Page 1

Instruction Manual

gyM

sy...

gyM

sy...

24-hour Continuous

Field Monitors

pH, ORP, and Conductivity

68X254901

Technol o

Technol o

adeEa

adeEa

68X254901

Rev. 5 08/03

Rev. 5 08/03

Page 2

Preface

This manual serves to explain the use for all models of the Field Monitors for pH,

ORP, and Conductivity (each model sold separately). If there are doubts in the use

of this meter, please do not hesitate to contact the Authorized Distributor.

Eutech Instruments/ Oakton Instruments cannot accept any responsibility for damage

or malfunction to the meter caused by improper use of the instrument.

The information presented in this manual is subject to change without notice as

improvements are made, and does not represent a commitment on the part of Eutech

Instruments Pte Ltd/ Oakton Instruments.

Note: Eutech Instruments Pte Ltd/ Oakton Instruments reserves the right to

make improvements in design, construction, and appearance of our products

without notice.

Copyright © 2002 All rights reserved.

Eutech Instruments Pte Ltd

Oakton Instruments

Rev.5 08/03

Page 3

TABLE OF CONTENTS

1 INTRODUCTION..........................................................................................................................................1

2 FRONT PANEL.............................................................................................................................................1

2.1 KEYS FOR PH MONITOR ............................................................................................................................1

2.2 KEYS FOR ORP MONITOR ........................................................................................................................1

2.3 KEYS FOR CONDUCTIVITY MONITOR .......................................................................................................1

3 CONNECTING THE PROBE......................................................................................................................2

3.1 TO CONNECT THE PH OR ORP PROBE:.......................................................................................................2

4 PH CALIBRATION.......................................................................................................................................3

4.1 IMPORTANT INFORMATION ON PH MONITOR CALIBRATION......................................................................3

4.2 PH CALIBRATION ......................................................................................................................................4

5 ORP CALIBRATION....................................................................................................................................5

5.1 IMPORTANT INFORMATION ON ORP MONITOR CALIBRATION...................................................................5

5.2 ORP CALIBRATION ...................................................................................................................................6

6 CONDUCTIVITY CALIBRATION.............................................................................................................7

6.1 IMPORTANT INFORMATION ON CONDUCTIVITY/TDS MONITOR CALIBRATION .........................................7

6.2 CONDUCTIVITY CALIBRATION ..................................................................................................................8

7 MONITORING..............................................................................................................................................9

8 ELECTRODE CARE AND MAINTENANCE ...........................................................................................9

8.1 PH/ORP ELECTRODE STORAGE .................................................................................................................9

8.2 PH/ORP ELECTRODE CLEANING..............................................................................................................10

8.3 CONDUCTIVITY ELECTRODE....................................................................................................................10

9 TROUBLE-SHOOTING GUIDE...............................................................................................................10

10 ERROR MESSAGES...............................................................................................................................11

11 SPECIFICATIONS..................................................................................................................................12

12 METERS AND ACCESSORIES............................................................................................................13

13 WARRANTY............................................................................................................................................15

14 RETURN OF ITEMS...............................................................................................................................15

Page 4

1 INTRODUCTION

Thank you for purchasing this pH, ORP, or Conductivity Field Monitor.

The Field Monitor Series feature microprocessor technology, which gives it many

reliable, user-friendly features. These monitors were designed for long-term lowmaintenance use. Just plug in the AC adapter, calibrate and the unit is ready for

continuous monitoring. No batteries required.

