WARNING

• These instructions must be read, understood, and followed: improper use or failure to wear the respirator during all times of exposure

may result in severe illness, permanent disability or death.

• Always be sure both mask and filter selection is: appropriate for the application; worn at all times during exposure; filters are replaced

when necessary.

• Refer to information supplied to check suitability or contact Euromarc 0800 278 600.

• Do not use in environments at less than 19.5% oxygen.

• Only use with Euromarc Craftsman filters listed in the table below and only in the stated applications.

• The wearer must be trained in the use of all equipment and in respect of relevant workplace health and safety regulations.

• Beards and facial hair will inhibit the effective sealing of the mask against the user’s skin. Use an alternative mask if a complete

and effective seal is not achievable.

• Do not use in flammable environments.

• Do not use if type, toxicity or concentration of contaminants is unknown. Do not enter hazardous area.

• Leave work area immediately, check integrity of respirator and replace any parts if: a) damage has occurred or is apparent.

b) dizziness, illness or irritation occurs. c) breathing resistance increases. Dispose of all used filters.

• Never modify or alter this product, doing so could jeopardize your safety.

• While materials in this mask do not commonly cause allergic reactions, if you notice any reaction or irritation cease use

and seek medical advice.

• P3 rated protection can only be achieved when using a full-face mask, irrespective of filter choice.

PREPARATION FOR USE

Check that the mask is complete, undamaged and assembled correctly.

Damaged or faulty respirators must be replaced - contact Euromarc 0800 278 600.

INSPECTION

The following points must be checked before use:

1. The material should be soft and pliable to conform to the face. Check the face-piece, valves and diaphragm for

any cracks or tears and ensure the shape of the mask is not distorted.

2. Make sure all seals are correctly positioned. Remove the front plastic piece to check the exhalation diaphragm.

3. Inspect head-straps, clips and harness to ensure an effective seal.

4. Ensure mask is clean. Dust and dirt in the valves or bayonet fittings can impair effective protection.

This product meets the requirements of AS/NZS 1716:2012 and should be used in

combination with a pair of approved Euromarc Craftsman filters to form a filtering

apparatus for respiratory protection.

USER INSTRUCTIONS

Please read these instructions before using the Euromarc Craftsman 710 series

masks and filters.

