W11E WHEEL LOADER

OPERATION MANUAL

P. de Heus en Zonen Greup B.V.

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel: +31 (0) 18 66 12 333

E-mail: info@eurotrac.nl

CONTENTS

1. SAFETY INFORMATION ............................................................................................................... 4

1.1 Revision record..................................................................................................................................... 4

1.2 General warning................................................................................................................................... 5

1.3 Information and operations ................................................................................................................. 7

1.3.1 Standard configuration ......................................................................................................... 7

1.3.2 Operator responsibility ......................................................................................................... 7

1.3.3 Mechanical responsibility ..................................................................................................... 9

2. GENERAL INFORMATION & OPERATING INSTRUCTIONS ........................................................... 10

2.1 Main components .............................................................................................................................. 10

2.1.1 Joystick for lifting frame ...................................................................................................... 18

2.1.2 Joystick for auxiliary hydraulics ........................................................................................... 19

2.2 Specifications and performance......................................................................................................... 24

2.3 Transport procedures......................................................................................................................... 27

2.4 Trailer procedure................................................................................................................................ 27

2.5 Stored procedures.............................................................................................................................. 28

3. MAINTENANCE PARTS .............................................................................................................. 29

3.1 General description............................................................................................................................ 29

3.2 General cleaning instructions............................................................................................................. 29

3.3 Service ................................................................................................................................................ 30

3.3.1 Preparation for use ............................................................................................................. 30

3.3.2 Regular maintenance form ................................................................................................. 31

3.3.3 Oil & Lubricant .................................................................................................................... 33

3.4 Troubleshooting ................................................................................................................................. 35

3.4.1 Kinetic energy reduction ..................................................................................................... 35

3.4.2 Drive axle ............................................................................................................................ 36

3.4.3 Brake system ....................................................................................................................... 37

3.4.4 Lithium battery .................................................................................................................... 38

FIGURE 1: W11E HYDRAULIC SCHEMATIC .......................................................................................... 39

FIGURE 2: ELECTRICAL SCHEMATIC .................................................................................................... 40

FIGURE 3: BODY LOGO LAYOUT ......................................................................................................... 41

DAILY EQUIPMENT INSPECTION ........................................................................................................ 42

4. SME ELECTRONIC CONTROL SYSTEM ........................................................................................ 43

4.1 About warning, caution and information notices .............................................................................. 43

4.2 Troubleshooting and fault codes........................................................................................................ 44

4.2.1 Fault levels .......................................................................................................................... 44

4.2.2 Fault list ............................................................................................................................... 44

5. AC SMARTMOTION AC-M2 OVERVIEW ..................................................................................... 51

5.1 Product description ............................................................................................................................ 51

5.1.1 Product Indication Label .................................................................................................... 52

5.2 General Specifications ....................................................................................................................... 52

5.3 Electrical Specifications ...................................................................................................................... 53

5.3.1 Input and Output Ratings .................................................................................................... 53

5.3.2 Signal: Inputs and Outputs ................................................................................................. 53

5.3.3 Interfaces ............................................................................................................................ 55

W11E | Operation manual

CONTENTS

5.3.4 EMC ..................................................................................................................................... 55

5.3.5 Safety .................................................................................................................................. 55

5.4 Operating Environment Specifications .............................................................................................. 55

6. INSTALLATION AND WIRING ..................................................................................................... 56

6.1 Controller ........................................................................................................................................... 57

6.2 Power Terminals................................................................................................................................. 59

6.3 Main contactor................................................................................................................................... 60

6.4 Fuse .................................................................................................................................................... 61

6.5 Signal ................................................................................................................................................. 62

6.5.1 Digital Inputs ....................................................................................................................... 63

6.5.2 Analog Inputs ...................................................................................................................... 64

6.5.3 Driver Outputs (PWM) ........................................................................................................ 65

6.5.4 Digital Outputs (ON/OFF) .................................................................................................... 66

6.5.5 Speed Sensor Inputs ............................................................................................................ 67

6.5.6 Thermal Probe .................................................................................................................... 68

6.5.7 Serial ................................................................................................................................... 68

6.5.8 CAN Network ....................................................................................................................... 69

6.6 SME external devices description ...................................................................................................... 70

6.6.1 Encoder ............................................................................................................................... 70

6.6.2 Displays ............................................................................................................................... 71

7. GRAPHICAL INTERFACE ............................................................................................................. 72

W11E | Operation manual

1. SAFETY INFORMATION

1.1 Revision record

Due to the continuous improvement and innovation of product design, the product changes; this manual might not

include these latest changes. Upon request we can send you the latest version of the manual.

We reserve the right to make improvements and changes to the loader of a model on our own products without any

representation.

If you need more maintenance information outside of this manual, please contact your EUROTRAC dealer.

Issue date:

Update number Disassembly Load Replacement instructions

Page 4/72

October 2019W11E | Operation manual

1.2 General warning

WARNING

Foreword

These operating instructions apply to all users of the loader: company manager, department head, driver and other

personnel associated with or working near the loader.

1. Read this manual and follow the instructions in the manual before using the loader.

2. Read the instructions on the loader carefully and keep the text legible.

3. All operators must read this manual.

4. All personnel qualified to use the loader can operate the loader in accordance with safe use regulations.

5. When the machine is idle, do not let other people touch the machine.

6. Do not use if the loader does not work properly.

7. Do not use the loader for work that exceeds its maximum load or maximum capacity.

8. Do not use the loader to perform work beyond its scope of use.

9. Be familiar with the safe operating rules associated with using this loader and follow the rules exactly.

10. The manufacturer assumes no responsibility for the consequences of dismantling or modifying the loader.

Obligation to read the manual

The company manager must familiarize the operator with the operating rules of

the manual.

Read the entire chapter before attempting to operate the loader. It is the

responsibility of the company manager to ensure that the operating rules in the

manual are implemented. The operator must read and be familiar with the

instruction manual so that it can be operated in accordance with the rules when

starting and using the loader. This instruction manual should be kept intact during

the life of the loader, even if the machine is resold, replaced by the user or

manager, etc.

This manual is not a training manual, but it can also be used as one of the training

materials if it is really necessary to train the operator.

General instructions

The company manager must ensure that the operating manual (including the

certificate of conformity issued by the European Community) is delivered with the

loader.

• When the product leaves the factory, the manual will be included.

• The product certificate is sent along with the shipping order. Under the

authority of the company manager, the trained personnel and the person

with the relevant driver's license can operate the loader and the operation

must not exceed the scope of the machine design. The loader must be

operated in accordance with the conditions specified by the manufacturer in

the operating manual. The manufacturer will not be liable for any personal

injury, property damage and environmental pollution caused by failure to

follow the procedures specified in the instruction manual. The

manufacturer's responsibility is to match the assembly structure of the

machine to the instructions in the certificate of conformity. Before each use,

the driver should check that the machine is all right. It is forbidden to use the

loader without checking the machine and without checking the warning

decals.

Page 5/72

October 2019W11E | Operation manual

Loader normal use range

W11E Electric Loader – Maximum allowable load and general conditions of use are included in this document.

Do not use the loader to load anything other than the scope of use. This loader is suitable for use in the temperature

range - 30 °C - 45 °C

Users should not ignore this rule: EUROTRAC is not responsible for all the dangers and injuries caused by this.

Loader modification

The manufacturer does not assume any responsibility for the modification of the loader and the addition of

accessories by equipment not manufactured by Eurotrac. The manufacturer assumes no responsibility for the

consequences of the replacement or modification of the machine's features or other mechanical, electrical,

hydraulic-related accessories or mechanically welded structures without the written consent of the manufacturer.

If the customer needs to modify the machine, please consult the manufacturer. For your safety and your ability to

benefit from all warranty terms of manufacture, use spare parts manufactured and warranted by the manufacturer.

Notice

Safe operation is very important to your personal safety and economic efficiency, which means that we have a

responsibility to promote safe operation knowledge. EUROTRAC has always regarded product safety as its

responsibility, so we pay great attention to the safety of the loader when designing the loader for you.

Your job is to operate safely. The safety of you and others depends on your competent operations, especially on

your understanding of the following brief safety rules and voluntary compliance.

Security Information

This manual provides you with some important information to help you familiarize yourself with the safe operation

and maintenance of the EUROTRAC loader. Even if you are familiar with the operation of a vehicle similar to a wheel

loader, you must read and become familiar with this manual before operating this loader. Safe operation is

everyone's responsibility and therefore your primary responsibility. Knowing the operating instructions in this

manual will ensure the safety of you and the staff around you.

Safety is a very important part that affects the life of your loader. Read and study this manual before you operate,

maintain or otherwise use this loader to know how to safely use the controls of the loader and the safety

maintenance you must do. If you have any questions about the safe use or repair of the loader, ask your boss - don't

guess - check often!

Remember that a careful driver will not only protect himself, but also protect his colleagues at work; at the same

time he will avoid the danger of damaging the loader and cargo at work.

