Page 1

Instruction Manual

CyberScan CON 1500

Bench Conductivity/ TDS/ Resistivity Meter

Copyright © 2006 All rights reserved.

Eutech Instruments Pte Ltd

Oakton Instruments

Version 1.1 ML

ENGLISH

Page 2

1 INTRODUCTION 3

2 DISPLAY AND KEYPAD FUNCTIONS 3

2.1 Display 3

2.2 Keypad 3

3 PREPARATION 4

3.1 Conductivity Electrode Information 4

3.2 Connectors 4

3.3 Connecting the AC/DC Adapter 4

3.4 Connecting the Electrode Holder 4

4 CALIBRATION 5

4.1 Important Information on Meter Calibration 5

4.2 Preparing the Meter for Calibration 5

4.3 Temperature Calibration 5

4.4 Automatic or Manual, Single or Multi point Calibration (P5.0) 5

4.4.1 Selection of Automatic or Manual Calibration (P5.0) 6

4.4.2 Selection of Single or Multi Point Calibration (P5.0) 6

4.5 Automatic Calibration (For Conductivity Calibration Only) 6

4.5.1 Multi point calibration 6

4.6 Manual Calibration (For Conductivity, TDS & Resistivity Calibration) 6

4.6.1 Multi point calibration: 7

4.7 TDS Calibration 7

4.7.1 Calibrating TDS with conductivity standards & adjusting TDS factor 7

4.7.2 Setting the TDS Conversion Factor (P6.0) 7

4.7.3 Calibrating for TDS using TDS standards 7

5 MEASUREMENT 8

5.1 Temperature Compensation 8

5.2 Taking Measurements 8

5.3 Set the Stability Indicator (P8.0) 8

6 MEMORY FUNCTION 8

6.1 Memory Input 8

6.2 Memory Recall 8

6.3 Clear Stored Data (P13.0) 8

7 COMMUNICATION / PRINT FUNCTION 9

7.1 Connecting the RS232C Cable 9

7.2 Using the Meter with Printer or Computer 9

7.2.1 Set the Baud Rate( P9.0) 9

7.2.2 Set the Parity Bit (P10.0) 9

7.2.3 Set the Stop Bit (P11.0) 9

7.3 Select Printing options (P12.0) 9

8 OTHER FUNCTIONS 10

8.1 Viewing Calibration & Electrode data (P1.0) 10

8.2 Clear User Calibration (P14.0) 10

8.3 Selection of cell constant (P2.0) 10

8.4 Setting the temperature coefficient (P3.0) 10

8.5 Setting the normalisation temperature (P4.0) 11

8.6 Selection of °C or °F (P7.0) 11

9 MAINTENANCE 11

9.1 Replatinisation of 2-Cell Electrode P15.0 11

9.1.1 Replatinisation procedure 11

9.2 Cleaning the meter 12

9.3 Electrode Care 12

10 ERROR MESSAGES 12

Oakton Instruments

P.O Box 5136,

Vernon Hills, IL 60061,

USA

Tel: (1) 888-462-5866

Fax: (1) 847-247-2984

info@4oakton.com

www.4oakton.com

www.oaktoninstruments.com

Eutech Instruments Pte Ltd.

Blk 55, Ayer Rajah Crescent,

#04-16/24 Singapore 139949

Singapore

Tel: (65) 6778 6876

Fax: (65) 6773 0836

marketing@eutechinst.com

www.eutechinst.com

Eutech Instruments Europe bv

Wallerstraat 125k

3862 CN Nijkerk

The Netherlands

Tel: (31) 33 2463887

Fax: (31) 33 2460832

info@eutech.nl

www.eutech.nl

Page 3

1 INTRODUCTION

This manual contains the operating features of this meter. At some points this manual will refer to our

website www.eutechinst.com,for further explanation and background information, it will be indicated with this

symbol:

On this website you can also find additional information regarding applications, measuring theories and hints

& tips.

At the final page of this manual you can find information about the specifications of this meter, warranty

issues and how to return your product to us.

