Page 1

Instruction Manual

CyberScan CON 10/100/200

Hand-held Conductivity/TDS/Temperature Meter

68X075513

09/2001 Rev 3

Technology Made Easy ...

Page 2

Preface

This manual serves to explain the use of the CyberScan series Conductivity meters. The

models covered are the CyberScan CON 10, CyberScan CON 100 and CyberScan CON 200

portable conductivity and total dissolved solids meters.

This manual functions in two ways: first, as a step by step guide to help the user operate the

meter; second, it serves as a handy reference guide.

This manual is written to cover as many anticipated applications of the CyberScan

Conductivity meters as possible. If there are doubts in the use of the CyberScan Conductivity

meters, do not hesitate to contact the nearest Eutech Instruments Authorized Distributor.

Eutech Instruments cannot accept any responsibility for damage or malfunction to the meter

caused by improper use of the instrument. Remember to fill in the guarantee card and mail it

back to your authorized distributor or Eutech Instruments Pte Ltd.

The information presented in this manual is subjected to change without notice as

improvements are made, and does not represent a commitment on the part of Eutech

Instruments Pte Ltd.

Copyright © 1998 Eutech Instruments Pte Ltd. All rights reserved.

Revised in September 2001.

Page 3

TABLE OF CONTENTS

1 INTRODUCTION 1

2 DISPLAY AND KEYPAD FUNCTIONS 2

2.1 Display 2

2.2 Keypad 3

3 PREPARATION 5

3.1 Inserting the Batteries 5

3.2 Attaching the electrode holder onto the meter 7

3.3 Attaching the electrode onto the electrode holder 8

3.4 Connecting the A.C. adapter 8

3.5 Connecting the RS 232C cable (only for CyberScan CON 200) 9

4 CALIBRATION 12

4.1 Standard solutions for calibration 12

4.2 Preparing the meter for calibration 12

4.3 Calibration procedure 13

5 MEASUREMENT 19

5.1 Automatic Temperature Compensation 19

5.2 Manual Temperature Compensation 20

5.3 Taking measurements 21

6 MEMORY FUNCTIONS (IN CYBERSCAN CON 100 & 200 ONLY) 22

6.1 Data Input 22

6.2 Memory Recall 22

6.3 Memory Clear 23

7 PRINT FUNCTION (IN CYBERSCAN 200 ONLY) 24

7.1 Printing data 24

7.2 Printing errors 25

7.3 Sending data to the computer 25

7.4 Printing measurement data 25

7.5 Printing data from memory 25

8 SETTING UP THE CYBERSCAN (FOR CYBERSCAN CON 100/200 ONLY) 27

8.1 SETUP program 27

8.2 Program 1: Common functions 28

8.3 Program 2: Instruments Setup 30

8.4 Program 3: TDS Setup (in CyberScan CON 200 only) 33

8.5 Program 4: Communication Setup (in CyberScan CON 200 only) 35

9 CYBERCOMM POTRABLE - DATA ACQUISITION SOFTWARE (DAS FOR

CYBERSCAN CON 200 ONLY) 38

9.1 System Requirements 38

9.2 Loading CYBERCOMM PORTABLE 38

9.3 Running CyberComm Portable 44

9.4 Capturing And Printing Data Into Computer Using CyberComm Portable 48

9.5 Trouble-shooting Guide 49

10 TROUBLESHOOTING & ELECTRODE CARE 50

10.1 Troubleshooting 50

10.2 Electrode Care 52

11 ADDITIONAL INFORMATION 53

12 ACCESSORIES AND CALIBRATION BUFFER SOLUTIONS 55

12.1 Replacement Meter and Meter Accessories 55

12.2 Calibration Solutions 56

13 SPECIFICATIONS OF CYBERSCAN CON 10/100/200 57

14 WARRANTY & RETURN OF ITEMS 58

Page 4

1 INTRODUCTION

Thank you for selecting Eutech Instruments portable meter. This meter is a microprocessorbased instrument that is designed to be handy, user-friendly and capable of allowing one-hand

operation. It has a large customized LCD for clear and easy reading. It also has user-friendly

features, all of which are accessible through the membrane keypad. It is a unique and

intelligent instrument that has capability to cater to the preferences of the discerning individual.

You have one of three models:

•

CON 10 meter:

•

CON 100 meter:

•

CON 200 meter

Your meter includes a conductivity electrode (cell constant K = 1.0) with built-in temperature

sensor (Order Code: EC-CONSEN41B for CON 10, EC-CONSEN21B for CON 100/200), and

batteries. Please read this manual thoroughly before operating your meter.

1

Page 5

2 DISPLAY AND KEYPAD FUNCTIONS

2.1 Display

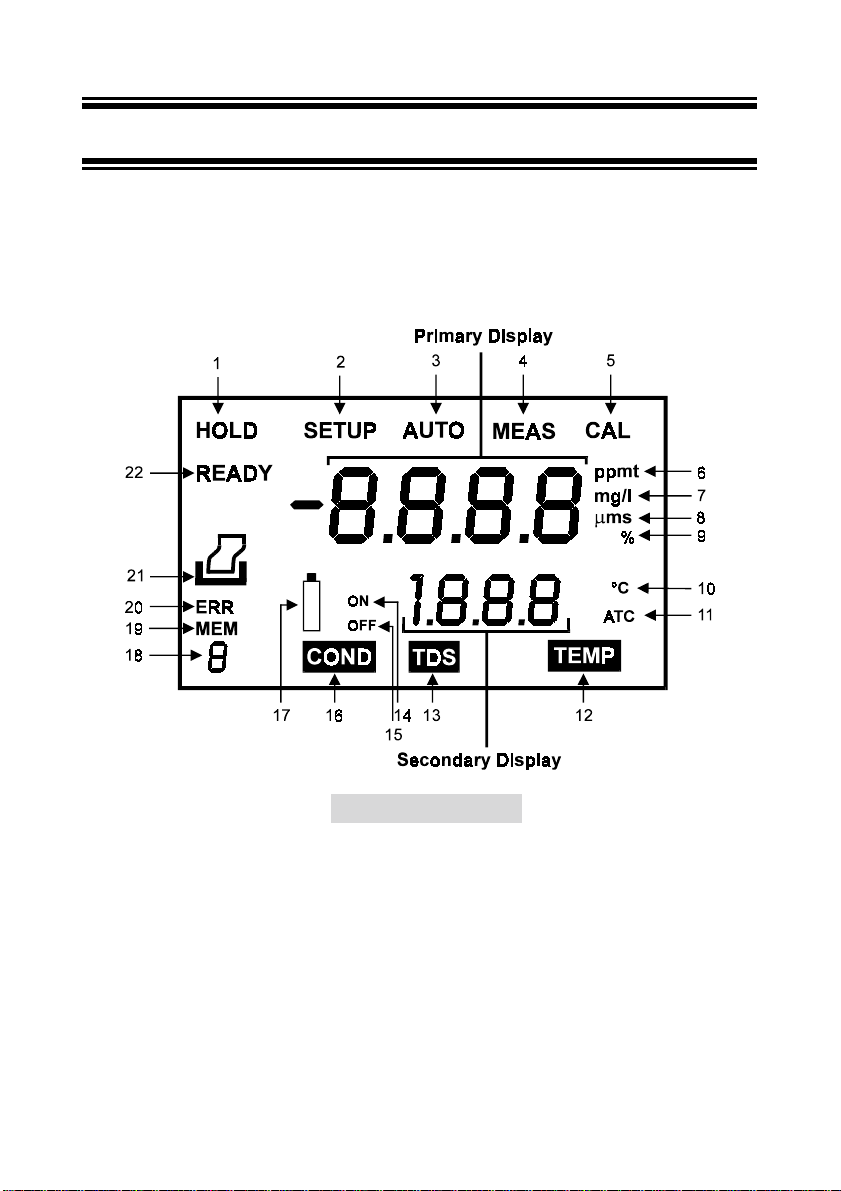

The LCD has a primary and secondary display. The primary display shows the measured

conductivity or TDS reading. The secondary display shows the measured temperature. The

display also shows error messages, keypad functions and program functions. See Figure 1.

Figure 1: Full LCD Screen

1. HOLD indicator 9. Temperature coefficient in % 16. CONDuctivity mode indicator

2. SETup mode indicator 10. Temperature indicator 17. Low battery indicator

3. AUTO indicator 11. Automatic Temperature

4. MEASurement mode indicator 12. TEMPerature mode indicator 19. MEMory recall mode indicator

5. CALibration indicator 13. TDS mode indicator 20. ERRor indicator

6. parts per thousand or parts per million

indicator (for CON 10 & 200 meters

only)

7.milligrams per liter or grams per liter

indicator (for CON 10 & 200 meters

only)

8. microsiemens or millisiemens indicator

Compensation indicator

14. ON/OFF indicator - option is

turned on

15. ON/OFF indicator - option is

turned off

18. Index number of the memory

recalled or stored (except CON 10)

(except CON 10)

21. Printer indicator (for CON 200

only)

22. READY indicator

2

Page 6

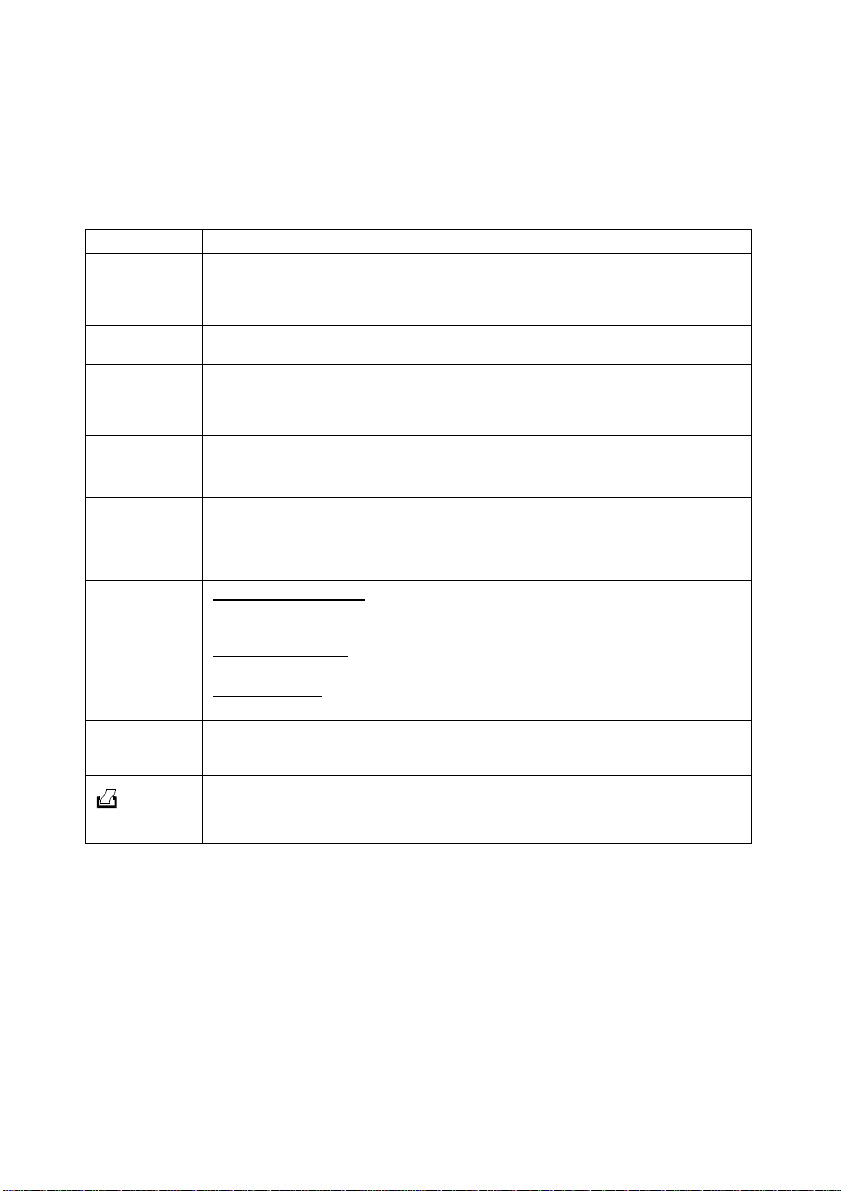

2.2 Keypad

The large membrane keypad makes the instrument easy to use. Each button, when pressed,

has a corresponding graphic indicator on the LCD. See Figure 2. Some buttons have several

functions depending on its mode of operation.

