EUROSEC CP 8, CP 7 Installation Instructions Manual

CCCCPPPP7777 //// CCCCPPPP88

88

IIIINNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONN

NN

IIIINNNNSSSSTTTTRRRRUUUUCCCCTTTTIIIIOOOONNNNSS

SS

TM

TM

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . 2

Mains Safety . . . . . . . . . . . . . . . . . . 2

Good Working Practice . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . 3

Control Panel Location . . . . . . . . . . 3

Mounting the Control Panel . . . . . . . 3

Mounting the RKP . . . . . . . . . . . . . . 3

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 4

General Detector Wiring . . . . . . . . . 4

Wiring Global Tampers . . . . . . . . . . 4

Wiring Contacts . . . . . . . . . . . . . . . 4 - 5

Wiring Passive Infra-Red Detectors . 5

General Bell Box Wiring . . . . . . . . . 6

Bell Tamper Ring . . . . . . . . . . . . . . . 6

Sample Bell Box Connections . . . . . 6 - 7

Wiring Notes . . . . . . . . . . . . . . . . . . 8

Control Panel Connections . . . . . . . 8

Programming . . . . . . . . . . . . . . . . . . . . . 9

Terminology . . . . . . . . . . . . . . . . . . 9

Engineer Programming Mode . . . . .10

Programmable Engineer Options . . .11 - 13

Engineer / User Mode . . . . . . . . . . .14

Engineer Reset . . . . . . . . . . . . . . . .15

Anti-Code Reset . . . . . . . . . . . . . . .15

Resetting to Factory Defaults . . . . . .16

Troubleshooting . . . . . . . . . . . . . . . . . .17 - 18

Specifications . . . . . . . . . . . . . . . . . . . .19

System Details . . . . . . . . . . . . . . . . . . .20

IIIInnnnssssttttaaaallllllllaaaattttiiiioooonnnn MMMMaaaannnnuuuuaaaall

ll

eeeeuuuurrrroooosssseeeecc

cc

II

II

nn

nn

tt

tt

rr

rr

oo

oo

dd

dd

uu

uu

cc

cc

tt

tt

ii

ii

oo

oo

nn

nn

Introduction

The eurosec control panel is supplied as a blank fronted end station complete with RKP. Up to

3 additional may be fitted if required. The unit is fully programmable by the installation and

comes pre-programmed with a set of factory defaults that will suit most installations. Seven

programmable zones are available on the CP7 and eight zones on the CP8

IMPOR

IMPOR

TTANT!

ANT!

Input: AC230V +/-10% ~50Hz 200mA Max. 49W Max

For Indoor Use Only

Nominal Temp Range: 0° - 50° Centigrade

This equipment is intended only for use as a Security Alarm Control Panel. Adequate ventilation

away from heat and humidity must be provided. The unit must be fixed securely to a nonflammable surface using suitable fixings.

All mains wiring must be to BS7671 (1992) IEEE wiring regulations (or appropriate international

regulatory standards). See relevant section within this manual for connection to mains supply.

Provision is provided for an earth connection within the mains connection block, this is for the

protection of the wiring and is not a functional part of the unit.

All low voltage (alarm) wiring must be to the appropriate international regulatory standards and

comply to good wiring practice.

Replacement fuses should be of the same type and rating conforming to IEC127.

The maximum current draw from the unit for all output combinations must not exceed 1Amp.

The unit is intended for use with a suitable re-chargeable battery permanently connected to the

appropriate terminals.

Mains Safety

The main unit must be connected to a mains supply via a 3Amp unswitched fused spur. This

must be carried out by a suitably qualified electrician. If you are in any doubt please contact your

local electricity company for advice.

Good Working Practice

The reliability of any security system may be greatly enhanced by following a few good working

practices. Do not connect the mains supply to any rings that have fridges, freezers or

fluorescent lights connected to them. When running low voltage alarm cables avoid running

parallel to mains wiring, if you do so separate by a least nine inches. When crossing mains

cables do so at 90°

PPPPaaaaggggeeee 22

22

eeeeuuuurrrroooosssseeeecc

cc

IIIInnnnssssttttaaaallllllllaaaattttiiiioooonnnn MMMMaaaannnnuuuuaaaall

ll

Control Panel & RKP Location

Consideration needs to be given to the location of the Control Panel & RKP with regards to-

The surface that the unit(s) are to be fixed to should be firm, vibration free, damp free and fire

resistant.