2 DISPLAY AND KEYPAD FUNCTIONS

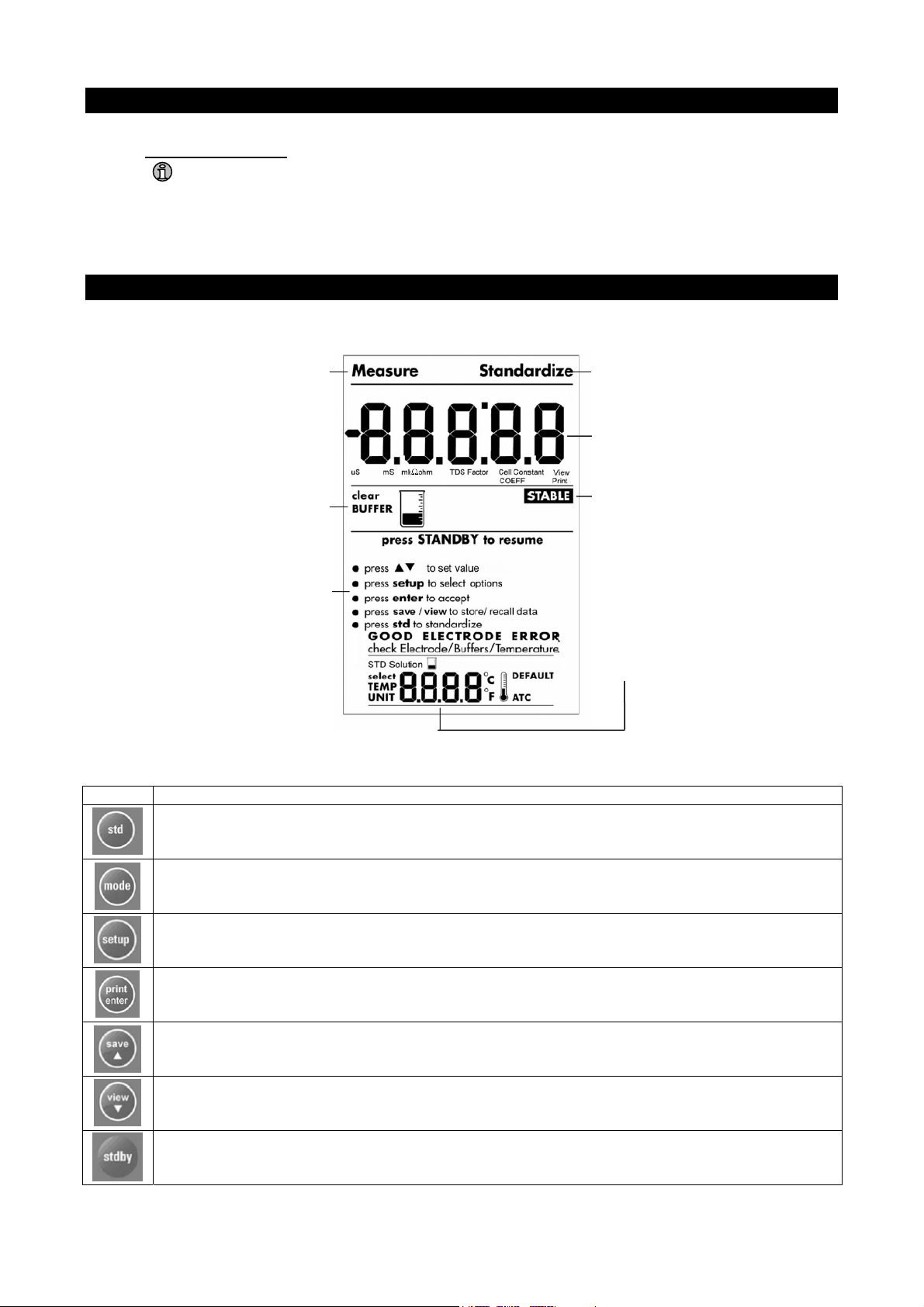

2.1 Display

Measurement

mode

Buffer

information

Calibration mode

Displays the Conductivity, TDS or

Resitivity value in measurement or

calibration mode

Stable icon

Prompts

Displays Temperature value

2.2 Keypad

KEY Function

Press to initiate standardisation or to exit and return to measurement without accepting the

calibration.

Press to select uS, kohm or TDS.

Press to access setup for configuration of meter setting.