Key Function

Powers on and shuts off the meter. When you switch on the meter, the meter starts

ON/OFF

HOLD

MODE

CAL/MEAS

ENTER /

RANGE

MI/

& MR/

!!!!

(CyberScan CON

100/200)

&

!!!!

""""

(CyberScan CON

10)

SET

(CyberScan CON

100/200 only)

up in the mode that you last switched off from. For example, if you shut the meter off

in TDS measurement mode (only in CON 10 & CON 200 meters), the meter will be in

TDS measurement mode when you switch the meter on.

Freezes the measured reading. To activate, press HOLD while in measurement

mode. To release, press HOLD again.

Selects the measurement parameter.

CON 10 meter

~

CON 100 meter

~

CON 200 meter

~

Toggles between Calibration and Measurement mode.

NOTE

: Temperature calibration is available from conductivity calibration mode; see

section 4.3 for directions.

ENTER function:

selections in SETUP mode.

RANGE function:

The MEAS indicator blinks while in manual ranging function.

In Measurement mode:

""""

Press MI

in the memory. Press MR (memory recall) to retrieve data from memory.

In Calibration mode:

Press to scroll through calibration values.

In SETUP mode:

Press to scroll through the setup subgroup programs.

Takes you into the SETUP mode. This mode lets you customize meter preference

and defaults, and view calibration, electrode offset data and select cell constant.

: Toggles between conductivity, TDS and temperature.

: Toggles between conductivity and temperature.

: Toggles between conductivity, TDS and temperature.

Press to confirm values in Calibration mode and to confirm

Press to enter manual ranging function.

/

!!!!

(memory input) to store values with its corresponding temperature values

(CyberScan CON

200 only)

Sends the displayed data through the RS 232C connector to the peripheral device

(computer or printer).

3

Page 7

CyberScan CON 10 CyberScan CON 100

CyberScan CON 200

Figure 2: Keypad

4

Page 8

3 PREPARATION

3.1 Inse rting the Batteries

Four AAA batteries are included with your meter.

1. Use a Philips screwdriver to remove the two screws holding the battery cover. See Figure

3 below.

2. Lift meter stand to expose battery cover. Remove battery cover.

3. Insert batteries. Follow the diagram inside the cover for correct polarity.

4. Replace the battery cover into its original position using the two screws removed earlier.

Remove Screws

Figure 3: Back panel of meter showing battery compartment

5

Page 9

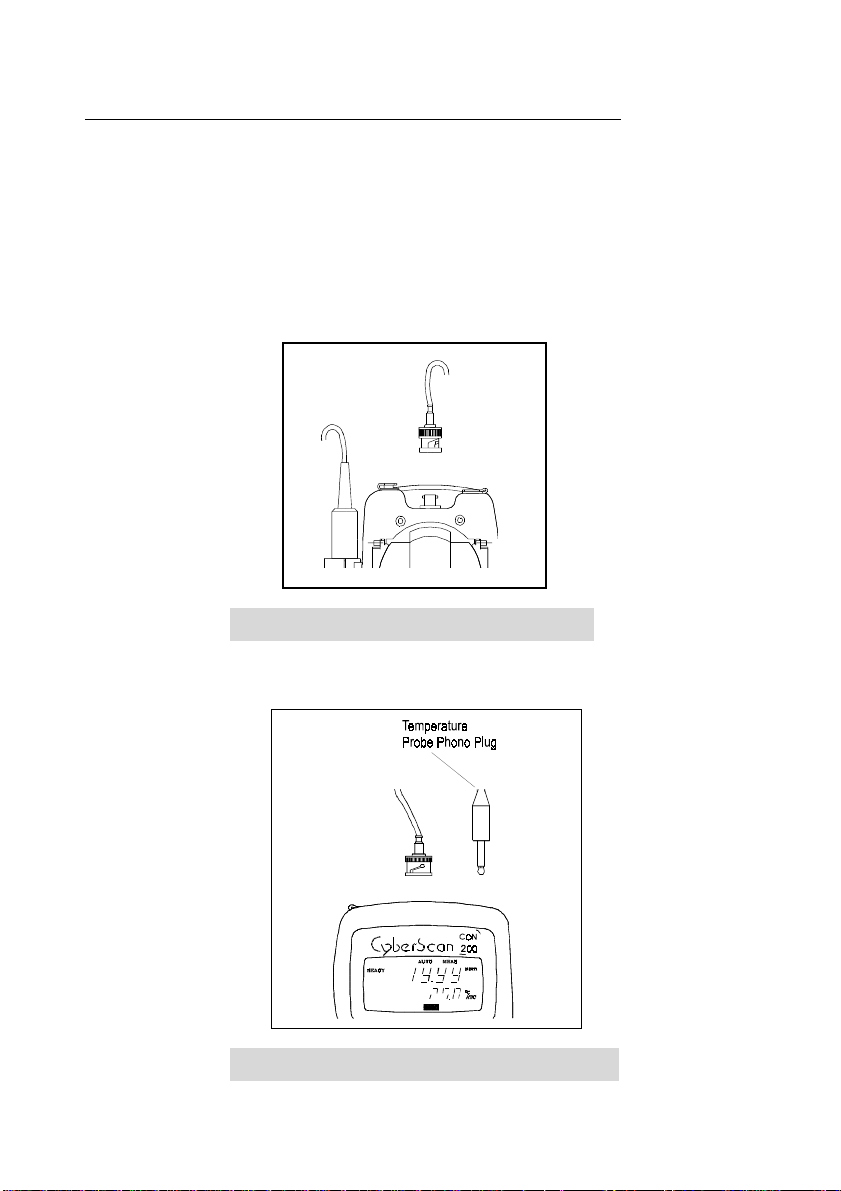

To connect the Conductivity/TDS electrode with built-in temperature sensor:

a) During this operation, it is important that water does not get onto the BNC connector.

Also avoid touching the connector with soiled hands.

Slide the electrode connector of electrode over the socket of the meter (BNC connector).

Ensure that the slot of the connector is inline with the protrusions of the socket.

Rotate the connector clockwise until it locks. Be careful not to use excessive force in this

operation.

Figure 4: Connecting the Conductivity /TDS probe

b) The built-in temperature probe uses a phono jack to connect with the socket on the

meter. Insert the jack into the socket as shown in Figure 5.

Figure 5: Connecting the built-in temperature sensor

6

Page 10

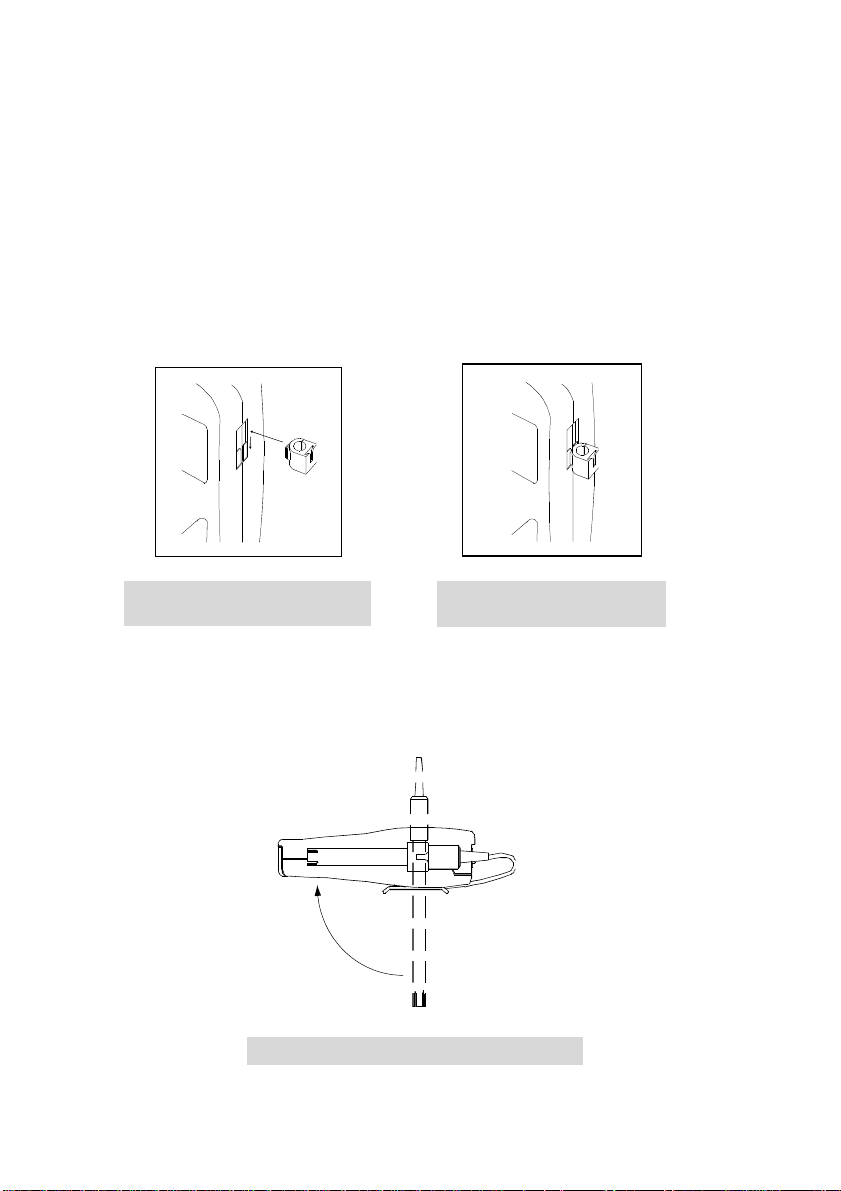

3.2 Attaching the electrode holder onto the meter

The meter has a slot on the side for the attachment of the electrode via the electrode holder.

a) The meter provides a slot on the side of the instrument for the electrode holder. Hold the

electrode holder over the slot of the meter. Ensure the flange of the electrode holder is

facing the slot. Note the orientation to make sure that it is the orientation that you desire

(see figure below).

b) Gently slide the flange of the electrode holder into the slot. Ensure that the electrode

holder is fixed properly into the slot.

Figure 6: Attaching the electrode

holder to the meter

Figure 7: Sliding the electrode

holder into the slot

3.2.1 Special Features

The electrode holder can be attached in different positions (multi-position) as shown. This

allows you the flexibility in measurement and storage.