Page 6/72

October 2019W11E | Operation manual

1.3 Information and operations

WARNING

1.3.1 Standard configuration

Standard loaders have the following features:

1. Travel motor

2. Power Steering

3. Electromagnetic parking brake

4. Electronic shift control

5. Multi-function hydraulic control handle

6. Attachment quick change and locking mechanism

7. Adjustable shock seat (seat belt)

8. Lift arm / boom

9. Non-slip flooring

10. Combination LED headlights

11. Roll cage with sunshade cover

12. Direction indicator

13. Work light

14. Combination meter

15. Adjustable steering wheel

16. Double ball joint hinge

17. SME Controller

18. 51.1V 400Ah Lithium battery

1.3.2 Operator responsibility

You must read this chapter and thoroughly understand it, then operate or perform any maintenance on the device.

Failure to observe the following safety precautions can result in serious injury or death, as well as equipment

damage.

1. Always follow global safety rules in your field.

2. Always check for proper operation and lighting, brakes, steering, parking brakes, parking brakes and tires

before using this loader.

3. Do not operate the loader with defective features; refer to the operation and service manual of the

maintenance section.

4. Always wear suitable shoes when handling the device and avoid loose clothing that may get stuck in moving

parts.

5. Before use of the loader, fasten the seat belt and confirm that the lock is fastened.

6. After the loader has completely stopped, place the gear in the neutral position. Before leaving the loader, turn

off the power and pull out the key.

7. Wait until the vehicle stops completely before the transition goes from forward to backward or from back to

forward.

8. Check the road after reversing.

9. When loading materials, the speed should be reduced to 5KM/H.

10. Raise the bucket to the transport position (minimum ground clearance greater than 20cm).

11. Be extremely careful when in crowded areas and near blind roads and trucking. Be alert to other devices and

people.

Page 7/72

October 2019W11E | Operation manual

12. Do not operate if the speed does not meet the operating conditions. Always limit the speed to ensure you have

NOTE

NOTE

NOTE

enough time to brake in an emergency.

13. Do not use the loader to shovel dangerous goods.

14. Before using this loader, the roll cage must be raised and the latch in the locked position.

15. Do not allow any form of traction on the loader other than the towing hook.

16. Do not perform repairs while the motor is running hot, as this can result in severe burns. Please perform

maintenance after cooling.

17. Do not attempt to touch the running motor and pump motor that is running or just stopped, otherwise it will

cause severe burns.

18. After the hood back cover is opened, make sure to not use clean water or other liquids since they can splash

into the controller and the battery causing a short circuit.

19. Do not use the battery of this car to start other vehicles.

When the vehicle is tilted or rolled over, do not jump, but hold on tight to the steering wheel.

The roll cage damaged by rollover is not allowed to be repaired and reused unless it is authorized or approved by

EUROTRAC.

The rated working load calibrated in this manual is based on the ground level of the machine. When operating on

non-standard road surfaces (such as soft, uneven roads or on slopes), the effects of these factors on the load should

be fully considered.

Page 8/72

October 2019W11E | Operation manual

1.3.3 Mechanical responsibility

WARNING

You must read this chapter and thoroughly understand it before performing any maintenance on the device.

Failure to observe the following safety precautions can result in serious injury or death, as well as equipment

damage.

1. Always follow local safety regulations.

2. The operator must be familiar with the operation of the machine before using it.

3. Always keep your hands and feet away from rotating parts and tires, and wear safety uniforms.

4. Always wear the right shoes when handling or servicing equipment. Avoid wearing loose clothing, which may

get stuck in moving parts.

5. Always ensure the cleanliness of the controller cooling fan.

6. Do not start the machine in an explosive environment.

7. Do not check gear oil when the motor is running.

8. Always disconnect the main power switch of the lithium battery when working on the travel motor.

9. If the lithium battery is overheated or abnormally discharged, do not attempt to perform repairs in private.

Please contact a professional for repair.

10. Do not touch the oil pump motor and the travel motor when it is hot, otherwise it will cause severe burns.

11. Do not smoke near a lithium battery. Always keep the lithium battery away from sparks, flames and smoking.

12. Always remove the metal bracelet, watch strap, etc. before installing, removing or maintaining the lithium

battery.

13. Do not allow short circuit lithium battery terminals.

14. When connecting a lithium battery, always connect the positive terminal first to prevent sparks.

15. Check all lights.

16. Check the reverse warning alarm.

17. Make sure the machine is in neutral when starting. Put the seat, handlebars and mirrors in the correct position

before use.

18. Check tire and wheel conditions for proper inflation pressure. Excessive inflation can cause tires to explode.

19. Tighten the rim nut to a torque of 130 ft-lbs. Check the torque after 5 hours of operation.

20. Use appropriate lifting equipment when removing or replacing heavy parts.

21. When working under the loader, make sure that it is properly supported on the safety crane. Not completely

dependent on hydraulic jack support loader.

22. If the loader is raised under a hydraulic or air lift, ensure that the loader has a secure support or fixed position

before working under the loader.

23. When checking or repairing the drive system failure, jack up the drive wheel.

24. Do not smoke when injecting oil.

25. Do not use the lithium battery of this car to start other vehicles.

Page 9/72

October 2019W11E | Operation manual

2. GENERAL INFORMATION & OPERATING INSTRUCTIONS

2.1 Main components

The W11E is a four-wheel drive mini loader. It contains:

• Hydraulic motor

• Travel motor

• Multi-function operating handle

• 12 volt electrical system

• 51.1V400Ah lithium battery

The loader is equipped with a powerful mobile motor that is certified by the

Travel motor

Drive axle

Brake system

Wheels and tires

manufacturer to meet the job requirements and environmental requirements for

zero emissions.

The rear axle of the W11E is driven by the travel motor and then transmitted by

the drive shaft to the front drive axle.

This wheel loader brakes on the front axle and driving engine by pressing the

brake pedal.

The loader tires are pneumatic and are able to travel smoothly and effectively

maximize traction. Remember to check the pressure on your pneumatic tires

regularly.

Unbalanced tire pressure will not only increase tire wear, but also reduce traction

performance.

Electrical System

Quick disassembly device

Seat

Battery charger

Multi-function joystick

Parking brake

Pedal

W11E tire model: 26x12-12AS Tire pressure: 3.0bar

The loader uses a 12 volt, automatic type, negative ground electrical system. The

system includes a 51.1V400Ah lithium battery (see battery instruction manual for

specific parameters), ignition switch, two headlights, amber flash, direction lights,

taillights, speakers, various meters and other circuits.

The attachment of the attachment is controlled by a multi-way valve for quick

assembly and disassembly.

The seat of the loader is equipped with a seat belt and can be adjusted back and

forth. The seat rating is EM8 (optional).

The loader is equipped with an integrated 220V battery charger with charging

indicator. Max. loading time 6 hours

The joystick is located to the right of the driver's position. As a standard, the

switch on the device can control the gear position of the loader. There are 3 gear

positions: forward gear, neutral gear and reverse gear, and reset button. The

handle can also control two multi-way valves, so that lifting and tilting can be

performed separately or in combination.

The electric driving motor is equipped with a parking brake drum. After the

vehicle stops for a few seconds, the electronic control motor is powered off, and

the brake is automatically locked.

The accelerator pedal on the right side of the driver is connected to the controller

via wires to control engine speed and thus control the speed of the loader The

inching pedal on the left side of the driver is connected to the front axle brake

drum via the brake hose to control the speed of the loader.

Page 10/72

October 2019W11E | Operation manual

NOTE

NOTE

The operation of the steering wheel is the same as usual, that is, when the

Steering wheel

steering wheel is rotated to the right, the loader turns to the right, and when the

steering wheel rotates to the left, the loader turns to the left.

Instrument panel Design control panel combined with the best driving comfort and efficiency.

It is important that the operator adjusts the seating position and gets familiar with the controls before starting to

work.

The root mean square value of the vibration acceleration of the machine acting on the arm is less than 2.5m/s2.

The root mean square value of the vibration acceleration of the machine acting on the whole body is less than 0.5m/s2.

Switch

Ignition switch Waterproof ignition switch for loader, including anti-restart function.

Horn control switch Mounted on the underside of the instrument panel.

Headlight switch Mounted on the underside of the instrument panel.

Warning light switch Mounted on the underside of the instrument panel.

Parking brake switch Mounted on the underside of the instrument panel.

Turning signal switch Mounted on the left handle of the instrument panel.

Far and near light switch Mounted on the left handle of the instrument panel.

Wide light switch Mounted on the left handle of the instrument panel.

Page 11/72

October 2019W11E | Operation manual

SME Dashboard

Wheel loader travel speed (km/h)

Hand brake switch.

This indicator lights when the hand brake is pulled up.

Safety seat switch.

If the seat switch is not closed, the dashboard will display the seat icon.

The seat switch does not pull in and the wheel loader cannot work until the seat

switch is closed.

Working hour meter (odometer).

Steering angle showing the position of the rear wheel.

Maintenance time prompt.

Prompt the user to the maintenance time.

Slow operation.

This light is on, indicating that the vehicle is operating in the slow mode, and the

speed and lifting speed are reduced.

Page 12/72

Accelerator pedal position (0 to 9 grids).

Motor temperature overheat alarm.

Battery power is indicated by 9 stripes:

9 = Fully charged

0= Empty

If the battery is completely discharged there is no stripe showed and the

meter will display fault code 12.

The battery must be charged when the display shows one stripe.

October 2019W11E | Operation manual

By pressing the E-S-H button, you can set the operating mode for your system (EEconomy, S-Middle Mode, H-High Mode)

H-up mode: At this time, the acceleration, deceleration rate and maximum grade of

the vehicle are higher. It is suitable for transporting a large amount of cargo and

climbing a steep slope in a short time, but it costs electricity, unless it is urgently

needed, it usually does not work in this mode.

