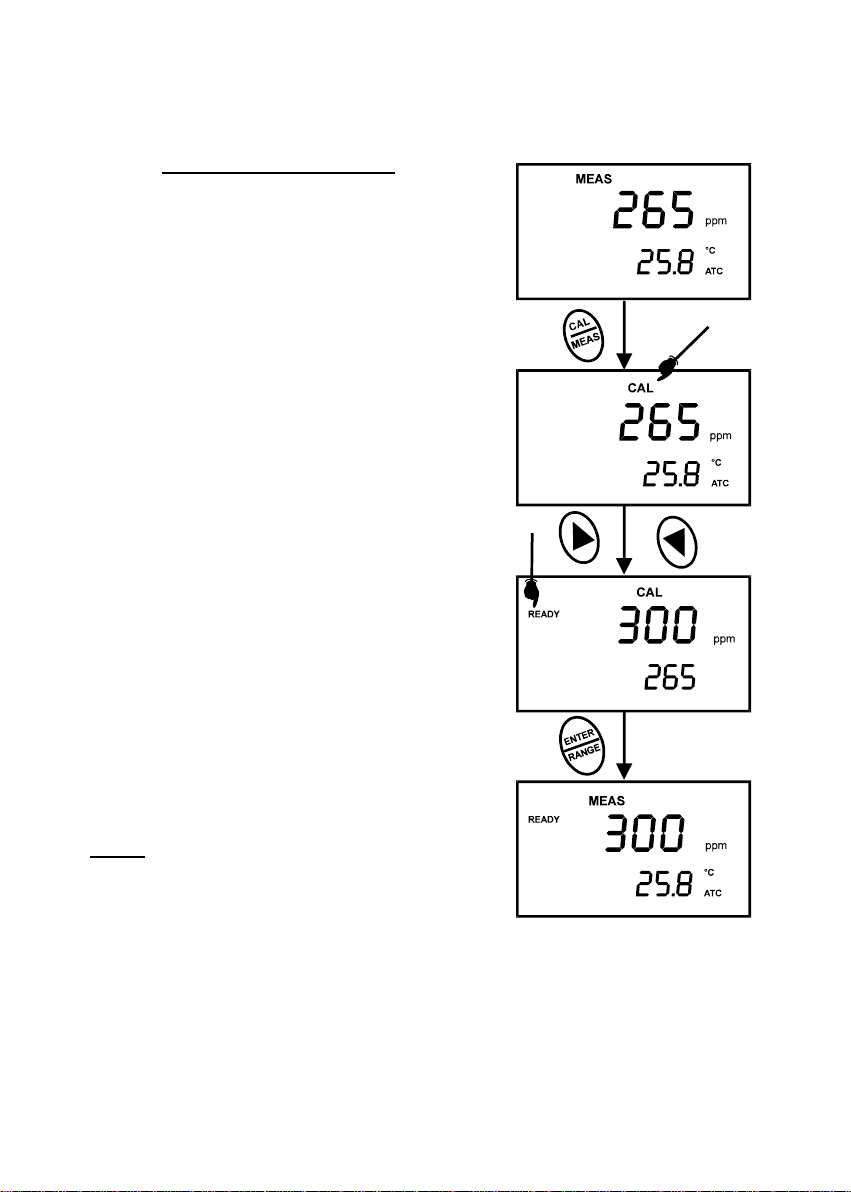

Calibrating for Conductivity:

1. If necessary, press the MODE key to select

conductivity mode.

2. Rinse the probe thoroughl y with de-ionized water

or a rinse solution, then rinse with a small amount

of calibration standard.

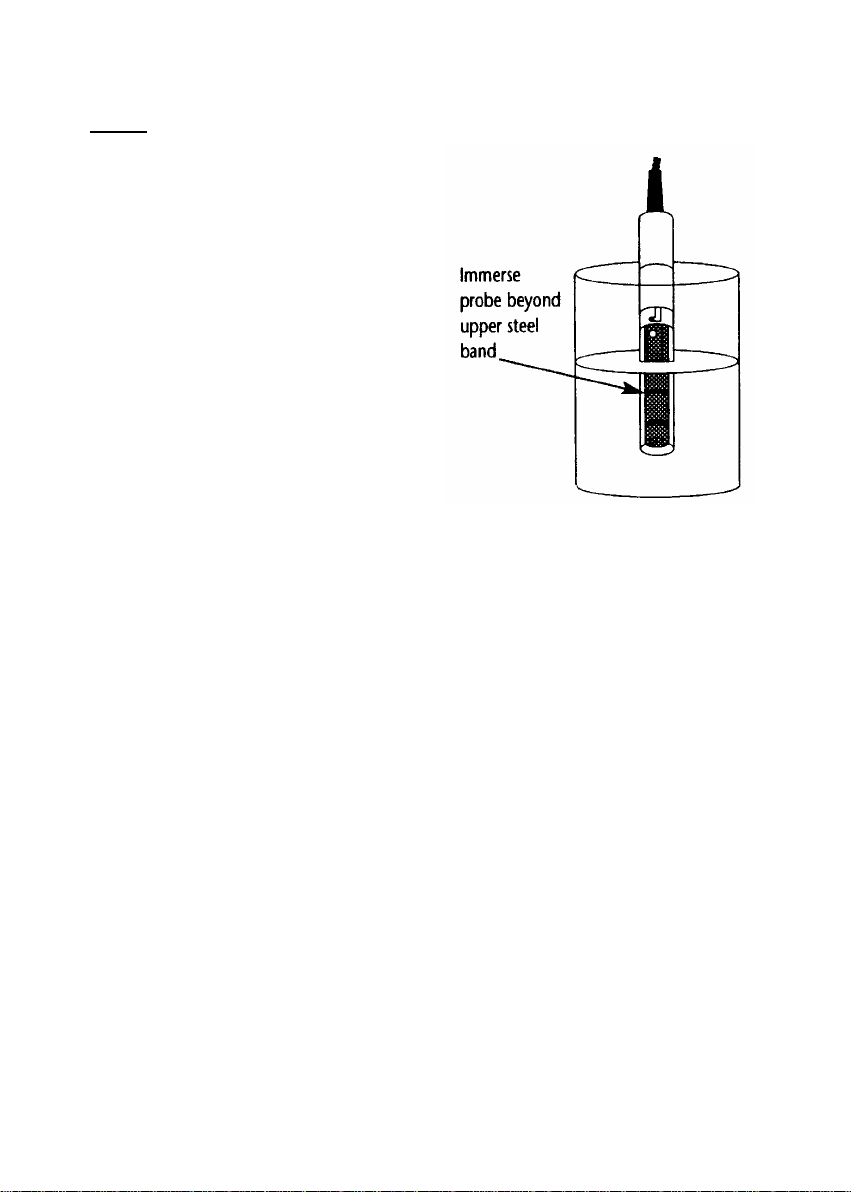

3. Dip the probe into the calibration standard.

Immerse the probe tip beyond the upper steel

band. Stir the probe gently to create a

homogeneous sample. See Figure 8.

4. Wait for the measured conductivity value to

stabilize. If the READY indicator has been

activated (SETUP program P7.1), the READY

annunciator lights when the reading is stable.

