gyM

sy...

Instruction Manual

2700 Series Benchtop

Meters

pH 2700 ● ION 2700 ● CON 2700 ● DO 2700 ● PC 2700

Tech nol o

adeEa

Part of Thermo Fisher Scientific 68X544001 Rev 1 Sep 2010

TABLE OF CONTENTS

1. Introduction......................................................................................1

2. Getting Started.................................................................................2

Keypad and Display...................................................................................................2

Navigation of Tabs .....................................................................................................3

Meter Connections.....................................................................................................4

3. System Setup & Configuration.......................................................5

Stability .......................................................................................................................5

Stability Criteria..........................................................................................................6

Auto Read ...................................................................................................................6

Print Set.......................................................................................................................7

Date & Time.................................................................................................................8

Password ....................................................................................................................8

Clear Datalog..............................................................................................................8

Factory Reset..............................................................................................................9

Contrast Adjustment..................................................................................................9

4. Setup pH & mV.................................................................................10

Sample ID....................................................................................................................10

Buffer (Group Selection)............................................................................................10

Cal Points....................................................................................................................11

Resolution...................................................................................................................11

Alarm ...........................................................................................................................11

Cal Due........................................................................................................................11

5. pH Calibration (with preset buffer group).....................................12

6. pH Calibration (with custom buffers) ............................................14

7. Millivolt (mV) Calibration (Offset Adjustment)..............................16

8. Temperature Setup..........................................................................17

9. Temperature Calibration.................................................................18

10. Conductivity, TDS, Salinity, & Resistivity Setup..........................19

Sample ID....................................................................................................................19

Cal Points....................................................................................................................20

Pure Water Coefficient...............................................................................................20

Temperature Coefficient (linear)...............................................................................20

Normalization Temperature (°C) ...............................................................................21

Cell Constant..............................................................................................................21

Alarm ...........................................................................................................................22

Cal Due........................................................................................................................22

11. Conductivity Calibration (automatic).............................................23

12. Conductivity, TDS, Salinity, & Resistivity Calibration (manual

adjustment).............................................................................................25

13. Ion Setup ..........................................................................................27

Sample ID....................................................................................................................27

Measure Unit...............................................................................................................27

Alarm ...........................................................................................................................27

Cal Due........................................................................................................................28

14. Ion Calibration..................................................................................29

15. Dissolved Oxygen Setup ................................................................31

Sample ID....................................................................................................................31

Offset Cal (% saturation only)...................................................................................31

Pressure Unit (% saturation mode only)..................................................................31

Pressure Cal (% saturation mode only) ...................................................................32

Pressure Compensation (% saturation mode only)................................................32

Measure Unit (concentration mode only) ................................................................32

Salinity Value (concentration mode only)................................................................33

Alarm ...........................................................................................................................33

Cal Due........................................................................................................................33

16. Dissolved Oxygen Calibration........................................................34

100 % Calibration .......................................................................................................34

0% Calibration ............................................................................................................35

mg/L or ppm (Concentration) Calibration................................................................35

17. Transferring and Printing Data.......................................................37

18. Calibration Report ...........................................................................38

19. Dissolved Oxygen Theory ..............................................................39

20. Calculating Temperature Coefficients...........................................42

21. Calculating TDS Conversion Factor ..............................................43

22. DO Electrode Maintenance .............................................................44

23. Troubleshooting ..............................................................................45

24. Specifications ..................................................................................47

25. Replacements and Accessories.....................................................50

26. Warranty ...........................................................................................52

27. Return of Items ................................................................................53

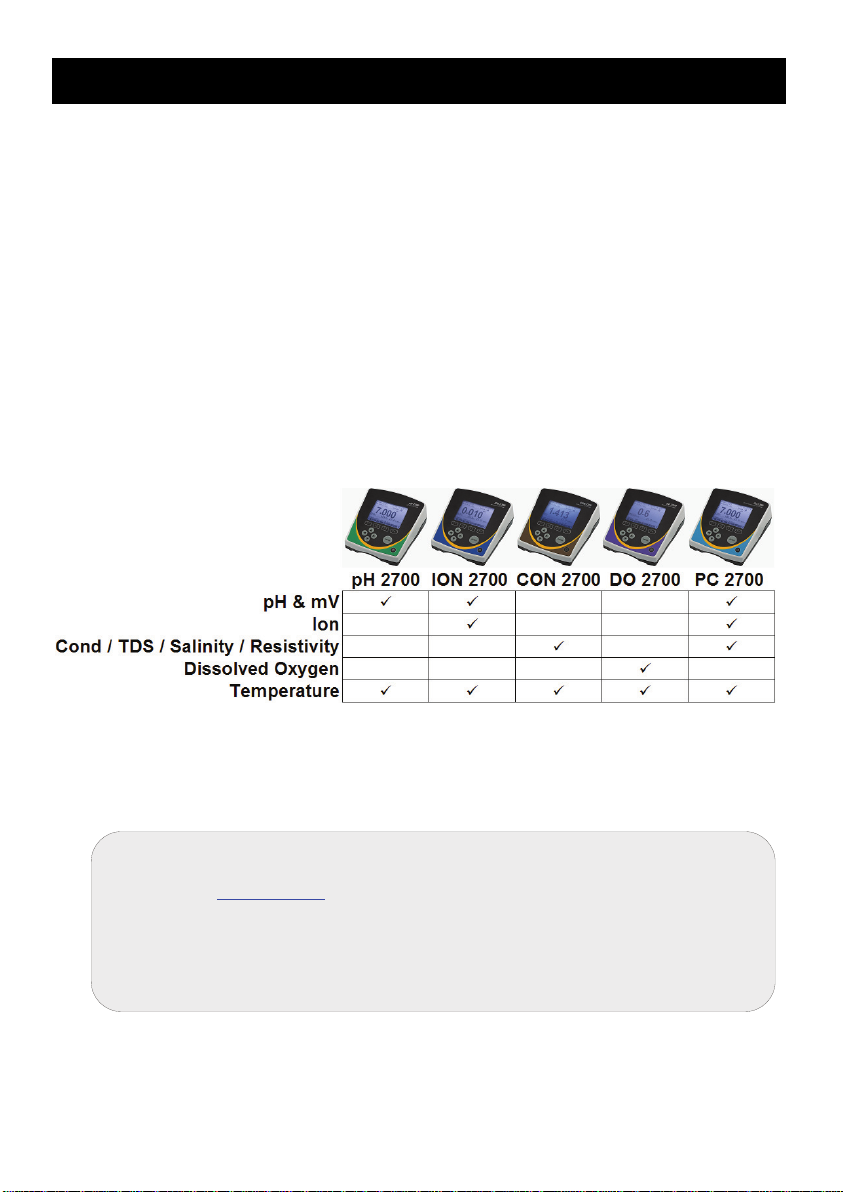

1. Introduction

Thank you for selecting our 2700 series research benchtop meter. This

microprocessor-based instrument incorporates a large LCD for clear viewing, yet

offers a small footprint to conserve space.

Each meter includes a convenient slide-out calibration card for quick reference. All

s (except for DO 2700) include an electrode arm and metal bracket which

model

can be easily attached to the left or right side of the meter according to your

preference.

The 2700 series benchtop meter replaces our popular 1100 and 2100 series

meters that were introdu

Please note that this manual serves all 2700

manual will be relevant to each model. The chart below lists the parameters

served for the various models:

ced in 2001.

models, so not all sections of the

We take great pride in every instrument we manufacture and hope this one

es you well.

serv

If you are viewing an electronic version of this manual, you

can use hyperlinks located in the Table of Contents and

elsewhere by holding down the CTRL key as you click the

hyperlink.

Find other helpful tips listed in grey boxes like this one!

1

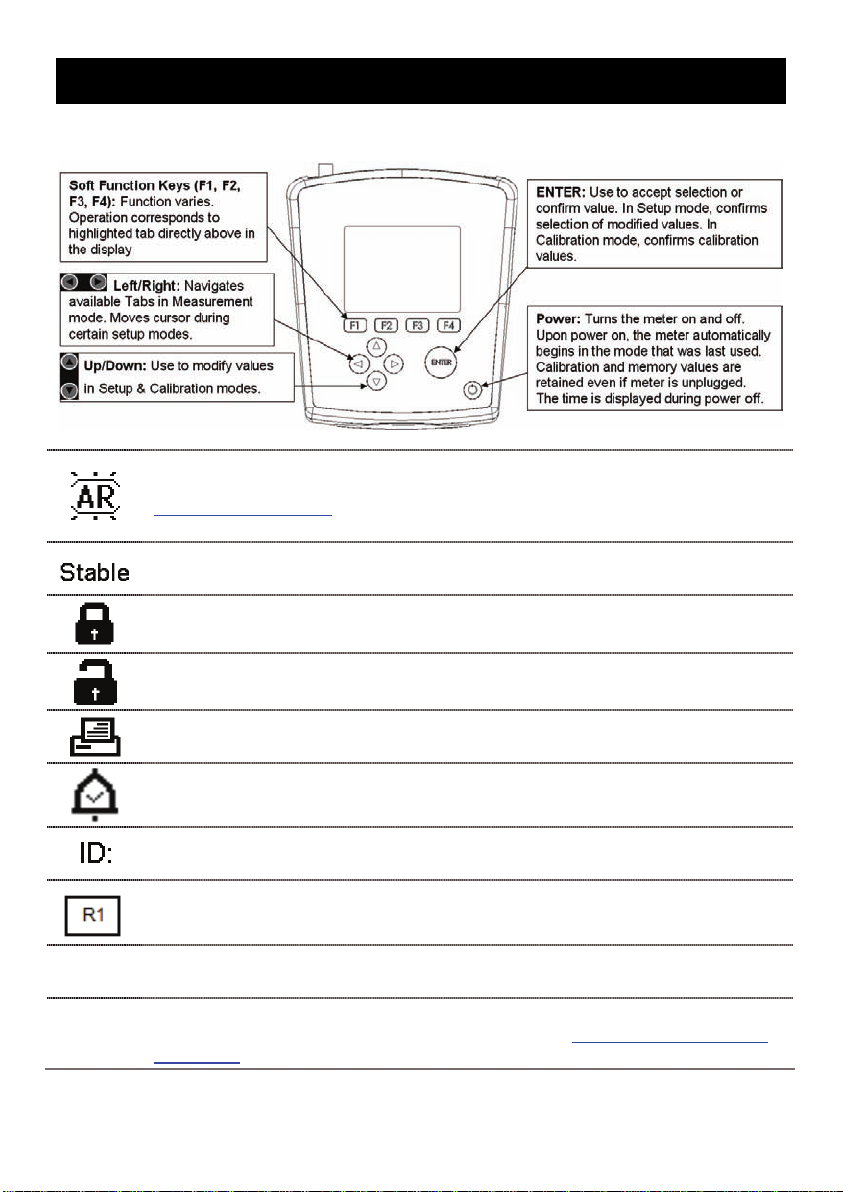

2. Getting Started

Keypad and Display

Auto Read is enabled. When flashing, the instrument has detected a ‘Stable’

reading and locked the value. Press MEAS to resume live reading. See

Section 3—Auto Read

SETUP…SYSTEM…AUTO READ.

Based on the stability criteria settings in System Setup, the instrument has

detected a stable reading.

Password Protection: Enabled. Requires password for all

calibration and setup menus

to disable this feature, or go to

(ATC)

(MTC)

Password Protection: Disabled. No password required for any menu.

Print Setting Timed interval is active; data is

“High Alarm”, “Low Alarm”, or “Cal Due” alarm limit had been reached.

High/

Low alarms also have an audible notification..

Sample ID: User selectable five digit number to identify samples.

Measuring Range # of displayed value (1 thru 5). Applicable to Conductivity,

TDS, Salinity, or Resistivity measurements only

Automatic Temperature Compensation is active; temperature is being actively

acquired with attached electrode. ATC is recommended.