S-mid-range mode: Each indicator is slightly lower than the high-end mode.

E-Economy: All parameters are optimized, power saving, it is recommended to work

in this mode.

1. When the key switch is activated, press the enter button for 3 seconds to enter

the adjustment and diagnosis mode.

2. During the operation, press for 3 seconds to enter the diagnostic mode.

3. If you press enter once in the diagnostic mode, you can exit, and the enter key

is usually used as the new parameter value.

1. Press this button to decrease the parameter value in the adjustment or

diagnosis mode.

2. In the adjustment state, the display parameter value can be reduced.

3. Press the button for 1 second to display the mileage or weight.

Note: The up button is the same as the down button. Some functions of the enter

button and the up and down buttons are not activated.

There are four LED indications on the left side of the instrument cluster. When the switch is operated, the

corresponding indicator will be displayed:

Warning sign: LED shows red

Light identification: LED display green

The steering switch is turned on, the turn signal indicator is activated, and the LED

flashes green.

Brake fluid low: LED red alarm (optional)

Instrument working process and instructions for use:

1. Turn on the key switch; the dashboard is switched on, some initial digital mode will be displayed for 3 seconds.

The dashboard states the speed indication content, the power indicator, the steering angle indication, the hand

brake indication, the seat switch indication, the E/S/H selection indication, the working time, and the like.

These pattern data will help confirm the vehicle's working status.

2. The top of the left row of the LCD screen is the fault indication. When this indicator is on, the following three

working states are displayed:

- Display normal operation (lights when the system switch is on or off).

- The meter is not connected to the control box (the indicator lights up after the connection stops for 3

seconds).

- The meter is not working (the indicator is on).

When the vehicle is working normally, there is no fault code and the fault light is off.

3. When the direction indicator is turned forward and backward, the left and right turn mark lights flash, and

when the headlights are turned on, the light indicator lights.

Page 13/72

October 2019W11E | Operation manual

4. Brake display. When the parking brake is used, the graphic [P] light is on; when the parking brake is released,

NOTE

NOTE

the marker light is off.

When the power indicator only shows one dash, it must be charged to extend the battery life.

Working environment:

1. The altitude does not exceed 1200 meters.

2. Working environment temperature -25 °C ~ +40 °C.

3. The maximum relative humidity is not more than 95%.

Precautions:

1. The dashboard is prohibited from water dripping. When the user washes the vehicle, be careful not to spray or

sprinkle water onto the inside of the instrument. If water is accidentally drenched onto the surface of the

instrument, immediately wipe it off with a dry cloth.

2. Do not plug or unplug the dashboard and the harness frequently to avoid loose contact.

3. It is forbidden to strongly impact and scratch the instrument.

4. If the instrument is not working properly, please contact the company in time for maintenance.

BEFORE DRIVING

• Be sure that all driving parts are in good working condition and fill all the fluid levels if necessary. Any defect or

failure has to be repaired before use.

• Set parking brake

• Walk around and inspect the loader for damage or missing equipment

Check for:

- Pressure and the good state of the pneumatic tires

- Look for cuts, cracks in side walls, foreign objects in treads

- Look for loose wheel nuts - Damage to lights

- Fire extinguishers fully loaded and in place (if have)

• Check to see if hydraulic or lubricating oil is leaking. If leaks are detected, they must be repaired as soon as

possible.

• Check the amount of fluid in the hydraulic tank to make sure there is enough hydraulic oil. If there is a very low

liquid level display, there is a serious leak in the system and it should be repaired as soon as possible.

• Check the power cabin for loose components, loose wires or equipment leaks.

• When all mechanical checks are completed, check that the stop lights and rear lights and dashboard lights are

working properly.

• Check the electricity meter to make sure the lithium battery power is sufficient.

• Make sure the roll cage is raised and locked firmly.

• Check if the driver's seat is damaged (replace the damaged one) and adjust the driver's seat according to your

needs.

• Check all operations in the work order.

The battery life will be damaged if the battery is undercharged. The battery should be charged after daily work to

ensure that the battery is fully charged.

Page 14/72

October 2019W11E | Operation manual

DRIVING INSTRUCTION

NOTE

• Place shift lever in park.

• Adjust the driver seat and steering wheel to the comfortable

location, fasten the seat belt.

• Make sure parking brake is set.

• Verify that nobody and nothing is ahead of you BEFORE starting

any motion of the wheel loader.

• Turn on the main power switch located at the left side, behind

the seat. Turn this for 3 seconds to the left till the green light

turns on (see picture).

• Turn on the ignition switch on the side of the dashboard.

• Release the handbrake by pressing the button on the dashboard.

• Move the transmission shift lever into the required position, Forward or Reverse.

• Press the acceleration pedal slowly with your feet. The wheel loader will move to the selected direction.

• To slow the wheel loader, slowly release the accelerator pedal and press the left brake pedal. For an emergency

stop, release the accelerator pedal and press brake pedal. By releasing the accelerator pedal slowly or quickly,

the wheel loader can be controlled by flat or sharp braking. Press the left-pedal when emergency brakes.

The main power switch will turn of automatically when there is nobody on the driver seat for longer than 60

seconds.

CHARGING THE BATTERY

The Eurotrac W11-E comes standard with a built-in 220V battery charger. With the supplied cord it is easy to

connect to the machine and charge via a 220V connection. The status of the battery can be easily seen on the load

indicator.

Red = less than 80% | Yellow = 80% | Green = 100% loaded |Max loading time = 6 hours

Page 15/72

October 2019W11E | Operation manual

WARNING

The maximum duration of control for an operator should not exceed 6h per day.

WARNING

WARNING

WARNING

WARNING

WARNING

Match driving speeds to loads being towed and weather conditions. Slow down when towing heavy loads and when

road surface is wet or icy, especially on grades.

When loading the goods, the speed should be lowered to 5km/h and the bucket should be raised to the

transportational position (about 20cm from the ground).

In the course of ramping on the road (uphill) for the temporary parking, drivers are not allowed to leave the driver's

seat and change gear switch. Right foot should press the micro-pedal gently to remove any slipping phenomenon

due to technical reasons. At the same time pull up hand brake. Downhill for the temporary parking. Drivers are not

allowed to leave the driver's seat and switch to a reverse gear shift, right foot should press the micro-pedal gently

and park slowly, at the same time pull up hand brake.

Parking on the ramp is not allowed. If necessary the car should be parked on a slope (due to breakdowns), you must

pull hand brakes and pad the wedge under wheels of the loader.

Make sure the roll cage arises and fixed before driving, it can‘t protect the driver if the roll cage don‘t arise or fixed

insecure.

LOADING INSTRUCTION

• Lift devices and attachments (bucket is standard) are only used for a specified purpose.

• Ensure the wheel loader is secure and is within the rated drawbar pull of the loader (See “General preventive

measures“).

• Ensure the rapid removal device in a locked position before filling.

• When driving with a load, the speed should be reduced to 5 km/h.

Page 16/72

October 2019W11E | Operation manual

• When driving with a load, the bucket should be raised to the transformational position (about 20cm from the

NOTE

WARNING

WARNING

WARNING

WARNING

WARNING

ground).

• When driving on the ramp, goods shall be towards the uphill direction. U-turns and parallel driving on ramps

must be avoided.

• Only operate the machine when having clear and unobstructed view.

• When uninstalling, raise the bucket to an appropriate height, as carefully as you can accurately to drive the

wheel loader to the truck or the place for goods storage; Carefully control the master control lever, uninstall,

reset; Confirming that the bucket and the truck (shelf) is completely separated, the loader moves slowly back

to leave the shelf.

• When reaching the parking spot, shift it into neutral position, raise the parking brake, and turn off the ignition

switch.

Safe and efficient loading, depends entirely on the operator. If you are an experienced driver, the following rules

will refresh your memory. If you are a student, they will help you to become a professional driver.

Only qualified and licensed drivers allowed to drive.

Before starting loading, please make sure the cylinder of the quick removal device is in the locking position, set the

locking tools, and cut the two-way ball valve off.

When driving on the ramp (forward or backward), goods shall be towards the uphill direction. Driving or u-turn

ramping on the horizontal should be avoided.

When the goods are in a lifting state, do not leave the loader.

When the goods are in a lifting state, the loader can not turn around and can not run at high speed.

Page 17/72

October 2019W11E | Operation manual

2.1.1 Joystick for lifting frame

WARNING

Accident hazard due to wheel loader tipping! Keep the lifting frame lowered during transport.

Accident hazard due to uncontrolled lifting frame movement!

Only operate the lifting frame and attachment from the driver's seat!

Always work calmly and cautiously. Hectic and rapid operation leads to accidents.

Always lower the lifting frame during interruptions and at the end of the shift.

