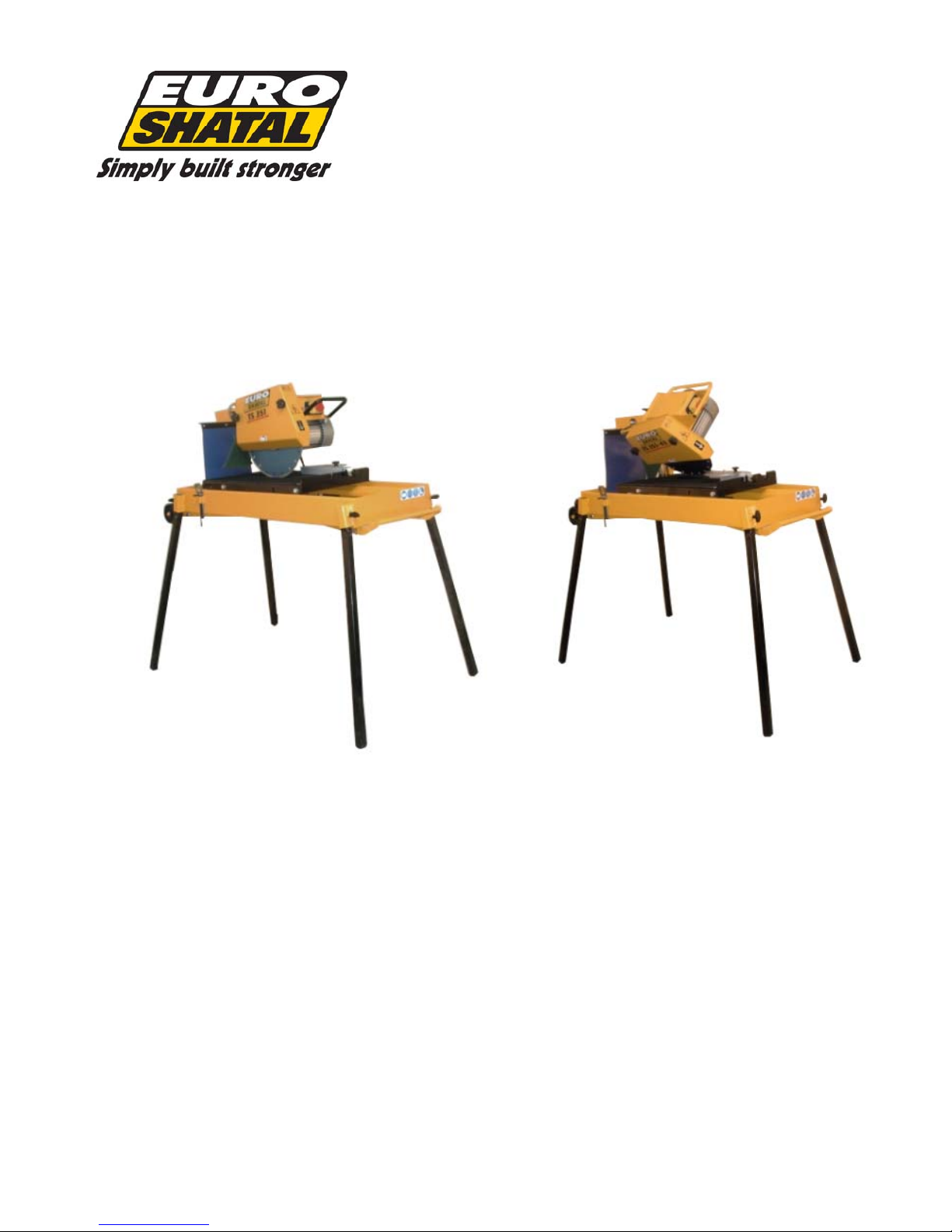

Euro Shatal TS301, TS351, TS301-45, TS351-45 Operating Instructions & Parts List Manual

