Euromatic SDC 300, SMC 1103, SDC 550, SVX 1100 Operating Instructions Manual

• TAUCHPUMPEN

• SUBMERSIBLE PUMP

• POMPE IMMERGÉES

• POMPE SOMMERSE

• DOMPELPOMPEN

• BOMBAS SUMERGIBLES

• BOMBAS SUBMERSÍVEIS

• DYKPUMPEN

• DRÄNKBARA PUMPAR

• UPPOPUMPUT

• NEDSENKETE PUMPER

•

ΒΥΘΙΜΕΝΕΣ AΝΤΛΙΕΣ

• DALGIÇ POMPA

• POMPY ZANURZENIOWE

•

PONORNÁ ČERPADLA

• MERÜLO ELEKTROSZIVATTYÚ

•

HACOCЫ ПOГPУЖHЫE

•

• PANARDINAMOS POMPOS

• SUKELPUMBAD

• POTOPNE PUMPE

• POMPE SCUFUNDATE

• POTOPNA ˇCRPALKA

• TAUCHPUMPEN

• SUBMERSIBLE PUMP

• POMPE IMMERGÉES

• POMPE SOMMERSE

• DOMPELPOMPEN

• BOMBAS SUMERGIBLES

• BOMBAS SUBMERSÍVEIS

• DYKPUMPEN

• DRÄNKBARA PUMPAR

• UPPOPUMPUT

• NEDSENKETE PUMPER

•

ΒΥΘΙΜΕΝΕΣ AΝΤΛΙΕΣ

• DALGIÇ POMPA

• POMPY ZANURZENIOWE

•

PONORNÁ ČERPADLA

• MERÜLO ELEKTROSZIVATTYÚ

•

HACOCЫ ПOГPУЖHЫE

•

• PANARDINAMOS POMPOS

• SUKELPUMBAD

• POTOPNE PUMPE

• POMPE SCUFUNDATE

• POTOPNA ˇCRPALKA

• SUBMERSIBLE PUMP

• POMPE SOMMERSE

• PONORNÈ ČERPADLO

• PONORNÈ ČERPADLO

GB

Operating instructions

I

Libretto istruzioni

CZ

Návod k obsluze

SK

Návod na obsluhu

Technical data - Dati tecnici - Technnická data - Techické údaje

• Supply voltage • Tensione nominale • napêti v síti • Siet’ové napätie

1103

230 V

50 Hz

SMC

SDC

300

230 V 230 V 230 V

230 V ~

50 Hz

SDC

550

230 V ~

50 Hz

SVX

1100

230 V ~

50 Hz

• Power consumption • Potenza assorbita

• Přikon • Príkon

• Current input • Corrente nominale

• Proud • Menovitý prúd

• Required fuse • Fusibile necessario

• Doporučené jištění zasuvky • Odporúcané istenie zasuvky

• Insulation class • Classe d’isolamento

• Izolačni třída • Izlačná trieda

• Protective device • Protezione

• Druh krytí • Druh krytia

•

Capacitor capacity • Capacità del condensatore

Kapacita kondenzátoru

•

•

Maximum head height • Prevalenza max.

• Maximálni výtlak

•

Maximum delivery • Portata max.

•

Maximálni dodávané množství

•

Pressure pipe min. • Diametro min. tubo mandata

•

Min. dimenze výtlaku

Submersion depth• Profondità d’immersione

•

•

Hloubka ponoru

• Kapacita kondenzátora

• Maximálny výtlak

• Maximálne dodávané množstvo

• Minimálny priemer výtlačného potrubia

• Hĺbka ponoru

1100 W

5,0 A

10 A

F

IP 68

16 μF

38 m

130

L/min

1”

10 m 5 m

300 W 550 W 1100 W

1,6 A 3,0 A 5,0 A

10 A 10 A 10 A

F F F

IP 68 IP 68 IP 68

5 μF

8 μF

16μF

7 m 8 m 10 m

100

L/min

1”1/2

165

L/min

1”

250

L/min

2”

5 m 5 m

Inlet opening for grain size up to this diameter

•

• Maximální průměr nasávanych cizich těles • Maximálny priemer nasávaných

cudzich telies

•

Horizontal suction up to approx

Minimální sací úroveň

•

• Weight • Peso

• Hmotnost • Hmotnost’

• Minimálna sacia úroveň

i

r

i

i

r

t

s

c

p

o

a

A

•

• Livello min.d’aspirazione

r

s

e

p

e

n

a

t

i

r

i

f

e

d

o

a

a

o

n

m

Ø 3 mm

60 mm

12,5 Kg.