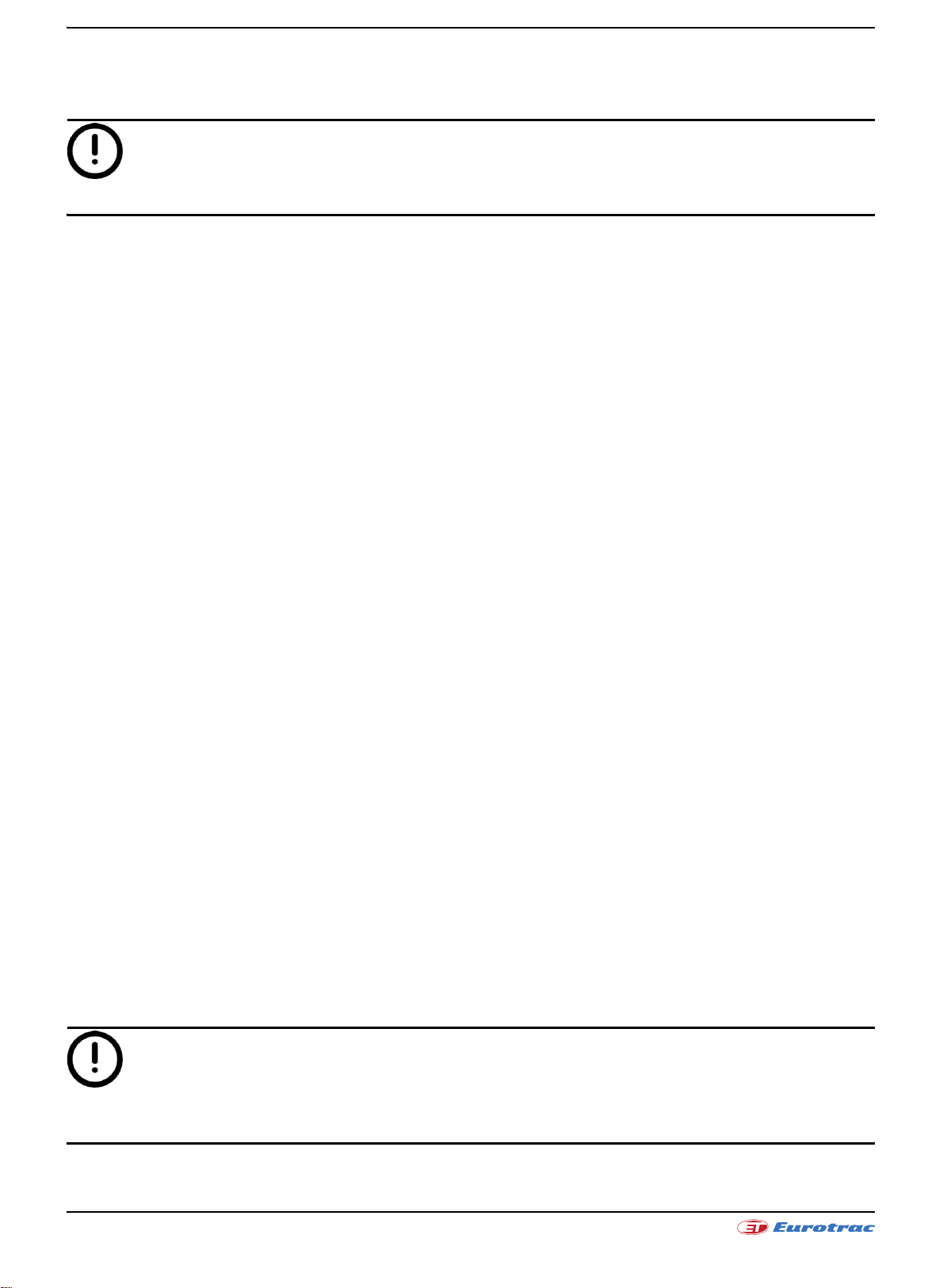

Lifting frame movements are controlled by the joystick. The joystick

is located to the right of the driver's seat.

Lifting frame

• Move the joystick backwards: the lifting frame rises.

• Move the joystick forwards: the lifting frame lowers.

• Move the joystick 2 step forwards: the lifting frame is now in the

floating position (optional extra).

Attachment

• Move the joystick left: the attachment tips inwards.

• Move the joystick right: the attachment tips outwards.

Page 18/72

October 2019W11E | Operation manual

2.1.2 Joystick for auxiliary hydraulics

WARNING

Hazard due to hydraulic system overheating! Ensure that the auxiliary hydraulics joystick is always in the "zero

position" when the auxiliary hydraulics are not required. Lock the auxiliary hydraulics joystick when it is not

required. (To do this, press the joystick down firmly until it locks into place. To unlock, you must pull the joystick

back up firmly.) Avoid soiling. Ensure that the hydraulic connections are clean!

The additional hydraulics on the front arm: press the auxiliary hydraulics button and move the joystick to the left

and right. The auxiliary hydraulics can be very precisely controlled. Take care to use the joystick carefully.

Eurotrac W11 Eurotrac W12/W13

• Push the joystick to the left (and simultaneously press the auxiliary hydraulics button):

The left connection is the pressure side, the right is the return.

• Push the joystick to the right (and simultaneously press the auxiliary hydraulics button):

The right connection is the pressure side, the left is the return.

This may vary from model to model. Please always check this before using the wheel loader with optional

equipment.

Auxiliary hydraulics

This can be operated using an additional lever with switching valve. Let yourself be instructed by qualified personnel

and complete this manual here.

Replace attachment

1. Push the small handle of multi-way valve to the left to retract the locking lever.

2. Lower the working device and tilt it forward to the appropriate position.

3. Connect the hook in the attachment.

4. Hoist and tilt working device.

5. Push the small handle of the multi-way valve to the right to make the locking lever extend and insert the

mounting hole under the fitting.

6. The two three-way valve rotates 90°, cut off the lock cylinder oil.

Page 19/72

October 2019W11E | Operation manual

Remove the attachment

WARNING

WARNING

WARNING

WARNING

WARNING

The step is reversing as changing attachment step.

Lifting devices and tools are only used for a specified purpose. Drivers must comply with the correctly and use the

lifting devices and tools. Do not enter or reach into the space between the arm and the frame.

Before the operation of hydraulic systems, check if the functions of the various hydraulic joysticks are correct.

Before disassemble the pipe of attachment, should release the rest pressure of this pipe, then disassemble the quick

change connector. The detailed method of release rest pressure is: swing the first valve handle (small handle) of

multi-valve left and right side several times.

Even if the engine flameout can also lower the lifting devices and tools.

If the tool is not delivered together with the loader, it can be only used after the authoritarian of stability and load

capacity by the dealer of EUROTRAC.

General preventive measures

• Do not operate any levers or pedals if anyone is in any position to be hurt by the machine's movement.

• Pay extra attention when working in narrow congested areas or in case of blind travel.

• Always look around in all directions BEFORE changing your direction of travel.

• Always follow all safety rules or each particular site during operation.

• Maintain a running speed which is compatible with the load and the ground conditions.

Page 20/72

October 2019W11E | Operation manual

• Slow down when approaching corners

• Observe pedestrians carefully and do not follow the vehicle in front too closely.

• Do not brake sharply and only select neutral once the loader has effectively stopped.

• Maintain a safe distance from the edge of loading wharf.

• When turning, pay close attention to the trajectory of the buckets.

• Make sure that bridges and ramps are able to withstand the weight of the loader and the load being towed.

• Before climbing or descending from vehicles (trucks, trails etc), ensure that the adequate precautions are been

taken to avoid all movements including the dumping.

• Stop, look at and listen when arriving to a rail way then to cross it in diagonal, slowly and only to the authorized

points.

• Always park at more than 2,5m of the rails.

• Hold the wheel steering in hand during the operation.

• When loading a larger load, more space for the overtaking of parked vehicles, objects or pedestrians should be

predicted.

• Never overtake another vehicle on crossroad or on bifurcations or when something affects the visibility for you.

• Never drive in elevators, truck or other until you have received the order and you are sure that they can stand

the combined weight of loader and the load.

• Doesn't brake roughly.

• Pay attention to the driving speed and be careful to the pedestrians approaching and other vehicles and to the

passage heights.

• Slow down on wet, irregular grounds and in the turning.

• Remove all objects in your way.

• On the crossroad, in the passages and the corridors, slow down and horn and drive on the right side of the road.

• Be careful to the pedestrians which can appear suddenly in the way.

• If your trip involves crossing road bridge, ensure they are secure and are strong enough to withstand the

combined weight of the loader and load.

• When approaching the destination, reduce the speed to ensure a smoothly slow stop in the far enough

distance. A sudden halt could cause the load displacement.

• In the event of an emergency, first place the load on the ground before you proceed with further action.

• Report any mechanical or electrical irregularities immediately.

• Always be alert; Watch out for pedestrians and never drive too close to the vehicles in front.

• Travel at a speed consistent with load and road conditions.

• Never operate the loader with any part of your body outside of the operator's compartment.

• DO NOT leave the driver's cab with the loader running.

• ALWAYS properly shut down the loader before leaving the loader.

• ALWAYS park the loader on solid, level ground.

On severe slopes

• ALWAYS park the loader perpendicular to the steepest slope to prevent accidental movement.

• Use proper flags, warning marks or barriers when parking in areas of traffic.

• Do not park your vehicle in the access points where obstruct the fire brigade.

• During parking, use the parking brake and put the key on the STOP position.

• If the tractor must leave with nobody watching it, remove the ignition key.

• Never park your vehicle on a slope.

• If it is necessary to park tractor on a slope (break down etc), use the wedge under the wheels of loader.

• Do not drive while the rear cover is open.

• Don't make dangerous modifications to lithium batteries.

