Wall-Mount Ultrasonic Flow Meter

EUROSONIC 2000

User Manual

READ AND KEEP THESE INSTRUCTIONS

TD 203-0-ENG

EUROSONIC 2000

EUROMAG | 3

INDEX

1. INTRODUCTION

1.1 Preface

1.2 Features

1.3 Flow measurement principle

1.4 Packaging list

1.5 Optional parts

1.6 Typical applications

1.6.1 Applications sorted by industry / process

1.7 Product identification

1.8 Specifications

2. INSTALLATION AND MEASUREMENT

2.1 Unpacking

2.2 Installation considerations

2.2.1 Mounting the main unit

2.2.2 Installing transducers

2.2.3 Distance from main unit to transducer

2.2.4 Cables

2.2.5 Power supply wiring

2.2.6 Other electrical connections

2.3 Power up

2.4 Keypad

2.5 Menu windows

2.6 Menu window list

2.7 Steps to configure the parameters

2.8 Transducer mounting allocation

2.9 Transducers wiring

2.10 Transducers installation

2.11 Installation check-up

2.11.1 Signal strength

2.11.2 Signal quality

2.11.3 Total transit time and delta time

2.11.4 Transit time ratio

7

7

7

8

8

9

9

9

9

10

13

13

13

13

13

14

14

14

14

15

16

16

17

18

19

20

20

21

21

22

22

22

4 | EUROMAG

EUROSONIC 2000

3. HOW TO

3.1 How to check if the instrument works properly

3.2 How to check the liquid flowing direction

3.3 How to change units systems

3.4 How to select a flow rate unit

3.5 How to use the totalizer multiplier

3.6 How to turn on / off the totalizers

3.7 How to reset the totalizers

3.8 How to restore the factory default setups

3.9 How to use the damper to stabilize the flow rate

3.10 How to use the low-flow cut off function

3.11 How to conduct zero calibration

3.12 How to change the scale factor

3.13 How to use the password locker

3.14 How to use the keypad locker

3.15 How to use scheduled data output

3.16 How to use 4-20ma current loop output

3.17 How to output analogue voltage signal

3.18 How to use the frequency output

3.19 How to use the totalizer pulse output

3.20 How to produce an alarm signal

3.21 How to use the oct output

3.22 How to use the relay output

3.23 How to use the built-in buzzer

3.24 How to modify the built-in calendar

3.25 How to adjust the lcd

3.26 How to use the RS232 serial interface

3.27 How to view the totalized flow

3.28 How to connect analogue input signals

3.29 How to compensate the flow not measured during offline

3.30 How to use the working timer

3.31 How to use the manual totalizer

3.32 How to use the batch process controller

3.33 How to calibrate the analogue output

3.34 How to check the ESN

4. MENU WINDOW DETAILS

23

23

23

23

23

24

24

24

24

24

24

24

25

25

25

25

25

26

26

26

27

28

28

28

28

29

29

29

29

30

30

30

30

30

31

33

EUROMAG | 5

INDEX

5. TROUBLESHOOTING

5.1 Introduction

5.2 Power-on errors

5.3 Working status errors

5.4 Other problems and solutions

6. COMMUNICATION PROTOCOL

6.1 RS232 connector pin-out

6.2 RS232 wiring

6.3 Communication protocol

6.3.1 Basic commands

6.3.2 Protocol prefix usage

6.4 The M command and the ASCII codes

6.5 Programming examples

7. MEASUREMENTS OF THERMAL AND OTHER

PHYSICAL PARAMETERS

7.1 Introduction

7.2 Wiring analogue inputs

7.3 Thermal energy measurement

7.4 Configure analogue measurement ranges

7.5 Read input analogue values from a network computer

8. WARRANTY AND SERVICE

8.1 Warranty

8.2 Service

45

45

45

46

47

49

49

50

50

50

52

53

53

55

55

55

56

57

57

59

59

59

6 | EUROMAG

9. APPENDIX

9.1 Wiring diagram and outline drawings

9.2 Clamp-on transducer installation guide

9.2.1 Choose installation method

V-method installation

Z-method installation

W-method installation

9.2.2 Transducer spacing

9.2.3 Prepare the pipe surface

9.2.4 Prepare the transducers

9.2.5 Install the transducers

9.2.6 Fine tune the installation

9.3 Standard pipe dimensions

9.4 Sound speed tables

61

61

63

63

63

63

63

63

64

64

64

65

65

66

EUROSONIC 2000

EUROMAG | 7

INTRODUCTION

1. INTRODUCTION

1.1 PREFACE

The wall-mount product family is designed to be installed in a fixed location for long-term flow

measurement.

The flow meter is based on transit-time flow measurement principle. It measures the flow rate of liquid in a

closed pipe by using a pair of clamp-on or wetted ultrasonic transducers. In general, the liquid should be full in

the pipe, and should contain no or small amount of particles or air bubbles. Examples of applicable liquids are:

water (hot water, chilled water, city water, sea water, etc.); sewage; oil (crude oil, lubricating oil, diesel oil, fuel

oil, etc.); chemicals (alcohol, acids, etc.); waste water; beverage, liquid food, solvents and other liquids.

The utilizes state-of-the-art technologies such as advanced signal processing, low-voltage transmitting,

small signal receiving, self-adaptation, the latest electronics, etc., to achieve high accuracy and reliable

performance. Besides, the EUROSONIC 2000 product provides versatile output interfaces, both analogue and

digital, which can be easily used by a host computer or a flow controller.

1.2 FEATURES

• Better than 1% linearity.

• ±0.2% of repeatability.

• ±1% of accuracy at velocity above 0.6ft/s (0.2m/s).

• Positive / negative / net flow totalizer.

• Proprietary low-voltage transmission and self-adaptation technologies.

• Anti-interference design.

• Dual CPU. 100 Pico-second time measurement resolution.

• Operates with all Euromag transducers.

• Die-cast aluminium weather-resistant enclosure (standard version).

• Able to measure electrically conductive and non-conductive liquids.

• RS-232 interface. Complete communication protocol for instrument networking.

• Can be used as a flow RTU.

• Up to 5 channel 12 bits analogue 4-20mA input

• 1 channel programmable 4-20mA output

• 2 channel programmable digital output (isolated OCT and Relay)

• Frequency output.

• Internal batch process controller.

• 2x20 letters backlight LCD display. 4x4-key, tactile-feedback membrane keypad.

8 | EUROMAG

EUROSONIC 2000

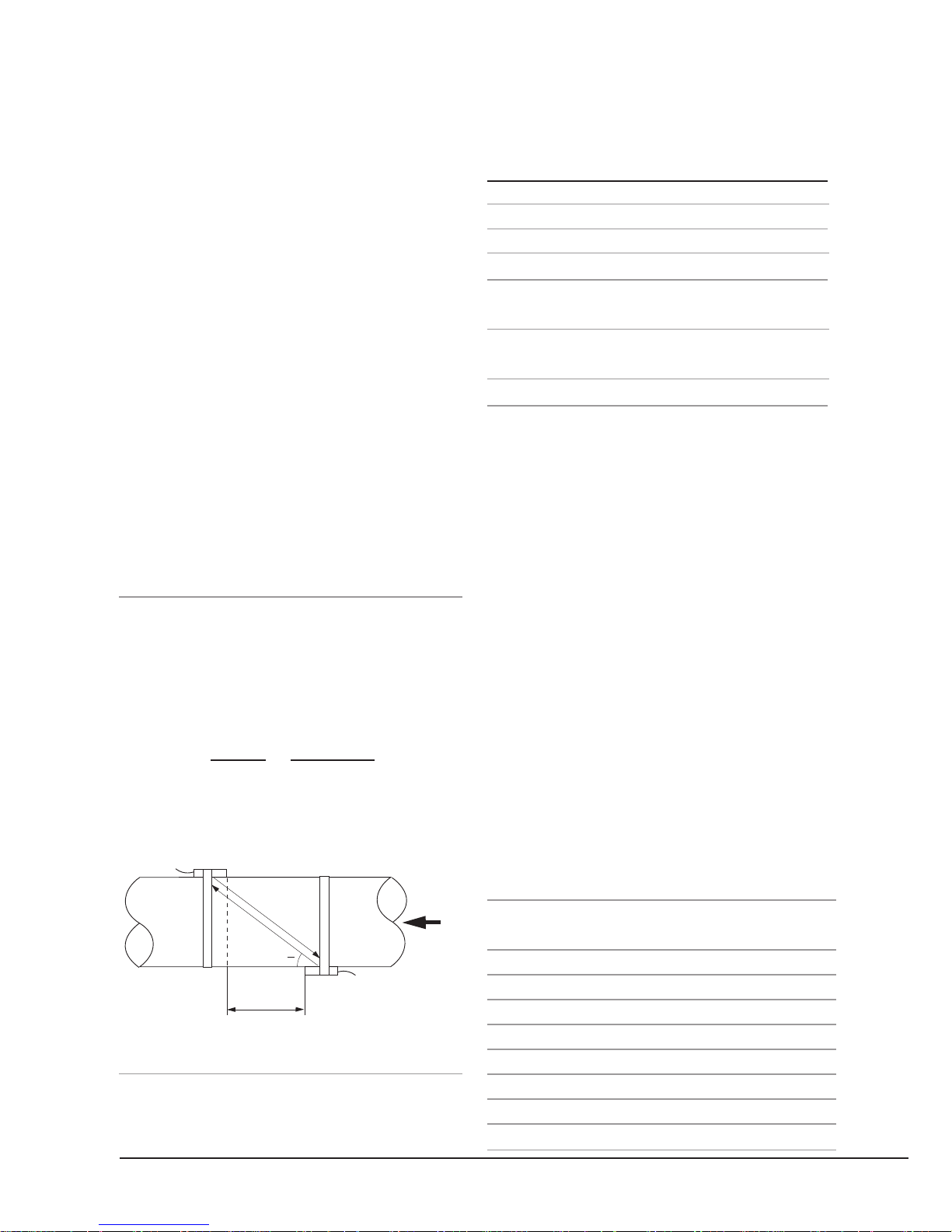

1.3 FLOW MEASUREMENT PRINCIPLE

The ultrasonic flow meter is designed to measure

the velocity of liquid within a closed conduit. It uses

the well-know transit-time measurement principle,

plus our proprietary signal processing and ultrasonic

transceiving technologies.