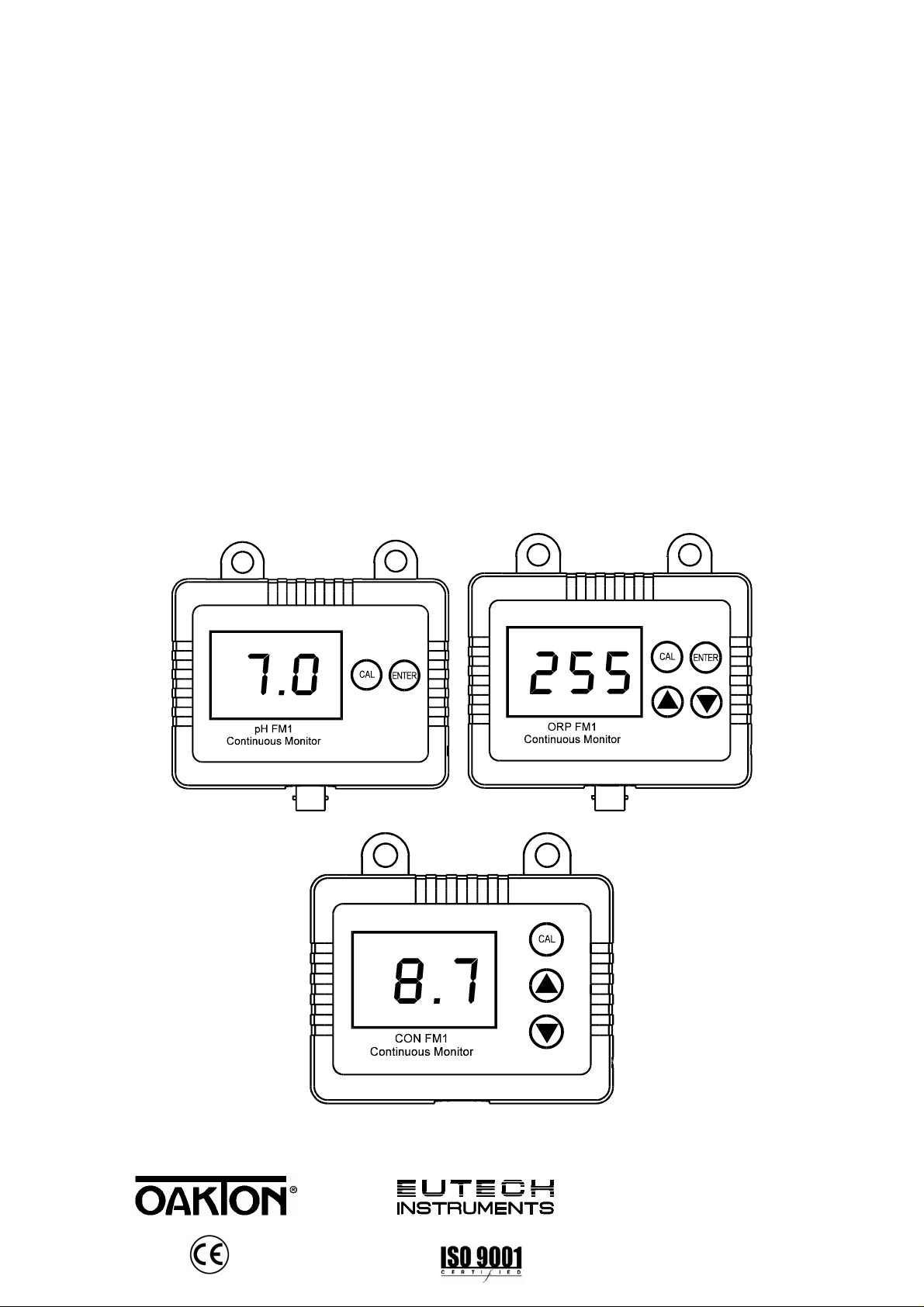

2 FRONT PANEL

The front panel consists of a 3-digit LED display, 2 keys for the pH Monitor, 4 keys for

the ORP Monitor, and 3 keys for the Conductivity Monitor.

2.1 Keys for pH Monitor

CAL The CAL key switches monitor into calibration mode

from measurement mode. In calibration mode CAL

switches monitor back to measurement mode. See

page 3 for details.

