Page 1

Instruction Manual

gyM

sy...

DO 700 Dissolved Oxygen/ºC/ºF

Bench Meter

Part of Thermo Fisher Scientific 68X541703 Rev. 2. Sep 2010

Tech nol o

adeEa

Page 2

Page 3

TABLE OF CONTENTS

1. INTRODUCTION.............................................................. 1

2. GETTING STARTED........................................................ 2

2.1 Keypad Functions ...................................................................2

2.2 LCD Annunciators...................................................................3

2.3 Meter Connections..................................................................3

3. DISSOLVED OXYGEN / ATC ELECTRODE................... 4

4. CALIBRATION................................................................. 5

4.1 Temperature Calibration .........................................................6

4.2 % Saturation Calibration .........................................................7

4.3 100% Calibration.....................................................................7

4.4 0% Calibration.........................................................................7

4.5 mg/L or ppm (Concentration) Calibration................................8

5. SETUP FUNCTIONS........................................................ 9

5.1 1.0 CAL (Calibration)...............................................................9

5.2 2.0 ELE (Electrode Information)..............................................10

5.3 3.0 ConF (Configuration).........................................................10

5.4 3.1 rdY (Ready Stability Indicator / Auto Hold)........................10

5.5 3.2 ºC ºF (Celsius or Fahrenheit)............................................10

5.6 3.3 dPr (Barometric Pressure Adjustment)..............................11

5.7 3.4 SALt (Salinity Adjustment) ................................................11

5.8 3.5 OFS (Offset Adjustment) from % mode.............................11

5.9 3.5 Unit (Unit Adjustment) from concentration mode...............12

5.10 4.0 rSt (Reset).........................................................................12

5.11 5.0 CLr (Clear Stored Memory)...............................................12

6. TAKING MEASUREMENTS............................................ 13

6.1 HOLD Function .......................................................................14

6.2 Storing and Recalling Data .....................................................14

7. ELECTRODE MAINTENANCE........................................ 15

8. DISSOLVED OXYGEN THEORY .................................... 18

Page 4

9.

REPLACEMENTS AND ACCESSORIES........................ 22

10. TROUBLESHOOTING GUIDE......................................... 23

11. SPECIFICATIONS............................................................ 25

12. WARRANTY..................................................................... 26

13. RETURN OF ITEMS......................................................... 27

Page 5

1. INTRODUCTION

Thank you for purchasing our DO 700 series benchtop meter.

This microprocessor-based meter is economical and simple to

use. The design incorporates a large LCD for clear viewing, yet

offers a small footprint to conserve space.

The DO 700 measures Dissolved Oxygen in % saturation or

centration (mg/L or ppm) with temperature (ºC or ºF).

con

Each meter includes a convenient slide-out card for quick

referen

ce. Also included is an electrode arm and metal bracket

which can be easily attached to the left or right side of the meter

according to your preference.

We take great pride in every instrument we manufacture

and hope

this one serves you well.

1

Page 6

2. GETTING STARTED

2.1 Keypad Functions

Powers the meter on and off. Upon power on, the meter

automatic

Calibration and memory values are retained even if meter

is unplugged.

Toggle between available measurement modes—%

saturatio

switch to Temperature calibration during DO calibration

modes.

Press and hold for 5 seconds to enter SETUP mode.

Toggles between measurement and calibration modes.

In SET

Confirms calibration values in CAL mode.

Confirms selections in SETUP mode.

View recalled values in memory mode.

S

MI (Memory Insert) stores values into memory.

ally begins in the mode that was last used.

n or concentration (mg/L or ppm). Also used to

UP mode, returns user to the measurement mode.

Increase value. Scroll up in SETUP & CAL modes.

MR (Memor

T Decrease value. Scroll down in SETUP & CAL modes.

Freezes measured reading. Press again to resume

live re

y Recall) recalls values from memory.

ading.