PRINT: Press to print stored data from memory or current reading to a PC or printer (depending on

meter setup).

ENTER: Press to confirm selection or change being made.

Press to increment value or scroll up selection.

Press to store displayed data into memory

Press to decrement value or scroll down selection.

Press to recall and select memory location of stored data

Press to start up or put the meter in standby mode.

Page 4

3 PREPARATION

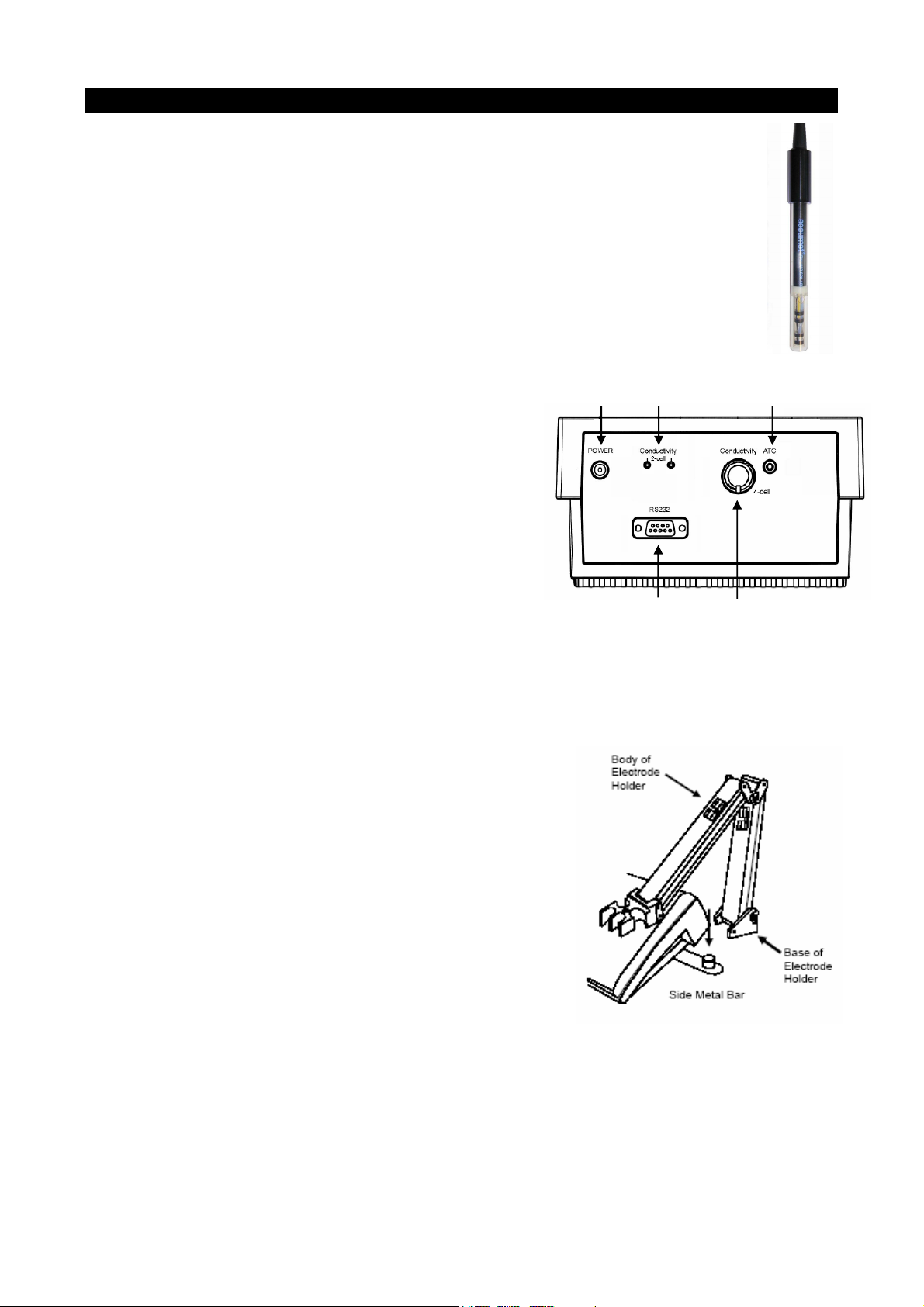

3.1 Conductivity Electrode Information

A 2-cell or 4-cell conductivity probe can be connected. Your meter includes a 4-Cell

conductivity electrode (Part No: EC620-165) with an electrode constant of K = 1.0. This

conductivity / TDS electrode features a built-in temperature sensor for Automatic

Temperature Compensation (ATC).