Manual Temperature Compensation is activ

be attached so the default temperature is used. See Section 9—Temperature

Calibration to calibrate the ATC or MTC temperature values.

being output at regular intervals.

e. A temperature sensor may not

2

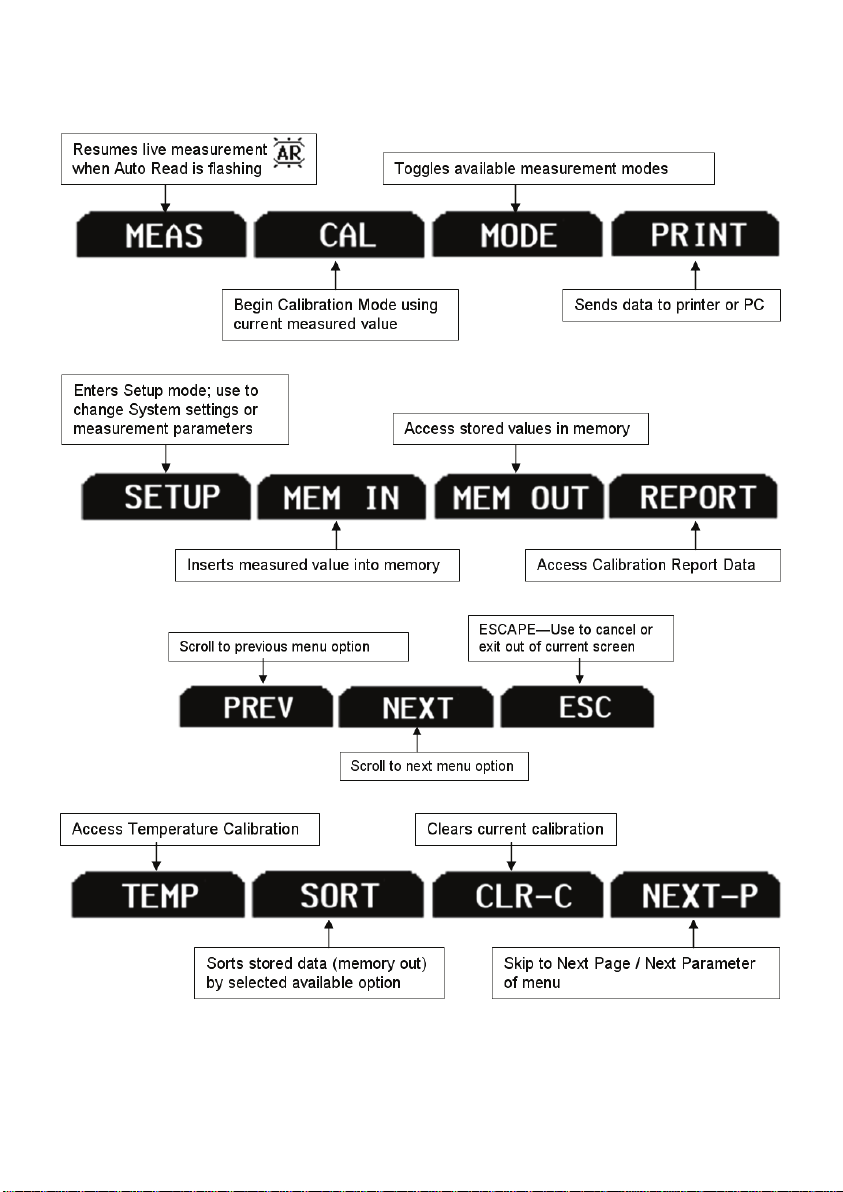

Navigation of Tabs

3

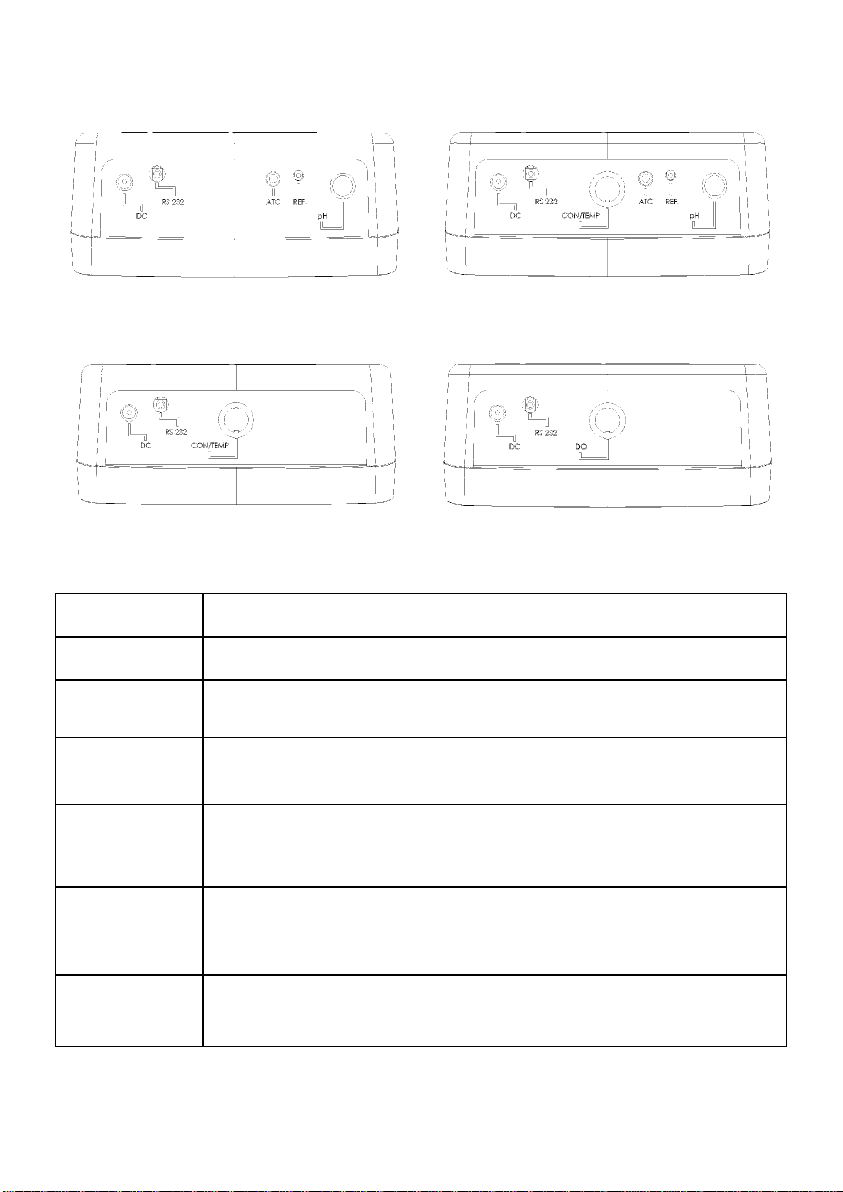

Meter Connections

DC

RS-232

CON/TEMP

DO

ATC

pH 2700

ION 2700

PC 2700

CON 2700 DO 2700

Power supply

RS-232 output, 2.5 mm jack for RS-232 cable

8-pin DIN connection for 2-cell or 4-cell Con/TDS/Temp

electrode

8-pin DIN connection for Dissolved Oxygen/Temp self stirring

electrode

For Automatic Temperature Compensation probe.

For PC 2

measurement associated with the BNC (“pH”) input.

s

700, this corresponds to the temperature

Pin connection for half cell reference electrodes.

REF

pH

Req

uires separate half cell electrode in the BNC (“pH”) input.

Note: REF is not commonly used and is not required.

BNC connection for combination pH, ORP (Redox), or Ion

Selective Ele

ctrodes (ISE), or half-cell indicating electrodes.

4

3. System Setup & Configuration

Use the System Setup to customize operation of your 2700 series meter.

Press

SYSTEM is highlighted to access these settings.

The following settings can be customized for each model:

STABILITY PRINT SET

STABILITY

CRITERIA

AUTO READ PASSWORD

BACKLIGHT CLEAR DATALOG

DATALOG FACTORY RESET

PRINT SETUP CONTRAST

PRINT FORMAT

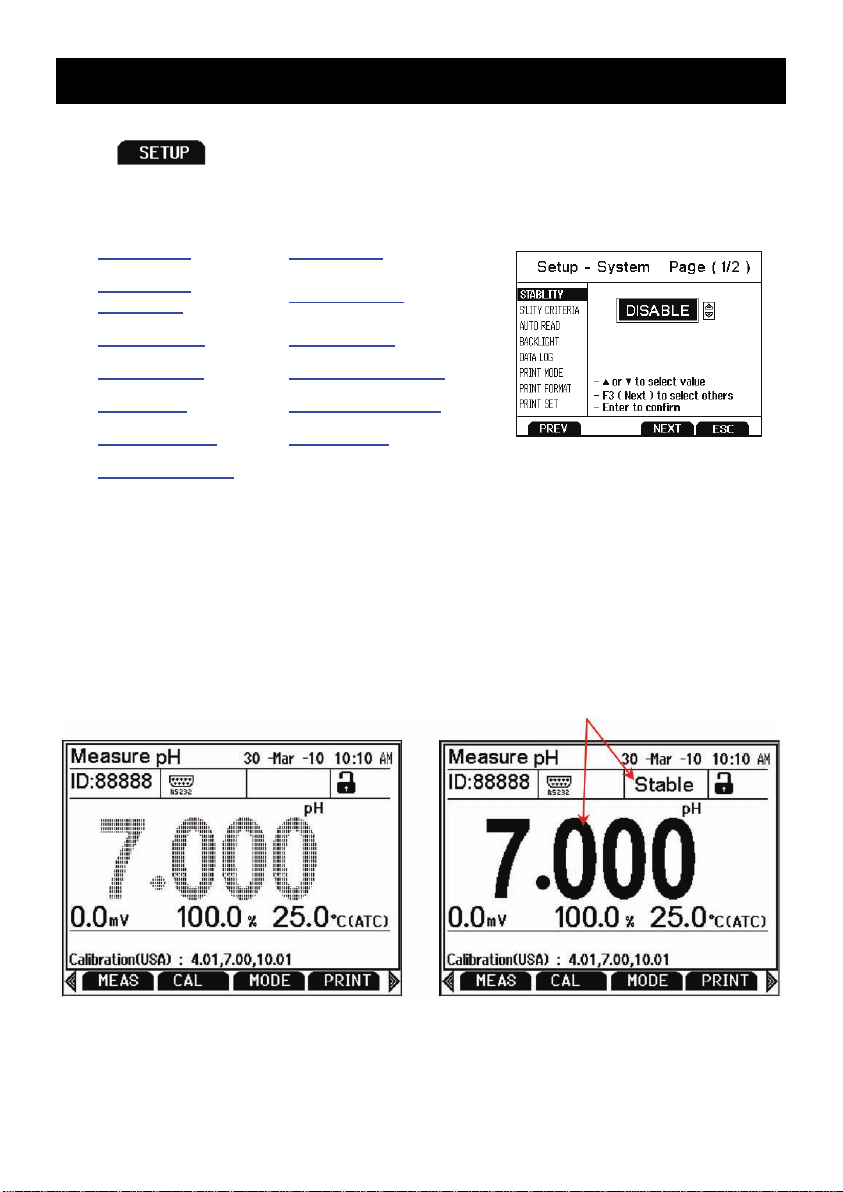

Stability

To aid with measurement and calibration, your meter has a unique feature that

provides an obvious visual indication when the reading becomes stable. If the

Stability feature is enabled, the digits on the primary reading will be faded when

unstable, becoming solid when stable. If this feature is disabled, the primary

reading will always be solid. The image below on the left is an unstable reading

during pH Measurement mode with Stability enabled. The image on the right

shows a stable reading.

from the measurement screen and then press ENTER when

DATE & TIME

5

Stability Criteria

The 2700 allows adjustment of the Stable indicator which relates to how fast and

frequent it appears. There are three levels of adjustment; SLOW, MEDIUM, &

FAST.