Access for the routing of mains and low voltage wiring.

Service Access to the unit(s).

Operation of the keypad.

Operation of ACE (if fitted).

Readability of the RKP display(s).

Mounting the Control Panel

Unscrew the two cover retaining screws and remove the front cover.

The PCB is held in place by two lower PCB retaining lugs and two upper sprung latches.

Push both upper latches upwards and pull the PCB forward and upward in one movement.

With the PCB removed from its retainers offer the unit to the wall and mark for the three fixing

points. Under no circumstances should you drill through the base.

Remove any knockouts that are required from the base and also the cover screw caps from

the moulding pips in the base and retain them for use after fixing the front cover in place.

Using suitable rawl plugs and 3 No.8 x 1.5” (min) screws fasten the base to the wall but do

not tighten until all cabling is in place.

Mounting the RKP

Lower the front cover of the RKP and unscrew the single cover fixing screw.

Offer the RKP base to the wall and mark the three fixing positions. Under no circumstances

should you drill through the base.

Remove one of the cover screw caps and retain for use after fixing the front cover.

Using suitable rawl plugs and 3 No.6 x 1” (min) screws fasten the base to the wall offering

the connecting cable through a suitable aperture in the base as you do so.

Wire the RKP as shown in the wiring section of this manual.

Replace the cover and tighten the cover fixing screw.

When finished put the cover screw cap in on the cover screw and push into place.

PPPPaaaaggggeeee 33

33

II

II

nn

nn

ss

ss

tt

tt

aa

aa

ll

ll

ll

ll

aa

aa

tt

tt

ii

ii

oo

oo

nn

nn

IIIInnnnssssttttaaaallllllllaaaattttiiiioooonnnn MMMMaaaannnnuuuuaaaall

ll

eeeeuuuurrrroooosssseeeecc

cc

General Detector Wiring

We would strongly suggest that you adopt a colour scheme for the detector wiring of your

system. This will enable you to quickly determine the source of any problems that may occur.

The security industry does not have recommended colour schemes because of the nature of

the wiring, one suggested scheme is given below.

