Euro-Kitchen 168 Series, 198 Series Installation Manual And User's Manual

Installation Guide

and Users Manual

168/198 Series Wall Mount Range Hood

Suitable for:

Standard Class

“R” Class

“E” Class

“SP” Class

IMPORTANT:

Read and save these instructions.

NOTICE:

Installer: Leave this guide with the homeowner

Homeowner: Keep this guide for future reference

Wall Mount Range Hood

Rev. 1016u.5a

Important Safety Notice

Read all Instructions before Installing and operating this appliance

The installation in this manual is intended for qualied installers, service technicians or persons with •

similar qualied background. Installation and electrical wiring must be done by qualied profession-

als and in accordance with all applicable codes and standards, including re-rated construction.

• attempt to install this appliance yourself. Injury could result from installing the unit due to

DO NOT

lack of appropriate electrical and technical background.

Range hood may have very sharp edges; please wear protective gloves if it is necessary to remove any •

parts for installing, cleaning or servicing.

Activating any switch ON before completing installation may cause ignition or an explosion.•

Due to the size and weight of this range hood, two people installation is recommended.•

To reduce the risk of re, electric shock, or injury to persons:

For general ventilating use only. • DO NOT use to exhaust hazardous or explosive materials and vapors.

The combustion air ow needed for safe operation of fuel-burning equipment may be affected by this •

unit’s operation. Follow the heating equipment manufacturer’s guideline and safety standards such

as those published by the National Fire Protection Association (NFPA), and the American Society of

Heating, Refrigeration and Air Conditioning Engineers (ASHRAE), and the local code authorities.

Before servicing or cleaning unit, switch power OFF at service panel and lock service panel to pre-•

vent power from being switched ON accidentally.

Clean grease laden surfaces frequently. To reduce the risk of re and to disperse air properly, make

•

sure to vent air outside. DO NOT vent exhaust into spaces between walls, crawl spaces, ceiling, attics

or garages.

Ducted fans MUST always be vented to the outdoors.•

Use only metal ductwork and this unit MUST be grounded.•

Sufcient air is needed for proper combustion and exhausting of gases through the duct to prevent •

back drafting.

•

When cutting or drilling into wall or ceiling, be careful not to damage electrical wiring or other hid-

den utilities.

All electrical wiring must be properly installed, insulated and grounded.•

Old duct work should be cleaned or replaced if necessary to avoid the possibility of a grease re.•

Check all joints on duct work to insure proper connection and all joints should be properly taped.•

Use this unit only in the manner intended by the manufacturer. If you have questions, contact the •

vendor.

To reduce the risk of a stove top grease re:

Keep all fan, bafe, spaces, lter, grease tunnel, oil container and grease-laden surfaces clean. Grease •

should not be allowed to accumulate on fan, bafe, spaces, lter, grease tunnel and oil container.

Always turn range hood ON when cooking at high heat or when cooking aming foods. •

Use high settings on cooking range only when necessary.•

Never leave surface units unattended at high settings. Boil overs cause smoking and greasy spillovers •

that may ignite. Heat oils slowly on low or medium settings.

Page 1

Important Safety Notice

Read all Instructions before Installing and operating this appliance

Clean ventilating fan frequently.

•

Always use appropriate cookware and utensils size.•

Always use cookware appropriate for the size of the surface element.•

To reduce the risk of injury to persons in the event of a stove top grease re:

SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray, then turn OFF the burner. •

BECAREFUL TO PREVENT BURNS. NEVER PICK UP A FLAMING PAN—you may be burned.

KEEP FLAMMABLE OR COMBUSTIBLE MATERIAL AWAY FROM FLAMES. If the ames DO

NOT go out immediately, EVACUATE AND CALL THE FIRE DEPARTMENT or dial your local

emergency service immediately.

•

DO NOT USE WATER, including wet dishcloths or towels — a violent steam explosion will result.