To display a ‘Stable’ reading more quickly and more often, use “FAST” setting.

MEDIUM or SLOW

enabled, a stability criteria setting of “SLOW” is recommended to for best results.

SLOW: T

frequently. Use this setting if you want the best results and don’t mind waiting

longer to get them.

MEDIUM: This is the factory default setting. It provides a balanced response

whi

he Stable indicator will take longer to appear and will appear less

ch works best for most applications.

is recommended for most applications. When Auto Read is

FAST: The S

Stable indicator frequently appears and disappears, you may want to select a

slower setting. This setting is not recommended when AUTO READ is enabled. It

is also not suitable for most non-refillable electrodes which are generally slower to

respond.

Auto Read

If AUTO READ is enabled, the measured value will automatically lock

when the Stable indicator appears. A flashing “AR” icon confirms this

condition. To resume a live reading again, it is necessary to press MEAS

each time Stable appears. Disable this feature to continuously view the active

reading.

table indicator will appear quickest of any setting. If you find that the

Backlight

Select “PERMANENTLY ON” on to keep the backlight on at all times that the

meter is powered on. This will offer the best visibility but consumes the most

power.

Select “ON WITH KEY

any key press. Select “0” to keep the backlight off at all times that the meter is

powered on.

PRESS” to turn on the backlight for a specified time after

6

Data Log (storing data to internal memory)

Select “SINGLE” to manually save one point at a time. Press the “MEM IN”

function key any time during measurement to save data.

Select “TIMED” to

3 to 3600 seconds. Data will be collected until the data limit is reached or until

“SINGLE” data log is selected. This feature is useful for gathering data from a

single sample over time. Note that “MEM IN” is not available during TIMED

setting. As data is collected, the display will indicate how much memory has been

used.

To view stored data, use “MEM

acquired memory, the longer the data will take to display.

automatically save data at selectable intervals— ranging from

OUT”. Note: the more data that has been

Print Setup

Adjust the RS-232 output settings for baud rate, parity, data bit, and stop bit to

match your printer or computer settings as necessary.

Print Format

When utilizing the RS-232 output; choose “TEXT/PRINTER” option to send the

data in an easily viewable format—best for printing.

Choose “CYBERCOMM” option to send the data as a comma separated value

(CSV)—best for exporting data into spreadsheet software.

Print Set

This is identical to the Data log function, but data is sent via RS-232 output

instead of internal memory.

Select “SINGLE” to manu

collecting data to your PC from many samples.

Select “TIME

from 3 to 3600 seconds. Data will be output until “SINGLE” Print set is selected.

This feature is most useful for gathering data for use with software. Unlike the

Data Log setting, data can be saved to memory using “MEM IN” during TIMED

setting.

D” to automatically output live data at selectable intervals— ranging

ally output one value at a time—best for printing or

7

Date & Time

Setting the correct date and time is required for GLP and will apply to power off,

measurement, data log, and print functions. Instrument has battery backup to

retain date/time settings upon power loss. Factory reset will not apply to date and

time setting once it has been set. Changes related to daylight savings time must

be manually entered.

Date Format: Selec

Time Format: Select 12

t (MM DD YY) or (DD MM YY)

Hrs (AM/PM) or 24Hrs

Password

Select “ENABLE” to restrict access to Calibration and Setup modes. When

password protection is enabled, password entry is required before performing any

calibration, or making changes to the setup mode. Setup parameters can be

viewed, but can not be changed without correct password entry. The password is

a user selectable number from 1 to 99999.

Select “DISA

The meter does not allow you to edit setup parameters or perform a new

calib

ration unless you enter the correct password. If an incorrect password is

entered 3 consecutive times, the meter returns to measurement mode.

In the event the password can not be recovered, a

a written request to Eutech Instruments/Oakton Instruments. The instrument

serial number and your contact information are required.

BLE” if password protection is not desired.

password can be provided via

Clear Datalog

Select “YES” to delete all saved data that was manually or automatically stored

into memory. This step is most commonly required when the “TIMED” data log

interval is not turned off and as a result, fills the memory to capacity. When the

memory is full, deleting the saved data is required in order to save additional

data/ The 2700 will never erase old data in favor of new data when the memory is

full.

If you wish to view, print or send the saved data to a PC before deleting, use the

“MEM OUT” function from measurement mode.

8

Factory Reset

Select “YES” to reset the 2700 to the factory default settings except; Date & Time,

Temperature calibration, and data stored in memory.

Contrast Adjustment

Optimize the contrast setting of your 2700 display for best visibility in your

surrounding lighting conditions. Test various contrast settings for best results.

This setting will be applied to both backlight and non-backlight conditions.

9

4. Setup pH & mV

Use Setup pH or mV mode to customize these parameters. Note: mV setup offers

Sample ID and Alarm setting only.

Press

or mV is selected.

from the measurement screen and then press ENTER when pH

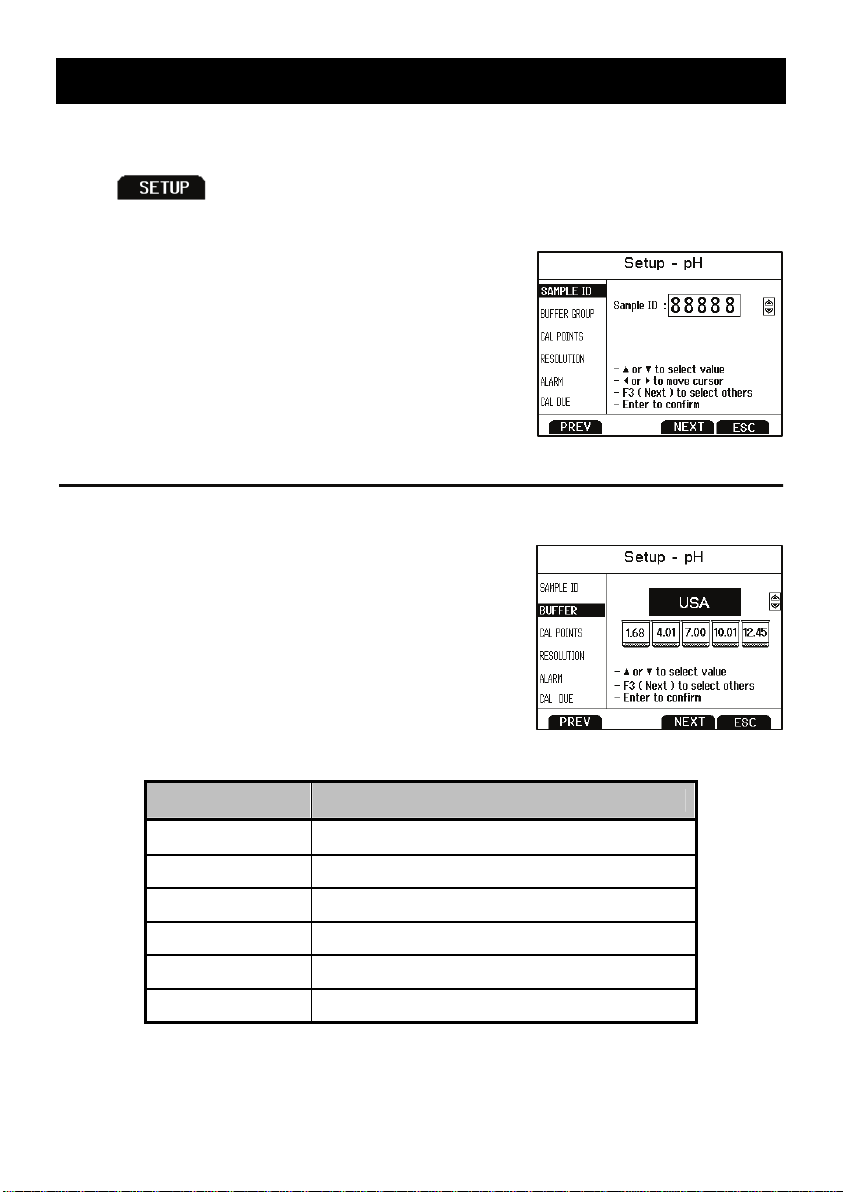

Sample ID

This is a user selectable number from 1 to 99999.

Incorporating a sample ID to identify one or more

data points is useful to distinguish data that is

saved into memory or sent to a PC or printer. Use

the up/down arrow keys to adjust the values and

left/right arrow keys to move the cursor.

Buffer (Group Selection)

Choose one of (6) pH buffer groups for calibration;

USA, NIST, DIN, USER 1, USER 2, and CUSTOM.

The pH values in the selected buffer group are

used for auto-recognition during pH calibration.

Choose the appropriate buffer group, based on the

pH calibration standards you intend to use.

Buffer Group pH Values

USA 1.68, 4.01, 7.00*, 10.01, 12.45

NIST 1.68, 4.01, 6.86*, 9.18, 12.45

DIN 1.09, 3.06, 4.65, 6.79*, 9.23, 12.75

USER 1 1.68, 4.01, 7.00*, 9.18, 12.45

USER 2 1.68, 4.01, 6.86*, 10.01, 12.45

CUSTOM Any 2 - 5 values, ≥ 1.0 pH unit apart

10

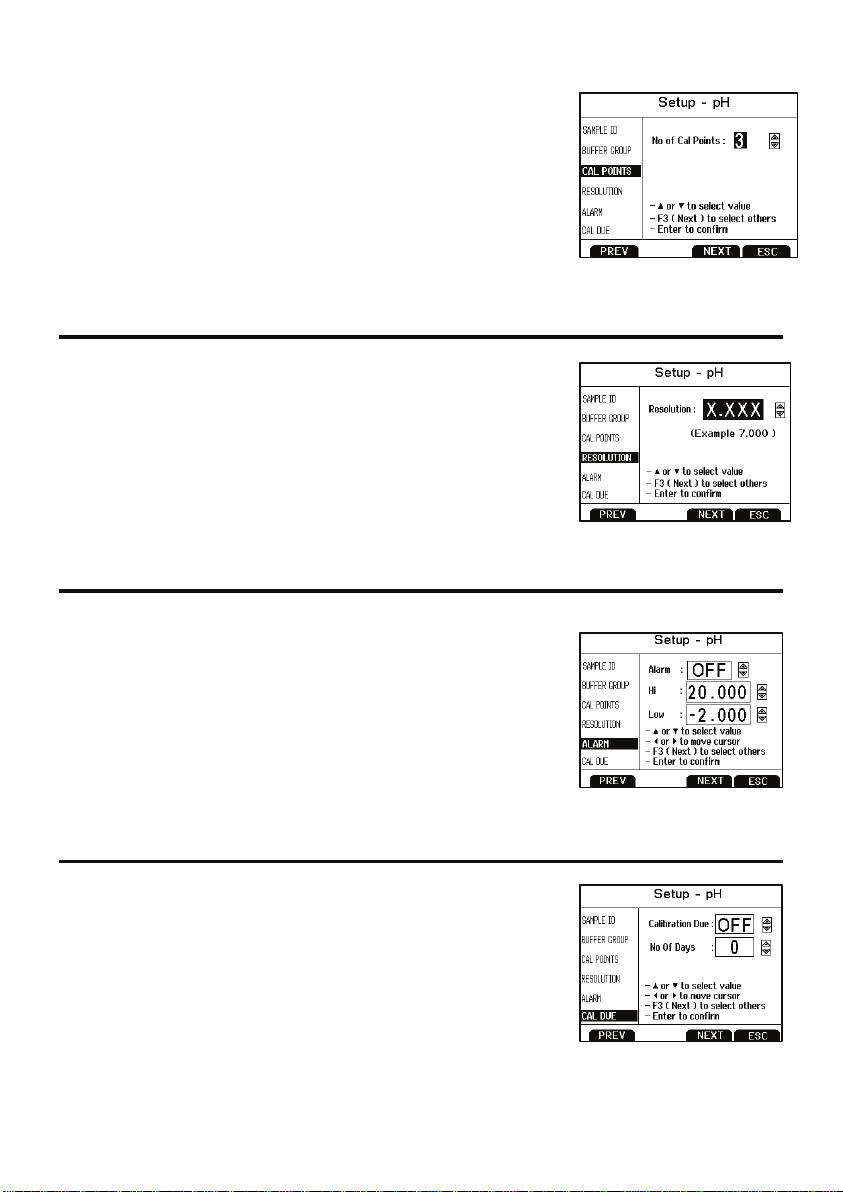

Cal Points

Specify the number of pH calibration points you intend to

calibrate with. Select the number of calibration points

from 1 to 5 with preset buffer groups or from 2 to 5

points with custom buffer group.