5. Press CAL/MEAS to enter conductivity or TDS

calibration mode. The CAL indicator will appear in

the upper right corner of the display.

6. Press the or keys to chang e the value on the

primary display to match the value of the

calibration standard.

7. Press ENTER to confirm calibration value. The

meter returns to the MEAS (measurement) mode.

8. Repeat steps 1 to 7 for other measuring ranges.

See figure 8.

12

Figure 8 - Conductivity Calibration

Page 17

Instruction Manual PC 300

NOTES:

When entering calibration mode, the meter will

display the factory default value. If the meter

was previously calibrated, the display may

“jump” to the factory default value when

switching from measurement to calibration

mode.

To exit from Conductivity calibration mode

without confirming calibration, DO NOT

press the ENTER key in step 7. Press

CAL/MEAS instead. This will retain the

meter’s old calibration data in the measuring

range of the calibration.

You can offset the conductivity reading up to

± 40% from default setting. If your measured

Figure 9 - Proper Immersion of

the conductivity probe

value differs by more than ± 40%, clean or

replace probe as needed.

Eutech Instruments/ Oakton Instruments offers a wide selection of high-quality calibration

standards. See section on Accessories for more information.

13

Page 18

Instruction Manual PC 300

4.5 TDS Calibration

4.5.1 Calibrating for TDS directly

The factory default setting for TDS conversion factor is

0.5. If your solution has a different TDS factor, you can

improve calibration accuracy by setting the TDS factor

prior to calibration. See P7.4 for directions.

1. If necessary, press the MODE key to select TDS

mode.

2. Rinse the probe thoroughly with de-ionized water or

a rinse solution, then rinse with a small amount of

calibration standard.

3. Dip the probe into the calibration standard. Immerse

the probe tip beyond the upper steel band. Stir the

probe gently to create a homogeneous sample.

Allow time for the reading to stabilize.

4. Press CAL/MEAS to enter TDS calibration mode.

The CAL indicator will appear in the upper right

corner of the display.

5. Press the or keys to change the value on the

primary display to match the value of the calibration

standard.

6. Press ENTER to confirm the calibration value. The

meter returns to the MEAS (measurement) mode.

See Figure 10.

7. Repeat steps 1 to 6 for other measuring ranges.

NOTES

To exit from TDS Calibration mode without confirming

calibration, DO NOT press the ENTER key in step 6.

Press CAL/MEAS instead. This will retain the meter’s old

calibration data in the measuring range of the calibration.

You can offset the TDS reading up to ± 20% from the

default setting. If your measured value differs by more

than ± 40%, clean or replace probe as needed.

14

Figure 10 - TDS Calibration

Page 19

Instruction Manual PC 300

4.6 Calibration with Conductivity Standard and TDS factor

The concentration of salts dissolved in solution increases the conductivity of that solution. This

relationship varies from salt to salt and is roughly linear over a given range for a given salt.

The TDS conversion factor is the number used by the meter to convert from conductivity to

TDS.

Instead of calibrating for TDS directly (described above), you can calibrate the PC 300 meter

by:

1. calibrating to conductivity standards (as described above) and then

2. entering the appropriate TDS conversion factor into the meter.

To determine the conductivity to TDS conversion factor for your solution:

• Addendum 1 lists some commonly used conversion factors.

• Addendum 2 describes how to calculate the TDS conversion factor for other

solutions.

Enter the TDS conversion factor into your meter as described under Section 7.5, in P7.4

Setting the TDS Factor.

15

Page 20

Instruction Manual PC 300

4.7 Te mperature Calibration

The conductivity electrode (EC-CONSEN91W/ 35608-50)

supplied with the meter has a built-in temperature sensor. In

addition you can also use a separate temperature sensing

element supplied by Eutech Instruments (as such

temperature probe (EC-PHWPTEMP-01W/ 35618-05), or the

“3-in-1” pH/Temperature combination electrode, (ECFE73528-01W/ 35808-71) for ATC purpose.

The conductivity probe is factory calibrated. Temperature

calibration can be done only if you suspect temperature

errors that may have occurred over a long period of time, or if

you have a replacement probe.

Temperature calibration is accessible during pH or

conductivity or TDS calibration.

Temperature Calibration

1. Make sure the conductivity electrode (or temperature

probe or “3-in-1” electrode) is attached to the 6-pin

connector.

2. Switch the meter on.

3. Press the CAL/MEAS key to enter calibration mode

(either from pH or conductivity mode). The CAL

indicator will appear above the primary display.

4. While in pH (or conductivity or TDS) calibration mode,

press the MODE key to enter temperature calibration

mode. The primary display shows the last set

temperature value and the secondary display shows the

temperature reading with zero offset.

5. Dip the ATC probe into a solution of known temperature

(i.e. a temperature bath). Allow time for the temperature

probe to stabilize.

Figure 11 - Temperature

Calibration in pH mode.

16

Page 21

Instruction Manual PC 300

6. Scroll with the and keys to set the correct temperature value (i.e. the temperature of

the temperature bath). You can adjust the reading increments of 0.1 °C.

7. Once you have selected the correct temperature press the ENTER key. The meter

automatically returns to pH measurement mode. See Figure 11.

NOTES:

• You can offset the temperature reading up to ±5 °C from original reading.

• To exit this program without confirming the temperature calibration value,

DO NOT press ENTER. Press CAL/MEAS instead.

17

Page 22

Instruction Manual PC 300

5 MEASUREMENT

5.1 Taking pH Measurements

5.1.1 Automatic Temperature Compensation

Automatic Temperature Compensation only occurs when a

temperature sensing element is plugged into the meter.

Temperature sensing element refers to the following probes

made specifically for this meter:

• The conductivity electrode (EC-CONSEN91W/

35608-50) with a built-in temperature sensor;

• Temperature probe (EC-PHWPTEMP-01W/

35618-05); or

• The “3-in-1” pH/Temperature combination

electrode (EC-FE73528-01W/ 35808-71).

Figure 12 - ATC annunciator will

light up when connected to

temperature probe

If there is no temperature sensor plugged into the meter, the default manual temperature

setting is automatically 25 °C. You can manually set the temperature to match your working

conditions using a separate thermometer.

For automatic temperature compensation (ATC) simply plug the temperature probe into the

meter (see page 6 for directions). The ATC indicator will light up on the LCD. See figure 12.

NOTE: The temperature sensing element must be submersed in the liquid yo u are

measuring.

18

Page 23

Instruction Manual PC 300

5.1.2 Manual Temperature Compensation (pH)

IMPORTANT: For manual compensation, you must

disconnect the temperature probe (see section 3.2: Probe

Information).

1. Switch the meter on. Press the MODE key to select

pH mode.

2. Press the CAL/MEAS key to enter pH calibration

mode. The CAL indicator will appear above the

primary display.

3. While in pH calibration mode, press the MODE key to

enter temperature calibration mode. The primary

display shows the current temperature setting and the

secondary display shows the default value 25 °C.

4. Check the temperature of your sample using an

accurate thermometer.

5. Press the or keys to set the temperature to the

measured value from step 4.

6. Press ENTER to confirm the selected temperature

and to return to the pH measurement mode.

See Figure 13.

