Eurtotherm 2216e, 2208e, 2204e Engineering Handbook

2200e

Engineering

Handbook

2200e Series Controllers

HA029989/3

July 2014

2200e Series Installation and Configuration Handbook Contents

2200e Series Controllers

Installation and Configuration Handbook

Models 2216e, 2208e and 2204e

Contents

1 Installation ................................................................................................................................................ 1-1

1.1 Instrument Layouts ......................................................................................................................................... 1-1

1.1.1 Outline Dimensions ................................................................................................................................................................................... 1-2

1.1.2 Recommended minimum spacing of controllers ............................................................................................................................. 1-2

1.2 Introduction.................................................................................................................................................... 1-3

1.2.1 Controller labels ......................................................................................................................................................................................... 1-3

1.3 Mechanical Installation ................................................................................................................................... 1-3

1.3.1 Unplugging and plugging-in the controller ........................................................................................................................................ 1-3

1.4 Wiring ............................................................................................................................................................. 1-4

1.4.1 Wire Sizes ..................................................................................................................................................................................................... 1-5

1.4.2 Sensor input connections ........................................................................................................................................................................ 1-6

1.4.3 Outputs 1 and 2 connections ................................................................................................................................................................. 1-6

1.5 PDS Modes ...................................................................................................................................................... 1-7

1.6 Snubbers ......................................................................................................................................................... 1-7

1.7 Typical single loop wiring diagram ................................................................................................................. 1-7

1.8 Logic Drive Fan Out ........................................................................................................................................ 1-8

1.9 EIA232/485/422 Communication connections .................................................................................................. 1-8

1.9.1 Wiring of EIA-485 serial communication links................................................................................................................................... 1-9

1.10 DeviceNet® Wiring to Series 2200e Controllers ............................................................................................ 1-10

1.10.1 DeviceNet Terminal Functions ............................................................................................................................................................. 1-10

1.10.2 Wiring Interconnections for DeviceNet Communications ........................................................................................................... 1-10

2 Operation .................................................................................................................................................. 2-1

2.1 Front Panel Layout .......................................................................................................................................... 2-1

2.2 Getting Started ............................................................................................................................................... 2-3

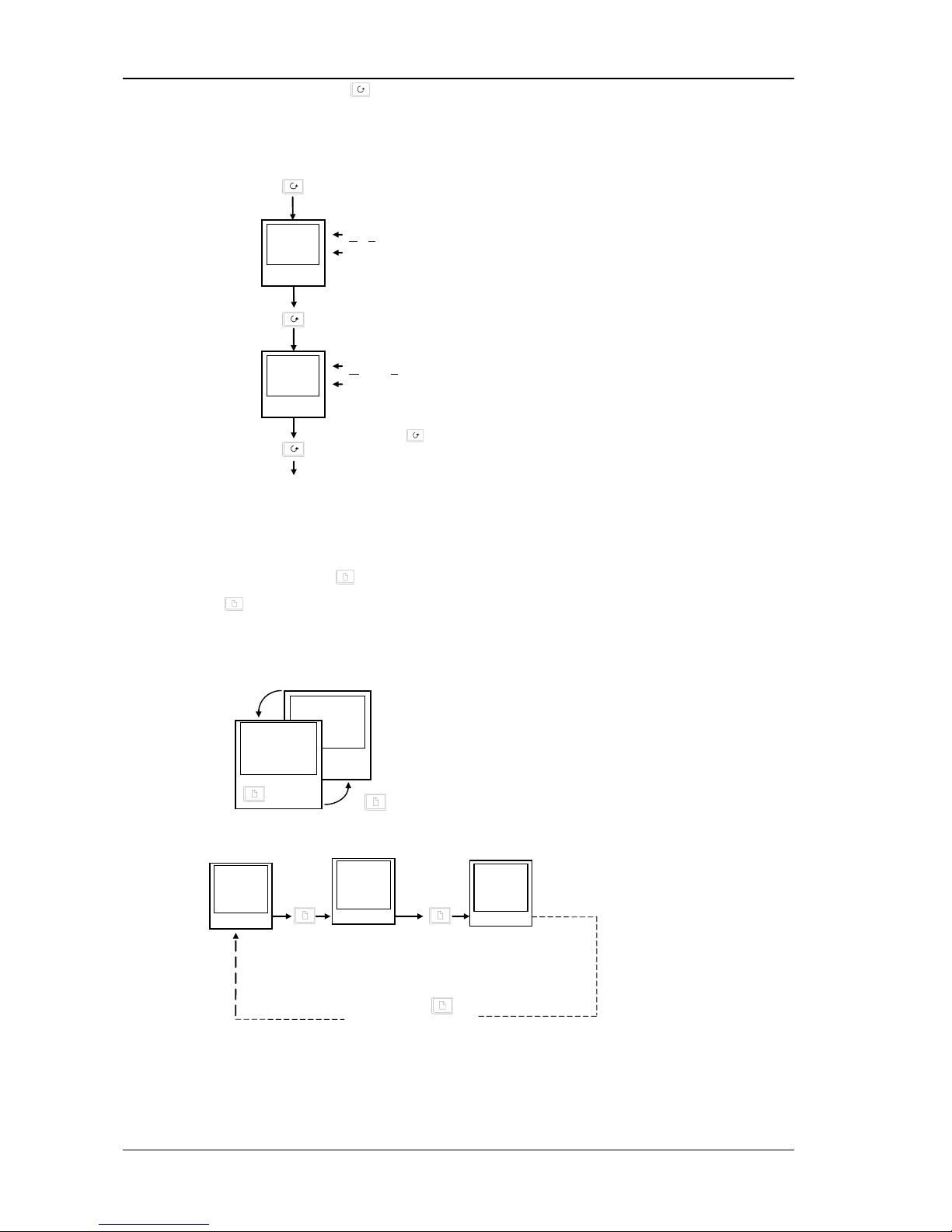

2.2.1 To View The Process Value and Setpoint ........................................................................................................................................... 2-3

2.2.2 To Adjust The Setpoint ............................................................................................................................................................................. 2-3

2.2.3 To View The Display Units ....................................................................................................................................................................... 2-3

2.2.4 Use Of The “SCROLL” Button ........................................................................................................................................................ 2-4

2.2.5 Use Of The ‘PAGE’ Button ............................................................................................................................................................... 2-4

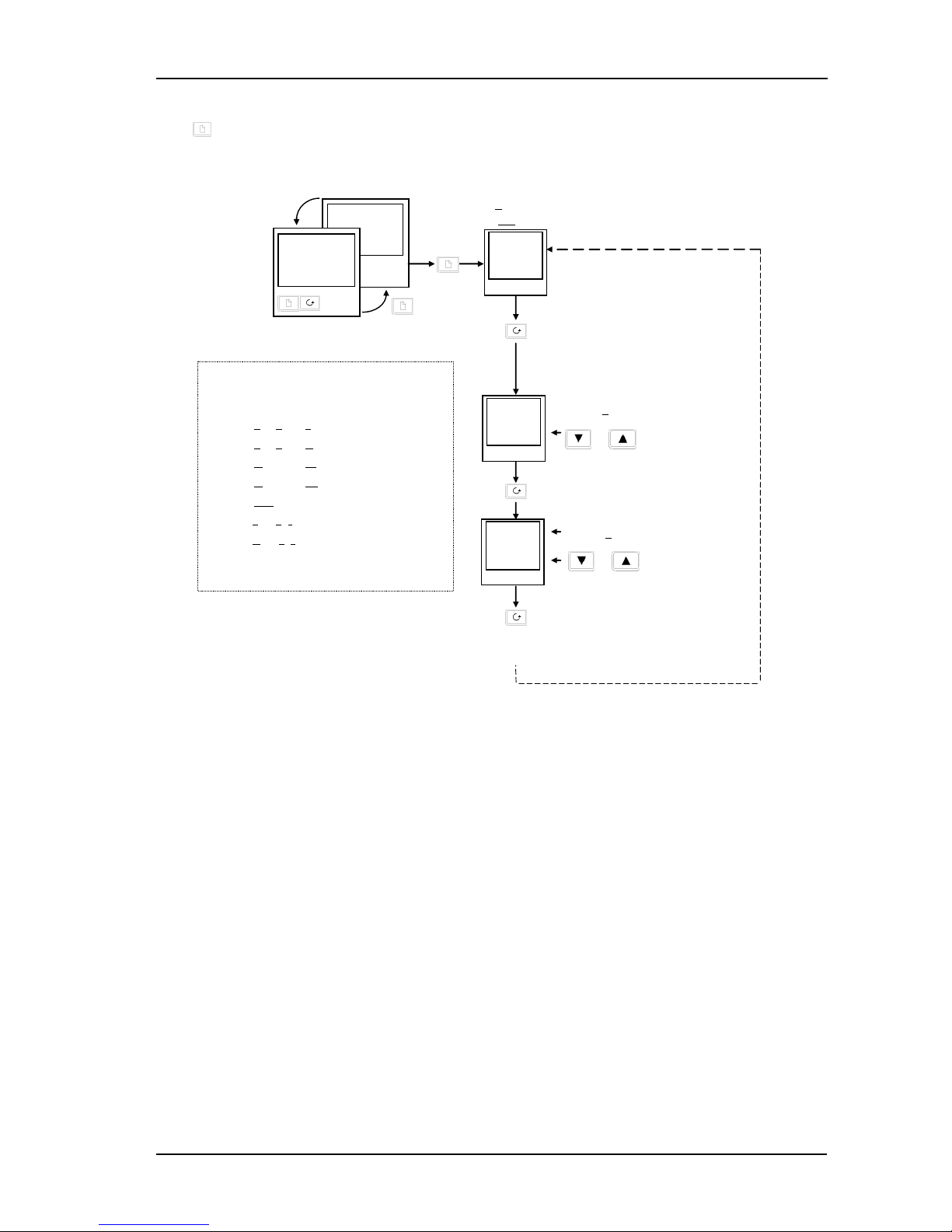

2.3 Parameter Lists ............................................................................................................................................... 2-5

2.4 Manual or Automatic Control ......................................................................................................................... 2-6

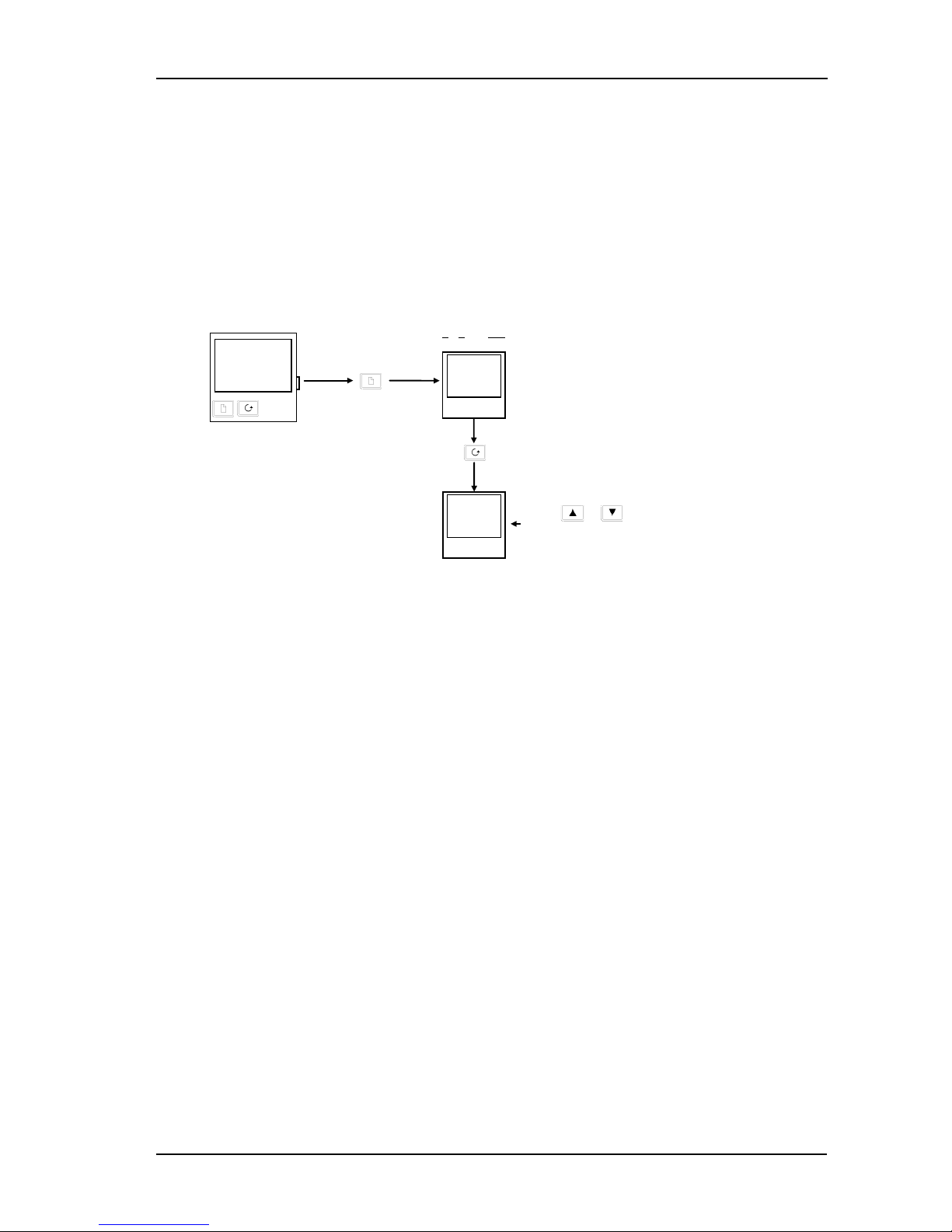

2.4.1 To Select Auto/Manual Operation ........................................................................................................................................................ 2-6

2.4.2 To Manually Adjust Output Power........................................................................................................................................................ 2-6

2.5 Selecting SETPOINT 1 OR SETPOINT 2 ............................................................................................................. 2-7

2.5.1 To Select Setpoint 1 orSetpoint 2 ......................................................................................................................................................... 2-7

2.6 Ramp Dwell Function ...................................................................................................................................... 2-7

2.6.1 To Set up a Ramp/Time Program .......................................................................................................................................................... 2-8

2.6.2 To Run the Program .................................................................................................................................................................................. 2-8

2.6.3 Power Failure During Program Run ...................................................................................................................................................... 2-8

2.7 Location of Parameters - Block Diagram ......................................................................................................... 2-9