Red/Black.................... Alarm Pair

Green.......................... + Supply

White........................... - Supply

Yellow/Blue.................. Tamper Pair

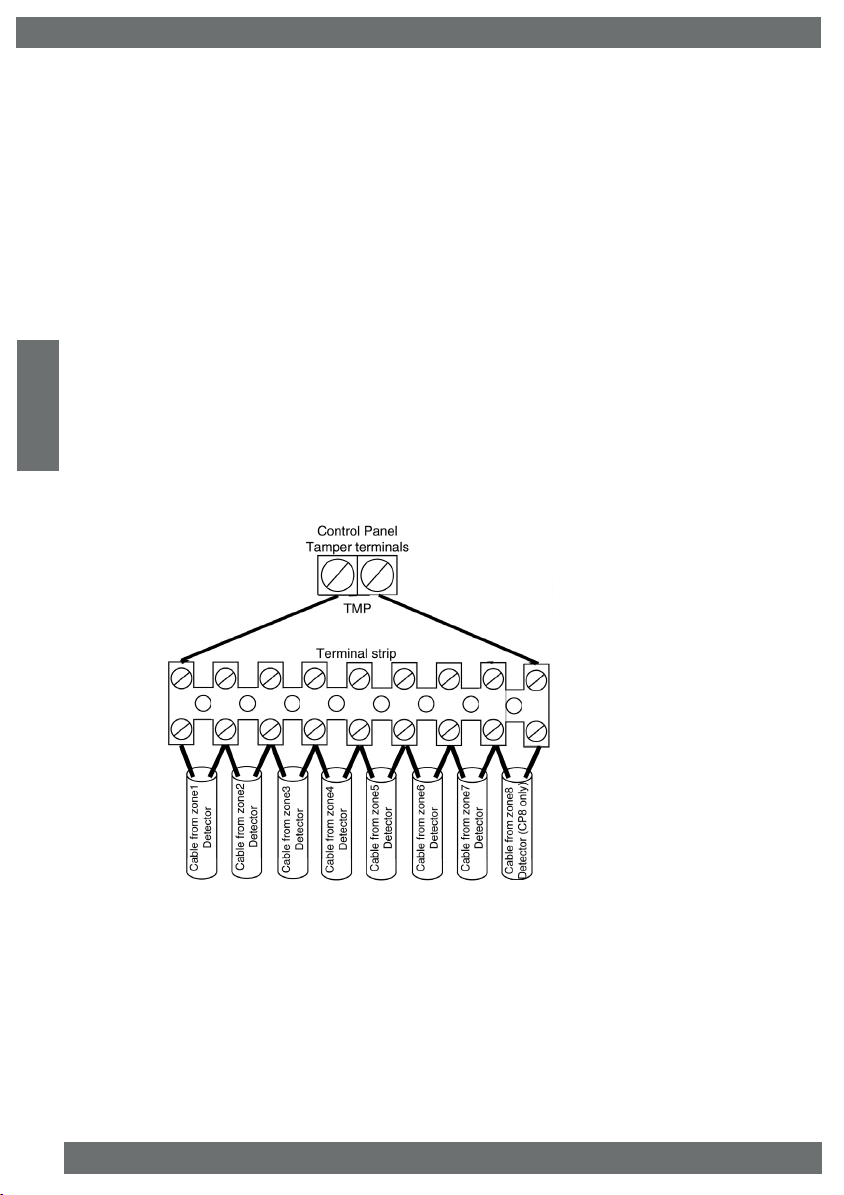

Wiring Global Tampers

One pair of tamper terminals is provided on the control panel PCB for tamper protection of the

zones. This is termed as a Global Tamper, one simple method of wiring Global Tampers is

shown in Fig. 1 below.

Fig. 1 Wiring Global Tampers

Wiring Contacts

Many types of contacts are available and fall in to two categories, surface or flush.The method

of operation is the same for both. One half of the contact is fitted to the door or window frame,

inside is a reed switch that is pulled together in the presence of a magnetic field. The other half

that is fitted to the opening section of the door or window contains the magnet. These devices

are referred to as normally closed (NC or N/C). The gap allowed for reliable operation will vary

(usually between 5mm & 20mm) dependant on the model used, you should check this

specification with your supplier before fitting.

In Figs. 2 & 3 we have used 5 screw surface contacts for clarity of the illustration.