The meter will now compensate pH readings for the

manually set temperature.

Figure 13 - Manual temperature

compensation

NOTES:

To exit this program without confirming the manual temperature compensation value, DO NOT

press ENTER in step 6. Press CAL/MEAS instead.

19

Page 24

Instruction Manual PC 300

5.1.3 Taking Measurements (pH)

Be sure to remove the electrode soaker bottle or

protective rubber cap on the electrode before

measurement.

To take readings:

1. Rinse the pH electrode with de-ionized or distilled

water before use to remove any impurities

adhering to the probe body. If the pH electrode

has dehydrated, soak it for 30 minutes in Eutech

Instruments electrode storage solution or 2M –

4M KCl solution (sold separately).

2. Press ON to switch on meter.

3. Press the MODE key to select pH measurement mode. The MEAS annunciator app ears

on the top center of the LCD. The ATC indicator appears in the lower right-hand corner to

indicator Automatic Temperature Compensation.

NOTE: For pH manual temperature compensation, you must disconnect the conductivity cell

from the 6-pin connector. The ATC indicator will disappear from the display. You also need to

set a manual temperature compensation value. See Section 5.1.2 to set Manual Temperature

Compensation.

Figure 14 - Measurement mode

4. Dip the probe into the sample. Since the conductivity cell contains the temperature

sensor, make sure it is also immersed in your solution.

When dipping the probe into the sample, the sensor or the glass bulb of the electrode must be

completely immersed into the sample. Stir the probe gently in the sample to create a

homogeneous sample.

5. Allow time for the reading to stabilize. Note the reading on the display. Note the reading

on the display. If the Ready indicator is selected on, it will appear when the reading is

stable.

20

Page 25

Instruction Manual PC 300

Taking measurements with READY indicator selected on

If the READY indicator has been activated, the READY annunciator lights when the reading is

stable*. Switch the READY indicator on or off in SETUP program P3.1. See Section 7.4.

* The READY indicator appears and the reading holds until the measured value exceeds the

±

tolerance (

0.02 pH; ± 0.8 mV <400; ±1.2 mV > 400). Then, the READY annunciator turns

off.

Taking measurements with the auto endpoint feature selected on

When a reading is stable for more than 5 seconds, the auto endpoint feature will automatically

“HOLD” the reading. The “HOLD” indicator appears on the left side of the display. Press the

HOLD key to release the reading. Switch the Auto endpoint feature on or off in SETUP

program P 3.1, see Section 7.4.

21

Page 26

Instruction Manual PC 300

5.2 Taking Conductivity or TDS Measurement

5.2.1 Automatic Temperature Compensation

For automatic temperature compensation (ATC) simply

plug the conductivity probe into the meter (see page 6 for

directions). The ATC indicator will light on the LCD.

NOTE: If the ATC indicator does not light, manual

temperature compensation may be selected in

the meter’s SETUP mode. See Program P7.3 in

Section 7.8 for directions on selecting Automatic

Temperature Compensation.

Figure 15 - ATC annunciator will

light up when connected to

temperature probe

5.2.2 Manual Temperature Compensation

IMPORTANT: For manual compensation, you must deactivate the temperature probe.

Selecting Manual Temperature Compensation for conductivity

Selecting between Automatic Temperature

Compensation (ATC) and Manual Temperature

Compensation in the SETUP program P7.3 on in

Section 7.8. Meter default is ATC on.

From Conductivity or TDS measurement mode

1) Press SETUP key to enter Set Up mode.

2) Press the or keys keys to scroll through subgroups until you view parameter P7.0.

See Figure 16.

3) Press the ENTER key three times to select parameter 7.3. The upper display shows “ATC”

and the lower display shows “P7.3”.

Figure 16 - P7.0 Configuration Setup

for conductivity & TDS

4) Press the ENTER key again. The upper display shows “ATC” and the lower display shows

“YES” or “NO”.

22

Page 27

Instruction Manual PC 300

5) Press the or keys to select the Automatic

Temperature Compensation feature on (ATC on) or

off (ATC off). See Figure 18.

6) Press the ENTER key to confirm selection and to

return to the subgroup menu. Press the

CAL/MEAS key to return to measurement mode.

Note that the ATC indicator no longer appears on the

display.

Proceed to next section to select a manual temperature

compensation value.

Figure 18 - Turning ATC feature

23

ON or OFF

Page 28

Instruction Manual PC 300

5.2.3 Setting a manual temperature compensation valu e

To use manual temperature compensation, you need to enter the temperature value of your

process into the meter. This is the value at which reading will manually temperature

compensates. You can select any temperature between 0 and 100 °C (32 to 212 °F). Default

value is 25 °C (77 °F).

To select a manual temperature compensation value

1. Switch the meter on. Press the MODE key to select

conductivity or TDS measurement mode.

2. If necessary, select ATC off as described in section

5.2.2. The ATC indicator will not appear on the

display.

3. Press the CAL/MEAS key to enter conductivity or

TDS calibration mode. The CAL indicator will

appear above the primary display.

4. While in conductivity (or TDS) calibration mode,

press the MODE key to enter temperature

calibration mode. The primary display shows the

current temperature setting and the secondary

display shows the default value 25 °C (77 °F) or its

last set value.

5. Check the temperature of your sample using an

accurate thermometer.

6. Press the or keys to offset the temperature to

the measured value from step 5.

7. Press ENTER to confirm the selected temperature

and to return to the conductivity measurement

mode. See Figure 19.

Figure 19 - Manual Temperature

Compensation

The meter will now compensate conductivity or TDS

readings for manually set temperature.

NOTES:

To exit this program without confirming the manual temperature compensation value, DO NOT

press ENTER in step 6. Press CAL/MEAS instead.

Setting the manual temperature compensation value for conductivity will change the manual

temperature compensation value for pH to the same value, and vice versa.

24

Page 29

Instruction Manual PC 300

5.2.4 Taking Measurements (Conductivity or TDS)

To take readings:

1. Rinse the probe with de-ionized or distilled water

before use to remove any impurities adhering to the

probe body. Shake or air dry. To avoid contamination

or dilution of your sample, rinse probe with a small

volume of your sample liquid.

2. Press ON to switch on meter.

3. Press the MODE key to select conductivity or TDS measurement mode. The MEAS

annunciator appears on the top center of the LCD. The ATC indicator appears in the

lower right hand corner to indicate Automatic Temperature Compensation.

• NOTE: For conductivity manual temperature compensation, you must

de-activate the temperature sensor built into the conductivity probe and

set manual temperature compensation. See Section 5.2 for more

information. The ATC indicator will disappear from the display.

4. Dip the probe into the sample.

When dipping the probe into the sample, take care to ensure that the liquid

level is above its upper steel band. Stir the probe gently in the sampl e to

create a homogenous sample. See Figure 9 in Section 4.4.

Figure 20 - During measurement

5. Allow time for the reading to stabilize. Note the reading on the display. If the READY I

indicator is selected on, it will appear when the reading is stable. See P7.1 in Section 7.8

for more information.

6. Press the MODE key to toggle between conductivity, TDS and pH readings.

NOTES: You can use the conductivity manual ranging function to select a specific range in which

your readings will appear. See Section 5.2.5: Manual ranging for directions.