Prior to use, remove the protective cover from the end of the probe, soak the probe in

distilled or deionised water for 10 minutes. You may either:-

1. Connect the 2-cell probe by plugging its pin connectors into the dual pin sockets located

at the rear panel of the meter.

2. Connect the 4-cell probe by plugging its DIN connector into the DIN socket at the rear

panel of the meter.

3. Connect the ATC probe by plugging the 1/8” mini-phone jack into the ATC socket l

at the rear panel of the meter.

Note: DO NOT use both probes together (2 and 4 cell)

1.

ocated

2.

4-Cell Conductivity

probe EC620-165

3.

3.2 Connectors

The meter has 6 connectors:

1. Power connector (center negative)

2. 2-Cell conductivity connector

3. Temperature connector

4. RS232 connector

5. 4-Cell conductivity connector with built in Temperature

probe

CAUTION: Do not pull on the electrode cord to avoid internal

wire breakages.

4.

5.

3.3 Connecting the AC/DC Adapter

The AC/DC adapter must be unplugged. Ensure that main voltage matches the adapter. Slide the AC/DC

adapter jack into the socket marked POWER of the meter. AC/DC adapter specifications: Input Voltage: 110

or 220 V • Output Voltage: 12 VDC • Current: 500 mA.

NOTE: Ensure the input voltage matches your adapter before connection.

3.4 Connecting the Electrode Holder

This meter’s base plate has a side metal bar for a swivel electrode

holder. The holder can be mounted on either right or left side of the

meter.

To position the electrode arm:

Use a screwdriver to remove the screw holding the side bar. Line up

the side bar with the second screw slot. Use the earlier removed

screw to secure the side bar.

To install the electrode arm to the meter:

Align the slot of the arm with the metal rod at the metal side bar.

Push it down until it fully sits into position.

Page 5

4 CALIBRATION

4.1 Important Information on Meter Calibration

Your meter has four measuring ranges. You have an option of calibrating your meter in a single point

calibration for all the 4 ranges or for better accuracy; you can calibrate one point in each of the measuring

ranges (up to four points).

When you perform a

single point recalibration, the old calibration will be replaced by the new one even if the

new calibration is done in a different range from the old calibration. For example, if you have previously

calibrated at 1413 µS in 0 to 2000 µS range, and you recalibrate at 12.88 mS in 0 to 20.00 mS range, the

new calibration will override the previous calibration in 0 to 2000 uS range.

In the case of

multi point calibration, when you perform a multi point recalibration, old calibrations are

replaced only on a range basis. For example, if you previously calibrated at 1413 µS in 0 to 2000 µS range

and you recalibrate at 1500 µS (also in 0 to 2000 µS range), the meter will replace only the old calibration

data (1413µS) in that range. The meter will retain all calibration data in other ranges. To completely

recalibrate your meter, or when you use a replacement electrode, it is best to clear all calibration data.

The measuring ranges are:

Meter range symbol Conductivity range TDS range Resistivity range

r1 0 µS – 200.0 µS/cm 0 – 200.0 ppm 0 – 20.00 KΩ

r2 200.0 µS – 2.000 mS/cm 200.0 – 2000 ppm 20.00 – 200.0 KΩ

r3 2.000 mS – 20.00 mS/cm 2000 – 20000 ppm 200.0 KΩ – 2.000 MΩ

r4 20.00 mS – 500.0 mS/cm 20000 – 99999 ppm 2.000 – 100.0 MΩ

4.2 Preparing the Meter for Calibration

Before starting calibration, make sure you are in the correct measurement mode. For best results, select a

standard value close to the sample value you are measuring.

4.3 Temperature Calibration

Your electrode features a built-in temperature sensor which is factory calibrated. Calibrate your sensor only if

you suspect temperature errors may have occurred over a long period of time or if you have a replacement

electrode.