2

Page 7

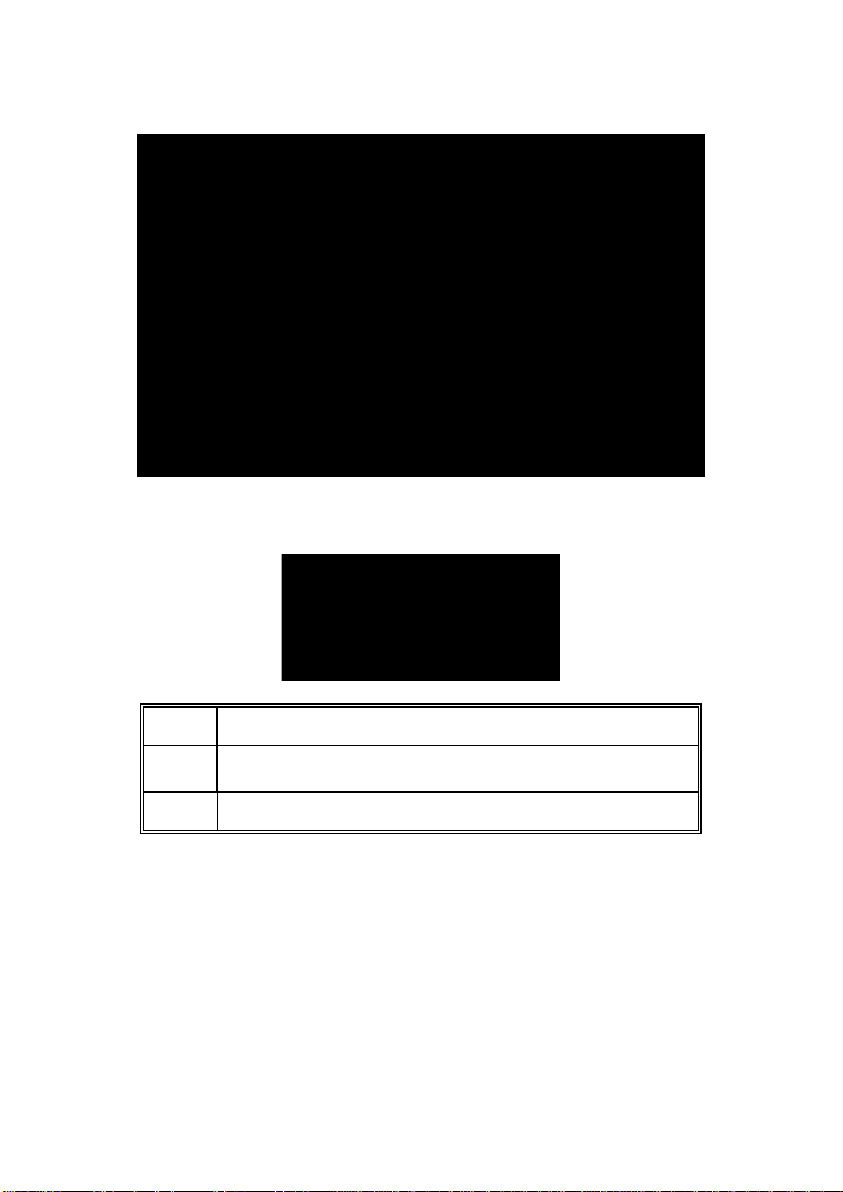

2.2 LCD Annunciators

2.3 Meter Connections

DC

ATC

DO

Power supply

Temperature connection of Dissolved Oxygen electrode

BNC connection of Dissolved Oxygen electrode

3

Page 8

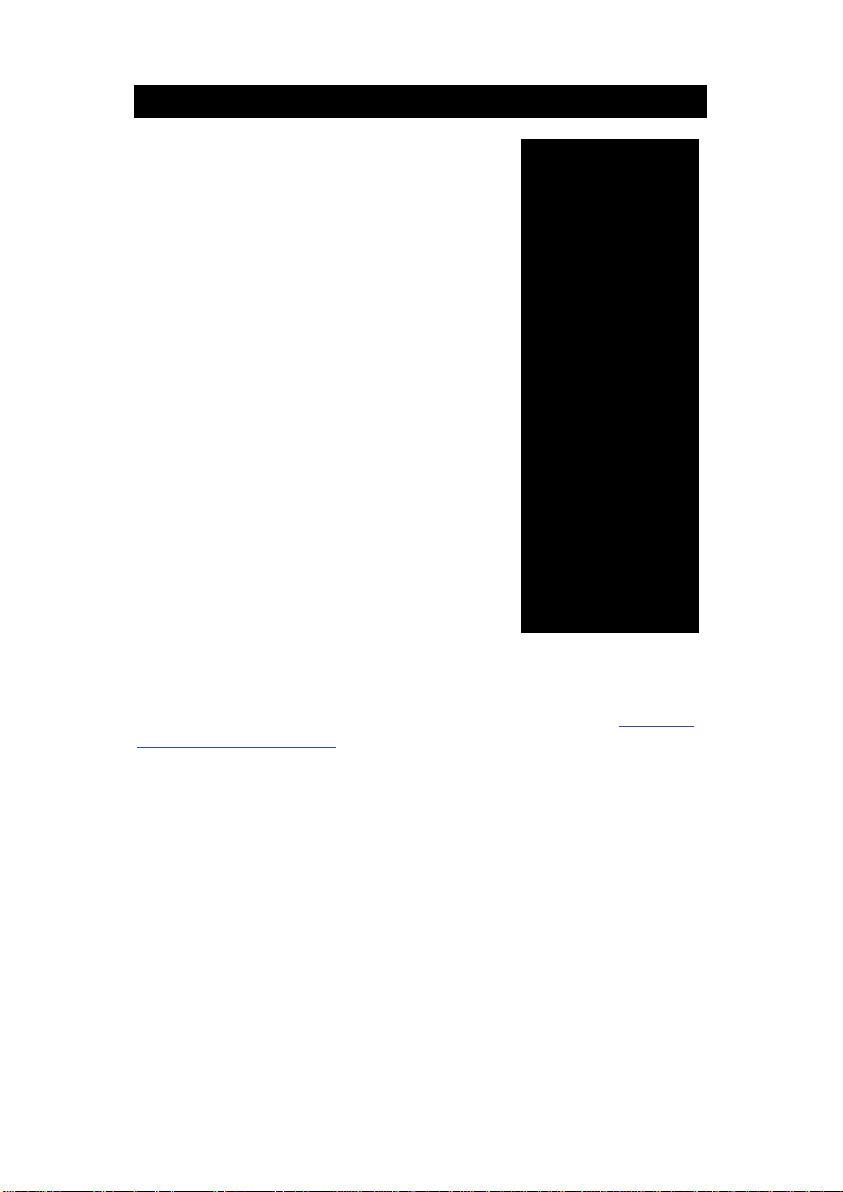

3. DISSOLVED OXYGEN / ATC ELECTRODE

The DO 700 includes a galvanic DO

electrode with built in temperature

measurement.