Figure 8: Multi-position of the electrode holder

7

Page 11

3.3 Atta ching the electrode onto the electrod e holder

Your meter comes complete with an electrode holder. It is designed for easy use and

installation. Care must always be taken to avoid use of excessive force in the process of

attaching these components.

a) Align the end of the electrode (sensor side) with the hole of the holder. Note that the top

side of the holder is where the slot begins.

b) Always ensure that the diameter of the electrode you intend to use is 12 mm. Otherwise,

the electrode may not fit properly.

c) Insert the electrode into the hole of the holder until the top housing of electrode touches

the top of the holder. Remember not to force the electrode into the holder.

3.4 Connecting the A.C. adapt er

The CyberScan CON 10/100/200 meter has the flexibility of operating from an A.C. powe r

source. This is extremely useful if you have an A.C. source available near the meter (e.g.

Laboratory).

1. Before plugging in the A.C. adapter, switch off the meter and the po wer source of the

A.C. adapter. This is a safety precaution that should be adhered to safeguard your meter.

2. The A.C. adapter should have the following settings:

Output Voltage: 9 V D.C.

Current: 500 mA

NOTE: Ensure that the input mains voltage (110/220/240 V) matches your adapter

requirements.

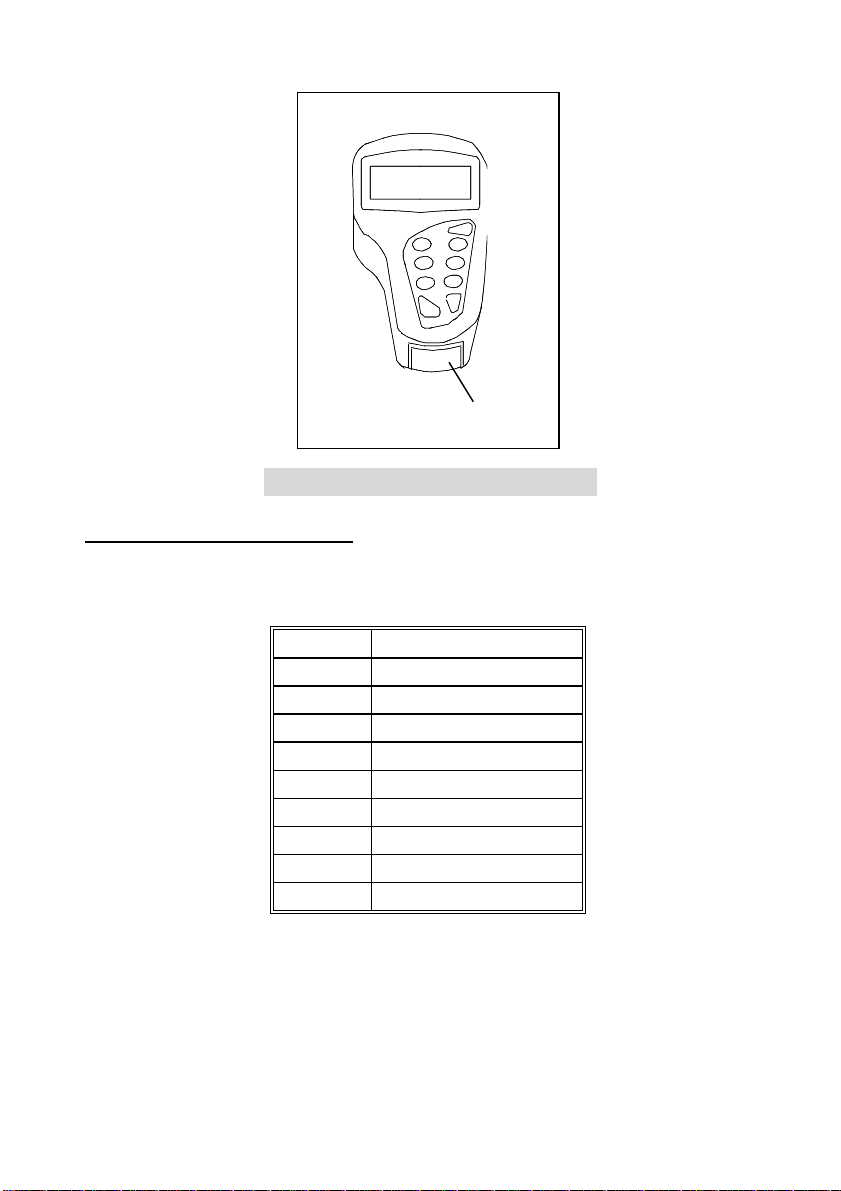

3. Insert the D.C. jack into the socket of the meter as shown in Figure 9.

4. Switch on the power to the adapter, followed by the meter.

8

Page 12

Figure 9: Inserting the A.C. power adapter

3.5 Connecting the RS 232C cable (only for CyberScan CON 200)

The CyberScan Conductivity CON 200 meter provides an RS 232C output for you to transmit

the reading either to a printer or a computer. This is extremely useful in instances where the

meter is used for continuous monitoring of a certain process or experiment. The data output to

the printer or computer can be then evaluated.

The data is output in the ASCII format. This format allows the data to be imported by a wide

variety of software that read ASCII data (e.g. LOTUS 123 C, Microsoft Excel, etc.).

Eutech Instruments also provides software that can capture the data transmitted into an ASCII

file for later use.

a) Open the communication port cover located at the bottom of the meter as shown in

Figure 10. Do not use excessive force when doing this.

b) Noting the orientation of the RS 232C connector, plug the RS 232C male connector into

the RS 232C port of the meter.

c) Fasten the connector by fastening the two screws at the side of the male connector.

9

Page 13

Location of

RS 232 port

Figure 10: The CyberScan CON 200 RS 232 port

3.5.1 RS 232C Configuration

The CyberScan CON 200 meter has a 9-pin female RS 232C connector with the following pinout:

PIN NO DESCRIPTION

12 Transmit Data

34 DSR (Data Set Ready)

5GND

67 CTS (Clear to Send)

89-

A one-is-to-one connection can be made with a 9-pin RS 232C port of the computer.

In case the meter output has to be sent to a 25-pin RS 232C connector, the following cable

configuration may be used:

10

Page 14

CyberScan CON 200 25-pin connector

g

2 (TxD) --------------------------------------- (RxD) 3

4 (DSR) -------------------------------------- (DTR) 20

5 (GND) -------------------------------------- (GND) 7

7 (CTS) --------------------------------------- (RTS) 4

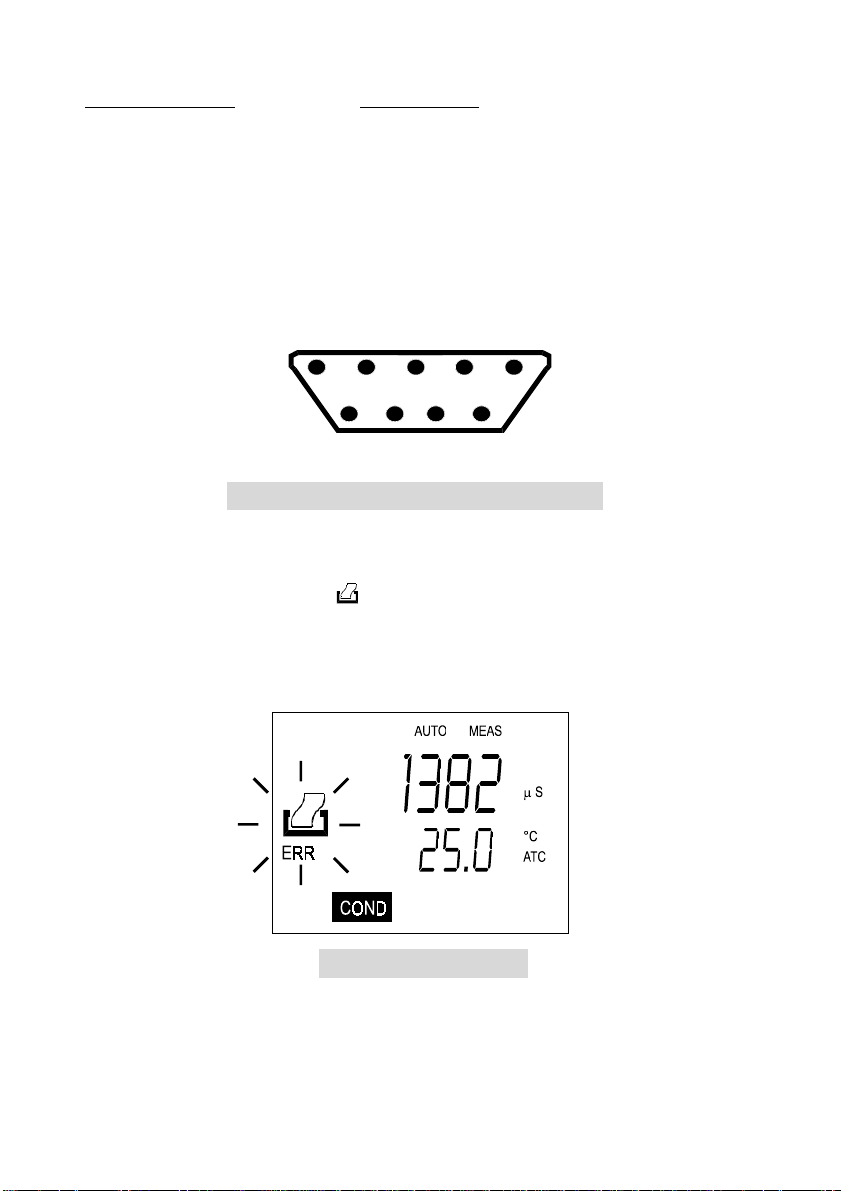

Refer to Figure 11 for the pin number position.