ENTER Press the ENTER key to confirm the calibration while

in calibration mode.

pH FM1

Continuous Monitor

CAL

ENTER

2.2 Keys for ORP Monitor

CAL The CAL key switches monitor into calibration mode

from measurement mode. In calibration mode CAL

switches monitor back to measurement mode. See

page 5 for details.

ENTER Press the ENTER key to confirm the calibration while

in calibration mode.

ORP FM1

S

The S Up/Increment key scrolls value up in

Continuous Monitor

calibration mode.

T

The T Down/Decrement key scrolls value down in

calibration mode.

2.3 Keys for Conductivity Monitor

CAL The CAL key switches monitor into calibration mode

from measurement mode. In the calibration mode,

pushing CAL key confirms the calibration value and

returns to measurement mode. See page 7 for details.

S

The S Up/Increment key scrolls value up in

calibration mode.

T

The T Down/Decrement key scrolls value down in

calibration mode.

CON FM1

Continuous Monitor

Pressing S and T together while in calibration mode

switches the monitor back to measurement mode from calibration mode.

CAL

ENTER

CAL

1

Page 5

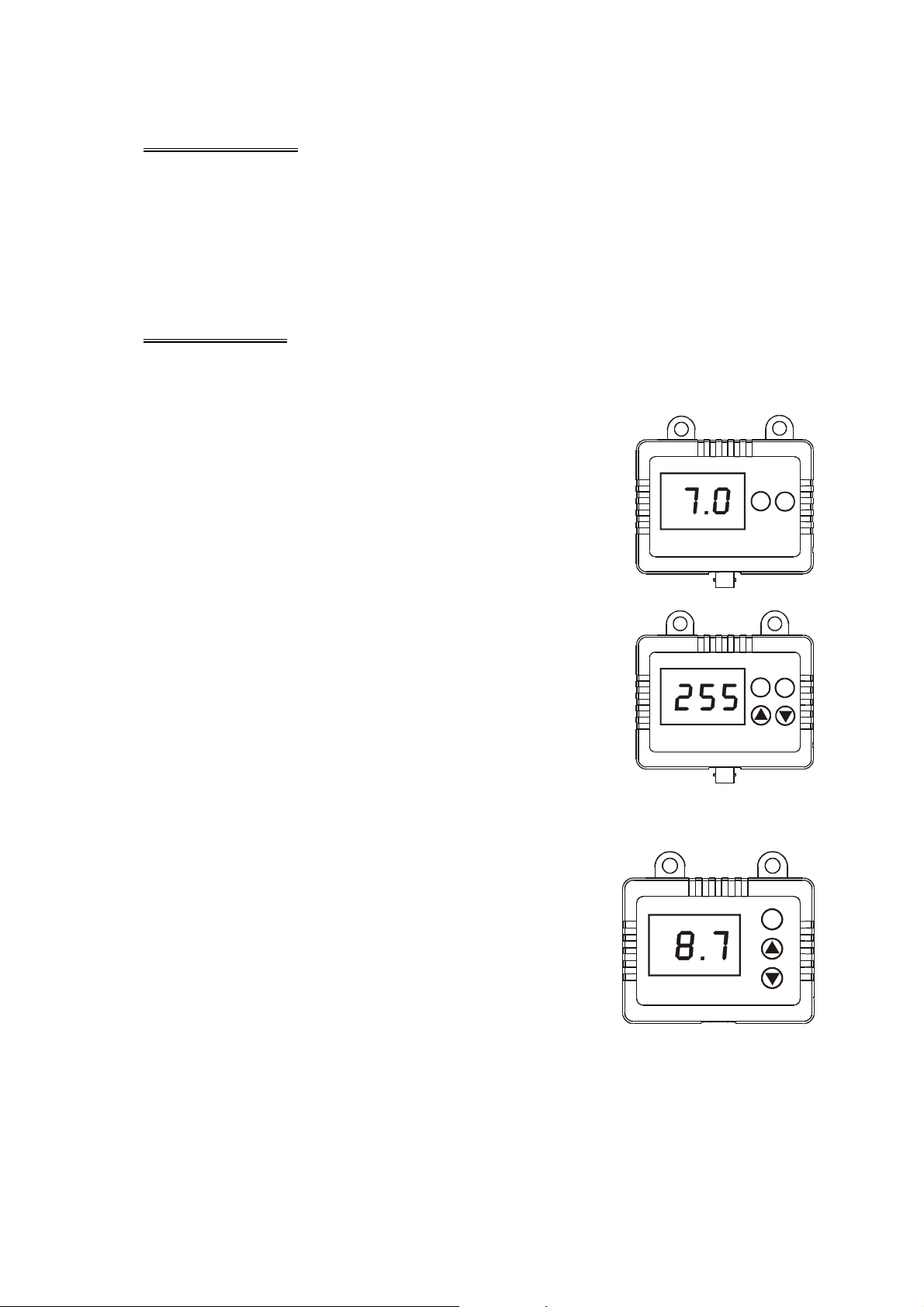

3 CONNECTING THE PROBE

The pH or ORP monitor uses any standard pH or ORP electrode with a BNC

connector. The probe for the Conductivity monitor is hard-wired into the unit, no

connection is necessary.

NOTE: Keep connector dry and clean. Do not touch connector with soiled hands.

3.1 To connect the pH or ORP probe:

Slide the BNC connector of the probe over the BNC connector socket on the monitor.

Make sure the slots of the connector are in line with the posts of the socket. Rotate

and push the connector clockwise until it locks. See Figure 1.

Power

Adapter

CAL

ENTER

7.0

pH FM1

Continuous Monitor

Push in the po w er

adapter plug to

connect the power supp ly

Push in the BNC

connector and turn

to tighten it.

Protection bottle for pH electrode

pH Electrode

Figure 1 - Connection diagram for Field Monitor

To remove probe, push and rotate the connector counter-clockwise. While holding

onto the metal part of the connector, pull probe away from the meter.