The electrode has a dual cable; a BNC

connector for DO measurement and a miniphono plug for temperature. The electrode is

pre-filled with electrolyte that is separated

from the sample by an oxygen permeable

membrane. The membrane is pre-assembled

for you and fixed to a detachable cap. The

pre-assembled cap design allows simple

replacement and fast conditioning.

The electrode is light-weight with a 12-mm

bod

y diameter and a 16-mm tip diameter

from at the detachable Noryl cap. The

compact sensing area reduces air

entrapment resulting in quick, accurate, and

stable readings.

Provide simple stirring for best results—

ally achieve a minimum water flow rate of

ide

2 inch/second on the membrane.

The probe is not recommended for samples

be

yond 0 to 50 °C.

The membrane is thin and can be replaced if damaged. Use care to

protect from scratches, abras

results keep membrane clean by rinsing after daily use. See Section 7

– Electrode Maintenance.

ion, or contact with solids. For best

4

Page 9

4. CALIBRATION

The DO 700 has three measurement modes; DO as % saturation, DO

as mg/L (or ppm) concentration, and temperature.

Dissolved oxygen levels vary with temperature, barometric pressure,

linity, so calibration must be performed with consideration of

and sa

these factors. It is necessary to set the proper temperature,

barometric pressure and salinity values prior to performing any

DO calibration or measurement.

See Section 4.1 — Temperature Calibration

See Section 5.6 — Barometric Pressure Adjustment.

See Section 5.7 — Salinity Adjustment.

The DO 700 will accept two % saturation calibration points; 100%

g saturated air or air-saturated water, and 0% using zero oxygen

usin

solution. When 100% or 0% calibration is performed, the concentration

value is adjusted accordingly. Therefore, it is not necessary to calibrate

the concentration mode. If calibrating for 0% oxygen, note that the

meter will take several minutes to reach 0% saturation value and

constant stirring is not required.