For example, if you have selected the USA buffer group

ch contains 5 standards, but you will only be using 3

whi

standards (pH 4, 7, and 10), selecting 3 calibration

points here will speed up the calibration process—the 2700 will automatically

recognize calibration is finished after the 3

rd

point has been completed.

Resolution

Select your desired pH resolution;

0.0, 0.00, or 0.000. Tip: Don’t choose more than you

really need—0.00 is the factory default setting since it is

most commonly used. Choosing 0.000 will lead to more

“unstable” conditions and cause a delay in obtaining the

final reading as the last digit (which is often not needed)

changes.

Alarm

The 2700 offers a visual and audible alarm to alert you

when the High or Low values that have been set from

this menu are exceeded.

“High Alarm” or “Low Alarm” will blink on the displ

the values are exceeded while simultaneously, a loud,

intermittent beeping sound is heard. The alarms will continue until the conditions

are no longer met, and will only be active during measurement mode.

ay if

Cal Due

When enabled, the “Cal Due” indicator blinks if the

number of days since the last calibration has been

exceeded. Set the number of days from 1 to 31.

11

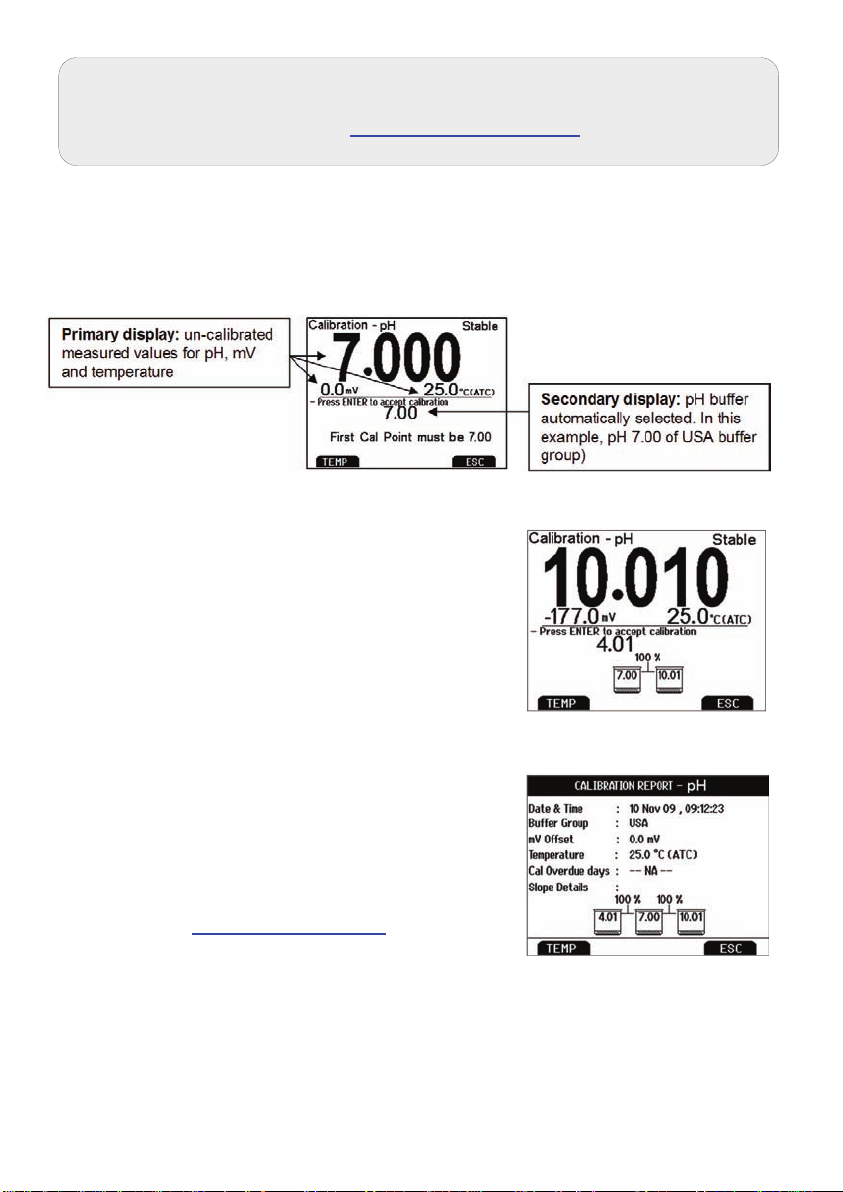

5. pH Calibration (with preset buffer group)

For best results, periodic calibration with known accurate standards is

recommended prior to measurement. Calibrate with standards that bracket your

intended measuring range while including a neutral point (7.00, 6.86, or 6.79). For

example, if you expect to measure samples from pH 6.2 to 9.5, calibration with

4.01, 7.00, and 10.01 will work well.

The 2700 series meters can be calibrated with up to 5 preset or custom buffers

(up to 6 with

values upon meter shut down.

The 2700 series automatically recognizes the following pH calibration buffers in

the grou

DIN buffer group). The non-volatile memory retains all calibration

ps listed below. See Section4—Buffer

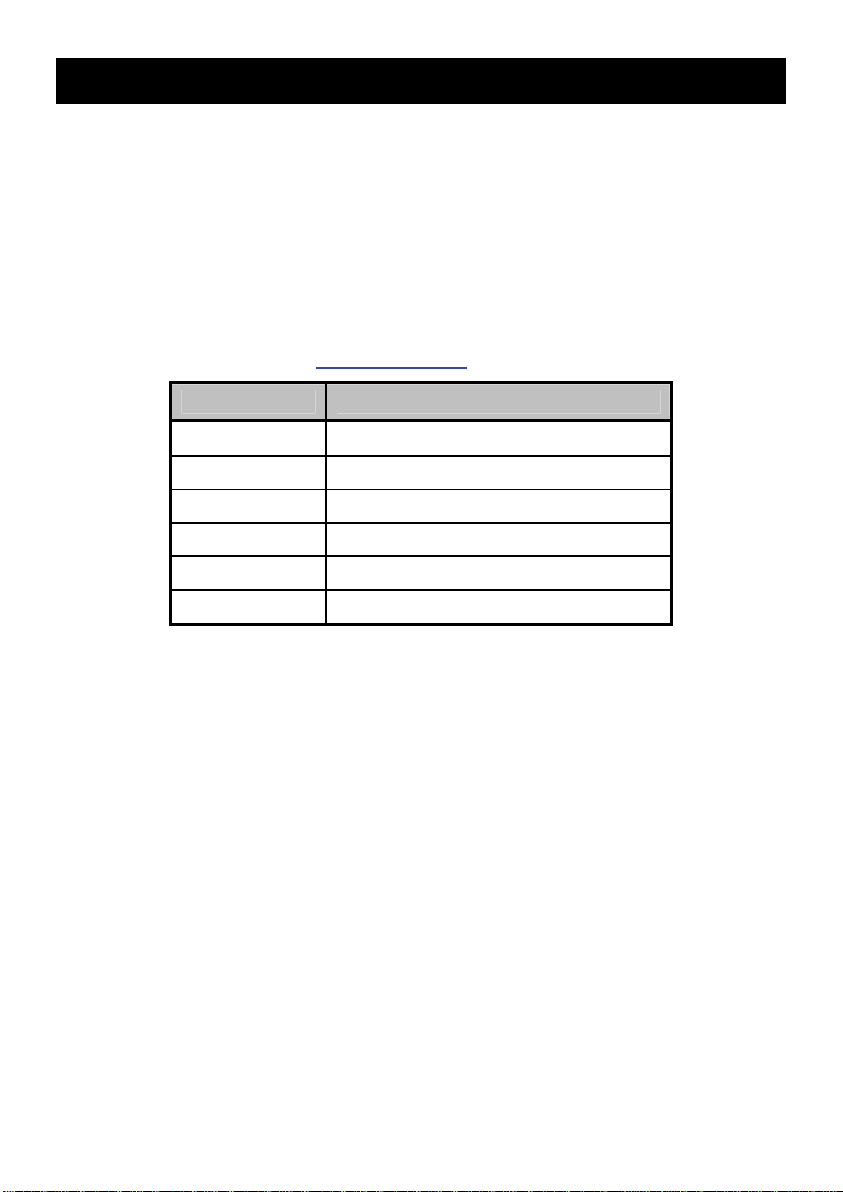

Buffer Group pH Values

USA 1.68, 4.01, 7.00*, 10.01, 12.45

NIST 1.68, 4.01, 6.86*, 9.18, 12.45

DIN 1.09, 3.06, 4.65, 6.79*, 9.23, 12.75

USER 1 1.68, 4.01, 7.00*, 9.18, 12.45

USER 2 1.68, 4.01, 6.86*, 10.01, 12.45

CUSTOM Any 2 - 5 values, ≥ 1.0 pH unit apart

*Required as 1st calibration point value (offset determination)

to select a different buffer group;

To eliminate temperature errors associated with the pH electrode, attach the

automatic te

temperature compensation, pH accuracy will worsen as samples deviate from

25ºC and pH 7.

If the pH electrode has been stored dry, soak in storage solution for 10 minutes

before

minimize drift. If storage solution is not available, use a neutral pH buffer. Do not

reuse buffer solutions after calibration. Contaminants in the solution can affect the

calibration, and eventually the accuracy of the measurements.

1) Turn meter on, press

2) Rin

pH buffer—the 1st calibration point must be either 7.00, 6.86, or 6.79

depending on the buffer group used.

3) Press

mperature compensation (ATC) probe for best accuracy. Without

calibrating or taking readings to saturate the pH electrode surface and

MODE if needed for pH Measurement.

se the pH and ATC electrodes with clean water then submerse in neutral

CAL to enter calibration mode.

12

If the meter is password protected, you will be prompted to

enter a password. See Section 3—Password.

4) The p

automatically searches for and selects the appropriate value from your buffer

group in the secondary display. This value will blink when the ‘Stable’

indicator appears. Selecting CLR-C will clear the existing calibration.

rimary display is the un-calibrated measured value. The 2700

5) Press ENTER to accept the calibration value

of the measured buffer. When successful the

accepted value will be visible inside of a

beaker icon. Percentage slope is visible after

two or more calibration points have been

completed.

6) Repeat Steps 4 & 5 with additional pH buffers

in any order or press ESC to escape and save

your calibration. When the specified number of

calibration points is met, the pH calibration

report page is automatically displayed.

To specify a different number of pH calibration

points see

Section 4—Cal Points

.