CAUTION: Do not pull on the probe cord or the probe wires might disconnect.

2

Page 6

4 pH CALIBRATION

This section is applicable for the following models:

• Eutech Instruments: EC-PHFM1ST11 & EC-PHFM1ST21

• Oakton Instruments: 35623-00, and -05 only

4.1 Important Information on pH Monitor Calibration

This monitor has 3 pH calibration points: 4, 7 and 10 with automatic buffer

recognition. For best accuracy, calibrate to all 3 pH points close to the temperature of

the solution you will be monitoring, starting with pH 7. We recommend that you

perform at least a 2-point calibration—at pH 7 first followed by pH 4 or pH 10

depending on the range of the operation. You can also perform a 1-point calibration,

but make sure that the buffer value is close to the sample value you are measuring.

Calibration should be performed regularly to ensure accuracy. Frequency of

calibration will vary and should be checked regularly until the required schedule has

been determined.

Be sure to remove the protective electrode storage bottle or rubber cap of the probe

before calibration or measurement. If the electrode has been stored dry, wet the

probe in tap water for 10 minutes before calibrating or taking readings to saturate the

pH electrode surface and minimize drift.

Do not reuse buffer solutions after calibration. Contaminants in the solution can affect

the calibration, and eventually the accuracy of the measurements.

.

NOTE: All new calibration data will over-ride existing calibration data.

3

Page 7

4.2 pH Calibration

1. Plug in the pH monitor to turn on. The monitor will

be in pH measurement mode.

2. Rinse the probe thoroughly with de-ionized water or

a rinse solution. Do not wipe the probe; this causes

a build-up of electro-static charge on the glass

surface.

3. Dip the probe into the calibration buffer pH 7. The

end of the probe must be completely immersed into

the sample. Stir the probe gently to create a

homogeneous sample.

4. Press the CAL key to enter the calibration mode.

"CA" will flash on the display for a second and then

a value close to pH 7.0 will flash.