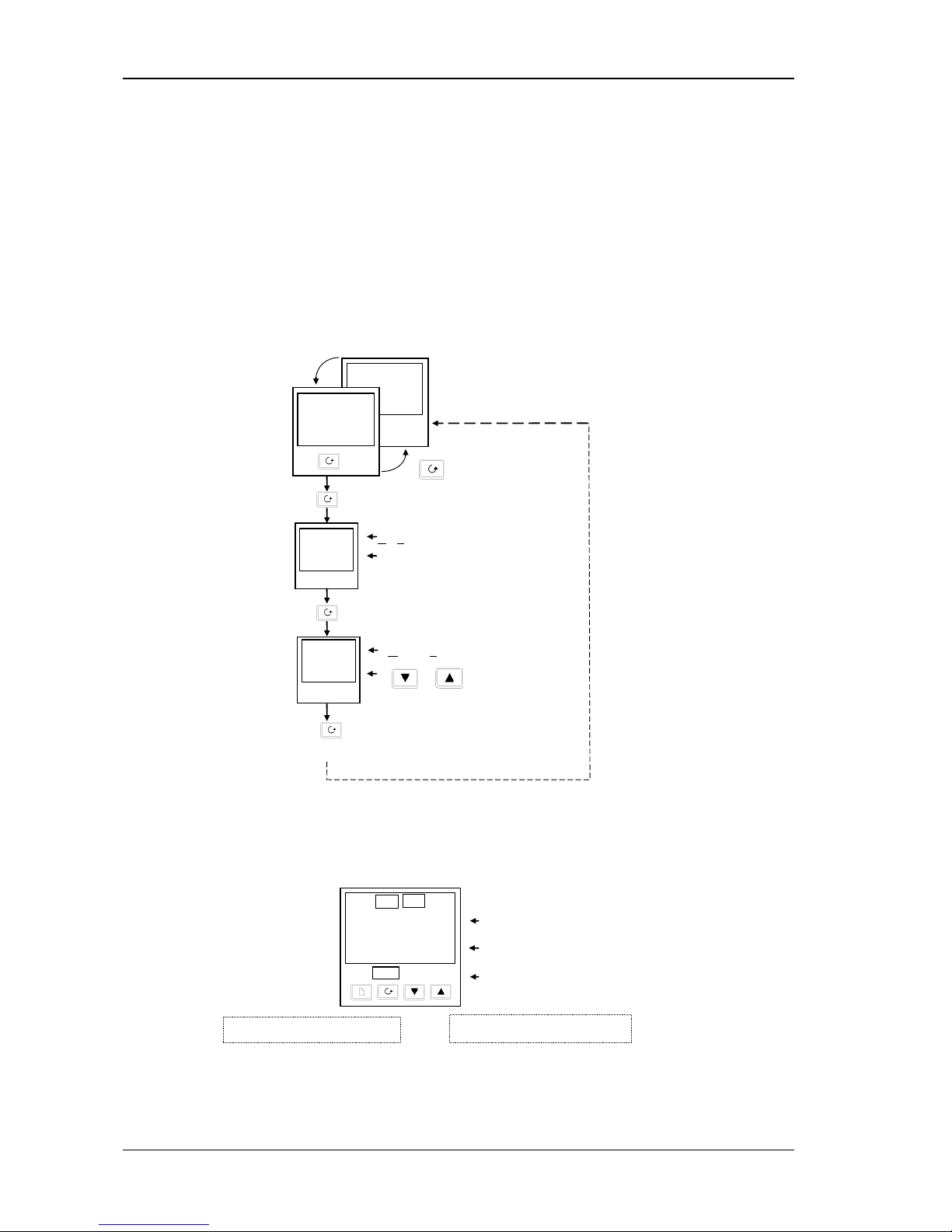

2.8 Navigation Diagram ...................................................................................................................................... 2-10

2.9 Parameter Tables .......................................................................................................................................... 2-11

2.9.1 HOME Display ............................................................................................................................................................................................ 2-11

2.9.2 Alarm List .................................................................................................................................................................................................... 2-11

2.9.3 Autotune List ............................................................................................................................................................................................. 2-12

2.9.4 PID List ......................................................................................................................................................................................................... 2-12

2.9.5 Setpoint List ............................................................................................................................................................................................... 2-12

2.9.6 Input List ..................................................................................................................................................................................................... 2-13

2.9.7 On/Off List.................................................................................................................................................................................................. 2-13

2.9.8 Output List ................................................................................................................................................................................................. 2-13

2.9.9 Communications List ............................................................................................................................................................................... 2-14

2.9.10 Access List .................................................................................................................................................................................................. 2-14

2.10 Alarms .......................................................................................................................................................... 2-15

2.10.1 Types of Alarm Used in the 2200 ........................................................................................................................................................ 2-15

2.11 Alarm Relay Output ...................................................................................................................................... 2-16

2.11.1 Setting Alarm Levels ................................................................................................................................................................................ 2-16

2.11.2 Alarm Indication and Acknowledgement.......................................................................................................................................... 2-17

2.11.3 Diagnostic Alarms .................................................................................................................................................................................... 2-18

i Part No. HA029989 Issue 3 CN31940 July-14

Contents 2200e Series Installation and Configuration Handbook

3 Access Levels ............................................................................................................................................ 3-1

3.1 The Different Access Levels ............................................................................................................................. 3-1

3.2 Selecting An Access Level ................................................................................................................................ 3-1

3.2.1 Access list header ....................................................................................................................................................................................... 3-1

3.2.2 Password entry ............................................................................................................................................................................................ 3-1

3.2.3 Level Selection ............................................................................................................................................................................................. 3-2

3.2.4 Configuration password ............................................................................................................................................................................ 3-2

3.2.5 Configuration level ..................................................................................................................................................................................... 3-2

3.2.6 To Return to Operator Level ................................................................................................................................................................... 3-2

3.3 Edit Level ........................................................................................................................................................ 3-3

3.3.1 To Set Operator Access to a Parameter .............................................................................................................................................. 3-3

3.3.2 To Hide or Reveal a Complete List ........................................................................................................................................................ 3-3

3.3.3 To Promote a Parameter .......................................................................................................................................................................... 3-3

4 Tuning....................................................................................................................................................... 4-1

4.1 What Is Tuning?............................................................................................................................................... 4-1

4.2 Automatic Tuning ............................................................................................................................................ 4-1

4.2.1 Heating and Cooling Output Cycle Times ........................................................................................................................................... 4-1

4.3 How To Tune ................................................................................................................................................... 4-2

4.3.1 Typical automatic tuning cycle ............................................................................................................................................................... 4-2

4.3.2 Calculation of the cutback values .......................................................................................................................................................... 4-2

4.4 Manual Tuning ................................................................................................................................................ 4-3

4.4.1 Setting the cutback values ....................................................................................................................................................................... 4-3

4.4.2 Integrating Action and Manual Reset ................................................................................................................................................... 4-4

4.4.3 Automatic Droop Compensation (Adc) ............................................................................................................................................... 4-4

5 Configuration ........................................................................................................................................... 5-1

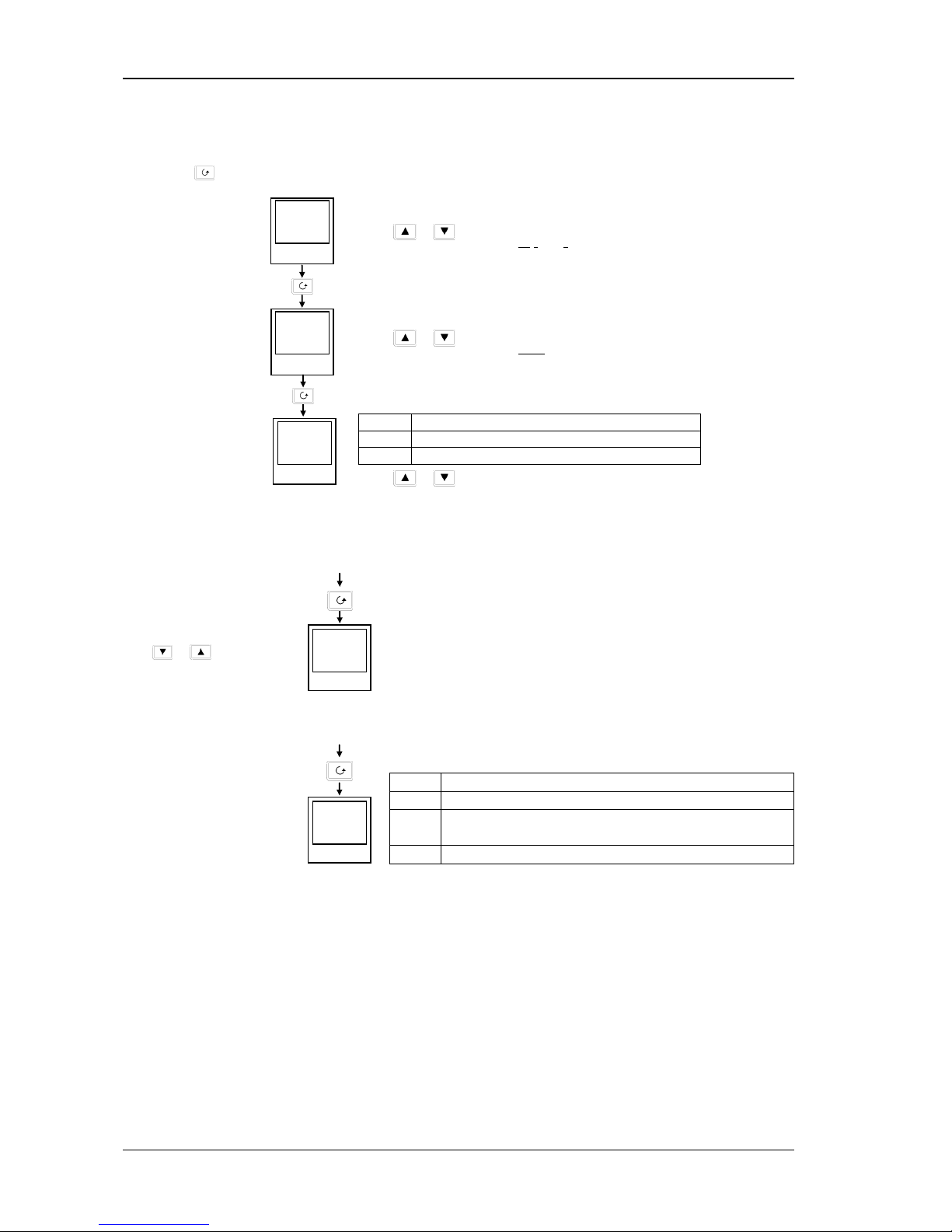

5.1 To Select Configuration Level .......................................................................................................................... 5-1

5.2 To Select a Configuration Parameter ............................................................................................................... 5-2

5.3 To Leave Configuration Level .......................................................................................................................... 5-2

5.4 Steps Involved In Configuring A Controller ..................................................................................................... 5-2

5.5 Navigation Diagram (PART A).......................................................................................................................... 5-3

5.6 Configuration Parameter Tables ...................................................................................................................... 5-5

5.6.1 Instrument Configuration ......................................................................................................................................................................... 5-5

5.6.2 Input Configuration .................................................................................................................................................................................... 5-6

5.6.3 Calibration Configuration ......................................................................................................................................................................... 5-6

5.6.4 Alarm Configuration .................................................................................................................................................................................. 5-7

5.6.5 Logic Inputs Configuration - 2208e and 2408e only. ....................................................................................................................... 5-7

5.6.6 AA Alarm Relay Configuration - 2208e and 2408e only ................................................................................................................. 5-8

5.6.7 Digital Communications Configuration ................................................................................................................................................ 5-8

5.6.8 Output 1 Configuration ............................................................................................................................................................................ 5-9

5.6.9 Output 2 Configuration ......................................................................................................................................................................... 5-10

5.6.10 Output 3 Configuration ......................................................................................................................................................................... 5-10

5.6.11 Output 4 Configuration ......................................................................................................................................................................... 5-10

5.6.12 Password Configuration ......................................................................................................................................................................... 5-10

5.6.13 Exit Configuration .................................................................................................................................................................................... 5-10

5.7 Configuration of Digital Communications ..................................................................................................... 5-11

5.7.1 To Configure the Function, and Baud Rate ..................................................................................................................................... 5-11

5.7.2 To Set Instrument Address ................................................................................................................................................................... 5-11

5.8 DeviceNet...................................................................................................................................................... 5-12

5.8.1 The EDS File ............................................................................................................................................................................................... 5-12

5.8.2 ODVA Compliance ................................................................................................................................................................................... 5-12

6 User Calibration ........................................................................................................................................ 6-1

6.1 What is the Purpose of User Calibration? ........................................................................................................ 6-1

6.2 User Calibration Enable ................................................................................................................................... 6-1

6.2.1 The User calibration configuration List ................................................................................................................................................ 6-1

6.3 Single Point Calibration ................................................................................................................................... 6-2

6.4 Two Point Calibration ...................................................................................................................................... 6-3

6.5 Calibration Points and Calibration Offsets ....................................................................................................... 6-3

7 Alarm Configuration ................................................................................................................................. 7-1

7.1 Definition Of Alarms And Events ..................................................................................................................... 7-1

7.1.1 Types of Alarms ........................................................................................................................................................................................... 7-1

7.2 Digital Output Functions ................................................................................................................................. 7-2

7.3 Step1 - To Configure the Four ‘Soft’ Alarms .................................................................................................... 7-3

7.4 Step 2 - To Attach an Alarm to A Physical Output ........................................................................................... 7-4

ii Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Contents

7.5 Step 3 - To Group Alarms on a Single Output ................................................................................................. 7-5

7.6 Step 4 - To Remove Alarms From An Output ................................................................................................... 7-5

8 Motorised Valve Control ........................................................................................................................... 8-1

8.1 Parameters For Motorised Valve Control ........................................................................................................ 8-1

8.2 Commissioning the Motorised Valve Controller .............................................................................................. 8-1

8.2.1 Adjusting the minimum on-time ‘Ont.H’............................................................................................................................................ 8-1

8.3 Motorised Valve Applications ......................................................................................................................... 8-2

8.3.1 Auto Tuning ................................................................................................................................................................................................. 8-2

8.3.2 Valve Positioner Set-up Table ................................................................................................................................................................ 8-2

9 Load Current Monitoring and Diagnostics ................................................................................................ 9-1

9.1 Load Current Monitoring and Diagnostics ....................................................................................................... 9-1

