Euronics Sole cleaning machine, ESCD3 Operation Manual

1

Sole cleaning machine operation manuals

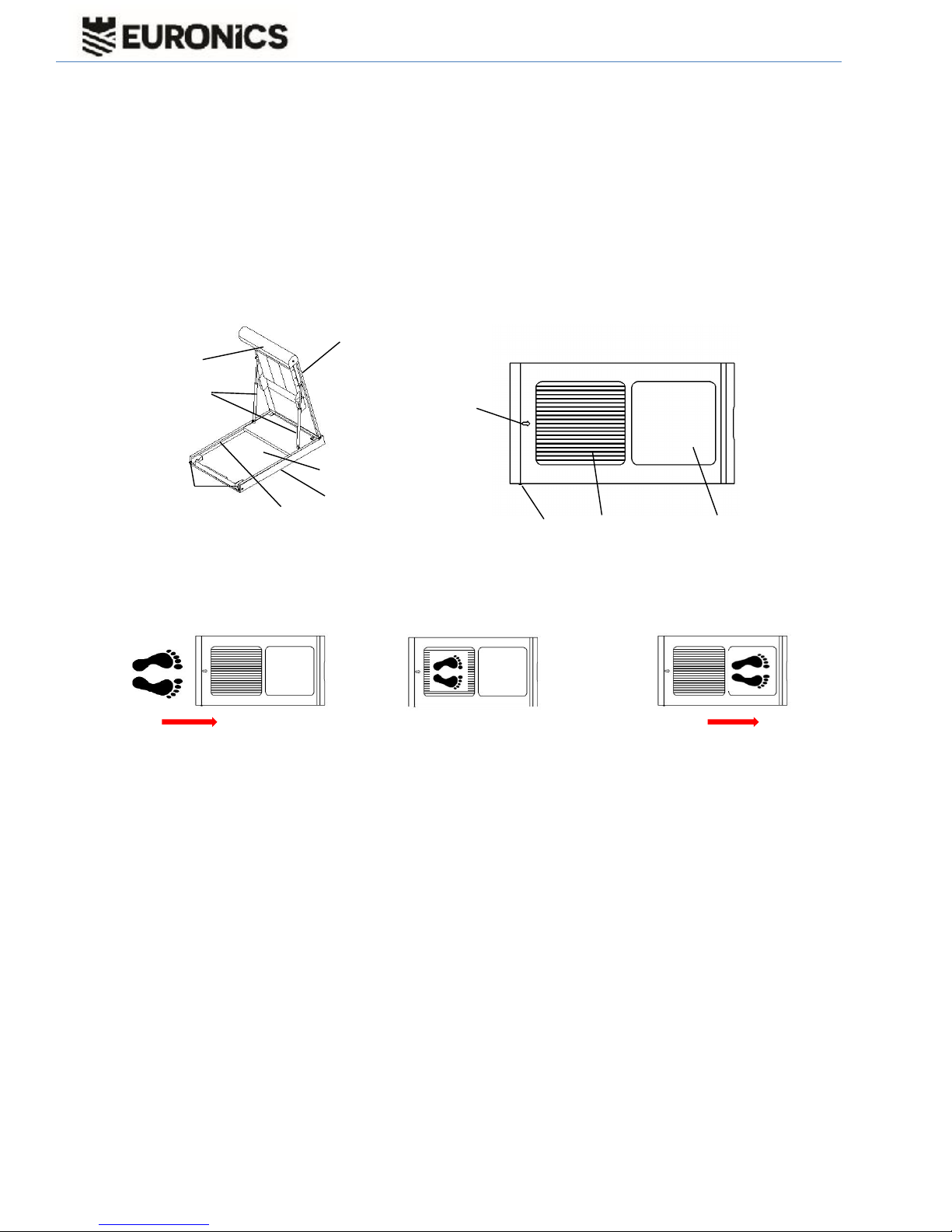

I.Instruction

III. Maintenance

1、 Placed sole cleaning machine on flat ground;

2、 Placed dry pad on cover plate, side of dry pad into quadrilateral frame;

3、 Unlock on two sides, then open the cover, please referring to Figure1.1;

4、 Add water, level line between “min” and “max”;

5、 Close the cover slowly and lock it, connect the power.

6、 Before removing make sure it locked

1、Cleaning machine: Regular clean the dust of the machine and brushes surface dirty.

2、Cleaning dry mat: Clean once every day, or more times than that, just depend on the actual situation to keep

the dry mat clean and absorbing effect. After cleaning, reset the mat to dry zone. Do not wring dry mat to

prevent damage. If you don't use the mats, seal it with plastic film.