1. Connect the electrode.

2. Switch the meter on.

3. Press std.

4. Press mode to enter temperature calibration mode.

5. Dip the electrode into a solution of known temperature (i.e. a temperature bath). Allow

time for the built-in temperature sensor to stabilize.

6. Scroll with save/▲ or view/▼ to set the correct temperature value (i.e. the temperature

of the temperature bath). Maximum offset value is ±5.0 °C.

7. Press enter to confirm. The meter will be calibrated and return to measure mode.

Note: To exit without confirming the temperature calibration value, press std.

Note: Since temperature affects the accuracy of conductivity, TDS and Resistivity, it is recommended to

carry out a conductivity, TDS or Resistivity calibration after a temperature calibration is done.

4.4 Automatic or Manual, Single or Multi point Calibration (P5.0)

You can either choose automatic conductivity calibration or manual conductivity, TDS or Resistivity

calibration.

In the

automatic calibration mode, the meter automatically detects and verifies the appropriate known

calibration standards solutions before accepting these particular calibration standards as one of its

calibration values in a specific measurement range. The known calibration standards used for automatic

calibration are:

At 25.0°C : 84µS , 1413µS , 12.88mS , 111.8mS

At 20.0°C : 76µS , 1278µS , 11.67mS , 102.1mS

manual calibration, non-standard calibration values can be used. You can manually input the

In the

appropriate values as your desired calibration standards in each specific range.

Page 6

4.4.1 Selection of Automatic or Manual Calibration (P5.0)

Automatic calibration is applicable in conductivity measurement mode only, manual calibration is applicable

in conductivity, TDS and Resistivity mode. Only from the conductivity measurement

mode;

1. Press setup.

2. Press save/▲ or view/▼ until you view parameter P5.0 (ACAL).

3. Press enter

4. Press save/▲ or view/▼ to select. “YES” activates automatic calibration, “NO”

activates manual calibration.

5. Press enter to confirm or std to return to measurement mode.

4.4.2 Selection of Single or Multi Point Calibration (P5.0)

Single point calibration lets you have a single calibration factor for all 4 ranges by calibrating one point in

either one of the ranges, this factor is applied to all the ranges.

Multi point calibration gives better calibration accuracy by letting you calibrate in each of the 4 ranges, this

calibration factor would only be applicable in the particular range where the calibration is done.

1. Press setup

2. Press save/▲ or view/▼ until you view SPCAL. This will only be shown if setup is

entered from Resistivity or TDS mode. When setup is entered from the conductivity

mode you need to repeat step 1 to 5 from p 4.41 first.

3. Press enter

4. Press save/▲ or view/▼ to select. “YES” activates single point calibration, “NO”

activates multi point calibration.

5. Press enter to confirm or std to return to measurement mode.

4.5 Automatic Calibration (For Conductivity Calibration Only)

Standard buffer values: 84.0 uS/ 1.413 mS/ 12.88 mS/ 111.8 mS

This procedure describes the method for calibration to a 1413 µs calibration standard.

Note: select

Note: select

automatic or manual calibration as described in p 4.4.1

single -or multi point calibration as described in p 4.4.2

Note: To exit without confirmation, press std to go back to measurement mode.

1. If necessary, press mode to select conductivity mode.

2. Rinse the electrode with de-ionized water or a rinse solution, then rinse with a small

amount of calibration standard.

3. Dip the electrode into the calibration standard. Immerse the electrode tip beyond the

upper steel band. Stir the electrode gently to create a homogeneous sample. Allow

time for the reading to stabilize.

4. Press std to enter calibration mode. Standardize will appear in the upper corner of the display. The

primary display shows the current measured value, the secondary display shows the calibration standard

value.

5. Wait for Stable to appear

6. Press enter to confirm. The meter will now return to the measurement mode.

4.5.1 Multi point calibration

Repeat step 1 to 6 for every calibration point in each measuring range using the known calibration solutions

until all points have been calibrated.

4.6 Manual Calibration (For Conductivity, TDS & Resistivity Calibration)

This procedure describes calibration to a 1413 µs calibration standard.

Note: select

Note: select

automatic or manual calibration as described in p 4.4.1

single -or multi point calibration as described in p 4.4.2

Page 7

Note: To exit without confirmation, press std to go back to measurement mode.

