Page 1

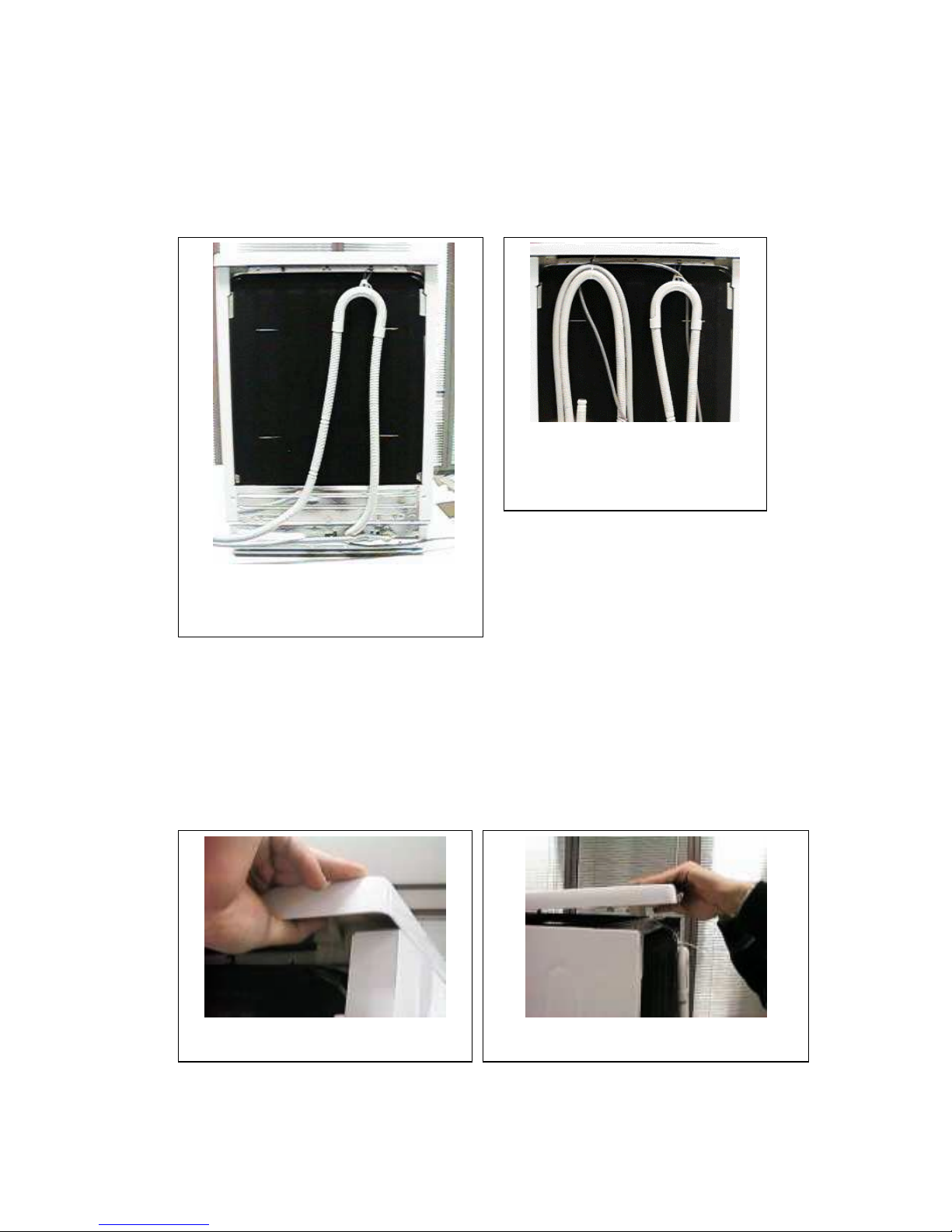

Position of the Drain and Water

Supply hoses before disassembling.

ASSEMBLY AND DISASSEMBLY METHODS FOR KEY

COMPONENTS

1) DRAIN HOSE

For the purpose of avoiding any

siphonage in the drain hose, the

hose is kept at a certain sufficient

level by means of 1 hose clamp.

This clamp should never be

removed while assembling the

machine in the desired position.

When the hose is to be replaced, the unit, which is seen at the right back top

corner of the machine is required to be removed after being cut.

3 wire clamps and 2 plastic hose clamps are removed for dismantling the

drain hose.

