Page 1

CyberComm 5000 Version 1.0.0

gyM

sy...

Data Acquisition Software

Installation & User Guide

CyberScan pH 5000/ 5500

CyberScan PC 5000/ 5500

CyberScan DO 5000/ PCD 5500

68X292334

Rev. 1 10/03

Technolo

adeEa

Page 2

PREFACE

Thank you for selecting a CyberScan Series 5000 touch screen meter. This meter comes with the

CyberComm 5000 Data Acquisition Software which allows you easy access and communication via a

computer with connection to the meter.

The instruction manual serves to explain the use of the CyberComm 5000 step-by-step installation and user

guide to help you familiarize with the software’s features and functions. It is structured sequentially with

illustration of active software screens and diagrams that explains the various functions and menus available.

This manual is written to cover as many anticipated applications and uses of the CyberComm 5000 software

along with CyberScan Series 5000 bench meters only. If there are doubts in the use of the software, please

do not hesitate to contact Technical Support at techsupport@eutechinst.com

assistance.

CyberComm 5000 software update is available to all customers who have purchased the Series 5000

meters. Please download the latest CyberComm 5000 version via our website at

www.eutechinst.com/cybercomm-software.htm

Eutech Instruments reserves the rights to change, make improvement and modify specifications without prior

notice and cannot accept any responsibility for damage or malfunction to the instrument caused by improper

use.

Copyright

Eutech Instruments Pte. Ltd.

Rev 1, 10/03.

©

2003 All rights reserved.

or call us at (65) 6778-6876 for

Page 3

TABLE OF CONTENTS

1 DATA ACQUISITION IN WINDOWS VERSION 4

1.1 The CyberComm 5000 Data Acquisition Software 4

1.2 System Requirements 4

1.2.1 Setting the Communication Parameters 4

2 INSTALLATION OF CYBERCOMM 5000 5

2.1 Loading of CD-ROM 5

2.2 User Name and Organisation Entry 6

2.3 Choose Destination Location 6

2.4 Setup Type 7

2.5 Select Program Folder 7

2.6 Start Copying Files 8

2.7 Setup Completion 8

3 GETTING STARTED 9

3.1 Welcome Screen 9

3.2 Print Configuration 10

3.3 Confirmation Prompt 11

3.4 File Options 12

3.5 Data File Information 13

3.6 Mode Selection 14

4 METER CONNECTED (SINGLE CHANNEL) 15

5 EXPORT DISSOLVED OXYGEN MEASUREMENT RESULTS

(FOR CYBERSCAN DO 5000 & PCD 5500 ONLY) 17

5.1 To export BOD Results to CyberComm 5000 17

5.2 To export OUR Results to CyberComm 5000 20

5.3 To export SOUR Results to CyberComm 5000 22

6 MENU BAR 24

6.1 Data Results Recording 25

7 COPY & PRINT PLOTS 26

7.1 Copy Plot 26

7.2 Print Plot 27

8 METER CONNECTED (DUAL CHANNEL) 28

8.1 Channel Configuration (For Dual Channel meters only) 28

8.2 Functions from Menu Bar 28

8.3 Data Results Recording 29

8.4 Copy & Print Plot 30

9 MEASUREMENT MODE OVERVIEW 31

10 RETRIEVE SAVED DATA 32

10.1 Display data in Notepad program 32

10.2 Import Data Readings into Microsoft Excel© 33

10.2.1 Steps to import data readings from a Microsoft Excel © worksheet: 33

10.2.2 Text Import Wizard- Step 1 of 3 34

10.2.3 Text Import Wizard- Step 2 of 3 35

10.2.4 Text Import Wizard- Step 3 of 3 36

11 ERROR MESSAGES AND PROMPTS 38

11.1 Communication Error 38

11.2 Print Configuration Settings Error 38

11.3 No Model Detected 38

11.4 Save Settings 38

12 PRINT READINGS 39

12.1 Printing using a serial printer 39

12.2 Setting Up the Printer 39

12.3 Connecting the Cable to the Computer 39

Page 4

1 DATA ACQUISITION IN WINDOWS VERSION

1.1 The CyberComm 5000 Data Acquisition Software

The CyberComm 5000 Data Acquisition Software (DAS) package is a user-friendly data acquisition package

that provides a convenient way to capture data for future analysis. This CyberComm 5000 is only able to run

on Windows

your meter and PC is bi-directional as the meter functions can be remotely controlled by the DAS. Data type

stored is in the ASCII format.

©

Windows is the registered trademark of Microsoft Corporation

1.2 System Requirements

To run the CyberComm 5000 Data Acquisition Software, the following items are required:

©

Operating System (refer to 1.2 System Requirements for details). Communication between

1 IBM Compatible PC Pentium and above

2 Windows Operating Systems 95 and above

3 VGA/SVGA Monitor with minimum 800 X 600 resolution

4 RS232C Serial Communication Cable

1.2.1 Setting the Communication Parameters

The meter is capable of different communication configurations for baud rate, parity and stop bits. The

values chosen for these parameters of the meter must match those chosen for the computer, same goes for

the serial printer if it is connected.