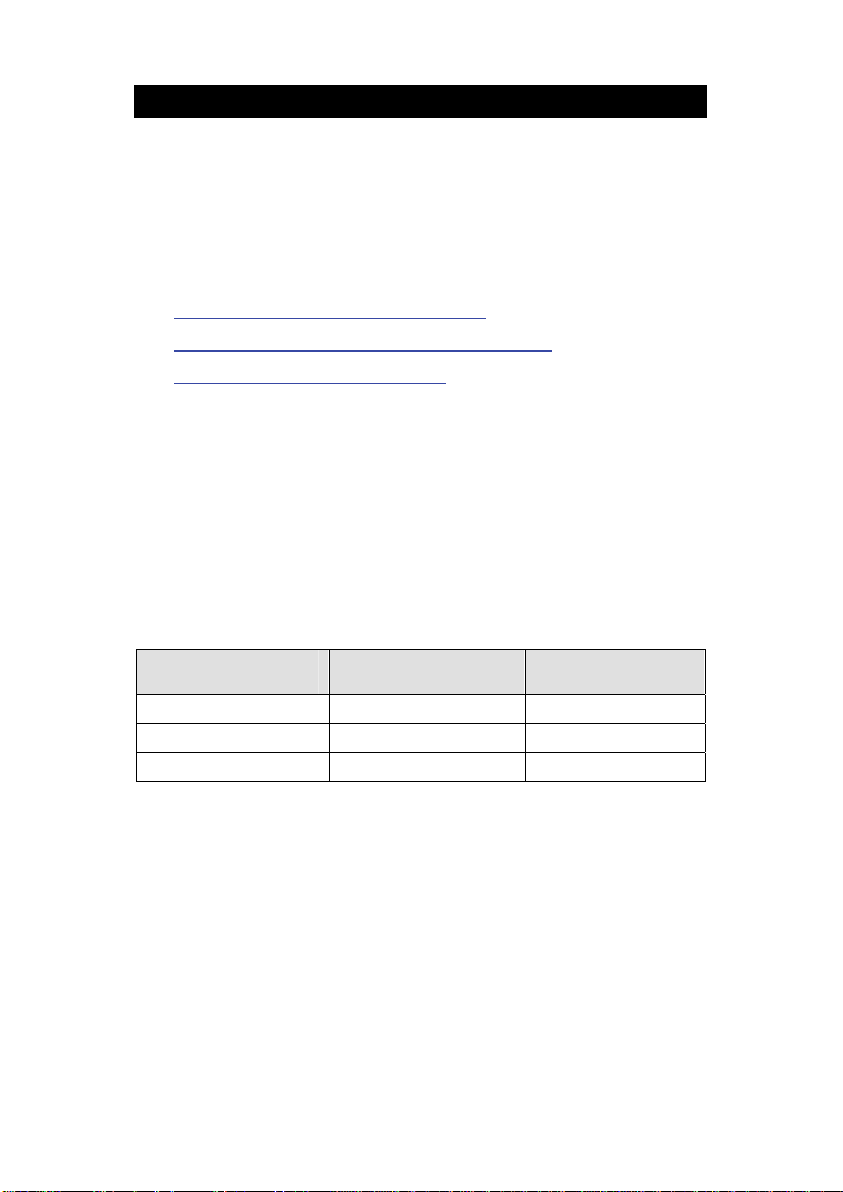

The following table lists calibration values in % saturation calibration

mode

with two different barometric pressures. Note that the saturation

value (92.1%) has decreased due to the lower barometric pressure

entered.

.

% Saturation

(of factory default value)

less than 10% 0% 0%

10.1% to 49.9% CAL ERR CAL ERR

50% to 150% 100% 92.1%

Calibration Value

(760mmHg)

Calibration Value

(700mmHg)

If calibration is attempted from 10.1% to 49.9%, CAL Err message is

shown—calibration is rejected and the display will return to calibration

mode.

5

Page 10

The DO 700 will accept one calibration point in concentration mode.

The minimum value is 2 mg/L (ppm), and the calibration window is +/40% of the factory default value.

Temperature and % saturation calibration should take place be

attempting to perform mg/L (ppm) concentration calibration.

Calibration of the concentration mode

concentration calibration and does not affect the % saturation

calibration.

To offset your % saturation reading to match

Section 5.8 – Offset Adjustment

Perform daily calibration for best results. Ne

automatically override the existing data. To completely recalibrate the

meter and when installing a replacement electrode, it is best to clear all

calibration data. See Section 5.10 – Reset

4.1 Temperature Calibration

For best DO accuracy, ensure that the temperature is accurate. The

thermistor sensor used for automatic temperature compensation and

measurement is accurate and stable, so frequent calibration isn’t

required. Temperature calibration is recommended upon probe

replacement, whenever the temperature reading is suspect, or if

matching against a certified thermometer is desired.

The DO 700 will default to 25 ºC / 77 ºF when the ATC plug is not

ected.

conn

1) Place the pr obe into a solution with a known accurate temperature

such as a co

nstant temperature bath.

will only replace the previous

another instrument, see

.

w calibration values will

.

fore

2) Press

measured temperature while the secondary displa y shows the

factory default temperature.

4) Adjust the tem

º

5

C (or ± 9ºF) from the factory default temperature.

followed by . The primary display shows the

perature using

to cancel. The meter allows an adjustable maximum value of ±

or . Press to accept or

6

Page 11

4.2 % Saturation Calibration

The DO700 can be easily calibrated in air. For best accuracy, ensure

that the barom

The barometric pressure factory default is 760 mm Hg (1.013 bar),

hich results in a theoretical calibration value of 100% saturation in air.

w

If the barometric pressure setting has been changed from 760 mm Hg,

the meter will automatically adjust to a new % saturation calibration

value instead of 100%. This new value is correct for the adjusted

barometric pressure.

4.3 100% Calibration

1) Rinse the probe well with clean water (do not dry).

etric pressure value is accurate.

2) Press

3) Hold the probe in the air with the tip facing downwards. Wait for

the read

4) Press

indicate the calibration point, 100.0.

5) Press

briefly before calibrating to 100.0%.

6) Press to return to measurement mode, or continue with 0%

calibration if desired.

4.4 0% Calibration

1) Rinse the probe well with clean water (do not dry).

2) Press

3) Submerse probe in zero oxygen calibration solution and stir

slo

more than 10 minutes!

to select % saturation.

ing to stabilize.

. The CAL indicator will blink and secondary display will

to confirm the calibration. T he primary display will blink

to select % saturation.

wly. Wait for the reading to stabilize—this can often take

7

Page 12

4) Press . The CAL indicator will blink and the secondary display

will indicate the calibration point, 0.0.

5) Press to confirm the calibration. T he primary display will blink

briefly before calibrating to 0.0%.

6) Press

calibration if desired (note 0% calibration followed by 100%

calibration is not recommended---always perform 100% calibration

first).

4.5 mg/L or ppm (Concentration) Calibration

Performing a saturation calibration at 100% or 0% will simultaneously

calibr

ate the corresponding mg/L (ppm) concentration value.

Therefore, additional mg/L (ppm) calibration isn’t required in most

circumstances.

If desired, you can perform a calibration adjustment in mg/L (ppm)

ithout affecting your % saturation calibration value.

w

1) Rinse the probe well with clean water (do not dry).

2) Press

3) Dip the probe into a sample of known oxygen concentration (i.e.

determi

to stabilize.

4) Press

briefly, before CAL flashes. The concentration value based on the

factory default calibration is shown.