Use an extinguisher ONLY if:•

You know you have a Class A, B, C extinguisher, and you already know how to operate it.•

The re is small and contained in the area where it is started.•

The re department is being called.•

You can ght the re with your back to an exit.•

To reduce the risk of injury to persons in the event of a gas leaks:

Extinguish any open ame.•

DO NOT turn on the range hood fan or any type of ventilator.•

DO NOT turn on the lights or any type of appliance.•

Open all doors and windows to disperse the gas. If you still smell gas, call the gas company and re •

department, or dial your local emergency service immediately.

Your safety and the safety of others is very important. We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety messages. All safety mes-

sages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you

what can happen if the instructions are not followed.

WARNING

This is the safety alert symbol. This symbol alerts you to potential hazards that can hurt you and others.

All safety messages will follow the safety alert symbol and the word “WARNING”.

The manufacturer and/or distributor/reseller declines all responsibility in the event of failure to observe the instructions given here for installation, maintenance and suitable use of the product.

The manufacturer and/or distributor/reseller further declines all responsibility for injury due to negligence and the warranty of the unit automatically expires due to improper maintenance.

The manufacturer and/or distributor/reseller will not be held responsible for any damages to personal property or real estate or any bodily injuries whether caused directly or indirectly by the range

hood.

Page 2

Table of Contents

INSTALLATION

Tools needed....................................................3

Parts supplied...................................................4

Venting requirements.......................................5

Mount heights & clearance...........................5-6

Calculating vent system length.......................6

Venting methods & ductless conversion..........7

Charcoal lters & electrical requirements.......8

Preparation......................................................9

Installation................................................10-12

Range hood operations............................13-22

Tools needed:

USE AND CARE

Troubleshooting...........................................23

Use and care information...............................24

Specications..............................................24

MAINTENANCE

Cleaning...............................................25

Replacing lter & light bulb....................25-26

WARRANTY

Coverage & exceptions.................................27

Disclaimer & contact information..................28

Marker or

pencil

Level

Utility knife

Powered

screwdriver

or drill

Measuring

tape

Flat-blade and

Phillips screw-

drivers

Page 3

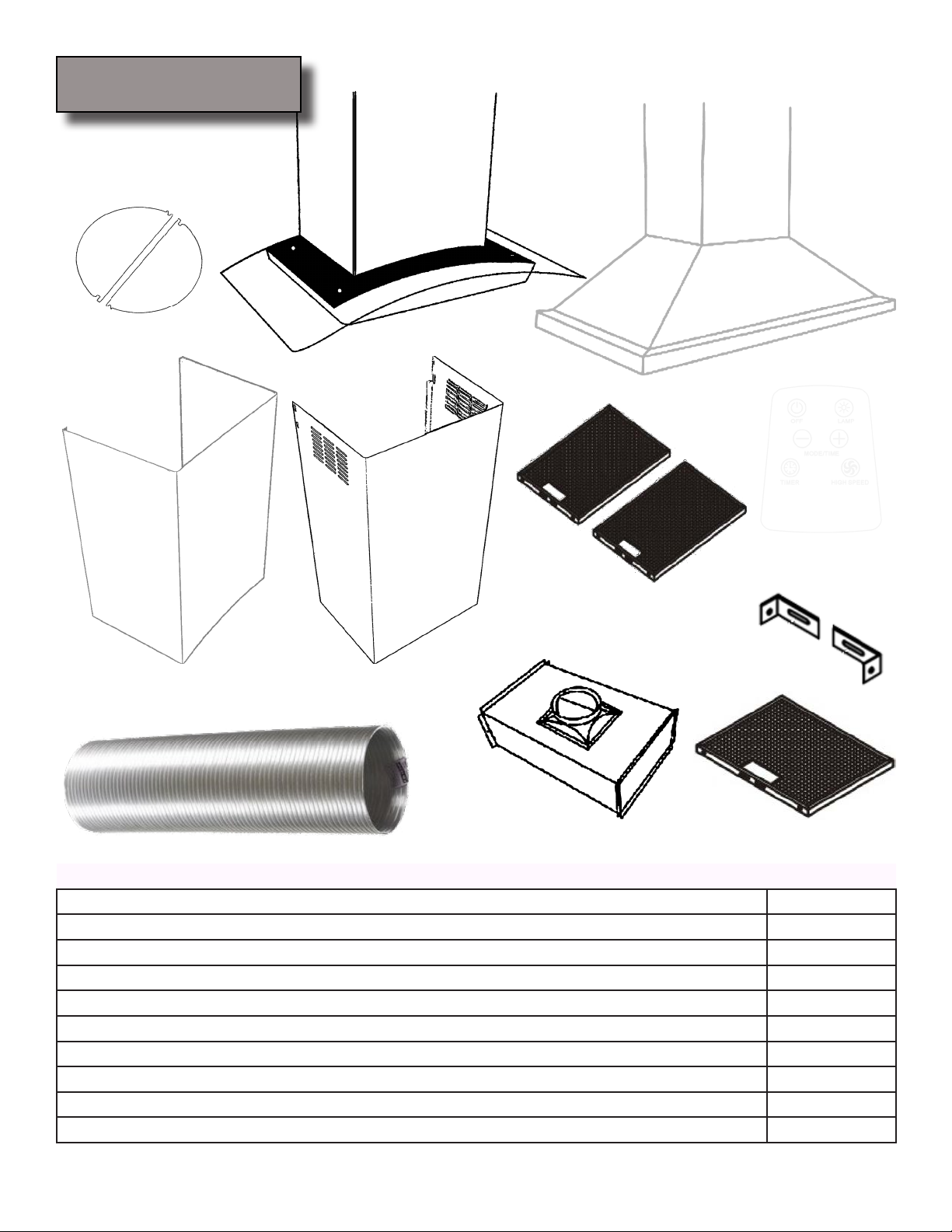

Parts supplied:

Flappers

Range Hood

(vary with model)

Lower standard chimney Upper standard chimney

Flexible Duct Tube (Optional)

Description Quantity

Toggle Bolts 2 Pcs

Duct Set 1 Set

Body Hook (vary with model) 2 Pcs

Chimney Mounting Bracket 1 Set

This Guide and Warranty Card 1 Set

5mm x 16mm Screw with Washer 4 Set

4mm x 16mm Tapping Screw 6 Pcs

4mm x 10mm Tapping Screw 16 Pcs

Optional: Toggle Bolt with Tapping Screw for Air Diverter 2 Set

Optional: Screw for Charcoal Filter 3 Pcs

SS Panel, Bafe or

Aluminum Filter(s)

Air diverter

(Optional re-circulating kit)

Remote Control

(Optional w/ “R” Class

Control)

Mounting Bracket

Charcoal Filter

(Optional re-circulating kit)