L=230 mm

• Packing dimensions • Dimensioni imballo

• Rozměry balení(kartonu) • Rozmery balenia (kartonu)

B=185 mm

H=420 mm

Ø 5 mm

15 mm

4,4 Kg.

L=230 mm

B=200 mm

H=310 mm

Ø 5 mm

15 mm

5,4 Kg.

L=230 mm

B=200 mm

H=340 mm

Ø 40 mm

60 mm

7,5 Kg.

L=230 mm

B=200 mm

H=400 mm

Technical data - Dati tecnici - Technnická data - Techické údaje

350/S

SDX

SVX

550

• Supply voltage • Tensione nominale • napêti v síti • Siet’ové napätie

• Power consumption • Potenza assorbita

• Přikon • Príkon

• Current input • Corrente nominale

• Proud • Menovitý prúd

• Required fuse • Fusibile necessario

• Doporučené jištění zasuvky • Odporúcané istenie zasuvky

• Insulation class • Classe d’isolamento

• Izolačni třída • Izlačná trieda

• Protective device • Protezione

• Druh krytí • Druh krytia

•

Capacitor capacity • Capacità del condensatore

Kapacita kondenzátoru

•

•

Maximum head height • Prevalenza max.

• Maximálni výtlak

•

Maximum delivery • Portata max.

•

Maximálni dodávané množství

•

Pressure pipe min. • Diametro min. tubo mandata

•

Min. dimenze výtlaku

• Kapacita kondenzátora

• Maximálny výtlak

• Maximálne dodávané množstvo

• Minimálny priemer výtlačného potrubia

230 V

50 Hz

350 W

1,7 A

10 A

F

IP 68

8 μF

7 m

150

L/min

1”¼

230 V

50 Hz

550 W

3 A

10 A

F

IP 68

8 μF

7 m

180

L/min

1”½

Submersion depth• Profondità d’immersione

•

•

Hloubka ponoru

Inlet opening for grain size up to this diameter

•

• Maximální průměr nasávanych cizich těles • Maximálny priemer nasávaných

cudzich telies

•

Horizontal suction up to approx

Minimální sací úroveň

•

• Weight • Peso

• Hmotnost • Hmotnost’

• Hĺbka ponoru

i

s

p

A

•

• Livello min.d’aspirazione

• Minimálna sacia úroveň

t

i

r

r

i

r

c

o

a

s

e

p

i

i

f

t

e

d

r

n

e

n

a

o

a

a

o

m

5 m

Ø 2 mm

2 mm

5,1 Kg.

L=230 mm

• Packing dimensions • Dimensioni imballo

• Rozměry balení(kartonu) • Rozmery balenia (kartonu)

B=200 mm

H=310 mm

5 m

Ø 35 mm

35 mm

6,2 Kg.

L=200 mm

B=230 mm

H=400 mm

SUBMERSIBLE PUMP

�

the well so that the muddy bottom is not sucked up with

the water.

Never handle or hang the pump by gripping the power

supply cable.

In pumps with a floating switch, the latter is adjusted in

order to make immediate starting possibile.

Note

The pump well must have minimum dimensions of

40x40x50 cm. so that the floating switch can move freely.

It is also possible to use round, prefabricated concrete

wells with an inner diameter of approx. 40 cm.

4. Maintenance instructions

Your canned motor pump is a quality product, free from

maintenance. It has been subjected to rigorous final

checks.

However, for a long service life and continuous operation,

we recommend constant care and regular checks.

• Before every maintenance job, disconnect the plug.

• For transportable use the pump should be washed with

clear water after every use.

• For fixed installation it is recommended to check the

operation of the floating switch every 3 months.

• Using a jet of water, get rid of the fibre and spindly

particles that may get deposited in the pump’s cassing.

• In the event of excessive deposits in the pump cassing,

dismantle the inlet filter by unscrewing the star screw.

Wash the pump casing and fit the inlet filter back on.

• Every 3 months remove the mud from the bottom and

walls of the well.

• Eliminate the deposits from the floating switch, washing

it with fresh water.

• Protect the pump from frost.