Taking measurements with READY indicator selected on

If the READY indicator has been activated, the READY annunciator lights when the reading is

stable*. Switch the READY indicator on or off in SETUP program P 7.1. See Section 7.8 for

directions.

Taking measurements with the auto endpoint feature selected on

When a reading is stable for more than 5 seconds, the auto endpoint feature will automatically

“HOLD” the reading. The “HOLD” indicator appears on the left side of the display. Press the

HOLD key to release the reading. Switch the Auto endpoint feature on or off in SETUP

program P 7.1, See Section 7.8 for directions.

25

Page 30

Instruction Manual PC 300

5.2.5 Using Auto and Manual Ranging Function (for conductivity & TDS)

Auto-ranging

Your meter automatically selects the range in which your

readings appear. For example:

1. If you dip the conductivity probe into a standard solution,

say, 12.88 mS.

2. It will automatically select the most appropriate range,

r 4, which is 0.00 to 19.99 mS (refer to Table 1 in

Section 4.4).

3. The secondary display on the LCD will momentarily

display r 4 before it switches to measured temperature

value.

4. The primary display will show the actual conductivity

value. See Figure 21.

Figure 21 - Auto-ranging

feature

26

Page 31

Instruction Manual PC 300

Manual-ranging

The manual ranging function lets you select the specific range

you want to work in. Refer to Section 4.4 for the table of range.

1. To select the desired measuring range, press the

RANGE key while in Measurement mode. The first range

will appear on the display and the “MEAS” indicator

blinks. See Figure 22.

2. Press the RANGE key again (if needed) until desired

range is selected.

3. To re-select the Auto-ranging function, repeatedly press

the RANGE key until the “MEAS” indicator appears

without blinking.

Figure 22 - Manual ranging

NOTES

If the value of the solution you are measuring is higher than

the range selected “Or” will appear on the primary display.

Press RANGE until the correct range is selected.

The meter resets to the Auto-ranging function once it is turned

off. You will have reset the manual ranging function each time

you turn the meter off.

27

Figure 23 - Out-of-range

Page 32

Instruction Manual PC 300

6 HOLD FUNCTION

This feature lets you freeze the display for a delayed observation. HOLD can be used any time

in MEAS mode.

1. To hold a measurement, press the HOLD key while

in measurement mode. “HOLD” will appear on the

display.

2. To release the held value, press the HOLD again.

Continue to take measurements.

NOTE:

• This meter shuts off automatically after 20 minutes of last key press.

• If the meter is shut off either automatically or manually, the HOLD value will be lost.

• Your meter has an auto endpoin t feature. When this feature is switched on, and

when a reading is stable for more than 5 seconds, the display will automatically

“HOLD” the reading. The “HOLD” indicator appears. Press the HOLD key to release

the reading. To switch on or off the auto endpoint feature, see SETUP program P3.1

in Section 7.4 for pH and SETUP, program P7.1 in Section 7.8 for conductivity/TDS.

Figure 24 - HOLD function

28

Page 33

Instruction Manual PC 300

7 ADVANCED SETUP FUNCTIONS

The advanced setup mode lets you customized your meter’s preferences and defaults. This

Waterproof handheld meter features different sub-groups that organize setup parameters.

The sub-groups are:

For pH For Conductivity & TDS

P 1.0 View calibration data (CAL) P 5.0 View calibration data (CAL)

P 2.0 View electrode data (ELE) P 6.0 View electrode data (ELE)

P 3.0 Unit Configuration (COF) P 7.0 Unit Configuration (COF)

P 4.0 Reset to factory default

P 8.0 Temperature (tPr)

settings (rSt)

P 9.0 Reset to factory default

settings (rSt)

See Figure 25 on next page.

29

Page 34

Instruction Manual PC 300

Figure 25 - Overall view of SETUP programs for pH (on left) and conductivity/TDS (on right)

30

Page 35

Instruction Manual PC 300

7.1 Ad vanced SETUP Mode Overview

1. In either pH or Conductivity measurement mode, press the SETUP key to enter Set up

mode.

2. Press the or keys to scroll through sub groups.

3. Press ENTER key to enter a particular parameter.

See Addendum 4 for a table of meter factory default settings.

SETUP in pH Measurement Mode

P1.0: View previous calibration data

P1.1 First calibration point (pH 1.68)

P1.2 Second calibration point (pH 4.01)

P1.3 Third calibration point (pH 7.00 or 6.86)

P1.4 Fourth calibration point (pH 10.01 or 9.18)

P1.5 Fifth calibration point (pH 12.45 )

Instructions on Section 7.2.

P2.0: View electrode data

P2.1 pH electrode offset

P2.2 pH electrode slope

Instructions in Section 7.3.

P3.0: Unit configuration

P3.1 READY indicator and auto endpoint function

P3.2 Number of pH calibration points: 2, 3, 4 or 5

P3.3 Select buffer group: USA or NIST

P3.4 Select °C or °F

Instructions in Section 7.4.

P4.0: Reset to factory defaults

P4.0 Reset meter to factory defaults

Instructions in Section 7.5.

– select on or off

31

Page 36

Instruction Manual PC 300

SETUP in Conductivity Measurement Mode

P5.0: View previous calibration data

P5.1 First range calibration point (0.00 – 19.99 µS)

P5.2 Second range calibration point (0.0 – 199.9 µS)

P5.3 Third range calibration point (0 – 1999 µS)

P5.4 Fourth range calibration point (0. 00 – 19.99 mS)

P5.5 Fifth range calibration point (0.0 – 199.9 mS)

Instructions in Section 7.6.

P6.0: View electrode data

P6.1 Effective cell constant for first range

(0.00 – 19.99 µS)

P6.2 Effective cell constant for second range

(0.0 – 199.9 µS)

P6.3 Effective cell constant for third range (0 – 1999 µS)

P6.4 Effective cell constant for fourth range

(0.00 – 19.99 mS)

P6.5 Effective cell constant for fifth range

(0.0 – 199.9 mS)

Instructions in Section 7.7.

P7.0: Unit configuration

P7.1 READY indicator and auto endpoint function –

select on or off

P7.2 Select °C or °F

P7.3 Select Automatic or Manual Temperature

Compensation

P7.4 Setting TDS conversion factor

Instructions in Section 7.8.

P8.0: Temperature

P8.1 Adjusting temperature coefficient

P8.2 Adjusting normalization temperature

Instructions in Section 7.9.

P9.0: Reset to factory defaults

P9.0 Reset meter to factory defaults

Instructions in Section 7.9.1.

32

Page 37

Instruction Manual PC 300

SETUP in TDS Measurement Mode

P5.0: View previous calibration data

P5.1 First range calibration point (0.00 – 9.99 ppm)

P5.2 Second range calibration point (0.0 – 99.9 ppm)

P5.3 Third range calibration point (0 – 999 ppm)

P5.4 Fourth range calibration point (0.00 – 9.99 ppt)

P5.5 Fifth range calibration point (0.0 – 200 ppt)

Instructions in Section 7.6.