TS301 / TS301-45

TS351 / TS351-45

OPERATING INSTRUCTIONS & SPARE PARTS LIST

BRICK & TILE SAW

BEDIENUNGSMANUAL & ERSATZTEILLISTE

STEIN-, ZIEGEL- & FLIESSEBSÄGE

MANUAL & RESERVEDELSLISTE

VÅDSKÆRER

FIRST EDITION – FEBRUARY 2016

Sales office and Warehouse:

Euro Shatal ApS

Murervej 5

DK-6710 Esbjerg V , DENMARK

Tel:(+45) 75168411

Fax: (+45)75168412

E-mail:euroshatal@shatal.com

www.shatal.com

Euro Shatal Deutschland GmbH

Wernher von Braun Str.3

D-86368 Gersthofen ,GERMANY

Tel:(+49) 8214609580

Fax:(+49)8214609581

E-mail:info@euroshatal.biz

www.euroshatal.de

SAFETY INSTRUCTION- QUICK GUIDE

SIKKERHEDS INSTRUKTIONER- Forkortet udgave

SICHERHEITSINSTRUKTIONEN- Kurzausgabe

VEILIGHEIDSINSTRUKTIES- Korte uitgave

INSTRUCCIONES DE SEGURIDAD - GUIA RAPIDA

-1- TS

ENGLISH

Laws governing safety aspects on machinery may vary between countries but the following guides will be useful to all operators:

Users should carefully follow any operating instructions given.

Never operate the machine without protection covers for all moving parts or components.

Never operate the machine in any dangerous fire zone or under weak lighting conditions.

When operating the machine, always wear noise reduction ear protectors and safety glasses.

When operating the machine, always wear safety shoes and safety clothing.

Before use always fill the water container with clean and enough water.

Only operate the machine with a fully earthed-plug , do not operate the machine in case of doubt.

Always ensure that the machine is standing in a level position on a firm base.

This machine may only be used under frost - free conditions.

DANSK

Sikkerhedslovgivningen på maskiner kan være forskellige landene imellem, men de følgende retningslinier er nyttige for alle operatører.

Følg brugsanvisning og service anvisning og alle instruktioner før start, venligst læs nøje.

Anvend aldrig maskinen motor, rem og blad beskyttelse.

Hold finger og fødder væk fra bevæglige dele når maskinen arbejder.

Brug ikke maskinen i lukkede eller brandfarlige områder.

Brug kun maskinen i veloplyste områder med rigtig arbejdsbelysning.

Høreværn skal altid bruges.

Sikkerhedssko skal altid bruges.

Rør aldrig ved varme flader.

Påfyld altid vand på maskinen før brug.

Brug kun jordet 220 volt stikkontakt.

Alle 4 stålben skal altid monteres på maskinen.

Stil altid maskinen på en stærk og jævn arbejdsplads.

Rør aldrig ved den roterende bladklinge.

Maskinen skal altid stå og anvendes frostfrit.

Brug aldrig maskinen uden blad beskytter.

Maskinen skal altid bruges under tag og ikke i regnvejr.

DEUTSCH

Die Sicherheitsgesetze für Maschinen kønnen verschiden sein, aber die folgende anleitungen sind für alle operatoren verwändlich.

Vor Arbeitsbeginn bitte Bedienungs- und Wartungsanleitung sorgfältig lesen und allen Empfehlungen folgen.

Benutzen Sie nie die Maschine ohne Motor- Riemen- und Klingenschutz.

Berühren Sie nie die beweglichen Teile wenn die Maschine arbeitet.

Benutzen Sie nie die Maschine in geschlossenen oder brandgefährdeten Gebieten.

Benutzen Sie nur die Maschine bei ausreichender Beleuchtung.

Tragen Sie bitte immer einen Hörschutz.

Tragen Sie bitte immer Sicherheitsschuhe.

Berühren Sie nie heiße Flächen.

Füllen Sie immer Wasser auf bevor Sie die Maschine benutzen.

Benutzen Sie immer nur 220V Steckdosen mit Erdanschluß.

Alle vier Stahlbeine sollten immer an der Maschine befestigt sein.

Stellen Sie die Maschine immer nur auf einer ebenen Fläche.

Berühren Sie nie die rotierende Klinge.