CAUTION!

“DRAINAGE”

Special instructions: It is not suitable for pumping:

sewage, sandy water.

The pump must never run dry.

The manufacturer’s warranty is null and void in

the event of damage to the pump caused by it

running dry.

“VORTEX”

The pump must never run dry.

The manufacturer’s warranty is null and void in

the event of damage to the pump caused by it

running dry.

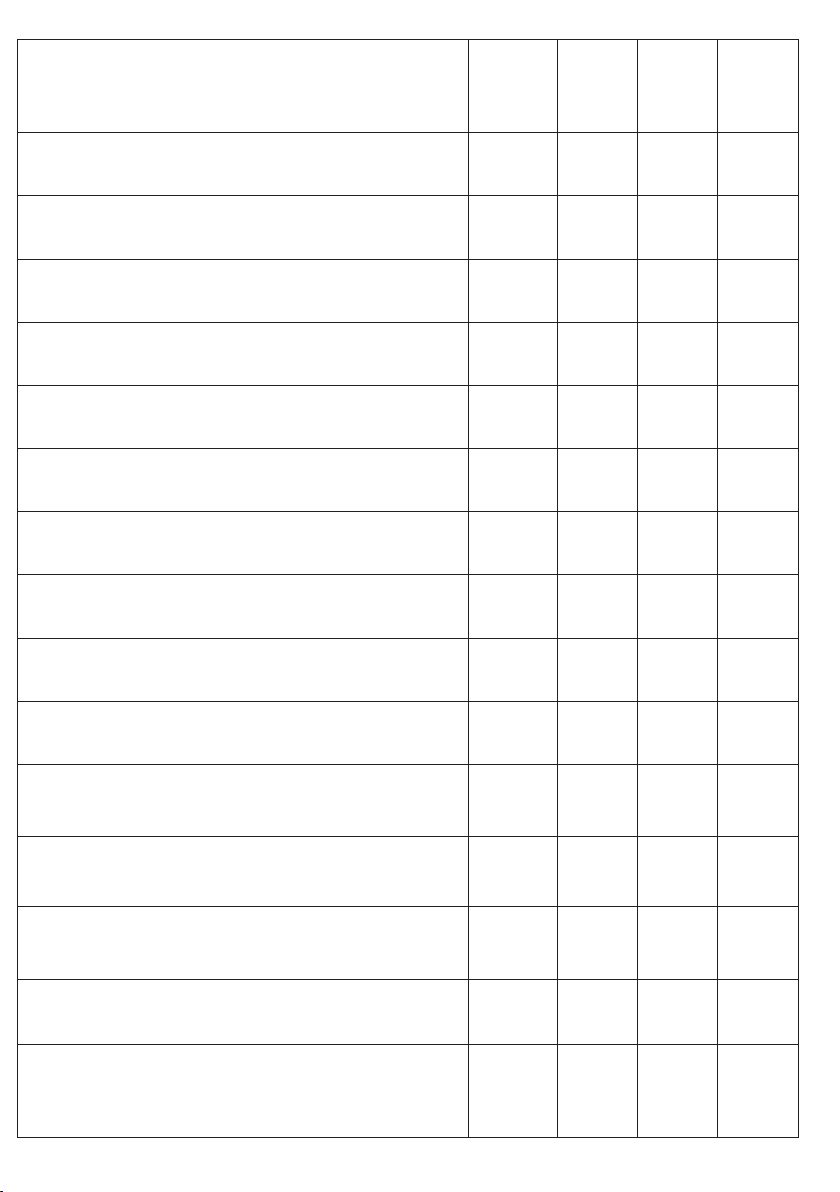

CAUSES

The motor will not work

The motor works, the pump will not convey

Insufficient flow rate

Repeated switching off with disconnection of the protection switch

TROUBLE

No mains voltage, the floating swittch will not connect

Defective protection device

Motor protection disconnected, pump straining/blocked

Dry operation protection disconnected, the water level has fallen too much

Defective pump

Clogged suction opening

Check valve blocked or delivery pipe bent

Delivery pipe clogged

Foreign bodies in the pump, pump impeller blocked

The pump runs dry

If it is not possibile to eliminate the trouble, please call our service department.

To avoid damage during transport, please ship in the ORIGINAL PACKING.

Troubleshooting Table

19

�

the well so that the muddy bottom is not sucked up with

the water.