5) Press

oxygen concentration value.

to return to measurement mode, or continue with 100%

to select concentration mg/L (ppm).

ned by titration or another instrument). Wait for the reading

. The CAL indicator and current concentration display

or to adjust the reading to match the known

8

Page 13

6) Press to confirm the calibration. T he primary display will blink

briefly before returning to measurement mode.

NOTE:

calibration is limited to ±40% adjustment of the factory default value to

prevent erroneous calibrations.

The minimum calibration value is 2 mg/L. In addition, the

5. SETUP FUNCTIONS

Use the setup feature to customize your instrument operation.

There are two setup menus; one menu is derived from the %

saturation mode and the other from the mg/L (or ppm) concentration

mode.

First, select the appropriate measurement mode you wish to adjust by

pressi

ng

until the desired units are displayed. During

measurement, press and hold

mode of the parameter being measured.

Press

Press to select the program or confirm selection.

Press to go back one level or return to measurement mode.

5.1 1.0 CAL (Calibration)

or to change programs or change options.

Press

Note: % saturation mode will list two points, while

concentration mode has only one point.

to view stored calibration points.

for 5 seconds to enter SETUP

9

Page 14

5.2 2.0 ELE (Electrode Information)

Press

TIP: The factor is an indication of the probe’s efficiency. It is

the ratio of the actual mV produced by the probe to the

theoretical mV value. The ratio displays from 0.5 to 1.999.

Press

Press

Press

5.3 3.0 ConF (Configuration)

Press

5.4 3.1 rdY (Ready Stability Indicator / Auto Hold)

Press

Press or to choose READY “On”, READY “OFF”, or

Auto HOLd.

Press

5.5 3.2 ºC ºF (Celsius or Fahrenheit)

Press

Press

to view calibration factor (CAL.F)

to view mV output for 100% (HI).

to view mV output for 0% (LO).

to view Offset % (OFS)—% saturation mode only.

to access set-up programs 3.1 thru 3.5.

.

to confirm.

.

or to select ºC or ºF.

Press to confirm.

10

Page 15

5.6 3.3 dPr (Barometric Pressure Adjustment)

Press

Press

Press

Press or to adjust the value, press to accept.

5.7 3.4 SALt (Salinity Adjustment)

For best accuracy, enter the actual salinity value if your samples are at

least 0.1 ppt (100 ppm). Maximum adjustment is 50 ppt (50,000 ppm or

5% salt).

Press

Press or to adjust the value (in parts per thousand).

Tip: 0.1 ppt = 100 ppm salinity

Press

5.8 3.5 OFS (Offset Adjustment) from % mode

Use this feature to offset the meter’s value to another DO meter.

Using the % saturation mode, observe the reading a sample solution

after it has stabilized. Similarly, observe the reading of the same

sample using another DO meter as a reference. The probe of the

reference meter should be immersed in the same sample at the same

depth.

The DO 700 allows +/- 10.0% offset adjustme

user calibrations will reset the offset adjustment back to the factory

default value of 0.0 %.

.

or to select units; Hg (mm Mercury) or bAr.

to confirm.

.

to confirm.

nt. Note that subsequent

Press

Press or to adjust the % offset.

.

11

Page 16

Press to confirm.

5.9 3.5 Unit (Unit Adjustment) from concentration mode

Press .

Press or to select ppm or mg/L units.

Press

5.10 4.0 rSt (Reset)

Press

Press or to select “Yes” (Reset) or “No” (Cancel).

If “Yes”, press or to select “Cal” (calibration reset

only) or “FCt” (complete reset to factory default settings).

Press

5.11 5.0 CLr (Clear Stored Memory)

Press

Press or to select “Yes” (Erase memory) or “No”.

Press

to confirm.

.

to confirm.

.

to confirm.

12

Page 17

6. TAKING MEASUREMENTS

During measurement the dissolved oxygen reading is

automatically compensated for pressure and salinity. For best

accuracy, ensure the pressure and salinity settings are adjusted

accordingly from the setup menu. The factory default value for

barometric pressure is 760 mm Hg or 101.3 bar (sea level). The

factory default value for salinity is 0.0 ppt (no salinity).

See Section 5.6 — Barometric Pressure Adjustment

See Section 5.7 — Salinity Adjustment

Press

to select the desired measurement mode:

•

Percentage Saturation (%) and Temp (

•

Concentration (mg/L or ppm) and Temp (

.

.

º

C or ºF)

º

C or ºF)

Follow these general rules when taking measurements:

•

Keep the membrane free from contact with solid

objects.

•

Provide stirring of your solution⎯this helps to overcome

oxygen consumption of the probe and prevents air

bubble entrapment.

Do not submerge the cable for extended periods.

•

•

Use with aqueous solutions only.

•

The pre-assembled cap must be completely submersed

to obtain an accurate reading in solutions.

•

Rinse the probe well with DI water or rinse solution

between measurements.

13

Page 18

6.1 HOLD Function

For prolonged observation of a reading, press

measurement mode to freeze the display. The “HOLD” indicator will

display when the reading is held. To release the held value and

resume measurement, press

memory by pressing .

6.2 Storing and Recalling Data

The DO 700 can retain up to 100 data points into memory for

later retrieval.