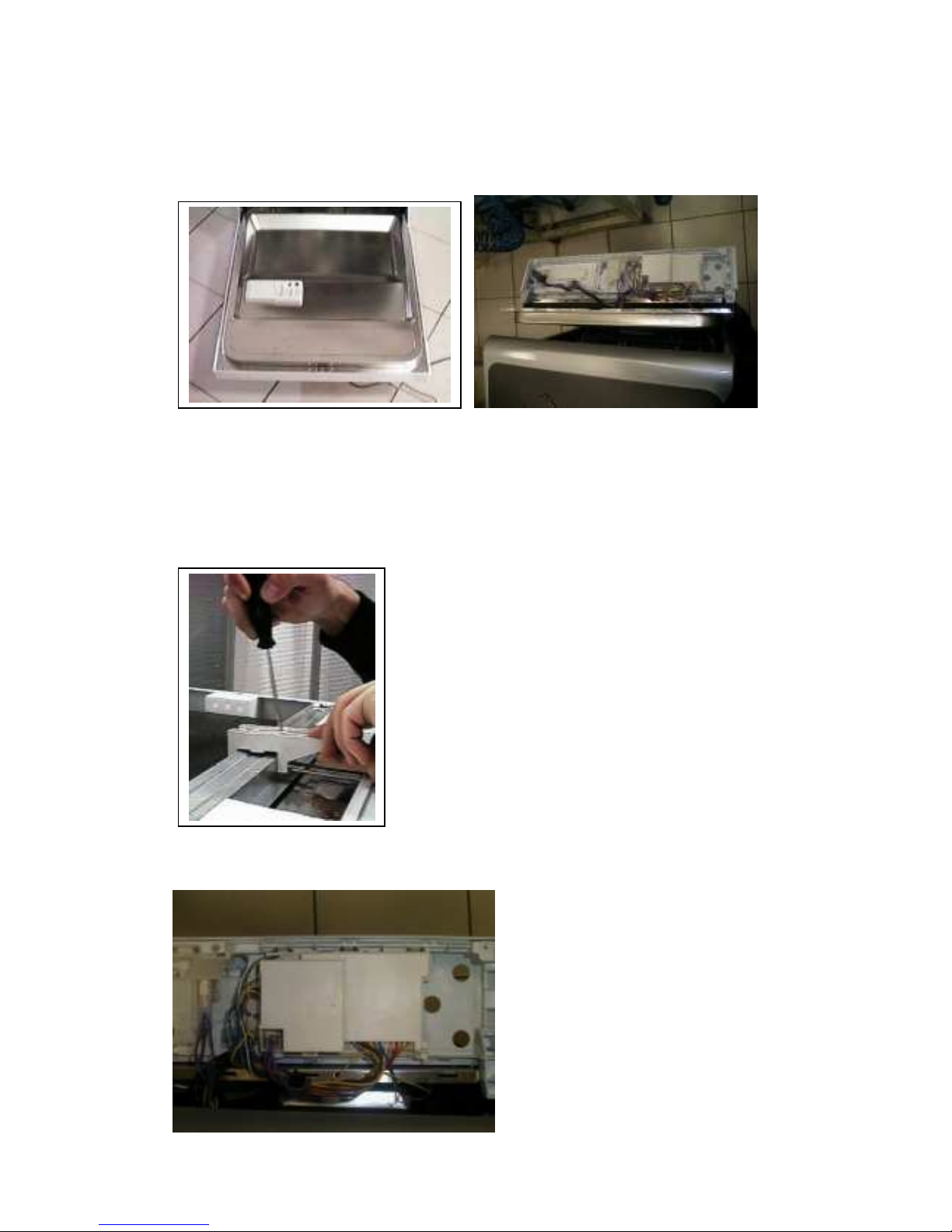

2) TOP PLATE

The plate is pulled back for approximately 1 cm. by pressing the latches

located at both sides of the upper plate in upward direction. Afterwards, the

plate is removed by pulling it upwards.

The position of the drain hose during the

assembly of the product.

Manner of opening the latch of the upper

plate.

Manner of removing the upper plate after the

latches are released.

Page 2

In case the machine is to be installed under the counter, the support of the

upper plate should be dismantled.