HALF FACE

RESPIRATOR

A RT. Pcs. SIZES

C710-7 S1

C710-8 M1

C710-9 L1

Euromarc 710 Series Filter

710

AS/NZ 1716 : 2012 Lic 40344

SAI Global

FITTING INSTRUCTIONS

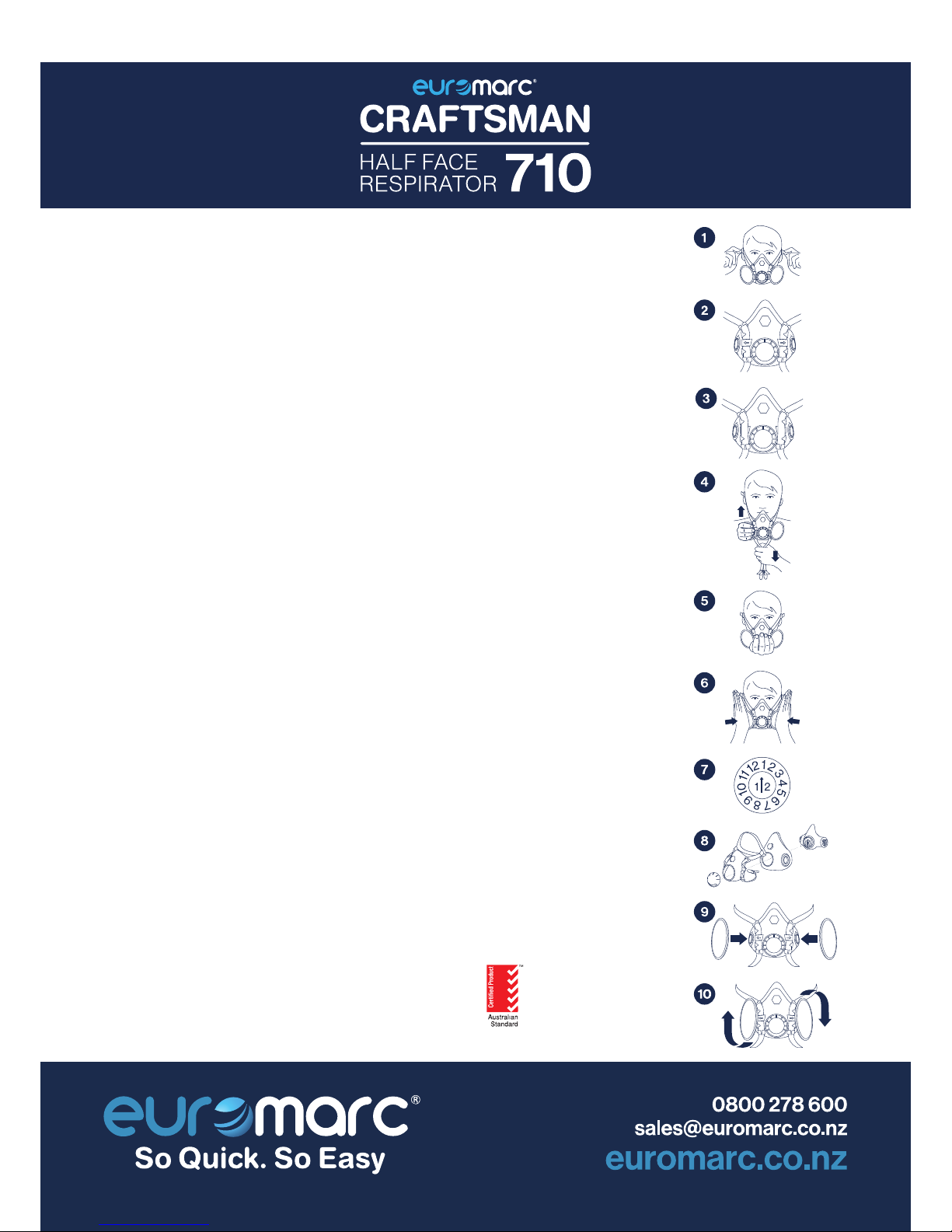

1. The filters have a 3-point locking system - align openings on the back of the filter with

the fitting on the mask, press and turn filter clockwise until it is firmly attached (fig. 9 and

10).

2. With one hand hold the respirator over the mouth sitting it on the bridge of the nose,

then fit head harness over the crown of the head with the other hand, taking care that

the elastic straps are not twisted (fig. 1).

3. Hook the two bottom straps together behind the neck.

4. Firstly, tighten the head harness by pulling on the ends of the straps – ensure

a comfortable but firm and secure fit. Tighten the bottom straps in a similar manner

(fig. 1) (Strap tension may be decreased by pushing out on the back

side of the buckles).

5. For a drop-down suspensed mask, adjust the harness as shown on

(fig.2, 3 to fig. 4) then repeat steps 2, 3 and 4 to fit mask.

FIT CHECK

1. Positive-Pressure test: place the palm of your hand over vent in the exhalation valve

cover and breathe out (fig. 5). If no air leaks are present the mask will bulge out – you

have a good seal.

2. Negative-Pressure test: press your palms firmly over the filters, try and cover as much

area as possible, inhale gently and hold your breath briefly. If no air leaks are present

the face piece will collapse slightly - you have a good seal (fig. 6).

3. If you detect any air leaks in either test try repositioning the respirator on the

face and/or adjust the tension on the elastic straps. You may need to use a different size.

4. Repeat steps 1-3 until you have a good seal.

If you CANNOT achieve a proper fit DO NOT enter the hazardous area. It is recommended

that wearers should be fit tested in accordance with AS/NZS 1715.

MAINTENANCE AND CLEANING

Euromarc recommends cleaning the mask after each use. Use designated respirator

cleaning wipes, and wipe the face seal and internal surfaces. Or remove the filters and

wash in warm clean water (below 50° C).

Leave to air-dry at room temperature in a clean environment (fig. 8).

CAUTION: using cleaners containing oils, detergent or abrasive chemicals can destroy the

integrity of the mask. Masks and filters should be inspected before each use as described

above. Damaged masks should be discarded.

STORAGE

Masks should be stored in their original packaging in dry, clean conditions, between -10 to

+40°C, and away from direct sunlight, high temperature, chemicals and vapours. Masks

have a life-span of 5 years from date of manufacture, including shelf-life and time in-use.

The date of manufacture can be established by examining the date clock on the inside of

the face piece as shown in (fig. 7). After each use and cleaning, masks should be stored in

their original packaging or a sealed container, do not store in contaminated areas.