5432 1

987 6

Figure 11: Pin number position of the 9-pin RS 232 port

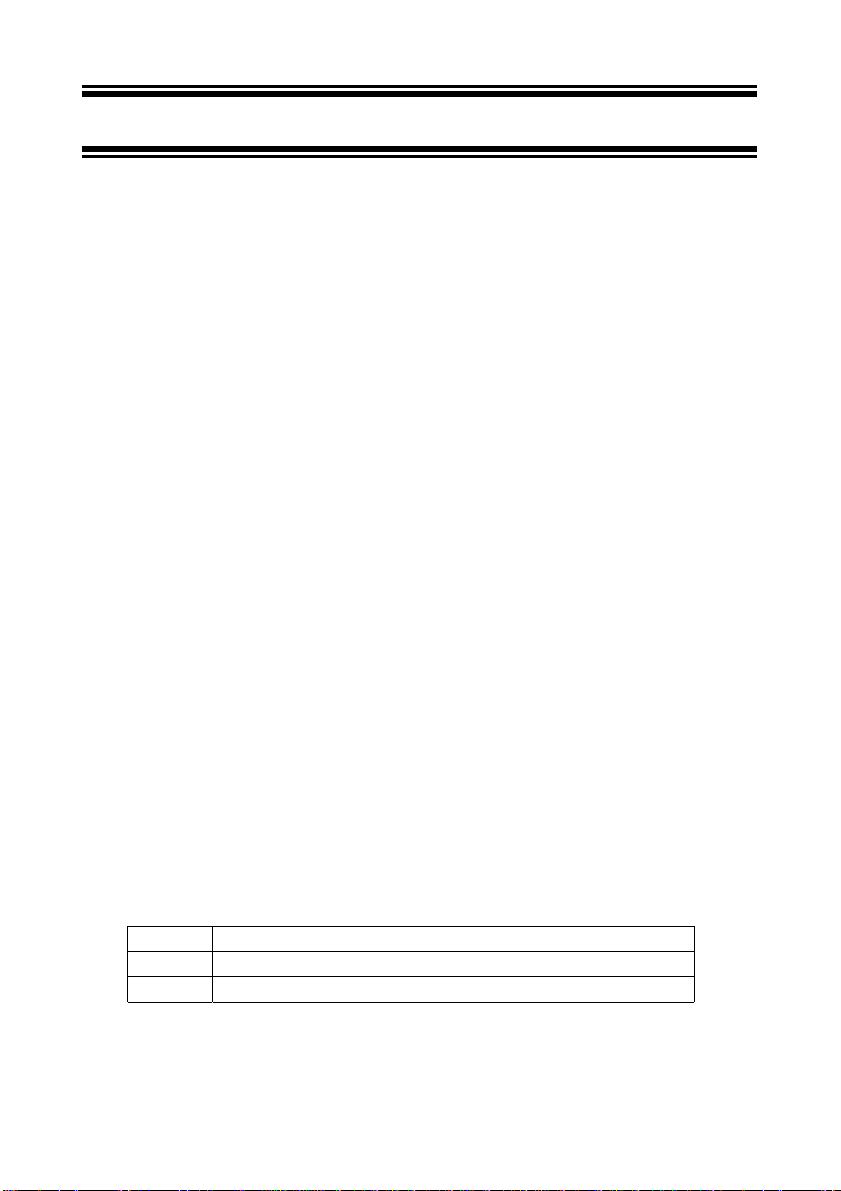

The meter uses hardware handshake i.e. the meter expects both DSR and CTS lines to be

active before it sends data. If the

key is pressed while the printer is not ready or if the

printer is off, the meter displays error by blinking the printer and the ERR annunciators

alternately, and waits for the printer to be ready. While the meter is displaying printer error, the

user may press the CAL/MEAS key to return to the measurement (MEAS) mode.

Figure 12: Error in printin

11

Page 15

4 CALIBRATION

4.1 Stand ard solutions for calibrat ion

Select conductivity or TDS calibration solution (available from the distributor) which is close to

the expected conductivity of the sample that you want to measure. Ensure that the calibration

solution which you use comes with a “Temperature vs Conductivity” or a “Temperature vs

TDS” label on it. This information is required during calibration.

NOTE: Eutech’s calibration solutions are supplied in shatterproof bottles of 480 ml. Refer to

section 12 for Ordering Information and details for other accessories.

In CON 100 meter, calibration is only done in the conductivity (COND) mode. The CON 10

and CON 200 meters allow calibration either in the conductivity range or the TDS range but

not both. As such, a calibration in the TDS mode of a particular range will replace a prior

calibration in the conductivity mode if both ranges are the same (i.e. Range 2 in COND and

Range 2 in TDS).

In general, it is recommended that calibration be performed around a point close to 2/3 of f ull

scale. For better accuracy, perform a calibration close to the expected measurement range

prior to the measurement.

Corresponding TDS values are obtained by multiplying the recommended conductivity values

by the TDS factor. The default TDS factor is 0.5.

4.2 Prep aring the meter for calibration

Before starting calibration, make sure you are in the correct measurement mode. When you

switch on the meter, the meter starts up in the measurement mode you shut it off in previously.

For example, if you shut the meter off in COND measurement previously, the meter will come

back into COND measurement when you switch the meter on.

Before calibrating, select the correct mode by pressing the MODE key. There are 3 modes:

COND for conductivity measurements,

TDS for total dissolved solids (TDS) measurements,

TEMP for temperature measurements.

12

Page 16

4.3 Calibration procedure

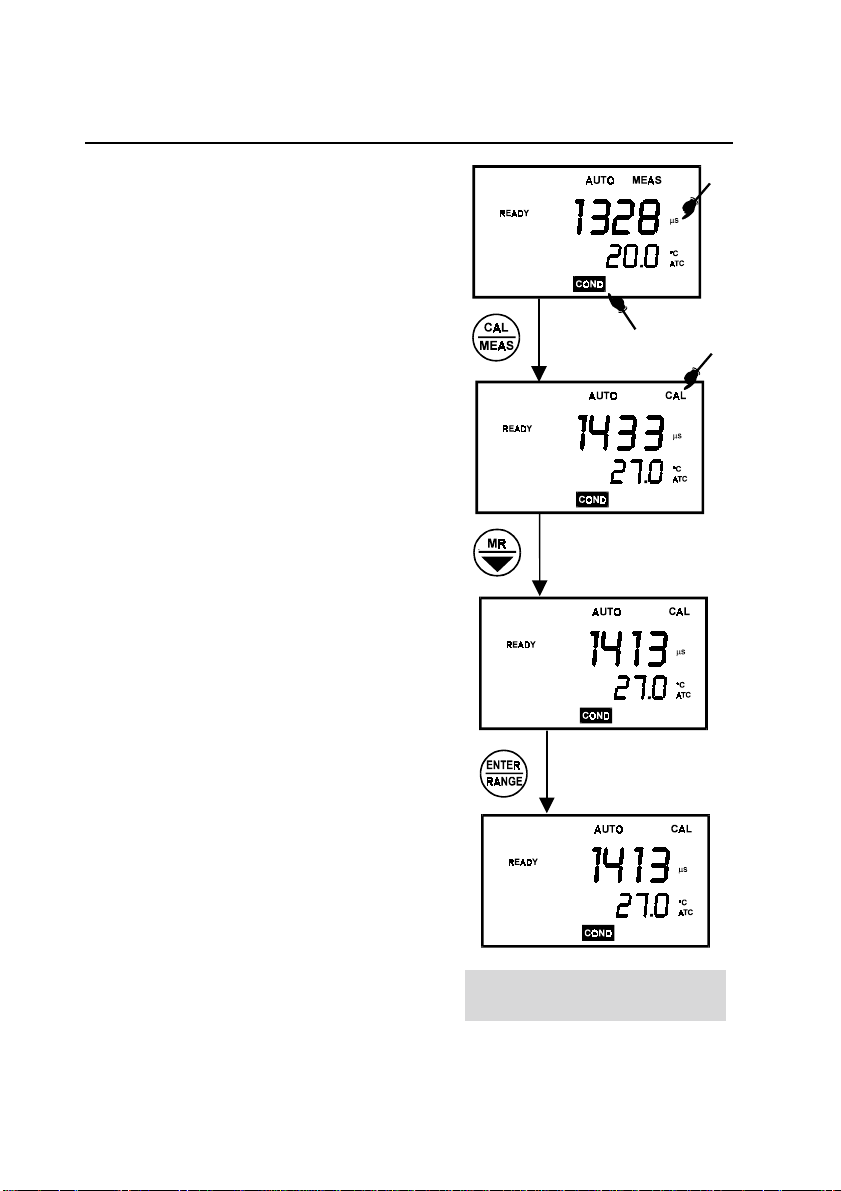

4.3.1 Procedure for conductivity calibration (CyberScan CON 10/100/200)

1. If necessary, press the MODE key to select

COND mode. The µs indicator appears in the

upper right hand corner of the display.

2. Rinse the probe thoroughly with de-ionized

water or a rinse solution.

3.

Dip the probe into the buffer solution. The

end of the probe must be completely

immersed into the buffer solution. Stir the

probe gently to create a homogeneous

sample. Agitate the probe in the solution to

dislodge air bubbles that are trapped in the

probe.

4. Press the CAL/MEAS key to enter the COND

calibration mode. The CAL indicator will be

shown. The primary display will show the

measured reading.

5. Use the ! or " key for CON 10, or MI/! or

MR/" key for CON 100/200, to adjust the

measured value to that of the standard

solution.

6. Wait for the measured conductivity value to

stabilize. See Figure 13 for the conductivity

calibration procedure.

NOTE: To exit without confirming the

calibration, press the CAL/MEAS key.

For calibration in the other ranges (maximum:

5 ranges, repeat steps of the procedure, this

time using a solution with a conductivity of a

different range).

13

Figure 13: Conductivity calibration

procedure

Page 17

4.3.2 Procedure for TDS calibration (CyberScan CON 10/200 only)

Two methods are available for TDS calibration. The first method (Method 1) applies to both

CyberScan CON 10 and 200 meters. Method 1 relies on the availability of a table that shows

the TDS values of the TDS calibration buffer solution at various temperatures. The second

method (Method 2) relies on the availability of conductivity-to-TDS conversion factors at

standard temperature such as at 25 °C. Method 2 applies only to CyberScan CON 200 meter.

The advantage of Method 1 is that it is simpler to perform than Method 2. However, one

should note that much of calibration buffer solutions do not reference the TDS values at

temperatures other than 25 °C, and that without the use of proper conductivity-to-TDS

conversion factor, this calibration may not be as accurate over a wider range of measurement.

Also, in some cases, the meter may not accept the TDS value input into it giving an error

message because the calibration value exceeds the allowable slope adjustment limits of the

meter when using a default conductivity-to-TDS conversion factor such as 0.50.

Method 2 overcomes the shortcomings of Method 1 by ensuring the TDS measurement

accuracy over a broader range of TDS measurements around the calibration value. The meter

will virtually accept any TDS calibration input from virtually any commonly used TDS

calibration buffer solution. The only requirement is that the buffer solution indicates the TDS at

a standard temperature such as 25 °C.

NOTE: It is important to have knowledge of the conductivity-to-TDS conversion factor or the

factor can be calculated using the formula below:

Factor =

TDS

Conductivity

14

@ 25°C

Page 18

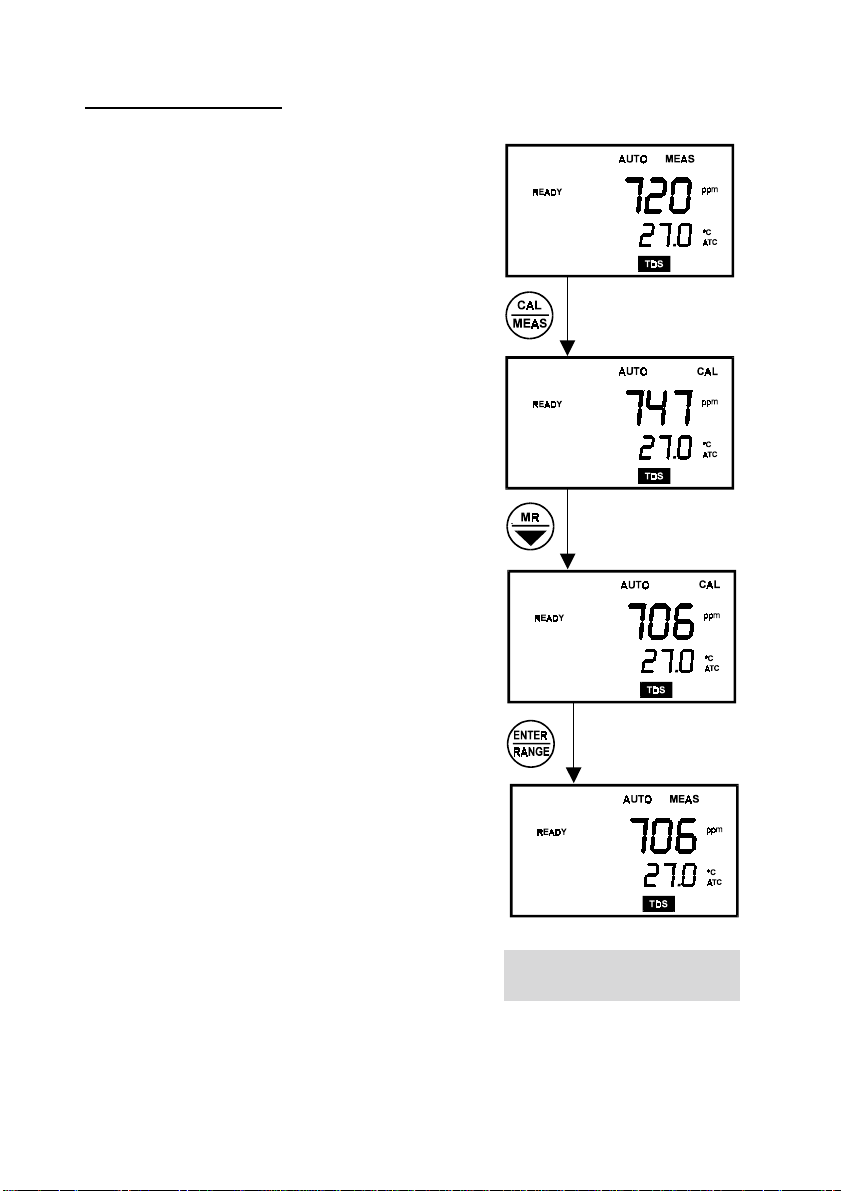

TDS calibration: Method 1

1. Select the TDS standard solution with a value that

is closest to the measurements expected in the

sample (in this manual, the KCI standard solution

1413 µS is about 706.5 ppm).

Check this number by multiplying the conductivity

reading by the factor and the result should be the

TDS in equivalent units.

2. First, pour enough of the selected sample into two

separate clean containers so as to allow the

probe to be immersed up to the bleed hole.

3. Rinse the end of the probe into one of the

containers by gently stirring it in the standard

solution. This helps remove contaminants that

offset the calibration and introduce error.

4. Dip the rinsed probe into the other container

containing the unused solution.

5. Allow the probe some time to stabilize to the

solution temperature.

6. Select the TDS mode using the MODE key. Note

the temperature of the calibration solution and

find the corresponding TDS value of the

calibrating solution at that temperature.

For example, the meter displays the temperature

of 27 °C, and a TDS value of 720 ppm (when

normalized to 25 °C) with the uncompensated

value at 27 °C should be 733 ppm.

7. Upon pressing the CAL/MEAS key, the CAL

annunciator on the screen will blink, indicating the

calibration mode is on. The LCD displays the

uncompensated TDS value.

15

Figure 14: TDS calibration

procedure Method 1

Page 19

8. Use the ! or " key for CyberScan CON 10, or MI/! or MR/" key for CyberScan 200 to

scroll up or down respectively to the value of the standard solution at 25 °C.

9. Press the ENTER/RANGE key to confirm the calibration. The CAL indicator will stop

flashing and remains on the screen for 3 seconds. Then the meter switches back into the

measurement mode and the calibrated value, compensated to the current temperature, is

shown on the display.

The display will now show 706 ppm that is the correct value of the standard solution at 27

°

C. Measurements can be performed now.

10. To exit from this process without confirming the calibration, press the CAL/MEAS key.

For calibration in the other ranges (maximum: 5 ranges for CON 200 only) repeat steps of the

procedure as outlined in Method 1, this time using a solution with a TDS of a different range.

Error upon confirmation

If an ERR error message appears, it probably means that the meter does not allow the slope

adjustment that has been made via the calibration procedure given the value of the

conductivity-to-TDS conversion factor currently in the memory.

If you are using CyberScan CON 200 meter, consider Method 2 of the TDS calibration. Press

the CAL/MEAS key to escape the ERR message and abort the calibration attempt.

Inaccuracies after calibration

If the TDS value is not within 2 digits of the TDS standard solution value at 25 °C or 20 °C

(depending upon which value was selected in the SETUP), an adjustment of either of the

following is required.

•

Temperature coefficient

•

Calibration

•

Conductivity-to-TDS conversion factor (see Method 2)

16

Page 20

TDS calibration: Method 2 (for CyberScan CON 200 only)

1. Select the TDS standard solution with a value

that is closest to the measurements expected in

the sample (in this manual, the KCI standard

solution 1413 µS is about 706.5 ppm at 25 °C).

2. Pour about 3 cm of the selected sample into two

separate clean containers.

3. Rinse the end of the probe into one of the

containers by gently stirring it in the standard

solution. This helps remove contaminants that

offset the calibration and introduce error.

4. Dip the rinsed probe into the other container

containing the unused buffer solution.

5. If the Eutech standard solution is used, the correct

Conductivity-to-TDS conversion factors are given

for KCI, NaCI & 442 natural water formulation at

25 °C under the “Multiply By:” on the label. If

another brand of TDS calibration is used, refer to

the formula:

Press ENTER key

repeatedly until you

come to P3.0.

Factor =

Select the correct factor according to the protocol

of the method, or that is closest to the solution to

be measured.

6. Enter into the SETUP mode by pressing the SET

key (note that this mode can be entered only from

the MEAS mode).

Press the ENTER/RANGE key repeatedly until Program 3.0 (TDS factor) is shown.

TDS

Conductivity

@ 25 °C

17

Figure 15: TDS calibration

procedure Method 2

Page 21

7. Using the MI/! or MR/" key, adjust the value of the primary display until it is the same

or close to the selected/calculated value.

Confirm the selected value by pressing the ENTER/RANGE key.

8. Exit the SETUP mode and return to the MEAS mode by pressing the CAL/MEAS key

upon completion of step 7. Press the MODE key until the TDS mode is entered. The TDS

value will be the buffer solution value for the type of TDS solution selected. The value will

also be temperature compensated and the conductivity-to-TDS conversion input will

ensure greater accuracy over a broader range of TDS curves used.

18

Page 22

5 MEASUREMENT

This meter is capable of taking measurements with automatic or manual temperature

compensation. Automatic temperature compensation only occurs when a temperature sensor

is plugged into the meter. If there is no temperature sensor plugged into the meter, the default

manual temperature setting is automatically 25 °C. You can manually set the temperature to

match your working conditions using a separate thermometer.

5.1 Auto matic Temperature Compensation

For automatic temperature compensation (ATC) simply plug the built-in temperature sensor

probe into the meter. The ATC indicator will light up on the LCD (see figure 16).

Figure 16: Automatic Temperature Compensation

(ATC) indicator

19

Page 23

5.2 Manual Temperature Compensation

IMPORTANT: For manual compensation, you must disconnect the temperature probe. The

ATC annunciator will disappear from the LCD.

1. Press the MODE key to select TEMP mode.

2. Press the CAL/MEAS key to enter

Temperature calibration mode. The CAL

indicator will appear above the primary

display.

3. The primary display shows the current

conductivity/TDS reading and the

secondary display shows the default

temperature value 25 °C.

4. Check the temperature of your sample

using an accurate thermometer.

5. Press the ! or ", or MI/! or MR/" key to

set the temperature to the measured value

obtained in step 4. To confirm, press

ENTER/RANGE key.

6. Press the CAL/MEAS key to exit and return

to conductivity measurement mode.

NOTE: To exit this program without confirming

the manual temperature compensation value, DO

NOT press ENTER/RANGE in step 5. Press

CAL/MEAS instead.

20

Figure 17: Setting the Temperature

Compensation manually

Page 24

5.3 Taking measurements

To take readings

1. Rinse the probe with de-ionized or distilled water before use to remove any impurities

adhering to the probe body.

2. Press ON/OFF key to switch on the meter. The MEAS annunciator appears on the top

center of the LCD. The ATC indicator appears in the lower right-hand corne r to indicate

Automatic Temperature Compensation.

3. Dip the probe into the sample.

4. When dipping the probe into the sample, the sensor of the electrode must be completely

immersed into the sample. Stir the probe gently in the sample to create a homogeneous

sample. Agitate the probe in the sample to dislodge air bubbles that are trapped in the

probe.

5. Allow time for reading to stabilize. Note the reading on the display.

21

Page 25

6 MEMORY FUNCTIONS (IN CYBERSCAN CON 100 &

200 ONLY)

6.1 Data Input

Press the MI/! key in the measurement (MEAS) mode, to input any data into the memory.

The meter will automatically store the displayed data into the memory.

Model Parameters

CON 100 Conductivity & temperature

CON 200 Conductivity & temperature and/or TDS & temperature

A total of 16 sets of data can be stored into the memory of the meter. The memory stored is

identified by the memory number (in hexadecimal numbering format, i.e. from 0 to 9 followed

by A to F) as displayed at the bottom left corner of the screen. The Last-In-First-Out (LIFO)

method of memory management is used. See section 7.5 (Printing data from Memory) for

illustration.

If the memory is full, the first memory contents (i.e. memory #1) will be erased. Memory #2 is

reassigned #1 and so on, leaving the last space #F free to receive the latest input.

To store the value of the measurement into the

memory of the meter, press the MI/! button. This

will store both the parameter (conductivity or TDS)

and the temperature into the memory. The MEM

annunciator will be displayed briefly to indicate that

the data has already been stored into memory. The

memory number indicator, at the bottom left hand

corner, will flash the number of memory stored.

Figure 18: Data input to the

memory

6.2 Memory Recall

Memory recall is invoked to recall the data sets

stored in memory. Memory recall is activated in the

following sequence:

22

Figure 19: Memory Recall

Page 26

1. Press the MR/" once to recall the last data set.

NOTE: Memory Recall (MR) is only accessible in the MEAS mode. Press CAL/MEAS key

to return to the measurement mode.

2. Press the MR/" key again to recall the next latest data set stored.

NOTE: Memory data is retained even if the power of the unit is switched off (even with

the batteries removed). Memory is erased when using Program 1.0 of SETUP (see

section 8.2.1).

6.3 Memory Clear

Under normal operating conditions, fresh data sets will automatically be stored at the expense

of data sets stored earlier. The instrument holds up to a maximum of 16 sets of data. The

meter also has a feature that enables easy but safe clearing of memory facilities. The process

to be followed in clearing the memory is outlined in SETUP (see section 8.2.1). The

accessibility of this function through the SETUP mode is to limit accidental clearing of memory

from the measurement mode.

23

Page 27

7 PRINT FUNCTION (IN CYBERSCAN 200 ONLY)

7.1 Printing data

The CyberScan CON 200 meter is equipped with a key that facilitates the printing of data

into the computer in the form of a data file.

Using the CyberScan CON 200 meter with the printer

1. To use the CyberScan CON 200 meter directly with a printer, the printer should have

either a 9-pin or a 25-pin RS 232 serial port.

2. Printer dip switches should match with the meter communication setup. The printer

should have options to receive 8 data bits, even (2), odd (1) or none (0) parity bit and one

(1) or two (2) stop bits. These parameters are standard printer options.

3. Use the cable provided to connect the meter to the printer. If the printer has a 25-pin

connector, use a 9 to 25-pin converter (if available) or make your own cable taking note

of the connection parameters as described in Section 3.5 (Connecting the RS 232 cable).