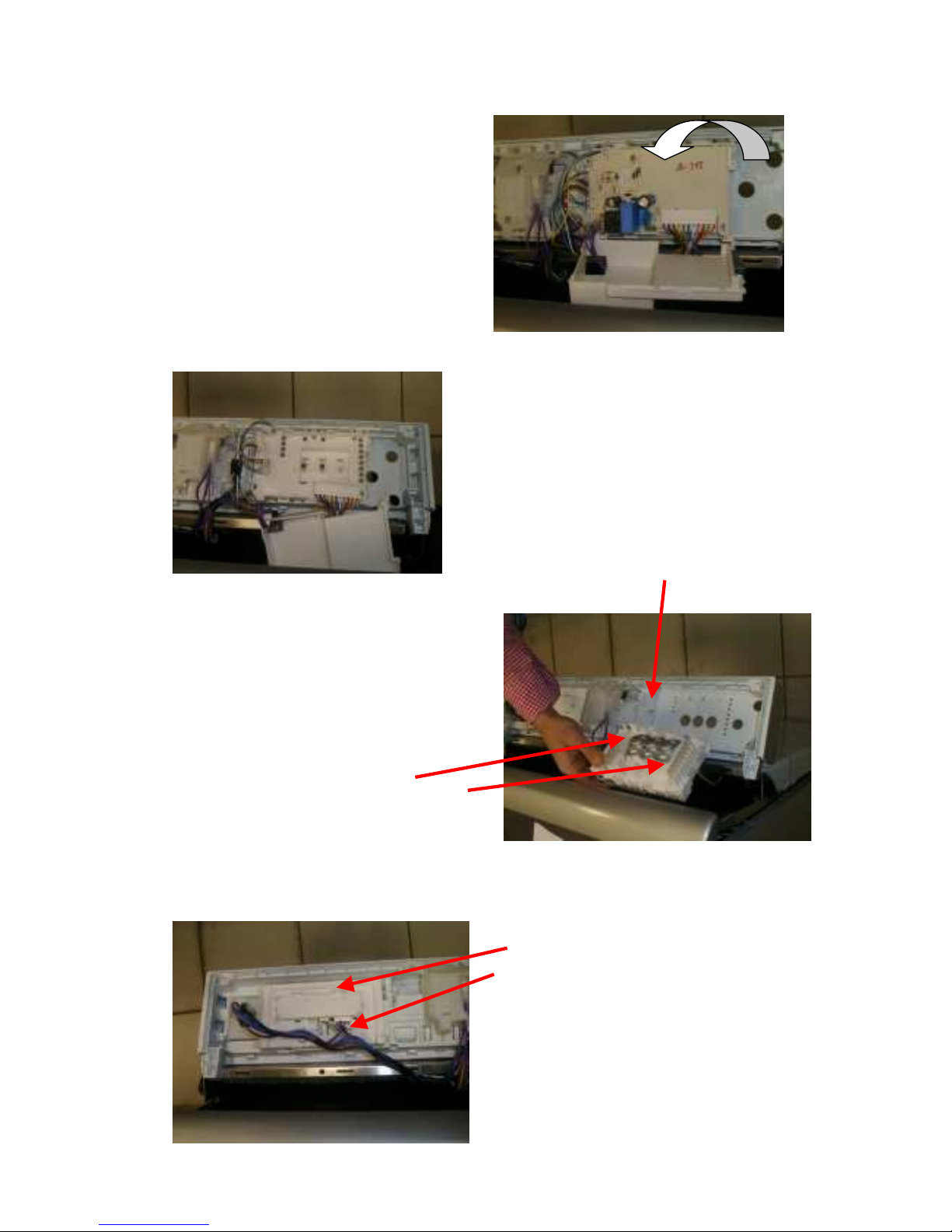

3) CONTROL PANEL

The control panel is detached from the inner metal plate, after unscrewing the

6 screws located on the front side of the inner door, as is seen at the photo.

4) TOP PLATE MID SUPPORT

The part can be dissembled by loosening 2

snops screw driver

5) PANEL GROUP

There exists a main board holder

assembled on the back structure

of the panel.