PPPPaaaaggggeeee 44

44

WW

WW

ii

ii

rr

rr

ii

ii

nn

nn

gg

gg

eeeeuuuurrrroooosssseeeecc

cc

IIIInnnnssssttttaaaallllllllaaaattttiiiioooonnnn MMMMaaaannnnuuuuaaaall

ll

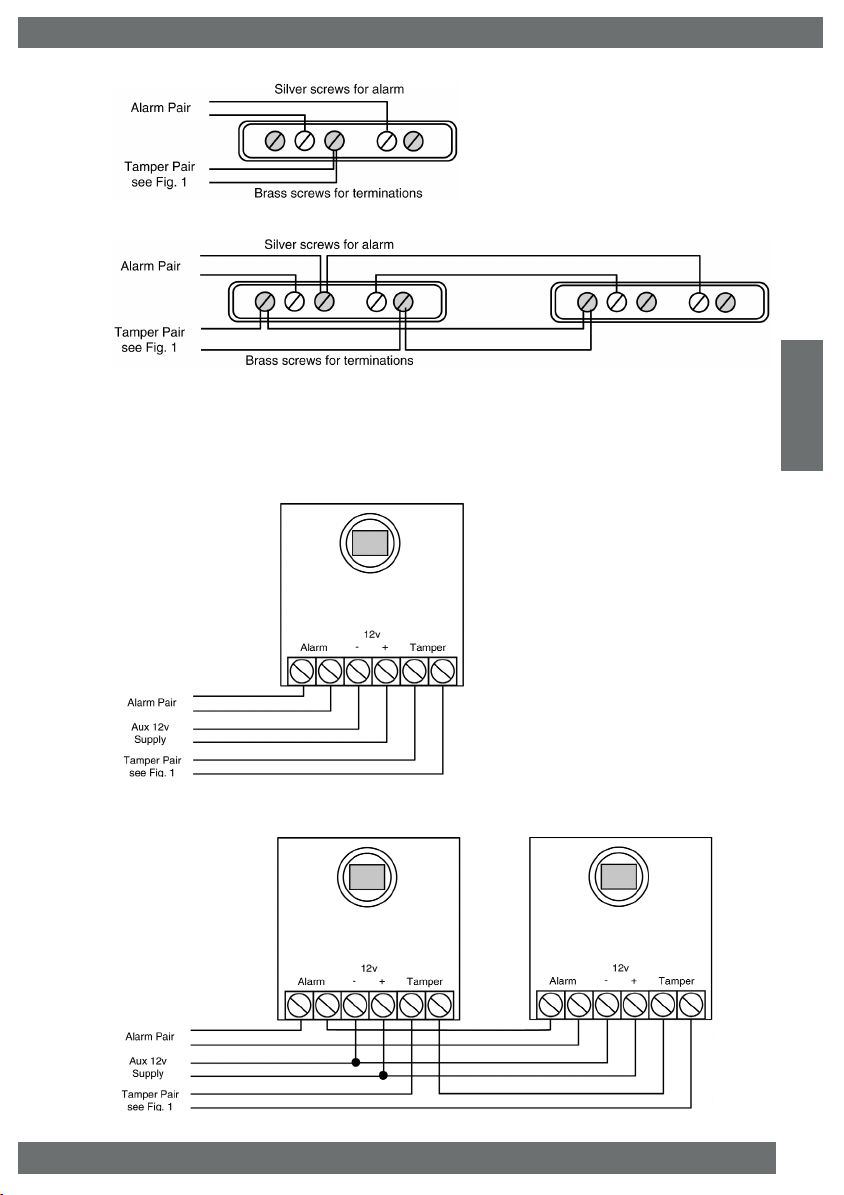

Fig. 2 Wiring Single Contact

Fig. 3 Wiring Double Contact (on the same zone)

Wiring Passive Infra-Red Detectors

It is essential when using Passive Infra-Red Detectors that you refer to the manufacturers

instruction as to the positioning and settings of the detector. This section is intended as a

guide to the wiring of the detectors.

Fig. 4 Wiring Single PIR

Fig. 5 Wiring Double PIR (on same zone)

PPPPaaaaggggeeee 55

55

WW

WW

ii

ii

rr

rr

ii

ii

nn

nn

gg

gg

Notes

Positions of terminals will vary

according to make.

All PIR wiring diagrams apply

also to Dual Technology

Detectors and Vibration sensors.

IIIInnnnssssttttaaaallllllllaaaattttiiiioooonnnn MMMMaaaannnnuuuuaaaall

ll

eeeeuuuurrrroooosssseeeecc

cc

General Bell Box Wiring

As with the detector wiring we would suggest that you adopt a standard for your Bell Box wiring,

the colour scheme below is provided as a suggestion only.

Hold Off Supply +................. Red

Hold Off Supply - .............. .. Black

Trigger................................... Blue

Tamper Return...................... Yellow

Strobe +................................ Green

Strobe -................................. White

Bell Tamper Ring

It should be noted that many bell boxes that are fitted with rechargable batteries will sound when

the battery is connected. This connection may take the form of manually connecting the battery

wires to terminals or placing a link into the On position. Dependant on the bell box being used

the sounder may sound when the battery is connected unless power from the control panel is

connected or the bell box tamper is closed or in some cases both. Most bell boxes produce

high volume noise adequate ear protection MUST be used.