4. Set the dip switch of the printer to accept serial data. This is required if the printer has

both serial and parallel interfaces. Set the dip switch to accept 8 data bits.

5. Switch on the meter.

6. Change the CON 200 meter setup parameters for the proper baud rate, parity and stop

bits. Ensure that these parameters are identically set on both the printer and the meter.

7. Insert the paper and switch the printer on.

8. To send data to the printer, press the

key.

24

Page 28

7.2 Printing errors

The meter displays an error by blinking the printer

and error annunciators if the printer is not ready to

receive data or if the printer is off. As soon as the

printer is ready, the error display will automatically go

off. While the meter is displaying the printer error, the

user may press the CAL/MEAS key to go back to the

measurement mode.

7.3 Sending d ata to the computer

To send data to the computer, connect the RS 232C

cable from the base of the meter to the COMM port 1

of the computer. Load and run the CYDATA data

acquisition program ensuring that the parameters of

the settings in the meter and the CYDATA are

identical.

Figure 20: Display of printing

error

To send data to the computer, press the

key.

Figure 21: Sending data to the

computer

7.4 Printing measurement data

To print any data that is currently being measured, press the key. Note that the printing

capability is available for the COND, TDS and TEMP modes.

The data will be printed onto the printer paper or the screen of the CYDATA program

automatically as illustrated in Page 26.

7.5 Print ing data from memory

The CyberScan CON 200 meter can print data that is stored in the memory. Firstly, ensure

that the cables are properly connected to either the printer or the computer and the units are

configured to receive the data from the meter.

Change the mode to the mode of measurement from

which data needs to be printed.

Scroll to the data that needs to be printed by pressing

the MR/" key. To print, press the

displayed will then be sent to the printer or the computer.

An example of the printout is shown in Page 26.

key. The data

Figure 22: Printing data from

memory

25

Page 29

An example of a printout for Printing Measurement Data:

Cond: 1.00 mS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 09

Cond: 100 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 11

Cond: 10.0 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 14

Cond: 1.00 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 24

Cond: 199.9 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 28

Cond: 1999 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 30

Cond: 19.99 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 32

Cond: 199.9 uS Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 34

TDS: 0.00 ppm Temp: 33.2 Date: 07-30-96 Time: 14 : 00 : 59

TDS: 0.64 ppm Temp: 33.2 Date: 07-30-96 Time: 14 : 01 : 32

TDS: 10.0 ppm Temp: 33.2 Date: 07-30-96 Time: 14 : 01 : 38

TDS: 10.0 ppm Temp: 33.2 Date: 07-30-96 Time: 14 : 01 : 40

TDS: 0.00 ppt Temp: 33.2 Date: 07-30-96 Time: 14 : 01 : 59

TDS: 0.00 ppt Temp: 33.2 Date: 07-30-96 Time: 14 : 02 : 02

TDS: 1.05 ppm Temp: 33.2 Date: 07-30-96 Time: 14 : 01 : 06

An example of a printout for Printing Data from Memory

Mem: 7 Cond: 13.21 mS Temp: 25.0 Date: 07-30-96 Time: 14 : 00 : 52

Mem: 6 Cond: 199.9 mS Temp: 25.0 Date: 07-30-96 Time: 14 : 00 : 55

Mem: 5 Cond: 1999 uS Temp: 25.0 Date: 07-30-96 Time: 14 : 00 : 57

Mem: 4 Cond: 14.52 uS Temp: 25.0 Date: 07-30-96 Time: 14 : 00 : 59

Mem: 3 Cond: 14.52 uS Temp: 25.0 Date: 07-30-96 Time: 14 : 01 : 06

Mem: 2 T DS: 0.06 ppm Temp: 25.0 Date: 07-30-96 Time: 14 : 02 : 11

Mem: 1 T DS: 0.06 ppm Temp: 25.0 Date: 07-30-96 Time: 14 : 02 : 13

Mem: 0 T DS: 0.06 ppm Temp: 25.0 Date: 07-30-96 Time: 14 : 00 : 15

26

Page 30

8 SETTING UP THE CYBERSCAN (FOR CYBERSCAN

CON 100/200 ONLY)

8.1 SETUP program

In the SETUP mode in CyberScan CON 100/200 meter, there are four main programs. Each

has been divided into several options. The programs and options are elaborated under the

following sections:

PROGRAM DESCRIPITION SECTION

1 Common functions 8.2

2 Instruments setup 8.3

3 TDS units and factor 8.4

4

To enter the SETUP mode, press the SET key from either the µS or ppm measurement MEAS

mode. The meter automatically enters Program 1, Option 0 (P1.0). The meter prompts you

with the program numbers in the secondary field of the display.

NOTE: Entry to SETUP is only accessible from the MEAS mode.

Selection of the ENTER/RANGE key confirms selection of the options chosen. The instrument

then automatically scrolls to the next program. Within each program, you can use MI/! or

MR/" key to make appropriate selections. There are some options that permit the viewing of

data and are useful for diagnostic purposes.

Communication

parameters

8.5

Ensure that the ENTER/RANGE key is pressed to confirm your option in each program.

To exit from the program after the confirmation of choice or to abort from the SETUP mode,

press the CAL/MEAS key to return to the MEAS mode.

NOTE: You may press the CAL/MEAS key to exit SETUP mode at any time.

To exit SETUP

27

Page 31

8.2 Prog ram 1: Common functions

y

The following 3 options are commonly used:

8.2.1 P1.0: Memory Clear

16 sets of readings can be stored in the meter. Both

conductivity and temperature or TDS and temperature

readings are stored.

ON Clears all values stored in memory

OFF Memory values remain in storage

Activation of this option by selecting ON and confirmation of

memory clears all memory values. This is done by toggling

the annunciator to ON using the MI/! or MR/" key, and

pressing ENTER/RANGE to confirm the selection.

8.2.2 P1.1: %Temperature coefficient

adjustment

The amount of change in conductivity per degree centigrade

is referred to as the Temperature Coefficient, expressed in

%/°C at a particular temperature. The meter provides the

options of selecting the appropriate temperature coefficient,

from 0.0 to 10.0 %/°C, depending on the type of solution

measured.

The primary display indicates the temperature coefficient in

%/°C. You can use the MI/! or MR/" key to scroll to a

required value from 0.0 to 10.0 %/°C. Once you have made

your selection, press ENTER/RANGE key to confirm the

value.

The program will automatically scroll to the next SETUP

parameter. Under default condition, the temperature

coefficient is set to 2.0%/°C.

28

Figure 23: Memory clear displa

Figure 24: Temperature

coefficient adjustment setup

Page 32

8.2.3 P1.2: Calibration Status Display

y

The meter can be used to a maximum of five different calibrations in its five ranges of

measurement. This SETUP program not only allows you to see if a particular range has been

calibrated, but indicates the calibrated value. The secondary value shows P1.2. The range

number (i.e. 1, 2, 3, 4 & 5) is indicated in the left corner of the display. While in P1.2, you can

press MI/! or MR/" key which will scroll from range number 1 to 5 to display all the

calibration status of the five ranges shown in the primary display. On pressing ENTER/RANGE

key, the meter scrolls into the next SETUP parameter.

The meter will display the calibrated value in each range and the units (ppt/ppm/µS/mS)

depending upon which modes were used during calibration. This allows a greater ease of use.

NOTE: The meter stores a maximum of five calibration values per range i.e. one calibration

value per range. See Section 4 on Calibration. If the TDS factor (see Program 3.0) is changed,

all previous TDS calibration values will not have a meaningful relationship to physical

parameters and the meter displays “-- -- -- --“ for all TDS calibration values.

This indicates that the meter is not calibrated in any of the five ranges using the new TDS

factor.

NOTE: The previous calibration status would not be restored if the previous TDS factor were

re-entered.

It is, therefore, necessary to calibrate the meter once the TDS factor is changed. Then, the

SETUP mode will show the status of the five calibration ranges, indicating the TDS values in

which you have calibrated with the respective range numbers.

Figure 25: Calibration status displa

Otherwise, the meter will continue to function with the previous calibration values and the new

TDS factor, unless calibration is specifically reset by the SETUP option P2.2.

29

Page 33

8.3 Prog ram 2: Instruments Setup

8.3.1 P2.0: Ready selection

Activation of the READY option ensures that the READY

indicator is displayed when the electrode reading

stabilizes. READY options can be switched on or off by

pressing the MI/! or MR/" key as indicated by ON or

OFF in the display, followed by ENTER/RANGE key.

Under factory default, the option is ON.

READY annunciator appears when variation is

ON

within 1 LSD (Least Significant Digit)

OFF READY annunciator will not appear

8.3.2 P2.1: Auto-Off

To conserve the power, the meter has an AUTO-OFF

feature. Activation of the auto-off option will automatically

power off the instrument 20 minutes after the last key

selection. This feature is useful for conserving battery

power. If this feature is not required, it can be switched off

by using the MI/! or MR/" key, and pressing

ENTER/RANGE key.

Figure 26: READY option

Under default condition, the option is activated.

ON

Meter switches off automatically 20

minutes after the last key operation

Meter will operate continuously until

OFF

switched off manually using the

ON/OFF key

Figure 27: Auto-Off option

30

Page 34

8.3.3 P2.2: Calibration Reset

P2.2 provides the option to reset all user selectable

functions to the default settings. If you toggle the

annunciator to ON using the MI/! or MR/" key, and press

ENTER/RANGE key, all data will be reset.

RESET clears

all calibration data in memory (of both conductivity

and TDS)

. You need to power ON the instrument before

proceeding with any other functions.

Under default condition, RESET option is OFF.

NOTE: Data cannot be selectively deleted.

ON Reset all calibration points

OFF Reset off

8.3.4 P2.3: Temperature Normalization

The ATC (Automatic Temperature Compensation)

function automatically compensates for the variation

caused by temperature difference during measurement

and at the standard temperature (20 or 25 °C) and gives

the corrected read-out of the equivalent conductivity of

the solution. Hence, the conductivity/TDS can be

normalized to display the equivalent conductivity/TDS at

either 20 or 25 °C.

Figure 28: The RESET option

Normalization temperature can be selected between 20 &

25 °C using the MI/! or MR/" key. The primary display

shows normalization temperature. Pressing

ENTER/RANGE key registers the selected temperature at

which the conductivity/TDS value is normalized. Default is

at 25 °C.

31

Figure 29: The Temperature

Normalization option

Page 35

8.3.5 P2.4: Cell Constant Selection - 0.1 / 1.0 / 10.0

This option allows you to select the cell constant of the

electrode supplied has a nominal cell constant of 1.0. This

option is important to obtain optimal readings in the various

ranges of measurement. A table is shown below for K value

selection of electrodes.

Ranges available K=0.1 K=1.0 K=10.0

0.00 -19.99 µS**

0.0 -199.9 µS**

0 - 1999 µ S*

0.00 - 19.99 mS * *

0.0 - 199.9 mS * *

In Program 2.4, use the MI/! or MR/" key to select the

required cell constant and confirm by pressing

ENTER/RANGE. The display then shows the selected cell

constant.

Figure 30: The cell constant selection

32

Page 36

8.4 Prog ram 3: TDS Setup (in CyberScan CON 200 on ly)

p

8.4.1 P3.0 TDS factor

The TDS factor for a particular standard solution is a

multiplication factor which relates the measurement of

conductivity in µS/cm to its equivalent reading in

ppm/mg/l. This factor is unique for each solution.