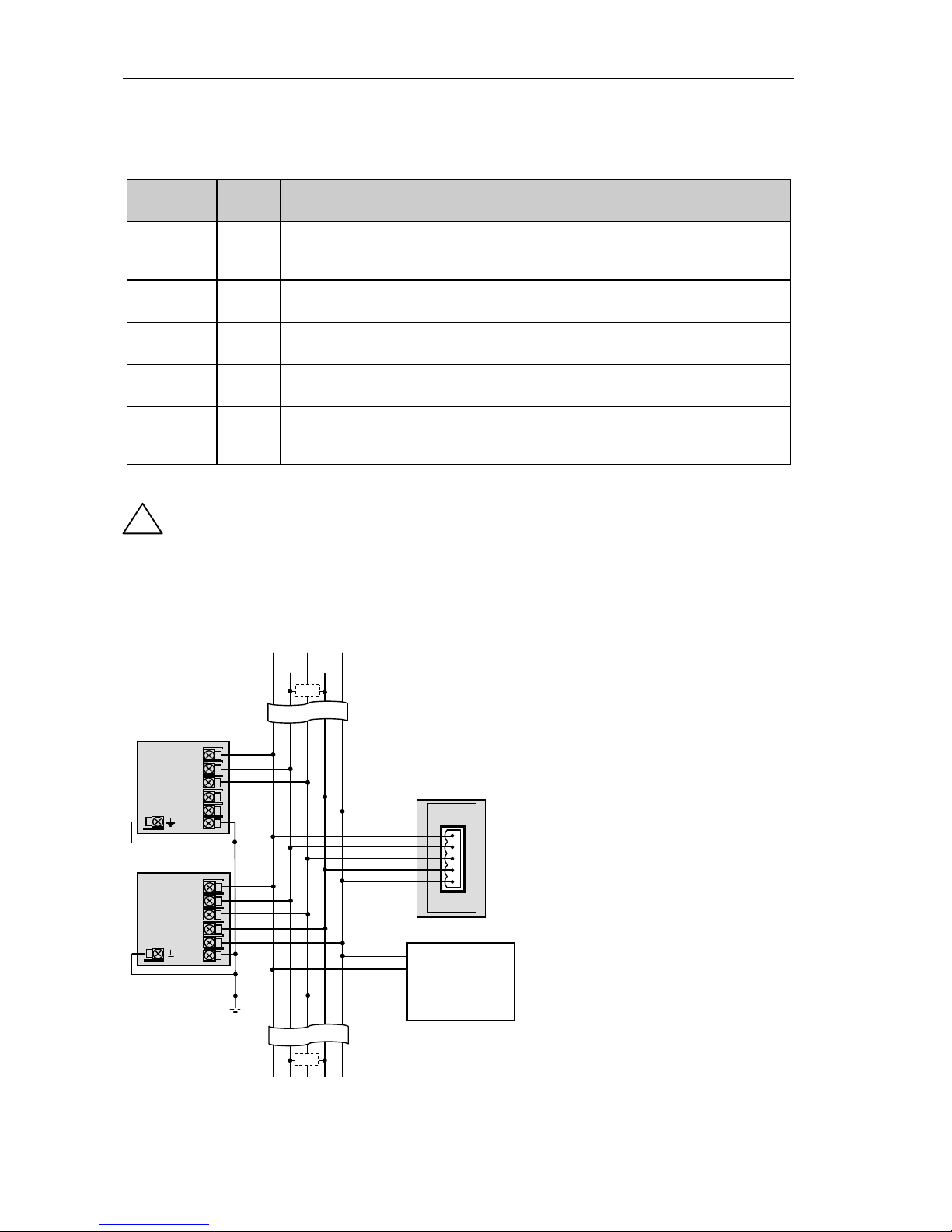

9.2 Example Wiring Diagram (For mode 1 & 2 operation) ..................................................................................... 9-2

9.3 Example Wiring Diagram (for mode 5 operation) ............................................................................................ 9-3

9.4 Operation ....................................................................................................................................................... 9-4

9.4.1 To Read Load Current (modes 2 and 5 only) .................................................................................................................................... 9-4

9.4.2 To Display Load Current Continuously in the Lower Readout (modes 2 and 5 only) ........................................................... 9-4

9.4.3 Display Modes ............................................................................................................................................................................................. 9-4

9.4.4 How Heater Alarms Are Displayed ........................................................................................................................................................ 9-5

9.5 To Set The Alarm Trip Levels .......................................................................................................................... 9-5

9.6 Relay Outputs ................................................................................................................................................. 9-6

9.7 To Configure PDS Load Current Diagnostics.................................................................................................... 9-6

9.7.1 To Configure the Logic Module for PDS modes 1 or 2 .................................................................................................................. 9-6

9.7.2 To configure Logic Input 1 for PDS (Mode 5 only) ......................................................................................................................... 9-7

9.8 To Configure Low and High Current Trip Alarms............................................................................................. 9-7

9.9 To Attach Soft Alarms To A Relay Output ....................................................................................................... 9-8

9.10 The Scaling Factor .......................................................................................................................................... 9-9

9.10.1 To Adjust The Scaling Factor .................................................................................................................................................................. 9-9

10 Retransmission .............................................................................................................................. 10-1

10.1 What is retransmission .................................................................................................................................. 10-1

10.2 To Configure Retransmission ........................................................................................................................ 10-1

10.3 To Scale Retransmitted Output Signals ......................................................................................................... 10-2

10.3.1 To Range Retransmitted Output OP ................................................................................................................................................. 10-2

10.3.2 To Range Retransmitted Setpoint SP or Process Variable PV ................................................................................................ 10-2

10.3.3 To Range Retransmitted Error Err .................................................................................................................................................. 10-2

11 Understanding the Order Code ..................................................................................................... 11-1

12 SAFETY and EMC Information ....................................................................................................... 12-1

12.1 Technical Specification ................................................................................................................................. 12-3

13 Supplement 2208e Instruments ..................................................................................................... 13-1

14 Index ............................................................................................................................................. 14-3

This product is cove red by one or more of the f ollowing US Patent s :

5,484,206 and 5,793,754; Additional patents pending.

PDS is a registered trademark of Eurotherm.

INSTANT ACCURACY™, SSRx Load Doct or™ and SSRx Enhanced Load Doc t or ™

are trademarks of Eurotherm

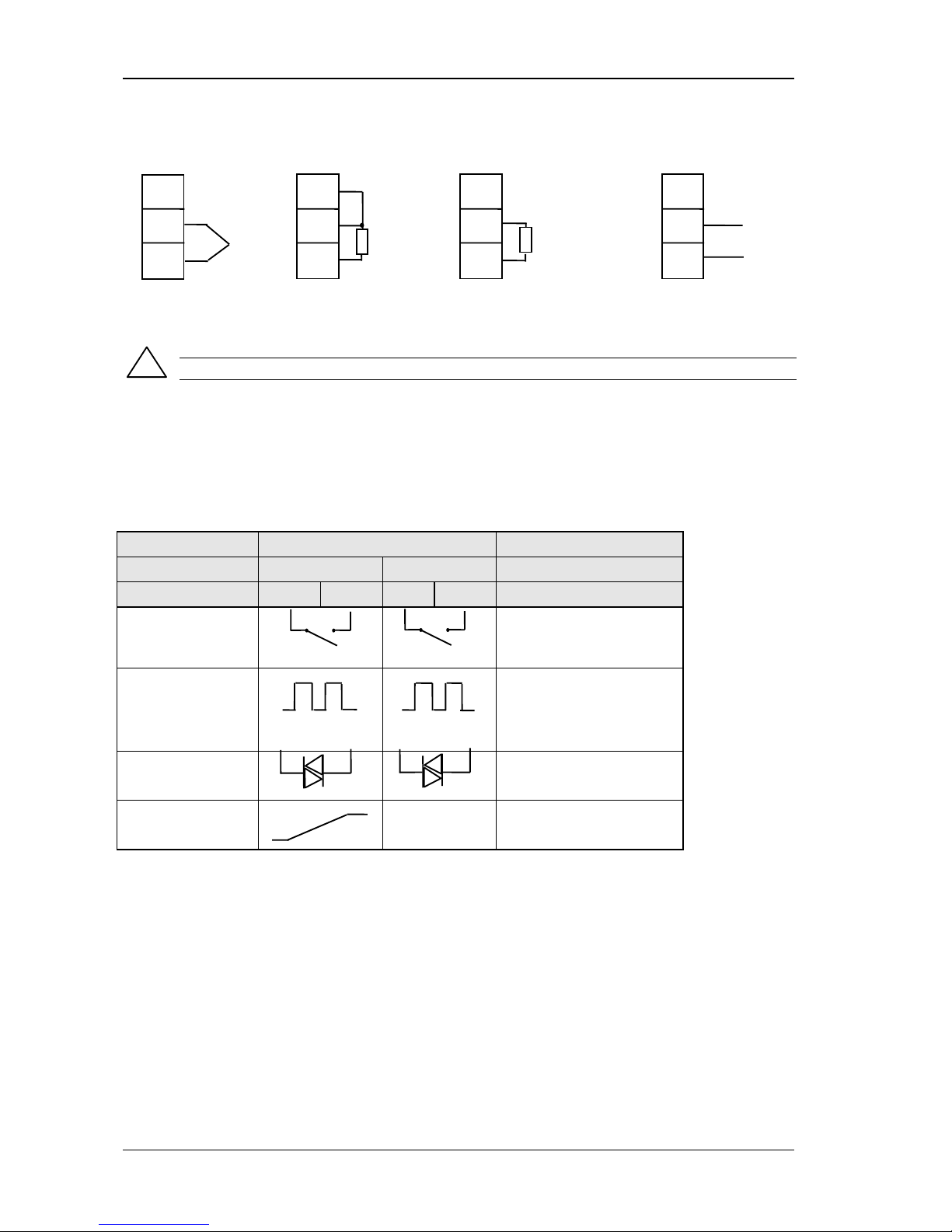

Symbols in Use In This Handbook

Tip

Useful information

Button Operation

Caution, (refer to the

accompanying documents)

!