P6.0: View electrode data

P6.1 Effective cell constant for first range

(0.00 – 9.99 ppm)

P6.2 Effective cell constant for second range

(0.0 – 99.9 ppm)

P6.3 Effective cell constant for third range (0 – 999 ppm)

P6.4 Effective cell constant for fourth range

(0.00 – 9.99 ppt)

P6.5 Effective cell constant for fifth range

(0.0 – 200 ppt)

Instructions in Section 7.7.

P7.0: Unit configuration

P7.1 READY indicator and auto endpoint function –

select on or off

P7.2 Select °C or °F

P7.3 Select Automatic or Manual Temperature

Compensation

P7.4 Setting TDS conversion factor

Instructions in Section 7.8.

P8.0: Temperature

P8.1 Adjusting temperature coefficient

P8.2 Adjusting normalization temperature

Instructions in Section 7.9.

P9.0: Reset to factory defaults

P9.0 Reset meter to factory defaults

Instructions in Section 7.9.1.

33

Page 38

Instruction Manual PC 300

7.2 P1.0: View ing previous pH calibration data

This mode lets you recall previous pH calibration data, which helps you know when to recalibrate your meter. This is a “view only” mode.

From measurement mode:

1. Press the MODE key to select pH measurement

mode if necessary.

2. Press the SETUP key to enter Set up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P1.0.

4. Press the ENTER key repeatedly to view previous

calibration data. See Figure 26.

USA

NIST

• P1.1 = pH 1.68 1.68

• P1.2 = pH 4.01 4.01

• P1.3 = pH 7.00 6.86

• P1.4 = pH 10.01 9.18

• P1.5 = pH 12.45 12.45

5. When you have scrolled through all calibration data,

you will automatically return to the subgroup menu.

Press CAL/MEAS key to return to measurement

mode.

NOTES:

Figure 26 – P1.0: View calibration

data for pH

If there is no previous calibration data at a particular point, the primary display will show “- - -“.

34

Page 39

Instruction Manual PC 300

7.3 P2.0: View ing pH electrode data

Program 2 has two “view only” options that let you check

the electrode parameters for diagnostic purposes. It lets

you view:

• P2.1 = Electrode offset

• P2.2 = Electrode slope

From pH measurement mode

1. Press the MODE key to select pH measurement

mode.

2. Press the SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P2.0.

4. Press the ENTER key to select parameter 2.1.

5. The display shows the electrode offset value. It is the

mV offset at pH 7.00. If you have not calibrated at any

buffer, the primary display shows 0.00 mV.

6. Press the ENTER key to proceed to P2.2.

7. The display shows electrode slope in percentage.

Slope displayed is the average slope based on the pH

calibrations. Default setting is 100.0.

8. At any point, you can press the CAL/MEAS key to

Figure 27 - Viewing electrode's

offset and slope status from pH

measurement mode

return to measurement mode.

See Figure 27.

(The values shown above are for illustration purpose. Your meter may display different values depending on

the settings & your environmental conditions)

35

Page 40

Instruction Manual PC 300

7.4 P3.0: p H Measurement configuration

This subgroup program allows to customize the meter to

your specific needs. You can program the meter to:

1. Select READY indicator ON or OFF

2. Select the number of pH calibration points

3. Select between USA and NIST buffers

4. Select between °C and °F units for temperature

readings

Figure 28 on the right shows the setup sequence for this

program subgroup.

SETUP

SETUP

READY

ON

SETUP

READY

ON

SETUP

T

N

E

A

R

E

T

N

E

N

A

R

T

N

E

A

R

cof

p 3.0

R

E

E

G

N

p 3.1

R

E

G

3 p

p 3.2

R

E

E

G

N

pH

usa

p 3.3

R

E

T

N

E

E

G

N

A

R

SETUP

C

p 3.4

Figure 28 – P 3.0: Unit

configuration program

36

°C

Page 41

Instruction Manual PC 300

P3.1: READY Indicator and auto endpoint function

This program lets you select:

• “READY indicator on

” to indicate when the reading

is stable.

• “READY indicator off

• Auto endpoint function on

” for faster meter response.

. Select auto endpoint

on to “hold” the reading when it is stable for more

than 5 seconds. The display automatically freezes,

and the HOLD indicator appears on the left side of

the display. Press the HOLD key to release the

display and access other functions.

From measurement mode

1. Press the MODE key to select pH measurement

mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P3.0.

4. Press the ENTER key to select parameter 3.1.

5. Press the or keys to select the configuration

you require.

• OFF switches the READY indicatory off.

• ON switches the READY indicator on.

• ON and HOLD together switches the auto

endpoint feature on.

6. Press the ENTER key to confirm selection and to

proceed to step 4 of P3.2. Press the CAL/MEAS

Figure 29 – P 3.1: Selecting

READY function)

key to return to measurement mode.

NOTES:

Meter default is set for READY indicator on and auto endpoint function off.

37

Page 42

Instruction Manual PC 300

You can also change the Ready indicator and auto endpoint function in Program P7.1

(available from conductivity or TDS mode). Any changes you make to the Ready indicator/auto

endpoint function in pH mode will also change in conductivity mode.

P3.2: Selecting number of pH calibration points

Program P3.2 lets you select the number of calibration

points that appear in pH calibration mode: 2, 3, 4, or 5.

The meter will automatically exit calibration mode after

you have calibrated to your selected number of points.

From measurement mode.

1. Press the MODE key to select pH measurement

mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P3.0.

4. Press the ENTER key twice to select parameter 3.2.

5. Press the or keys to select 2, 3, 4, or 5 point

pH calibration.

6. Press the ENTER key to confirm selection and to

return to the subgroup menu. Press CAL/MEAS key

to return to measurement mode.

See Figure 30.

P3.3 Selecting USA or NIST buffer

Program P3.3 lets you select between the following buffer

sets:

USA: pH 1.68, 4.01, 7.00, 10.01, 12.45

NIST: pH 1.68, 4.01, 6.86, 9.18, 12.45

Factory default is USA buffer set. Please refer to

Addendum 5 for P3.3 procedure.

38

Figure 30 – P3.2: Select number

of pH calibration points

Page 43

Instruction Manual PC 300

P3.4 Selecting °C or °F

R

E

T

N

E

E

G

This meter lets you select between °C and °F units for

N

A

R

temperature readings.

From measurement mode

SETUP

1. Press the MODE key to select pH measurement

mode.

2. Press SETUP key to enter Set Up mode.

C

°C

p 3.4

3. Press the or keys to scroll through subgroups

until you view parameter P3.0.

4. Press the ENTER key four times to select parameter

3.4.

5. Press the or keys to toggle between °C and

°F.

SETUP

F

°F

p 3.4

6. Press the ENTER key to confirm selection and to

return to the subgroup menu. Press the CAL/MEAS

key to return to measurement mode.

Figure 31 – P3.4: Select

temperature units

See Figure 31.

NOTES:

• You can switch between °C and °F in Program P7.2 (available from conductivity or TDS

mode). If you switch between °C and °F in pH mode, the meter will also switch in

conductivity or TDS mode.

39

Page 44

Instruction Manual PC 300

y)

7.5 P4.0: Resetting to factory default settings (pH)

This program lets you reset all pH parameters to factory

default settings. This clears all calibration data and any

other pH setup functions you might have changed.