13

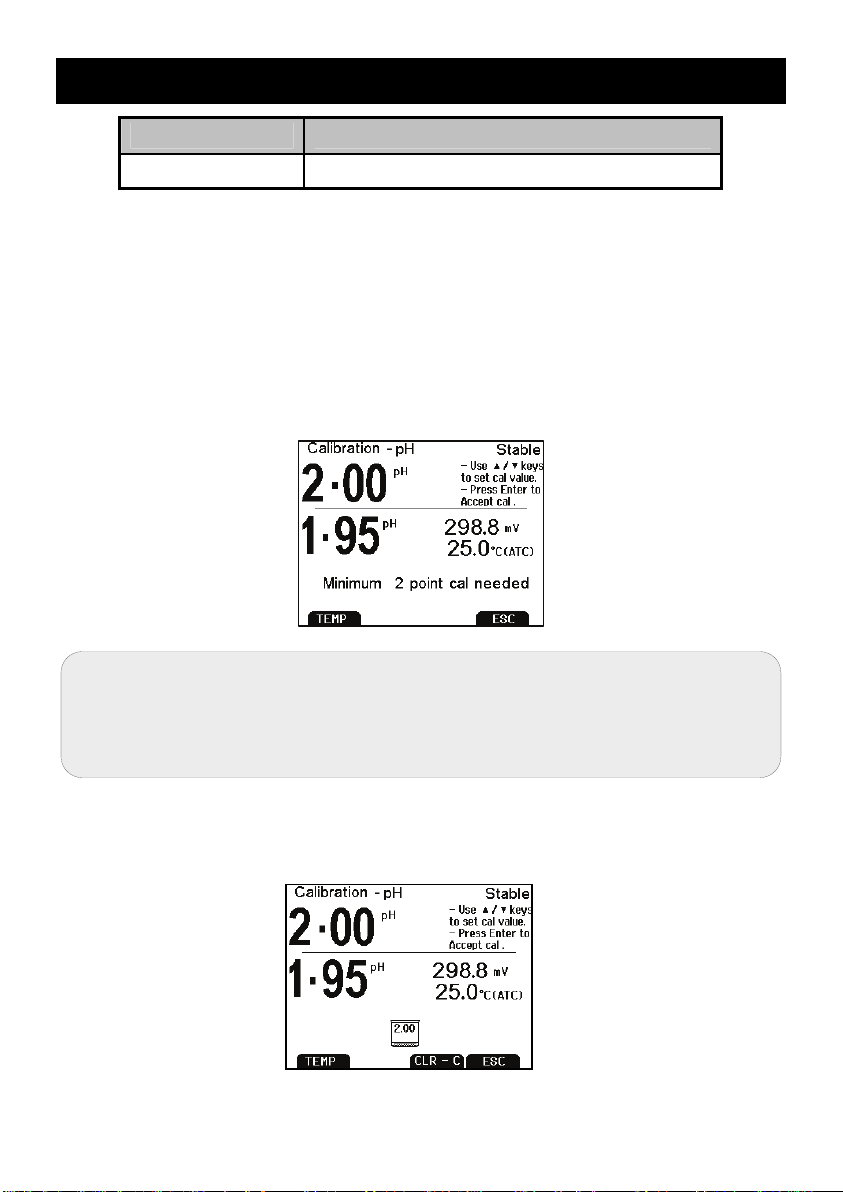

6. pH Calibration (with custom buffers)

Buffer Group pH Values

CUSTOM Any 2 - 5 values, ≥ 1.0 pH unit apart

1) Turn meter on, press MODE if needed for pH measurement mode.

2) Rin

3) Press

4) Press

se the pH and ATC electrodes then submerse in your custom pH buffer—

any pH value can be used.

CAL (enter password if required) to enter calibration mode. If desired,

select CLR-C to clear the previous calibration. The lower pH value

corresponds to the factory default setting for reference. When stable, use the

up/down arrows to adjust the upper pH value to your custom pH buffer value.

For best results, enter the value of the buffer that corresponds

to the measured temperature. For example, pH 10 buffer is

actually 10.06 at 20°C, so adjust to 10.06 instead of 10.00 if

the temperature is 20°C.

ENTER to accept the calibration value. When successful, the accepted

value will be visible inside of a beaker icon.

14

5) Rinse the pH and ATC electrodes then submerse in next custom pH buffer.

Use any pH value that is at least 1.0 pH unit from custom pH standards that

have already been calibrated.

6) Rep

eat Step 5 with additional pH buffers (up to 5 custom buffers) in any

order. Press ESC to escape and save your calibration at any time. When the

specified number of calibration points is met, the pH calibration report page is

automatically displayed. Percentage slope is visible after two or more

calibration points have been completed.

Additional pH calibration notes:

A single point (called “offset”) calibration is allowed with pH 7.00, 6.86, or 6.79

buffers but is not allowed with Custom buffer group. Although single point

calibration is allowed with preset buffer groups, we do not recommend this.

Instead, perform at least a 2-point calibration on a regular basis.

As soon as the first calibration value is a

calibration values are erased.

The pH calibration is a calibration of the

together, not the individual meter or electrode.

ccepted during a new calibration, all prior

complete meter / electrode(s) system

15

7. Millivolt (mV) Calibration (Offset Adjustment)

Oxidization Reduction Potential (ORP or Redox) as measured by an ORP

electrode in mV units is not a precise measurement, but is useful as a relative

indicator. As such, mV offset adjustment is not meant to enhance accuracy, but

rather to make readings comparable to a reference.

Commercial ORP solutions are commonly used as a check standard—a

meter/ele

adjustments are not made. These solutions can be used as a calibration standard

in which adjustments are made in an attempt to match the ORP value, however

results are often difficult to reproduce.

1) Turn m

(or R.mV) measurement.

2) Dip the ORP

Light’s, quinhydrone, or iodidetriiodide) with brief or slow stirring.

3) Press

millivolt value (mV) while the lower display shows the factory default mV value

without calibration. The example below at right shows a mV calibration that

had previously been calibrated with a 10.0 mV offset.

ctrode system is verified to be close to a given value although

eter on, connect an ORP electrode, and press MODE if needed for mV

electrode into a solution with a known mV value (i.e. Zobel,

CAL when the reading is stable. The upper display shows the active

4) Adjust the upper display using up/down arrows, press ENTER to accept the

calibration offset. The maximum adjustable value is ±150 mV from the factory

default mV value.

Additional mV calibration notes:

When an offset has been stored successfully, R

mode.

.mV replaces mV in measurement

16

8. Temperature Setup

Use Setup Temperature mode to desired temperature units; º C or º F.

Press

TEMPERATURE is selected.

Choose º C or º F temperature units of measure.

Automatic Temperature Compensation (ATC) is automatically applied when a

temperature

Manual Temperature Compensation (MTC) of 25 º C i

sensor is not connected. See Section 9—Temperature Calibration

MTC temperature value.

from the measurement screen and then press ENTER when

sensor is connected.

s used if the temperature

to adjust the

17

9. Temperature Calibration

The thermistor sensor used for automatic temperature compensation and

measurement is both accurate and stable, so require frequent calibration isn’t

required. Temperature calibration is recommended upon electrode replacement,

whenever the temperature reading is suspect, or if matching against a certified

thermometer is desired.

Connect the temperature probe to the meter and place into a solution with a

1)

known accurate temperature such as a constant temperature bath.

The temperature probe may be separate or built into a pH, Conductivity, or

Oxygen electrode. The PC 2700 has two temperature sensors available—one

built into Conductivity, and another for use with the BNC connection.

2) When the readin

The upper display shows the active temperature while the lower display shows

3)

the factory default temperature without calibration. The example below at right

shows a temperature calibration that had previously been calibrated with a 3.0

ºC offset.

g is stable, press CAL from any mode, then press

.

Adjust the upper display using up/down arrows, press ENTER to accept the

3)

calibration temperature. The maximum adjustable value is ±5 ºC (or ± 9 ºF)

from the factory default temperature value.

Additional temperature calibration notes:

For Manual Temperature Compensation (MTC) the procedure is the same

althoug

parameter, and connection of a separate ATC probe is not necessary.

For nearly all applications however, ATC is recommended.

If calibration is performed, be sure that the thermometry source used as a

referenc

h the maximum adjustable value is the full temperature range of the

e is accurate!

18

10. Conductivity, TDS, Salinity, & Resistivity Setup

Use Setup mode to customize Conductivity, TDS, Salinity, & Resistivity

parameters.

Press

Conductivity, TDS, Salinity, or Resistivity is selected.

from the measurement screen and then press ENTER when

Sample ID

This is a user selectable number from 1 to 99999.

Incorporating a sample ID to identify one or more

data points is useful to distinguish data that is

saved into memory or sent to a PC or printer. Use

the up/down arrow keys to adjust the values and

left/right arrow keys to move the cursor.

Cal Method

The 2700 is capable of automatic or manual

ration for conductivity, and manual calibration

calib

for TDS, Salinity, and Resistivity. This option

allows you to select AUTO (automatic) or

MANUAL conductivity calibration.

In the automatic calibration mode, the meter will

automatically sel

calibration standard values depending on the range and normalization

temperature being used (see table below).

(conductivity mode only)

ect one of (4) conductivity

Range

#

r 1 0.00 – 20.00 µS None None

r 2 20.1 – 200.0 µS 84 µS 76 µS

r 3 201 – 2000 µS 1413 µS 1278 µS

r 4 2.01 – 20.00 mS 12.88 mS 11.67 mS

r 5 20.1 – 200.0 mS 111.8 mS 102.1 mS

If you will only use one or more of the (4) calibration standards listed here,

Conductivity

Range

Automatic Calibration Values

Normalization Temperature

25 ºC 20 ºC

19

automatic calibration is recommended. Otherwise, manual calibration should be

selected.

The factory default is automatic conductivity calibration. Note that automati

calibration is not available for conductivity range 1.

c

Cal Points

Use SINGLE for Single-Point Calibration (SPC) to

apply a single calibration value across all ranges.

Use M

calibrate each range individually. This will restrict

an individual calibration so that it is applied to one

range only. When using multi-point calibration,

perform a calibration in each range that you

expect to use for best results.

The factory default is SPC. SPC or MPC will be shown with the calibration details

in measurement mode.

ULTI for Multi-Point Calibration (MPC) to

Pure Water Coefficient

Choose ENABLE to automatically apply pure

water temperature correction for measurements

below 2

Note: this option does not apply to Salinity mode.

µS (ultra pure water).

Temperature Coefficient (linear)

The temperature coefficient is the amount of

change in conductivity per degree temperature (%

per ºC). The factory default setting is a

temperature coefficient of 2.1 % per ºC. For most

applications this will provide good results. The

meter allows adjustment from 0.0 to 10.0.

TIP: Select 0.0% for uncompensated

measurements. The temperature will be measured

by the electrode and displayed in measurement mode—without compensation.

20

Note: this option does not apply to Salinity mode.

For more information, see Section 20—Calculating Temperature Coefficients

Normalization Temperature (°C)

When Automatic Temperature Compensation is

used, measurements are adjusted by the

temperature coefficient to the normalization

temperature.

Adjust the value from 15.0 to 35.0 º C.

Note: Use the normalization temperature that is

referenced on your cali

factory default value (25 º C).

bration standard(s). This will usually match the 2700

TDS Factor (TDS mode only)

The TDS conversion factor is the number used by

the 2700 to convert from

TDS conversion factor automatically adjusts the

reading. Select the desired TDS factor from 0.400

to 1.000.

See

Section 21—Calculating TDS Conversion

Factor for information on Calculating TDS factor

conductivity to TDS. The

.

Cell Constant

The 2700 includes a probe with a nominal cell

constant (k) of 1.0. Use probes with k = 0.1 and 10

(sold separately) for improved performance in

extreme sample ranges. The factory default is 1.0

to match the included probe. Cell constant can be

adjusted from 0.010 to 10.000.

k = 0.1 ideal for low measurements <20 µS (<10 ppm).

k = 1.0 ideal for mid-range measurements

k = 10 ideal for high measurements >20 mS (>10 ppt).

21

Alarm

The 2700 offers a visual and audible alarm to alert

you when the High or Low values that have been

set from this menu are exceeded.

“High Alarm” or “Low Alarm” will blink on the

displ

ay if the values are exceeded while

simultaneously, a loud, intermittent beeping sound

is heard. The alarms will continue until the

conditions are no longer met, and will only be active during measurement mode.