Note: Ensure you set the correct TDS factor before TDS calibration.

1. Repeat step 1 to 4 from p 4.5. Both displays will show the current value.

2. Wait for the value to stabilize and press save/▲ or view/▼, adjust the value in the

upper display to the calibration standard used.

3. Press enter to confirm and return to measurement mode.

4.6.1 Multi point calibration

Repeat step 1 to 3 for every calibration point in each measuring range using the

calibration solutions until all points have been calibrated.

Note: If the standardisation is successful, the meter displays buffer icon in the middle part of the display in

the measurement mode.

4.7 TDS Calibration

4.7.1 Calibrating TDS with conductivity standards & adjusting TDS factor

Instead of calibrating for TDS directly using TDS calibration standard solutions, you can calibrate by using

the conductivity calibration method and enter the appropriate TDS conversion factor into the meter. For more

information regarding TDS Conversion Factor determination, please refer to our website:

www.eutechinst.com

4.7.2 Setting the TDS Conversion Factor (P6.0)

The factory default setting for TDS conversion factor is 0.5. If your

solution has a different TDS factor, you can improve accuracy by

setting the TDS factor prior to calibration.

1. Press mode to select TDS mode.

2. Press setup.

3. Press save/▲ or view/▼ until you view P6.0

4. Press enter.

5. Press save/▲ or view/▼ to select your calculated TDS conversion

factor.

6. Press enter to confirm and return to measurement mode or std to return to measurement mode.

4.7.3 Calibrating for TDS using TDS standards

After setting the correct TDS Factor, you can calibrate in the TDS mode.

1. Press mode to select the TDS mode.

2. Follow the instructions in p 4.6 for the rest of the calibration process, this time using the TDS calibration

standards.

Note: You can offset the TDS reading up to ± 40% from the default setting. If your measured value differs by

more than ± 40%, clean or replace electrode as needed.

Page 8

5 MEASUREMENT

5.1 Temperature Compensation

This meter can take measurements with automatic (ATC) or manual (MTC) temperature compensation (MTC

for 2-Cell electrode only). Factory default is ATC on. For ATC, attach the temperature electrode.

5.2 Taking Measurements

1. Rinse the electrode with de-ionized or distilled water before use. Shake or air dry. To avoid

contamination or dilution of your sample, rinse electrode with a small volume of your sample liquid.

2. Press stdby to switch on meter.

3. Dip the electrode into the sample. When dipping the electrode into the sample, ensure that the liquid

level is above its upper band. Stir the electrode gently in the sample to create a homogenous sample.

4. Allow time for the reading to stabilize.

5. Press mode to toggle between conductivity, TDS & Resistivity readings (if necessary).

5.3 Set the Stability Indicator (P8.0)

For activating or de-activating the stability indicator (STABLE icon appears when reading stabilises).

1. Press setup.

2. Press save/▲ or view/▼ until you view P8.0

3. Press enter to select.

4. Press save/▲ or view/▼ to select: “YES”, stable is on or “NO”, stable is off.

5. Press enter to confirm selection or std to return to measurement mode.

6 MEMORY FUNCTION

The meter stores up to 100 sets of data. Sets include conductivity, TDS, Resistivity and temperature.

6.1 Memory Input

Press save/▲ during measurement to input data into the memory. A memory location will appear for a

moment. If necessary, measure the next sample solution and press view/▼ key to input the next data into

the memory.

Note: If the memory is full the first value stored will be overwritten.

6.2 Memory Recall

1. Press view/▼ once to retrieve the last reading stored.

2. Press enter to recall the reading

3. Press enter to return to the next memory location screen.

4. Press save/▲ or view/▼ to scroll to a specific memory location, press enter to select.

5. Press std to exit Memory Recall.

Note: Readings stored in memory are retained even if the unit is turned off.

6.3 Clear Stored Data (P13.0)

Clears all stored data sets (from previous measurements) in the meter’s memory.

1. Press setup

2. Press save/▲ or view/▼ until you view P13.0.

3. Press enter

4. Press save/▲ or view/▼ to select: “YES”, to clear all data or “NO”, retains all data.

5. Press enter to confirm selection or std to return to measurement mode.

Note: After pressing enter to confirm the clearing of memory, “clear” will blink. Wait till it stops blinking

before proceeding with the next button press.