As shown in Figure 1, they utilize a pair of ultrasonic

transducers which are mounted on the pipe upstream

and downstream respectively. Each transducer

functions as both ultrasonic transmitter and receiver.

The main unit operates by alternately transmitting and

receiving a coded burst of sound energy between the

two transducers. The transit-times in the upstream

direction as well as in the downstream direction are

measured. The difference of the two transit times is

directly and exactly related to the velocity of the liquid

in the pipe.

TRANSIT TIME FLOW MEASUREMENT PRINCIPLE

The flow rate is then computed by combining the

velocity information with pipe parameters and a

scale factor. The scale factor is normally determined

by calibration in factory.

Three types of transducers can be used with the main

unit in order to cover the range of diameters from

15 to 6000mm. The transducers can be mounted in

V-method where the sound transverses the pipe fluid

twice, or in W-method where the sound transverses

the pipe fluid four times, or in Z-method where the

transducers are mounted on opposite sides of the

pipe and the sound crosses the pipe fluid once. The

selection of the mounting methods depends on pipe

and liquid characteristics.

1.4 PACKAGING LIST

• EUROSONIC 2000 main unit,

240VAC/8-36VDC 1 unit

• EST-M1-type clamp-on transducer

for 2”~28” pipe 1 pair

• Dedicated shielded transducer cable 5 Meters

• Potting Mix, Silicon compound 1 tube

• Clamp-on fixture 1 set

• Couplant 1 unit

• User’s Manual 1 unit

• 4-20mA Analogue Output Module 1 channel

• Relay Output Module 1 channel

V = x

MD

sin 2Ø

∆T

Tup • T

down

O

SPACING

DOWNSTREAM TRANSDUCER

UPSTREAM TRANSDUCER

FLOW

T

up

T

down

REFERENCES

Ø is the angle between the sound path and the flow direction

M is the number of times the sound traverses the flow

D is the pipe diameter

Tup is the time for the beam travelling from upstream the

transducer to the downstream transducer

T

down

is the time for the beam travelling from the downstream

transducer to the upstream transducer

∆T = Tup – T

down

f. 1

EUROMAG | 9

INTRODUCTION

1.5 OPTIONAL PARTS

• EST-S1-type clamp-on transducer for small pipe

(0.5”~4”)

• EST-L1-type clamp-on transducer for large pipe

(12”~240”)

• Analogue Input Modules (3 channels)

1.6 TYPICAL APPLICATIONS

The flow meter can be applied to a wide range of pipe

flow measurements. Applicable liquids include pure

liquids as well as liquid with small quantity of tiny

particles. Examples are:

• Water (hot water, chilled water, city water, sea

water, waste water, etc.);

• Sewage with small particle content;

• Oil (crude oil, lubricating oil, diesel oil, fuel oil,

etc.);

• Chemicals (alcohol, acids, etc.);

• Plant effluent;

• Beverage, liquid food;

• Ultra-pure liquids;

• Solvents and other liquids

1.6.1 APPLICATIONS SORTED BY INDUSTRY / PROCESS

• Water and waste water management;

• Water and waste water treatment plants;

• Power plants, such as nuclear power plants and

hydraulic power plants;

• Mining and metallurgy plants;

• Petroleum process monitoring and control;

• Chemical process monitoring and control;

• Pulp and paper process monitoring and control;

• Food and beverage processing;

• Marine maintenance and operation;

• Pipeline leakage detection;

• HVAC, hydronic balancing;

• Energy supply and production systems;

• Flow measurement networking.

1.7 PRODUCT IDENTIFICATION

Each set of the series flow meter has a unique

product identification number or ESN (electronic

serial number) written into the software that can only

be modified with a special tool by the manufacturer.

In case of any hardware failure, please provide this

number which is located on menu window M61 when

contacting the manufacturer.

10 | EUROMAG

1.8 SPECIFICATIONS

Main Unit

Linearity

Accuracy

Repeatability

Velocity

Measurement Period

Display

Keypad

Units

Outputs

Input

Others

Enclosure

Transducer

Clamp-on

Better than ±1%.

±1% of reading at rates >0.6 ft/s (0.2m/s). Assume a fully developed flow profile.

±0.2%.

±0.03 ~ ±105 ft/s (±0.01 ~ ±30 m/s), bi-directional

0.5s

LCD with backlight. 2x20 letters.

4x4-key membrane keypad with tactile feedback

English (U.S.) or metric.

Analogue output: 4-20mA or 0-20mA current output. Impedance 0~1kΩ. Accuracy 0.1%.

Isolated OCT output: for frequency output (0~9,999Hz), alarm driver, or totalizer pulse

output, ON/OFF control, etc.

Relay output 1A@125VAC or 2A@30VDC. For ON/OFF control, alarm driver, totalizer

output, etc.

Internal Alarm (Buzzer): user programmable.

External Alarm Driver: alarm signal can be transmitted to Relay or OCT output terminals

to drive an external alarm.

RS-232 serial port.

Five channel 4-20mA current inputs for signals such as temperature, pressure, liquid

level, and etc.. Accuracy 0.1%.

Two of the five input channels are wired to terminal blocks. The remaining three

channels are optional.

Capable of offline compensation for flow totalizer, automatic / manual selectable.

Self-diagnosis.

Automatically record the following information:

• The totalizer data of the last 64 days / 64 months / 5 years;

• The power-on time and corresponding flow rate of the last 64 power on and off

events. Allow manual or automatic flow loss compensation

• The instrument working status of the last 64 days

Die-cast aluminum enclosure.

Protection Class: IP65 (NEMA 4X). Weather-resistant.

Size: 9.88”x7.56”x3.15” (251x192x80mm3) for standard version

S1-type: for pipe size 1”~4” (DN30~DN100mm)

M1-type: for pipe size 2”~28”(DN50~DN700mm)

L1-type: for pipe size 11”~240”(DN300~DN6,000mm)

EUROSONIC 2000

EUROMAG | 11

Liquids

Liquid Types

Liquid Temp

Suspension

concentration

Pipe

Pipe Size

Pipe Material

Pipe Straight run

Cable

Shielded transducer cable. Standard length 15’ (5m). Can be extended to 1640’ (500m). Contact the manufacturer for

longer cable requirement.

Cable should not be laid in parallel with high-voltage power lines, neither should it be close to strong interference source

such as power transformers.

Environment

Temperature

Humidity

Power

AC 110 V; AC: 240V; DC: 8VDC~36V to be defined at order stage. Power consumption: < 2W

Weight

Standard main unit: 6.6lb (3kg)

Virtually all commonly used clean liquids.

Liquids with small quantity of tiny particles may also be applicable.

Particle size should be less than 75um, particle concentration less than 10,000ppm.

Liquids should contain no or very minor air bubbles.

Examples are chilled/hot water, sea water, waste water, chemical liquids, oil, crude oil,

alcohol, beer, etc.

32˚F - 212˚F (0˚C - 100˚C) for clamp-on transducer.

Higher temperatures can be accommodated. Consult the manufacturer for assistance.

32˚F - 302˚F (0˚C - 150˚C) for wetted transducer.

< 10,000ppm and particle size less than 80um.

May contain very small amount of air bubbles.

1” ~ 240” (DN25mm ~ DN6,000mm).

All metals, most plastics, fiber glass, etc. Allow pipe liner.

15D in most cases, 30D if a pump is near upstream, where D is pipe diameter.

Main unit: 14˚F ~ 158˚F (-10˚C ~ 70˚C)

Clamp-on transducer: -22˚F ~ 212˚F (-30˚C ~ 100˚C)

Main unit: 85% RH

Transducer: water-submersible, water depth less than 10’ (3m)

INTRODUCTION

12 | EUROMAG

EUROSONIC 2000

EUROMAG | 13

INSTALLATION AND MEASUREMENT

2. INSTALLATION AND MEASUREMENT

2.1 UNPACKING

Please unpack the shipping box and check the parts and documents against the packing slip. If there is

something missing, the device is damaged, or something is abnormal, please contact us immediately and do

not proceed with the installation.

2.2 INSTALLATION CONSIDERATIONS

This section provides guidelines for installing the main unit (electronics enclosure) and its transducers.

2.2.1 MOUNTING THE MAIN UNIT

The main unit electronics (standard version) are housed in an IP65 (NEXA 4X) weather-resistant and dust-tight

enclosure. Therefore, the main unit can be installed indoors and outdoors. Usually, it is mounted in a meter

shed or on a location where one can easily access for meter testing and servicing. Please refer to

Appendix

9.1

for the enclosure dimensions.

2.2.2 INSTALLING TRANSDUCERS

First, you need to select a proper installation site. For this, one usually needs to consider the accessibility of

the location, operating space needed for the installation, safety code compliance, etc. In addition, flow and

pipe conditions near the installation site are also very important. Please refer to

section 2.8

for site selection

details.

Then, follow the installation guidelines given in

Appendix 9.2

for installing clamp-on transducers.

WARNING!