Part No. HA029989 Issue 3 July-14 iii

2200e Series Installation and Configuration Handbook Installation

1 Installation

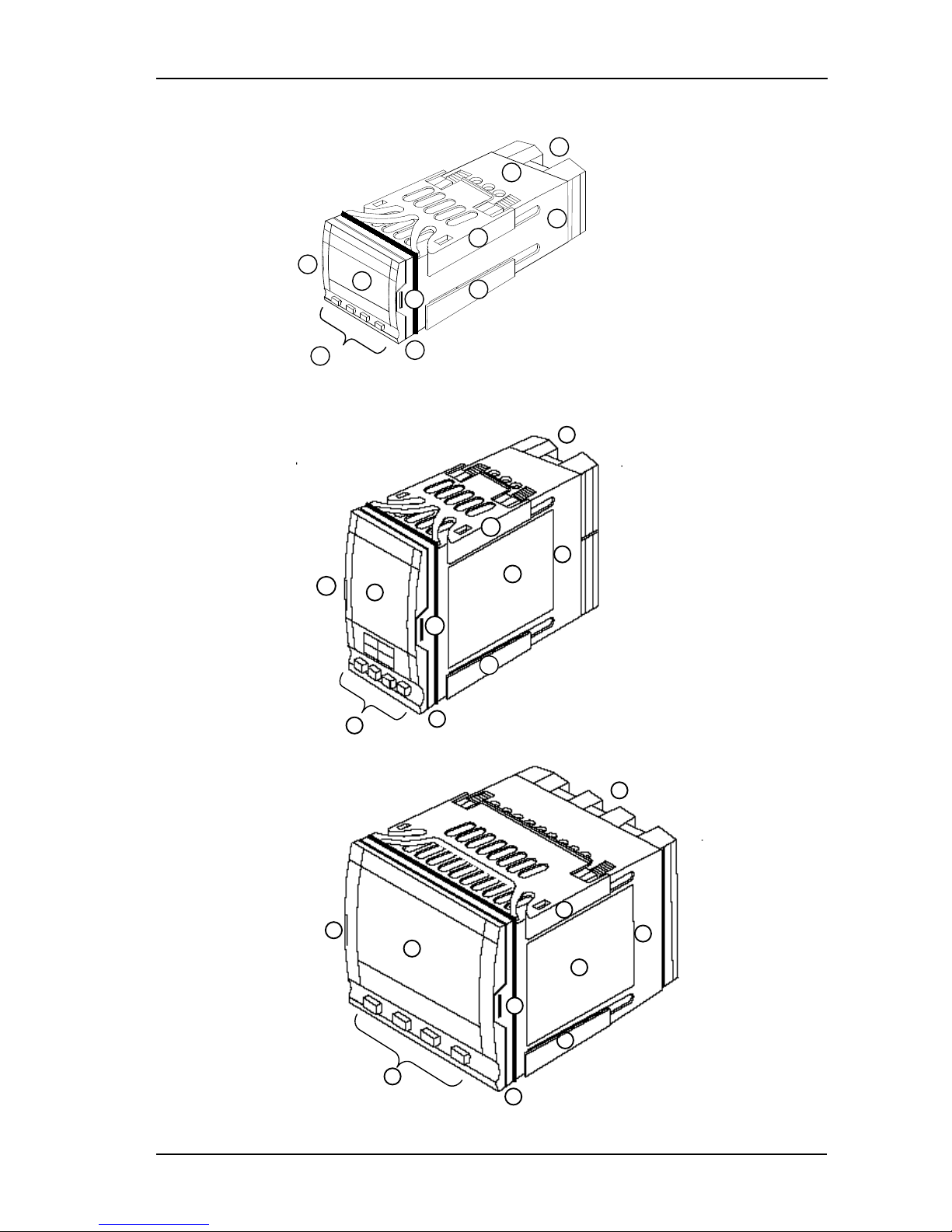

1.1 Instrument Layouts

Figure 1-1: 2216e 1/16 DIN Controller

Figure 1-2: 2208e 1/8 DIN Controller

Figure 1-3: 2204e 1/4 DIN Controller#

KEY

1. Display screen

2. Latching ears

3. Panel sealing gasket

4. Panel retaining clips

5. Label

6. Sleeve

7. Connection Terminals

8. Keypad

5

6

7

8

3

1

2 2 4

4

1

2

3

4

4

5

6

7

8

2

5 2 1 8 6 7 3 2 4

4

Part No. HA029989 Issue 3 July-14 1-1

Installation 2200e Series Installation and Configuration Handbook

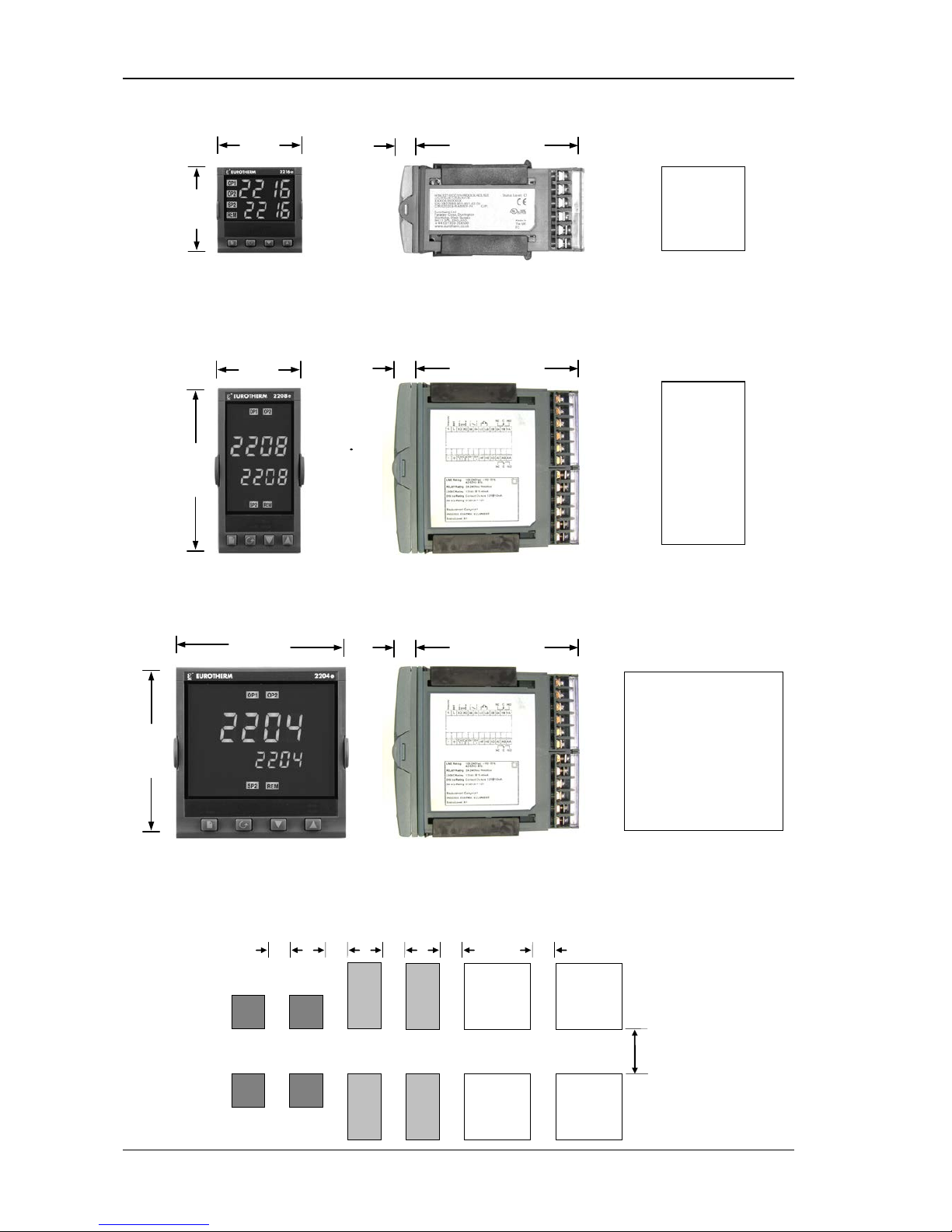

1.1.1 Outline Dimensions

Figure 1-4: 2216e Controller

Figure 1-5: 2208e Controller

Figure 1-6: 2204e Controller

The controller plugs into a plastic sleeve, which in turn fits into the panel cut-out.

1.1.2 Recommended minimum spacing of controllers

Panel cutout

45 x 45

-0 + 0.6 mm

1.77 x 1.77

-0 + 0.02

in

48mm

(1.89in)

48mm

(1.89in)

103mm (4.01in)

12.5mm

(0.5in)

103mm (4.01in)

12.5mm

(0.5in)

48mm

(1.89in)

96mm

(3.78in)

Panel cutout

45 x 92 mm

-0 + 0.6 -0 + 0.8

1.77 x 3.62 in

-0 + 0.02 -0 + 0.03

Panel cutout

92 x 92

-0 +0.8mm

3.62 x 3.62

-0 +0.03

in

103mm (4.01in)

12.5mm

(0.5in)

96mm

(3.78in)

96mm

(3.78in)

38mm

(1.5in)

X = 10mm (0.4in)

(Not to

scale

)

X X X X X

1-2 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Installation

1.2 Introduction

The Models 2216e, 2208e and 2204e are precision temperature controllers with self tuning. They have a modular

hardware construction which provides two control outputs, alarm relays and one communications port. Two logic

inputs are provided as standard in 2208e and 2204e.

1.2.1 Controller labels

The labels on the sides of the controller identify the ordering code, the serial number, and the wiring connections.

Section 11, Understanding the Ordering Code explains the hardware and software configuration of your particular

controller.

1.3 Mechanical Installation

To install the controller

1. Cut the panel to the relevant hole size shown in Section 1.1.1.

2. Fit the IP65 sealing gasket behind the front bezel of the controller.

3. Insert the controller in its sleeve through the cut-out.

4. Spring the upper and lower panel retaining clips into place. Secure the controller in position by holding it level

and pushing both retaining clips forward.

5. Peel off the protective cover from the display.

Note: If the panel retaining clips subsequently need removing, they can be unhooked from the side with either your

fingers or a screwdriver.

1.3.1 Unplugging and plugging-in the controller

The controller can be unplugged from its sleeve by easing the latching ears outwards and pulling it forward out of the

sleeve. When plugging the controller back into its sleeve, ensure that the latching ears click into place to maintain

moisture sealing protection.

Part No. HA029989 Issue 3 July-14 1-3

Installation 2200e Series Installation and Configuration Handbook

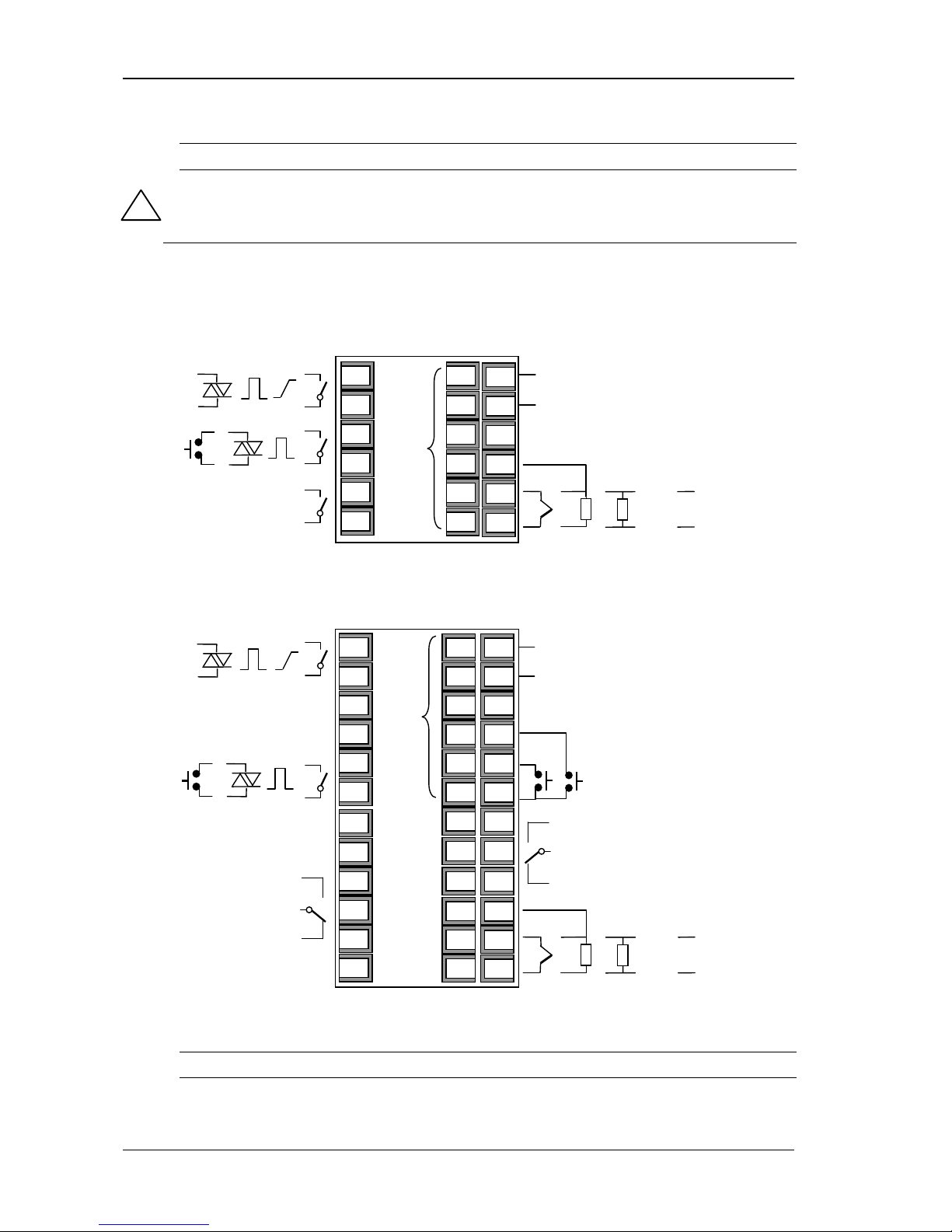

1.4 Wiring

Please read Section 12, Safety and EMC information before proceeding.

WARNING

Please ensure that the controller is correctly configured for your application. Incorrect configuration

could result in damage to the process being controlled, and/or personal injury. The controller may

either have been configured when ordered, or may need configuring now. See Section 5,

Configuration.

The wiring connections are shown below. Outputs are factory fitted modules which can be any one of the types

shown in section 1.4.3. Check the ordering code on the controller side label to determine which have been fitted.

Model 2216e Connections

Figure 1-7: 2216e Terminals

Model 2208e Connections

Figure 1-8: 2208e Terminals

Do not use unused terminals as wire holders.

!

- -

-

HA

HB

HC

HD

HE

HF

+ +

+

L

N

VI

V+

V-

1A

1B

2A

2B

3A

3B

2.49Ω

- + T/C

Pt100 mA

-

+

mV/V

-

+

Output 1

Output 2

Output 3

Line

Neutral

Digital

Comms

Sensor Input

L

N

LA

LB

LC

AA

AB

AC

VI

V+

V-

3A

3B

3C

1A

1B

2A

2B

HA

HB

HC

HD

HE

HF

+ +

- -

+

-

+

+

-

2.49Ω

-

+

T/C

Pt100

mA

-

+

mV/V

-

+

Output 1

Output 2

Output 3

Line

Neutral

Digital

Comms

Sensor Input

Output AA

Logic Inputs

1-4 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Installation

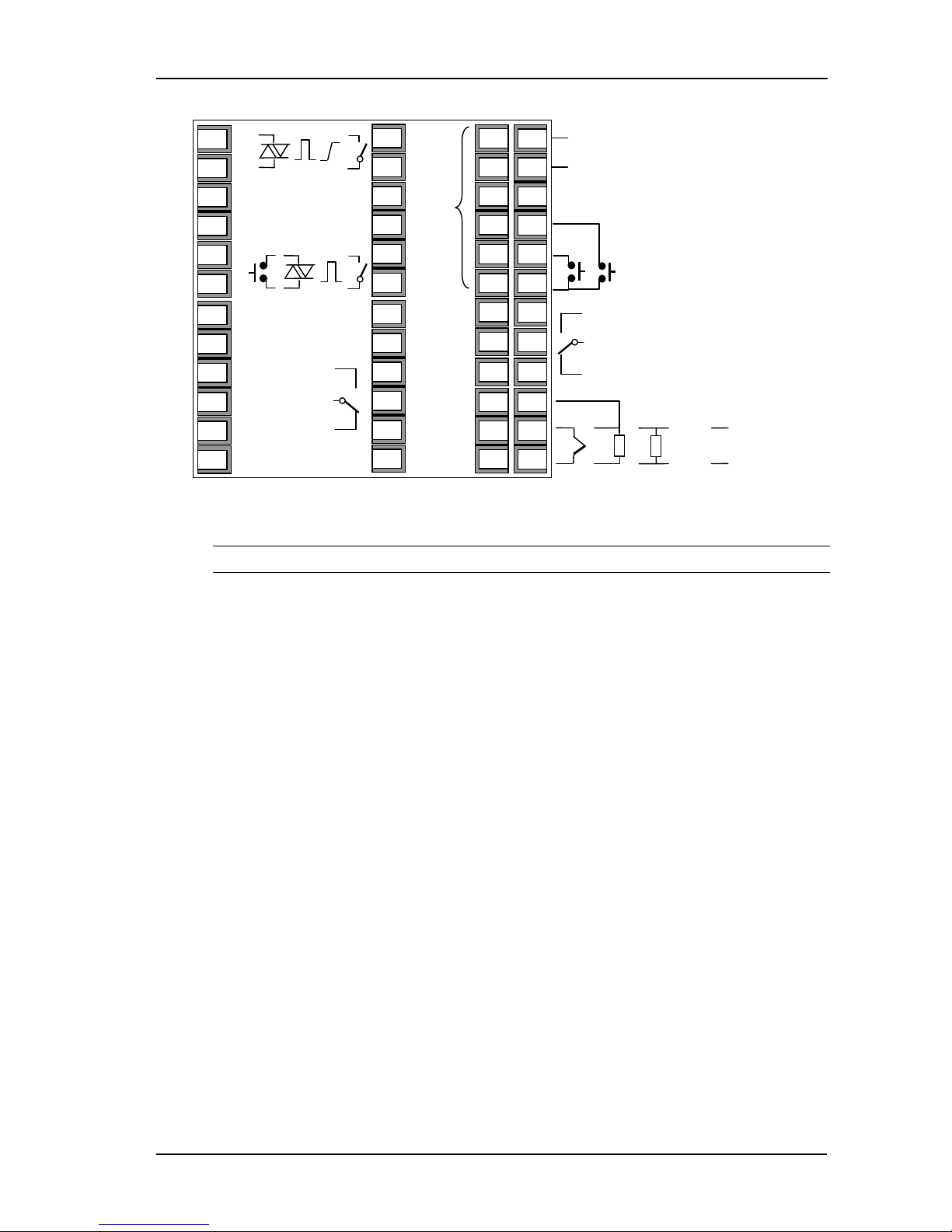

Model 2204e Connections

Figure 1-9: 2208e Terminals

Do not use unused terminals as wire holders.

1.4.1 Wire Sizes

All electrical connections are made to the screw terminals at the rear of the controller. They accept wire sizes from

0.5 to 1.5 mm

2

(16 to 22 AWG), and are protected by a hinged cover to prevent hands or metal making accidental

contact with live wires. Rear terminals should be tightened to a torque of 0.4Nm (3.5 lb in).