Page 9

7 COMMUNICATION / PRINT FUNCTION

7.1 Connecting the RS232C Cable

The meter provides an RS232C output for transmitting readings to a p

or computer via a cable. The output data is in the ASCII format. This for

rinter

mat

allows the data to be imported by a variety of software that reads ASCII

data (e.g. Microsoft’s Excel, Lotus, Quattro-pro etc.). A complimentar

Acquisition Software (DAS) is provided and it captures data transm

y Data

itted

into an ASCII file for later use.

1. Plug the RS232C connector into the RS232C port of the meter ensuring

the correct orientation.

2. Secure the RS232C connector by fastening the two screws at the side o

f

the male RS232C connector. The meter has an RS232 communication port for printing data to a printer or

computer. To use the meter directly with a printer, the printer should have either a 9 pin or a 25 pin RS

232C serial port.

7.2 Using the Meter with Printer or Computer

1. Insert CD-ROM containing Data Acquisition Software (DAS) into your CD-ROM drive and follow the

instructions on your screen.

2. Connect the meter with the RS232C cable to the computer.

3. Open the program on you computer, go to “File” and open “Communication settings” . The settings MUST

match the following parameters: a. Baud Rate: 9600 / b. Parity Bit: None / c. Stop Bit: 1 / d. Data Bit: 8 / e.

Flow Control: None

7.2.1 Set the Baud Rate( P9.0)

This setup page allows you to set the baud rate (bits per second).

1. Press setup

2. Press ▲/save or ▼/view until you view bAud.

3. Press enter

4. Press ▲/save or ▼/view to set the baud rate as 4800, 9600, 19200

or 38400 bps.

5. Press enter to confirm or std to exit from this page.

7.2.2 Set the Parity Bit (P10.0)

This setup page allows you to set the parity bit.

1. Press setup

2. Press ▲/save or ▼/view until you view PArit.

3. Press enter

4. Press ▲/save or ▼/view to select 0 (none), 1 (odd) or 2 (even).

5. Press enter to confirm or std to exit from this page.

7.2.3 Set the Stop Bit (P11.0)

This setup page allows you to set the stop bit of the communication

protocol interface.

1. Press setup

2. Press ▲/save or ▼/view until you view StOP.

3. Press enter

4. Press ▲/save or ▼/view to select 1 or 2.

5. Press enter to confirm or std to exit from this page.

7.3 Select Printing options (P12.0)

The meter can be set up to print:

• Current reading or

• All stored data.

Note : All the communication protocol for both the meter and computer/printer must match

before printing can be performed.

Page 10

1. Press setup

2. Press ▲/save or ▼/view until you view P12.0.

3. Press enter.

4. Press ▲/save or ▼/view to select Current or Memory data print out.

5. Press enter to confirm or std to exit from this page.

Note: All stored memory will remain in the meter after printing.

8 OTHER FUNCTIONS

8.1 Viewing Calibration & Electrode data (P1.0)

For viewing the calibrated buffer depending on the mode (Conductivity/ Resistivity/ TDS), the electrode type

(2-Cell/ 4-Cell), calibrated electrode cell constants and the calibrated buffer value.

1. Press setup.

2. Press save/▲ or view/▼ until you view parameter P1.0 (CAL).

3. Press enter repeatedly to view the effective Cell Constant and previous calibration data on each range

(r1, r2, r3 or r4).

4. When you have scrolled through all calibration data, you will automatically come to the screen shown

below. This screen displays the meter’s calibrated value.

5. Press enter to confirm or std to return to the measurement mode.

Note: If there is no calibration data at a particular point, the display will show “----“.

Note: Cell constants of electrode will degrade with time and usage. You can use this feature to prompt you

the need for a new probe prior to total failure. Recommended value as an indicator for a replacement of

probe is either 0.60 or 1.40 (±40% of 1.000).

Note: Entering the setup mode from Conductivity mode, calibration data will be in µS or mS. Entering the

setup mode from TDS mode, calibration data will be in ppm or ppt.

8.2 Clear User Calibration (P14.0)

Allows you to clear the user calibrated values for each measurement mode separately.