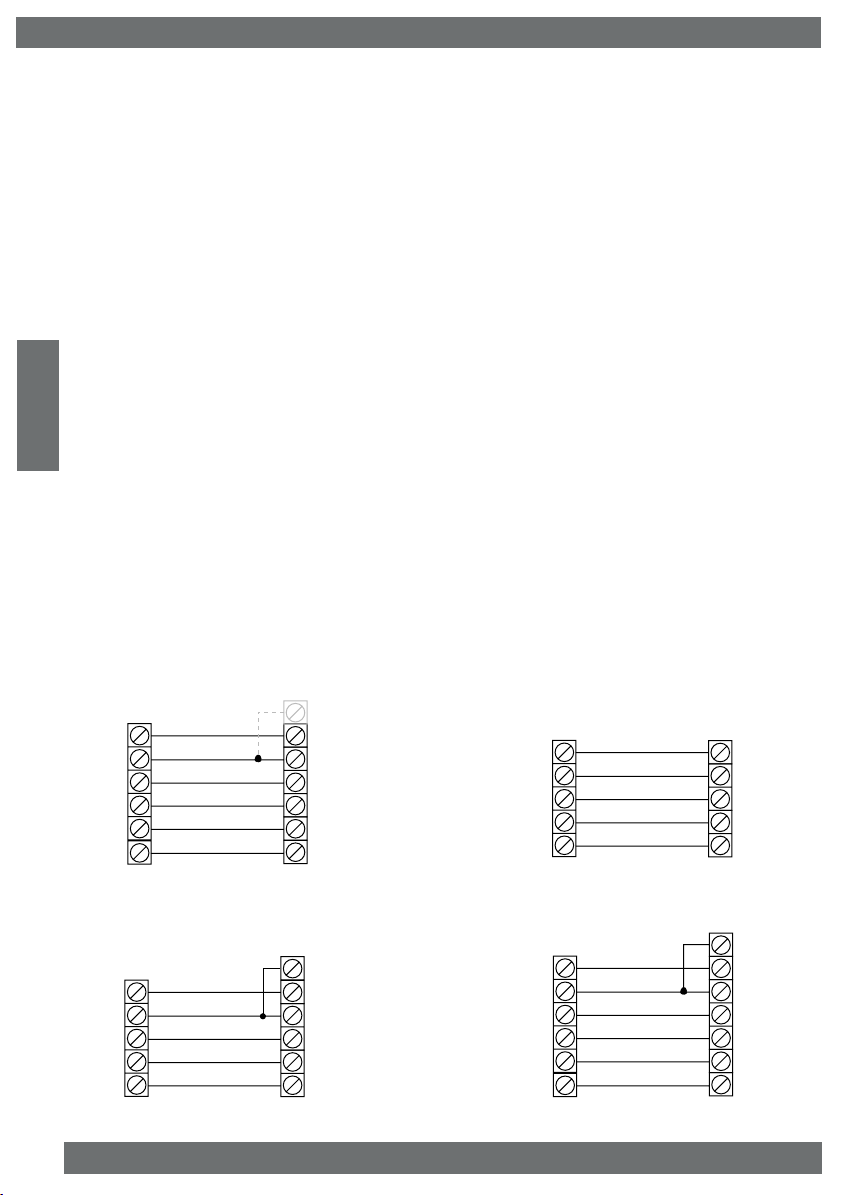

Sample Bell Box Connections

Below is shown general and sample bell box connections for some of the popular bell boxes that

are available.

PPPPaaaaggggeeee 66

66

WW

WW

ii

ii

rr

rr

ii

ii

nn

nn

gg

gg

Bell +

Bell -

Bell Hold -

SAB TMP

Strobe +

Strobe -

Tamper Return

Supply -

Bell Trigger

Supply +

Strobe -

Strobe +

eurosec control

panel terminals

General bellbox

connections

Check bellbox

terminal positions

Tamper Feed

Bell +

Bell -

Bell Hold -

SAB TMP

Strobe -

TMPR

12v

Bell SW-

0V

STR SW-

eurosec control

panel terminals

Novagard Delta

bellbox connections

Check bellbox

terminal positions

Bell +

Bell -

Bell Hold -

SAB TMP

Strobe -

R-TMP

0V

S-

12V+

ST-

eurosec control

panel terminals

Delta E, Novagard 1E & 6

bellbox connections

Check bellbox

terminal positions

TMP-F

Bell +

Bell -

Bell Hold -

SAB TMP

Strobe +

Strobe -

R Tamper Return

-12v Supply

Bell SW-

+12v Supply

Strobe -

Strobe +

eurosec control

panel terminals

Novagard 2&4

bellbox connections

Check bellbox

terminal positions

F Tamper Feed

Fig.6A

Fig.6B

Fig.6C

Fig.6D

Loading...

Loading...