Page 5

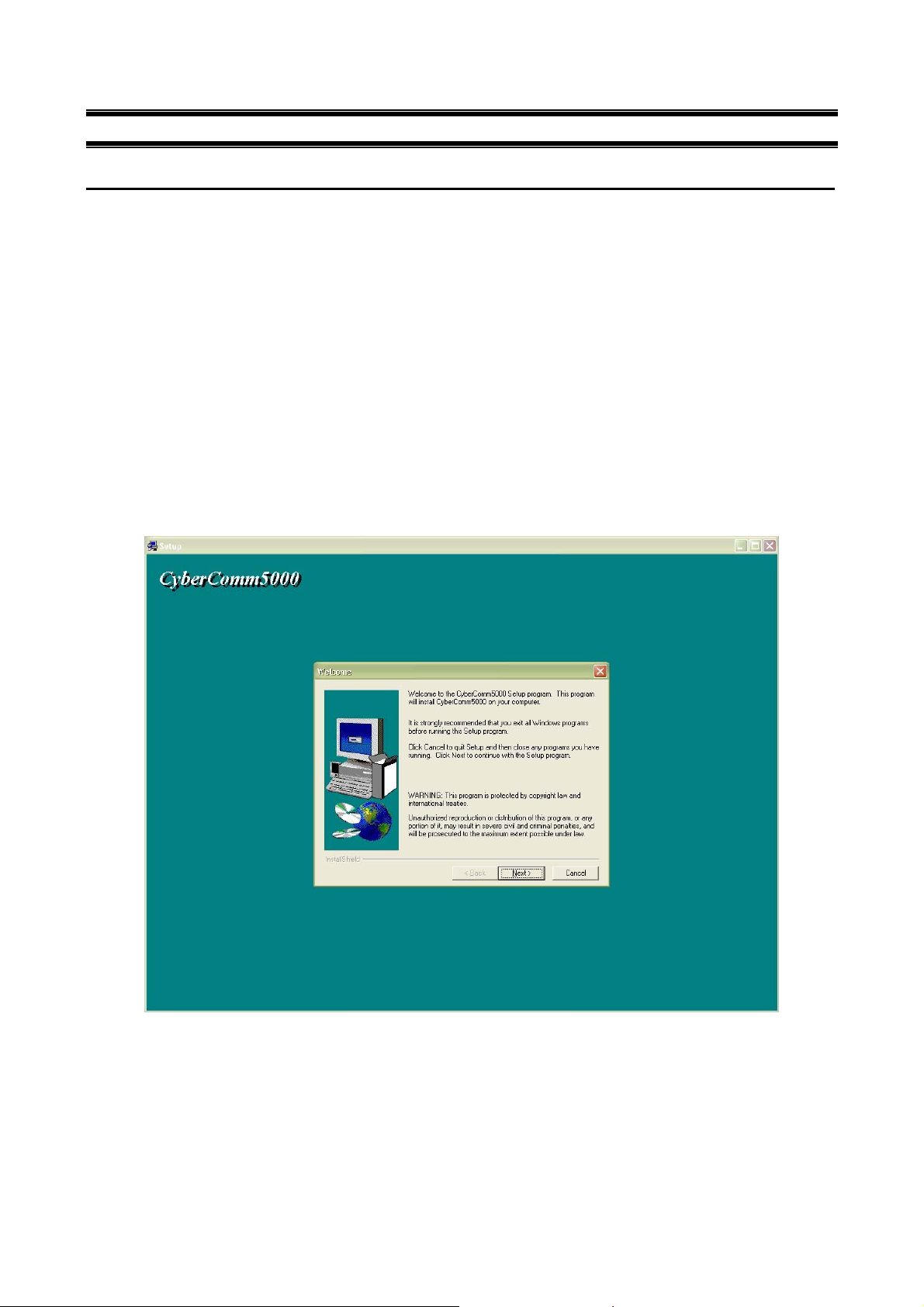

2 INSTALLATION OF CYBERCOMM 5000

2.1 Loading of CD-ROM

See Figure 1.

Before running the program, check that the CyberScan Series 5000 meter is properly connected to the

computer. It is preferable to connect to either one of the COM (serial) ports available on a computer. Note

the number of the COM port that you have connected to the meter as this will be required in setting up the

CyberComm DAS later.

a) Turn on the computer (PC).

b) Insert the CD-ROM provided into a CD-ROM drive of your PC.

c) To install the DAS, use the My Computer to view the file contents in your CD_ROM drive. Locate and

click onto the SETUP file under the CyberComm directory. Double-click again on this file and the

program automatically starts installation. Alternatively you can use the Add/Remove Programs feature in

Control Panel to install the CyberComm and follow the instruction accordingly. If in doubt, please refer to

your Microsoft Operating Manual for further details.

d) See Figure 1: Main Setup, click Next to continue setup process.