- -

L

N

LA

LB

LC

AA

AB

AC

VI

V+

V-

3A

3B

3C

1A

1B

2A

2B

HA

HB

HC

HD

HE

HF

+ +

+

-

+

+

-

2.49Ω

-

+

T/C

Pt100

mA

-

+

mV/V

-

+

Output 1

Output 2

Output 3

Line

Neutral

Digital

Comms

Sensor Input

Output AA

Logic Inputs

5C

5D

6A

6B

6C

6D

4A

4B

4C

4D

5A

5B

Part No. HA029989 Issue 3 July-14 1-5

Installation 2200e Series Installation and Configuration Handbook

1.4.2 Sensor input connections

The connections for the various types of input are as follows:

Figure 1-10: Sensor Input Connections

Do not connect more than one sensor to any one input.

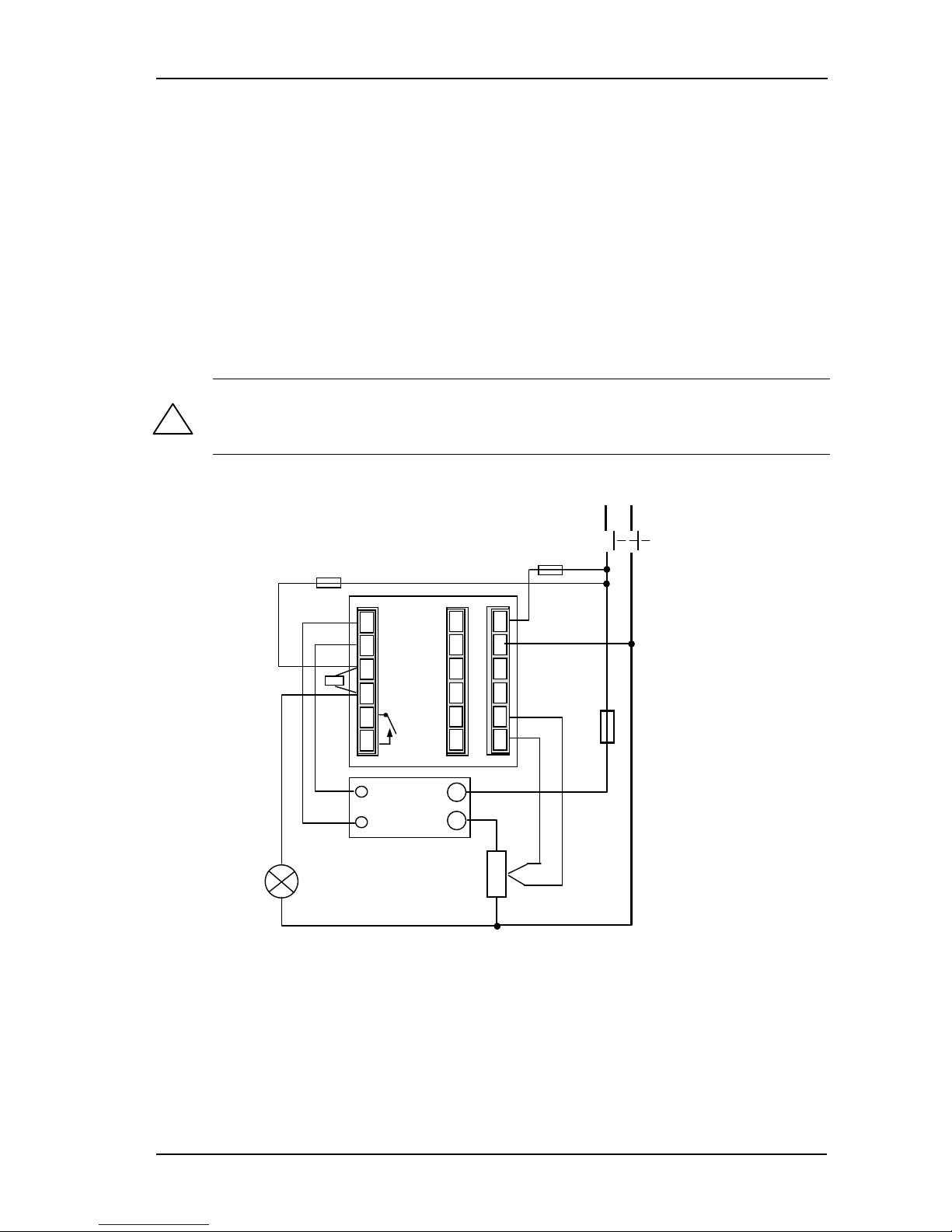

1.4.3 Outputs 1 and 2 connections

Outputs 1 and 2 can be any one of the types shown in the table below, configured to perform any one of the

functions shown.

To check which outputs are installed, and their configuration, refer to the ordering code and the wiring information

on the controller side labels.

Connections

Output 1 Output 2 Possible functions

Module type 1A 1B 2A 2B

Relay: 2-pin

(2A, 264 Vac max.)

Heating

Cooling

Alarms

Logic: non-isolated *

(18Vdc at 24mA)

+ - + -

♦

PDS modes 1 or 2 (SSRx)

Heating

Cooling

Alarms

Triac

(1A, 30 to 264Vac)

Heating or cooling

DC control: isolated

(18Vdc, 20mA max)

+

-

DC not available

in output 2

PID Heating or cooling

* Logic output can also be configured as logic input on module 2A.

♦

PDS Mode 1 & 2 are only supported in Module 1A.

Figure 1-11: Outputs 1 and 2 Connections

VI

V+

V-

VI

V+

V-

VI

V+

V-

VI

V+

V-

Thermocouple

Resistance

Thermometer

mA Input

Volts or mV

Inputs

+

PV

2.49Ω

current

sense

resistor

Line

Load

Line

Load

!

1-6 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Installation

1.5 PDS Modes

PDS is a proprietary technique developed for bi-directional communication over a single pair of wires. There are

several operating modes.

In SSRx Load Doctor™ a logic output delivers a power demand signal to a TE10 solid state (SSR) relay and the SSR

responds with a single load circuit failure message.

In SSRx Enhanced Load Doctor™ a logic output delivers a power demand signal to an SSR and the SSR responds with

the ON state rms load current, and two fault messages - SSR failure or heater circuit failure.

1.6 Snubbers

The controller is supplied with ‘snubbers’ (15nF +100Ω) which should be wired across the relay or triac outputs when

switching inductive loads such as mechanical contactors and solenoid valves. The snubbers are used to prolong

contact life and to suppress interference when switching such loads. Snubbers pass 0.6mA at 110Vac and 1.2mA at

240Vac, which may be sufficient to hold in high impedance relay coils. They should not, therefore, be used in such

installations.

WARNING

When a relay contact is used in an alarm circuit ensure that the current passing through the

snubber when the relay contact is open does not hold in low power electrical loads and thereby

interfere with the failsafe operation of the alarm circuit.

1.7 Typical single loop wiring diagram

Figure 1-12: Typical Wiring Diagram, Model 2216e Controller

Safety requirements for permanently connected equipment state:

• A switch or circuit breaker shall be included in the building installation

• It shall be in close proximity to the equipment and within easy reach of the operator

• It shall be marked as the disconnecting device for the equipment.

Note: a single switch or circuit breaker can drive more than one instrument.

!

Comms

Neutral

Heating

power fuse

(load

dependent)

Line

Thermocouple

Cooling Power

Fuse 1A(T)

Controller

Fuse 2A(T)

Solid State

Relay

e.g. TE10

+

-

Snubber

Heater

JA

JF

HA

HB

HC

HD

HE

HF

1A

1B

2A

2B

3A

3B

L

N

V1

V+

V-

Cooling

solenoid

valve

Circuit

breaker

Part No. HA029989 Issue 3 July-14 1-7

Installation 2200e Series Installation and Configuration Handbook

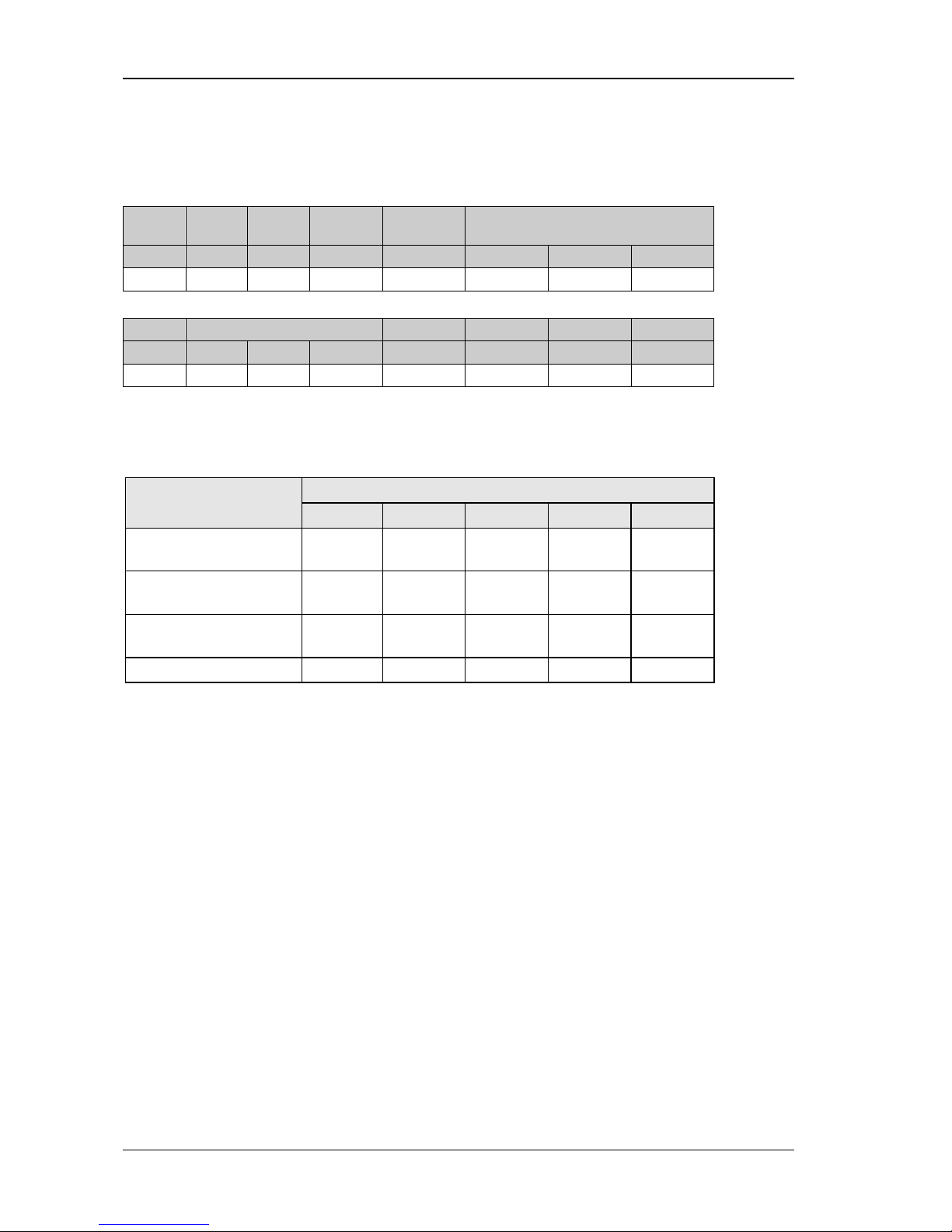

1.8 Logic Drive Fan Out

The logic outputs from the 2200 series controllers are capable of driving more than one solid state relay (SSR) in

series or parallel. The following table shows the number of SSRs which can be driven depending on type of SSR.

S = Series; P = Parallel.

Drive

mA

SVDA RVDA TE10S 425S

Logic DC Logic DC Logic DC Logic 10V Logic 24V Logic 20mA

Logic 18V@24 4S 6P 4S 4P 3S 3/2P 3S 3P 1S 2P 6S 1P

450 TC1027CE TE200S TC2000CE RS3DA

Standard TTL Multi-drive Logic V Logic DC Logic DC Logic DC

Logic 2S 3P 1S 2P 6S 1P 3S 4/3P 3S 4P 3S 2/1P 4S 2P

1.9 EIA232/485/422 Communication connections

The communication option can be either of four types shown in the table below:-

Connection

Communications type HB HC HD HE HF

4-wire EIA-422 serial

communications

A’

(RX +)

B’

(RX -)

Common A

(TX +)

B

(TX -)

2-wire EIA-485 serial

communications

Do not use Do not use Common A (+)

B (-)

EIA-232 serial

communications

Not used Not used Common A B

PDS Setpoint input Not used Not used Not used Signal Common

Figure 1-13: Communications Connections

1-8 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Installation

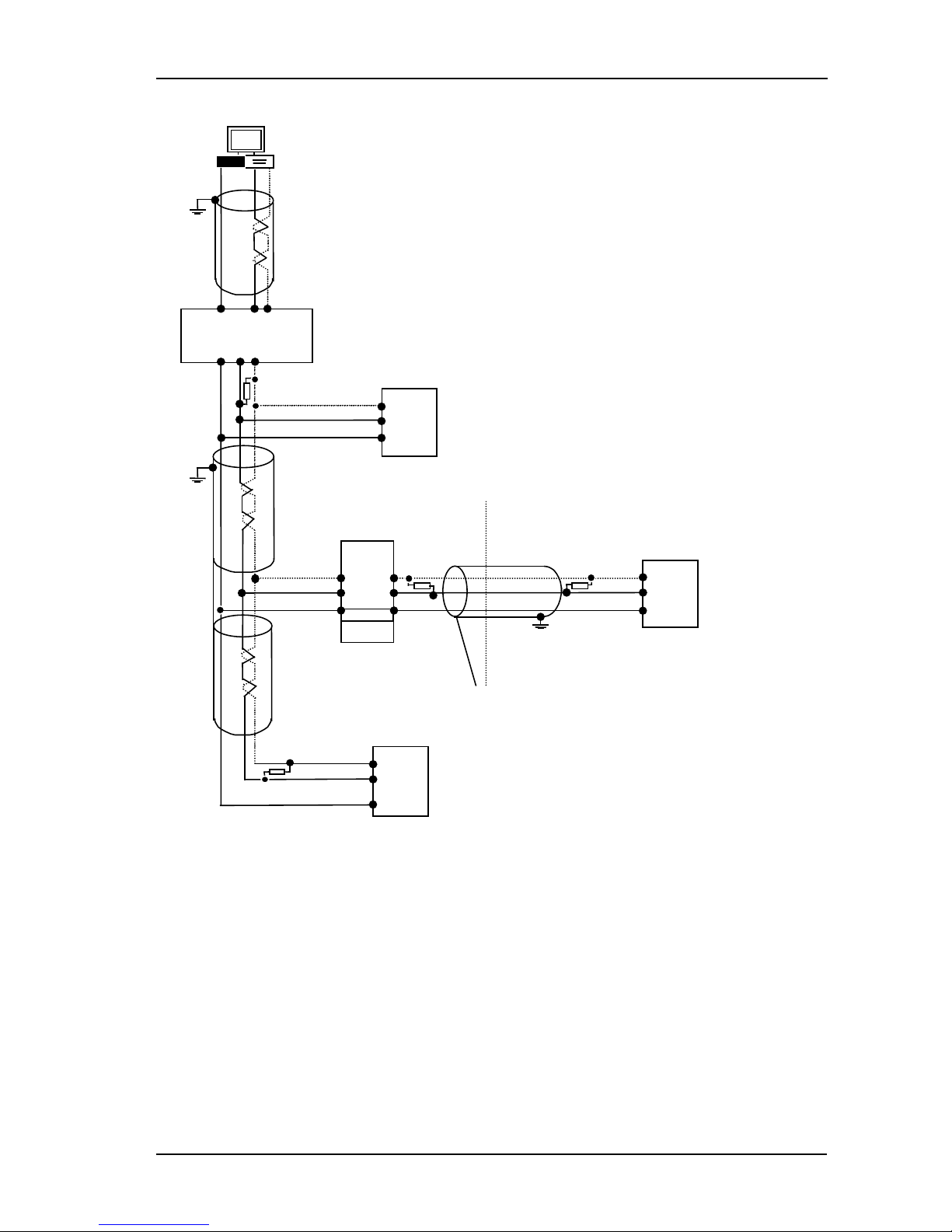

1.9.1 Wiring of EIA-485 serial communication links

Local

Local

Earth

HF +

Series 2000™

Controller

Com

Note:

All termination resistors are 220 ohm 1/4W carbon composition.