5. Let the electrode soak in the buffer until reading is

stable, stirring occasionally (time will vary

depending on temperature and electrode

condition). When the display has flashed the same

pH value for 15 seconds or more, press the ENTER

key. "CO" will flash on the display. The reading

should now display pH 7.0. See Figure 2.

Immerse pH electrode into

buffer solution,

for example, pH 7

Press

Press

If necessary, repeat steps 2 through 5 for the

remainder of the buffer values (pH 4.0 and 10.0).

Figure 3 - pH

Calibration

4

Page 8

5 ORP CALIBRATION

This section is applicable for the following models:

• Eutech Instruments: EC-ORPFM1ST11 & EC-ORPFM1ST21

• Oakton Instruments: 35649-00 and -05 only

5.1 Important Information on ORP Monitor Calibration

Typically ORP measurements are taken on a relative basis and calibration is not

required. This monitor has ±100 mV offset adjustment, adjustable in 5 mV

increments. Choose a calibration standard that is close to your working condition.

Calibration should be performed regularly to ensure accuracy. Frequency of

calibration will vary and should be checked regularly until the required schedule has

been determined.

Be sure to remove the protective electrode storage bottle or rubber cap of the probe

before calibration or measurement. If the electrode has been stored dry, wet the

probe in tap water for 10 minutes before calibrating or taking readings to saturate the

ORP electrode surface and minimize drift.

Do not reuse calibration solutions after calibration. Dispose of any used calibration

solution. Contaminants in the solution can affect the calibration, and eventually the

accuracy of the measurements.

IMPORTANT: ORP offset adjustment is limited to ±100 mV from the original reading.

Adjustable in 5 mV increments.

NOTE: All new calibration data will over-ride existing calibration data.

5

Page 9

5.2 ORP Calibration

1. Plug in the ORP monitor to turn on. The monitor will

be in ORP measurement mode.

2. Rinse the probe thoroughly with de-ionized water or

a rinse solution. Do not wipe the probe; this causes

a build-up of electro-static charge on the surface.

3. Dip the probe into the calibration standard. The end

of the probe must be completely immersed into the

sample. Let probe soak 2 to 5 minutes or until

readings stabilizes.

4. Press the CAL key to enter the calibration mode.

"CA" will flash on the display for a second and then

a value close to the calibration standard will flash.

5. Press the S or T keys to adjust the display to

match the calibration standard value. Press the

ENTER key. "CO" will flash on the display. The

reading should now display the same value as the

calibration standard. See Figure 3.

Immerse ORP electrode into

a calibration standard solution,

for example, 255 mV

Press

Press

Press

Figure 5 - ORP

Calibration Procedure

6

Page 10

6 CONDUCTIVITY CALIBRATION

This section is applicable for the following models:

Description Eutech Instruments Oakton Instruments

Conductivity FMCON 1 with Conductivity

electrode and 110/120 VAC power adapter.

Conductivity FMCON 1 with Conductivity

electrode and 220/230 VAC power adapter.

Conductivity FMCON 2 with Conductivity

electrode and 110/120 VAC power adapter.

Conductivity FMCON 2 with Conductivity

electrode and 220/230 VAC power adapter.

Conductivity FMCON 3 with Conductivity

electrode and 110/120 VAC power adapter.

Conductivity FMCON 3 with Conductivity

electrode and 220/230 VAC power adapter.

EC-CONFM1ST11 35660-00

EC-CONFM1ST21 35660-05

EC-CONFM2ST11 35660-02~

EC-CONFM2ST21 35660-07~

EC-CONFM3ST11 35660-04~

EC-CONFM3ST21 35660-09~

6.1 Important Information on Conductivity/TDS Monitor Calibration

This monitor has ±30% adjustment. Adjustable in 0.1 mS increments. Choose a

calibration standard that is close to your working solution.

Calibration should be performed regularly to ensure accuracy. Frequency of

calibration will vary and should be checked regularly until the required schedule has

been determined.