THE FLOW METER CAN BE USED

TO MEASURE THE FLOW OF MANY

LIQUIDS. SOME OF THE LIQUIDS

MAY BE HAZARDOUS. IT IS VERY

IMPORTANT THAT YOU COMPLY

WITH LOCAL SAFETY CODES AND

REGULATIONS IN INSTALLING AND

USING ELECTRONIC DEVICES IN

YOUR AREA.

2.2.3 DISTANCE FROM MAIN UNIT TO TRANSDUCER

In general, the closer the transducer to the main unit,

the better the signals. All major cable suppliers can

supply up to 1640ft (500m) long transducer cable as

per specifications.

2.2.4 CABLES

The flow meter utilizes a double-balanced driving

technique for high performance ultrasonic

transimission and receiving. It requires twisted

shielded cable for the transducer. We recommend to

use the cable supplied by the manufacturer. If you

want to do the transducer cabling yourself please

contact the manufacturer in advance.

Try not route the transducer cable along with high

current AC lines. Avoid strong interference sources.

Make sure the cables and cable connections are

protected from weather and corrosive conditions.

2.2.5 POWER SUPPLY WIRING

The user normally selects the type of power supply

when the order is placed. There are three types

of power supply options, 110VAC, 220VAC and

8-36VDC. You must make sure the power supply

type of your flow meter matches the power source to

which the flow meter will be connected.

Open the flow meter enclosure. On the lower right

corner (refer to the figures in Appendix 9.1), you

should see three terminal blocks which pins are

labelled as 11, 12 and 13. Normally, pin 13 should

be connected to your Earth ground. Make sure your

Earth ground is good. Pins 11 and 12 should be

connected to Neutral and Line, respectively.

If 8-36VDC power source is used, its positive lead

and negative lead should be connected to pin 24 and

23 respectively.

Please refer to

Appendix 9.1

for more wiring

information.

2.2.6 OTHER ELECTRICAL CONNECTIONS

Wiring RS232 Port

Refer to

sections 6.1, 6.2

and

Appendix 9.1

for

details.

Wiring 0/4-20mA Output

Using standard twisted-pair wiring. Refer to

Appendix

14 | EUROMAG

WARNING!

WARNING!

THE TRANSDUCERS MAY HAVE

STATIC CHARGES ACCUMULATED

DURING TRANSPORTATION.

BEFORE CONNECTING THE

TRANSDUCERS TO THE MAIN

UNIT, PLEASE DO DISCHARGE

THE TRANSDUCERS IN A

SAFE AREA BY SHORTING

THE CENTRE CONDUCTOR

OF THE TRANSDUCER CABLE

CONNECTORS TO THE METAL

SHIELD OF THE CONNECTOR.

BE CAREFUL ABOUT THE POWER

SUPPLY TYPE OF YOUR FLOW

METER AND THE POWER SUPPLY

WIRING! CONNECTING TO A

WRONG TYPE POWER SOURCE

OR IMPROPER CONNECTION OF

LINE POWER COULD DAMAGE

THE FLOW METER. IT MAY ALSO

CAUSE HAZARDOUS VOLTAGE AT

ENCLOSURE, THE TRANSDUCER,

FLOW CELL, AND ASSOCIATED

PIPING.

NOTE

WITH 8-36 V DC POWER SUPPLY

THE 4-20MA OUTPUT MAY NOT

BE AVAILABLE, EXCEPT SPECIAL

INSTRUCTION WAS GIVEN WHEN

THE ORDER WAS PROCESSED.

EUROSONIC 2000

9.1

for details.

Wiring 0/4-20mA Inputs

There are five analogue input channels which

can be used to accommodate five channels of

analogue input signals. Two of them are wired to

terminal blocks (pin 65, 64 and 63). You can assign

temperature, pressure and other physical signals to

those channels. An internal 24VDC is provided for

loop-powered transmitters.

Using standard twisted-pair wiring. Refer to

Chapter

7

for details.

Wiring Alarms

Using standard twisted-pair wiring. Refer to

sections

3.21 and 3.22

for details.

2.3 POWER UP

The flow meter does not have power ON/OFF switch.

When it is connected to power, it will start to run

automatically.

After the power is turned on, the flow meter will

run a self-diagnostic program, checking first the

hardware and then the software integrity. If there is

any abnormality, corresponding error messages will

be displayed. (Please refer to

chapter 5

for error code

explanations.)

After successful internal checks, the flow meter

will display menu window #01 (short for M01), or

the menu window which was active at last power

off. It will also start the measurements by using the

parameters configured last time by the user or by the

initial program.

The flow measurement program always operates in

the background of the user interface. This means that

the flow measurement will keep running regardless

of any user menu window browsing or viewing. Only

when the user enters new pipe parameters will the

flow meter change measurement to reflect the new

parameter changes.

When the power is turned on or new pipe parameters

are entered, the flow meter will enter into a selfadjusting mode to adjust the gain of the receiving

circuits so that the signal strength will be within a

proper range. By this step, the flow meter finds the

best system gain which matches the pipe material

and fluid type. The user will see the progress by

the number s1, s2, s3 and s4, located on the upper

left corner of the LCD display. If the self-adapting

process is completed successfully, letter “#R” will

be displayed.

When the user adjusts the position of the installed

transducers, the flow meter will re-adjust the signal

gain automatically.

Any user-entered configuration value will be stored in

the NVRAM (non-volatile memory), until it is modified

by the user.

EUROMAG | 15

WARNING!

BEFORE CONNECTING THE DEVICE

TO POWER SOURCE, PLEASE DO A

FINAL CHECK TO MAKE SURE ALL

THE WIRINGS ARE CORRECT AND

ALL THE LOCAL SAFETY CODES

ARE FOLLOWED.

INSTALLATION AND MEASUREMENT

16 | EUROMAG

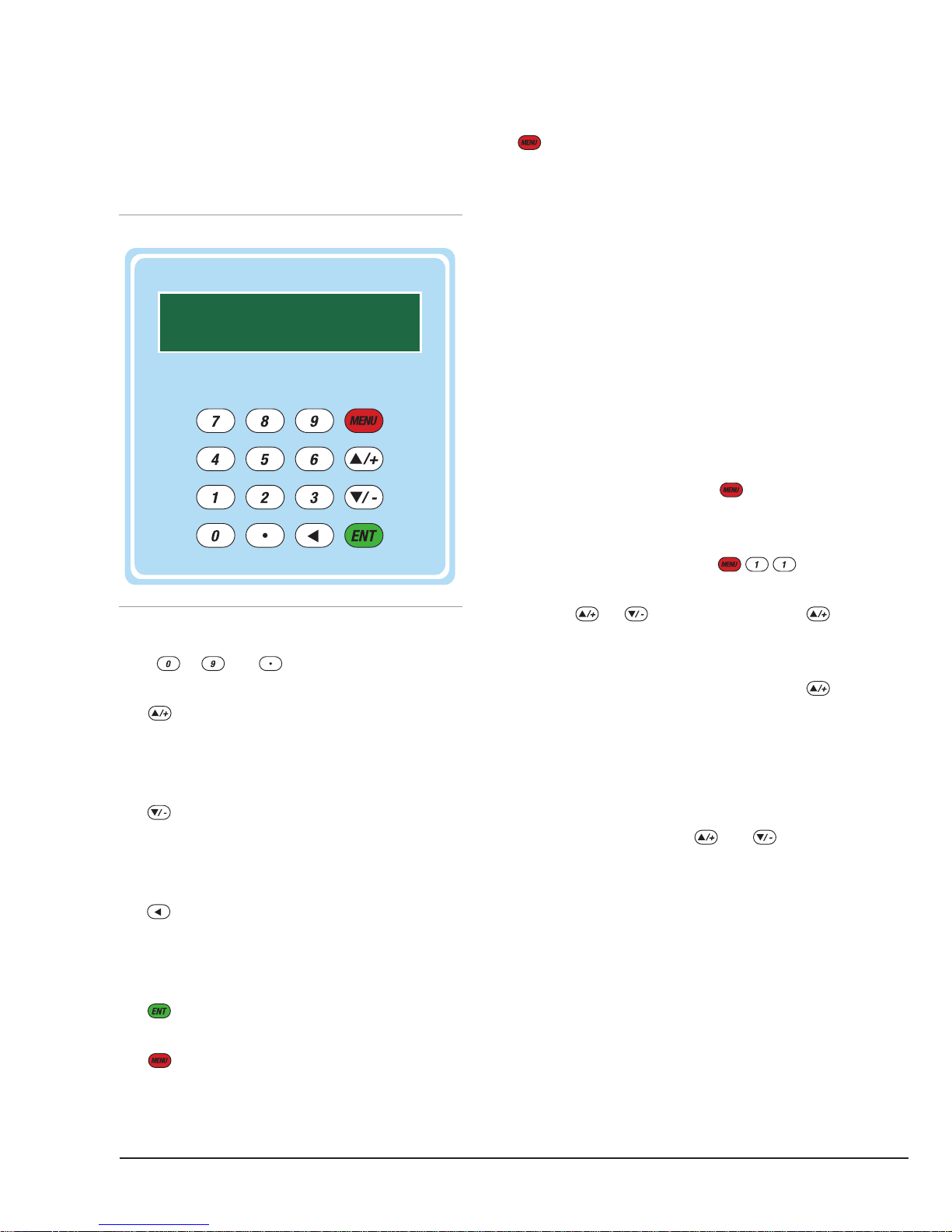

2.4 KEYPAD

The keypad of the flow meter has 16 keys (Figure 2).

Keys ~ and are keys to enter numbers.

Key is the going UP key when the user wants to

go to the upper menu window. It also works as “+”

key when entering numbers.

Key is the going DOWN key when the user wants

to go to the lower menu window. It also works as the

“–” key when entering numbers.

Key is the backspace key when the user wants to

go left or wants to backspace the left character that

is located to the left of the cursor.