Local grounds are at equipotential. Where equipotential is not available wire into

separate zones using a galvanic isolator.

A

B

PC

Universal Convertor

RXTXCom

ComTXRX

Up to 32

controllers or

Interface Units may

be included on the

network

232

ComBA

Com

A

B

Galvanic

Isolation

Barrier

Com

A

B

Com

A

B

Local Earth

Com

A

B

Earth

Universal

Converter

MMI

Series 2000™

Controller

Series 2000™

Controller

For safety reasons,

do not connect to

local earth here.

HD

HF+

HE

HD

HF+

HE

HE

HD

Figure 1-14: 2-Wire EIA-485 Wiring

Standard EIA-485 is a 2-

wire connection which allows up to 32 controllers to

be multi-dropped from a single communications link over a distance of up

to 1.2Km. To ensure reliable operation of the communications link, (without

data corruption due to noise or line reflections) the connections between

the controller should be made using a twisted pair of wires inside a shielded

cable with the connections terminated with resistors in the manner shown in

this diagram. This diagram also shows the use of a Comms converter to

connect the 2-wire EIA-485 link into a standard EIA-232 computer port.

Common and Local

Earth cannot be

connected together.

Part No. HA029989 Issue 3 July-14 1-9

Installation 2200e Series Installation and Configuration Handbook

1.10 DeviceNet® Wiring to Series 2200e Controllers

This section covers the DeviceNet digital communications option for the model 2208e and 2204e controllers. To

configure DeviceNet communications refer to section 5.8.

1.10.1 DeviceNet Terminal Functions

Series 2200e

Terminal

CAN

Label

Color

Chip

Description

HA V+ Red DeviceNet network power positive terminal. Connect the red wire of the DeviceNet

cable here. If the DeviceNet network does not supply the power, connect to the

positive terminal of an external 11-25 Vdc power supply.

HB CAN_H White DeviceNet CAN_H data bus terminal. Connect the white wire of the DeviceNet cable

here.

HC SHIELD None Shield/Drain wire connection. Connect the DeviceNet cable shield here. To prevent

ground loops, the DeviceNet network should be grounded in only one location.

HD CAN_L Blue DeviceNet CAN_L data bus terminal. Connect the blue wire of the DeviceNet cable

here.

HE V- Black DeviceNet network power negative terminal. Connect the black wire of the DeviceNet

cable here. If the DeviceNet network does not supply the power, connect to the

negative terminal of an external 11-25 Vdc power supply.

Notes:

Power taps are recommended to connect the DC power supply to the DeviceNet trunk line. Power taps

include:

A Schottky Diode to connect the power supply V+ and allows for multiple power supplies to be connected.

Two fuses or circuit breakers to protect the bus from excessive current which could damage the cable and

connectors.

1.10.2 Wiring Interconnections for DeviceNet Communications

Figure 1-15: Wiring Connections for 2200e Series DeviceNet Controllers

!

Note:

The DeviceNet network is powered by an external

independent 24V supply which is separate from the

internal powering of the individual controllers.

The earth connection, HF, to be connected to the

main supply earth terminal at one point only.

* 121 1% 1/4W terminating resistor must be

connected across the blue and white wires at each

end of the DeviceNet trunk cable.

Note: this resistor is sometimes included in the

master or other devices but should only be switched

into circuit on the last device on the trunk cable.

DeviceNet Trunk Cable

DeviceNet Power

Supply

24Vdc (+/

- 1%)

250mV p

-p Ripple max

V+

V-

Ground

V- Shield V+

↑

Further Devices

2200_1

HA

HB

HC

HD

HE

HF

Drop

Line

MASTER

Drop Line

Drop

Line

Further Devices

↓

2200_2

HA

HB

HC

HD

HE

HF

*

*

CAN-L CAN-H

1-10 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

2 Operation

2.1 Front Panel Layout

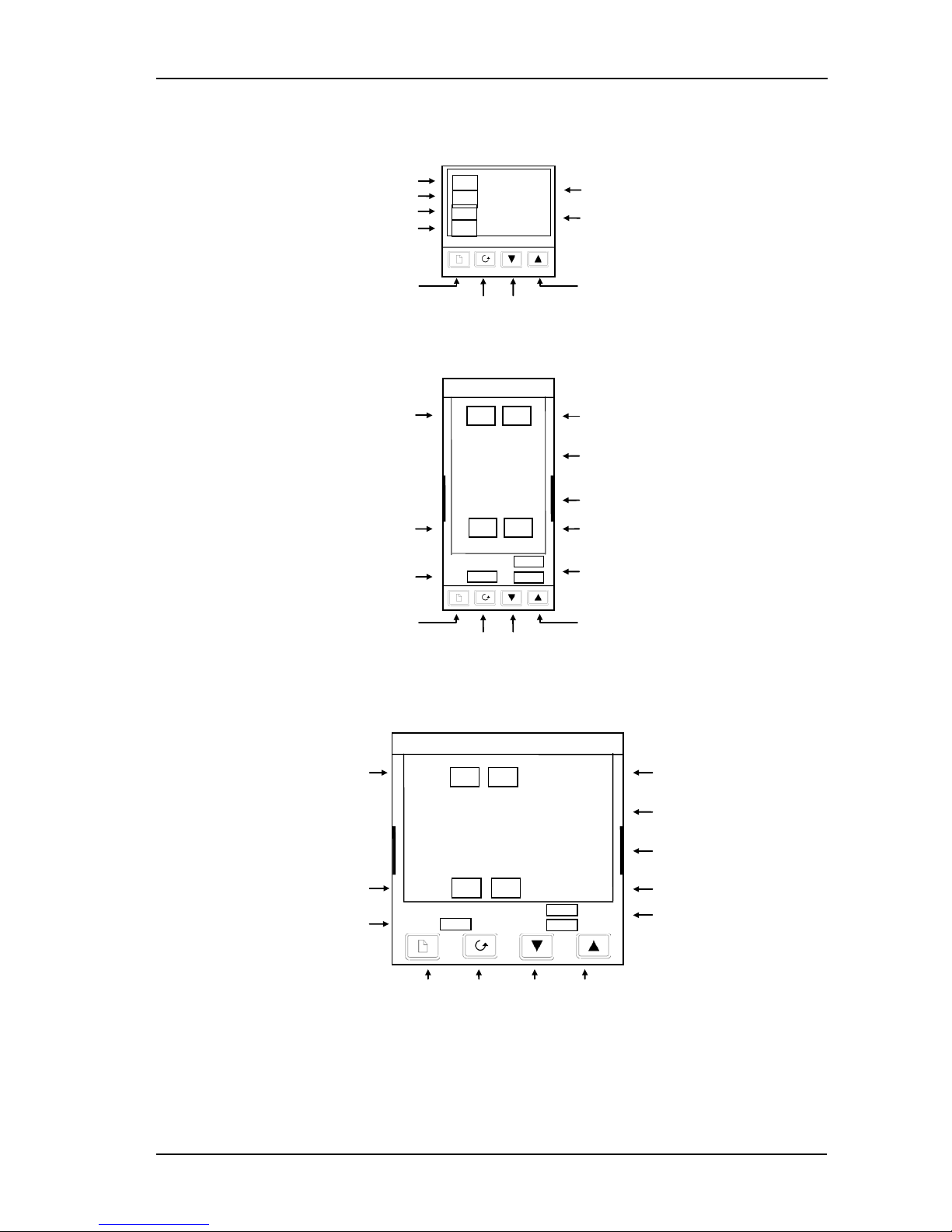

Figure 2-1: Model 2216e Front Panel Layout

Figure 2-2: Model 2208e Front Panel Layout

Figure 2-3: Model 2204e Front Panel Layout

Tip: The display may flash an alarm message. Refer to the Parameter Tables in section 2.9 for a complete

list and meaning of the messages.

Down

Button

Manual mode

Page

Button

Scroll

Button

Up

Button

Remote Setpoint

Output 2

Upper readout

Lower readout

Output 1

Setpoint 2 active

Setpoint rate limit active

20.00

20.00

OP1

OP2

2204e

SP2 REM

MAN

RUN

HOLD

Page Button

Scroll Button

Down Button

Up Button

Manual mode

Setpoint 2 active

PDS Remote Setpoint

Setpoint rate limit active

20.0.0

20.0.0

OP1

OP2

SP2

REM

2208e

Output 1

Output 2

Upper readout

Lower readout

MAN

RUN

HOLD

PDS Remote Setpoint

Setpoint 2 active

Output 1

Actual Temperature (Process Value)

Output 2

Required Temperature (Setpoint)

20.0

23.0

OP1

OP2

SP2

Rem

Page Button

Scroll Button

Down Button

Up Button

Part No. HA029989 Issue 3 July-14 2-1

Operation 2200e Series Installation and Configuration Handbook

Button or indicator Name Explanation

OP1 Output 1 When lit, it indicates that heating output is on.

OP2 Output 2 When lit, it indicates that cooling output is on.

SP2 Setpoint 2 When lit, this indicates that Setpoint 2 has been selected.

REM Remote Setpoint When lit, this indicates that the PDS remote Setpoint input has

been selected. ‘REM’ is also used to indicate that user comms is

active.

MAN Manual light When lit, it indicates that manual mode has been selected

RUN Run light When lit, it indicates that Setpoint rate limit is active.

Page button Press to select a new list of parameters.

Scroll button Press to select a new parameter in a list.

Down button Press to decrease a value in the lower readout.

Up button Press to increase a value in lower readout.

Figure 2-4: Controller Buttons and Indicators

Tip: For Valve Positioning, please refer to section 8 ‘Motorised Valve Control.

2-2 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

2.2 Getting Started

Thank you for selecting this controller.

This section shows the principle of operation. Views are generally shown for 2404 controller.

2.2.1 To View The Process Value and Setpoint

Install and wire up the controller as explained in section 1.4 and switch on.

Following a 3 second self-test sequence, this is the display you will see,

Figure 2-5: The "HOME Display"

Tip: The display may flash an alarm message. Refer to the Parameter Tables in section 2.9 for a

complete list and meaning of the messages.

2.2.2 To Adjust The Setpoint

Figure 2-6: The Lower Readout Shows the Setpoint

After 2 seconds the lower readout will ‘blink’ indicating that the new value has been accepted.

For everyday use you may not need to do anymore than this.

2.2.3 To View The Display Units

Figure 2-7: Viewing the Display Units

Tip: If you get lost, pressing and together will return you to the Home display.

Press and hold to

increase temperature

Press and hold to

decrease temperature

20.0

140.0

OP1

OP2

Output 1

Actual Temperature (Process Value)

Output 2

Required Temperature (Setpoint)

20.0

23.0

OP1

OP2

Display Units

“

C

Degrees Centigrade

“

F

Degrees Farenheit

K

Degrees Kelvin

No units - Linear inputs

Momentarily press either button

0.5 sec.

23.0

“

C

20.0

140.0

Part No. HA029989 Issue 3 July-14 2-3

Operation 2200e Series Installation and Configuration Handbook

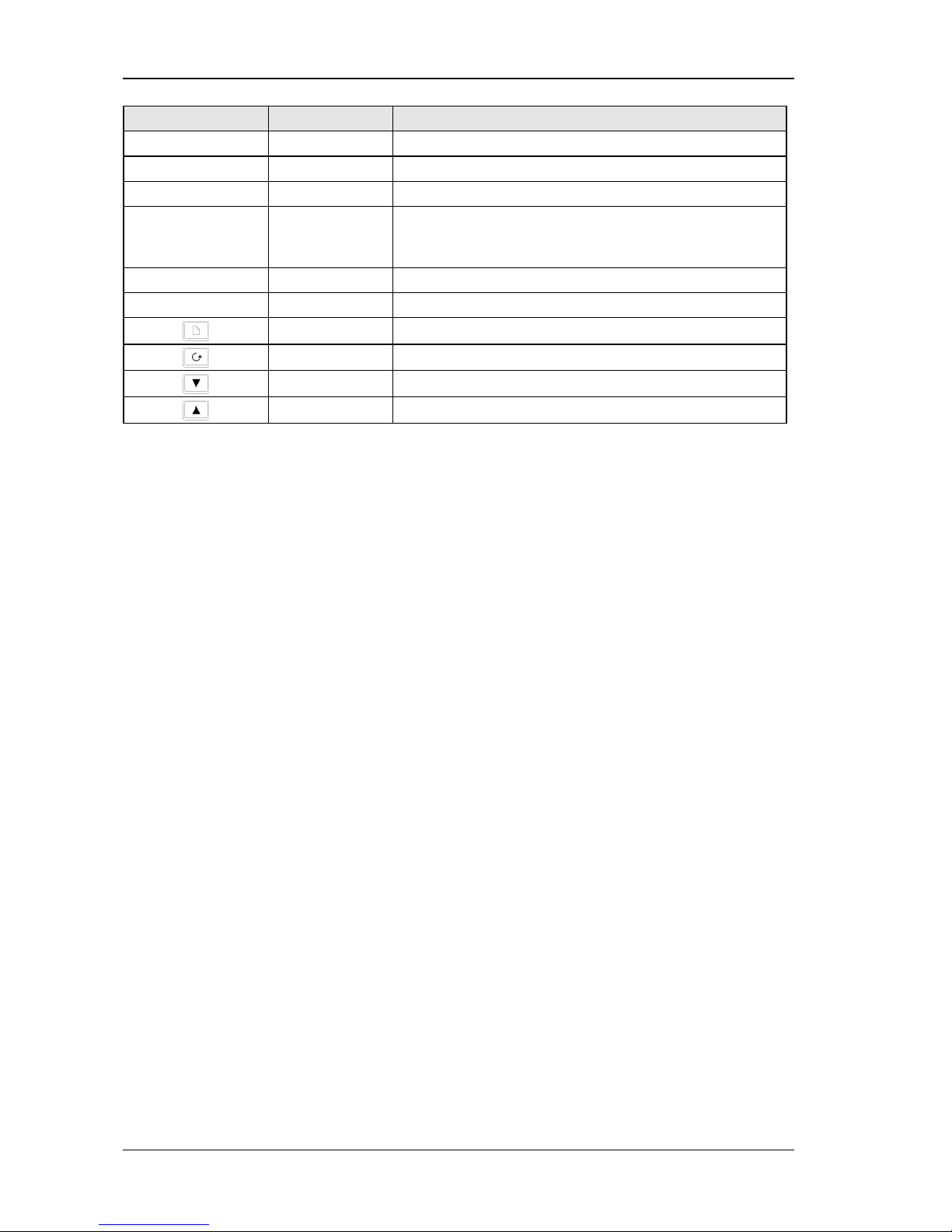

2.2.4 Use Of The ‘SCROLL’ Button

Pressing the scroll button will display the output power level. Continued pressing will display further parameters in

the operator scroll list.