Page 21/72

October 2019W11E | Operation manual

WARNING

If problems or equipment malfunctions occur while operating the loader, it must be properly to shut down and

WARNING

correct the problem.

Continuing to use malfunctioning equipment can not only be unsafe for the operator and other personnel, but can

lead to further damage to the loader as well.

In case of an accident, report to your superior immediately. Never neglect an injury even if it appears insignificant,

go immediately to the doctor, which could avoid complications.

AREA RISK SAFETY STEPS

CAUSES OF FAILURE

ENTIRE MACHINE

WHAT CAN HAPPEN IF PRECAUTIONS

AND SAFEGUARDS ARE NOT OBEYED

A moving wheel loader can run over or

crush body parts between tractor and

other object and cause irreparable

injury or death.

HOW TO PREVENT THE FAILURE

Keep away all people from around tractor and

always switch off the engine before leaving

the driver's cab.

DRIVING STATION

UNDERNEATH

DURING SERVICE

MOTOR

LITHIUM BATTERIES

ROLLING OR ROLLING

OVER OF VEHICLE

TIRE

Personnel injuries may happen if parts

of the body or members (hands, legs,

etc.) are outside of the driver's cab.

Unit lifted for service could fall and

injure or kill personnel around.

Hot (motors) will cause severe burns

and cause serious injuries if persons

are struck by moving parts or caught in

belts.

Lithium batteries can explode when

dangerous operations such as welding

and drilling. Contact with a battery

socket or all unprotected electronic

parts (or when removed) can result in

an electrical shock.

When a vehicle rolls or rolls over, do

not jump off, as the loader is installed

with a safety roll cage. Jumping of may

lead to the drivers death.

Welding near the tire may damage the

tire or lead the lead an explosion and

bring damages or dangers for people.

Keep head, arms, hands, legs and feet inside

the operator's compartment all the time.

If loader must be lifted for service, it must be

securely blocked so that all 4 (four) wheels

may safely turn.

DURING SERVICE: Turn off the main power. If

maintenance operation requires starting

motor, personnel should avoid contact with

rotating equipment. Disconnect the lithium

battery power supply to prevent accidental

startup. Be careful to avoid hot surfaces.

Lithium batteries should be well ventilated

before use, especially when welding near

them. When operating a lithium battery, wear

protective clothing, protective gloves and

protective glasses. Avoid removing plastics

and avoid contact with electrical parts.

At this point your hands should hold the

steering wheel, and feet hold the mounting

brackets.

If welding has to be done on the wheel or near

the wheel, remove the tire first.

Page 22/72

October 2019W11E | Operation manual

• To avoid loaders accidental movement, put some wedge blocks under tires when provide services and

maintenance vehicles.

• Always stop the engine when working after the wheels.

• Don’t try to repair the machine by yourself if you haven‘t been approved by EUROTRAC.

• Don't carry out any modification that is not showed in the section 3. “MAINTENANCE PARTS“ of this manual.

• EUROTRAC is not responsible in case of any modification, addition or combination with equipment from

another origin, which maybe cause danger.

• Don‘t change the structure and performance of vehicle when EUROTRAC is not informed.

Electrical equipment

• Do not change the electronic- or hydraulic factory settings to prevent short circuit when working in the

electrical system disconnecting the battery; similarly, it also can to prevent unexpected start-up when the

engine is working.

• Do not check battery status near open fires, especially when lithium batteries are recharged.

• Do not smoke in the lithium battery charging area.

• No unauthorized disassembly by non-professional personnel.

• Do not tamper with the battery.

• Do not use wires to directly short circuit the outlet of the battery pack.

• The charging and discharging shall not exceed the maximum current specified in the technical parameters.

• Keep the battery away from the hot heat source.

• Avoid charging in direct sunlight.

• Do not keep the battery in a damp place or in water.

• Do not force the battery or make it fall from high altitude.

Welding

Before any arc welding operation on the loader, the operation is as follows:

1. Disconnect the battery.

2. Disconnect electronic control system and electrical equipment.

3. Place the ground clamp where the soldering is done as close to the ground as possible.

Page 23/72

October 2019W11E | Operation manual

2.2 Specifications and performance

TECHNICAL PERFORMANCE PARAMETER

Type of loader W11E

Motor parameters

Manufacturers

Motor model

Maximum power 11Kw- 48V

Electrical systems SME Controller

Operating voltage 12V

Battery capacity 60V/400Ah (19.2KwH)

Battery type Dry Lithium

Self-weight (with standard bucket) 2300

Rated load (0.2m³ bucket) (kg) 650

Maximum lifting force (DaN) 1100

Cargo bucket overturning Load (ginseng ISO8313)

Vehicle Straight line (kg) 1250

Vehicle articulated (kg) 900

Vehicle parameters

Walking speed (km/h) 0-14

Hydraulic Oil (L) 30

Hydraulic system

Hydraulic working elements

Working pressure (BAR) 170

Dimensions (mm)

A Protection device width 950

B Off-ground clearance 178

C Tire Center Width 803

DTotal width 1104

E Maximum operating height 3480

F Maximum height of bucket fulcrum 2900

G Bucket horizontal height 2649

H Tipping height 2228

I Tilting working distance (tilting state) 690

J Shovel depth 120

K To the center of the lifting pin of the bucket 550

L Axle distance 1476

M Rear overhang 923

N Without bucket overall length 2950

O With bucket overall length 3815

Q Seat height 1208

Page 24/72

October 2019W11E | Operation manual

TECHNICAL PERFORMANCE PARAMETER

W11E

S 860kg

T 800kg

U 600kg

V 480kg

R To protect device top height 2268

S Angle of max lifting height 48°

T Max tilting angle 45°

U Turning corner of level position surface 48°

VDeparture angle 23°

W Turning corner 45°

X Maximum turning radius 2530

Y Out edge radius 2220

Z Inner turn radius 1110

Load center distance = 400, load capacity of W11E cargo fork:

Page 25/72

October 2019W11E | Operation manual

Page 26/72

October 2019W11E | Operation manual

2.3 Transport procedures

WARNING

NOTE

Hiking up

In the position marked with the lifting mark, use a reliable cable lifting loader.

Lithium battery

Switch off the connector of lithium battery.

Leave the lithium battery in battery box.

Check

Make sure the main power switch is disconnected.

Fixing

Tighten the front and rear frame with a locking plate.

Use a strong rope at the vehicle bundling point and take care not to damage the paint surface.

Tighten the front and rear wheels with wedge blocks.

2.4 Trailer procedure

When the loader needs rescue, only the short haul of the loader is allowed, but the following steps should be

followed before dragging the loader.

Draught loaders are no longer capable of braking and steering.

Trailer steps

• Place the shim (wedge) at the slip side behind the wheel.

• Discharge cargo and equipments.

• Start the tractor

• The tractor (which has sufficient traction and braking force) is connected to the towing pin (which must be

strong and fixed reliably) at the counterweight at the rear of the loader through a rigid traction bar.

After the trailer

Wedge a block against the sliding edge of the wheel.

The brake function of the loader should be checked after maintenance.

The towing point when being towed is at the rear counterweight. The maximum force allowed for these points is

20KN.

Page 27/72

October 2019W11E | Operation manual

NOTE

This machine can be used for short-distance dragging unpowered trailers:

1. The traction device is located at the trailing part of the rear of the counterweight.

2. The maximum traction of the W11E is about 7.5KN.

3. Maximum traction speed ≤ 5km / h.

4. Only allowed to be pulled by rigid drawbar.

5. Not for long distance traction.

2.5 Stored procedures

Once a month Indefinite duration

Travel motor No special attention is required. Remove the motor and cover it with protection.

No special attention is required. By removing the drain plug under the differential

Drive axle

Tire

Lubricating oil

Liquid

Wheel bearing

Lithium battery

The loader must be raised or

the axles are padded to prevent

the tires from coming into

contact with the ground. The

tire pressure must be reduced

to 15PSI.

Make sure all the points are

lubricated with special oil.

All levels must be checked and

filled if necessary.

Wheel bearings must be

repackaged.

Disconnect the lithium battery

terminal.

housing to drain the drive shaft, the plug is reloaded

after it is finished.

The loader must be raised and the axle is padded to

prevent the tire from contacting the ground. The tire

pressure must be reduced to 15PSI and sprayed with

rubber preservatives.

Make sure all the points are lubricated with special oil.

Drain all the liquid.

Wheel bearings must be repackaged.

Lithium batteries must be removed and stored

separately. Lithium batteries must be stored in a cool,

dry place and must not be exposed to direct sunlight.

If a lithium battery is stored in an open area, it must be

covered to protect it from contaminants and moisture.

Lithium-ion batteries must be recharged slowly every

one or two months.

Note:

1. The ambient temperature range of this loader is -30°C-50°C

2. Long-term storage may damage the gaskets in the hydraulic system.

Page 28/72

October 2019W11E | Operation manual

3. MAINTENANCE PARTS

WARNING

WARNING

CAUTION

3.1 General description

By definition, preventive maintenance, including regular maintenance and inspection operations, is to prevent

failures. Preventive maintenance operations allow the operator to detect wear or deterioration on the equipment

early.