Page 3

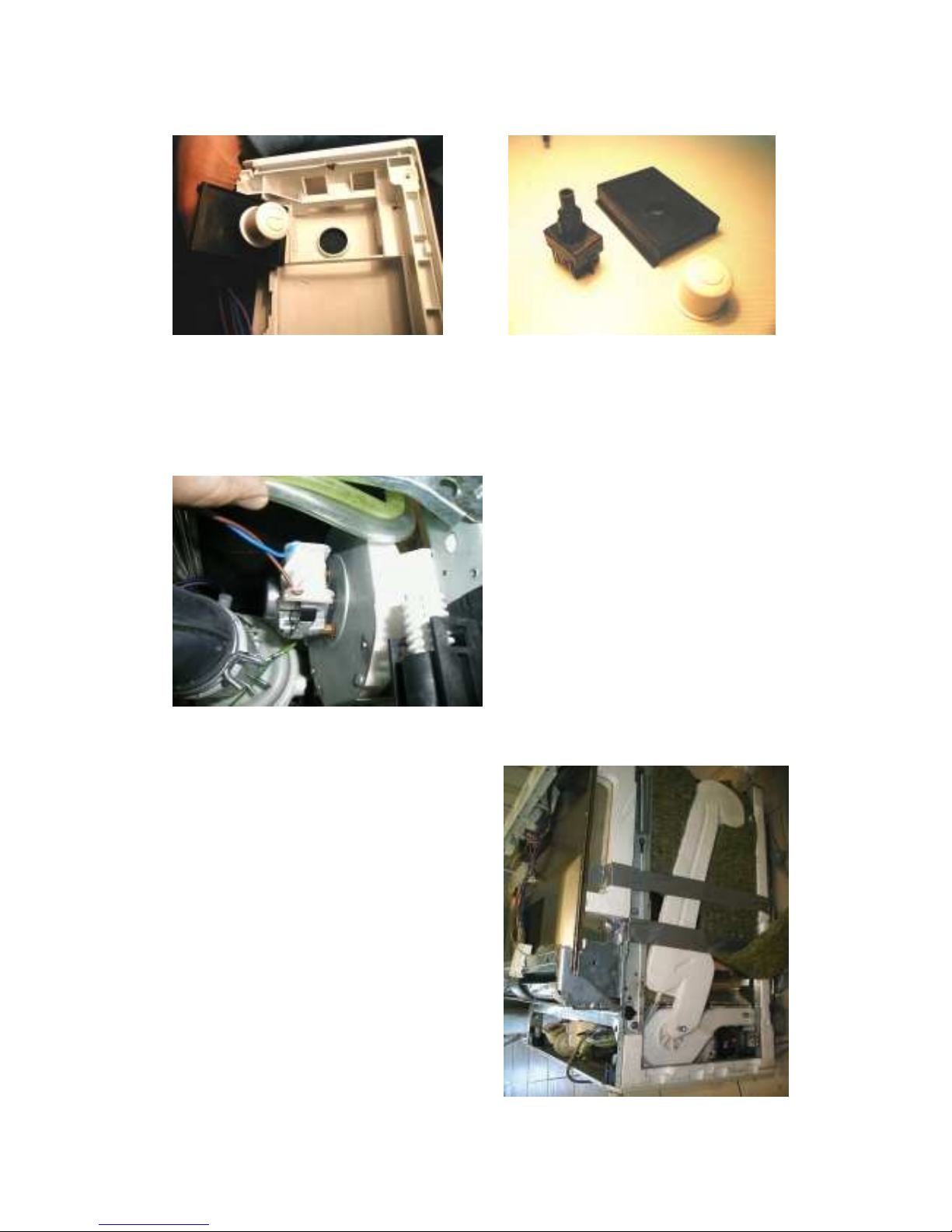

6) DISPLAY GROUP

Release the 3 snap fits in

order to open the cover of

the card holder.

In order to dismantle the

main card pull out the

sockets assembled to the

card.Then bend the snap fits

and pull out the main card.

A

s the main card is removed

the leds are easily

dismantled.

Main card holder is

dismantled by bending the

snap fits located on the panel

back structure.

The program select,

start/stop and the ½ load

key caps then easily be

dismantled.

For the models that have a

display, display board holder

can be disassembled by

releasing the snap fits

similiar to the main board

holder. Then display

electronics can then be taken

out in the similiar manner.

Page 4

7) ON-OFF BUTTON KEY HOLDER

The key holder is fixed to the panel back structure by snap fits. The key cap

should be mounted before the holder assembled to the panel back structure

8) FAN GROUP

The Fan motor is located

under the contsruction and

over the heater.

The fan motor is assembled

to the holder and air funnel

by using screw. Fan

propeller is located inside the

air funnel and assembled to

the fan motor shaft by the

help of a snap fit.

The air discharge way is

located at the right side of

the machine.