Die Maschine sollte nie Frost ausgesetzt werden.

Benutzen Sie die Maschine nie ohne Klingenschutz.

Die Maschine sollte nur überdacht und nie im Regen benutzt werden.

DUTCH

o Wetgeving inzake veiligheidsaspecten van machines kunnen verschillen naargelang het land. Volgende gids kan door iedere gebruiker gebruikt worden.

Lees altijd eerst de veiligheidsvoorschriften voordat de machine in gebruik genomen wordt.

Gebruik nooit de machine zonder beschermingkappen van de draaiende delen.

Gebruik de machine nooit de machine in brandgevaarlijke omgeving en bij onvoldoende verlichting.

Draag altid veiligheidsschoenen en werkhandschoenen.

Draag altid gehoorbeschermers en veiligheidshelm.

Raak nooit warme viakken en bewegende delen van de machine aan met de handen en voeten.

Voor gebruik altijd de waterbak vullen met zuiver en voldoende water.

Gebruik alleen geaarde stekkers en stopkontakten, zowel voor 220 en 380 volt aansluiting.

Zorg ervoor dat de machine op een horizontaal en stevige bodem staat met alle 4 staalbenen gemonteerd.

De machine moet altid in een vorstvrije omgeving gebruikt worden.

ESPAÑOL

Las leyes referentes a seguridad en el trabajo pueden cambiar de pais en pais. Las siguientes directivas son de provecho para todos los

usuarios:

Antes de usar la maquina por primera vez, lea cuidadosamente el Manual de Instrucciones y siga todas las instrucciones, precauciones y

advertencias.

El usuario debe seguir todas las instrucciones de seguridad.

Nunca trabaje con la maquina si todas las guardas de partes moviles no estan colocadas en su lugar.

Nunca trabaje con la maquina en ambientes inflamables o con malas condiciones de iluminacion.

Utilice siempre protector de oidos y gafas de seguridad cuando trabaje con la maquina.

Utilice calzado de seguridad para trabajar con la maquina.

Antes de comenzar a trabajar llene el deposito de agua con suficiente agua fresca.

Solamente trabaje con la maquina con tomacorriente con buena coneccion a tierra. En caso de duda no haga funcionar la maquina.

Asegurese siempre que la maquina esta nivelada y sobre una base firma.

Esta maquina puede ser usada solo en ambientes no congelados. (frost-free conditions)

OPERATING INSTRUCTIONS-QUICK GUIDE

ALWAYS READ THE FULL INSTRUCTIONS IN

OPERATING MANUAL BEFORE FIRST USE

-2- TS

BRUGSANVISNING-hurtigudgave

Lies altid hele instruktionsbogen inden

første ibrugtagning

BEDIENUNGS ANLEITUNG

LESEN SIE IMMER ALLE AUSFUHRLICHEN ANWEISUNGEN

BEVOR DIE MASCHINE IM BETRIEB GENOMMEN WIRD

GEBRUIKSAANWIZING ON

SNEL VAN START TE KOMEN

LEES ALTIJD DEZE VOLLEDIGE HANDLEIDING VOOR

INGEBRUIKNAME VAN DE MACHINE

INSTRUCCIONES DE USO-GUIA RAPIDA

LEA SIEMPRE LAS INSTRUCCIONES COMPLETAS

ANTES DEL PRIMER USO DE LA MAQUINA

TS301- 45 / TS351- 45 ONLY TS301- 45 / TS351- 45 ALLEEN

TS301- 45 / TS351- 45 KUN TS301- 45 / TS351- 45 SOLAMENTE

TS301- 45 / TS351- 45 NUR

MODELS TS301 / 351; TS301- 45 / TS351- 45

ST92 -3- FEB. 2016

Josef Levy

Murervej 5 GENERAL MANAGER

DK-6710 Esbjerg V , Denmark

Tel:(+45) 75168411

Fax: (+45)75168412

E-mail:euroshatal@shatal.co

m

Esbjerg V, October 2008

ENGLISH

CE DECLARATION OF CONFORMITY

We hereby declare that the equipment described below conforms to the relevant fundamental safety and health requirements of the appropriate CE Directives, both in its basic design

and construction. This declaration will cease to be valid if any modifications are made to the machine without our expressed approval.