Never handle or hang the pump by gripping the power

supply cable.

In pumps with a floating switch, the latter is adjusted in

order to make immediate starting possibile.

Note

The pump well must have minimum dimensions of

40x40x50 cm. so that the floating switch can move freely.

It is also possible to use round, prefabricated concrete

wells with an inner diameter of approx. 40 cm.

4. Maintenance instructions

Your canned motor pump is a quality product, free from

maintenance. It has been subjected to rigorous final

checks.

However, for a long service life and continuous operation,

we recommend constant care and regular checks.

• Before every maintenance job, disconnect the plug.

• For transportable use the pump should be washed with

clear water after every use.

• For fixed installation it is recommended to check the

operation of the floating switch every 3 months.

• Using a jet of water, get rid of the fibre and spindly

particles that may get deposited in the pump’s cassing.

• In the event of excessive deposits in the pump cassing,

dismantle the inlet filter by unscrewing the star screw.

Wash the pump casing and fit the inlet filter back on.

• Every 3 months remove the mud from the bottom and

walls of the well.

• Eliminate the deposits from the floating switch, washing

it with fresh water.

• Protect the pump from frost.

CAUTION!

“DRAINAGE”

Special instructions: It is not suitable for pumping:

sewage, sandy water.

The pump must never run dry.

The manufacturer’s warranty is null and void in

the event of damage to the pump caused by it

running dry.

“VORTEX”

The pump must never run dry.

The manufacturer’s warranty is null and void in

the event of damage to the pump caused by it

running dry.