Figure 1: Main Setup

5

Page 6

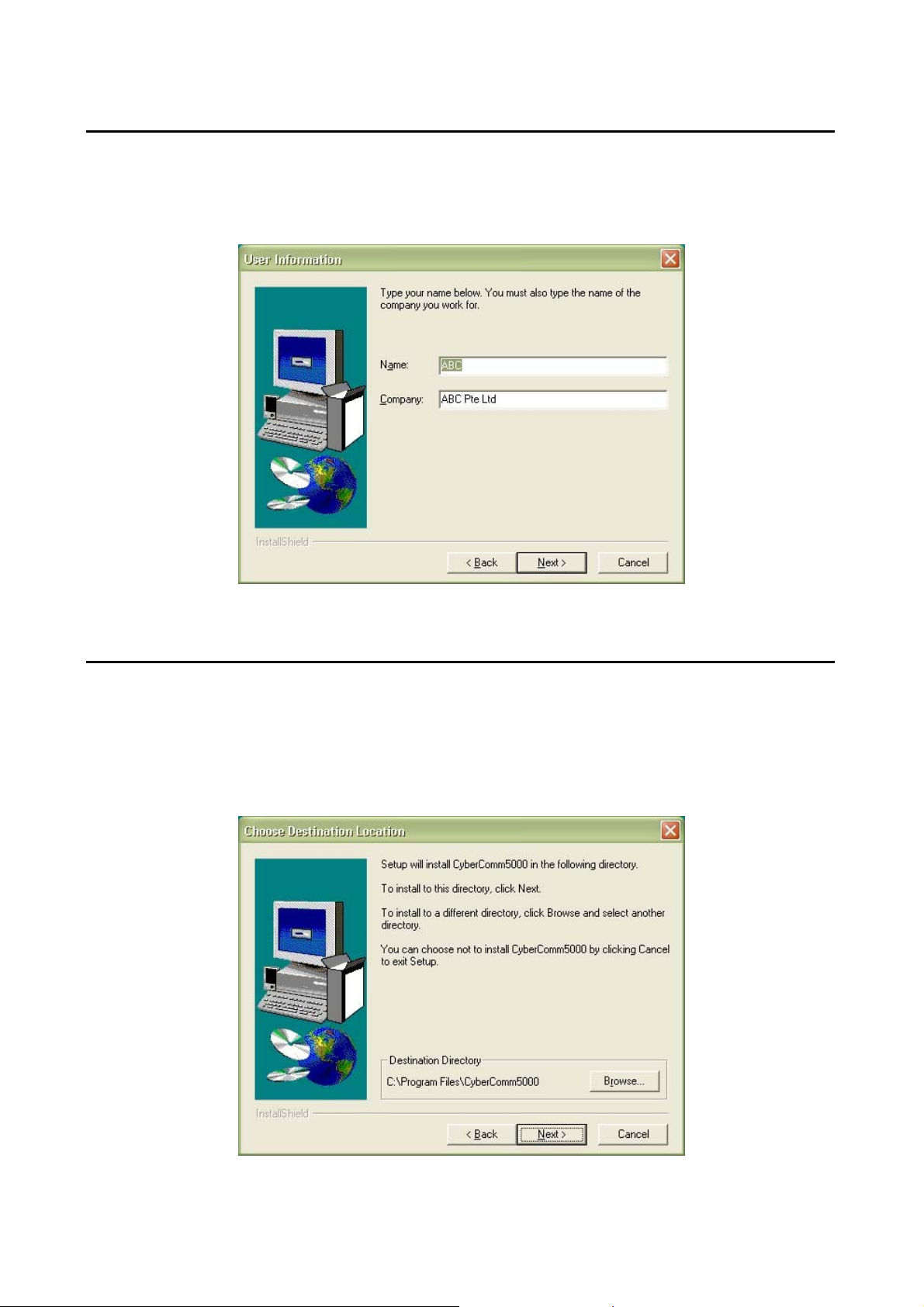

2.2 User Name and Organisation Entry

The CyberComm program (as below) prompts you to enter the name of the user and organization. See

Figure 2: User Information.

a) Key in the information in the respective fields.

b) Click Next to continue setup process. Click Back make changes to previous setup option.

Figure 2: User Information

2.3 Choose Destination Location

This setup option will install the CyberComm 5000 after the destination location is selected. See Figure 3:

Choose Destination Location.

a) Click Browse to select destination location.

b) Click Next to continue setup process. Click Back make changes to previous setup option.

Figure 3: Choose Destination Location

6

Page 7

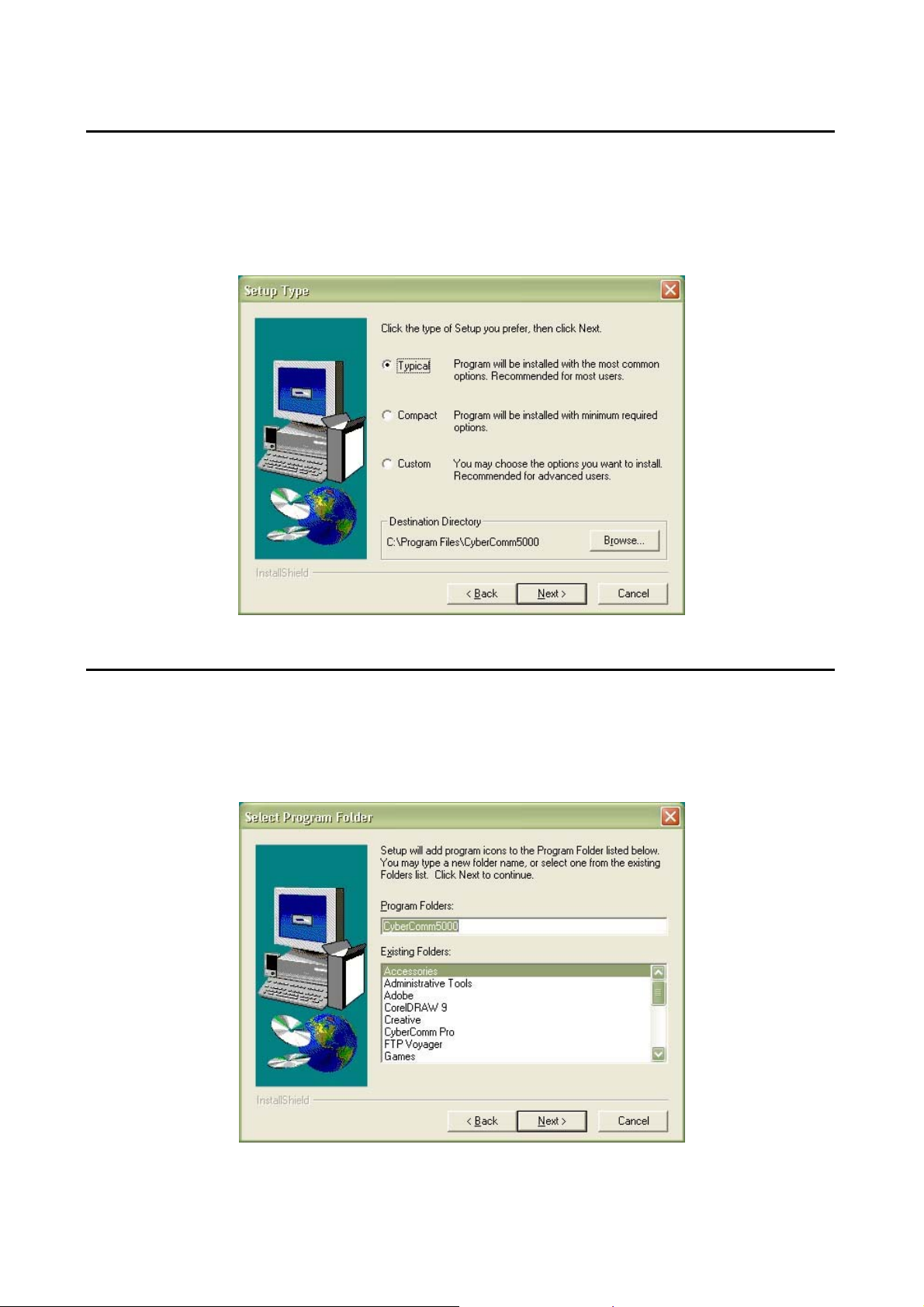

2.4 Setup Type

Select the setup type of the CyberComm 5000 preferred. Default is set as Typical. The destination directory

for the software to be located must be specified as well. See Figure 4: Setup Type.

a) Select Typical from the list of setup types.

b) Click Browse to select destination location.

c) Click Next to continue setup process. Click Back make change s to previous setup option.