The following settings will remain as you have set them:

• Temperature unit of measure (°C or °F)

• The temperature offset calibration value

• All conductivity calibration data and parameters

From measurement mode

1. Press the MODE key to select pH measurement

mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P4.0.

Figure 32 – P4.0: Reset to factory

default values (pH 300 meter

onl

4. Press the ENTER key to enter parameter P4.0. See

Figure 32.

5. Press the or keys to toggle between NO and

YES.

• NO retains current settings

• YES resets to factory default settings.

6. Press the ENTER key to confirm selection and to return to the measurement mode.

Otherwise press CAL/MEAS key to return to measurement mode without resetting to

factory default.

Notes:

• To clear all conductivity & TDS data, see Section 7.9.1.

• See Addendum 4 for a table of factory default settings.

40

Page 45

Instruction Manual PC 300

7.6 P5.0: View ing Previous Conductivity Calibration data

This mode lets you recall previous calibration data, which

helps you know when to re-calibrate your meter. This is a

“view only” mode.

This function applies for conductivity & TDS mode.

From conductivity or TDS measurement mode:

1. Press the MODE key to select conductivity or TDS

measurement mode.

2. Press the SETUP key to enter Set up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P5.0.

4. Press ENTER key repeatedly to view previous

calibration data.

5. Each calibration data corresponds to each

measurement range.

• P5.1 = Range 1 (0.00 – 19.99 µS or

• P5.2 = Range 2 (0.0 – 199.9 µS or

• P5.3 = Range 3 (0 – 1999 µS or

• P5.4 = Range 4 (0.00 – 19.99 mS or

• P5.5 = Range 5 (0.0 – 199.9 mS or

0.00 – 9.99 ppm)

0.0 – 99.9 ppm)

0 – 999 ppm)

0.00 – 9.99 ppt)

0.0 – 99.9 ppt)

6. When you have scrolled through all calibration data,

you will automatically return to the subgroup menu.

Press CAL/MEAS key to return to measurement

mode.

NOTES:

If there is no previous calibration data at a particular

point, the primary display will show “- - -“.

41

Figure 33 - View calibration data

in conductivity probe

Page 46

Instruction Manual PC 300

7.7 P6.0: View ing Conductivity Probe Data

Program 6 has five “view only” options that let you check

the probe’s parameters for diagnostic purposes. These

options show you the effective cell constant for each

range. The cell constant is adjusted according to your

calibration.

This function applies for conductivity & TDS mode.

From conductivity or TDS measurement mode

1. Press the MODE key to select conductivity or TDS

measurement mode.

2. Press the SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P6.0.

4. Press the ENTER key repeatedly to view the

effective cell constant for each range.

• P6.1 = Range 1 (0.00 – 19.99 µS or

0.00 – 9.99 ppm)

• P6.2 = Range 2 (0.0 – 199.9 µS or

0.0 – 99.9 ppm)

• P6.3 = Range 3 (0 – 1999 µS or

0 – 999 ppm)

• P6.4 = Range 4 (0.00 – 19.99 mS or

0.00 – 9.99 ppt)

• P6.5 = Range 5 (0.0 – 199.9 mS or

0.0 – 99.9 ppt)

5. When you have scrolled through all probe data, you

will automatically return to the subgroup menu. Press

the CAL/MEAS key to return to measurement mode.

See figure 34.

Notes

Figure 34 - View probe data for

each measurement range

Cell constants will degrade with time and usage. You

can use this feature to alert you to the need for a new

probe prior to total failure.

(The values shown above are for illustration purpose. Your meter may display diffe rent values depending on the settings &

your environmental conditions)

42

Page 47

Instruction Manual PC 300

7.8 P7.0: Condu ctivity or TDS Measurement Configuration

P7.1: READY indicator and auto endpoint function

This program lets you select:

• “READY indicator on

” to indicate when the reading

is stable.

• “READY indicator off

• Auto endpoint functi on on

” for faster meter response.

. Select auto endpoint on

to “hold” the reading when it is stable for more than 5

seconds. The display automatically freezes, and the

HOLD indicator appears on the left side of the

display. Press the HOLD key to release the display

and access other functions.

From measurement mode

1. Press the MODE key to select conductivity or TDS

measurement mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P7.0.

4. Press ENTER key to select parameter 7.1.

5. Press the or keys to select the configuration

you require.

• OFF switches the READY indicator off;

• ON switches the READY indicator on.

• ON and HOLD together switches the auto

endpoint feature on.

6. Press ENTER key to confirm selection and to

proceed to step 4 of P7.2. You can also press the

CAL/MEAS key to return back to measurement

Figure 35 - Configuring the

Figure 36 – P 3.1: Selecting

READY feature

READY function)

mode.

NOTE: Meter default is set for Ready Indicator on, and auto endpoint function off.

43

Page 48

Instruction Manual PC 300

P7.2 Selecting °C or °F

You can select between °C and °F units for temperature

readings. Meter default is °C.

From measurement mode

7. Press the MODE key to select conductivity

measurement mode.

8. Press SETUP key to enter Set Up mode.

9. Press the or keys to scroll through subgroups

until you view parameter P7.0.

10. Press the ENTER key two times to select parameter

7.2.

11. Press the or keys to toggle between °C and °F.

12. Press the ENTER key to confirm selection and to

proceed to step 3 of P7.3. Press the CAL/MEAS

key to return to measurement mode.

Figure 37 - Change Temperature

measurement unit

See Figure 37.

NOTES:

• You can switch bet ween °C and °F in Program P3.3 (available from pH mode). If you

switch between °C and °F in conductivity mode, the meter will also switch in pH mode.

44

Page 49

Instruction Manual PC 300

P7.3 Selecting Automatic or Manual Temperature Compensation

This feature lets you select between Automatic

Temperature Compensation (ATC) and Manual

Temperature Compensation. Meter default is ATC.

From measurement mode

1. Press the MODE key to select conductivity

measurement mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through subgroups

until you view parameter P7.0.

4. Press the ENTER key three times to select

parameter 7.3. The upper display shows “ATC” and

the lower display shows “P7.3”.

5. Press the ENTER key again. The upper display

shows “ATC” and the lower display shows “YES” or

“NO”.

6. Press the or keys to select the Automatic

Temperature Compensation on or off.

• YES = ATC on; NO = ATC off

7. Press the ENTER key to confirm selection and

proceed to P7.4 next page. Press the CAL/MEAS

key to return to measurement mode.

45

Figure 38 - Selecting ATC on or off

Page 50

Instruction Manual PC 300

P7.4 Setting the TDS factor

The concentration of salts dissolved in solution increases

the conductivity of that solution. This relationship varies

from salt to salt and is roughly linear over a given range

for a given salt. The TDS conversion factor is the

number used by the meter to convert from conductivity to

TDS.

To determine the conductivity to TDS conversion

factor for your solution:

Addendum 1 and 2 on this sheet describes the

conversion factors and how to calculate the TDS

conversion factor for other solutions.

You can set the TDS conversion factor between 0.4 and

1.0; meter default is 0.5.

From measurement mode

1. Press SETUP key to enter Set Up mode.

2. Press the or keys to scroll through subgroups

until you view parameter P7.0.