Key is the ENTER key for any input or selections.

Key

is the key for the direct menu window jump

over. Whenever the user wants to proceed to a certain

menu window, the user can press this key followed

by a 2-digit number.

The

key is shortened as the ‘M’ key hereafter

when referring to menu windows.

Key-pressing induced beep sound can be enabled /

disabled in menu window M77.

2.5 MENU WINDOWS

The flowmeter user interface comprises about 100

independent menu windows that are numbered by

M00, M01, M02, …, M99, M+0, M+1, etc.

There are two methods to visit a menu window:

1) Direct jump in. Simply press the key followed

by a 2-digit number. For example, if you want to visit

menu window M11 for pipe outer diameter, press the

following three keys consecutively, .

2) Press the or key. Each time of the

key pressing will lead to the lower-numbered menu

window. For example, if the current window is on

M12, the display will go to window M11 after the

key is pressed once.

You do not need to remember all the menu windows.

Just remember the most commonly used window

numbers and the approximate window number

of some uncommonly used windows would be

sufficient. You can always use and keys to

find the right window.

There are three different types of menu windows:

1) Menu windows for number entering, e.g., M11 for

setting up pipe outer diameter.

2) Menu windows for option selection, e.g., M14 for

the selection of pipe materials.

3) Results display windows, e.g., window M00 for

displaying flow rate, etc.

f. 2

EUROSONIC 2000

EUROMAG | 17

For number entering windows, the user can directly

press the digit keys if the user wants to modify the

value. For example, if the current window is on M11,

and the user wants to enter 219.2345 as the pipe

outer diameter, then, the flowing keys should be

pressed: .

For option selection windows, the user should first

press the key to get into option selection mode.

Then, use , , or digit key to select the right

option. Consequently, press the to make the

selection.

For example, assume your pipe material is stainless

steel and you are currently on menu window M14

which is for the selection of pipe materials (if you

are on a different window, you need to press

first in order to enter into the M14 window.)

You need to press the key to get into the option

selection mode. Then, either press the and

keys to make the cursor on the line that displays “1.

Stainless Steel”, or press the key directly. At the

end, press again to make the selection.

Generally, the key must be pressed to get into

the option selection mode for option modifications.

If the “Locked M47 Open’ message is indicated on

the bottom line of the LCD display, it means that the

modification operation is locked out. In such cases,

the user should go to M48 to have the instrument

unlocked before any further modification can be

made.

2.6 MENU WINDOW LIST

M00~M09 windows for the display of the

instantaneous flow rate, net totalizer value, positive

totalizer value, negative totalizer value, instantaneous

flow velocity, date time, current analogue input

values, current working status, etc.

M10~M29 windows for entering system parameters,

such as pipe outer diameter, pipe wall thickness,

liquid type, transducer type, transducer installation

method, etc. Transducer installation spacing is

then calculated according to those parameters and

displayed on one of the windows.

M30~M38 windows for flow rate unit selection and

totalizer configuration. User can use these windows

to select flow rate unit, such as cubic meter or liter,

as well as to turn on / off each totalizer, or to reset

the totalizers.

M40~M49 windows for setting response time,

zeroing / calibrating the system, locking / unlocking

keypad, changing network address ID, password,

etc.

M50~M89 windows for digital and analogue outputs,

such as scheduled output, RS232 output, relay

output, analogue current loop output, LCD, frequency

output, alarm output, analogue inputs. Besides, there

are also windows for configuring analogue inputs,

date / time, and day/month/year accumulator.

M90~M94 windows for displaying diagnostic data,

including the installation triplet. Those data are very

useful when doing a more accurate measurement.

M95 Upon entering into this window, the circular

display function is started automatically. The

following windows will be displayed one by one, each

window will stay for about 4 seconds: M95 ->M00

-> M01 -> M02 -> M03 -> M04 -> M05 -> M06 ->

M07 -> M08 -> M09 -> M90 -> M95.

M+0~M+9 windows for some additional functions,

including a single precision calculator, display of the

total working time, and display of the time and the

flow rate when the device is turned on and turned off.

INSTALLATION AND MEASUREMENT

18 | EUROMAG

EUROSONIC 2000

Other menu windows are used for factory

debugging.

For detailed explanation of the above windows please

refer to

chapter 3 “How to”

and

chapter 4 “Menu

Window Details”

.

2.7 STEPS TO CONFIGURE THE PARAMETERS

In order to make the flowmeter work properly, the

user must follow the following steps to configure the

system parameters:

1) Pipe size and pipe wall thickness

For standard pipe, please refer to

Appendix 9.4

for

outer diameter and wall thickness data. For nonstandard pipe, the user has to measure these two

parameters.

2) Pipe materials

For non-standard pipe material, the sound speed

of the material must be entered. Please refer to

Appendix 9.5

for sound speed data.

For standard pipe materials and standard liquids, the sound

speed values have already been programmed into the flow

meter, therefore there is no need to enter them again.

3) Liner material, its sound speed and liner thickness,

if there is any liner.

4) Liquid type (for non-standard liquid, the sound

speed of the liquid should be entered.)

5) Transducer type.

6) Transducer mounting methods (the V-method and

Z-method are the common methods)

7) Check the transducer distance displayed on window

M25 and install the transducers accordingly.

Example: For standard (commonly used) pipe

materials and standard (commonly measured) liquids,

the parameter configuration steps are as following:

1) Press keys to enter into M11 window.

Input the pipe outer diameter through the keypad and

press key.

2) Press key to enter into M12 window. Input the

pipe thickness through the keypad and press

key.

3) Press key to enter into M14 window. Press

key to get into the option selection mode. Use keys

and to scroll up and down to the proper pipe

material, and then press key.

4) Press key to enter into M16 window. Press

key to get into the option selection mode. Use keys

and to scroll up and down to the proper liner

material, and then press key. Select “No Liner”,

if there is no liner.

5) Press key to enter into M20 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

liquid, and then press key.

6) Press key to enter into M23 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

transducer type, and then press key.

7) Press key to enter into M24 window. Press

key to get into the option selection mode. Use

keys and to scroll up and down to the proper

transducer mounting method, and then press

key.

8) Press key to enter into M25 window. The

transducer installation distance will be displayed

EUROMAG | 19

INSTALLATION AND MEASUREMENT

on the window. Based on this distance and the

transducer installation method selected above, install

the transducers on the pipe (refer to

Appendix 9.2

for

more installation details.)

9) After installation is completed, check if the triplet

(signal strength S, signal quality Q and transit-time

ratio R) are in the right range. Press keys

to enter into M90 window for visiting S and Q and

press to visit R.

10) Press to enter into window M01 to

visit the measurement result.

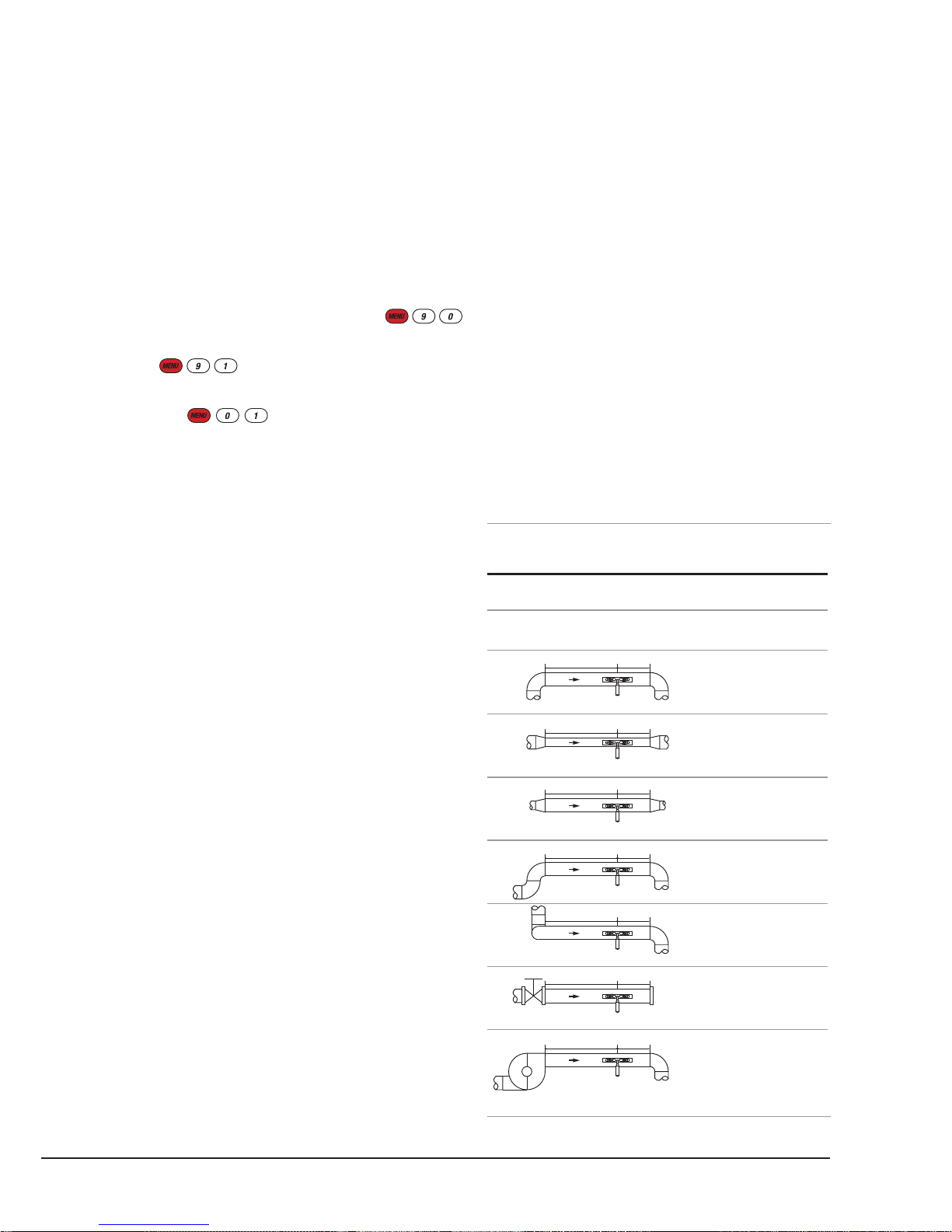

2.8 TRANSDUCER MOUNTING ALLOCATION

The first step in the installation process is to select an

optimal location for installing the transducers in order

to make the measurement reliable and accurate. A

basic knowledge about the piping and its plumbing

system would be advisable.