Do not reuse calibration solutions after calibration. Dispose of any used calibration

solution. Contaminants in the solution can affect the calibration, and eventually the

accuracy of the measurements.

NOTE: All new calibration data will over-ride existing calibration data. Minimum

calibration value is 2.5 mS.

Adjustments and Minimum Calibration Value are according to specific conductivity

meter model:

Models Calibration Adjustments Minimum Calibration Value

FM CON 1 0.1 mS increments 2.5 mS

FM CON 2

FM CON 3

10 µS increments 250 µS

1 µS increments 37.5 µS

7

Page 11

6.2 Conductivity Calibration

1. Plug in the Conductivity monitor to turn on. The

monitor will be in conductivity measurement mode.

2. Rinse the probe thoroughly with de-ionized water or

a rinse solution, then rinse with a small amount of

calibration solution.

3. Dip the probe into the calibration solution. Immerse

the probe tip at least 2 cm into the solution. Stir the

probe gently to create a homogeneous sample.

4. Press the CAL key to enter the calibration mode.

"CA" will flash on the display for a second and then

a value close to the calibration standard will flash.

5. Press the S or T keys to adjust the display to

match the calibration standard value. Press the

CAL key. "CO" will flash on the display. The

reading should now display the same value as the

calibration standard. See Figure 4.

Immerse conductivity electrode

into a standard solution,

for example, 4 mS

Press

Press

Press

Figure 7 - Conductivity

Calibration Procedure

8

Page 12

7 MONITORING

Once the monitor is calibrated it is ready for monitoring. The monitor has two eyelet

holes. Mount the monitor where it can be easily viewed.

See figure below.

Mounting Eyelets

CAL

ENTER

pH FM1

Continuo us Monitor

8 ELECTRODE CARE AND MAINTENANCE

Since your pH/ORP electrode is susceptible to dirt and contamination, clean it every

one to three months depending on the extent and condition of use. Like batteries, a

pH/ORP electrode has limited life. Depending on the environment and the solution it

is immersed in, it may last from 6 to 12 months, or longer. Knowing when to change

your pH/ORP electrode usually comes after some experience. It is best to have

another pH/ORP tester such as pHScan/ pHTestr 1, Waterproof pHScan/ pHTestr

WP2, or ORPScan/ ORPTestr as reference.

8.1 pH/ORP electrode storage

For best results, always keep the pH/ORP bulb wet. Use the protective electrode

storage bottle filled with electrode storage solution (0.1M KCl) or pH 7 for overnight

and long term storage. DO NOT store in distilled water. The sensor should never be

stored dry. If left dry, soak in tap water or pH 7.0 buffer solution overnight.

9

Page 13

8.2 pH/ORP electrode cleaning

• Salt deposits: Dissolve the deposits by immersing the electrode in tap water for

ten to fifteen minutes. Then thoroughly rinse with distilled water.

• Oil/Grease film: Wash electrode pH/ORP bulb gently in some detergent and

water. Rinse electrode tip with distilled water or use a general-purpose electrode

cleaner (see ordering information).

• Clogged reference junction: Heat a diluted KCl solution to 60 to 80 C. Place the

sensing part of the electrode into the heated solution for about 10 minutes. Allow

the electrode to cool in some unheated KCl solution.

8.3 Conductivity electrode

For general cleaning, the use of deionized water will be sufficient. Rinse the

electrode thoroughly in the deionized water. After cleaning, wipe the electrode dry.

Never touch the metal sensors.

For intensive cleaning, when the electrode is contaminated, wash it carefully with a

mild detergent, after which wash thoroughly with deionized water. Always ensure

that there are no blockages of the electrode cavity. If there is, use a gentle jet of

water to dislodge any particles that may have been stuck there.

9 TROUBLE-SHOOTING GUIDE

Problem Cause Solution

No display a). Power adapter is not

connected properly or is

faulty.