Cal Due

When enabled, the “Cal Due” indicator blinks if the

number of days since the last calibration has been

exceeded. Set the number of days from 1 to 31.

22

11. Conductivity Calibration (automatic)

For best results, periodic calibration with known accurate standards is

recommended prior to measurement. Calibrate with standards that are close in

value to your intended sample(s).

When using multi-point calibration, perform a calibration in each range that you

expect to use

If the conductivity electrode has been stored dry for some time, soaking in alcohol

or cle

an water for a few minutes can help performance.

for best results.

1) Turn meter on, press

2) Press

3) Use the

4) Wait for the

Before and after a one-point automatic conductivity calibration with 1.413 mS

CAL if needed to enter calibration mode. Rinse the electrode with

clean water then submerse

µS, 12.88 mS, or 111.8 mS. Provide stirring for best results.

up/down arrows to adjust the cell constant manually or press NEXT

to keep the nominal cell constant value and proceed with a typical automatic

calibration (recommended). If adjusting the cell constant manually, press

ENTER after ‘Stable’ appears to confirm the adjustment.

Before and after a manual calibration constant adjustment

meter to lock on the calibration standard and press ENTER after

‘Stable’ appears to confirm the calibration point. The calibrated value, Range

(R) that was calibrated and the calculated cell constant are now shown.

MODE if needed for conductivity measurement mode.

into your conductivity standard— either 84 µS, 1413

23

5) For multi-point calibration repeat steps 2 & 3 with additional standards. Press

ESC to save the calibration, or press NEXT to view the calibration report.

Calibrate one point per range, up to 4.

Addition

A maximum of one calibration point per range can be performed. If multiple

calib

the previous one.

al automatic conductivity calibration notes:

ration points are used in the same range, the most recent one will replace

When the electrode is replaced, it is best to cl

default values.

Rinse or immerse the probe before calibration and between samples with clean

water

(deionized water is ideal).

To protect from erroneous calibrations, the allowable tolerance is ±40% of the

factory defaul

For best results always begin with your

followed by the next lowest, and so on.

Low conductivity standard solutions (less than 20 µS

temperature dependent. As a result, reproducible calibration results are

challenging in lowest measurement range #1 (0.00 to 20.0 µS).

t value.

ear the calibration to the factory

lowest calibration standard value,

) are unstable and are very

“2 Cell’ or “4 Cell’ electrode is automatically detected and

displayed on the measurement screen when connected.

24

12. Conductivity, TDS, Salinity, & Resistivity

Calibration (manual adjustment)

For best results, periodic calibration with known accurate standards is

recommended prior to measurement. Calibrate with standards that are close in

value to your intended sample(s).

When using multi-point calibration, perform a calibration in each range that you

expect to use

If the electrode has been stored dry for some time, soaking in alcohol or clean

water fo

for best results.

r a few minutes can help performance.

1) Turn meter on, press

2) Press

3) Use the

4) The up

CAL if needed to enter calibration mode. Rinse the electrode with

clean water then submerse into your calibration standard.

up/down arrows to adjust the cell constant manually or press NEXT

to keep the nominal cell constant value and proceed with a typical manual

calibration (recommended). If adjusting the cell constant manually, press

ENTER after ‘Stable’ appears to confirm the adjustment.

Before and after a manual calibration constant adjustment

per display is the active reading while the lower display is the factory

default value without calibration. Use the up/down arrows to adjust the upper

display to match the desired calibration value. Press ENTER after ‘Stable’

appears to confirm the calibration. The calibrated value, Range (R) that was

calibrated and the calculated cell constant are now shown.

MODE if needed for the appropriate mode.

25

Before and after a manual calibration

5) For

Additional manual calibration notes:

A maximum of one calibration point per range can be performed. If multiple

calib

the previous one.

When the electrode is replaced, it is best to cl

default values.

Rinse or immerse the probe before calibration and between samples with clean

water

To protect from erroneous calibrations, the allowable tolerance is ±40% of the

factory defaul

For best results always begin with your

followed by the next lowest, and so on.

Low conductivity standard solutions (less than 20 µS

temperature dependent. As a result, reproducible calibration results are

challenging in lowest measurement range #1 (0.00 to 20.0 µS).

multi-point calibration repeat with additional standards. Press ESC to

save calibration or press NEXT to view the calibration report. Calibrate one

point per range, up to 5 points.

ration points are used in the same range, the most recent one will replace

ear the calibration to the factory

(deionized water is ideal).

t value.

lowest calibration standard value,

) are unstable and are very

Note: If using the 2-cell electrode, the protective probe guard

can be removed temporarily for cleaning however it must be

re-attached during measurement and calibration. Erroneous

results will occur while the probe guard is removed.

26

13. Ion Setup

Use Setup Ion mode to customize this parameter. Press from the

measurement screen and then press ENTER when ION is selected.

Sample ID

This is a user selectable number from 1 to 99999.

Incorporating a sample ID to identify one or more

data points is useful to distinguish data that is saved

into memory or sent to a PC or printer. Use the

up/down arrow keys to adjust the values and

left/right arrow keys to move the cursor.

Measure Unit

Select ppm, molar, or mg/L ion concentration units.

Alarm

The 2700 offers a visual and audible alarm to alert

you when the High or Low values that have been

set from this menu are exceeded.

“High Alarm” or “Low Alarm” will blink on the display

if the value

loud, intermittent beeping sound is heard. The

alarms will continue until the conditions are no

longer met, and will only be active during

measurement mode.

s are exceeded while simultaneously, a

27

Cal Due

When enabled, the “Cal Due” indicator blinks if the

number of days since the last calibration has been

exceeded. Set the number of days from 1 to 31.

Refer to your Ion Selective Electrode instruction manual for

details on conditioning, storage, maintenance, calibration

standard preparation, Ionic Strength Adjustment,

troubleshooting, etc. Each ISE is unique and requires care

and operation that is specific to the electrode and ion of

interest.

28

14. Ion Calibration

The ION 2700 can measure ion concentration such as ammonia or fluoride when

using an ion selective electrode (ISE) for the specific ion of interest.

Ion calibration is required with at least two standards from (8) available values;

0.001, 0.01, 0.1, 1.0, 10, 100, 1000, an

The primary display will show “- - - -” when ion

calibration is required for ion measurement.

Prepare ion calibration standards that bracket your measurement range. Follow

the ion

adjustment and sample preparation.

For best results always begin with your

followed by the next lowest, and so on.

1) Connect the ISE and press MODE as n

2) Rinse the ISE with clean water then dIp into

3) The lower display is the mV reading of the ISE. Press ENTE

4) Rinse the ISE with clean water and dp into your next lowest calibration

selective electrode instruction manual for the appropriate ionic strength

your lowest calibration standard and stir.

Press CAL. Use up/down arrows to match

the upper display to your calibration

standard.

value is stable to accept the calibration point.

stand

ard and stire. PressENTER after “Stable” appears to accept the

next calibration point.

d 10000.

lowest calibration standard value,

eeded for concentration mode.

R when this

29

Before and after a two point ion calibration using 0.001 and 0.01 standards

5) The mV/decade

“Slope Error” indicates that the calibration for the current point was not

successful. This occurs when the slope (mV difference between two

consecutive points) is < 15 mV/decade or > than 90 mV/decade.

6) Rep

To view the Ion Calibration Report at any time from the measure screen, press

REPORT.

eat steps 4 & 5 with additional ISE standards or press ESC to escape

and save your calibration.

At left; a three point ion calibration, at right; the Ion calibration report

slope value will be displayed if the calibration is successful.

30

15. Dissolved Oxygen Setup

Use Setup Dissolved Oxygen mode to customize the parameter. Press

from the measurement screen and then press ENTER when DO% or DO (mg/L)

is selected for percent saturation or concentration modes respectively. Note that

setup parameters differ slightly depending on which is selected.

Sample ID

This is a user selectable number from 1 to 99999.

Incorporating a sample ID to identify one or more

data points is useful to distinguish data that is

saved into memory or sent to a PC or printer. Use

the up/down arrow keys to adjust the values and

left/right arrow keys to move the cursor.

Offset Cal (% saturation only)

Use this feature to offset the meter’s value to

another DO meter. Using the % saturation mode,

observe the reading a sample solution after it has

stabilized. Similarly, observe the reading of the

same sample using another DO meter as a

reference. The probe of the reference meter should

be immersed in the same sample at the same

depth.

The DO 2700 allows ±10% offset adju

calibrations will reset the offset adjustment back to the factory default value of 0.0

% offset.

stment. Note that subsequent user

Pressure Unit (% saturation mode only)

Select mmHg or kPa pressure units.

31

Pressure Cal (% saturation mode only)

The DO 2700 includes a built-in barometer that is

factory calibrated. While frequent pressure

adjustment is not required, adjustments can be

made in the Adjusted Pressure field. The

Measured Pressure is the active pressure value

measured by the DO 2700.

Note: if adjusting, “true” barometric pressure—that

has not been corrected to sea level, must be used.

Pressure reported by weather services are almost always corrected and therefore

are not appropriate for entry in the adjusted pressure field here.

Pressure Compensation (% saturation mode only)

Select ENABLE or DISABLE.

Measure Unit (concentration mode only)

Select mg/L or ppm concentration units.

32

Salinity Value (concentration mode only)

Enter the salinity value of your samples in parts per

thousand (ppt) units. Select from 0 to 50.0 ppt.

Alarm

The 2700 offers a visual and audible alarm to alert

you when the High or Low values that have been

set from this menu are exceeded.

“High Alarm” or “Low Alarm” will blink on the displ

if the values are exceeded while simultaneously, a

loud, intermittent beeping sound is heard. The

alarms will continue until the conditions are no

longer met, and will only be active during measurement mode.

ay

Cal Due

When enabled, the “Cal Due” indicator blinks if the

number of days since the last calibration has been

exceeded. Set the number of days from 1 to 31.

33

16. Dissolved Oxygen Calibration

The DO 2700 utilizes a self-stirring polargraphic electrode with a built-in

temperature sensor. The electrode is designed for use in BOD bottles.

Power the meter on 5-15 minutes before calibration or taking a

measurement

up. Longer warm up times are recommended when the membrane cap

and/or electrolyte in replaced—this permits the probe to use up all

oxygen retained inside the cap.

The DO 2700 has two modes; % saturation and concentration (mg/L or

ppm). In %

(100%) or two point (100% & 0%) calibration. For a one point

calibration, 100% air calibration is recommended. For best accuracy

below 2.0 ppm, use zero oxygen solution to calibrate 0%. 0% calibration followed

by 100% calibration is not recommended—always perform 100% calibration first.

Always rinse the probe with clean water before and after each calibration/sample

measurement

droplets from the probe’s membrane.

100 % Calibration

1) Power meter on with DO electrode attached for 5-15 minute warm

up.

2) Rinse the probe well with clean water then place into a BOD bottle

partially filled with water (100 mL or so).

3) Press

4) Press CAL. The primary reading is the current

measured value. Note: the stirrer is not

required for air calibration. For air-saturated

water calibration however, switch the stirrer

motor on (the switch is located at the top of the

electrode) during calibration and measurement.

5) Allow the

100%. Press ENTER to confirm the calibration.

6) Press

step 7 if desired.

as this will allow adequate time for the electrode to warm

saturation mode, the DO 2700 will accept either a one

. When performing air calibration, gently shake remaining water

MODE if needed for % measurement mode.

reading to stabilize and lock on

ESC to return to measurement mode, or continue with 0% calibration in

34

0% Calibration

7) After compl

eting steps 1 thru 6 for 100% saturation calibration, place your

electrode in zero oxygen solution (0.08M sodium sulfite). Continuous stirring

is not required.

8) The primary reading is the current measured

value. Be patient—the reading can take

several minutes to reach 0% saturation!

9) Whe

n the reading has finally stabilized and

locked on 0% press ENTER to confirm the

calibration.

mg/L or ppm (Con

1) Con

nect the DO electrode and power on DO 2700 for 5-15 minute warm up.

centration) Calibration

2) Press

MODE if needed for concentration measurement mode.