Page 5

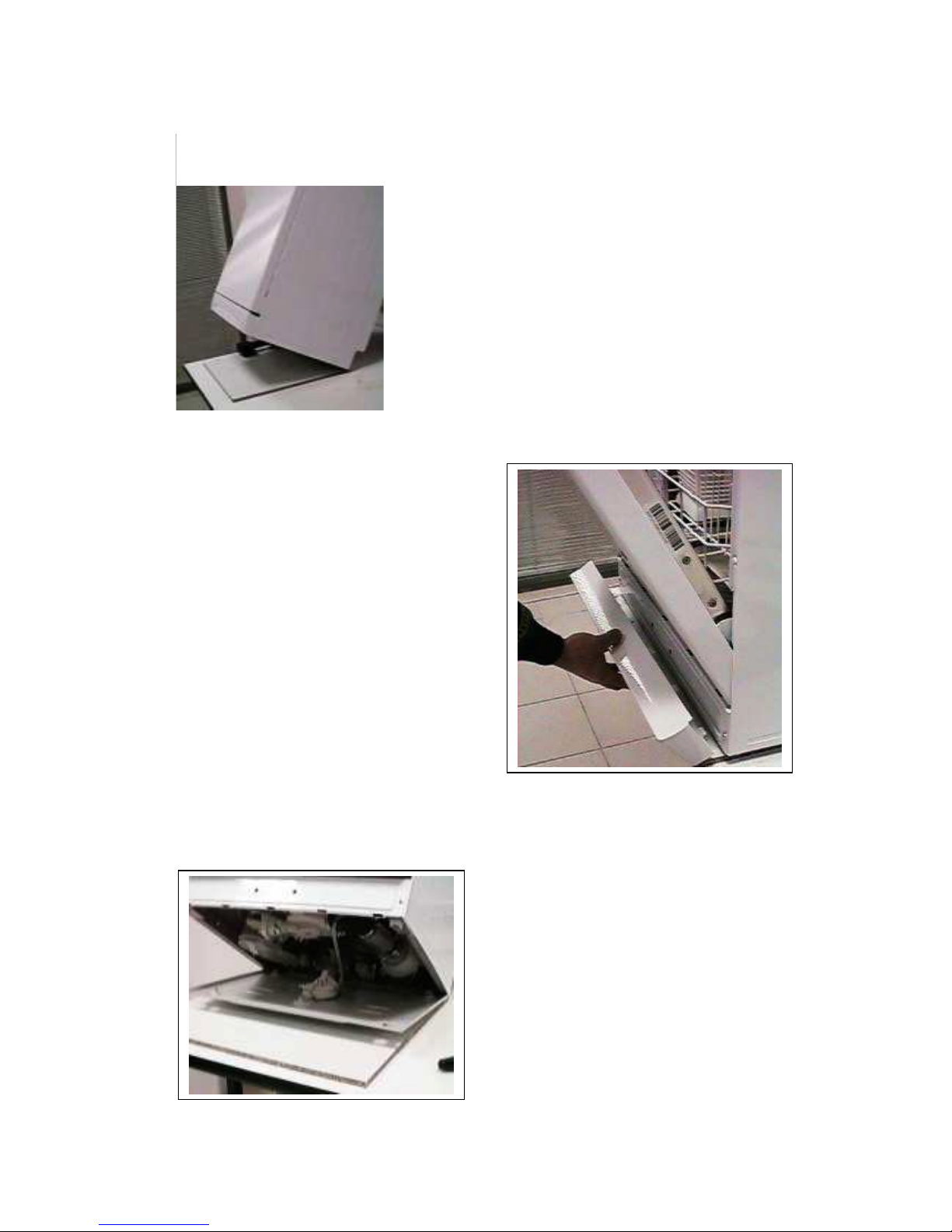

9) BOTTOM TRAY

While providing service to the components

located beneath the machine, the machine is

moved to a place other than the place of

installation.

For dismantling the tray, the machine is inclined

backwards with an angle of approximately 40˚.

2 screws holding the base and located

on the front side are removed and the

components beneath the machine are

accessed. Thus, it is possible to work

on all the components except for the

Water Inlet Valve, Clip Holder and the

Drain Hose.

The door is swiftly opened and the

plastic cover located at the bottom of

the machine is taken out, by being

rotated in the downward direction

without using any tool. Afterwards

when this plastic cover is repositioned,

the similar procedure is applied but this

time by being rotated in the reverse

direction

Page 6

10) OVERFLOW GAUGE

The mechanism attaching the

overflow gauge to the base is

pulled to the front direction, by

pressing the latches and then is

taken out.