An optimal location would be defined as a long

straight pipe line full of liquid that is to be measured.

The piping can be in vertical or horizontal position.

The following table shows examples of optimal

locations.

Principles to select an optimal location:

1) Pipe must be full of liquids at the measurement

site.

2) No heavy corrosion of deposition inside of the

pipe.

3) Must be a safe location.

4) The straight pipe should be long enough to

eliminate irregular-flow-induced error. Typically, the

length of the straight pipe should be 15 times of the

pipe diameter. The longer the better.

The transducers should be installed at a pipe section

where the length of the straight pipe at upstream side

is at least 10D and at downstream side is at least 5D,

where D stands for pipe outer diameter.

5) If there are flow disturbing parts such as pumps,

valves, etc. on the upstream, the straight pipe length

should be increased (refer to figure 3 for more

details.) The disturbance strength are in the following

order (low to high): Single Bend -> Pipe Reduction /

Enlargement -> Outflow Tee -> Same Plane Multiple

Bends -> Inflow Tee -> Out of Plane Multiple Bends

-> Valve -> Pump.

INSTALLATION SITE SELECTION

PIPING CONFIGURATION

AND TRANSDUCER POSITION

UPSTREAM

DIMENSION

L

up

x

Diameters

10D

10D

10D

12D

20D

20D

30D

L

down

x

Diameters

5D

5D

5D

5D

5D

5D

5D

DOWNSTREAM

DIMENSION

f. 3

L

up

L

up

L

up

L

up

L

up

L

up

L

up

L

down

L

down

L

down

L

down

L

down

L

down

L

down

20 | EUROMAG

EUROSONIC 2000

6) Make sure that the temperature on the location does

not exceed the range for the transducers. Generally

speaking, the closer to the room temperature, the

better.

7) Select a relatively new straight length of pipe line

if it is possible. Old pipe tends to have corrosions and

scale, which could affect the results. If you have to

work on an old pipe, we recommend you to treat the

corrosions and depositions as if they are part of the

pipe wall or as part of the liner. For example, you

can add an extra value to the pipe wall thickness

parameter or the liner thickness parameter to take

into account the deposition.

8) Some pipes may have a kind of plastic liner

which creates a certain amount of gaps between

liner and the inner pipe wall. These gaps could

prevent ultrasonic waves from direct travelling. Such

conditions will make the measurement very difficult.

Whenever possible, try to avoid this kind of pipe. If

you have to work on this kind of pipe, try our plugin transducers that are installed permanently on

the pipe by drilling holes on the pipe while liquid is

running inside.

9) When select the measurement site, you may need

to consider where to mount the flow meter main

unit. Normally, the EUROSONIC 2000 electronics are

housed in a weather-resistant enclosure. It can be

mounted in a meter shed, or a location that allows

easy access to the flow meter for programming and

servicing.

10) When select the measurement site, you may

also need to consider how to install the transducers.

Make sure you have enough spatial space for easy

operation.

2.9 TRANSDUCERS WIRING

Since the flowmeter utilizes balanced topology

for high-performance ultrasonic transmitting and

receiving, it is recommended to use high-frequency

twisted cable with shielding as the transducer cable

in order to guarantee the signal quality. Please refer

to

section 2.2

and

Appendix 9.1

on how to wire

transducers to the flow meter terminals.

2.10 TRANSDUCERS INSTALLATION

The transducers used by the flowmeter series

ultrasonic flow meter are made of piezoelectric

crystals both for transmitting and receiving ultrasonic

signals through the wall of liquid piping system. The

measurement is realized by measuring the travelling

time difference of the ultrasonic signals. Since

the difference is very small, the spacing and the

alignment of the transducers are critical factors to the

accuracy of the measurement and the performance

of the system. Meticulous care should be taken for

the installation of the transducers.

Clamp-on transducer installation steps:

1) Locate an optimal position where the straight

pipe length is sufficient (see the previous section),

and where pipes are in a favourable condition, e.g.,

newer pipes with no rust and ease of operation.

2) Calculate the transducer spacing. Just enter

the pipe, fluid and transducer information through

menu M11 to M24, the flow meter will calculate the

transducer spacing automatically. The value will be

shown in M25. Marking the transducer installation

spots on the pipe according to this spacing value.

3) Clean any dust and rust on the spot where the

transducers are to be installed. For a better result,

EUROMAG | 21

INSTALLATION AND MEASUREMENT

polishing the pipe outer surface with a sander is

strongly recommended.

4) Apply adequate ultrasonic coupling (grease, gel or

Vaseline) onto the transducer surface as well as to

the installation area on the pipe surface.

5) Strap on the transducers using clamp fixture. If the

pipe is metal, no need to use clamp fixture since the

transducer has magnetic built-in. Make sure there is

no gap between the transducer surface and the pipe

surface.

6) Fine tune transducer position until the triplet,

signal strength S, signal quality Q and transit-time

ratio R, have the best readings and those reading are

in their operational ranges (S≥60, Q≥60 and 97%≤

R ≤103%). It is even better if you can tune those

readings into their optimal ranges (S≥80, Q≥80 and

99%≤ R ≤101%.

For more details on clamp-on transducer installation,

please refer to

Appendix 9.2

.

2.11 INSTALLATION CHECK-UP

After the completion of transducer installation, the

user should check the following items: the receiving

signal strength S, the signal quality Q value, the delta

time (travelling time difference between the upstream

and the downstream signals), the estimated liquid

sound speed, the transit time ratio R, and etc. As

such, one can be sure that the flow meter is working

properly and the results are reliable and accurate.

2.11.1 SIGNAL STRENGTH

Signal strength S indicates the amplitude of receiving

ultrasonic signals by a 3-digit number. [000] means

there is no signal detected, and [999] refers to the

maximum signal strength that can be received.

Although the instrument works well when the signal

strength ranges from 60 to 99, stronger signal

strength should be pursued, because a stronger

signal means a better result. The following methods

are recommended to obtain strong signals:

1) If the current location is not good enough for

a stable and reliable flow reading, or, if the signal

strength is lower than 60, relocate to a more

favourable location.

2) Try to polish the outer surface of the pipe, and

apply more couplant to increase the signal strength.

3) Tenderly adjust the position of the two transducers,

both vertically and horizontally, while checking the

signal strength. Stop at the position where the signal

strength reaches to maximum. Then, check the

transducer spacing to make sure it is the same as or

very close to what window M25 shows.

4) If the installation method is V-method and the pipe

is big, you may need to try Z-method in order to get

stronger signals.

NOTE

NOTE

FOR HIGH VELOCITY FLOW, THE R

VALUES MAY EXCEED THIS RANGE

TO SOME DEGREE.

IN THE FOLLOWING DESCRIPTIONS

WHEN THERE WOULD BE NO RISK

OF MISUNDERSTANDING, S VALUE

IS EXPRESSED BY TWO DIGITS (00-

99) FOR SIMPLICITY.

22 | EUROMAG

2.11.2 SIGNAL QUALITY

Signal quality is indicated as the Q value in the

instrument. A higher Q value would mean a higher

Signal to Noise Ratio (SNR), and accordingly a higher

degree of accuracy able to be achieved. Under normal

pipe condition, the Q value is in the range of 60-99,

the higher the better.

Causes for a lower Q value could be:

1) Interference from other instruments and devices

nearby, such as a power frequency inverter which

could cause strong interference. Try to relocate the

flow meter to a new place where the interference can

be reduced.

2) Bad sonic coupling between the transducers and

the pipe. Try to polish the pipe surface again, clean

the surface and apply more couplant, etc.

3) The selected pipe section is difficult to conduct the

measurement. Relocate to a more favourable pipe

line.

2.11.3 TOTAL TRANSIT TIME AND DELTA TIME

The total transit time (or travelling time) and the delta

time are displayed on menu window M93. They are

the primary data for the instrument to calculate the

flow rate. Therefore, the measured flow rate will vary

as the total transit time and delta time vary.

The total transit time should remain stable or vary in

a very small range.

The delta time normally varies less than 20%. If the

variation exceeds 20% in either positive or negative

direction, there could be certain kinds of problems

with the transducer installation. The user should

check the installation for sure.

2.11.4 TRANSIT TIME RATIO

Transit-time ratio R is usually used to check whether

the transducer installation is good and whether the

entered pipe parameters are in consistency with their

actual values. If the pipe parameters are correct and

the transducers are installed properly, the transit time

ratio should be in the range of 100±3 %. Particularly,

when the flow is stand-still, the ratio should be very

close to 100%. If this range is exceeded, the user

should check:

a) If the entered pipe parameters are correct?

b) If the actual spacing of the transducers is the same

as or close to what shown on window M25?

c) If the transducer are installed properly in the right

direction?

d) If the mounting location is good, if the pipe has

changed shape, or if the pipe is too old (i.e., too much

corrosion or deposition inside the pipe)?

e) If there is any interference source inside of the

pipe?

f) If there are other aspects which do not meet

the measurement requirements as recommended

earlier?