Figure 2-8: The Scroll Button

2.2.5 Use Of The ‘PAGE’ Button

The page button accesses parameter LISTS.

Parameters are settings in the instrument which, generally, can be changed by the user to suit the process. Examples

are: Alarms, Self Tune, etc. They are found under headings called LISTS and a full set is given later in this chapter.

Figure 2-9: The Page Button

Tip: The actual list headings may be longer or shorter than indicated above and you can customise this for the

operator’s convenience in EDIT level, section 3.

Keep pressing to return to the Home display or select

further parameters (if available)

2nd press

3rd press

Output

Actual output level %

OP

100.0

Manual/Auto

Actual state

m-A

Auto

Keep pressing to

select more list headings

1st press

0.2 sec.

23.0

“

C

20.0

1400

3rd press

2nd press

AL

LiSt

atun

LiSt

20.0

14.00

2-4 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

2.3 Parameter Lists

Press to choose a LIST - “ALARMS” is a good one. This list allows you to set the alarm trip levels. The

parameters which appear in the list will vary according to the configuration of your controller.

Tip: If, at any time, no key is pressed within 45 seconds, the display will always return to the “HOME” display.

A description of the parameter lists is given in section 2.9.

Figure 2-10: Choosing a List of Parameters

or to change trip level

or to change trip level

1st press

2nd press

0.2 sec.

23.0

“

C

20.0

140.0

There are 4 alarms in the controller. The first

character is the alarm number. The following

three letters indicate alarm type as follows:

-FSL

Full Scale Low

-FSH

Full Scale High

-dHi

Deviation High

-dLo

Deviation Low

-dEv

Deviation Band

-Lcr

Low current

-Hcr

High current

Disabled alarms will not be displayed.

Section

7 gives a full description of alarms.

Alarm

List

Alarm 1

Now press the

SCROLL button

2nd press

AL

LiSt

1---

50.0

2---

200.0

Keep pressing

2. to scroll through further parameters

3. to return to list header

Alarm 2

Part No. HA029989 Issue 3 July-14 2-5

Operation 2200e Series Installation and Configuration Handbook

2.4 Manual or Automatic Control

The controller can be used in two modes:

Automatic mode - in which the output power is automatically adjusted to hold the temperature at the required

value. The controller normally operates in this mode.

Manual mode - in which the output is manually adjusted by the Operator. In this mode the ‘MAN’ light will be on.

One other mode is available:

Remote setpoint - The setpoint is generated as an input signal from a master 2000 or 3000 series controller. In this

mode the REM light is on.

2.4.1 To Select Auto/Manual Operation

Figure 2-11: Auto/Manual Select

2.4.2 To Adjust Output Power in Manual Mode

Figure 2-12: The "Home" Display in Manual Mode

Tip: Manual mode is generally used for test and commissioning purposes, take care not to leave the controller in

this mode since damage to the process or personal injury could occur.

or to select

Auto automatic mode

Man manual mode

2 sec.

23.0

“

C

20.0

1st press

Output

Actual output level %

Manual/Auto

2nd press

3rd press

OP

100.0

m-A

Keep pressing

to return to “HOME” display

Actual Temperature (Process Value)

20.0

50.0

OP1

OP2

Output Power Demand

Manual Indicator on

Press and hold to increase power

Press and hold to decrease power

2-6 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

2.5 SETPOINT 1 OR SETPOINT 2

The instrument has the facility to select between two setpoints. This may be useful, for example, where it is required

to switch control between two different setpoints or to control in a standby condition, thus avoiding the necessity to

change the setpoint manually each time.

2.5.1 To Select Setpoint 1 or Setpoint 2

This may be done in two ways:-

1. By an external switch or relay contact wired to a digital input

2. Through the front panel using the SP list

Figure 2-13: Selecting Setpoint 1 or 2

2.6 Ramp Dwell Function

The ramp dwell function is selected by turning the setpoint rate limit parameter SPrr to a value. It can be set to

RUN in two ways:-

1. Through the front panel using the SP list

2. By an external switch or relay contact wired to a digital input configured for reset (rset). When closed the

program will reset. When open the program will run. To run the program from the initial reset state, it is

necessary to first close the switch then open it.

The controller will then ramp from setpoint 1 to setpoint 2 at a rate set by the SPrr parameter.

When the controller reaches setpoint 2 it can remain at this level for a timed period, using the dwel parameter.

At the end of the dwell period the action of the controller is determined by the End Type parameter End.t.

Press to select SP list

20.0

140.0

Setpoint List

Press scroll button to SSEL

SP

LiSt

SSEL

SP

Press

o r

to change between SP 1 and SP 2

When setpoint 2 is selected

the SP2 beacon illuminates.

Part No. HA029989 Issue 3 July-14 2-7

Operation 2200e Series Installation and Configuration Handbook

2.6.1 To Set up a Ramp/Time Program

Set setpoint 1 to the value at which to start the ramp. Set setpoint 2 to the value which you wish to ramp to. This is

described in the previous section.

Figure 2-14: Ramp/Dwell Program

2.6.2 To Run the Program

Figure 2-15: Program Run

A program may also be reset or run using an external switch contact if a digital input has been configured. See

Configuration section 5.

2.6.3 Power Failure During Program Run

1. During Ramp. After return of power, the working setpoint will servo to the current PV value, and the ramp

continues to SP2 followed by the timed dwell.

2. During Dwell. After return of power the working setpoint will servo to PV, the ramp continues to SP2 followed

by full programmed dwell. In effect this causes the program to restart.

Tip: Use the Hide, Reveal and Promote features to customise the display for a programmer. See section 3.

In Run mode the controller will ramp from SP 1 to SP 2 at 20.0 units per minute

Press scroll button to dwEl

SPrr

20.0

dwel

60.0

Press

or

to set the SP ramp rate in units per minute

Press

o r

to set the dwell time in minutes

In Run mode the controller will dwell at SP 2 for 60 minutes

Press scroll button to End.t

End.t

rSEt

In Run mode the controller will reset at the end of the dwell time. Other choices are:-

HoLd

The program will freeze

StbY

The program will go into standby

dwel

The program will dwell for an unlimited period

Press

o r

to choose the action required at the end of the dwell time

Now press until

SPrr

is displayed

From the previous view, press

scroll button to ProG

Prog

run

Press or to choose run

To reset the controller to start conditions, select

rSEt

From the previous view,

press scroll button to StAt

StAt

rmp

The status may be any one of the following:

rmp

Ramping from SP1 to SP2

dwel

Dwelling at SP2

End

The program is complete.

If

End.t

=

rSEt, End

will flash briefly before changing to

OFF

OFF

The program is in the reset state

In Full access level the Status of the

program can be read as follows:

-

2-8 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

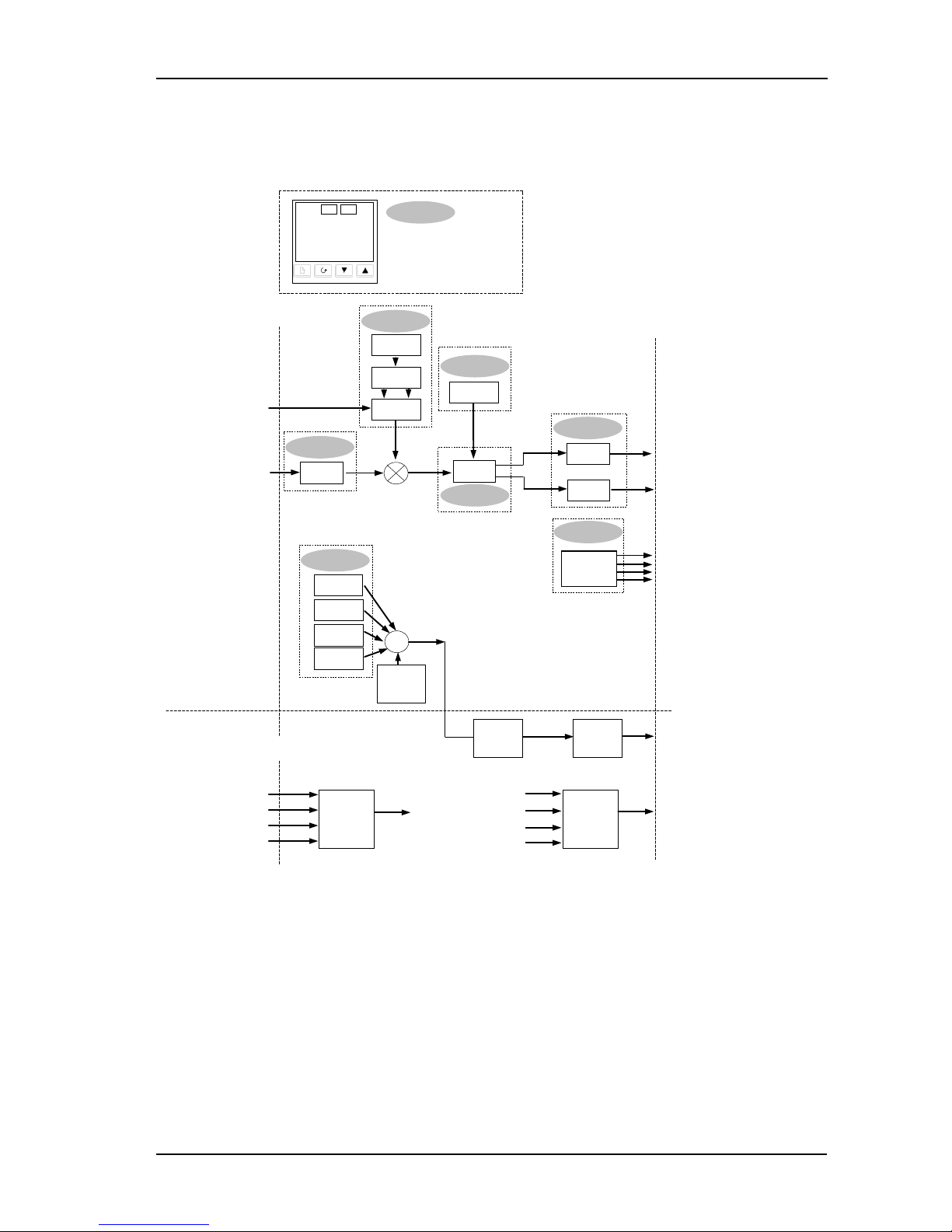

2.7 Location of Parameters - Block Diagram

The controller consists of a number of internal function blocks connected together to create a temperature

controller. Each function block has a number of parameters found in lists to which the user has access. The block

diagram shows location of these parameters within the controller.