Unstable

readings

a). Air bubbles in probe.

b). Dirty probe.

c). Probe not deep enough

in sample.

d). External noise pickup or

induction caused by

nearby electric motor.

a). Check that power adapter and

its wire are in place and

making good contact.

b). Check power supply.

a). Tap probe to remove bubbles.

b). Clean the probe and re-

calibrate.

c). Make sure sample entirely

covers the probe sensors.

d). Move or switch off interfering

motor.

No response a). Broken probe. a). Replace probe

Slow response a). Dirty / Oily probe. a). Clean probe. See “Electrode

Care & Maintenance” section.

10

Page 14

10 ERROR MESSAGES

pH

When pH value is

more than 14.0 pH

When pH value is

less than 0.0 pH

Displays when there

is an error in

calibration.

ORP

When ORP value is

more than 995 mV.

Conductivity

When Conductivity

value is more than

10.0 mS.

When ORP value is

less than 0 mV

When Conductivity

value is less than 0

mS.

Displays when there

is an error in

calibration.

11

Page 15

11 SPECIFICATIONS

Conductivity SPECIFICATIONS pH ORP

FM

CON1

Range 0.0 to 14.0 pH 0 to 995 mV 0 to 10.0

mS

Accuracy ± 0.1 pH ± 5 mV ±0.2

mS/cm

Resolution 0.1 pH 5 mV 0.1

mS/cm

Calibration Up to 3 points;

pH 4.0, 7.0 & 10.0

Automatic Buffer Recognition Yes

Automatic Temperature

Compensation

Operating Temperature 0 to 50 °C (0 to 120 °F)

Inputs BNC BNC Permanently wired

Display 3-digit LED (Red)

Environmental Requirements Operating: 0 to 50 °C (0 to 120 °F)

Power Requirements AC / DC Adapter 9 V, 200 mA

Dimension / Weight Meter: 19 x 10 x 6 cm; 80 g

Yes

Humidity Limits: 10 to 95% RH (non condensing)

Single- point,

Offset ± 100 mV

Storage: - 10 to 60 °C (14 to 140°F)

Boxed: 24 x 23 x 7 cm; 550 g

FM

CON2

0.0 to

990 µS

±20

µS/cm

10

µS/cm

Single- point,

± 30% full scale

FM

CON3

0.0 to

150 µS

±2

µS/cm

1 µS/cm

12

Page 16

12 METERS AND ACCESSORIES

Meters

Item Eutech Instruments

pH Field Monitor with pH electrode , 1 Strip of 10 pH

7 buffer tablets and 110/120 VAC power adapter.

pH Field Monitor with pH electrode , 1 Strip of 10 pH

7 buffer tablets and 220/230 VAC power adapter.

ORP Field Monitor with ORP electrode and 110/120

VAC power adapter.

ORP Field Monitor with ORP electrode and 220/230

VAC power adapter.

Conductivity FMCON 1 with Conductivity electrode

and 110/120 VAC power adapter.

Conductivity FMCON 1 with Conductivity electrode

and 220/230 VAC power adapter.

Conductivity FMCON 2 with Conductivity electrode

and 110/120 VAC power adapter.

Conductivity FMCON 2 with Conductivity electrode

and 220/230 VAC power adapter.

Oakton Instruments

Ordering Code

EC-PHFM1ST11 35623-00

EC-PHFM1ST21 35623-05

EC-ORPFM1ST11 35649-00

EC-ORPFM1ST21 35649-05

EC-CONFM1ST11 35606-00

EC-CONFM1ST21 35606-05

EC-CONFM2ST11 35660-02

EC-CONFM2ST21 35660-07

Ordering Code

Conductivity FMCON 3 with Conductivity electrode

and 110/120 VAC power adapter.

Conductivity FMCON 3 with Conductivity electrode

and 220/230 VAC power adapter.