3. Press the ENTER key five times to select parameter

7.4. The upper display shows “tdS” and the lower

display shows “P7.4”.

4. Press the ENTER key again. The upper display

shows a value and the lower display shows “tdS”.

5. Calculate the TDS factor of your solution. See

Addendum 2 on this sheet for information on how to

calculate the TDS factor.

6. Press the or keys to select your calculated

TDS conversion factor.

7. Press the ENTER key to confirm selection and to

return to the subgroup menu. Press the CAL/MEAS

key to return to measurement mode.

46

Figure 39 - Change of TDS factor

Page 51

Instruction Manual PC 300

7.9 P8.0 Temperature

P8.1 Selecting the temperature coefficient

The temperature coefficient is the amount of change in

conductivity per degree of temperature; it is expressed

in percent per °C. Entering the exact temperature

coefficient of your solution lets you accurately

compensate temperature for almost any solution *.

You can adjust 0.0 to 10.0 % per °C. Meter default is

2.1% per °C.

From measurement mode

1. Press the MODE key to select conductivity

measurement mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through

subgroups until you view parameter P8.0.

4. Press the ENTER key to select parameter 8.1.

The display shows “t.CO” on the upper display.

5. Press the ENTER key again. The upper display

shows the temperature coefficient and the lower

display shows “t.CO”.

6. Press the or keys to select the temperature

coefficient of your solution.

7. Press the ENTER key to confirm selection and to

proceed to step 3 of P8.2. Press the CAL/MEAS

key twice to return to measurement mode.

Notes

* If you do not know the temperature coefficient of your

solution you can determine the correct value using the

formula in Addendum 3 “Calculating Temperature

Coefficients”.

47

Figure 40 - Changing the

temperature coefficient

Page 52

Instruction Manual PC 300

P8.2 Adjusting the normalization temperature

Your meter will normalize its conductivity

measurements to a standard temperature that you can

select. You can adjust the normalization temperature

from 15 to 30 °C (59 to 86 °F). Meter default is 25 °C

(77 °F).

From measurement mode

1. Press the MODE key to select conductivity

measurement mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through

subgroups until you view parameter P8.0.

4. Press the ENTER key three times to select

parameter 8.2. The display shows “t.nr” on the

upper display.

5. Press the ENTER key again. The upper display

shows the normalization temperature and the

lower display shows “t.nr”.

6. Press the or keys to select the

normalization temperature.

7. Press the ENTER key to confirm selection and to

return to the subgroup menu. Press CAL/MEAS

key to return to measurement mode.

48

Figure 41 - Adjusting the

normalization temperature

Page 53

Instruction Manual PC 300

7.9.1 P9.0: Resetting to factory default settings (conductivity)

Program 9.0 lets you reset all parameters to factory

default settings. This clears all calibration data and

any other conductivity setup functions you might

have changed.

From measurement mode

1. Press the MODE key to select conductivity

measurement mode.

2. Press SETUP key to enter Set Up mode.

3. Press the or keys to scroll through

subgroups until you view parameter P9.0.

4. Press the ENTER key to enter parameter P9.0.

5. Press the or keys to toggle between NO

and YES.

• NO retains current settings; YES resets

to factory default settings.

6. Press the ENTER key to confirm selection and

to return to the measurement mode. Otherwise

press CAL/MEAS key to return to

measurement mode without resetting to factory

default.

See Figure 42.

Notes:

To clear all pH data, see Section 7.5.

See Addendum 4 for a table of factory default settings.

Figure 42 – P9.0: Reset to factory

default values

49

Page 54

Instruction Manual PC 300

8 PROBE CARE AND MAINTENANCE

8.1 pH Electrode care

Since your pH electrode is susceptible to dirt and contamination, clean it every one to three

months depending on the extent and condition of use.

NOTE: For specialty electrode care, consult the instruction manual included with your

electrode.

pH electrode storage

For best results, always keep the pH bulb wet. Use the protective electrode storage bottle or

rubber cap filled with electrode storage solution to store your electrode. Also, you can store in

a pH 4 buffer with 1/100 part of saturated KCl. Other pH buffers are OK for storage, but

NEVER use distilled water for storage.

After measuring

1. Rinse the pH electrode and reference junction in de-ionized water.

2. Store the electrode as recommended above in “pH electrode storage,” or as

recommended by the manufacturer.

3. Prior to next use, rinse the liquid junction with de-ionized water and tap dry – never wipe

electrode.

NOTE: If this does not restore electrode to normal response, see “Reactivating the pH

electrode” section below.

pH electrode cleaning

• Salt deposits: Dissolve the deposits by immersing the electrode in tap water for ten to

fifteen minutes. Then thoroughly rinse with distilled water.

• Oil/Grease film: wash electrode pH bulb gently in some detergent and water. Rinse

electrode tip with distilled water or use a general purpose electrode cleaner (see

ordering information).

• Clogged reference junction: Heat a diluted KCl solution to 60 to 80 C. Place the

sensing part of the electrode into the heated solution for about 10 minutes. Allow the

electrode to cool in some unheated KCl solution.

• Protein deposits: Prepare a 1% pepsin solution in 0.1 M of HCl. Set the electrode in

the solution for five to ten minutes. Rinse the electrode with distilled water.

50

Page 55

Instruction Manual PC 300

Reactivating the pH electrode

If stored and cleaned properly, your pH electrode should be ready for immediate use.

However, a dehydrated bulb may cause sluggish response. To rehydrate the bulb, immerse

the electrode in a pH 4 buffer solution for 10 to 30 minutes. If this fails, the electrode requires

activation. Never touch or rub glass bulb. Contact builds up an electro-static charge.

pH electrode activation (for glass body electrodes only)

WARNING: Only qualified persons proficient with the safe handling of dangerous chemicals

should perform the procedure below. Provide proper containers, fume hoods, ventilation, and

waste disposal. Safety goggles and protective clothing must be worn while performing this

procedure. If possible, replace with another electrode instead of performing this re-activation

procedure.

1. Dip or stir the pH electrode in alcohol for 5 minutes.

2. Leave the electrode in tap water for 15 minutes.

3. Dip and stir the electrode in concentrate acid (such as HCl or H

) for five minutes.

2SO4

4. Repeat Step 2.

5. Dip and stir in strong base (NaOH) for five minutes.

6. Leave for 15 minutes in tap water.

7. Now test with standard calibration buffer solutions to see if the electrode yields

acceptable results. You may repeat step 3 through 6 up to three times for better

response. If the response does not improve, then your electrode is no longer functioning.

Replace with a new electrode – call your distributor for information.

51

Page 56

Instruction Manual PC 300

8.2 Conductivity Electrode

Keep the conductivity probe clean. Rinse the probe twice,

and gently swirl it while you take readings. For best

accuracy, soak a dry probe for at least 5 to 10 minutes or

longer before calibration. Rinse the probe with de-ionized

water before storing. Never scratch the bands with a hard

substance. Do not strike the probe against any hard

surface.

Do not immerse the probe in oily solutions. Clean the

electrode thoroughly by stirring it in a mild detergent bath

or isopropyl alcohol. Wipe the probe with a soft tissue

paper. Rinse thoroughly in tap water and then in deionized water. Recalibrate the meter after cleaning the

probe.