Figure 1-14 Controller Block Diagram

20.0

23.0

OP1

OP2

For example

Output power

Setpoint

Auto/Manual

HOME List

LA*, LB*,

Module 2

Logic I/P

Alarm 1

Input

SP

PLANT INPUTS

PLANT OUTPUTS

Remote SP

TCs

PRT

Pyrometer

mA. mV, Volts

Relay, Logic, triac,

mA, Volts

Setpoint

PV

SP List

PiD List

OP List

iP List

Atun List

Control

Parameters

Digital

Comms

RS232

RS484

RS422

cms List

Digital Comms

Retrans-

mission

mA,

Volts

OP

PV

Err

SP

2 to 5 logic inputs

Functions

listed in

LA/LB

Relay

output

Relay, Logic,

triac

Alarm 2

Alarm 3

Alarm 4

Other

alarms

Normal/

Invert

OR

AL List

These are available in configuration level only

Alarms

Logic Inputs

Retrans-mission

Display Parameters

* LA & LB are not

available in 2216

Part No. HA029989 Issue 3 July-14 2-9

Operation 2200e Series Installation and Configuration Handbook

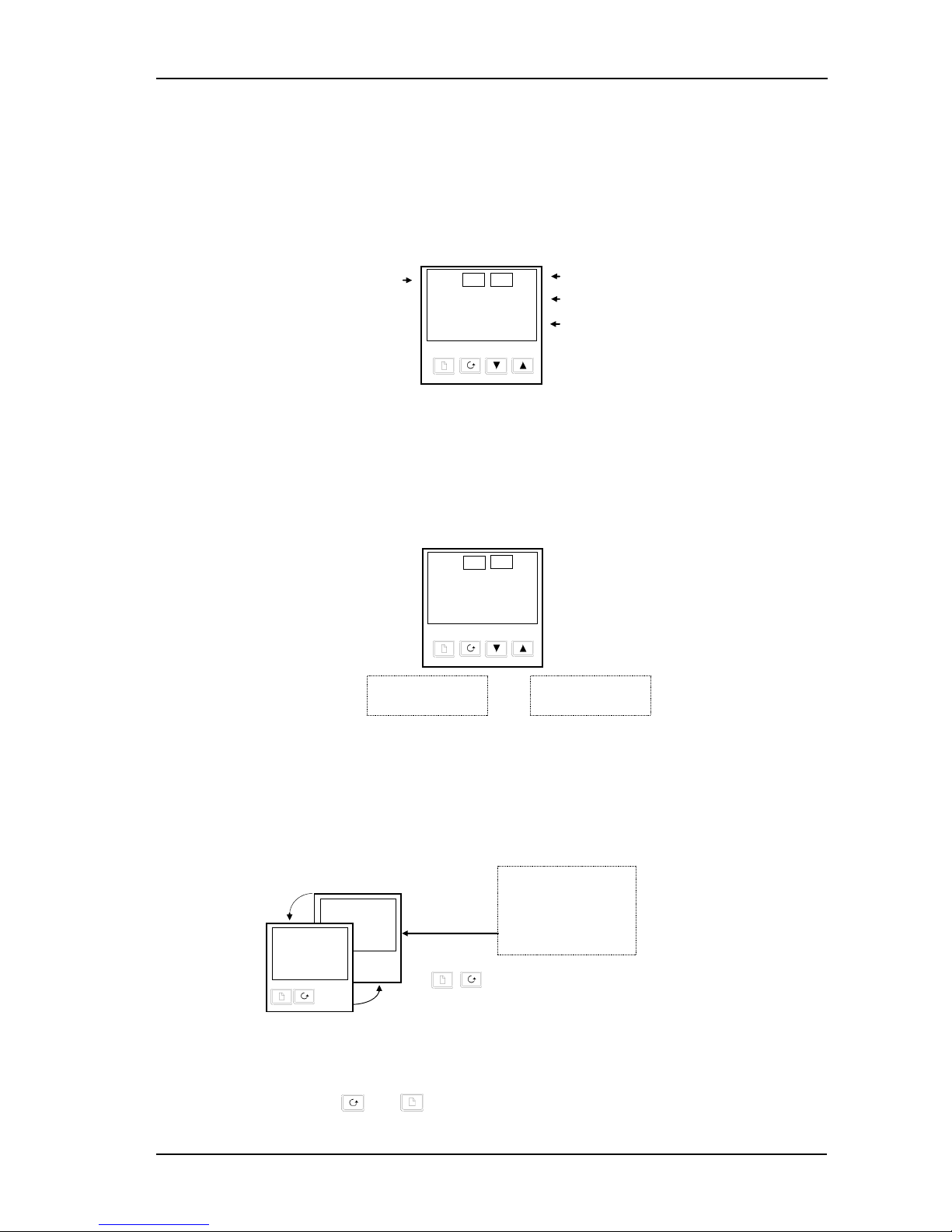

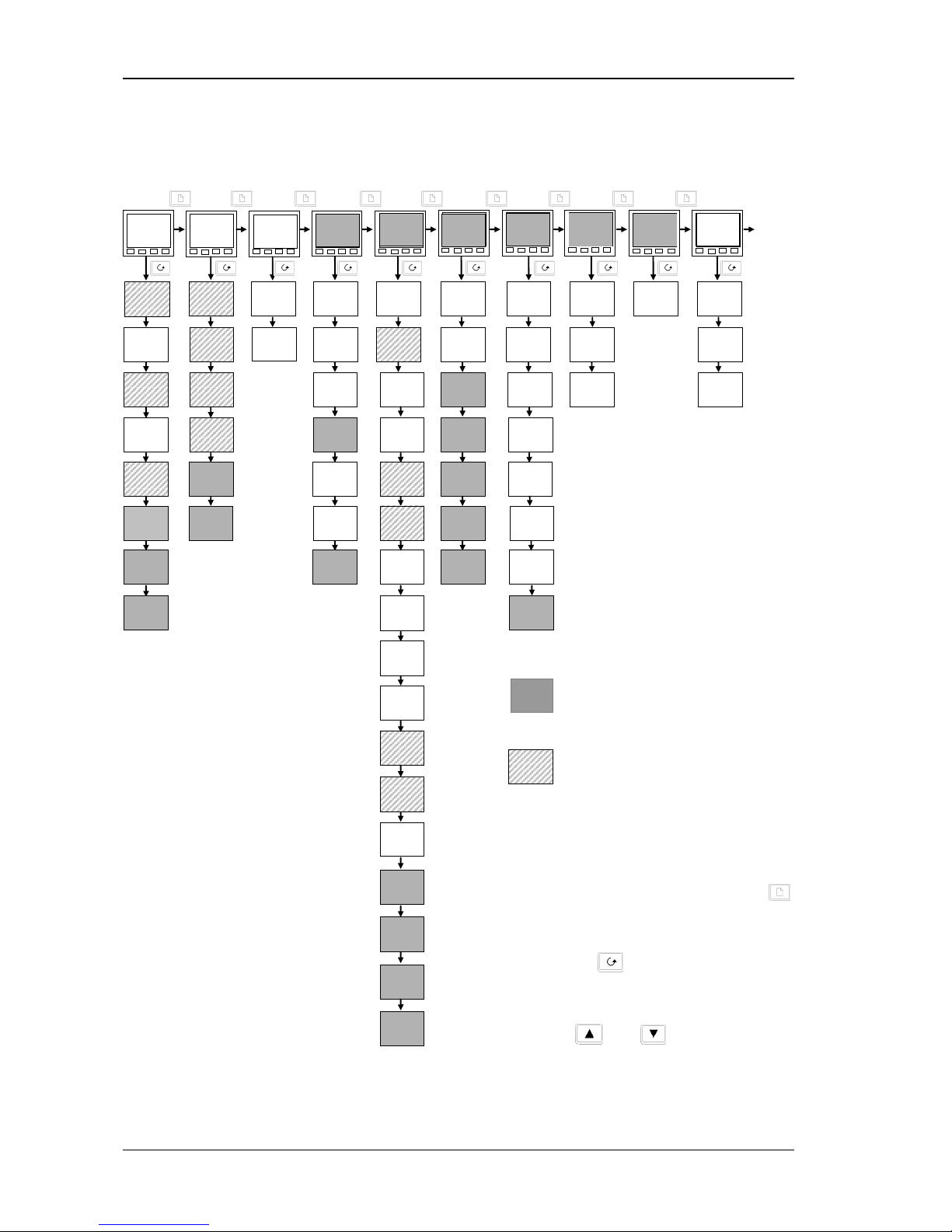

2.8 Navigation Diagram

The navigation diagram shows a complete list of possible parameters. However, some may not appear because they

are dependent upon a particular controller variant.

Figure 2-16: Navigation Diagram

20.0

20.0

Home

List

Atun

LiSt

Pid

LiSt

PID

(1)

List

AL

LiSt

Alarm

List

Autotune

List

SP

LiSt

Setpoint

List

OP

100.0

AmPS

5

5

m-A

Auto

1---

2

100.0

2--

2

20.00

3--

2

0.0

4--

2

0.0

TunE

OFF

Lbt

OFF

Pb

50

Ti

300

td

50.0

rES

0.0

Lcb

Auto

Hcb

Auto

SSEL

SP 1

L-r

8

Loc

SP 1

20.0

SP 2

0.0

rm.SP

8

0.0

Loc.t

8

0.0

rEL.C

1.00

SP1.L

3

0.0

SP1.H

3

10

0.0

Loc.L

8

100.0

Loc.H

8

0.0

SPrr

OFF

SP2.H

3

100.0

SP2.L

3

0.0

VPOS

4

100.0

WSP

9

20.0

SP

20.0

diSP

stnd

CID

1.0

HY

1.0

Adc

Notes:

1. Either the PID list or the On/Off list

will be present depending upon the

type of control in use.

2. The last three characters depend

upon the type of alarm configured

3. Absolute setpoint limits are set in

configuration, see section 5.

4. VPOS only for VP. Refer to VP Ch8.

5. Amps is Mode 2 or Mode 5 PDSIO.

6. mtr used for VP version. Refer to

VP Ch 8

7. Beware! Used for calibration. See

section 6.

8. Is only available if using PDSIO®

comms in the HA slot.

9. WSP is available if using ramp to

setpoint.

Return

to

Home

Display

DwEl

0.0

End.t

rset

ProG

rset

StAt

OFF

iP

LiSt

Input

List

oP

LiSt

Output

List

CmS

LiSt

Comms

List

ACCS

LiSt

Access

List

OnOF

LiSt

On Off

List

(1)

FiLt

1.0

CAL

7

FACT

CAL.S

7

Lo

OP.Lo

0.0

OP.Hi

100.0

Sb.OP

100.0

CYC.H

20.0

ont.H

1.0

CYC.C

5.0

hYS.H

1.0

hYS.C

1.0

HC.db

0.0

Addr

1

coDE

PASS

Goto

OPEr

ont.C

1.0

ConF

0

OFST

0.0

Mtr

6

20.0

AdJ

7

0.0

CJC

21.0

mV

1.17

Complete lists or individual parameters

normally hidden in Operator level. To see

all the available parameters you must select

Full level. See section 3 Access Levels

Only displayed when option selected

Summary

To step through list headers press the Page button

until the required header is obtained

To step through parameters within a particular list press

the Scroll button

until the required parameter is

obtained

To change the value (or state) of a parameter press the

Raise button

or the Lower button

2-10 Part No. HA029989 Issue 3 July-14

2200e Series Installation and Configuration Handbook Operation

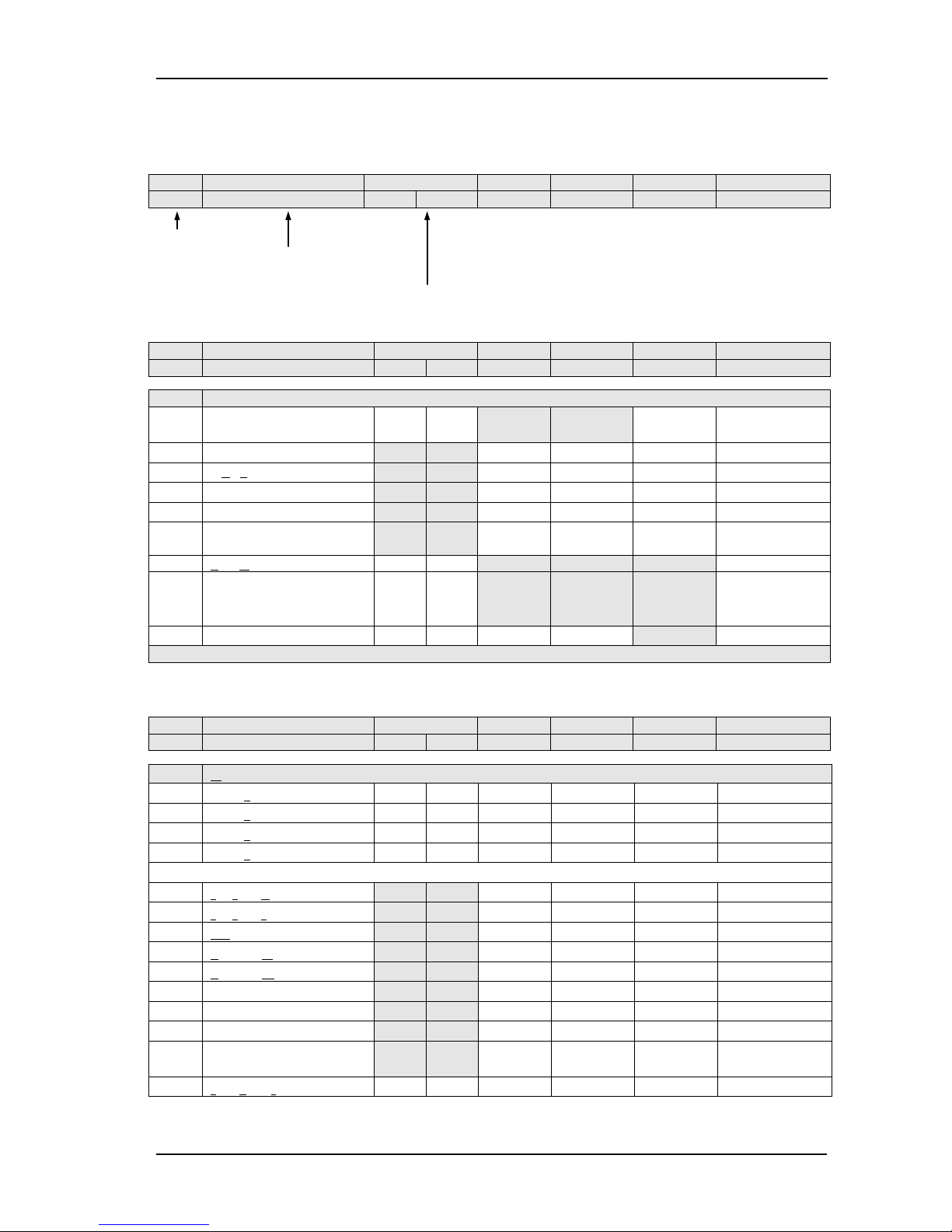

The remainder of this chapter provides a complete list of all parameters available.

2.9 Parameter Tables

The tables which follow list all parameters that are available in Full operator level.

Name

Parameter Description

Default Value

Min Value

Max Value

Units

Customer Setting

UK

USA

Display mnemonic

Brief description of

parameter or function

Factory configured value

2.9.1 HOME Display

Name

Parameter Description

Default Value

Min Value

Max Value

Units

Customer Setting

UK

USA

Home List

Home

Measured Value and

Setpoint(SP)

SP=25°C SP=75°F

as display

vPoS

Valve positioner output power

0.0 100.0

%of mtr

OP

% Output Level

-100.0 100.0

%

wSP

Working setpoint

as display

SP

Setpoint

-999 9999

as display

AmPS

Heater current (PDS modes 2

and 5)

0 100 Amps

m-A

Auto/manual select

Auto Auto

diSP

Configure lower readout of

home display

StD StD

None“ StD“

AmPS“ OP“

stat“ vPoS

Cid

Customer ID

0 0 0 9999

Additional parameters may appear in the Home display if the ‘promote’ feature has been used (see Edit Level, section 3).

2.9.2 Alarm List

Name

Parameter Description

Default Value

Min Value

Max Value

Units

Customer Setting

UK

USA

AL

Al

arm List

1---

Alarm 1 set point value

0 0

as display

2---

Alarm 2 set point value

0 0

as display

3---

Alarm 3 set point value

0 0

as display

4---

Alarm 4 set point value

0 0

as display

In place of dashes, the last three characters indicate the alarm type, as follows:

-FSH

Full Scale High alarm

-999 9999

as display

-FSL

Full Scale Low alarm

-999 9999

as display

-DEv

Deviation band alarm

0 9999

as display

-dHi

Deviation High alarm

0 9999

as display

-dLo

Deviation Low alarm

0 9999

as display

-Lcr

Low current alarm

0 100

AMPS

-Hcr

High current alarm

0 100

AMPS

Hy

Hysteresis

0 9999

as display

Hy.EV

Hysteresis for event alarms.

See Note 1

0 9999

as display

Lbt

Loop break time

OFF OFF 0 9999

secs

Note 1: This parameter has been added from software version 4. Event alarms are configured in the AL Conf List.

Part No. HA029989 Issue 3 July-14 2-11

Loading...

Loading...