EC-CONFM3ST11 35660-04

EC-CONFM3ST21 35660-09

Electrodes and Accessories

General Purpose, Epoxy-body double junction pH

Combination Electrode, 12x146 mm, 1-m cable

length

General Purpose Epoxy-body double junction ORP

Electrode, 12x146 mm, 1-m cable length

110/120 VAC Power Adapter (50/60 Hz) 2-pin type EC-120-ADA 35615-07

220/230 VAC Power Adapter (50/60 Hz) 2-pin type EC-220-ADA 35615-08

EC-FE72522-01B 35641-51

EC-FE79602-01B 35649-51

13

Page 17

Calibration Solutions

Item Eutech Instruments

Ordering Code

pH 4.01 buffer solution, 480 ml bottle (1 pint) EC-BU-4BT 00654-00

pH 7.00 buffer solution, 480 ml bottle (1 pint) EC-BU-7BT

pH 10.01 buffer solution, 480 ml bottle (1 pint) EC-BU-10BT

pH 4.01 buffer sachets, 20 ml x 20 pcs. EC-BU-4BS

pH 7.00 buffer sachets, 20 ml x 20 pcs. EC-BU-7BS

pH 10.01 buffer sachets, 20 ml x 20 pcs. EC-BU-10BS

12.88 mS KCl Calibration Solution in 480-ml leak-

proof bottle (1 pint)

2,764 µS KCl Calibration Solution in 480-ml leak-

proof bottle (1 pint)

10 µS conductivity standard sachet, 20 ml x 20 pcs

447 µS Conductivity Sachets (20 units x 20 ml per

box)

1,413 µS Conductivity Sachets(20 units x 20 ml per

box)

2,764 µS Conductivity Sachets(20 units x 20 ml per

box)

EC-CON-1288BT 00606-10

EC-CON-2764BT 00653-20

EC-CON-10BS

EC-CON-447BS 35653-10

EC-CON-1413BS 35653-11

EC-CON-2764BS 35653-12

Oakton Instruments

Ordering Code

00654-04

00654-08

35653-01

35653-02

35653-03

35653-09

15,000 µS Conductivity Sachets(20 units x 20 ml per

box)

EC-CON-15000BS 35653-13

14

Page 18

13 WARRANTY

The Field Monitor series is supplied with a 1-year warranty from manufacturing

defects and electrodes for 6 months from the date of purchase unless otherwise

stated.

If repair or adjustment is necessary and has not been the result of abuse or misuse

within the designated period, please return – freight pre-paid – and correction will be

made without charge. Eutech Instruments/ Oakton Instruments will determine if the

product problem is due to deviations or customer misuse.

Out of warranty products will be repaired on a charged basis.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

• Improper or inadequate maintenance by customer

• Unauthorized modification or misuse

• Operation outside of the environment specifications of the products

14 RETURN OF ITEMS

Authorization must be obtained from our Customer Service Department or authorized

distributor before returning items for any reason. A “Return Goods Authorization”

(RGA) form is available through our Authorized Distributor. Please include data

regarding the reason the items are to be returned. For your protection, items must be

carefully packed to prevent damage in shipment and insured against possible

damage or loss. Eutech Instruments/ Oakton Instruments will not be responsible for

damage resulting from careless or insufficient packing. A restocking charge will be

made on all unauthorized returns.

NOTE: Eutech Instruments Pte Ltd/ Oakton Instruments reserves the right to make

improvements in design, construction, and appearance of products without notice.

15

Page 19

For more information on Eutech Instruments/ Oakton Instruments’ products, contact your

nearest distributor or visit our website listed below:

Oakton Instruments

P.O Box 5136,

Vernon Hills, IL 60061, USA

Tel: (1) 888-462-5866

Fax: (1) 847-327247-2984

E-mail: info@4oakton.com

Web-sites:

www.4oakton.com

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah Crescent,

#04-16/24 Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

E-mail: marketing@eutechinst.com

Web-site: www.eutechinst.com

Distributed by:

Loading...

Loading...