Figure 4: Setup Type

2.5 Select Program Folder

Choose to have a new Program Folder or select one from the list of existing folders in which the CyberComm

5000 is to be located. Default is set as CyberComm 5000 to be named as a new Program Folder. See Figure

5: Select Program Folder.

a) Select to create a New Folder (e.g.: CyberComm 5000) or utilise an existing folder.

b) Click Next to continue setup process. Click Back make changes to previous setup option.

Figure 5: Select Program Folder

7

Page 8

2.6 Start Copying Files

This setup option displays the current settings selected in the previous setup options. See Figure 6: Start

Copying Files.

a) Click Next to continue setup process. Click Back make changes to previous setup option. Click Cancel

to terminate setup process.

Figure 6: Start Copying Files

2.7 Setup Completion

“Launch the program file” if you wish to use it instantaneously. Note: The file is now stored in your

designated hard-disk location. A shortcut of CyberComm 5000 will be created automatically on your desktop

upon setup completion. See Figure 7: Setup Complete.

a) Select to launch program file: CyberComm 5000.

b) Click Finish to complete setup process.

Figure 7: Setup Complete

8

Page 9

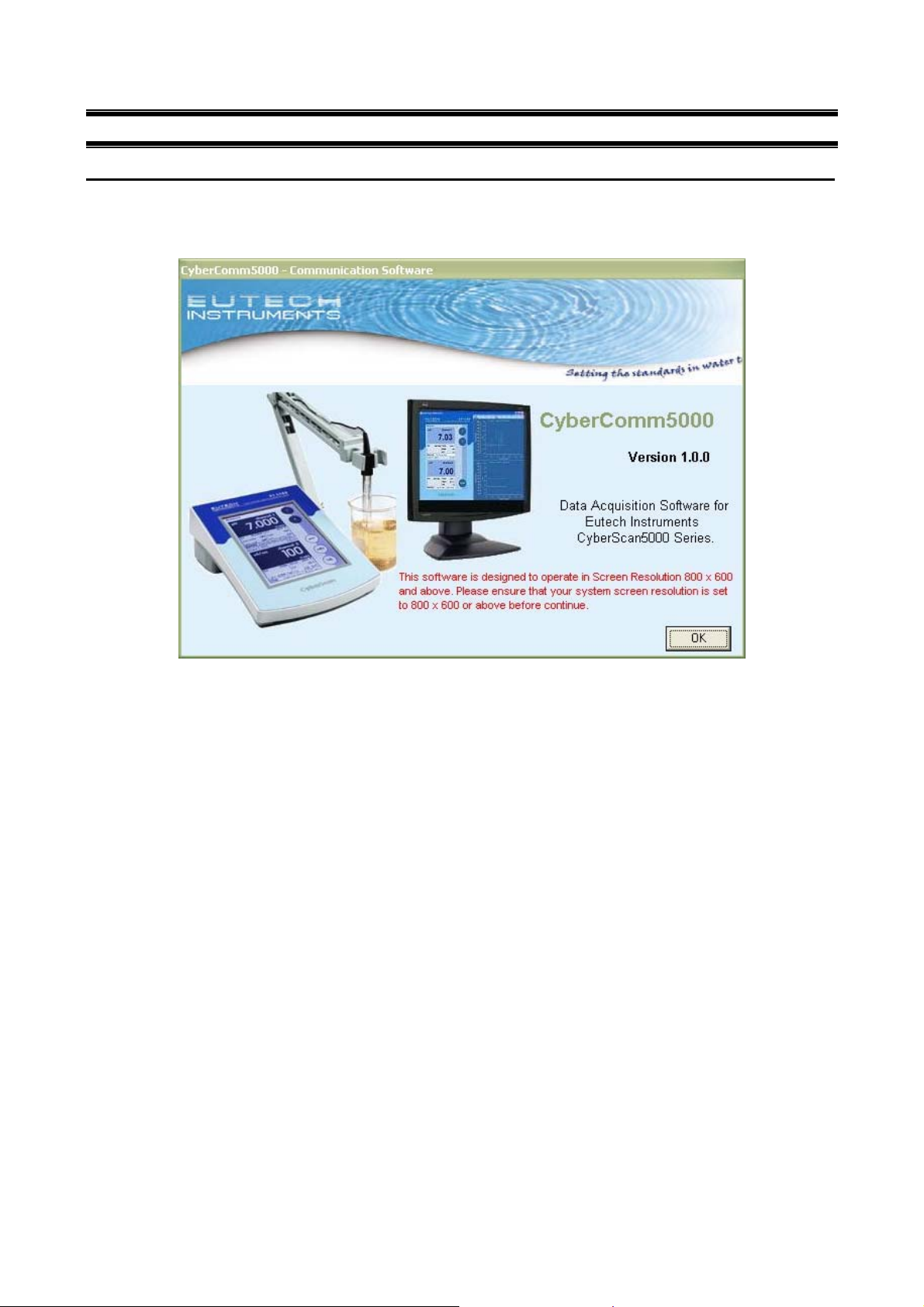

3 GETTING STARTED

3.1 Welcome Screen

See Figure 8: Welcome Screen.

a) Click OK after assessing the information provided.