3.2 General cleaning instructions

When thoroughly cleaning the loader, use normal methods (do not use high pressure cleaning) to avoid wearing

electrical equipment, safety equipment, trademarks and labels. When cleaning electrical components, it is

recommended to blow dry air with a maximum pressure of 29 PSI. When cleaning mechanical parts, first clean the

oil with a degreasing product and then dry it with dry air. Lithium batteries must be protected from chemical

reactions and severe damage to current branches.

Solutions may affect the skin, eyes and respiratory tract. Use only in well ventilated areas.

Avoid breathing under water vapor for a long time. Keep away from sparks and flames.

To avoid possible personal injury, do not perform cleaning and drying steps with more

than 30 PSI air pressure. Use eye protection and defense and approve air hose nozzles.

Before removing the hydraulic hose, the filler cap must be loosened and the residual pressure in the tank must be

released.

Do not immerse electronic components, packaging, or rubber, plastic, or plastic parts in a cleaning solvent.

Wipe the parts with a clean cloth. Cleaning solvents can affect materials and cause serious damage or damage to

parts.

• Wash parts in a tank that specializes in cleaning parts or spray the cleaning agent on the surface of the part.

• Rinse or spray to clean the parts. If necessary, brush with a non-metallic brush.

• Except the bearings, dry the parts with compressed air after cleaning.

• Do not use metal scrapers, wire brushes, grinding wheels, or abrasive compounds when cleaning parts unless

there are special requirements for maintenance procedures.

• Clean electronic parts such as relays or switches with a cloth dampened with cleaning solvent.

• Clean the heat exchanger with a steam cleaner or a pressure washer and soap. Do not use the aluminum or

copper cleaner that will affect it.

• Clean the outer surface of the battery with a weak solution of soda and water.

Page 29/72

October 2019W11E | Operation manual

• Use a non-metallic brush to remove corrosion from the lithium battery cable terminals.

WARNING

•Use 1∕4 pound of soap to add a gallon of water to clean the painted surface of the vehicle.

• Clean with clean water and dry with linen or air.

First maintenance program

• First time maintenance must be performed between 10 and 125 hours of operation.

• For motor maintenance, see the motor operating manual (this unit comes with the motor operating manual).

• Check for oil leaks and correct if necessary.

• Check hoses and connections and check the wires.

• Check the rim nut torque after 10 hours of operation, also for more than 50 hours and check the rim nut torque

after each wheel change.

3.3 Service

3.3.1 Preparation for use

Lithium battery

Brake system

Travel motor

Rear axle and reducer Check the axle oil level and refuel if necessary.

Tire Air Refill

Hydraulic oil

Due to pressure in the hydraulic tank, loosen the filler cap and slowly release the pressure before opening.

Connect the lithium battery cable. If it is disconnected, connect the positive pole first.

Make sure the lithium battery is fully charged.

Check if the brake fluid leaks.

Slowly start the vehicle, release the throttle, and step on the jog pedal to check the

brake effect.

Check that the travel motor is operating normally.

Check the line connection.

Check the tire air pressure and inflate if necessary.

After removing the wheel, it is recommended to tighten the nut: 2 hours, 50 hours,

every 200 hours.

Recommended wheel nut tightening: 372N.m

Recommended wheel pressure W11E: 3.0Bar

Check the hydraulic tank level and the lowest level is indicated on the filter at the

filler.

Grease points

Add in each grease point

1. All joint bearings

2. All hinges

3. All bushings

Page 30/72

October 2019W11E | Operation manual

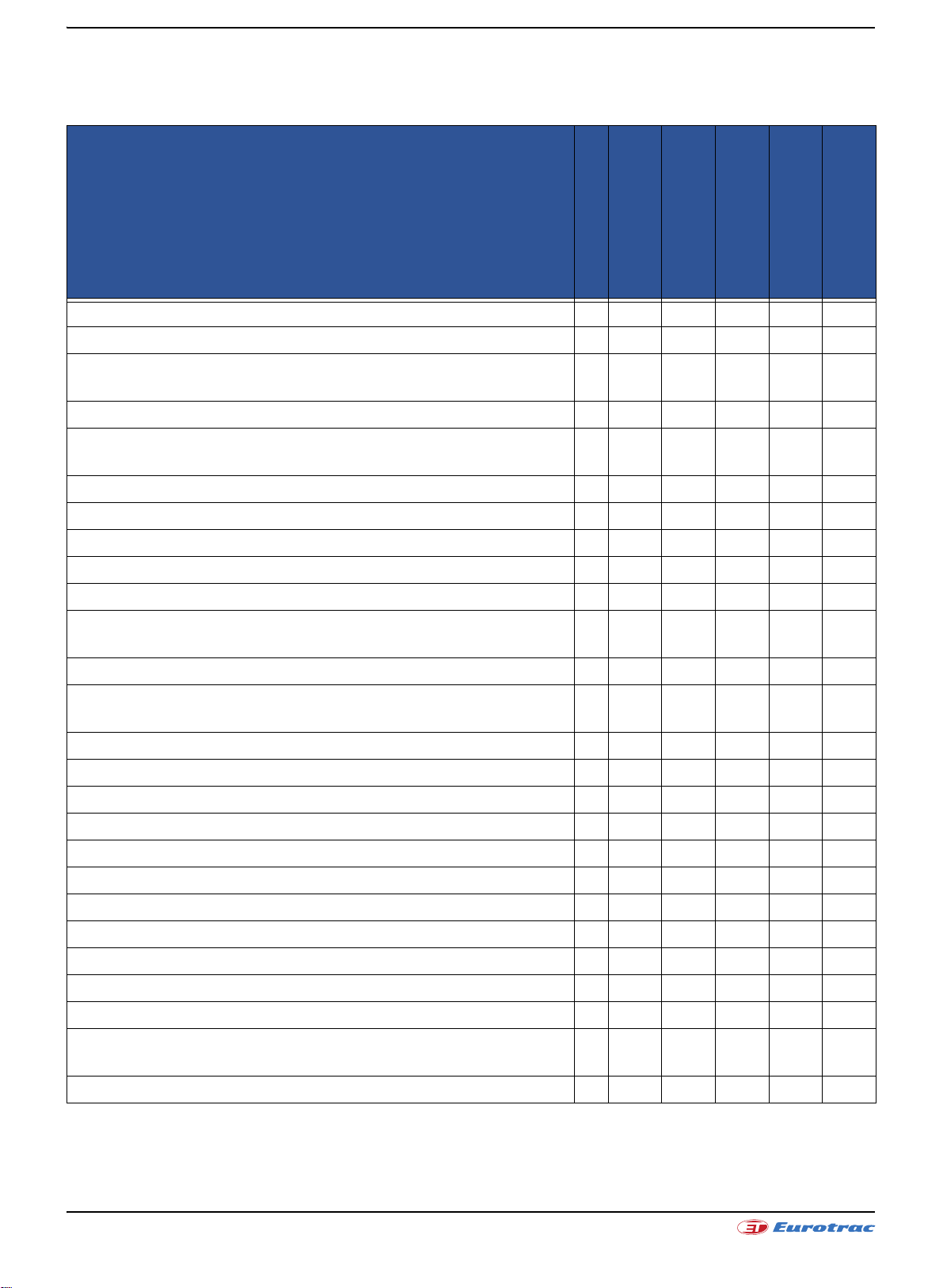

3.3.2 Regular maintenance form

The loader must be maintained according to the following table

Lithium battery capacity x

- 3.0/5.2BAR tire pressure x

Daily inspection

Weekly or

every 50 hours

Monthly or

every 200 hours

Every two months or

every 400 hours

Every six months or

every 1200 hours

Every year or

every 2400 hours

Tire tread, check

Remove foreign objects such as stones in gaps

x

Adjust headlights, aim correctly x

Work light, tail light, double jump light, work light and turn signal

operation

x

Cab sign lights, heaters, wiper operation and cab lights (if installed) x

Horn x

Hydraulic oil level x

372N.M (*) Wheel nut fastening x

Drive axle fixing bolts, tighten when needed x

Tighten the cylinder head bolts and all nuts and bolts. Adjust the

specific torque to the specific requirements if necessary.

x

Drive axle oil level x

Replace the axle oil (replace the oil after 50 hours for the first time;

then replace it once a year)

x

Hydraulic oil x

Hydraulic suction oil filter x

Parking brake x

Handbrake on the engine has to be adjusted when the power is off. x

Hydraulic oil x

Driver seat adjuster x

Pedal point x

Oil all greasing points x

Cab door lock (if installed) x

Check motor idle speed and speed, adjust if necessary x

Replace the brake pads of the parking brake x

The hydraulic oil in the hydraulic system drains out, cleans the system

and refills the new hydraulic oil.

x

Drive axle gear oil replacement. x

(*):The tire nut must be re-adjusted to the position: 372N.M. After each replacement of the wheel, and at any time the nut has

been loose, and maintenance is required at this specified time interval.

Page 31/72

October 2019W11E | Operation manual

Proper regular maintenance will allow the operator to avoid any mechanical failure. Pay attention to the frequency

CAUTION

of the lubricating oil.

Lithium battery inspection and replacement

Use and maintain the battery according to the Lithium Ion Power Battery Installation Operation and Maintenance

Manual provided by the lithium battery manufacturer.

Replace the lithium battery

1. Place the loader in a safe and open horizontal position.

2. Disconnect the main power switch.

3. Use a wooden wedge on the front and rear wheels to prevent the vehicle from moving when replacing the

battery.