EUROSONIC 2000

EUROMAG | 23

3. HOW TO

3.1 HOW TO CHECK IF THE INSTRUMENT WORKS PROPERLY

Switch to menu M08 by entering keys. If ‘R’ is displayed on the screen, the instrument is working

properly.

If ‘E’ is displayed, the current loop output is over-ranged. Increasing the range setting in M57 will make the ‘E’

letter disappear. If you do not use current loop output, you may ignore this error.

If ‘Q’ is displayed, the frequency output is over-ranged. Increasing the range setting in M69 will make the ‘Q’

letter disappear. If you do not use frequency output, you may ignore this error.

If ‘G’ is displayed, the flow meter is adjusting system gain. This is normal as far as it does not last long.

If ‘I’ is displayed, there is no signal received. Check if the transducer cables are connected properly and

transducers are clamped firmly.

If ‘J’ is displayed, there is hardware problem. Turn off the power, then, turn on the power again. If the problem

remains, refer to

Chapter 5

for diagnosis details.

If an ‘H’ flashes instead, the received signal is poor.

Please refer to

Chapter 5

for diagnosis information.

3.2 HOW TO CHECK THE LIQUID FLOWING DIRECTION

Assume that transducer A is connected to the upstream terminals and transducer B is connected to the

downstream terminals.

First, make sure that the instrument works properly.

Then, check the flow rate reading. If the value is positive, the direction of the flow will be from transducer A to

B. Otherwise, the flow is from B to A.

3.3 HOW TO CHANGE UNITS SYSTEMS

Use menu window M30 for the selection of units systems, either English (option 0) or in Metric (option 1).

3.4 HOW TO SELECT A FLOW RATE UNIT

Use menu window M31 to select the flow rate unit, use menu window M32 to select the flow totalizer unit.

HOW TO

24 | EUROMAG

3.5 HOW TO USE THE TOTALIZER MULTIPLIER

Use window M33 to select a proper multiplying factor

for the totalizers (POS, NEG and NET). Make sure that

the rate of the totalizer pulse is not too fast, neither

too slow. A speed of several pulses per minute is

preferable.

If the totalizer multiplying factor is too small, the

output pulse will be very fast and there could be a

loss of pulses. The designed minimum pulse period

is 500 milliseconds.

If the totalizer multiplying factor is too large, the

output pulse will be very slow, which might be a

problem if the master device requires fast response.

3.6 HOW TO TURN ON / OFF THE TOTALIZERS

Use M34, M35 or M36 to turn on or turn off the POS,

NEG or NET totalizer, respectively.

3.7 HOW TO RESET THE TOTALIZERS

Use M37 to reset the flow rate totalizers.

3.8 HOW TO RESTORE THE FACTORY DEFAULT SETUPS

Go to window M37. Press the Keys. This

operation will erase all the parameters entered by the

user and setup the instrument with factory default

values.

3.9 HOW TO USE THE DAMPER TO STABILIZE THE

FLOW RATE

The damper acts as a filter for a stable reading. Its

damping constant is entered in window M40. Its unit

is in second. If ‘0’ is entered, that means there is no

damping. A bigger constant number brings a more

stable effect. But bigger numbers will prevent the

instrument from acting quickly.

A constant from 5 to 30 is commonly used for the

damper value.

3.10 HOW TO USE THE LOW-FLOW CUT OFF FUNCTION

The value displayed in window M41 is the low-flow

cut off. When the absolute value of the measured flow

velocity is below this value, the measured velocity as

well as flow rate will be replaced with ‘0’. This is to

avoid any invalid accumulation when the actual flow

is below the low-flow cut off value.

Application example: when a pump is shut down,

the liquid will not stop immediately. It will keep

moving (may be backward) for a little while. During

this period, the totalizer should be prevented from

accumulating. This can easily be done by setting the

low-flow cut off velocity to a certain value, such as

0.1ft/s (0.03m/s)

The low-flow cut off operation does not affect the

flow measurement when the actual flow is greater

than the low-flow cut off value.

3.11 HOW TO CONDUCT ZERO CALIBRATION

When the flow in a pipe is absolutely stopped, the

flow meter could still give a small non-zero flow rate

reading. In order to make the measurement accurate,

it is necessary to remove this “zero point” reading.

Window M42 allows us to take care of this issue.

At first, the user should make sure that the liquid in

the pipe is totally stopped (no velocity). Then, go to

window M42 and press the

key to start the zero

point setup function. Wait until the counter reading

goes down to ‘00’.

EUROSONIC 2000

EUROMAG | 25

3.12 HOW TO CHANGE THE SCALE FACTOR

A scale factor is the ratio between the ‘actual flow

rate’ and the flow rate measured by the flow meter. It

can be determined by calibration with standard flow

calibration equipment. You may change the scale

factor in menu window M45.

The scale factor is transducer dependent. Prior

to shipment from the factory, the scale factor of a

transducer pair is calibrated on a pipe with water

flowing inside. If you ordered multiple pairs of

transducers, be sure you entered the scale factor of

the transducer pair you are using.

The scale factor is also affected by other factors such

as pipe size, fluid viscosity, installation variation, etc.

It is therefore recommended to do on-site calibration

when accuracy is of crucial importance.

3.13 HOW TO USE THE PASSWORD LOCKER

The password locker provides a means of preventing

inadvertent configuration changes or totalizer resets.

When the system is locked, the user can still browse

menu windows, but cannot make any modifications

on the windows.

The password locking / unlocking is done in window

M47. The system can be locked without a password

or with a password consisted of 1 to 4 digits.

For no-password locking / unlocking, just press

key in window M47.

If the password is forgotten, please contact the

manufacturer.

3.14 HOW TO USE THE KEYPAD LOCKER

First, switch to the menu window which will be

displayed after the keypad is locked.

Then, press

to switch to menu M48.

Press and enter a 1-8 digit long password.

Password should be numerical only. Press

again

to set the password. The system will return to the

previously selected window automatically.

3.15 HOW TO USE SCHEDULED DATA OUTPUT

Data can be sent to RS232 serial port by a preset

schedule.

The data items to be output are selected in M50.

Switch to menu M50, select “ON”, followed by data

items, then press . If you do not want to output

data through RS232, select “OFF” in M50 and press

.

The output time, interval and last period are set in

window M51. Refer to the

next chapter

for details on

M51.

3.16 HOW TO USE 4-20MA CURRENT LOOP OUTPUT

The accuracy of the current loop output is better than

0.1%. It can be configured to different mode, such as

4-20mA mode, 0-20mA modem, etc. Mode selection

can be made in menu M55. Refer to the

next chapter

for details on M55.

In order to use the 4-20mA output function, you need

not only select the mode to be 4-20mA in M55, but

also set the flow rate values which correspond to the

minimum current (4mA) and the maximum current

(20mA). Enter the two values in M56 and M57.

Example A: flow rate range is 0-500m3/h. Just enter

0 in M56 and 500 in M57.

Example B: flow rate range is -500-0-1000m3/h. If

flow direction is not an issue for you, you may select

20-4-20mA mode in M55. Then, enter 500 in M56

and 1000 in M57. If flow direction is an issue, you

may select 0-4-20mA mode in M55. This means that

the current loop will output 0-4mA when flow rate

HOW TO

26 | EUROMAG

is negative and 4-20mA when flow rate is positive.

Enter -500 in M56 and 1000 in M57.

You may need to calibrate and test the current loop

output before using it. Just go to menu M58 and do

the following:

First, connect an ammeter to the current loop

output.

Press , then, to enter into menu

M58.

Use and to display “0mA”, “4mA”, “8mA”,

“16mA”, “20mA” orderly, record the corresponding

reading on the ammeter. Calculate the differences

between the readings and the selected ones. For

instance, when 4mA is selected, the actual output

current shown on the ammeter is 4.01mA. Then, the

difference is 0.01mA.

If the differences are not within tolerance, calibrate

the current loop (see

section 3.33

.)

The present current loop output is displayed in Window

M59. It changes along with flow rate change.

3.17 HOW TO OUTPUT ANALOGUE VOLTAGE SIGNAL

Connect a 250Ohm/0.25W resistor across the two

current loop output terminals (terminals 21 and 22).

This will convert the 4-20mA current signal into 1-5V

voltage signal.

3.18 HOW TO USE THE FREQUENCY OUTPUT

All the flow meters have Frequency Output

functionality. This frequency output signal, which

represents the flow rate, is intended to connect with

other instruments.

The Frequency Output is totally user-configurable.

Usually, four parameters should be configured.

Enter the lower limit of flow rate in window M68 and

the higher limit of flow rate in window M69.

Enter the frequency maximum and minimum in

window M67.

For example, assume that the flow rate varies in a

range from 0m3/h to 3000m3/h, and the required

output signal frequency should be in a range from

200Hz to 1000Hz. The user should enter 0 in M68

and 3000 in M69, and enter 200 and 1000 in window

M67.

Please note that the user needs to select the

frequency output option (the 13th option, “FO

output”) in window M78. The user must also make

the OCT hardware connection to the device which is

supposed to use the frequency output signal. Refer to

Appendix 9.1

for wiring information.

3.19 HOW TO USE THE TOTALIZER PULSE OUTPUT

The flow meter is able to produce a pulse output

every time when it reaches a unit flow of liquid. This

pulse could be used by an external pulse counter to

accumulate the flow rate.

Refer to

3.4 and 3.5

for the setup of the totalizer units

and multiplier.

The totalizer pulse output can only be transmitted

through OCT or relay devices. Therefore, it is

necessary to configure the OCT or relay. This can

be done in menu M78 and M79. Refer to the next

chapter for detail on M78 and M79.