Product: Tile saws Model : TS301 ; TS351 ; TS301-45 ; TS351-45

Relevant CE Machinery Safety Directives : 2006/42/EEC ( 98/37/EEC, 89/392/EEC )

And Low Voltage Directives:( 73/23/EEC) amended by 93/68/EEC

Appropriate internal measures have been taken to ensure that series-production units conform at all times to the requirements of current CE Directives and relevant standards.

The signatories are empowered to represent and act on behalf of the company’s management.

DANSK

CE OVERENSTEMMELSESDEKLARATION

Vi erklærer hermed, at det nedenstående produkt er fremstillet i overenstemmelse med de tilhørende og fundamentale sikkerheds- og sundhedsbetingelser fra de behørige CE direktiver,

både i dets grundliggende formgivning og konstruktion. Denne deklaration vil ophøre med være gyldig, hvis der bliver foretaget nogen som helst ændring på maskinen uden vores

tydelige tilladelse.

Produkt:

Vådskæresav model : TS301 ; TS351 ; TS301-45 ; TS351-45

Relevant CE maskinsikkerhedsdirektiv : 2006/42/EEC ( 98/37/EEC, 89/392/EEC )

Og svagstrømsdirectiv:( 73/23/EEC) ændret af 93/68/EEC

Der er foretaget interne forholdsregler for at sikre, at produkter, der er fremstillet i serieproduktion, altid efterlever foreskrifterne fra gældende CE direktiver og relevante standarder.

Underskriverne har tilladelse til at representere og handle på vegne af firmaets ledelse.

DEUTSCH

CE BESTÄTIGUNG VON DEKLARATION

Wir erklären, dass das beschreibene Produkt sich an die relevante, fundamentale Sicher- und Gesundheits-behörden in die passende CE Direktiven richten, auch in seinem

grundsätlichen Design und Konstruktion. Diese Deklaration verliert seine Gültigkeit, falls irgend eine Modifikation auf der Maschine ohne unsere Zulassung gemacht wird.

Produkt: Stein-, Ziegel- und Fliessensäge : TS301 ; TS351 ; TS301-45 ; TS351-45

Relevante CE Maschienesicherheitsdirektiven : 2006/42/EEC ( 98/37/EEC, 89/392/EEC )

Und Schwachstrohmdirektiven:( 73/23/EEC) neu bei 93/68/EEC

Wir haben interne Vorsichtsmassnahmen genommen, die Einheiten der Serienproduktion immer laut die Verlangen der laufenden CE Direktiven zu sichen und die relevanten Standarden

zu erfüllen.

Die Signaturen sind in Auftrag der Management der Firma representiert.

ESPAÑOL

DECLARACION DE CONFORMIDAD CE

Nosotros declaramos que el producto descripto a continuacion cumple con los requerimientos fundamentales de seguridad y salubridad relevantes de las Directivas CE

correspondientes, tanto en su diseño basico como en su produccion. Esta declaracion sera anulada si se efectua cualquier cambio en la maquina sin nuestro expreso consentimiento.

Producto: Mesa de Corte Modelo : TS301 ; TS351 ; TS301-45 ; TS351-45

Directiva Relevante: CE Machinery Safety Directives : 2006/42/EEC ( 98/37/EEC, 89/392/EEC )

And Low Voltage Directives:( 73/23/EEC) amended by 93/68/EEC

Fueron tomados los recaudos necesarios para asegurar que las unidades producidas en serie cumplan en todo momento con las Directivas CE vigentes y los standares relevantes.

Los signatarios estan autorizados para representar y actuar en nombre de la Direccion de la Compania.

TS301;351 TS301/45;351/45 - 4 - FEB. 2016

ENGLISH

Before leaving our factory every machine passes an exacting inspection programme.

Following the instructions will ensure that your machine gives long service, in normal operating conditions.

