Page 1

Upright Vacuum

Item # XSG825

for Model EP825

Upright Vacuum

Item # XSG825

for Model EP825

10 Paper Bags – 2 Belts – 1 Bulb 10 Paper Bags – 2 Belts – 1 Bulb

Warning: To reduce the risk of electric shock, the power cord

must be disconnected before changing the bag or

performing maintenance/trouble shooting checks.

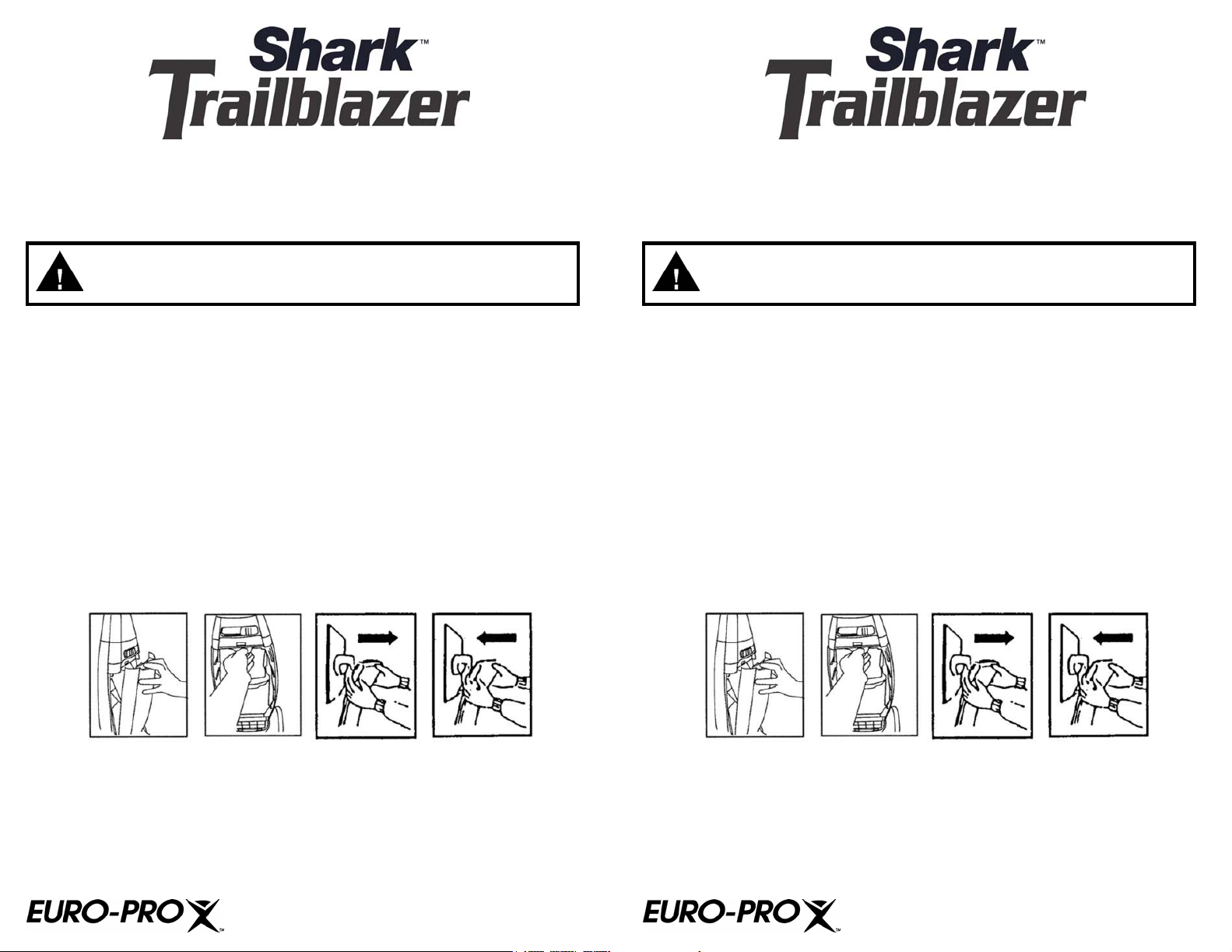

Changing the Dust Bag:

A) Unplug power cord from wall outlet.

B) Remove the front panel of the unit.

C) Remove the old dust bag by holding the cardboard tab and pull

towards you. Remove carefully to avoid dust/dirt spilling from dust

bag.

D) Take a new dust bag and while holding the cardboard tab push the bag

over the opening of the dirt discharge tube until it is seated against the

rear of the enclosure.

E) Make sure that the entire bag is inside the housing, before replacing

the front panel. Always check the pre-motor and post motor filters

every time you change the dust bag.