For example, assume that we need to output the POS

totalizer through the relay in pulse form, and every

pulse represents 0.1cubic meter of liquid flow. The

following steps must be performed:

1) Select the Cubic Meter (m3) unit in window M32.

2) Select the Multiplier factor as ‘2. X0.1’ in window M33.

EUROSONIC 2000

EUROMAG | 27

3) Select the output option ‘9. POS INT Pulse’ in

window M77. (INT stands for integrated or totalized)

3.20 HOW TO PRODUCE AN ALARM SIGNAL

There are two types of hardware alarms that are

available with this instrument. One is the audible

alarm, and the other is the ON/OFF output signal

which can drive an alarm. The audible alarm is also

called Buzzer. It is generated internally and can be

configured in M77. The ON/OFF output signal is

generated through the OCT or relay output which is

connected to an external alarm circuitry.

The triggering sources of the alarming events for both

the Buzzer and the ON/OFF alarm signal could be:

1) There is no receiving signal.

2) The signal received is too weak.

3) The flow meter is not in normal measurement

mode.

4) The flow direction is changed.

5) Overflow occurs at the analogue outputs by 120%

or more.

6) Overflow occurs at the frequency output by 120%

or more.

7) The flow rate is out of the specified range, which

is configured in windows M73 and M74 for Alarm #1,

and in windows M75 and M76 for Alarm #2.

Example A: assume we need the Buzzer to start

beeping when the flow meter is not ready in normal

measurement. Switch to M77, select item “2.

Abnormal Measurement State”

Example B: assume we need the Buzzer to start

beeping when the flow rate is less than 300 m3/h

and greater than 2000m3/h. The following setup

steps would be recommended:

1) Enter flow rate lower limit 300 in M73 for #1

alarm,

2) Enter flow rate upper limit 2000 in M74 for #1

alarm,

3) Select item ‘6. Alarm #1’ in M77.

Example C: assume we need the OCT output to

activate when flow rate exceeds 100~500m3/h and

the relay output to activate when flow rate exceeds

600~1000m3/h. The following setup steps would be

recommended:

1) Enter flow rate lower limit 100 in M73

2) Enter flow rate upper limit 500 in M74

3) Enter flow rate lower limit 600 in M75

4) Enter flow rate lower limit 1000 in M76

5) Select item ‘6. Alarm #1’ in M78

6) Select item ‘6. Alarm #1’ in M79.

HOW TO

NOTE

THE TOTALIZER PULSE MUST BE

SET PROPERLY. IT SHOULD BE

NEITHER TOO LARGE NOR TOO

SMALL. IF IT IS TOO LARGE (E.G.,

LONG PERIOD), THE OUTPUT

PULSE WILL BE VERY SLOW. IF

IT IS TOO SMALL (E.G., SHORT

PERIOD), THE RELAY MAY ACTIVATE

TOO FREQUENTLY AND ITS

LIFETIME MAY BE SHORTENED.

FURTHERMORE, PULSE LOSS

ERROR MAY OCCUR. IT IS

RECOMMEND TO SET VALUES THAT

WOULD GENERATE 1 TO 60 PULSE/

MINUTE. YOU CAN ADJUST THE

PULSE PERIOD BY SELECTING

DIFFERENT TOTALIZER MULTIPLIER

FACTOR IN M33.

28 | EUROMAG

3.21 HOW TO USE THE OCT OUTPUT

The OCT output is an ON/OFF type, electrically isolated

collector open circuit output. It is user-configurable.

You can program it to be an ON/OFF type alarm signal

or a totalizer pulse signal.

Notice that the Frequency Output shares the same

OCT hardware. When used as Frequency Output, the

OCT cannot be used for other purpose (neither alarm

signal nor totalizer pulse signal).

WIRE AN EXTERNAL ALARM DEVICE

TO THE FLOWMETER OCT OUTPUT

The OCT has two wiring terminals, terminals 61

and 62. Terminal 61 is collector and terminal 62 is

emitter. Be careful of the polarity. An external DC

power supply Vx and an external pull-up resistor Rx

are needed for using the OCT (Figure 4). Vx can be

from +8VDC to +24VDC. Rx can be from 1KOhm to

10KOhm. The OCT can drive an alarm, pulse counter,

frequency counter, etc. It can also be used to drive a

relay, which operates a valve system, for instance.

Refer to the

next chapter

on menu M78 for OCT

configuration.

3.22 HOW TO USE THE RELAY OUTPUT

The relay output is a single-pole single-throw (SPST),

normally ON output device. Its maximum operating

frequency is 1Hz. Its load current is 1A at 125VAC,

or, 2A at 30VDC.

WIRE AN EXTERNAL ALARM DEVICE TO THE FLOW

METER RELAY OUTPUT TERMINALS

The relay output is user-configurable and can be

configured as an ON/OFF type alarm signal or a

totalizer pulse signal. Its signal is sent to terminals 71

and 72, which can be connected to a remote counter

or alarm device (Figure 5). Refer to the next chapter

on menu M79 for relay configuration.

3.23 HOW TO USE THE BUILT-IN BUZZER

The built-in buzzer is user-configurable. It can be

used as an alarm. Use M77 for setups.

3.24 HOW TO MODIFY THE BUILT-IN CALENDAR

The current date and time is displayed in menu M04

in format “yy-mm-dd hh:mm:ss”. If this is the first

time you run the flow meter, please do make sure

that the date and time are correct. If not, please

make correction. Besides, if “daylight saving” applies

in your area, you may also need to change the time

accordingly.

To make changes on the date and time, press

EUROSONIC 2000

C

E

61

62

Vx

Rx

OPTOCOUPLER

ISOLATION

External Alarm

or Relay Control

TERMINALS

f. 4

f. 5

NO

C

71

72

External Alarm

TERMINALS

RELAY

EUROMAG | 29

to switch to menu M61 and modify the

settings. Use the key to skip over these digits that

need no modifications.

3.25 HOW TO ADJUST THE LCD

Use M70 to adjust the LCD backlight. Press

. You should see “>” on the screen, which

indicates that the system is ready for modification.

Use and to select the desired option. “Always

On” means that the backlight will remain on always.

“Always Off” means that the backlight will remain off

always. “Time=” means that the backlight will keep

on for “x” seconds which should be keyed in after

selecting “Time=”.

Use M71 to adjust the LCD contrast. This is necessary

when the letters on the screen are not clear and the

viewing angle is offset. Press . You

should see “>” on the screen. Use or to

increase or decrease the contrast.

3.26 HOW TO USE THE RS232 SERIAL INTERFACE

The flowmeter family flow meters are equipped

with a RS232C standard serial interface. The RS232

interface is wired to a DB9 connector. The data rate

can be set to 75-115200 Baud. Use M62 to configure

this interface. Refer to

Chapter 6

for more details

You may use an external RS232-to-RS485 converter

to connect the flow meter to a 485 bus.

3.27 HOW TO VIEW THE TOTALIZED FLOW

Use M82 to view the daily, monthly and yearly

totalized flow.

To view the last 64 days’ flow history, press

, then, select item 0 for “Day”. You should see the

serial number and the date on the first line, and the

net totalized flow for this specific day.

Note that, on the upper right corner, you may see

“----”, which indicates that the system was normal

during that day. If you see other characters, error

occurred in that day. Please refer to

chapter 5

for

error code explanation and resolution.

To view the flow for a month or a year, press

and select item 1 for “Month” or 2 for “Year”.

3.28 HOW TO CONNECT ANALOGUE INPUT SIGNALS

There are five analogue input channels which can

be used to connect to five channels of 4-20mA

signals. They are digitized and then acquired by the

flow meter. The data can then be sent to a remote

computer or controller through RS232 upon request.

Refer to

chapter 6

for communication details.

The input analogue signal can be of pressure,

temperature or other physic quantities. When

analogue inputs AI1 and AI2 are connected to the

“hot” and “cold” temperature sensors of a liquid

thermal energy supply system, the flow meter can

measurement the thermal energy consumption of the

system.

Menu window M06 displays the present current and

its corresponding pressure / temperature value.

The terminals assigned to these analogue inputs are

(refer to

Appendix 9.1

):

AI1: 64 and 63; AI2: 65 and 63; AI3: 73 and 63; AI4:

74 and 63; AI5: 75 and 63.

HOW TO

30 | EUROMAG

AI3, AI4 and AI5 are not connected to terminals.

Please contact the manufacturer if needed.

3.29 HOW TO COMPENSATE THE FLOW NOT

MEASURED DURING OFFLINE

When the power is down, the flow meter will not

be able to conduct flow measurement. In order to

compensate the flow uncounted during the offline

period, you need to enable Automatic Amending

function before the flow meter is offline.

To enable the Automatic Amending function, switch

to M83, press key, then, select YES and press

again.

To disable this function, just select OFF in menu

M83.

Refer to the

next chapter

for M83 details and how the

uncounted flow is estimated.

3.30 HOW TO USE THE WORKING TIMER

Use the working timer to check the time that has

passed with a certain kind of operation.

The working timer value is displayed in window M72.

To reset the timer, press key and select YES.

3.31 HOW TO USE THE MANUAL TOTALIZER

Use M38 for the manual totalizer setup. Switch to

M38. Press key to start and stop the totalizer.

This function can be used for flow meter calibration.

3.32 HOW TO USE THE BATCH PROCESS CONTROLLER

The flowmeter has a batch process controller built-in.

It can be used for flow quantity control or the batching

of specific volumes.

This batch controller utilizes the keypad or the rising

edge or falling edge of an analogue input signal as

its control signal input (or triggering signal). It utilizes

the OCT or relay as its output. When using analogue

as the input signal, the input current must be larger

than 2mA to indicate a logic “1” and 0mA to indicate

a logic “0”.