The user advice and spare parts mentioned in this document are given as an indication, and do not constitute an undertaking. No warrantee will be granted in the

event of errors or omissions, or for damage occurring during delivery, or caused by the design or use of the machine. We are very concerned about the quality of our

products and we reserve the right to make any technical modifications to improve them, without advance notice.

This document will:

Provide the user with information about the machine.

Information about its possible uses.

Prevent accidents due to unsuitable use, by an untrained person, during maintenance, repairs, overhauls, handling or transport.

Improve the reliability and durability of the machine.

Ensure correct use, regular maintenance, and fast fault finding in order to reduce repair costs and reduce down time.

Laws governing safety aspects on machinery vary between countries but the following guides will be useful to all operators.

Users should carefully follow any operating instructions given.

Never operate the machine without blade guard.

Never operate the machine in any dangerous fire zone or under bad lighting conditions.

When operating the machine, always wear noise reduction ear protectors and safety glasses.

When operating the machine, always wear safety shoes and safety clothing.

Before use always fill the water container with clean water.

Only operate the machine with a fully earthed plug. Do not operate the machine in case of doubt.

Always use a disc suitable for the type of material being cut.

Always ensure that the machine is standing in a level position on a firm base.

This machinery may only be used under frost- free conditions.

Keep hands away from the rotating disc.

Store in a dry place, not accessible to children. Maintain the tools carefully.

Use of a saw blade or abrasive blade is prohibited.

Tools: Water lubricated diamond blade diameter 300 mm- diameter 350mm (D) - bore 25.4mm .

(Apply to your usual EURO SHATAL agent for information.)

The manual should always be available at the place of work.

It should be read and used by any person installing or using the machine.

The obli

g

atory technical regulations in force in the country where the machine is used must also be adhered to for maximum safety.