11) DRAIN PUMP

The notch is opened and turned in the counter clockwise direction and taken

out by rotating it 10-15˚.

12) NTC

NTC is taken out by being rotated

30˚.

Page 7

13) HEATER

Pipe type heater is used in the machine. It is taken out by unscrewing the two

spring clamps.

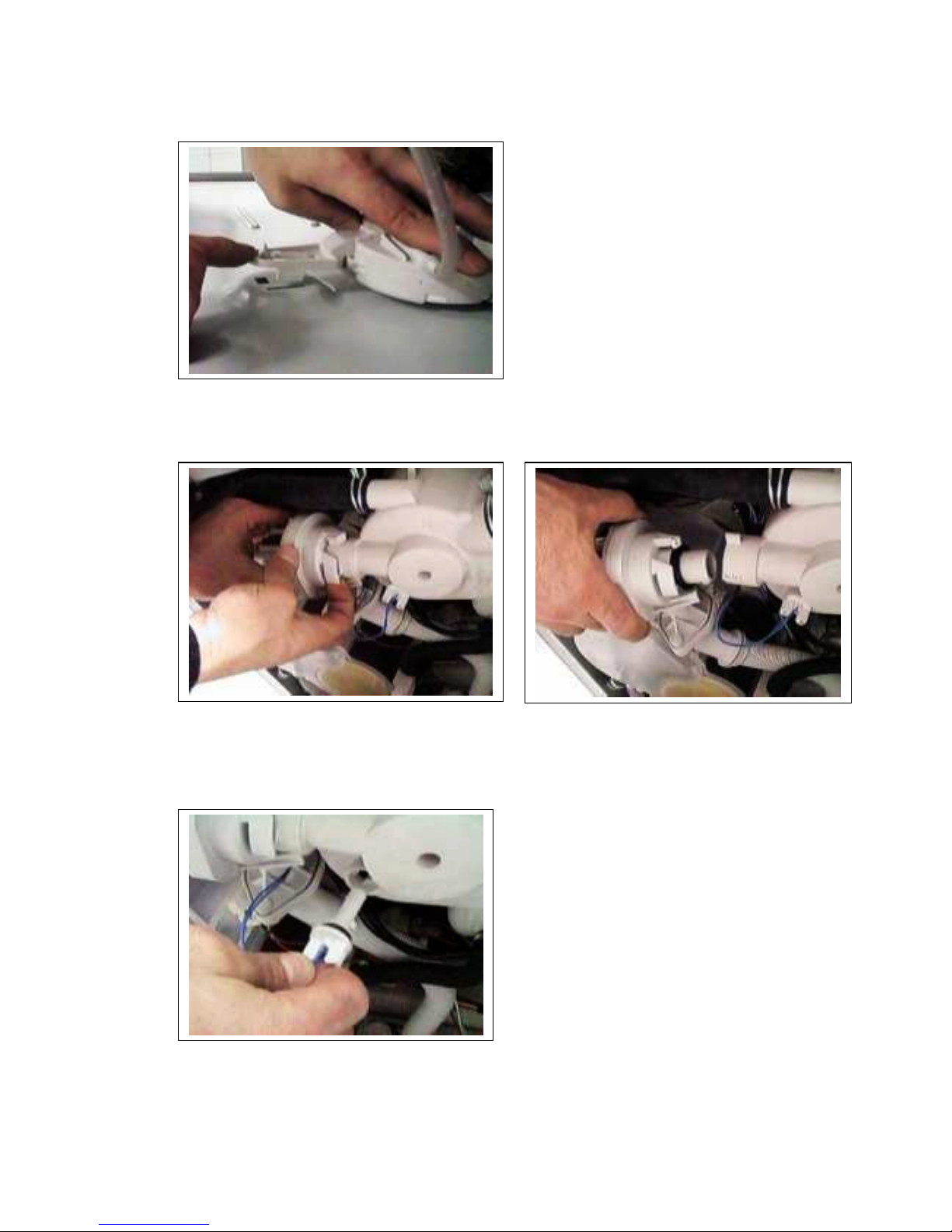

14) CIRCULATION PUMP

After the clamps and cable

connections of the circulation pump

are removed, the screws of the motor

holding plate connected to the body

frame are unscrewed. So as to detach

the circulation pump from the motor

holding plate, the connection is cut off

by breaking the white coloured auricle

shown in the photo, and a new auricle

is installed during the assembly.