4. Remove the rear bonnet, rear frame cover, traction seat assembly, battery fixing plate, remove the lithium

battery lever and disconnect all the connectors with the lithium battery and affect the lithium battery

replacement circuit.

5. Use a forklift and a special guide to command the forklift to operate. Use the shovel foot from the rear of the

loader to gently shovel from under the battery, slowly raise the shovel foot until the battery leaves the base

and pour the fork backwards. The lithium battery can be completely removed.

6. Barbaric operations are strictly prohibited during operation.

7. The replaced lithium battery should not be discarded at will, and it should be recycled by the lithium battery

manufacturer.

8. The above operation is reversed when installing a lithium battery and when restoring the loader.

Tire replacement

1. Never enter the loader after the loader has been jacked up by the jack.

2. Torque tighten the hub nut, 372N.M.

3. Adjust tire pressure after tire replacement, W11E: 3.0Bar.

4. Do not increase the air pressure beyond the specified range.

Front wheel

1. Place the loader in a horizontal position.

2. Use a parking brake and insert a jack under the body.

3. Use a jack to lift the body until the tire is almost off the ground and loosen the hub nut.

4. Use a jack to jack up the body so that the tire is off the ground and remove the hub nut and wheel.

5. After repairing and replacing the tires, repeat the reverse process to install the wheels. Tighten the hub nut

evenly in the diagonal direction in order.

6. Check and adjust the tire air pressure after the wheel is installed.

Page 32/72

October 2019W11E | Operation manual

Hydraulic oil replacement

WARNING

CAUTION

CAUTION

The front working unit should be lowered completely before draining the hydraulic fluid.

1. Drive the loader to the trench.

2. Lower the front working device completely.

3. Place a container on the bottom of the loader.

4. Open the rear cover.

5. Unscrew the hydraulic oil filler port.

6. Unscrew the suction filter.

7. Remove the drain plug of the hydraulic tank.

8. Fully drain the hydraulic oil.

9. Wipe the area near the drain plug.

10. Reinstall the drain plug.

11. Make sure the replaced oil filter is filled with oil to avoid damages.

12. Tighten the filler cap.

13. Fill the oil filter port with the hydraulic oil until it is full.

14. Tighten the oil filter cover back.

15. Start the engine, run for a while in the idle state, repeatedly turn the steering wheel to the left and right to the

maximum corner several times, let the car slowly drive for dozens of meters and lift down several times, and

check the oil level again.

Discarded oil should be disposed of in accordance with relevant regulations. Avoid skin contact with oil. Also don't

let the oil flow into the sewer or flow to the ground.

3.3.3 Oil & Lubricant

Hydraulic system

Model Specification Caltex HDZ-46

W11E 66L

Drive axle

Model Specification Gear Oil L-CKC 220

W11E 2L

The oil mentioned above is used under normal weather conditions. For a coldest or hottest country, please contact

EUROTRAC or dealer.

Page 33/72

October 2019W11E | Operation manual

NOTE

1. When replacing hydraulic components, in order to avoid component deterioration, it is essential to filter and

inspect hydraulic fluid before use.

2. Do not mix two oils.

Drive axle

Type NLGI grade No. 3 lithium grease

Rod end joint bearing

Type Lithium base grease every 500 hours.