PREFACE TO THE MANUAL

SAFETY INSTRUCTIONS

TS301;351 TS301/45;351/45 - 5 - FEB. 2016

ENGLISH

MODEL POWER VOLTAGE

5%

CURRENT PUMP

Standard

3 HP (2.2KW) 230V – 50 HZ

13.6 A 55 W – 230 V

Motor speed: 2800 RPM

Blade speed: 2800 RPM

Electric protection: IP 55

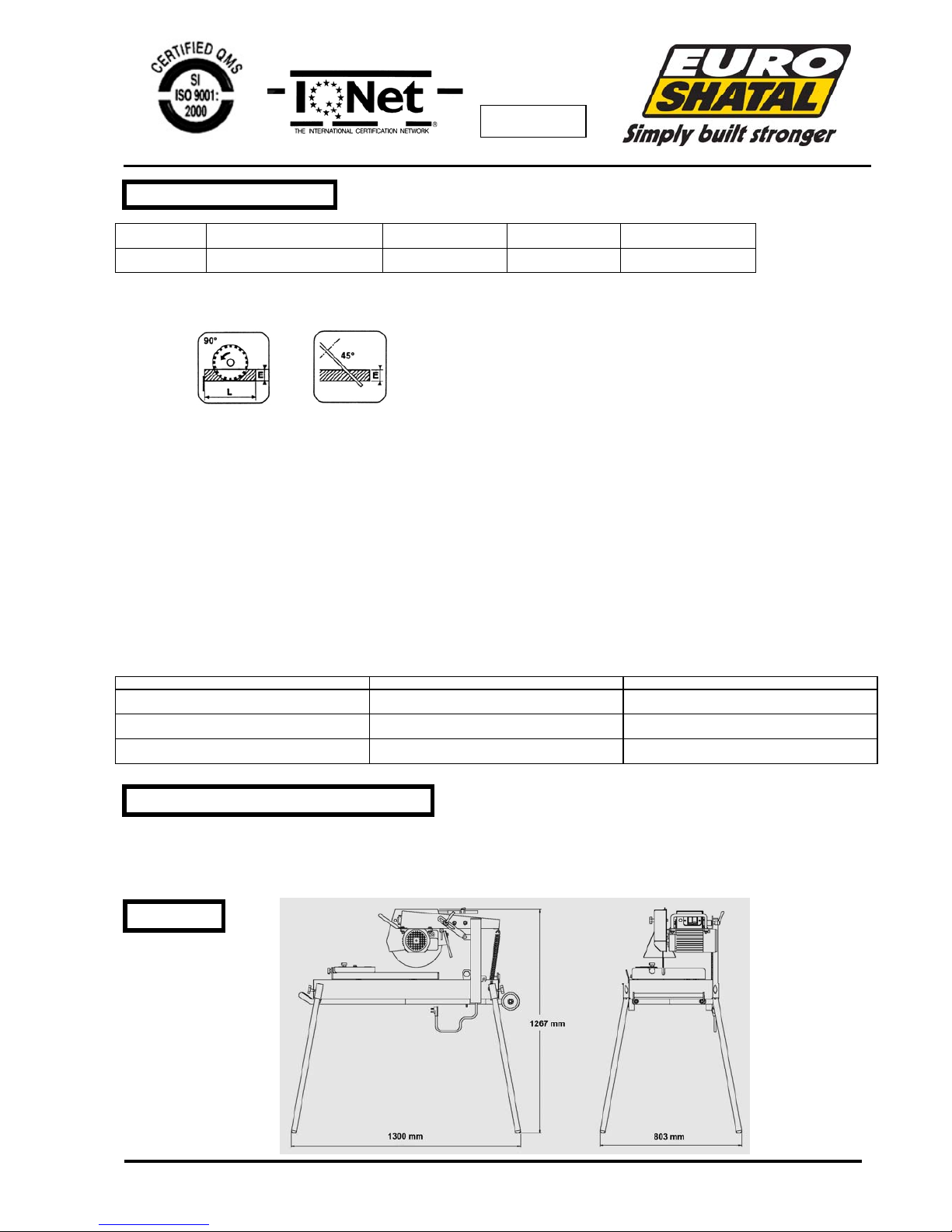

● Depth of cut (E):

- at 90º : ø 300 = 80 - 160 mm* - at 45º : ø300 = 80 - 160 mm*

- at 90º : ø 350 = 105 - 210 mm* - at 45º : ø350 = 105 - 210 mm*

* By reversing material.

● Length of cut (L): ● Dimensions (mm) Lx W x H ● Unladen weight:

Model: Model: Model:

* TS301: 600mm TS301: 1130 x 570 x 540 TS301: 70kg

* TS301/45: 600mm TS301/45: 1130 x 570 x 540 TS301/45: 66kg

* TS351: 600mm TS351: 1130 x 570 x 540 TS351: 71kg

* TS351/45: 600mm TS351/45: 1130 x 570 x 540 TS351/45: 67kg

* In order to increase rolling table stability when cutting tile of 480mm and less a 5th bearing was added to the rolling table. When a 600mm tile needed to be cut this

5

th

bearing should be removed by the user.

Blade cooling by water spray into the blade casing.

Minimum tank capacity: 38 liters.

Water pump: 55W – H-2.2 m.

Electricity supply: 230V: H07-RNF 3 x 0.75² - Lg 3m.

MODELS: TS301; TS301/45; TS351; TS351/45

POWER LEVEL PRESSURE LEVEL VIBRATION LEVEL

LWA (DB)

EN 23744

LPA (DB)

EN 31201

689/392/CEE

et 91/368/CE

CUTTING

113

CUTTING

105

CUTTING

2.3m/s²

NOT CUTTING

93

NOT CUTTING

85

NOT CUTTING

0.8m/s²

On receiving the machine, check its condition.

Always keep it perfectly clean.

Check the supply cable periodically.

Always keep alert when working.

Ensure that there is no abnormal vibration.