Page 8

15) FEEDING PIPE OF THE UPPER SPRAY ARM AND FILTER

SUPPORT

Filter support is freed after the related screw is loosened. After the notch of

the feeding pipe of the upper spray arm is released, both of the parts are

taken out. After the notch located on the filter support is extended, it is

removed from the upper feeding pipe.

16) SIDE WALLS

A total of 7 screws, as 3 in the front, 2 at the back and 2 at the top, are

loosened and the side walls are taken out.

Page 9

17) REGENERATION CONTAINER

The 2 metal notches are released through a

screwdriver. The lid of the regeneration container is taken out by being rotated

in the counter clockwise direction at 5-10˚.

18) FLOW-METER

The electronic counter on the flowmeter located at the left lower corner of the

regeneration container, is taken out as demonstrated in the photo and

detached from the socket.

Page 10

19) HINGE PLATES

3 screws on the both sides are loosened.

2 screws on the both sides of the

connection sheet of the hinge arm are

unscrewed and the plates are removed.

20) DETERGENT CONTAINER

The inner door plate, held by 8

notches, is taken out by releasing the

lobes.

Page 11

21) CABLE CASE

To replace any cable, the cable case is

opened and the replacement is made.

22) CONCRETE SHEET

Both of the sidewalls are dismantled. A total of 4 screws connecting the

concrete sheet to the frames from both sides are unscrewed. 2 screws that

connect the base to the concrete sheet are unscrewed. Water inlet hose is

taken out. Base is dismantled. The connection made to prevent the

occurrence of siphonage in the drain hose is removed by cutting the hose

clamp. The concrete is taken out and the sheet is freed from its connections.

23) DRAIN HOSE, WATER INLET VALVE, and CLIP BOX

Page 12

To render services to these components, the operators should work on the

backside of the machine. The concrete sheet should be removed.

The hose holder is taken out by turning as it is seen in the picture.

The drain hose holder is made up two symmetric parts, which fit together by

the help of the snaps, and should be located approximately 30 cm from the

hose end.

For disassembling the water inlet valve, the screw of the water inlet valve

located on the concrete sheet is unscrewed.

Water inlet valve is taken out by being rotated in the clockwise direction.

(according to the back of machine)

Page 13

For dismantling the interference filter and the main power cable first of all

dismantle the sockets. Unscrew the screw mounted on the main power cable

holder and release the cable.

Then unscrew the two screws, assembling the interference filter and the

concrete sheet. Push the filter as it is seen in the picture in order to release it.

24) THREE WAY VALVE

Unscrew four screws, after loosen the hose clamps disassemble the valve

Page 14

25) FOOTS

The notch in the middle is pressed by a screwdriver.

26) UPPER SPRAY ARM

First follow the instructions given for the top plate. After disassembling the top

plate, loosen the nut by turning to counter clockwise direction. Press the

snaps of upper spray arm group & pull down for dismantling

Page 15

BOTTOM LAYOUT

The inner tub differs because of the change made fo

r

the new sump, and sump connections .

Sump o-ring is placed between the sump

and the inner tub in order to preven

t

leakage

New filter support part is fixed to the sump

and inner tub by the screws numbered as 3,

4 and 5.

Sump

Gasket

1

2

3

4

The sump is fixed

to the inner tub by

the help of 5 PT

type screws as

shown in the

picture left.

5

Drain pump group should be fixed to the sump by the help of snap fits.

The drain hose is assembled to the

drain exit of the sump by using a

hose clamp

Page 16

The flow diverter is assembled to the sump by hot plate, for the DW models that have

flow diverter. This is default for factory outlet, and no serviceability for the flow

diverter alone.

3W valve should be fixed to the sump by PT

screws, for the DW models that have 3 wa

y

valve.

Motor bracket for the new bottom layout is also

changed but has no difference in the assembl

y

manner

The new filtering system is changed

because of better performance and because

of sump change. But has no difference in

the assembly manner.

For the models having

metal filter, metal filter

o-ring is used. The

assembly of the part is

shown on the pictures.

Page 17

The filtering system will be

effective if the assembly of the

filters are done in the righ

t

manner. For both the metal

and plastic filter, the filter ends

should be positioned under the

related region of the flo

w

diverter.

Loading...

Loading...