The user needs to select the type of input control

signal in menu M80. The user also needs to select the

output type to be item 8 “output as batch controller”

in M78 for OCT output or in M79 for relay output.

Use M81 to enter batch value. After completion, the

display will be in batch control mode and the batch

controller is waiting for triggering signal. If you

selected “0. Key Input” as the triggering source in

M80, you may press the key to start the batch

process. Otherwise, just wait the specified triggering

event is detected. Refer to the next chapter for M80

and M81 details.

3.33 HOW TO CALIBRATE THE ANALOGUE OUTPUT

In general, there is no need to calibrate the analogue

output since it has been calibrated in factory.

However, when conducting current loop calibration

(see

3.16

), if you find the current value shown in M58

differs from the actual current shown in the ammeter,

you do need to recalibrate the analogue output.

Calibration steps:

First, put the flow meter into calibration mode. Press

, enter password “4213068”, and

press

again.

Then, connect a precise ammeter to the current

output loop.

EUROSONIC 2000

EUROMAG | 31

Press to calibrate the current loop

4mA output. Read the ammeter. If the reading is not

4mA, use or to adjust the output current until

the ammeter reads 4.00mA.

Press again to calibrate 20mA output, similar to

the above step.

Press to save the results in the

internal non-volatile EEPROM.

3.34 HOW TO CHECK THE ESN

Each product of the flowmeter series has a unique

electronic serial umber (ESN) to identify itself. The user

can use the ESN for instrumentation management.

The ESN is displayed in window M61.

Use M+1 to view the total working time since the

instrument left the factory. Use M+4 to view the total

number of times the instrument has been turned on

and off since the instrument left the factory.

HOW TO

32 | EUROMAG

EUROSONIC 2000

EUROMAG | 33

4. MENU WINDOW DETAILS

Menu window No.

M00

M01

M02

M03

M04

M05

M06

M07

M08

M09

M10

M11

M12

Function

Display flow rate and net totalizer value.

If the net totalizer is turned off in M34, the net totalizer value shown on the screen is the

total prior to its turn off.

Display flow rate and velocity.

Display flow rate and POS (positive) totalizer.

Select the positive totalizer units in menu M31.

If the POS totalizer is turned off, its value shown on the screen is the total prior to its turn off.

Display flow rate and NEG (negative) totalizer. Select the negative totalizer units in M31.

If the NEG totalizer is turned off, its value shown on the screen is the total prior to its turn off.

Display the current date time and flow rate. The time setting method is found in M60.

Display Instantaneous Caloric and Totalized Caloric.

Display Analogue Input AI1 / AI2 current value and its corresponding temperature, pressure

or liquid level value.

System Error Codes

Display the working condition and the system error codes. Refer to

Chapter 5

for details.

Display today’s total NET flow

Window for entering the peripheral of the pipe.

If pipe outer diameter is known, skip this menu and go to menu M11 to enter the outer diameter.

Window for entering the outer diameter of the pipe. Valid range: 10 to 6000mm.

Note, you just need to enter either outer diameter in M11 or pipe peripheral in M10.

Window for entering pipe wall thickness. You may skip this menu and enter inner diameter

in M13 instead.

MENU WINDOWS DETAILS

NOTE

IT IS RECOMMENDED TO PRACTICE

THOSE MENU WINDOWS ON YOUR

FLOW METER WHILE READING THIS

CHAPTER FOR THE SAKE OF EASY

UNDERSTANDING.

TO QUICKLY SWITCH TO A MENU

WINDOW, JUST PRESS MENU

FOLLOWED BY THE WINDOW

NUMBER (A TWO DIGIT NUMBER).

TO MOVE FROM ONE WINDOW TO

THE NEXT, USE OR KEY.

34 | EUROMAG

Menu window No.

M13

M14

M15

M16

M17

M18

M19

M20

M21

M22

M23

Function

Window for entering the inner diameter of the pipe. If pipe outer diameter and wall thickness

are entered correctly, the inner diameter will be calculated automatically, thus no need to

change anything in this window.

Window for selecting pipe material.

Standard pipe materials (no need to enter the material sound speed) include:

0) carbon steel 1) stainless steel 2) cast iron 3) ductile iron

4) copper 5) PVC 6) aluminum 7) asbestos

8) fiberglass-epoxy 9) Other (need to enter sound speed in M15)

Window for entering the sound speed of non-standard pipe materials

Window for selecting the liner material. Select none for pipes without any liner.

Standard liner materials (no need to enter liner sound speed) include:

1) Tar Epoxy 2) Rubber 3) Mortar 4) Polypropylene

5) Polystryol 6)Polystyrene 7) Polyester 8) Polyethylene

9) Ebonite 10) Teflon 11) Other (need to enter sound speed in M17)

Window for entering the sound speed of non-standard liner materials

Window for entering the liner thickness, if there is a liner

Window for selecting fluid type

For standard liquids (no need to enter liquid sound speed) include:

0) Water 1) Sea Water 2) Kerosene 3) Gasoline 4) Fuel oil

5) Crude Oil 6) Propane at -45C 7) Butane at 0C

8) Other (need to enter sound speed in M21 and viscosity in M22)

9) Diesel Oil 10) Caster Oil 11) Peanut Oil 12) #90 Gasoline

13) #93 Gasoline 14) Alcohol 15) Hot water at 125C

Window for entering the sound speed of non-standard liquids. Used only when item 8

“Other” is selected in menu M20.

Window for entering the viscosity of non-standard liquids. Used only when item 8 “Other”

is selected in menu M20.

Window for selecting transducer type. There are 13 types:

0.Standard M 7. Not Used

1.Plug-in Type C 8. Standard-HS

2.Standard-S 9. Standard-HM

3.User Type 10. Standard-M1

4.Standard-B 11. Standard-S1

5.Plug-in Type B45 12. Standard-L1

6.Stand-L

EUROSONIC 2000

EUROMAG | 35

Menu window No.

M24

M25

M26

M27

M28

M29

M30

M31

Function

Window for selecting the transducer mounting methods

Four methods can be selected:

0. V-method (commonly used);

1. Z-method (most commonly used);

2. N-method (for small pipe. rarely used);

3. W-method (for small pipe).

Display the transducer mounting spacing or distance

Entry to store/load the system setup parameters (pipe parameters, fluid parameters,

transducer parameters, etc.). Three operation methods available:

1. Entry to Save

2. Entry to Load

3. To Browse

To save the current setup parameters, select “Entry to Save” and press . An

address number and original parameters will be displayed. Use or key to

change address number. Press again will save the current setup parameters into

the selected address space.

Display the cross-sectional area inside the pipe.

Entry to determine whether or not to keep the last good value when poor signal condition

occurs. This function allows continued flow totalizing. YES is the factory default.

Entry to set empty pipe signal threshold. When the signal strength is less than this

threshold, the pipe is classified as empty pipe, and the flow meter will not totalize the flow.

This is based on the fact that, when the pipe is empty, the transducer can still receive

signal, just smaller than normal. As a result, the flow meter will show normal operation,

which is not correct.

Window for selecting unit system. The conversion from English to Metric or vice versa

will not affect the unit for totalizers.

Window for selecting flow rate unit system.

Flow rate can be in

0. Cubic meter short for (m3) 5. Cubic feet (cf)

1. Liter (l) 6. USA liquid barrel (bal)

2. USA gallon (gal) 7. Imperial liquid barrel (ib)

3. Imperial Gallon (igl) 8. Oil barrel (ob)

4. Million USA gallon (mgl)

The flow unit in terms of time can be per day, per hour, per minute or per second. So

there are 36 different flow rate units in total for selection.

MENU WINDOWS DETAILS

36 | EUROMAG

Menu window No.

M32

M33

M34

M35

M36

M37

M38

M39

M40

M41

M42

M43

M44

M45

M46

M47

M48

M49

M50

M51

Function

Window for selecting the totalizers’ unit. Available unit options are the same as those in M31.

Window for setting the totalizer multiplying factor

The multiplying factor ranges from 0.001 to 10000. Factory default is 1.

Turn on or turn off the NET totalizer

Turn on or turn off the POS totalizer

Turn on or turn off the NEG totalizer

1) Totalizer reset

2) Restore the factory default settings. Press the key followed by the key.

Attention, it is recommended to make notes on the parameters before doing the

restoration.

Manual totalizer used for calibration. Press any key to start and press the key again to stop

the totalizer.

Not used,

Flow rate damper setup. The damping parameter ranges from 0 to 999 seconds.

0 means there is no damping. Factory default is 10 seconds.

Low flow rate (or zero flow rate) cutoff to avoid invalid accumulation.

Zero calibration / Zero point setup. Make sure the liquid in the pipe is not running while

doing this setup.

Clear the zero point value, and restore the factory default zero point.

Set up a flow bias. Generally this value should be 0.

Flow rate scale factor.

Keep this value as ‘1’ when no calibration has been made.

Network address identification number (IDN). Any integer can be entered except 13(0DH,

carriage return), 10 (0AH, line feeding), 42 (2AH*), 38 (26H&), 65535.

Every set of the instrument in a network environment should have a unique IDN. Please refer

to chapter 6 for communications.

System locker to avoid modification of the system parameters. Contact the manufacturer if

the password is forgotten.

Keypad locker to avoid any operation errors by unauthorized personnel. Contact the

manufacturer if the password is forgotten.

Communication tester.

Window to configure the scheduled output function.

To turn on the function, select YES. The system will ask for selecting the output data items.

There are 15 data items available. Turn on all the items you want to output.

Window to setup the time of the scheduled output function. This includes start time, time interval

and lasting period. Minimum time unit is second. Maximum time interval is 24 hours.

EUROSONIC 2000

EUROMAG | 37

Menu window No.

M52

M53

M54

M55

Function

Used for analogue input AI5.