APPROVALS

These filters comply with Australian/New Zealand Standard

AS/NZS 1716:2012 and have been accredited and certified

as such by SAI Global.

AS/NZ 1716 : 2012 Lic 40344

SAI Global

AS/NZ 1716 : 2012 Lic 40344

SAI Global

FITTING INSTRUCTIONS FOR USE

Craftsman Particulate Pre-Filter 713 is used in conjunction with Craftsman Gas/Vapour filter ABEK 719, for protection

against mechanically and thermally generated particles and clogging by sanding, polishing dust, or paint particles.

• To be used with 713R Retainers to connect the 713 filter to the 719 filter.

PARTICULATE

PRE-FILTER P2

For use against

both mechanically

and thermally

generated particulates.

C713 2

Euromarc 710 Series Respirator

When generating dusts

and fumes with sanding,

grinding, cutting, polishing,

or particles from welding

or fabricating.

713

PARTICULATE

PRE-FILTER P2

713

WARNING

• Always be sure that your respirator is: a) suitable for all

expected respiratory hazards in the workplace; b) your

respirator is fitted properly – refer to manufacturer’s

instructions; c) filter is replaced when necessary.

• Do not use for respiratory protection against unknown airborne

contaminants or when concentrations of contaminants are

unknown or as protection against substances immediately

dangerous to life or health.

• Do not modify or alter filters or face-pieces.

• Use with Euromarc 710 series respiratory.

• If in doubt about the correct use or suitability of this device for

any application, consult your supervisor, occupational health

professional or contact Euromarc.

• Always check the filters have not exceeded

the use-by date.

• Provides P3 protection only with full

face-piece espirator, and P2 protection

with half face-piece respirator.

PARTICULATE

FILTER GP3

For use against both

mechanically and thermally

generated particulates.

For use against all particulates

including highly toxic materials.

C718 2

Euromarc 710 Series Respirator

When generating dusts

and fumes with sanding, grinding,

cutting, polishing, or particles

from welding or fabricating.

Working with toxic particulates

such as mould remediation.

718

PARTICULATE

FILTER GP3

718

AS/NZ 1716 : 2012 Lic 40344

SAI Global

WARNING

• Always be sure that your respirator is: a) suitable for all expected respiratory hazards in the workplace; b) fitted properly – refer to

manufacturers instructions; c) filter is replaced when necessary.

• Do not use for respiratory protection against unknown airborne contaminants, when concentrations of contaminants are unknown or

exceed 10x workplace exposure limits, against substances immediately dangerous to life or health.

• Do not modify or alter filters or face-pieces.

• Use with Euromarc 710 series respiratory.

• If in doubt about the correct use or suitability of this device for any application, consult your supervisor, occupational health

professional or contact Euromarc.

• Always check the filters have not exceeded the use-by date.

• Do not use where there may be a deficiency of Oxygen.

718 & 719 FILTER INSTRUCTIONS FOR USE

1. Check identification on the filters to ensure you have the correct filters for the application.

2. a) Align the filter bayonet fitting with the facepiece bayonet fitting. b) Rotate 1/4 turn clockwise to attach (fig 9, 10).

CAUTION: Over rotation will result in damage to the filter and facepiece.

Note: These filters are supplied in pairs of identical classes and type and must be fitted, used and replaced at the same time.

3. Leave work area immediately, check integrity of respirator, and replace any parts if: a) damage has occurred or is apparent b)

dizziness, illness or irritation occurs c) breathing resistance increase. Dispose of all used filters.

STORAGE

Store in original packaging before use. Store between -10 and +35°C and less than 70% humidity. End of Shelf Life is 5 years after date of

manufacture.

APPROVALS

These filters comply with Australian/New Zealand Standard AS/NZS 1716:2012 and have been accredited and certified

as such by SAI Global.

GAS/VAPOUR

FILTER ABEK

Combination filter, for use against

Organic (boiling point >65°C),

Inorganic vapours, and Acid gases,

Ammonia and its derivatives.

C719 2

Euromarc 710 Series Respirator

When working with a variety of

solvents and acid gases such as

chlorine, hydrogen chloride,

sulfur dioxide, hydrogen fluoride,

hydrogen sulphide. Acid cleaning,

de-greasing, paints, thinners and

glues. Ammonia, refrigeration.

719

GAS/VAPOUR

FILTER ABEK

719

AS/NZ 1716 : 2012 Lic 40344

SAI Global

Loading...

Loading...