Figure 8: Welcome Screen

9

Page 10

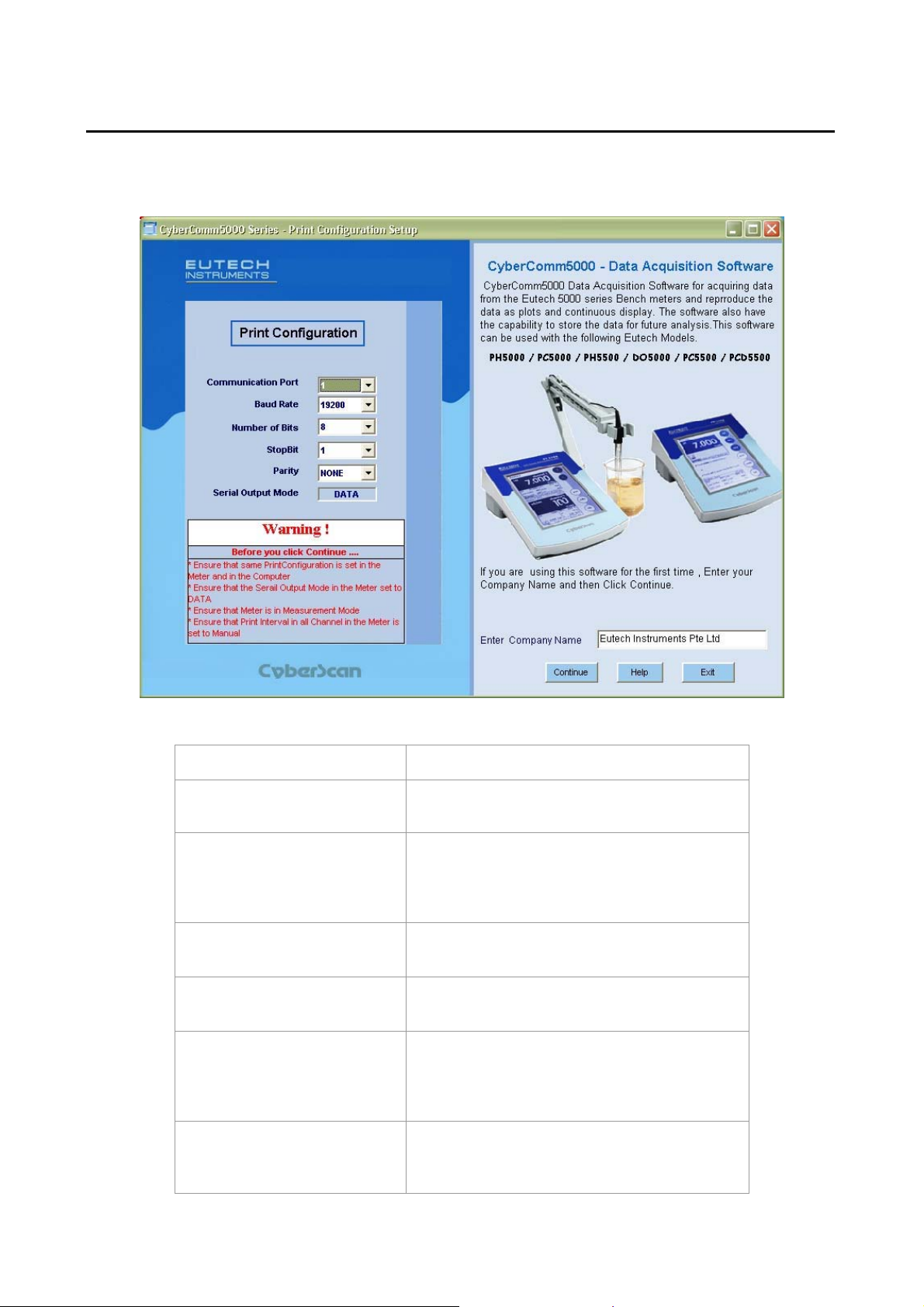

3.2 Print Configuration

See Figure 9: Print Configuration Setup.

Set the appropriate requirements for Print Configuration before connecting the meter.

Figure 9: Print Configuration Setup

Print Configuration Option Description

Communication Port

Connect using the preferred connection port

from the drop down menu; 1 or 2. Default is 1.

Baud Rate

Select preferred baud rate from the drop down

menu: 9600, 19200 and 38400. Default is

19200.

Number of Bits

Stop Bits

Select preferred Stop Bits from the drop down

menu; 7 or 8. Default is 8.

Select preferred Stop Bits from the drop down

menu; 1 or 2. Default is 1.

Parity

Select preferred parity from the drop down

menu: None (0), Odd (1) or Even (2). Default is

None (0).

Serial Output mode

Software default is set at DATA. Ensure meter

serial output mode is set at DATA.

10

Page 11

3.3 Confirmation Prompt

This Dialog box appears if from second DAS operation onwards, prompting user to overwrite on saved

measurement data or create another in the destinated directory. See Figure 10; Confirmation Prompt.

a) Click NO to create new measurement data. Go to Section 3.4: File Options, Page 12.

b) Click YES if you want to overwrite current saved data. Go to Section 3.5: Data File Information, Page

13.

c) Click Cancel if you do not want data to be saved.