This option allows the selection of the TDS factor for the

solution to be measured. The TDS factor is shown on the

primary display. Toggle the MI/! or MR/" key to select

the exact TDS factor. The range of values is from 0.4 to

1.0. Any values less than 0.4 or more than 1.0 would

cause an error. Press the ENTER/RANGE key to confirm

the TDS factor selected. Under default conditions, the

TDS factor is set to 0.5.

Figure 31: The TDS setu

33

Page 37

8.4.2 P3.1: TDS units

In default, the meter shows TDS measurement unit in

ppm. To select the TDS measurement in mg/l, toggle the

TDS units using the MI/! or MR/" key. Press enter key

to confirm the selection, and the meter scrolls into P4.0.

Figure 32: Selecting the TDS unit

34

Page 38

8.5 Prog ram 4: Communication Setup ( in CyberScan CON 200

only)

This program allows you to set up the instrument’s communication parameters of the

CyberScan CON 200 meter to enable proper communication with the printer or computer of

choice.

8.5.1 P4.0: Baud Rate

You can select a baud rate of 2.4, 4.8, 9.6 or 19.2 kbps

(kilo bits per second). Under default conditions, the baud

rate is set to 9.6 kbps (9600 bps).

1. From COND or TDS measurement mode, press

SET key.

2. Press ENTER/RANGE key until P4.0.

3. Use the MI/! or MR/" key to change different baud

rate.

4. Press ENTER/RANGE key to confirm and continue

to set Parity in P4.1.

See figure 33.

Figure 33: The Baud Rate option

35

Page 39

8.5.2 P4.1: Parity

Parity check allows the receiving unit to monitor the

integrity of the data that the meter transmits. To

accommodate for the variances in standards used, three

different parity checks have been provided. They are as

shown in the table below. The default parity is even (2).

Value Parity

0 No parity

1 Odd parity

2 even parity

Figure 34: The Parity Check option

36

Page 40

8.5.3 P4.2: Stop Bit

The Stop Bit allows the selection of the proper stop bit when transmitting to other pe ripheral

devices (such as printers). You can select the stop bit to be 1 or 2 depending upon the model

and make of the peripheral device (the instruction manual of the peripheral device should

indicate the number of stop bits used). Under default conditions, the stop bit is 2.

Figure 35: The Stop Bit option

At this point, if the ENTER/RANGE key is pressed, the unit reverts to its measurement mode.

37

Page 41

9 CYBERCOMM POTRABLE - DATA ACQUISITION

SOFTWARE (DAS FOR CYBERSCAN CON 200

ONLY)

The CyberComm Portable software is designed for Eutech’s CyberScan pH 100 and Con 200

meters to allow you a convenient means of capturing data for future analysis using other

software program such as LOTUS 123, EXCEL or DBASE in Windows

cumbersome to record and transfer data from one media to another before the required

processing can be done. With the CyberComm Portable, this redundant processing can be

eliminated or reduced.

9.1 System Requirements

To run the CyberComm Portable program, the following is required:

1. PC - IBM Compatible XT and above with CD-ROM Drive

2. EGA Monitor and above

3. Windows

4. Connecting communication RS232C cable

©

Operating System ’95 and above

9.2 Loading CYBERCOMM PORTABL E

©

. Often one finds it

Figure 36: Insert Eutech Instruments' CD-ROM containing Data Acquisition Software

(DAS) into your CD-ROM drive and click on START button and RUN command.

38

Page 42

Figure 37: Click on 'Browse' button and locate CD-ROM drive

Figure 38: Locate the CyberComm Portable Setup program in the CD-ROM under

"CyberComm Portable" sub-directory.

39

Page 43

Figure 39: Select "Setup" program and click the OPEN button.

Figure 40: InstallShield Wizard dialog box appears.

Figure 41: Click on Next button.

40

Page 44

Figure 42: Key in your name and company name and click NEXT button.

Figure 43: To select another Destination Directory to install the program, click on

BROWSE button. Otherwise, click NEXT button.

41

Page 45

Figure 44: Creating a new program folder. Click on NEXT button.

Figure 45: Click on NEXT button.

42

Page 46

Figure 46: The CyberComm Portable DAS program is fully installed. Click on FINISH

button to end installation.

43

Page 47

9.3 Running CyberComm Portable

Before running the CyberComm Portable program, please ensure that the RS232 cable is

connected between the computer’s serial port and the meter’s port.

A 1-meter RS232 cable, 9-pin male to 9-pin female connector (order no. EC-CA01M09F09) is

supplied with the CyberScan CON 200 meter.

For additional information on the connection, please refer to section 3.5 “Connecting the

RS232C cable (only for CyberScan Con 200)”.

Figure 47: Run the CyberComm Software program

44

Page 48

Figure 48: The opening screen will appear as above.

BUTTONS & CHECK-BOX

Enable Connection

•

– Click this button to enable communication between

meter and computer

Clear Readings

•

Save Readings

•

Time Stamp

•

– To clear all data and start all over again

– To save all data displayed in either *.dat or *.txt format.

– To include Time and Data stamp when collecting the data. Time

and date information comes from the computer.

45

Page 49

Figure 49: Under File Menu setting, you can change various parameters. Under ABOUT menu,

details of Eutech Instruments' contact information, email address and updates are shown.

MENU

Communication Settings

•

– To set communication port number, baud rate

speed, parity and stop bits protocol

Open

•

•

•

•

– To open previously saved data file

Save

– To save current data captured

Save As

Exit

– To save current data set in another format such as *.dat or *.txt

– To exit from CyberComm DAS program

46

Page 50

Figure 50: Communication Settings for computer's Com port. It must match with COM port settings on

CyberScan CON 200 meter. Please refer to Section 3.5.1 “RS232C Configuration” for the settings.

COMMUNICATION SETTINGS

Connecting Use

•

•

Baud Rate

- To select communication port, 1 or 2.

- To select different baud rate, 2400, 4800, 9600 or 19200 bps (bits per

second).

Parity

•

•

- To select different parity, Even, Odd or None.

Stop Bits

- To select different stop bits, 1 or 2.

Figure 51: Under SAVE AS menu, you can save your data as *.dat or *.txt formats

47

Page 51

9.4 Captu ring And Printing Data Into Computer Using

CyberComm Portabl e

After matching the Communication Settings between your computer using CyberComm DAS

and the CyberSCan CON 200 meter, you can now capture data into your computer for

analysis and storage purposes.

1. Ensure the 1-meter RS232 communication cable (supplied with the meter) is connected

between the computer and the CyberScan CON 200 meter’s Com port. Refer to section

3.5 “Connecting the RS232C Cable (Only For CyberScan CON 100)” for connection

procedure.

2. Switch on the CyberScan CON 200 meter and run the CyberComm DAS software as

indicated in Figures 47 and 48.

3. Click “ENABLE CONNECTION” button.

4. With the CyberScan CON 200 meter switched on, press the PRINT key to send data to

the computer. See Figure 52 below.

5. You can use MODE key on the meter and change to other parameter such as mV or Rel

mV and print data accordingly.

6. You can also check off the Time Stamp function, so as to print without the Time a nd Date

information.

7. You can click Clear Readings button to begin another set of measurements, or click Save

Readings to store readings for future retrieval.

Figure 52: A set of data print in CyberComm Portable DAS

48

Page 52

9.5 Trouble-shooting Guide

a) Problem: Unable to PRINT

When press PRINT key on the CyberScan CON 200 meter, the “Print” and “Err” annunciators

blink on the meter’s LCD screen as shown in Figure 53.

Figure 53: "Print" and "Err" icons blinking

POSSIBLE CAUSES SOLUTIONS

You have not "ENABLE CONNECTION" in the

CyberComm DAS program.

The "Communication Settings" in the CyberComm

DAS program is different from meter's setup.

The COM port number in the CyberComm DAS

program is wrong.

Your computer's COM port setting may be wrong. Check your computer's hardware settings (through

You may use the wrong communication cable. Make sure you use the RS232C cable supplied

Click on "ENABLE CONNECTION" in the CyberComm

DAS program.

Match the COM port number, baud rate, parity and

stop bits information between the CyberComm DAS

program and the meter.

Change the COM port number (1 or 2) in the

CyberComm DAS program.

Windows OS, BIOS, or any other OS) and refer to

computer's manual or consult with the computer's

manufacturer.

together with the meter (Part No. EC-CA01M09F09).

Check the RS232C configuration as described in the

meter's instruction manual.

b) Problem: Unusual characters appear in data

When press PRINT key on the CyberScan CON 200 meter, additional characters such as the

following appear.

06/18/2001 1:48:38 PM? Cond? -900? Temp: ?22.6

POSSIBLE CAUSES SOLUTIONS

The Baud rate, parity or stop bit information

are not matched.

To report any bugs, please e-mail to techsupport@eutechinst.com

Check the communication setup for both CyberComm DAS

program and meter and ensure both are the same.

49

Page 53

10 TROUBLESHOOTING & ELECTRODE CARE

10.1 Troubleshooting

ERROR

MESSAGE

(BLINKING)

ERR

ERR

CAL + ERR

PRINTER +

ERR

Unable to

switch on

INDICATES PROBABLE CAUSE CORRECTIVE ACTION

Invalid key

sequence

Upper/lower limit

reached

Unable to accept

calibration

Printing error

Battery problem

Wrong key press. Select correct key

INC/DEC keys presses

beyond the allowable limits.

1. Incorrect solution

conductivity/TDS value

entered.

2. Incorrect TDS factor

entered.

1. Printer is not ready or

unable to receive data.

2. Printer is improperly

connected.

1. Batteries not in place.

2. Incorrect battery

orientation.

3. Weak batteries.

Reselect parameter

within limits

1. Enter the correct

TDS or conductivity

value (note the

temperature of the

calibration

solution).

2. Enter the correct

TDS factor.

1. Ensure that printer

is set to receive

information. Check

also the SETUP

data

communication

settings.

2. Check the RS

232C port cable

connection.

1. Insert batteries.

2. Place the batteries

at the correct

orientation.

3. Replace with fresh

batteries or use

A.C. adapter.

50

Page 54

ERROR

MESSAGE

(BLINKING)

Incorrect

readings

Not

responding to

key press

Err 1 Memory write error

Err 2 Memory read error

Err 3 A/D error

Err 4 Keypad error

Err 5

INDICATES PROBABLE CAUSE CORRECTIVE ACTION

EEPROM read

error

1. Incorrect calibration.

2. Wrong temperature

coefficient %.

3. Wrong TDS factor.

4. Dirty electrode.

1. HOLD mode selected.

2. Internal program error.

1. Reset calibration

and re-calibrate

with correct

parameters.

2. Reset Temperature

compensation %.

3. Reset TDS factor.

4. Clean electrode in

isopropanol. If

electrode is coated

with contaminants,

clean using soft

tissue and recalibrate.

1. Cancel HOLD

mode.

2. Re-insert batteries.

Return to distributor for

repair or replacement.

Return to distributor for

repair or replacement.

Return to distributor for

repair or replacement.

Return to distributor for

repair or replacement.

Return to distributor for

repair or replacement.

51

Page 55

10.2 Electrode Care

The most important rule to follow is to always keep the electrode clean to ensure accurate

measurements. Always take care not to damage the cell.