TE

C

HNICAL SPECIFICATIONS

I

NSPECTIO

N

-

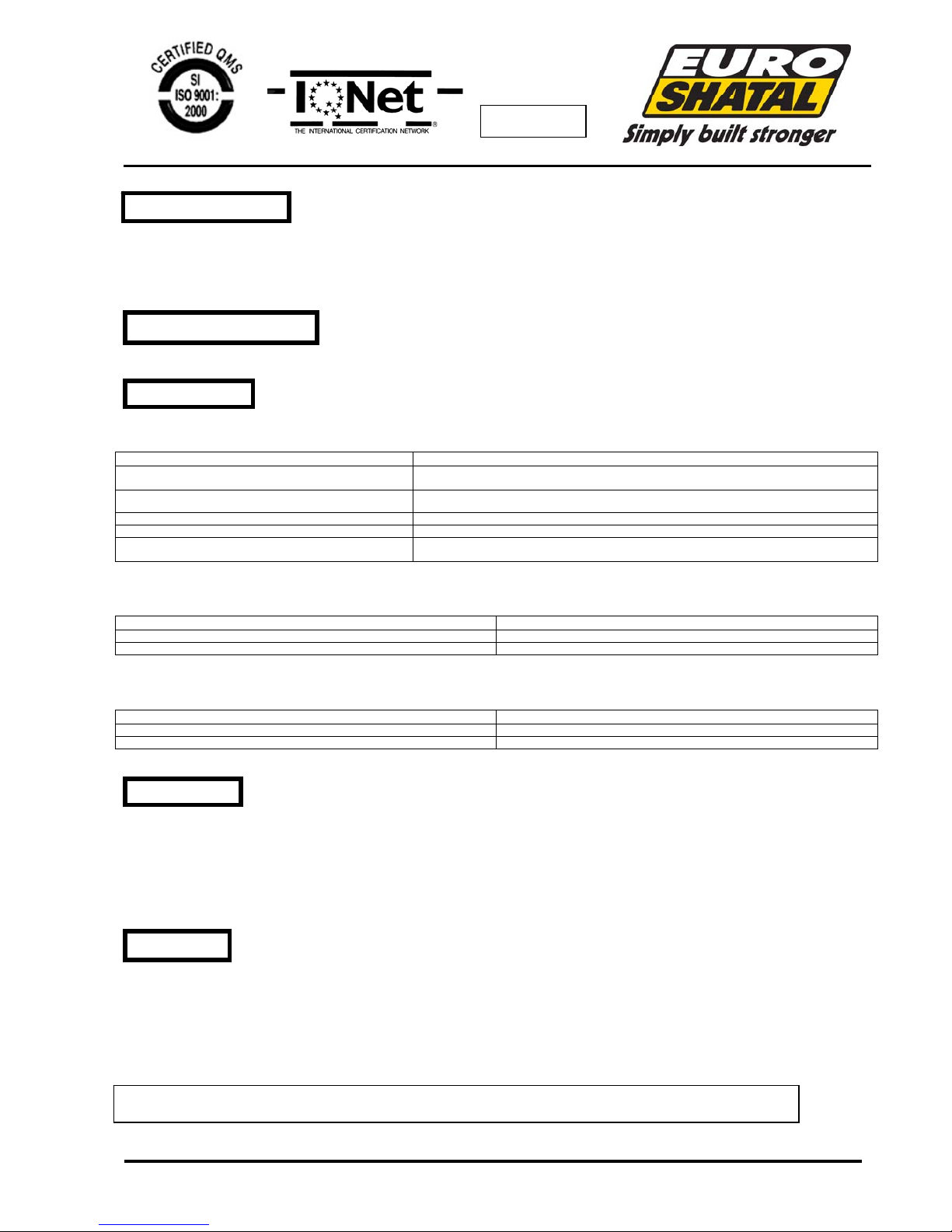

DESCRIPTION OF THE MACHINE

DIMENSION

TS301;351 TS301/45;351/45 - 6 - FEB. 2016

ENGLISH

SEE PICTURE 1-6 PAGE 16

SEE PICTURE 7-11 PAGE 16

Disconnect the machine by unplugging the supply cable

The blade locking nut has a left- hand thread.

Check that the blade is assembled correctly. Check that the arrow marked on the blade is in the same direction as the arrow on the blade guard.

- ELECTRICAL SAFETY:

Operate this machine only on a supply equipped with a 30 mA earthed current-limiting earth leakage relay.