Figure 10; Confirmation Prompt

11

Page 12

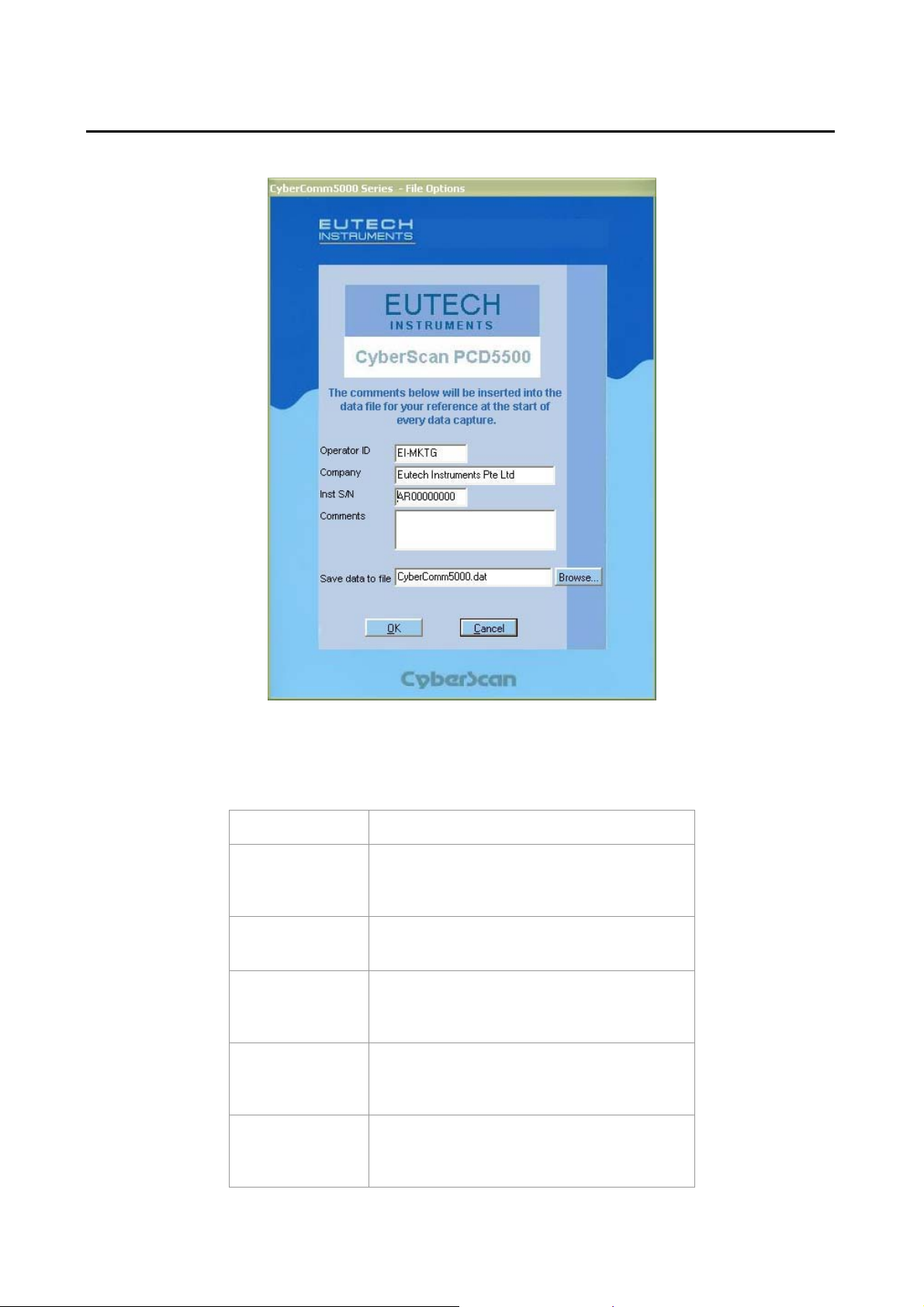

3.4 File Options

Clicking NO in Section 3.3: Confirmation Prompt will bring you to the File Options Screen.

Figure 11: File Options

This screen prompts user to enter information which will be inserted to the data file for reference at the start

of every data capture. See Figure 11: File Options.

Field Description

Operator ID

Identifies the user for every measurement

being conducted.

Company

Identifies the organisation of the user.

Inst S/N

The instrument’s serial number will be

reflected in reports generated.

Comments

Will be inserted to the data file for reference

at the start of every data capture.

Save Data to File

Assign the DAS to save data in the selected

destinated directory.

12

Page 13

3.5 Data File Information

Clicking YES in Section 3.3: Confirmation Prompt will bring you to the Data File Information Screen.

Figure 12: Data File Information

This screen displays the destination folder that eventual data will be saved as .dat format. See Figure 12:

Data File Information.

Single Channel Mode

This screen displays one channel’s data to be saved in the destination folder.

Dual Channel Mode

This screen displays both channels’ destination folders respectively.

13

Page 14

3.6 Mode Selection

See Figure 13: Standby Mode with Parameter Selection. The CyberScan PCD 5500 (as shown below)

allows you to select from several parameters (pH and Conductivity mode: pH, mV, Conductivity and Ion) (DO

mode selection: DO, BOD, OUR and SOUR). The selection of parameter modes depend on the meter

connected:

Meter Model

pH 5000 pH, mV

pH 5500 pH, mV, Ion

PC 5000 pH, mV, Conductivity

PC 5500 pH, mV, Conductivity, Ion

DO 5000 Dissolved Oxygen, BOD, SOUR, OUR

PCD 5500 pH, mV, Conductivity, Ion, Dissolved Oxygen, BOD, SOUR, OUR

Parameter Modes Available

Mode Selection

Dual Channel Selection

(For CyberScan pH 5500,

PC 5500 and PCD 5500

only)

Click to close/end DAS

operation

Figure 13: Standby Mode with Parameter Selection

14

Page 15

4 METER CONNECTED (SINGLE CHANNEL)

For CyberScan pH 5000, PC 5000 and DO 5000 which are single channel instruments, the DAS screen will

display a single parameter mode at one time. Select mode (Section 3.6: Mode Selection, Page 14) and the

current reading will be displayed respectively.

See

Figure 14: pH Measurement Mode- Single Channel.

Plot 1 shows Current Mode (pH, mV, conductivity, ion etc.) measurement graph on Channel 1 and Plot 2

shows Current measurement graph (Temperature).

Figure 14: pH Measurement Mode- Single Channel (pH 5000/5500, PC 5000/5500)

15

Page 16

Figure 15: Dissolved Oxygen Measurement mode- Single Channel (DO 5000, PCD 5500)

16

Page 17

5 EXPORT DISSOLVED OXYGEN MEASUREMENT RESULTS (FOR CYBERSCAN

DO 5000 & PCD 5500 ONLY)

5.1 To export BOD Results to CyberComm 5000

Select to go to DO mode on CyberComm 5000 (See Figure 16 ), click on BOD button to display screen as

shown in Figure 17.

Figure 16: Dissolved Oxygen (DO) Standby Mode

Figure 17: BOD Mode

17

Page 18

From the meter

Press BOD button during the BOD measurement mode on the meter. A screen on the meter will prompt to

enter a Bottle ID number that was saved previously. BOD Results will be shown as below on the meter. See

Figure 18.