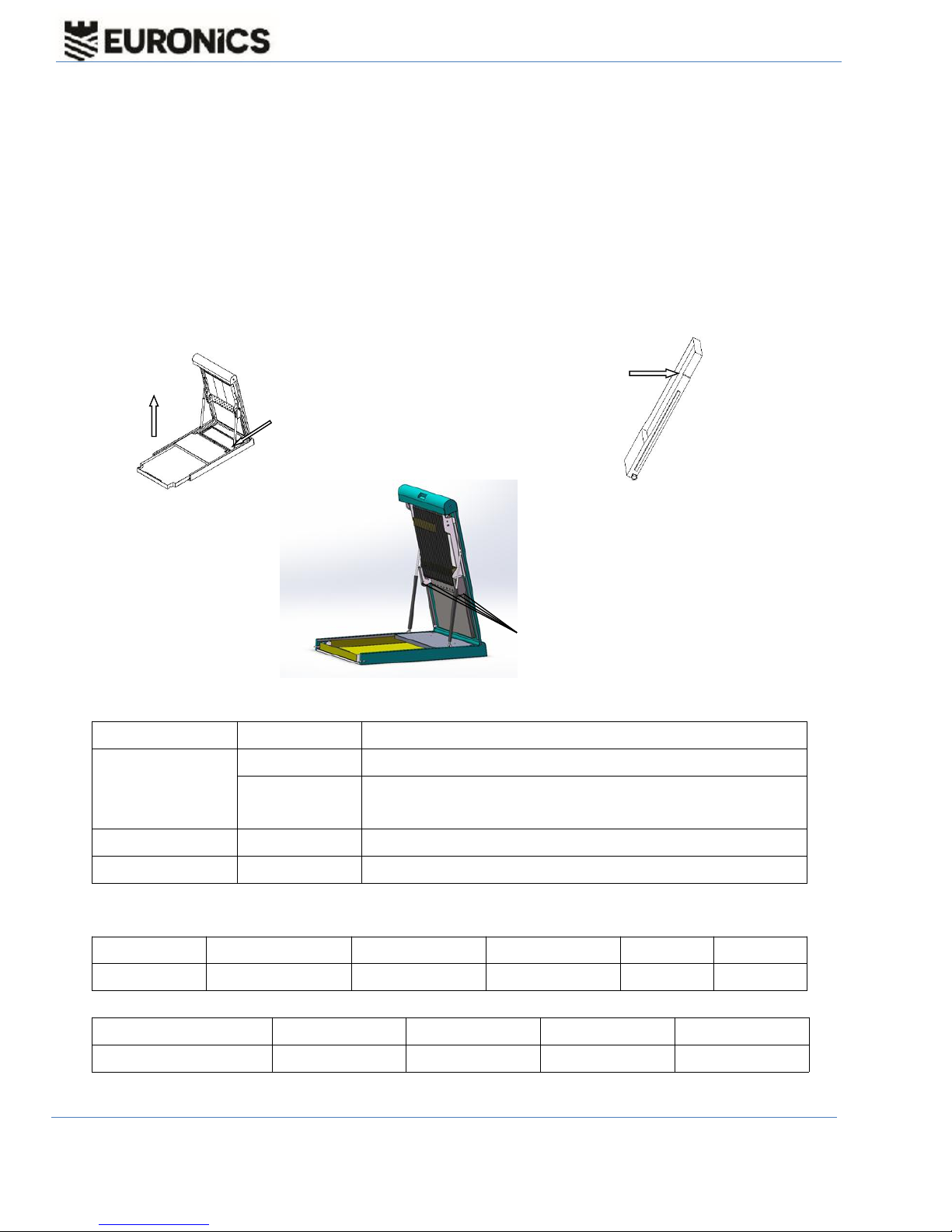

3、Changing water:

1) Power off, unlock two sides, lift up cover;

2) Back tank, referring to figure 3.3.1;

3) Lift tank handle, referring to figure 3.3.1;

4) Out of tank, water pouring, cleaning tank, add water to the liquid level scale, referring to figure 3.3.2;

5) Replace the tank;

6) Close cover slowly and lock it, then connect the power.

II. Usage

1、Pls stand upon clean zone as arrow

For the best cleaning result, pls pass through cleaning and dry zone referring to Figure 2.1-2.2. First the

cleaning zone. On the dry zone stay 2 seconds. More time cleaning, the effect will be better.

2、Piaffe 4 times

3、Pls walk to the dry zone, stay 2s

Clean zone

Figure2.1

Dry zone

Figure2.2

Tank

Handle

Figure1.1

Lower casing

Level indication

2

Questions

Reason

Troubleshooting

Machine doesn’t work

Loose power outlet

Check power plug

Perception sensor

fault

Check the sensor indicator light.

Brush doesn’t work

Loose Brush

Adjust brush by hand(Check Routine Maintenance No. 4).

Human absent, still work

Sensor is blocked

Make sure there is no obstruction above the sensor and clean the sensor surface.

Type

Dimension

Clean zone

Dry zone

Water tem.

Tank

ESCD3

900×470×85mm

345×325mm

335×325mm

0-40℃

4L

Voltage

Power

Noise

Overload

N.W

220V/50HZ

75W

<60db

150Kg

25Kg

Sole cleaning machine operation manuals

IV. Common trouble shooting

V. Specifications

4. Adjust the brushes: When the machine is running normally, you find the brushes do not work, then you

should adjust tension bolt tight.

① Power off, unlock two sides, lift cover;

② Find the brushes tension bolts (check Figure4.1), tighten it;

③ Both sides of a total 4 tension bolts are required to maintain a consistent adjustment, to ensure the equipment

work properly.

④ Connect the adapter, check brushes whether running normally, if the brushes still do not work, please repeat ①,

②,③ above, adjust the tension bolts, until the brush work.

Figure 4.1

Figure 3.3.1

Figure 3.3.2

Tension bolts

Loading...

Loading...