- The RCCB must be used correctly, including testing it regularly. For tools supplied with an integral RCCB in the cable or in the mains plug, if the

cable or plug has been damaged, repairs must be carried out by the manufacturer, one of his agents or by a qualified repair workshop to avoid any

risks resulting from errors.

- Make sure that the mains voltage corresponds with that marked on the manufacturer’s plate on the machine.

- Three- phase motor

Make sure that the motor rotates in the same direction as the arrow on the blade guard: If the motor does

not turn in the direction required, swap two of the supply leads.

- Use the following types of plug, single phase 2 P + E, according to the corresponding voltage.

- Extension lead: Cable size sufficient for the electrical power, connection to the mains by a H07 RNF type cable of the following size: 3 x 2.5 mm² up

to 50m for 230V.

Always pay extreme care and attention to the preparation of the machine before starting up.

Remove all adjustment tools and wrenches from floor and machine.

Always keep blade guard in place.

Fill the water tank.

The water pump should be covered with water all the times as without it there is no cooling and it will overheat and burn.

As each machine is fitted with a self-priming pump, the water is sprayed onto the blade as soon as the machine starts.

To start the machine press the green button.

To stop the machine, press the red button.

SEE PICTURE 12 PAGE 16

Loosen locking handle and lift head so that the required gap is obtained. Re tighten locking handle.

If the motor is overloaded as a result of too much pressure or because of unsuitable or worn out blade, the overload switch will automatically cut off the power.

Wait a few minutes for the motor to cool.

In 230 V Machines (with internal thermal protection overload) : Push the green start button.

TRANSPORT TO WORK

FITTING OF THE CUTTING DISC

ELECTRICAL CONNECTION

OPERATION

Ensure that the water supply is abundant, when cutting wet.

DEPTH OF CUT ADJUSTMENT

OVERLOAD

TS301;351 TS301/45;351/45 - 7 - FEB. 2016

ENGLISH

The manufacturer declines all responsibility for loss or damage resulting from misuse or any modification or alteration that does not conform to the

manufacturer’s original specifications.

At the workstation, the sound pressure level may exceed 85 db (A).

In this case individual protection measures must be taken.

When ordering spare parts, please mention machine serial no., part no. and description.

1. THE MACHINE DOES NOT WORK

POSSIBLE CAUSES REMEDIES

Not plugged in properly or cable damaged

- Make sure that the supply is correctly plugged in (plug, extension lead, etc.)

- Check the supply cable

No mains voltage

- Test or have tested by an electrician (circuit breaker, plug, etc.)

Switch defective, motor cable damaged - Have tested by an electrician or contact the service department

Motor faulty (burned out) - Contact the service department to have the motor replaced.

Overloaded motor triped - Wait a few minutes for the motor to cool down.

- 230 V Machines – Press green start button.

2. NO WATER SUPPLY

POSSIBLE CAUSES REMEDIES

No water supply - Fill up clean water in water tank

Pump does not work - Clean strainer

3. THE PUMP DOES NOT START

POSSIBLE CAUSES REMEDIES

The mains lead is not correctly connected or is damaged - Check the mains lead

No voltage in pump circuit or mains supply circuit - Check the pump circuit and mains supply circuit

*** Prior to any maintenance work, the machine must be disconnected from the power supply.

Clean the machine daily.

Drain the water reservoir regularly.

Remove all mud and silt deposits in order to avoid the clogging of the water pump.

Rinse water pump filter daily.

Check daily that the rails are kept clean.

In the event of uneven or sluggish cutting, the blade must be cleaned by pressing a silicat or any other abrasive stone lightly against it while spinning.

In the event of deterioration and scrapping of the machine, the following items must be disposed of in accordance with the requirements of the

legislation in force.

Main Materials:

1. Motor : Aluminium (AL), Steel (AC), Copper (CU), Polyamide (PA)

2. Machine : Steel sheet (AC)

The instructions for use and spare parts found in this document are for information only and are not binding. As part of our product quality

improvement policy, we reserve the right to make any and all technical modifications without prior notice.

IMPORTANT ADVICE

SPARE PARTS ORDERING

FAULT FINDING

MAINTENANCE

SCRAPPING

Loading...

Loading...