1) In the measur ement mode, press

into memory. The stored memory location value (StO) is briefly

displayed.

2) To recall data from memory, press . The location of the most

recent stored data is displayed first. Press

location of the desired data, then press

3) Press to return to the stored data location. Press to return

to measurement mode. To erase stored data, see Section 5.11 —

Clear Stored Memory

again or insert the held value into

to insert the measured value

.

during

or to select the

to accept.

14

Page 19

7. ELECTRODE MAINTENANCE

The DO 700 electrode produces an output proportional to the oxyge n

present in the medium in which it is placed. The galvanic probe design

allows for immediate use—unlike the typical 15 minute warm-up period

required for polargraphic electrodes.

The probe consists of two parts. The upper p

cathode, and dual cable. The lower part consists of a pre-assembled

cap, and electrolyte solution.

Oxygen diffuses through the membrane onto the cathode, where it is

consumed. This process produces an electrical current which flows

through the cable to the meter. The electric current produced is

proportional to the oxygen that passes through the membrane and the

layer of electrolyte. This makes it possible to measure the partial

pressure of oxygen in the sample at a given temperature.

Since the DO in the sample is consumed by the cathode it is essential

to have flow past the membrane of the probe to prevent the occurrence

of false readings. The probe uses very little oxygen for its

measurement. This enables it to function correctly with liquid

movement as low as 2 inch/sec across membrane.

The permeability of the membrane to oxygen varies greatly with

temperature. Therefore compensation is needed for this variation. The

DO 700 probe comes with built-in temperature compensation for the

membrane variation.

Proper maintenance will help you maximize probe life and achieve

most accurate

Deposits on the membrane surface act as a barrier to oxygen diffusing

h the membrane, so clean the membrane to assure maximum

throug

reliability. After each use, rinse the probe with clean water to avoid any

hardening of deposits or bacterial growth.

NOTE: Although the membrane is strong and not easily damaged,

wipe it gently while cleaning it. If the membrane is punctured,

damaged, or torn, the probe will not function properly.

readings.

art consists of the anode,

15

Page 20

There are no special probe storage requirements.

Cap and Electrolyte Replacement

Replacement of the pre-assembled cap is required only when you

cann

ot calibrate the probe, or if the membrane is damaged. Typical

membrane damages are punctures or wrinkles caused during

measurements or cleaning.

1) Unscrew the cap counter clockwise from the probe sensing tip.

2) Rinse the probe under running water.

3) Mount the nozzle tip onto the syringe provided. Fill the syringe

ith the refill solution through the tip of the plastic bottle.

w

4) Hold th e probe upside do wn. Insert the nozzle tip into one of the 4

hol

es surrounding the silver cathode. Inject the fill soluti on into the

probe body until solution leaks out from the fill hole (approximatel y

5 mL).

5) Replace pre-assembled cap by tightening clockwise until hand

ed.

tighten

6) Allow at least 1 hour for the electrode to equilibrate before

usage.

16

Page 21

1

2

3

4

5

6

Electrolyte Solution

The electrolyte solution in your probe’s cap will deplete on usage and

will need to be replaced periodically. The replacement electrolyte

solution included with your probe comes premixed and ready to use.

To order more electrolyte solution, see Section 9 – Replacements and

Accessories

.

17

Page 22

8. DISSOLVED OXYGEN THEORY

Dissolved Oxygen (DO) refers to the volume of oxygen that is contained in

water. There are two main sources of DO in water; atmosphere and

photosynthesis. Waves and tumbling water mix air into the water where

oxygen readily dissolves until saturation occurs. Oxygen is also produced

by aquatic plants and algae during photosynthesis.

The amount of DO that can be held b

1) TEMPER

ATURE:

y water depends on 3 factors:

DO increases with decreasing temperature

(colder water holds more oxygen)

ALINITY:

2) S

DO increases with decreasing salinity

(freshwater holds more oxygen than saltwater does)

TMOSPHERIC PRESSURE:

3) A

DO decreases with decreasing atmospheric pressure

(amount of DO absorbed in water decreases as altitude increases)

Solubility of oxygen in water contact with water saturated air at

16

14

12

10

8

6

Solubility mg/L

4

2

0

0 5 10 15 20 25 30 35 40 45 50

standard atmospheric pressure

Tem perat ure ° C

DO Solubility in Water vs. Temperature

18

Page 23

Measurement Units

One measure of DO in water is parts per million (ppm) which is the

number of oxygen molecules (O

) per million total molecules in a sample.

2

The “mg/L” unit is equivalent to ppm (a liter of water weighs 1 million

milligrams—one part in a million is similar to one milligram in a liter).

Calculating the % saturation is another way to analyze DO levels. %

saturation is the measured DO level divided by the greatest amount of

oxygen that the water could hold under various temperature and

atmospheric pressure conditions multiplied by 100.

What Is Being Measured?