F) Once the new dust bag is in place, replace the front panel by aligning

the bottom locking tabs with the slots in the body, close cover slowly

allowing the front panel to snap in place. The latch will self lock.

Warning: To reduce the risk of electric shock, the power cord

must be disconnected before changing the bag or

performing maintenance/trouble shooting checks.

Changing the Dust Bag:

A) Unplug power cord from wall outlet.

B) Remove the front panel of the unit.

C) Remove the old dust bag by holding the cardboard tab and pull

towards you. Remove carefully to avoid dust/dirt spilling from dust

bag.

D) Take a new dust bag and while holding the cardboard tab push the bag

over the opening of the dirt discharge tube until it is seated against the

rear of the enclosure.

E) Make sure that the entire bag is inside the housing, before replacing

the front panel. Always check the pre-motor and post motor filters

every time you change the dust bag.

F) Once the new dust bag is in place, replace the front panel by aligning

the bottom locking tabs with the slots in the body, close cover slowly

allowing the front panel to snap in place. The latch will self lock.

NEVER REUSE PAPER BAGS NEVER REUSE PAPER BAGS

For information or assistance, call 1-866-98SHARK (1-866-987-4275)

USA: EURO-PRO Operating LLC Canada: EURO-PRO Operating LLC

21 Lawrence Paquette Industrial Drive 4400 Bois Franc

Champlain, NY 12919 St. Laurent, QC H4S 1A7

or visit our website: www.sharkvac.com

Rev.12/03

Printed in China

USA: EURO-PRO Operating LLC Canada: EURO-PRO Operating LLC

For information or assistance, call 1-866-98SHARK (1-866-987-4275)

21 Lawrence Paquette Industrial Drive 4400 Bois Franc

Champlain, NY 12919 St. Laurent, QC H4S 1A7

or visit our website: www.sharkvac.com

Rev.12/03

Printed in China

Page 2

Warning: Always disconnect from power source when servicing or

cleaning the unit. Failure to do so could result in electrical

shock or personal injury from cleaner suddenly starting.

Warning: Always disconnect from power source when servicing or

cleaning the unit. Failure to do so could result in electrical

shock or personal injury from cleaner suddenly starting.