3) Rin

se the probe well with clean water then place into your solution with a

known dissolved oxygen concentration value (i.e. determined by titration or

another instrument).

4) Press

CAL and switch the stirrer on. The upper reading is the current

measured value. The lower reading is the factory default reading for

comparison, along with salinity and temperature correction shown.

A manual DO concentration calibration

5) Allow the

reading to match the DO concentration of your solution.

reading to stabilize. Use the up/down arrows to adjust the upper

The minimum

concentration calibration value is 2.00 mg/L. Press ENTER to confirm the

calibration.

35

Additional dissolved oxygen calibration notes:

Keep the membrane free from contact with solid objects.

•

Use with aqueous solutions only.

•

Do not submerse the probe past the immersion limit (see below).

•

• See Section 22—DO Electrode Maintenance for additional information.

•

Calibration adjustment is limited to ±40% of the factory default value to

prevent erroneous calibrations.

•

If % calibration is attempted with a value of 10.1% to 49.9%, a

“Calibration Error” will result. The following table lists corresponding

calibration values in % saturation calibration mode:

% Saturation

(of factory default value)

less than 10% 0%

10.1% to 49.9% Calibration Error

50% to 150% 100%

•

Calibration of the concentration mode will only replace the previous

concentration calibration and does not affect the % saturation calibration.

• To offset your % satu

Section 15—Offset Calibration.

•

Perform daily calibration for best results. New calibration values will

automatically override the previous calibration.

Calibration Value

ration reading to match another instrument, see

36

17. Transferring and Printing Data

To send data directly to a printer or PC, connect the 30X427301 / 35420-01 cable

to the RS-232 output port of the 2700. To connect to a USB port, an additional

adapter cable is required; see

The 2700 can be used to:

•

Print/send one or more data points directly to a dedicated printer or to

a PC. Press PRINT from measurement mode or from the MEM OUT

screen.

Print/send the calibration report to a printer or PC. Press REPORT

•

from measurement mode.

•

Send live data to a PC at intervals 3 seconds or higher. In the

System Setup, select a “TIMED” Print Set.

Section 25—Replacements & Accessories

.

Choose the “TEXT/PRINTER” Pri

viewable format—best for printing.

Choose the “CYBE

separated value (CSV)—best for exporting data into software

To make changes to the printer, datalog, and output settings, see Section 3—

System Setup.

Certain 2700 models will include a complimentary software

appli

cation called CyberComm 2700. For details on

installation, connection and usage of this software, please

read the manual that is included on the software CD. If you

did not receive a CD or lost the CD that was included with

your instrument, check our website. You can download the

latest version at no charge when it becomes available.

The 2700 is also compatible with 3

such as the popular Microsoft Windows® HyperTerminal®

which is pre-installed with many PC’s in use today.

RCOMM” Print Format option to send the data as a comma

nt Format option to transfer the data in an easily

rd

party capture software

Check out www.eutechinst.com/sup-software.html for

the latest CyberComm software available for your meter.

37

18. Calibration Report

Calibration report provides detailed information on the most recent calibration. It

includes date & time, calibration standard(s), offset, temperature, number of days

calibration is over due slope information, etc.

The calibration report is automatically displayed after a complete calibration.

To view the calibration report at any other time, press

desired measurement screen.

To send the calibration report to a printe

r or PC, press

from the

.

Examples of Calibration Reports from different parameters

38

19. Dissolved Oxygen Theory

Dissolved Oxygen (DO) refers to the volume of oxygen that is contained in water.

There are two main sources of DO in water; atmosphere and photosynthesis.

Waves and tumbling water mix air into the water where oxygen readily dissolves

until saturation occurs. Oxygen is also produced by aquatic plants and algae

during photosynthesis.

The amount of DO that can be held by

water depends on 3 factors:

1. TEMPERATURE:

DO in

creases with decreasing temperature

(colder water holds more oxygen)

2. SALINITY:

DO in

creases with decreasing salinity

(freshwater holds more oxygen than saltwater does)

3. ATMOSPHERIC PRESSURE:

DO de

creases with decreasing atmospheric pressure

(amount of DO absorbed in water decreases as altitude increases)

Solu b ili t y of o xyge n in wa t er co n t act with water satu rated air

at standard atmospheric pressure

16

14

12

10

8

6

Solubility mg/L

4

2

0

0 5 10 15 20 25 30 35 40 45 50

Temp eratu re °C

DO Solubility in Water vs. Temperature

Measurement Units

One measure of DO in water is parts per million (ppm) which is the number of

oxygen mole

cules (O

) per million total molecules in a sample. The “mg/L” unit is

2

equivalent to ppm (a liter of water weighs 1 million milligrams—one part in a

million is similar to one milligram in a liter). Calculating the % saturation is

39

another way to analyze DO levels. % saturation is the measured DO level

divided by the greatest amount of oxygen that the water could hold under various

temperature and atmospheric pressure conditions multiplied by 100.

What Is Being Measured?

DO probes respond to the partial pressure of oxygen in liquid or gas being

measured—t

hey measure the “pressure” of oxygen rather than concentration. All

of the oxygen entering the probe is consumed at the cathode where it is

electrochemically reduced to hydroxyl ions producing an electrical current within

the probe:

O

+ 2 H2O + 4 e- Æ 4 OH –

2

Since all oxygen entering the probe is chemi

cally consumed, the partial pressure

of oxygen in the electrolyte is zero. Therefore, a partial pressure gradient exists

across the membrane and the rate at which oxygen enters the probe is a function

of the partial pressure of oxygen in the gas or in liquid being measured.

When a probe is placed in air saturated water, the current it produces will

not be

affected by the temperature or salinity of the water. The DO concentration in the

water, however, will vary with temperature and salinity. Because it is convenient

to report DO concentration in mg/L or ppm, it is necessary to adjust for

temperature and salinity of the water to get correct readings in these units.

If DO were to be reported in terms of partial pressure or % Saturation, then

temperature

and/or salinity compensation for oxygen solubility would not be

necessary. Most probes are temperature compensated—i.e. they convert the

“partial pressure measurement” to mg/L of DO at whatever temperature the water

happens to be at for a given salinity and barometric pressure.

Air Calibration

Understanding the principle of air calibration

is easy, once you know that it is

partial pressure that the probe is responding to. When the probe is in air, it is

measuring the partial pressure of oxygen in air. If water is air saturated, then the

partial pressure of oxygen in the water will be the same as it is in air. Therefore,

all you need to know is the temperature of the air in which the probe is placed.

By consulting solubility tables for oxygen at the particular barometric pressure

and salinity of the water being measured, the corresponding concentration (mg/L

or ppm) can be found for air saturated water at the air calibration temperature,

and the meter can be set accordingly. Because most meters are temperature

compensated, they will still give correct readings in mg/L even though the actual

water temperature may be different to the air calibration temperature. Note: The

closer the air calibration temperature is to the water temperature, the more

accurate the calibration.

40

Applications

Oxygen is essential for fish, invertebrate, plant, and aerobic bacteria respiration.

DO level

s below 3 ppm are stressful to most aquatic organisms. Levels below 2

or 1 ppm will not support fish. Fish growth and activity usually require 5 to 6 ppm

of DO, an important consideration for Aqua-culture industry.

Low DO indicates a demand on the oxygen of the system. Natural organic

material

such as leaves accumulate in the stream and create an oxygen demand

as it is decomposed. Organic materials from human activities also create an

oxygen demand in the system. Micro-organisms consume oxygen as they

decompose sewage, urban and agricultural run-off, and discharge from foodprocessing plants, meat-packing plants and diaries. There is an optimum DO

level for this process and if the DO level falls too low, the micro-organisms die

and the decomposition ceases. When DO level is too high, this indicates too

much power is used than necessary for aeration resulting in an inefficient

process.

In boiler water application, presence of o

xygen in the water will increase corrosion

and helps build up boiler scale that inhibits heat transfer. In such instance it is

critical to keep DO concentration to a minimum.

Some pollutants such as acid mine drainage produce direct chemical demands

on oxygen in

introduced chemical compounds such as nitrate (NO

sulfate (SO

These are important consideration for water and

the water. DO is consumed in the oxidation-reduction reactions of

2-

), and sulfite (SO

4

2-

) and ferrous (Fe

3

1-

) and ammonia (NH

3

+

) and ferric (Fe

2

+

) ions.

3

wastewater treatment industry.

1+

),

4

41

20. Calculating Temperature Coefficients

To determine the temperature coefficient of your sample solution use this formula:

Where:

tc =

C

T1 = Tem

A controll

1. Immerse the probe into a sample of your solution a

2. Wait for 5 minutes. Note T1 and CT1 (conductivity at T1).

3. Condition the sample solution and probe to a temperature (T2) that is about 5

Record your results for future reference. Ideally T1 and T2 should bracket your

measurement

4. Calculate the temperature coefficient of your sol

5. Enter the calculated temperature coefficient into the meter.

The calculated temperature coefficient will now be applied to all the meter

readi

Temperature coefficient 25 = 25 º C

= Conductivity at Temp 1 CT2 = Conductivity at Temp 2

T1

p 1 T2 = Tem p 2

ed temperature water bath is ideal for this procedure.

nd adjust the temperature

coefficient to 0% (that is, no compensation) by following instructions as

described in

ºC to 10 ºC di

shown above.

ngs

.

Section 10—Temperature Coefficient

temperature, and should not differ by more than 5 ºC.

fferent from T1, and note the conductivity reading C

.

.

T2

ution according to the formula

42

21. Calculating TDS Conversion Factor

You can calibrate TDS using the value of the calibration standard solution at a

standard temperature such as 25 ºC. To determine the conductivity-to-TDS

conversion factor use the following formula:

Factor = Actual TD

• Act

• Actual Conductivity: Value measured using a properly

Both the Actual TDS and the Actual Conductivity values must be in the same

magnitud

must be in µS; if the TDS value is in ppt the conductivity value must be in mS.

Check your factor by multiplying the condu

above formula. The result should be in TDS value.

When the TDS factor is set to 1.0, Conductivity = TDS.

ual TDS: Value from the solution bottle label or as a standard

made using high purity water and precisely weighed salts.

ppm = milligram of salt(s) per liter of water = mg/L

ppt = gram of salt(s) per liter of water = g/L

calibrated Conductivity/Temperature meter.

e of units. For example, if the TDS value is in ppm the conductivity value

S ÷ Actual Conductivity @ 25 ºC

ctivity reading by the factor in the

43

22. DO Electrode Maintenance

Changing the Membrane Cap

The DO 2700 electrode utilizes a cap attached to a pre-installed membrane that

is easily replaced. Replace the membrane cap if it becomes damaged or worn

over time as needed. When calibration can not be completed, look to replace the

electrolyte first as this may help. Replace the membrane cap and electrolyte

together using the following procedure.

1) Un

2) With the me

3) Rin

Electrode Cleaning

Cleaning the BOD probe is only necessary after erratic

readings result; usually after many months of use.

Avoid excessive and un-necessary cleaning, as it can

reduce the life of the probe.

Gold Cathode

The gold cathode can become tarnished or plate with

silver after ex

adhesive backed sanding disc in the Membrane Kit

provided with the probe. Stick the disc to a flat object,

like a bottle cap, and gently sand the gold cathode with a twisting motion about 3

times or until all silver deposits are removed. The gold will have a matte finish.

Silver Anode

It is normal for a dark layer of silver chl

prolonged use it may become necessary to clean the anode. Soak the probe in

14% ammonium hydroxide for 2 to 3 minutes or overnight in a 3% ammonium

hydroxide solution. Rinse with deionized water, recharge the electrode, and install

a new membrane.