1. Press setup.

2. Press save/▲ or view/▼ until you view parameter P14.0.

3. Press enter.

4. Press save/▲ or view/▼ to select: NO retains current settings or YES clears all

calibrations and its data.

5. Press enter to confirm or std to return to measurement mode.

8.3 Selection of cell constant (P2.0)

The meter lets you select a cell constant of K = 0.1, 1.0 or 10. The cell included with your

meter has a cell constant of K=1.0.

1. Press setup.

2. Press save/▲ or view/▼until you view ‘2CEL’.

3. Press save/▲ or view/▼ to select the cell constant between K = 0.1, 1.0, or 10.

4. Press

enter to confirm selection and return to the subgroup menu.

5. Press std to return to measurement mode.

8.4 Setting the temperature coefficient (P3.0)

The temperature coefficient is the amount of change in conductivity per degree of

temperature; it is expressed in percent per °C. Entering the exact temperature coefficient

of your solution lets you accurately compensate temperature for almost any solution. You

can adjust 0.000 to 10.000 % per °C. Meter default is 2.100% per °C.

1. Press setup

Page 11

2. Press save/▲ or view/▼ until you view parameter P3.0.

3. Press enter to view the current temperature coefficient value.

4. Press save/▲ or view/▼ to select the temperature coefficient of your solution.

5. Press enter to confirm or std to return to the measurement mode.

8.5 Setting the normalisation temperature (P4.0)

Your meter will normalize its conductivity measurements to a standard temperature that

you can select. You can adjust the normalization temperature from 15°C to 30°C (59 to 86

°F). Meter default is 25.0°C (77 °F).

1. Press setup.

2. Press save/▲ or view/▼ until you view parameter P4.0. (“tnor”)

3. Press enter.

4. Press save/▲ or view/▼ to adjust the normalization temperature.

5. Press enter to confirm or std to return to measurement mode.

8.6 Selection of °C or °F (P7.0)

1. Press setup.

2. Press save/▲ or view/▼ until you view P7.0

3. Press enter.

4. Press save/▲ or view/▼ to select between °C and °F.

5. Press enter to confirm or std to return to measurement mode.

9 MAINTENANCE

9.1 Replatinisation of 2-Cell Electrode P15.0

Re-platinising the probe is only applicable for 2-cell probes. In this process the platinum on the surfaces of

the 2-cell probe are replaced.

Re-platinse when the cell constant changed by more than 50% from its typical value. Replatinisation takes

no more than 5 minutes.

9.1.1 Replatinisation procedure

1. Immerse the electrode in a suitable replatinising solution.

2. Press setup

3. Press save/

▲ or view/▼ until you view P15.0

4. Press save/▲ or view/▼ to select: “YES”, start procedure or “NO”, abort procedure.

5. Press enter to confirm or std to return to measurement mode.

6. Press save/▲ or view/▼, select “YES” to start replatinisation process, a timer will be shown.

7. Press enter to start the process, the timer will count down. After complete count down the meter will

return to measurement mode.

Note: Repeat step 2 if a longer replatinisation is required.

Note: A new cell constant must be established for the probe.

Page 12

9.2 Cleaning the meter

The meter requires no regular maintenance, but it is recommended to occasionally wipe down the front with

a damp cloth from time to time.

9.3 Electrode Care

1. Keep the electrode clean.

2. For best accuracy, soak a dry electrode for at least 5 to 10 minutes before calibration.

3. Rinse the electrode with de-ionized water before storing.

4. Never scratch the bands with a hard substance.

5. Do not strike the electrode against any hard surface.

6. Do not immerse the electrode in oily solutions.

7. Clean the electrode thoroughly by stirring it in a mild detergent bath or isopropyl alcohol. Wipe the

electrode with a soft tissue paper.

8. Recalibrate the meter after cleaning the electrode.

10 ERROR MESSAGES

Message Description

ERR. Error message for Conductivity Cal error.

Conductivity Reading > 500mS /

Or

Resistivity >100Mohm

TDS >99999 ppm

Ur Resistivity is short

-5.0°C/ 23.0°F When the temperature is under range

105°C/ 221.0°F When the temperature is under range

Err1 Communication error

Loading...

Loading...