The conductivity probe (Order Part No. ECCONSEN91W/ 35608-50) which is included with your

meter features a removable probe guard to make

cleaning easy.

To remove probe guard:

1. Grip yellow probe guard and twist clockwise. The

locking notch will release.

2. Slide probe guard off end of probe.

52

Figure 43 - Conductivity probe,

EC-CONSEN91W/ 35608-50

Page 57

Instruction Manual PC 300

9 TROUBLE SHOOTING GUIDE

Problem Cause Solution

Press ‘ON’ key but

no display

Not responding to

key press

Unstable readings d) Air bubbles in probe.

“OR” on upper

display

Temperature

reading erratic or

lower display reads

“OR”

Slow response a) Dirty / Oily probe. a) Clean probe. See “Probe

a) Batteries not in place

b) Batteries not in correct polarity

(+ and – position).

c) Weak batteries

a) HOLD mode in operation.

b) Damaged key pad.

c) Internal program error.

e) Dirty probe.

f) Probe not deep enough in

sample.

g) External noise pickup or

induction caused by nearby

electric motor.

h) Broken probe.

a) Probe is shorted.

b) Probe is in an out-of-range

solution.

c) Broken probe.

a) Temperature of solution is

out of range.

a) Check that batteries are in

place and making good

contact.

b) Re-insert batteries with correct

polarity.

c) Replace batteries.

a) Cancel HOLD mode by

pressing Hold key.

b) Return to dealer.

c) Reset all internal programs

by reinserting batteries.

d) Tap probe to remove

bubbles.

e) Clean the probe and re-

calibrate.

f) Make sure sample entirely

covers the probe sensors.

g) Move or switch off interfering

motor.

h) Replace probe.

a) Test probe. Make sure probe

is fully connected to meter.

b) Use different solution.

c) Replace probe. See

Accessories Section.

a) Heat or cool solution.

Care & Maintenance”,

Section 8.

53

Page 58

Instruction Manual PC 300

10 ERROR MESSAGES

LCD Display Indicates Cause Solution

Err annunciator Unrecognized input

CAL & Err

annunciators on /

Buffer and

electrode

indicators blink.

Battery indicator

blinks

from keypad

Calibration error. Wrong value input at

Low battery level. Need new batteries or

If an error persists, or the meter shows incorrect values, return the meter. Refer to “Warrant y”

and “Return of Items”.

For a complete diagram of the display see Section 1.

Wrong input in selected

mode.

calibration.

Dirty probe.

battery connection is

bad.

Release key. Select valid

operations depending on

mode.

Check your input value,

clean probe.

See Calibration sections or

Probe Maintenance

section.

Clean battery contacts.

Replace batteries with fresh

ones, noting polarity.

54

Page 59

Instruction Manual PC 300

11 SPECIFICATIONS

Mode pH Temperature Conductivity TDS

Range

-2.00 to 16.00 pH

Resolution

0.01 pH

Accuracy

Calibration

pH Slope & Offset

Display

pH Buffer Option

Conductivity Cell

constant (k)

Conductivity

Temperature

Coefficient

Normalization

Temperature

Auto-ranging Yes Yes

Inputs

Temperature

Compensation

Operating

Temperature

HOLD function Yes

Averaging/Stability

(READY)/Auto-hold

Display Custom Dual LCD

Auto Power off 20 minutes after last key operation

Power four 1.5 V AAA-sized batteries (included)

Battery life >100 hours

Dimensions / Weight

± 0.01 pH

Up to five points with

automatic buffer

recognition

Yes

USA (pH 1.68, 4.01,

7.00, 10.01, 12.45)

NIST (pH 1.68, 4.01,

6.86, 9.18, 12.45)

1.0 1.0

BNC

-10.0 to 110.0 °C

( 14.0 to 230.0

°F)

0.1 °C

(0.1 °F)

± 0.5 °C

(±0.5 °F)

Offset in 0.1 °C

increments

6-pin round

connector

Automatic / Manual from 0 to 100 °C

0 to 50 °C

Meter: 19 cm (L) x 10 cm (W) x 6 cm (H); 320 g

Case: 34 cm (L) x 40 cm (W) x 10 cm (H); 2.2 kg

0 to 19.99 µS

0 to 199.9 µS

0 to 1999 µS

0 to 19.99 mS

0 to 199.9 mS

0.01 µS

0.01 mS

±1% Full Scale +

Up to five points

(one point per

0.0 to 10.0 % per

15.0 to 30.0 °C

(adjustable)

6-pin round

connector

Yes

0.1 µS

1 µS

0.1 mS

1 digit

range)

°C

0 to 9.99 ppm

0 to 99.9 ppm

0 to 999 ppm

0 to 9.99 ppt

0 to 99.9 ppt

Max of 199.9 ppt

based on factor

setting

0.01 ppm

0.1 ppm

1 ppm

0.01 ppt

0.1 ppt

±1% Full Scale +

1 digit

Up to five points

(one point per

range)

0.0 to 10.0 % per

°C

15.0 to 30.0 °C

(adjustable)

6-pin round

connector

55

Page 60

Instruction Manual PC 300

12 ACCESSORIES

Replacement Meter and Meter accessories

Item Eutech Instruments

Ordering Code No.

Waterproof PC 300 Hand-held

pH/conductivity/TDS/Temperature meter complete

with pH electrode, conductivity probe of k=1.0

Epoxy body double junction pH electrode with 1-m

cable.

3 ring SS, Ultem body Electrode with ATC, cell

constant = 1.0, 12x110 mm, 1m cable length

“3-in-1” pH / Temperature combination electrode

with 1-m cable for waterproof PC 300

Temperature probe for Waterproof PC 300 EC-PHWPTEM-01W 35618-05

Carrying Kit with empty bottles EC-WPDRY-KIT 35632-98

Electrode Storage Solution EC-RE-005 00653-04

Electrode Cleaning Solution EC-DPC-BT 00653-06

EC-PCWP300/03K 35631-00

EC-FE72522-01B 35641-51

EC-CONSEN91W 35608-50

EC-FE73528-01W 35808-71

Oakton Instruments

Ordering Code No.

56

Page 61

Instruction Manual PC 300

Calibration Solutions

Item Eutech Instruments

Ordering Code No.

pH 4.01 buffer solution, 480 ml bottle (1 pint) EC-BU-4BT 00654-00

pH 7.00 buffer solution, 480 ml bottle (1 pint) EC-BU-7BT 00654-04

pH 10.01 buffer solution, 480 ml bottle (1 pint) EC-BU-10BT 00654-08

pH 4.01 buffer sachets, 20 ml x 20 pcs. EC-BU-4BS 35653-01

pH 7.00 buffer sachets, 20 ml x 20 pcs. EC-BU-7BS 35653-02

pH 10.01 buffer sachets, 20 ml x 20 pcs. EC-BU-10BS 35653-03

1,413 µS KCl Calibration Solution in 480-ml leakproof bottle (1 pint)

12.88 mS KCl Calibration Solution in 480-ml leakproof bottle (1 pint)

2,764 µS KCl Calibration Solution in 480-ml leakproof bottle (1 pint)