For general cleaning, the use of de-ionized water will be sufficient. Rinse the electrode

thoroughly in the de-ionized water. After cleaning, wipe the electrode dry. Never touch the

sensors.

For intensive cleaning, when the electrode is contaminated, wash it carefully with isopropanol,

after which wash thoroughly with de-ionized water. Always ensure that there is no blockage of

the electrode cavity. If there is, use a gentle jet of water to dislodge any particles that may

have been stuck there.

Important

Never leave the electrode immersed in dilute or concentrated acids after taking

measurements. Quickly remove the electrode and rinse with de-ionized water thoroughly.

Short period storage:

it in a cool place.

Long period storage:

Disconnect the electrode from the meter and store it in a cool place.

For storage of electrode over short periods, dry the electrode and store

Clean the electrode thoroughly with de-ionized water and dry it.

52

Page 56

11 ADDITIONAL INFORMATION

What is Conductivity?

In general, conductivity is a value that represents how easily electrical charges can be

transported through a conductor. Conductors are substances that permit the movement of

electrical charge with relative ease.

Figure 39 shows a conductivity cell. It is an electrochemical cell for measuring the conductivity

of an electrolyte solution. This cell consists of two electrodes; an anode and a cathode,

separated by an electrolyte solution. The two electrodes are in the shape of plates of identical

size, both having an identical surface area of A cm

separated by the distance, L. The space between them is filled completely with water-soluble

electrolyte solution. Alternating current flows through both electrode plates.

2

. They are aligned parallel and are

Figure 54: Conductivity cell. An electrochemical cell for

measuring conductivity.

The negatively charged ions (anions) in the electrolyte migrate towards the anode and the

positively charged ions (cations) move towards the cathode. The result is the flow of electrical

current by ion movement.

The resistance to the movement of the charge between the two electrodes is inversely

proportional to their surface area and in direct proportion to their surface and also in direct

proportion to the distance between them. This is true for both electron movements in the metal

electrodes and ion movement in electrolytes. This relationship may be expressed by the

equation below.

R = r. (L/A) = r.k

Equation 1

53

Page 57

Where

= the resistance in ohms (Ω)

R

= the resistivity (Ω-cm)

r

= the surface area of the electrode (cm

A

= the distance between the electrodes (cm)

L

= the cell constant (cm

k

-1

)

2

)

The resistivity r is the index of how difficult it is for the current to flow through the solution. This

is a constant, determined for each electrolyte. The reciprocal of r is called the conductivity, C,

where

C=1/r

.

(In electrochemical terms, the conductivity is proportionally constant of the electrolyte, which is

an intrinsic property of the solution; and C is the conductance, the inverse of resistance for a

certain segment of the electrolyte).

However, we can use the terms conductance and conductivity interchangeably as an index of

how easily current can flow through an electrolyte, and C will be referred to as the

conductivity. This is an accepted general practice.

-1

is expressed in units of Siemens (S ohms

C

) per cm (S/cm). Using C, equation1 can be

reformulated as equation 2.

From equation 2, it is clear that we have a conductivity cell with a cell constant, k of 1 (i.e. 1

-1

), then the inverse of the electrode resistivity, R, (in ohms) will be the conductivity, C, in

cm

Equation 2

R=k/C

S/cm.

A conductivity cell with a cell constant of 1 is defined as an electro-chemical cell where each of

the electrode plates has a surface area of 1 cm

2

and the electrodes are aligned in parallel and

separated by a distance of 1 cm.

Conductivity can be defined in this way; however, since it will fluctuate depending on the

temperature of the electrolyte, in general, conductivity is specified at a standard reference

temperature of 25 °C.

Since the conductivity of the electrolyte is based on ion movement, it is natural that the

concentration of ions in the solution will have a great bearing on this. Therefore, the

conductivity can provide us with valuable indicators in gathering data on the nature of the ions

in the solution. The results of conductivity measurements are widely used in the

electrochemical field.

54

Page 58

12 ACCESSORIES AND CALIBRATION BUFFER

SOLUTIONS

12.1 Replacement Meter and Meter Accessories

Ordering Code No. Item

Deluxe CyberScan CON 200 Portable Conductivity/TDS Meter with RS232C

EC-CON200/03N

EC-CON100/03

EC-CON10/03N

EC-CONSEN21B

(For CyberScan

CON 100/200)

EC-CONSEN41B

(For CyberScan

CON 10)

EC-CONSEN71B

(For CyberScan

CON 100/200)

EC-CONSEN81B

(For CyberScan

CON 100/200)

EC-CAO1M09F09

EC-DA-2000

EC-CONWP-KIT

EC-POUCH-02 Carrying pouch for CyberScan hand-held meters.

EC-120-ADA 120 VAC power adapter (120 VAC/9 VDC, 50/60 Hz), 2-pin type.

EC-220-ADA 220 VAC power adapter (220 VAC/9 VDC, 50/60 Hz), 2-pin type.

Communication Interface and 16 memory (µS/cm, mS/cm; ppm, ppt, °C)

complete with 1 pc of conductivity electrode (EC-CONSEN21B), 1 pc of electrode

holder (15X000700), 1 pc of communication cable (EC-CAO1M09F09) and 1 pc of

Data Acquisition Software in CD-ROM (EC-DA-2000).

Standard CyberScan CON 100 Portable Conductivity Meter with 16 memory

(µS/cm, mS/cm; °C) complete with 1 pc of conductivity electrode (ECCONSEN21B) and 1 pc of electrode holder (15X000700).

Basic CyberScan CON 10 Portable Conductivity /TDS Meter (µS/cm, mS/cm;

ppm, ppt, °C) complete with 1 pc of conductivity electrode (EC-CONSEN41B) and

1 pc of electrode holder (15X000700).

Epoxy body conductivity electrode (k=1.0) with 2 platinum rings and built-in

temperature sensor, 1 m cable length.

Epoxy body conductivity electrode (k=1.0) with 2 stainless steel pins and built-in

temperature sensor, 1 m cable length.

Epoxy body conductivity electrode (k=0.1) with 2 platinum rings and built-in

temperature sensor, 1 m cable length.

Epoxy body conductivity electrode (k=10.0) with 2 platinum rings and built-in

temperature sensor, 1 m cable length.

CyberScan to PC communication cable - 9-pin male to 9-pin female connector, 1

m cable length.

©

DAS (Windows

200 & DAS for Bench meters.

Conductivity Kit for CON 10/100/200 Meter - Plastic Carrying Case comprises of 1

x 1413 µS, 12.88 mS KCl and 3000 ppm442 standard solutions (60 ml) and 1 x

rinse/waste water bottle (480 ml – empty).

version – CyberComm Portable) for CyberScan pH 100 & CON

55

Page 59

12.2 Calibration Solutions

Ordering Code No. Item

EC-CON-100BT 100 µS KCI Calibration Solution *, 480 ml bottle.

EC-CON-500BT 500 µS KCI Calibration Solution, 480 ml bottle.

EC-CON-1413BT 1413 µS KCI Calibration Solution, 480 ml bottle.

EC-CON1288BT 12.88 mS KCI Calibration Solution, 480 ml bottle.

EC-CON2764BT 2764 µS KCI Calibration Solution, 480 ml bottle.

EC-442-50BT 50 ppm 442 Calibration Solution *, 480 ml bottle.

EC-442-300BT 300 ppm 442 Calibration Solution, 480 ml bottle.

EC-442-1000BT 1000 ppm 442 Calibration Solution, 480 ml bottle.

EC-442-3000BT 3000 ppm 442 Calibration Solution, 480 ml bottle.

EC-CON-447BS 447 µS conductivity Sachets, 20 ml x 20 pcs.

EC-CON-1413BS 1413 µS Conductivity Sachets, 20 ml x 20 pcs.

EC-CON-2764BS 2764 µS Conductivity Sachets, 20 ml x 20 pcs.

EC-CON-15000BS 15000 µS Conductivity Sachets, 20 ml x 20 pcs.

Note: Shelf Life for Calibration Solutions is 3 years (otherwise 1 year as marked *)

56

Page 60

13 SPECIFICATIONS OF CYBERSCAN CON 10/100/200

Models CON 10 CON 100 CON 200

0 to 19.99, 199.9,

Conductivity range

Accuracy

Resolution 0.05% of Full Scale

TDS range

Resolution

Temperature range 0.0 to 100.0 °C

Accuracy

Resolution 0.1 °C

TDS factor 0.5

No. of calibration

points

Auto-ranging

capability

Averaging/stability Yes

Auto-off Yes

Memory 16 sets

User customization Yes

HOLD function Yes

Cell constant 1.0 0.1, 1.0 & 10.0

Temperature

coefficient

Temperature

compensation

Display Custom LCD

Inputs BNC, phono, power jack

Printing option Yes

Outputs RS 232 port/printer

Power 4 AAA batteries; 9 V DC adapter

Battery life > 200 hours

1999 µS/cm;

19.99 mS/cm

0 to 9.99, 99.9,

999 ppm; 9.99 ppt

0.01, 0.1, 1 ppm;

0.01 ppt

4, maximum 1 per

range

2 % per °C 0.0 to 10 % per °C (selectable)

Auto/manual (from 0 to 80 °C)

0 to 19.99, 199.9, 1999 µS/cm;

19.99, 199.9 mS/cm

±

1% Full Scale

0 to 9.99, 99.9,

999 ppm;

9.99, 99.9, 199 ppt

0.01, 0.1, 1 ppm/ppt

±

0.5 °C

5, maximum 1 per range

Yes

0.40 to 1.00

(selectable)

57

Page 61

14 WARRANTY & RETURN OF ITEMS

Eutech Instruments warrants this meter to be free from significant deviations in material and

workmanship for a period of three years from date of purchase. Eutech Instruments warrants

this probe to be free from significant deviations in material and workmanship for a period of six

months from date of purchase. Each instrument will have a warranty card with a specific serial

number. The warranty card must be endorsed by the Authorized Distributor at the point of

sale.

If repair or adjustment is necessary and has not been the result of abuse or misuse within the

designated period, please return – freight pre-paid – and correction will be made without

charge. Eutech Instruments alone will determine if the product problem is due to deviations or

customer misuse.

Out of warranty products will be repaired on a charged basis.

Exclusions

The warranty on your instrument shall not apply to defects resulting from:

•

Imprope r or inadequate maintenance by customer

•

Unauthorized modification or misuse

•

Operation outside of the environment specifications of the products

Return of items

Authorization must be obtained from our Customer Service Department or authorized

distributor before returning items for any reason. A “Return Goods Authorization” (RGA) form

is available through our authorized distributor. Please include data regarding the reason the

items are to be returned. For your protection, items must be carefully packed to prevent

damage in shipment and insured against possible damage or loss. Eutech Instruments will

not be responsible for damage resulting from careless or insufficient packing. A restocking

charge will be made on all unauthorized returns.

NOTE: Eutech Instruments Pte Ltd reserves the right to make improvements in design,

construction, and appearance of products without notice.

58

Page 62

For more information on Eutech Instruments products, contact your nearest Eutech Instruments

distributor or visit our website listed below:

Manufactured by:

Eutech Instruments Pte Ltd.

Blk 55, Ayer Rajah Crescent,

#04-14/24 Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0863

E-mail: marketing@eutechinst.com

Web-site: http://www.eutechinst.com

Distributed by:

Loading...

Loading...