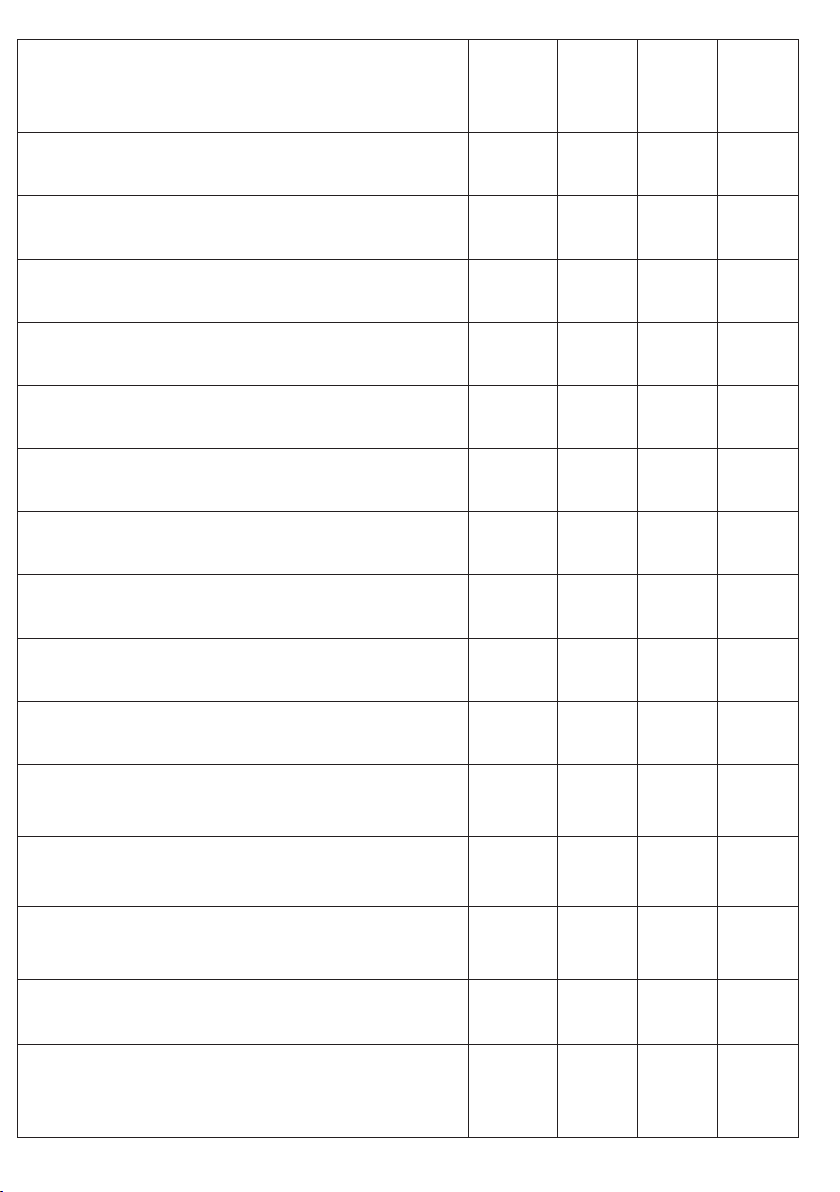

CAUSES

The motor will not work

The motor works, the pump will not convey

Insufficient flow rate

Repeated switching off with disconnection of the protection switch

TROUBLE

No mains voltage, the floating swittch will not connect

Defective protection device

Motor protection disconnected, pump straining/blocked

Dry operation protection disconnected, the water level has fallen too much

Defective pump

Clogged suction opening

Check valve blocked or delivery pipe bent

Delivery pipe clogged

Foreign bodies in the pump, pump impeller blocked

The pump runs dry

If it is not possibile to eliminate the trouble, please call our service department.

To avoid damage during transport, please ship in the ORIGINAL PACKING.

Troubleshooting Table

19

1. Safety measures

Carefully read the operating instructions before assembling

and starting. The appliance must not be used by persons

who are not thoroughly acquainted with the instructions

handbook (operating instructions). Children and persons

under the age of 16 cannot use the pump and must be

kept well away from the appliance when it is connected.

The user is liable towards third parties in the area where

the appliance is in operation.

While the pump is operating persons must

not be in the liquid to be pumped.

to the available mains voltage.

Before starting it is necessary to make sure by having a

check made by qualified personnel that there are the

necessary electrical protection measures.

• Earth connection.

• Earthed neutral.

• The safety switch for fault currents corresponds to the

• Plug connections must be protected from water. If there

• Definitely avoid pumping aggressive liquids and abrasive

In the event of the pump failing, repair work may only be

carried out by the repair workshops of the technical

service. Only genuine spare parts must be used.

The pump may be connected only by

means of a safety switch for fault currents, with

a rated opening current up to 30 mA and a socket

with an earth contact installed in conformity with

the regulations.

Protection: at least 10 Amps.

Operation in swimming pools and garden ponds is

admitted.

For other operation, the provisions in conformity with

the standard VDE 0100 part 702 must be respected.

CAUTION: Before checking, connect the pump and

the system with no voltage!

Replacing the line connecting up with the mains

requires using special tools and therefore may be

done only by the manufacturer or its service engineers.

The pump may operate only with a pipe connecting

the appliance (extension) that is no lighter than a

rubber hose mod. H07 RNF in conformity with the DIN

57282 or DIN 57245 standard.

(For your safety)

The voltage (230 Volts alternating current) indicated on the pump’s rating plate must correspond

safety regulations of the electricity board and functions

perfectly.

is a risk of flooding, plug connections must be placed

somewhere safe.

products.

It is notified that in conformity with the law on product

liability

for the damage caused by our appliance:

a) because of improper repairs not carried out by the

b) or if GENUINE SPARE PARTS are not used to replace

c) or if the indications and provisions given in the instruc-

we cannot be held responsible

personnel of the assistance points authorized by us;

parts;

tions handbook are not complied with.

The same provisions hold for the accessories.

Resistance

The maximum temperature of the delivery liquid should

never exceed +35°C in continuous operation.

Infiammable, combustible or explosive liquids cannot

be conveyed with this pump!

In particular, do not use engine fuels, detergents, or other

chemical products.

2. Use

CAUTION! Sector of use

“DRAINAGE” – To transfer and empty fresh to

slightly polluted water from rainwater barrels and

casks.

“VORTEX” – Portable submersible pump for

discharge and waste water with solids in suspension.

Also used as emergency pump, in case of overflowing with muddy water, thanks to its large

suction filter.

To achieve excellent motor cooling the pump

casing is provided with a breather hole that enables

water to flow out.

The pump must be protected from running dry.

Starting

First put the pump into water and then

connect the plug.

The pump is ready for use.

3. Before starting

Installation of your canned motor pump is:

• fixed with a fixd pipe, or

• fixed with a flexible hose.

Take care

When installing it is necessary to take care that the pump

is never fitted hanging from its delivery pipe, but is always

placed in a raised position with respect to the bottom of

Loading...

Loading...