BOD Results

mg/L

5

Seed ID: E1

Predilution:

Seed Volume:

NA

80 ml

Bottle Volume:

Initial DO:

Final DO:

Delta DO:

Figure 18: BOD Results screen displayed on meter

Press print to export BOD results to CyberComm 5000.

OK

150 ml

8.47 mg/L

5.86 mg/L

2.60 mg/L

print

18

Page 19

BOD Results information will be displayed on the CyberComm 5000 screen as shown below. See Figure 19.

Figure 19: BOD Results on CyberComm 5000

19

Page 20

5.2 To export OUR Results to CyberComm 5000

Select to go to DO mode on CyberComm 5000 (See Figure 16 ), click on OUR button to display screen as

shown in Figure 17.

Figure 20: OUR Mode

From the meter

Press OUR button from the DO mode main screen to go to OUR measurement mode. Press start to start

OUR measurement. See Figure 21. Press print to export OUR results to CyberComm 5000.

Measure - OUR (RUNNING)

mg/L/hr

0.00

1:35

STND

Not Standardized

z

Touch to begin measurement

stop

or

Touch to access stan dardize mode

std

z

August 12, 2002 9.32am

ID# ATC

autocal Salinity

mg/L mmHg

ON 0.0 ppt

1.28 732

STABLE

25.0°C

stop

Figure 21: OUR Measurement mode on meter

20

Page 21

OUR Results information will be displayed on the CyberComm 5000 screen as shown below. See Figure 22.

Figure 22: OUR Results on CyberComm 5000

21

Page 22

5.3 To export SOUR Results to CyberComm 5000

Select to go to DO mode on CyberComm 5000 (See Figure 16 ), click on SOUR button to display screen as

shown in Figure 23.

Figure 23: SOUR Mode

From the meter

Press SOUR button from the DO mode main screen to go to SOUR measurement mode. Press start to start

SOUR measurement. See Figure 21. Press print to export SOUR results to CyberComm 5000.

Measure - SOUR (RUNNING)

mg/hr/g

0.00

1:35

STND

Not Standardized

z

Touch to begin measurement

stop

or

Touch to access standardize mode

std

z

August 12, 2002 9.32am

ID# ATC

autocal salinity

mg/L mmHg

ON 0.0 ppt

1.28 732

STABLE

25.0°C

stop

Figure 24: SOUR Measurement mode on meter

22

Page 23

SOUR Results information will be displayed on the CyberComm 5000 screen as shown belo w. See Figure

25.

Figure 25: SOUR Results on CyberComm 5000

23

Page 24

6 MENU BAR

Figure 26: Menu Bar- Same for Single and Dual Channel Meters

Menu Button Description

Start/ Stop tracking

To stop current measurement and the DAS will immediately stop the data

recording. The button will change to ‘Start Tracking’ when Stop Tracking

mode is ON.

You are able to toggle between start and stop at any point of the

measurement to record data.

Zoom In/Out

These two buttons are for optimised view of the measurement graphs.

Click on the respective button to execute task.

Default

Click to have the display go to original settings.

Show Data

Click to view recorded data values in table format. The button will be

inactive when ‘Graph Value’ is ON.

Graph Value

Click to view recorded data values in graph format. The button will be

inactive when ‘Show Data’ is ON.

Copy Plot 1/ Plot 2 Click to copy the selected plot and paste it in other compatible application.

Print Plot1/ Plot 2

Click to print the selected plot via connected printer.

24

Page 25

6.1 Data Results Recording

When Show Data menu button is active, the display shows the values recording from the measurement

along with other information (time, temperature, slope etc) in a tabular format. See Figure 27: Data ResultsSingle Channel.

Data is captured approximately every 1 second upon start of measurement by default.

NOTE: Never touch the meter when the DAS is in operation.

Figure 27: Data Results- Single Channel

25

Page 26

7 COPY & PRINT PLOTS

7.1 Copy Plot

Select from the menu bar the function to be carried out. Select to Copy Plot 1 or Copy Plot 2.

See Figure 28: Copied plot in Word doc.

The figure below shows an example of copying a plot and pasting in a Microsoft word (.doc) document.

Figure 28: Copied plot in Word doc.

The DAS is capable of transferring the copied information to compatible applications.

Note:

Only one plot can be copied at a time.

26

Page 27

7.2 Print Plot

Select from the menu bar the function to Print Plot 1 or Print Plot 2.

See Figure 29: Print plot information. The figure below shows an example of printing a selected plot and the

print screen generated after this command. The selected information will be sent to the default printer on

your system for printing.

Note:

Only one plot can be printed at a time.

Figure 29: Print plot information

27

Page 28

8 METER CONNECTED (DUAL CHANNEL)

8.1 Channel Configuration (For Dual Channel meters only)

See Figure 30: Measurement mode: Dual Channel. Two display screens for respective parameters can be

viewed when dual channel selection is made on the meter. Select from the CyberComm 5000 screen for

Single OR Dual channel display.

a) Click 1 to display Channel 1 only.

(Plot 1 shows Channel 1 parameter readings and Plot 2 shows temperature readings)

b) Click 2 to display Channel 2 only.

(Plot 1 shows Channel 2 parameter readings and Plot 2 shows temperature readings)

c) Click Dual to display both channels (Dual button appears only in Mode Selection screen, page 14).

(Plot 1 shows Channel 1 parameter and temperature readings and Plot 2 shows Channel 2 parameter

readings and temperature readings)

8.2 Functions from Menu Bar

The current readings and data plots will be displayed whilst measurement is con ducted.

Select the functions to be executed from the menu bar same for the single channel mode of this program.

Figure 30: Measurement mode: Dual Channel

28

Page 29

8.3 Data Results Recording

See Figure 31: Data Results- Dual Channel. When Show Data menu button is active, the display shows the

values recording from the measurement along with other information (time, temperature, slope etc) in a

tabular format.

Data is captured approximately every 1 second upon start of measurement by default.