Page 34/72

October 2019W11E | Operation manual

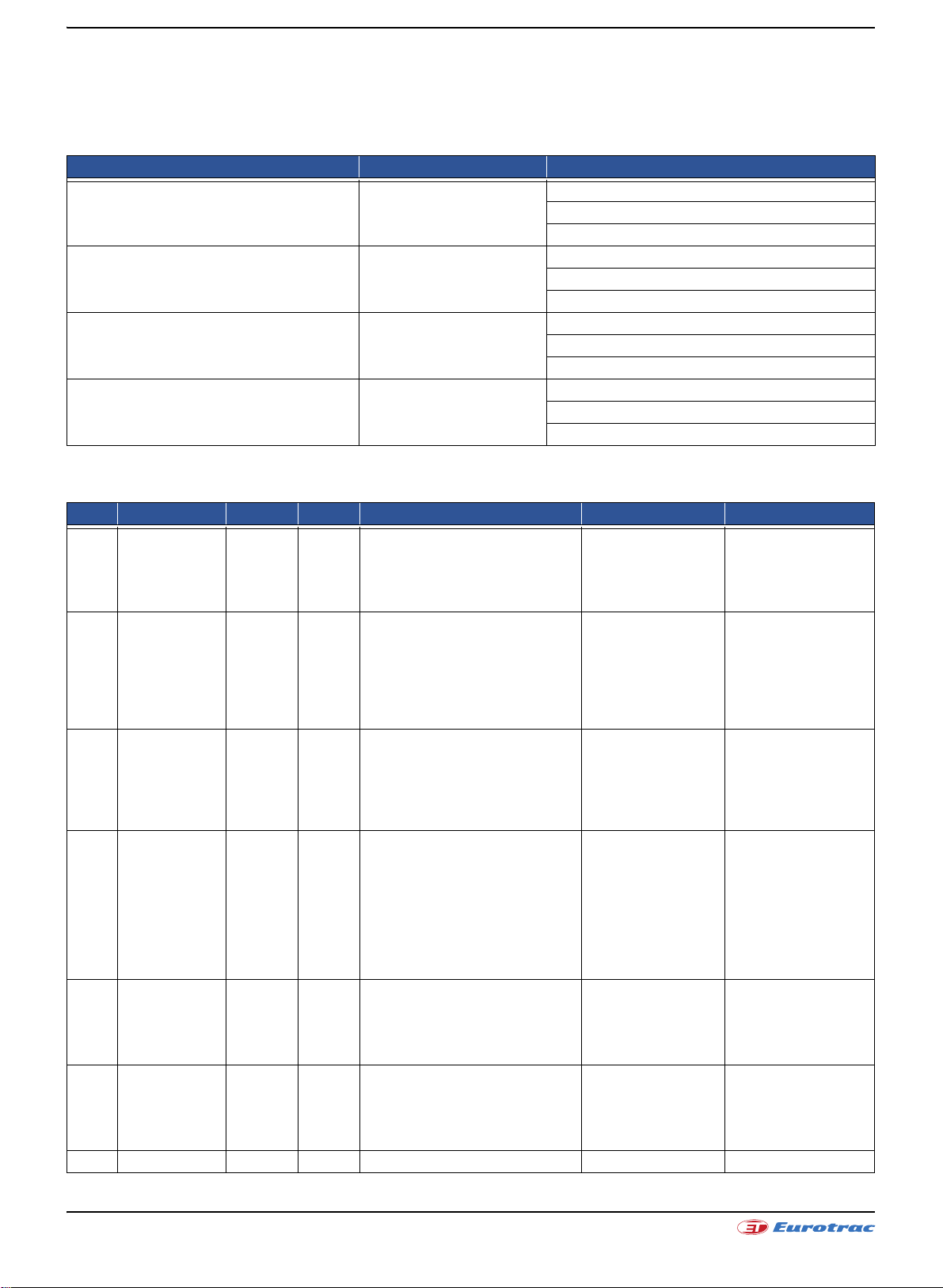

3.4 Troubleshooting

3.4.1 Kinetic energy reduction

Page 35/72

October 2019W11E | Operation manual

3.4.2 Drive axle

Page 36/72

October 2019W11E | Operation manual

3.4.3 Brake system

Page 37/72

October 2019W11E | Operation manual

3.4.4 Lithium battery

Page 38/72

October 2019W11E | Operation manual

FIGURE 1: W11E HYDRAULIC SCHEMATIC

Page 39/72

October 2019W11E | Operation manual

FIGURE 2: ELECTRICAL SCHEMATIC

Page 40/72

October 2019W11E | Operation manual

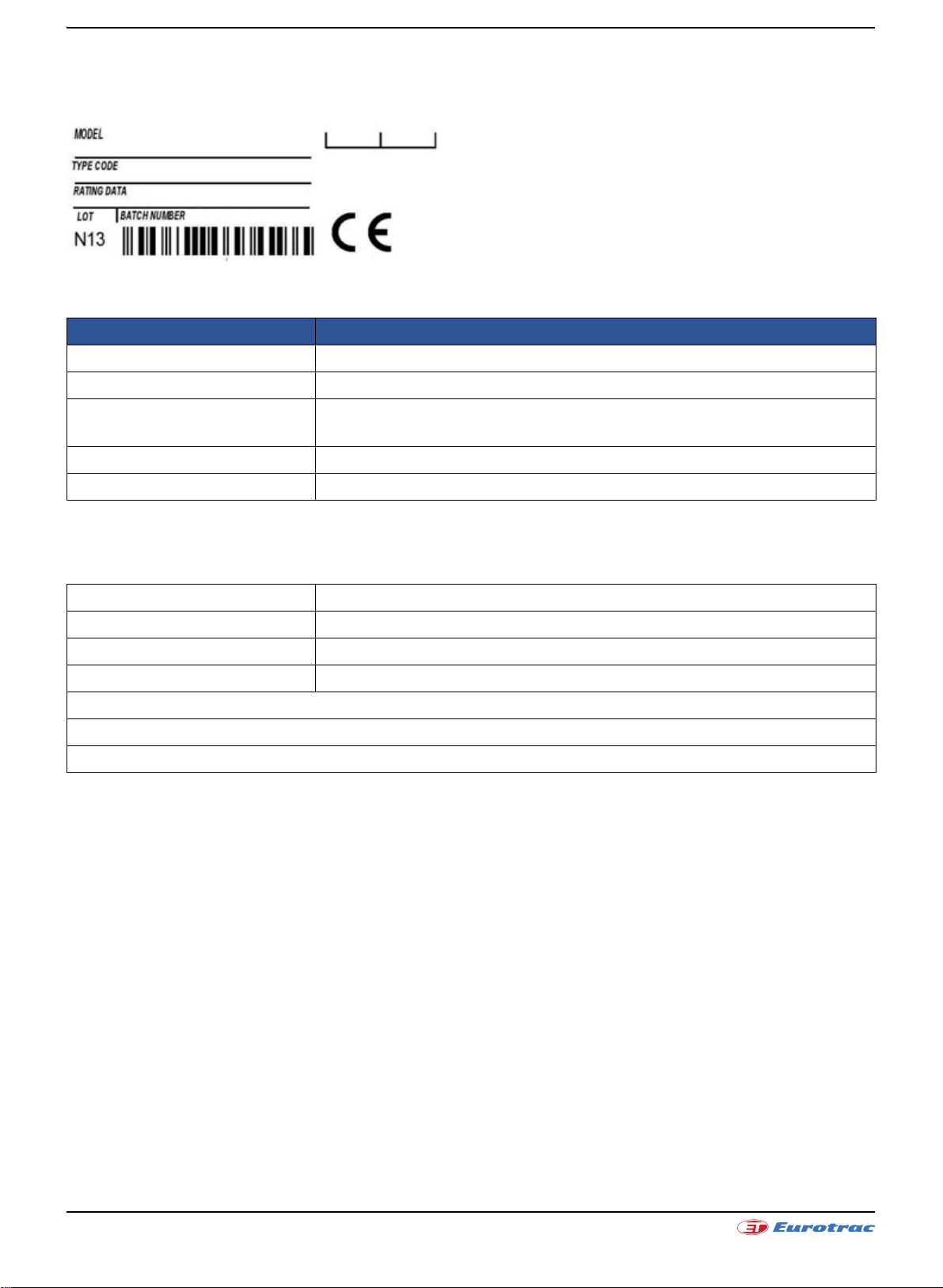

FIGURE 3: BODY LOGO LAYOUT

1. Hydraulic control tips 19. Brandname sticker

2. Model trademark 20. Read instructions for use

3. Parking brake sign (English) 21. Read the maintenance manual warning

4. Tire label 22. Make a trademark sticker

5. Tire pressure label 23. Lifting capacity sticker

6. Anti-slip mat 24. Anti-tip sticker

7. Vehicle nameplate 25. Vehicle nameplate - cab

8. Lifting label 26. Hydraulic oil label

9. Anti-sticker label 27. Seat belt label

10. Danger of crushing hand sticker 28. Anti-label

11. Fuel label

12. Water tank anti-scald label

13. Anti-cutting label

14. Greasing point indication

15. Noise statement label

16. Anti-slip mat

17. Reset button label

18. Transport fixed point label

Page 41/72

October 2019W11E | Operation manual

DAILY EQUIPMENT INSPECTION

WARNING

In the event of a problem, the operator should not attempt to repair and is responsible for immediately reporting

to the superior. Repairs must be performed by a professional.

Daily Equipment Inspection – W11E Loader

Car Number S/N: Date:

Operator:

[ ] Well [A] Commissioning completed [N] need to repair

[ ] Ensure that the travel motor and hydraulic motor are good.

[ ] Open the hydraulic tank cover and check the fluid level. Make sure the liquid level is within the operating

range and then close the lid.

[ ] Check the inflation pressure of each pneumatic tire. Wheel requirements 3.0BAR. Adjust tire pressure as

required.

[ ] Check for tread damage or wear. Remove the stone from the tread and report any damage, side tread

damage, or unusual wear.

[ ] Make sure the headlights are working properly.

[ ] Check other lights, including rear, tail stop lights and directional lights, if the vehicle is equipped with these

lights.

[ ] Make sure that the heater, wiper and cab ceiling lights in the cab work properly (if installed).

[ ] Operate the horn, it can be clearly heard under noisy sound.

[ ] Make sure all controls are good. Report any fault control and do not use the device until it is fully repaired.

[ ] Correct the driver's seat position and adjust it to suit your requirements.

Eurotrac

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel. + 31 (0) 186 612 333

info@eurotrac.nl

Page 42/72

October 2019W11E | Operation manual

4. SME ELECTRONIC CONTROL SYSTEM

4.1 About warning, caution and information notices

Special attention must be paid to the information presented in Warning, Caution and other kinds of information

notices when they appear in this manual. Failure to follow those recommendations may result in dangerous

situations or in damages to the components, for which SME will not respond.

Warnings: A Warning informs the user of a hazard or a potential hazard which could result

in serious or fatal injury if the precautions or instructions given in the warning notice are not

observed.

Cautions: A caution informs the reader of a hazard or a potential hazard which could result

in a serious damage to the appliance.

Information Notices: An information notice contains additional, not essential pieces of

information to complete or to clarify the meaning of the paragraph they are placed into.

User Manual Reference: A User Manual Reference informs the user to look up specified user

manual for more details.

Interactive Documentation Tips: An advice about where to find the related section in the

Interactive Documentation

Page 43/72

October 2019W11E | Operation manual

4.2 Troubleshooting and fault codes

4.2.1 Fault levels

PRIORITY LEVEL ACTIONS

Main contactor opened

1 (HIGHEST) Blocking

2 Stopping

3 Limiting

4 (LOWEST) Warning

4.2.1 Fault list

Code Fault Level Family Possible Causes Set Condition Clear Condition

1 Over Voltage Blocking All • Battery resistance too high while

regenerating.

• Battery disconnected while

regenerating.

2 Under Voltage Blocking All • Battery seriously damaged or

exhausted.

• Battery resistance too high.

• Battery disconnected while driving.

• Blown key-switch fuse.

• External load drains power from

battery.

3User

Over Voltage

4User

Under Voltage

5Inverter 1

Over Current

6Inverter 2

Over Current

7- - All - - -

Blocking TAU

System

Blocking TAU

System

Blocking All • External or internal short-circuit

Blocking All • External or internal short-circuit

• Battery resistance too high while

regenerating.

• Battery disconnected while

regenerating.

• Too low voltage level defined by the

user

• Battery serious damaged or

exhausted.

• Battery resistance too high.

• Battery disconnected while driving.

• Blown key-switch fuse.

• External load drains power from

battery.

• Too high voltage level defined by the

user.

between U1, V1 or W1 AC motor’s

phases.

• Incorrect motor 1 parameter/s.

• Inverter 1 power module damaged.

between U2, V2 or W2 AC motor’s

phases.

• Incorrect motor2 parameter/s.

• Inverter 2 power module damaged.

Key-switch voltage or

capacitors voltage is

above the maximum

level allowed for the

controller.

Key-switch voltage is

below the minimum

level allowed for the

controller.

Key-switch voltage is

above the maximum

level defined by the

user.

Key-switch voltage is

below the minimum

level defined by the

user.

Inverter 1 phase current

exceeded its current

limit.

Inverter 2 phase current

exceeded its current

limit.

Motors disabled

Outputs disabled

Main contactor closed

Motors stopped

Outputs enabled

Main contactor closed

Motors limited

Outputs enabled

Main contactor closed

Motors enabled

Outputs enabled

Bring key-switch voltage

below over-voltage limit

and then cycle key

switch.

Bring key-switch voltage

above under-voltage

limit and then cycle key

switch.

Bring key-switch voltage

below user over voltage

limit and then cycle key

switch.

Bring key-switch voltage

above user under voltage

limit and then cycle key

switch.

Cycle key switch.

Cycle key switch.

Page 44/72

October 2019W11E | Operation manual

Code Fault Level Family Possible Causes Set Condition Clear Condition

8Inverter 1

Over

Temperature

9Inverter 2

Over

Temperature

10 Inverter 1

High

Temperature

11 Inverter 2

High

Temperature

12 Inverter 1

Under

Temperature

13 Inverter 2

Under

Temperature

14 Inverter 1

Current Sensor

Fault

15 Inverter 2

Current Sensor

Fault

16 - - All - - -

17 Inverter 1

Temp Sensor

Fault

18 Inverter 2

Temp Sensor

Fault

19 Motor 1

Over

Temperature

20 Motor 2

Over

Temperature

21 Motor 1

High

Temperature

Blocking All • Operation in high temp environment.

• Operation with high load.

• Wrong mounting of the controller

heat sink.

• Wrong working of controller cooling

system.

Blocking All • Operation in high temp environment.

• Operation with high load.

• Wrong mounting of the controller

heat sink.

• Wrong working of controller cooling

system.

Limiting All • Operation in high temp environment.

• Operation with high load.

• Wrong mounting of the controller

heat sink.

• Wrong working of controller cooling

system.

Limiting All • Operation in high temp environment.

Blocking All Operation in low temp environment. Inverter 1 power

Blocking All Operation in low temp environment. Inverter 2 power

Blocking All • Leakage current due to motor 1 stator

Blocking All • Leakage current due to motor 2 stator

Stopping

Stopping All Inverter 2 internal temperature sensor