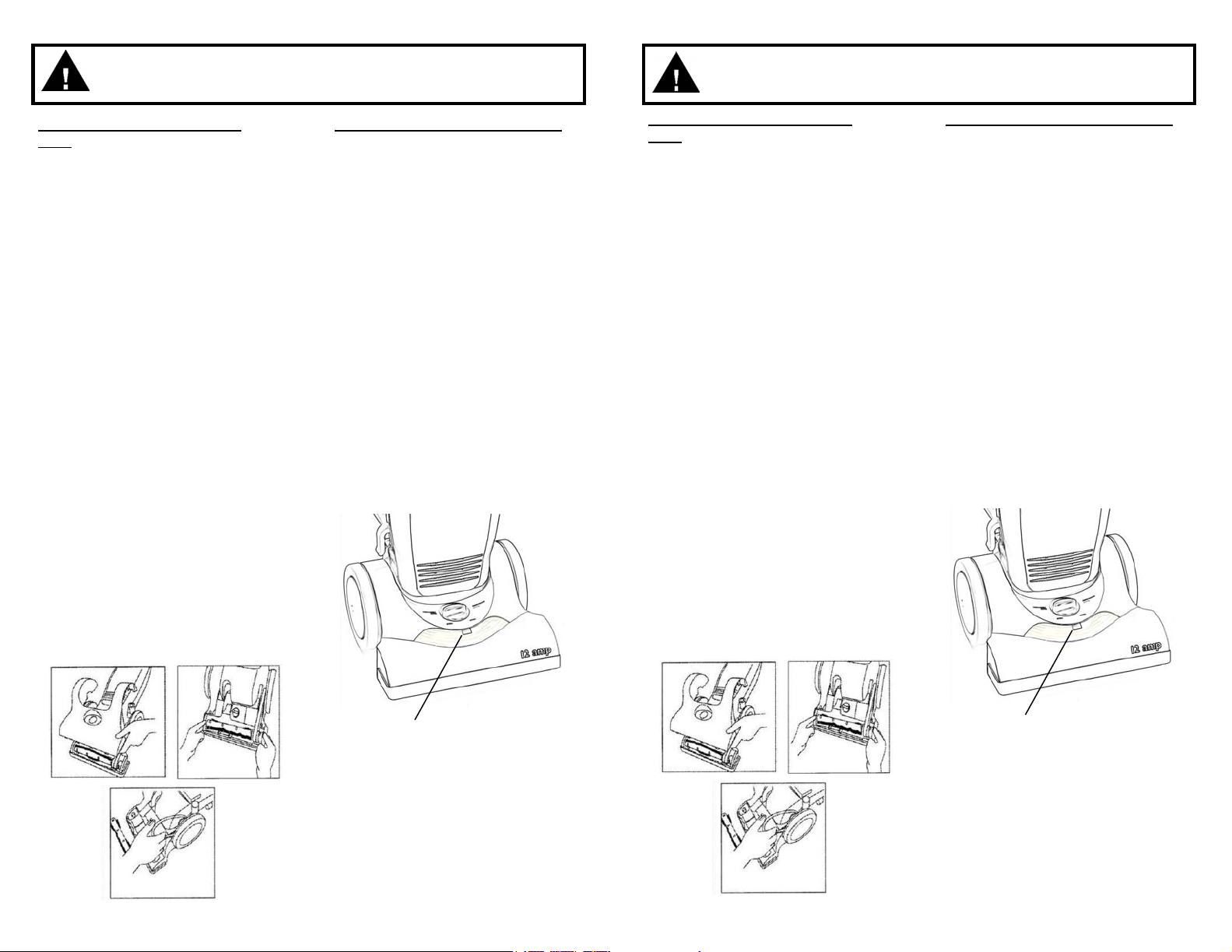

Changing the Power Nozzle

Belt:

A) Occasionally the power nozzle

drive belt will require changing,

the frequency will depend upon

the amount of use your vacuum

sees.

B) Turn unit “Off” and unplug from

wall outlet.

C) Use a Phillips screwdriver and

remove the two screws from the

back of the motorized power

head cover. (Fig. 1)

D) Remove the two screws from

the bottom of the motorized

power head. (Fig. 2)

E) If the belt has broken, remove

any loose pieces before replacing.

F) Grasp the beater bar at either

end and lift straight up.

G) Place one end of new belt over

motor shaft and the other on

the round pulley end of the

beater bar. (Fig. 3)

H) Align the rubber supports at the

ends of the beater bar, with the

slots in the motorized power

head. Push into place. Ensure

that the cut-outs on the rubber

supports face upwards.

I) Replace the two screws from

the bottom of the motorized

power head and then replace

the cover. Then replace the two

screws from the back side of the

motorized power head.

Changing the Head Light Bulb:

A) Turn unit “Off” and unplug from

wall outlet.

B) Insert the edge of a flat edge

screw driver into the locking tab

on the headlight lens and pull the

handle of the screw driver

towards you. Do NOT push with

the blade of the screw driver

against the lens because it might

cause it to break.

C) Remove the lens. (Fig. 4)

D) Remove the light bulbs by pulling

them out carefully.

E) Push the new light bulbs in and

replace the lens cover.

F) Make sure that it snaps in place.

Note: Always replace the light bulb with

the same or smaller wattage size (12V

4W) to prevent damage to the

surrounding parts.

Changing the Power Nozzle

Belt:

A) Occasionally the power nozzle

drive belt will require changing,

the frequency will depend upon

the amount of use your vacuum

sees.

B) Turn unit “Off” and unplug from

wall outlet.

C) Use a Phillips screwdriver and

remove the two screws from the

back of the motorized power

head cover. (Fig. 1)

D) Remove the two screws from

the bottom of the motorized

power head. (Fig. 2)

E) If the belt has broken, remove

any loose pieces before replacing.

F) Grasp the beater bar at either

end and lift straight up.

G) Place one end of new belt over

motor shaft and the other on

the round pulley end of the

beater bar. (Fig. 3)

H) Align the rubber supports at the

ends of the beater bar, with the

slots in the motorized power

head. Push into place. Ensure

that the cut-outs on the rubber

supports face upwards.

I) Replace the two screws from

the bottom of the motorized

power head and then replace

the cover. Then replace the two

screws from the back side of the

motorized power head.

Changing the Head Light Bulb:

A) Turn unit “Off” and unplug from

wall outlet.

B) Insert the edge of a flat edge

screw driver into the locking tab

on the headlight lens and pull the

handle of the screw driver

towards you. Do NOT push with

the blade of the screw driver

against the lens because it might

cause it to break.

C) Remove the lens. (Fig. 4)

D) Remove the light bulbs by pulling

them out carefully.

E) Push the new light bulbs in and

replace the lens cover.

F) Make sure that it snaps in place.

Note: Always replace the light bulb with

the same or smaller wattage size (12V

4W) to prevent damage to the

surrounding parts.

Fig. 1 Fig. 2

Fig. 3

Lens locking tab

Fig. 4

Fig. 4

Lens locking tab

Fig. 1 Fig. 2

Fig. 3

Loading...

Loading...