NOTE: Never touch the meter when the DAS is in operation.

Figure 31: Data Results- Dual Channel

29

Page 30

8.4 Copy & Print Plot

See Section 7: COPY & PRINT PLOTS, Page 26.

Select from the menu bar the function to be carried out. Select to Copy/ Print Plot 1 or 2.

The DAS is capable of transferring the copied information to compatible applications.

Note:

Only one plot can be copied/ printed at a time.

30

Page 31

9 MEASUREMENT MODE OVERVIEW

Plot 1

Graph Value

Use cursor to drag value line to show

the value at any point of

Menu Bar

Click respective button to execute the task.

measurement.

For Chann el 1

Title of Graph

Plot 2

For Ch an nel 2

Measurement Readings

only)

Channel Selection

12

Select or to switch screens

between Channel 1 and 2. Click

(Available in Dual Channel Meters

Figure 32: Measurement mode Overview

Last Calibration Done

to show both channels.

Dual

Current Date and Time

Current Measurement Value

Close Button

Click this button to

end DAS operation.

Perfor med

information

Sample ID & other

Scrolling Text Box

Last Standardization

to ease DAS operation.

Displays prom pts and information

31

Page 32

10 RETRIEVE SAVED DATA

10.1 Display data in Notepad program

a) Open up the Notepad program.

b) Go to File menu

c) Select Open

d) Select Program Files folder from the hard disk drive

e) Select CyberComm 5000 folder

f) Select CyberComm 5000

g) Select the ”.dat” file which you have saved your data readings.

See Figure 12: Data File Information

h) Double click on the selected “.dat” file

i) Data saved will be shown as per Figure 33: Data Results Report in Notepad .txt below.

Figure 33: Data Results Report in Notepad .txt

32

Page 33

10.2 Import Data Readings into Microsoft Excel©

You are able to view the Data Readings in a Microsoft

Excel© spreadsheet.

10.2.1 Steps to import data readings from a Microsoft Excel

In Microsoft Excel,

a) Go to File menu

b) Select Open

c) Select Program Files folder from the hard disk drive

d) Select CyberComm 5000 folder

e) Select CyberComm 5000

f) Select the ”.dat” file which you have saved your data readings

g) Double click on the selected “.dat” file

NOTE: The ‘Files of Type’ should be selected at ‘All Files (*.*)’.

See Figure 34.

©

worksheet:

Figure 34: Excel- File Open

33

Page 34

10.2.2 Text Import Wizard- Step 1 of 3

Once you open a “.dat” file from the CyberComm 5000 folder, a screen will appear. See Figure 35.

Fields

Delimited/ Fixed width

Default: ‘Delimited’

Select between delimited and fixed width for the preferred output layout of the file.

Start import at row

Default = ‘1’

Select the row of data to start importing into the Microsoft Excel

©

worksheet

File Origin:

Default: ‘Windows (ANSI)’

Figure 35: Step 1 of 3

34

Page 35

10.2.3 Text Import Wizard- Step 2 of 3

See Figure 36.

Fields

Delimiters

Default: ‘Tab’

Select ‘Comma’

Treat consecutive delimiters as one

Default: ‘Unchecked’

Text qualifier

Default: ‘*’

Figure 36: Step 2 of 3

35

Page 36

10.2.4 Text Import Wizard- Step 3 of 3

See Figure 37.

Fields

Column data format

Default: ‘General’

Advanced Text Import Wizard

See Figure 38.

Fields

Decimal Separator

Default: ‘.’

Thousands Separator

Default: ‘,’

Click OK to confirm and exit.

Figure 38: Advanced Text Import Settings

Click Finish to end the Text Import Wizard.

Figure 37: Step 3 of 3

36

Page 37

Figure below shows CyberComm data presented on a Microsoft Excel

©

worksheet. See Figure 39.

Figure 39: Excel Worksheet with imported “.dat” data

37

Page 38

11 ERROR MESSAGES AND PROMPTS

11.1 Communication Error

This error message appears when

a) An incompatible meter is connected

b) RS232 Cable is not connected

c) Mismatch in the communication settings

d) Meter not in measurement mode.

Figure 40: Communication Error

11.2 Print Configuration Settings Error

Meter’s print configuration’s serial output must be set at DATA. DATA is set as default for the CyberComm

5000.

Figure 41: Print Configuration Error

11.3 No Model Detected

This error message appears when an incompatible instrument is connected to the computer.

Figure 42: No model detected

11.4 Save Settings

Screen prompts to save the current settings or not.

Figure 43: Save Settings

38

Page 39

12 PRINT READINGS

12.1 Printing using a serial printer

Connect the CyberScan Series 5000 meter to the serial printer via RS232C cable (refer to the list of

accessories). The configuration of the RS232C port is as shown below.

Pin Number Description

1 2 Transmit Data

3 Receive Data

4 DSR (Data Send Ready)

5 GND (Ground)

6 7 8 RTS (Request to Send)

9 -

12.2 Setting Up the Printer

If the printer has a 25-pin connector, a 25-pin to 9-pin converter will have to be used. Use the following

configuration:

Pin of Meter Pin Number of Printer

2 (TXD) 3 (RXD)

4 (DSR) 20 (DTR)

5 (GND) 7 (GND)

12.3 Connecting the Cable to the Computer

a) If the computer has a 9-pin connector, insert the cable (EC-CA01M09F09) provided into the socket of the

computer, taking note of the gender of the two connectors.

b) If the computer has a 25-pin connector, use a 9-pin to 25-pin, male/ female converter with 9 pins and 25

holes for connection. This converter can be obtained from any computer store.

39

Page 40

For more information on Eutech Instruments products, contact your nearest distributor or visit our website

listed below:

Eutech Instruments Pte Ltd.

Blk 55, Ayer Rajah Crescent,

#04-16/24 Singapore 139949

Tel: (65) 6778 6876

Fax: (65) 6773 0836

E-mail: marketing@eutechinst.com

Web-site: http://www.eutechinst.com

Distributed by:

Loading...

Loading...