DO probes respond to the partial pressure of oxygen in liquid or gas being

ed—they measure the “pressure” of oxygen rather than

measur

concentration. All of the oxygen entering the probe is consumed at the

cathode where it is electrochemically reduced to hydroxyl ions producing

an electrical current within the probe:

+ 2 H2O + 4 e- Æ 4 OH –

O

2

Since all oxygen entering the probe is chemi

cally consumed, the partial

pressure of oxygen in the electrolyte is zero. Therefore, a partial pressure

gradient exists across the membrane and the rate at which oxygen enters

the probe is a function of the partial pressure of oxygen in the gas or in

liquid being measured.

When a probe is placed in air saturated

water, the current it produces will

not be affected by the temperature or salinity of the water. The DO

concentration in the water, however, will vary with temperature and

salinity. Because it is convenient to report DO concentration in mg/L or

ppm, it is necessary to adjust for temperature and salinity of the water to

get correct readings in these units.

If DO were to be reported in terms of partial p

ressure or % Saturation,

then temperature and/or salinity compensation for oxygen solubility would

not be necessary. Most probes are temperature compensated—i.e. they

convert the “partial pressure measurement” to mg/L of DO at whatever

temperature the water happens to be at for a given salinity and barometric

pressure.

19

Page 24

Air Calibration

Understanding the principle of air calibration is easy, once you know that it

is partial pressure that the probe is responding to. When the probe is in

air, it is measuring the partial pressure of oxygen in air. If water is air

saturated, then the partial pressure of oxygen in the water will be the

same as it is in air. Therefore, all you need to know is the temperature of

the air in which the probe is placed. By consulting solubility tables for

oxygen at the particular barometric pressure and salinity of the water

being measured, the corresponding concentration (mg/L or ppm) can be

found for air saturated water at the air calibration temperature, and the

meter can be set accordingly. Because most meters are temperature

compensated, they will still give correct readings in mg/L even though the

actual water temperature may be different to the air calibration

temperature. Note: The closer the air calibration temperature is to the

water temperature, the more accurate the calibration.

Applications

Oxygen is essential for fish, invertebrate, plant, and aerobic bacteria

respirati

organisms. Levels below 2 or 1 ppm will not support fish. Fish growth

and activity usually require 5 to 6 ppm of DO, an important consideration

for Aqua-culture industry.

Low DO indicates a demand on the oxygen of the system. Natural organic

material s

demand as it is decomposed. Organic materials from human activities also

create an oxygen demand in the system. Micro-organisms consume

oxygen as they decompose sewage, urban and agricultural run-off, and

discharge from food-processing plants, meat-packing plants and diaries.

There is an optimum DO level for this process and if the DO level falls too

low, the micro-organisms die and the decomposition ceases. When DO

level is too high, this indicates too much power is used than necessary for

aeration resulting in an inefficient process.

In boiler water application, presence of oxygen in the water will increase

corrosio

such instance it is critical to keep DO concentration to a minimum.

on. DO levels below 3 ppm are stressful to most aquatic

uch as leaves accumulate in the stream and create an oxygen

n and helps build up boiler scale that inhibits heat transfer. In

20

Page 25

Some pollutants such as acid mine drainage produce direct chemical

demands on oxygen in the water. DO is consumed in the oxidationreduction reactions of introduced chemical compounds such as nitrate

1-

) and ammonia (NH

(NO

3

ferrous (Fe

+

) and ferric (Fe

2

These are important consideration for w

1+

), sulfate (SO

4

+

) ions.

3

2-

), and sulfite (SO

4

2-

3

) and

ater and wastewater treatment

industry.

21

Page 26

9. REPLACEMENTS AND ACCESSORIES

Part number Ordering Code

Item Description

DO 700 meter with DO/ATC probe and

1-m cable, (2) Pre-assembled caps,

electrolyte, integral stand, & 100/240

VAC adapter.

DO/ATC probe, 1-m cable, (2) Preassembled caps, electrolyte, & plastic

syringe.

DO/ATC probe, 3-m cable, (2) Preassembled caps, electrolyte, & plastic

syringe.

Pre-assembled cap 01X241608 —

Pre-assembled cap, 10 mL

electrolyte, plastic syringe

SMPS, 100/240 VAC, 9V, 6W power

adapter

Zero Oxygen Solution (500 mL) — 00653-00

DO probe electrolyte refilling solution

(60 mL)

Eutech

Instruments

ECDO70042S

X543501

01

DO6HANDY

01

X233913

DO6HANDY3M

01

X233916

01X241609 35642-55

60X030130 35615-07

01X211226 —

Oakton

Instruments

35415-00

35642-50

35462-52

22

Page 27

10. TROUBLESHOOTING GUIDE

PROBLEM CAUSE SOLUTION

No display Main power not switched

“Ur” (Under

range)

“Or” (Over

range)

in primary or

secondar

display

Meter not

responding to

key press

Secondary

display

continually

shows

0 and 100,

during %

calibration

on. AC Adapter socket not

inserted properly.

DO or Temperature value

is out of range.

Probe is not connected.

Electrode dirty or broken.

y

Meter not calibrated.

Manual HOLD or Auto

HOLD is active.

Worn ke

Invalid key; Button is not

functional in the current

operation mod

The calibration value is too

high to be accept

0% standard, and too low

to be accepted as a 100%

standard (10.1% to

49.9%), compared against

factory default value.

ypad.

e.

ed as a

Switch on the power supply.