.

screw the old membrane cap from the probe. Before installing a new

membrane, clean the probe tip with deionized water to remove any

contaminants.

mbrane cap removed fill it approximately 50% full using the

electrolyte solution. Screw the membrane cap on moderately tight (do not

over-tighten). A small amount of electrolyte should overflow—indicating that

all of the air has been removed.

se off excess electrolyte with deionized water.

tended use. It is cleaned with the

oride to cover the silver anode. After

44

23. Troubleshooting

Parameter Cause Solution

pH Won’t accept 1st

calibration point

pH Cal points are too

close

pH Reading is 7.00

and won’t change

pH or Ion Slope error /

Calibration error

Ion Display reads “- - -“ 2-point Ion calibration is required; no

Conductivity Can’t adjust / can’t

calibrate

New calibrations must begin with

neutral standard (7.00 or 6.86)

Custom pH buffer calibration values

must be at least 1.0 pH unit apart.

Electrode tip may be cracked or

broken. Replace electrode.

Calibration values are too far apart, or

too far from ideal values. Check the

electrode, use fresh buffers, and check

meter settings. Electrode may require

filling solution, conditioning, or

complete replacement. Refer to

electrode manual.

calibration is stored in memory.

AUTO calibration values (84 µS, 1413

µS, 12.88 mS, or 111.8 mS) are not

used. Change Cal Method to MANUAL.

Conductivity 2nd Calibration point

replaces the 1st

TDS Standard does not

match

DO Reading is very

slow to stabilize

Only one point per range can be

calibrated. Re-consider your SINGLE or

MULTI Cal Points setting in Section 10.

Adjust TDS factor as needed to correct

value. Refer to “Calculating TDS

Conversion Factor”.

Ensure stirrer motor is on during

solution measurement and temperature

is stable. If electrode is old, gold

cathode may be tarnished—buff with

disk or pencil eraser. Replace

membrane, electrolyte and recondition

45

sensor.

DO Instrument will not

read zero in sodium

sulfite solution

Temperature Instrument reads

inaccurate

temperature

ALL Main digits are

faded in

measurement

mode &/or are

faded too often.

ALL I forgot my

password

ALL Memory Full Often when a timed datalog is used, it

Solution contains oxygen—use fresh

solution.

Replace membrane and recondition

s

ensor.

Calibrate using water bath or known

accurate thermometer. Faulty

thermistor—repair or replace.

When “Stability” is enabled, the digits

on the primary reading will be faded

when unstable, becoming solid when

stable. Disable this feature to keep

digits solid at all times or keep this

feature enabled while changing the

“Stability Criteria” to “Slow“

Please send us a written request with

your name, contact information, along

with the instrument serial number; a

temporary password will be provided.

runs until the memory is full. To erase

the stored data, go to System Setup,

CLEAR LOG.

ALL Reading doesn’t

change, “AR” is

blinking

ALL My problem is not

listed here.

46

Auto-Read is active (measurement

locks automatically when stable). Press

MEAS to resume. Select Auto-Read

“DISABLE” if this feature is not desired.

Please contact our authorized dealer or

email us directly with your feedback:

eutech@thermofisher.com

24. Specifications

We reserve the right to make changes, improvements and modifications to the

specifications listed here.

pH pH 2700, ION 2700, PC2700 only

Range -2.000 to 20.000 pH

Resolution 0.1 / 0.01 / 0.001 pH

Accuracy ±0.002 pH + 1 LSD

Cal. Points Up to 6 preset or 5 custom

Buffer Sets USA, NIST, DIN, User1, User2, Custom

Slope Display Yes (with offset)

Temp Compensation Automatic or Manual (0 to 100 ºC / 32 to 212 ºF)

Temp Range (Meter) 0.0 to 100.0 ºC / 32.0 to 212.0 ºF

Inputs BNC, ATC, Reference (Half-cell)

mV pH 2700, ION 2700, PC2700 only

Range ±2000.0 mV

Rel. mV Range ±2000.0 mV

Resolution 0.1 mV

Accuracy ±0.2 mV

Offset Adjustment Up to ±150 mV

Ion ION 2700, PC2700 only

Range 0.001 to 19999 ppm (±2000 mV)

Resolution 2 or 3 digits

Accuracy

Cal Points

Slope Range 15 to 90 mV/decade

Temperature ALL MODELS

Resolution 0.1 ºC / 0.1 ºF

Accuracy ±0.3 ºC / ±0.5 ºF

Calibration

0.5% full scale (monovalent)

1% full scale

2 to 8 points;

0.001, 0.01, 0

Offset in 0.1 º increments;

Offset range: ± 5 ºC / 9 ºF

(divalent)

.1, 1, 10, 100, 1000, 10000

47

Conductivity CON 2700, PC 2700 only

Range 0.050 µS to 500.0 mS

Resolution 0.01 / 0.1 µS; 0.001 / 0.01 / 0.1mS

Accuracy ±1% full scale

Cal. Points

Cell Constant 0.010 to 10.000

Coefficient (Per ºC) Linear & Pure; 0.000 to 10.000%

Normalization 15.0 to 30.0 ºC / 59.0 to 86.0 ºF

Compensation Automatic with supplied cel l or Manual

Temp Compensation

Automatic (4 points); Maximum 1 per range

Manual

0.0 to 100 ºC / 32.0 to 212.0 ºF (0.0 to 80 ºC / 32.0

to 176.0 ºF wi

(5 points); Maximum 1 per range

th supplied cell)

TDS CON 2700, PC 2700 only

Range 0.050 ppm to 500 ppt (@ TDS factor 1.00)

Resolution 0.01 / 0.1 ppm; 0.001 / 0.01 / 0.1 ppt

Accuracy ±1% full scale

Cal. Points Up to 5

TDS factor 0.400 to 1.000

Salinity CON 2700, PC 2700 only

Range 0 to 80.0 ppt

Resolution 0.01 / 0.1 ppm; 0.001 / 0.01 / 0.1 ppt

Accuracy ±1% full scale

Resistivity CON 2700, PC 2700 only

Range 2.000 Ω to 20.0 MΩ

Resolution 0.01 / 0.1Ω; 0.001 / 0.1 kΩ; 0.01 MΩ

Accuracy ±1% full scale

48

Dissolved Oxygen DO2700

Range 0 to 50.00 mg/L

Resolution 0.01 mg/L

Accuracy ±0.5% full scale

Offset Adjustment ±10.0%

Cal. Points (%) 2 points; 0%, 100%

Cal. Points (conc)

Salinity Correction 0 to 50.0 ppt (manual input)

Barometric Pressure

Correction

Temperature 0.0 to 50.0 ºC / 32.0 to 122.0 ºF

1 point; ± 50% from the factory default value.

Minimum rea

450 to 825 mmHg (automatic with built in sensor);

adjustable ±150 mmHg

ding allowed is 2.00.

Other ALL MODELS

Backlight Yes

Memory 500 data sets

Cal Due Alarm user selectable from 1-31 days

High / Low Alarms user selectable, visual & audible

Power 9 V DC adapter, 1.3 A (100 / 240 VAC, SMPS)

Dimensions (mm) meter only = 175 (L) x 155 (W) x 69 (H)

49

25. Replacements and Accessories

Part number Ordering Code

Item Description

pH 2700 meter with pH electrode (ECFG7370101B), ATC probe

(PH5TEMB01P), integral electrode holder, 100/240 VAC adapter &

pH electrode refill solution

pH 2700 meter with integral electrode holder & 100/240 VAC

adapter

ION 2700 meter with pH electrode (ECFG7370101B), ATC probe

(PH5TEMB01P), integral electrode holder, 100/240 VAC adapter &

pH electrode refill solution

ION 2700 meter with integral electrode holder & 100/240 VAC

adapter

CON 2700 meter with 4-cell conductivity/ATC probe

(CONSEN9201D), integral electrode holder & 100/240 VAC adapter

DO 2700 meter with self-stirring dissolved oxygen / BOD / ATC

electrode (EC620SSP), RS232C cable & 100/240 VAC adapter

PC 2700 meter with pH electrode (ECFG7370101B),

conductivity/ATC electrode (01X244730), integral electrode holder,

100/240 VAC adapter & pH electrode refill solution

PC 2700 meter with integral electrode holder & 100/240 VAC

adapter

pH electrode, glass, refillable, double-junction ECFG7370101B 35805-04

pH electrode, plastic, gel-filled, double-junction, 3 m cable ECFC7252203B 35816-77

pH electrode, plastic, gel-filled, double-junction, 1 m cable ECFC7252201B 35641-51

ORP electrode, plastic, platinum, double-junction ECFC79602R01B 59001-77

Conductivity/ATC electrode, 4-Cell Graphite With Epoxy-Body, Cell

Constant K=0.530, 120 x 12 mm

Conductivity/ATC electrode, 2-cell epoxy/platinum, k = 0.1 — 35608-72

Conductivity/ATC electrode, 2-cell glass/platinum, k = 1.0 — 35608-76

Conductivity/ATC electrode, 2-cell Ultem/stainless steel, k = 1.0

Conductivity/ATC electrode, 2-cell epoxy/platinum, k = 10.0 — 35608-78

ATC Probe, Stainless Steel, 117 x 3 mm

Dissolved Oxygen/BOD/ATC self-stirring electrode

pH 1.68 buffer solution, 480 mL bottle ECBU1BT 00654-01

pH 4.01 buffer solution, 480 mL bottle ECBU4BT 00654-00

Eutech

Instruments

ECPH270042GS

01X543902

ECPH270040S

01X543901

ECION27004GS

01X543904

ECION270040S

01X543903

ECCON270043S

01X543905

ECDO270042

01X543907

ECPC270043S

01X543906

— 35414-20

CONSEN9201D

01X244730

CONSEN9501D

01X466601

PH5TEMB01P

01X210303

EC620SSP

01X295704

Oakton

Instruments

35420-20

35420-22

35421-00

35421-02

35412-00

35416-00

35414-00

35412-10

35608-74

35613-13

35420-82

50

pH 6.86 buffer solution, 480 mL bottle ECBU686BT 00654-03

pH 7.00 buffer solution, 480 mL bottle ECBU7BT 00654-04

pH 9.18 buffer solution, 480 mL bottle ECBU918BT 00654-07

pH 10.01 buffer solution, 480 mL bottle ECBU10BT 00654-08

pH 12.45 buffer solution, 480 mL bottle ECBU12BT 00654-12

pH 4.01, 7.00, & 10.01 buffer solution pack, 480 mL bottles — 05942-10

Zero oxygen solution (500 mL) — 00653-00

pH electrode storage solution ECRE005 00653-04

Double-junction pH electrode refilling solution, saturated KCl

10 µS, (20) x 20 mL sachets ECCON10BS 35653-09

84 µS, 480 mL bottle* ECCON84BT 00653-16

447 µS, 480 mL bottle ECCON447BS 00653-47

500 µS, 480 mL bottle ECCON500BT —

1413 µS, 480 mL bottle* ECCON1413BT 00653-18

1413 µS, (20) x 20mL sachets* ECCON1413BS 35653-11

2764 µS, 480 mL bottle ECCON2764BT 00653-20

2764 µS, (20) x 20mL sachets ECCON2764BS 35653-12

5.0 mS, 480 mL bottle ECCON5000BT —

12.88 mS, 480 mL bottle* ECCON1288BT 00606-10

15 mS, (20) x 20mL sachets ECCON15000BS 35653-13

111.8 mS, 480 mL bottle* ECCON1118BT —

100/240 VAC, SMPS, 9V, 6W power adapter, USA/UK/EUR Plug 60X426401 35615-07

RS232 cable for connecting 2700 meter to PC or printer, phono plug

to RS232 9-pin (F), 1.5 m cable

Electrode arm and bracket 01X321801 —

Serial impact micro printer: dot-matrix, portable with 25-pin, female

connector. Includes roll of paper and 110/120 VAC power adapter

Serial impact micro printer: dot-matrix, portable with 25-pin, female

connector. Includes roll of paper and 220/230 VAC power adapter