Re-insert AC Adapter.

Confirm measurement condition,

ensure temp is

Check electrode connections.

Check electrode-add electrolyte

&/or replace me

Reset meter & recalibrate.

Press

HOLD.

See Section 5.4 — Auto Hold

disable Auto Hold feature if

enabled.

Contact Technical Service.

Press alternate key.

Select valid key depending on

current mode.

Service probe.

Check calibration solution.

Check sample conditions (temp,

and pressure settings).

salinity

Reset meter.

within range.

mbrane.

to deactivate manual

to

23

Page 28

PROBLEM CAUSE SOLUTION

CAL

CAL

Slow

response or

unstable

readings

% calibration value is not

acceptable.

Electrode is disconnected

or failing.

ppm or mg/L calibration is

attempted

calibrated absolute value is

below 2.00

External noise pickup or

induction caused b

nearby electric motor

Insufficient electrolyte in

probe

Air bubbles near sensor

Dirt

Probe not deep enough in

sample

Broken probe

when the factory

y

y or damaged probe

Check electrode connections.

Check that corre

selected & repeat cal procedure.

Service electrode.

Reset meter.

Replace electrode.

Use concentration calibration

solution higher than 2.00.

Check electrode connections.

Check that corre

selected & repeat cal procedure.

Service electrode.

Reset meter.

Replace electrode.

Remove or switch off interfering

device

Fill probe with electrolyte & / or

replace pre-

Stir or tap probe to remove

bubbles, reduce

Clean the probe and re-calibrate

Submerse sensor cap into sample

Replace probe o

ct DO unit is

ct DO unit is

assembled cap

stirring

r membrane

24

Page 29

11. SPECIFICATIONS

DO % Saturation

Range

Resolution

Relative accuracy

Offset adjustment

Calibration Points

DO mg/L or ppm

Range

Resolution

Relative accuracy

Calibration

Temperature

Range

Resolution

Relative accuracy

Calibration

Salinity Correction

Range

Resolution

Method

Pressure Correction

Range

Resolution

Method

Probe (DO / Temp) Galvanic / Thermistor

Avg. Response Time 60 seconds to achieve 95% of the reading

Hold Function Yes

Memory 100 data sets

Input BNC for DO & 2.5 mm phono plug for temperature

Power AC/DC 9V, 6W Adapter (100/240 VAC, 50-60Hz)

Dimensions (mm) meter only = 175 (L) x 155 (W) x 69 (H)

(2 points) 100% in saturated air or air-saturated water,

(1 point) ± 40% from the factory default value.

Offset in 0.1 º increments; Offset range: ± 5 ºC / 9 ºF

Automatic correction after manual input

Automatic correction after manual input

± 10.0% of reading

0% in zero oxygen solution

Minimum reading allowed is 2.00.

0.0 to 50.0 ºC / 32.0 to 122.0 ºF

450 to 825 mmHg/ 0.6 to 1.1 bar

1 mm Hg / 0.1 bar

0 to 300%

0.1 %

± 0.5% of value

0.0 to 30.0

0.01

± 0.5% of value

0.1 ºC / 0.1 ºF

± 0.5ºC / ± 0.9ºF

0.0 to 50.0 ppt

0.1 ppt

25

Page 30

12. WARRANTY

This meter is supplied with a warranty against significant deviations in

material and workmanship for a period of THREE years from date of

purchase whereas probe with a SIX month warranty.

If repair or adjustment is necessary a

or misuse within the designated period, please return – freight prepaid –

and correction will be made without charge. Eutech Instruments/Oakton

Instruments will determine if the product problem is due to deviations or

customer misuse.

Out of warranty products will be repaired on a charged basis.

The warranty on your instrument shall not ap

nd has not been the result of abuse

ply to defects resulting from:

• Improper or inadequate maintenance by customer

• Unauthorized modification or misuse

• Operation outside of the environment specifications of

the products

26

Page 31

13. RETURN OF ITEMS

Authorization must be obtained from our Customer Service Department or

authorized distributor before returning items for any reason. A “Return

Material Authorization” (RMA) form is available through our authorized

distributor. Please include data regarding the reason the items are to be

returned. For your protection, items must be carefully packed to prevent

damage in shipment and insured against possible damage or loss.

Eutech Instruments will not be responsible for damage resulting from

careless or insufficient packing. A restocking charge will be made on all

unauthorized returns.

NOTE: Eutech Instruments Pte Ltd /Oakton Instruments res

to make improvements in design, construction, and appearance of

products without notice.

erve the right

27

Page 32

Page 33

Page 34

Page 35

NOTES

Page 36

For more information on our products, please contact our channel

partner or visit our websites listed below:

Oakton Instruments

625 E Bunker Court

Vernon Hills, IL 60061

USA

Tel: (1) 888-462-5866

Fax: (1) 847-247-2984

info@4oakton.com www.4oakton.com

Distributed by:

Eutech Instruments Pte Ltd

Blk 55, Ayer Rajah Crescent,

#04-16/24

Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

eutech@thermofisher.com

www.eutechinst.com

Part of Thermo Fisher Scientific

Loading...

Loading...