Page 4

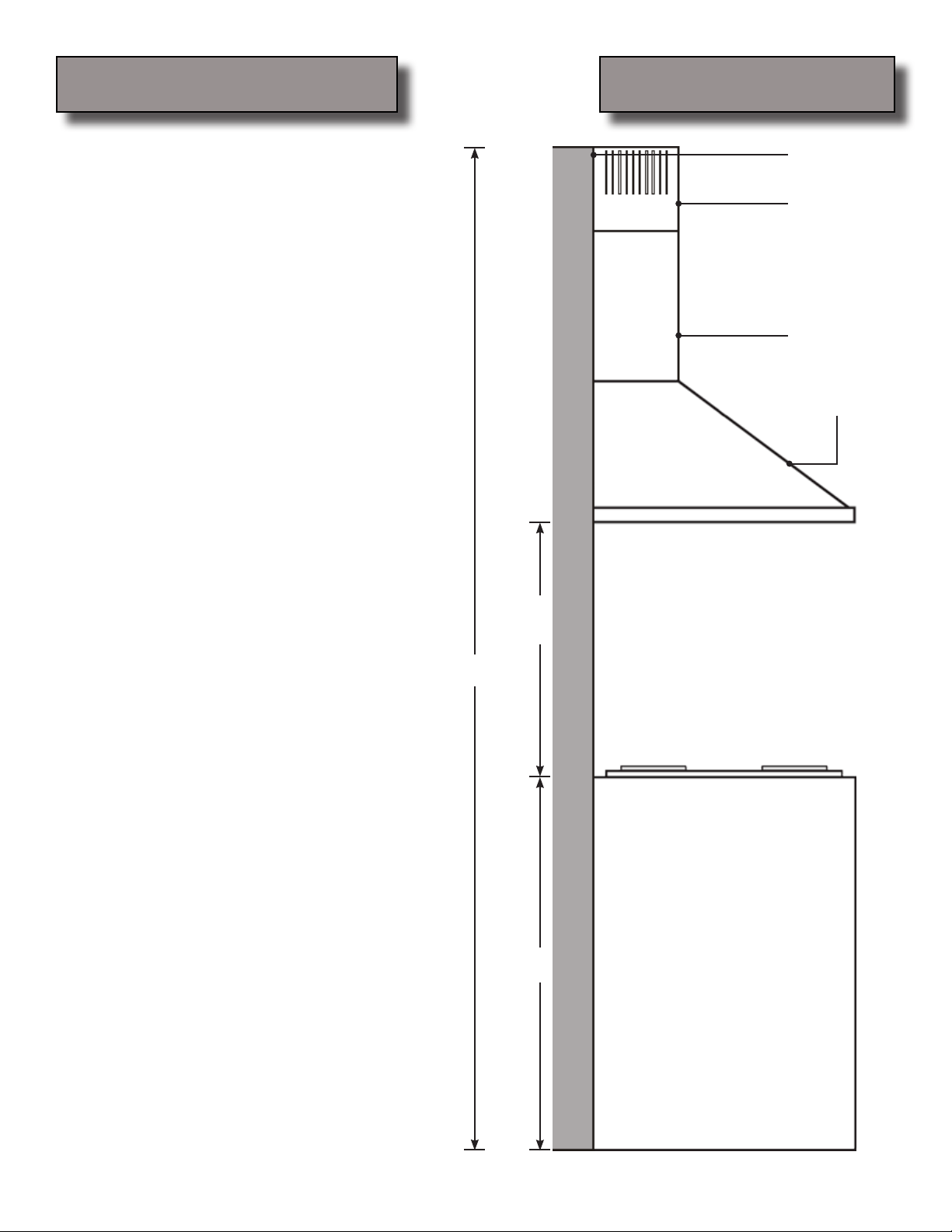

Venting Requirements Height & Clearance

Vent system must terminate to the outside •

(roof or side wall).

DO NOT terminate the vent system in an at-•

tic or other enclosed area.

DO NOT use 4” (10.2 cm) laundry-type wall •

caps.

Use metal/aluminum vent only. Rigid metal/•

aluminum vent is recommended.

DO NOT use plastic vent.

•

Always keep the duct clean to ensure proper •

airow.

Calculate the following gures before instal-•

lation:

Distance from the oor to the ceiling.1.

Distance between the oor to the coun-2.

tertop/stove (recommend* 28” to 31”).

Distance between the countertop/stove 3.

to the range hood.

Height of hood and duct cover.4.

For the most efcient & quiet operation:

A distance of 28” to 31” is recommended* •

between stove top and the bottom of range

hood.

It is recommended that the range hood be •

vented vertically through the roof through 6”

(15.2 cm) or bigger round metal/aluminum

vent work.

The size of the vent should be uniform.•

Use no more than three 90° elbows.•

Make sure there is a minimum of 24” (61 •

cm) of straight vent between the elbows if

more than one elbow is used.

DO NOT install two elbows together.•

The length of vent system and number of •

elbows should be kept to a minimum to pro-

vide efcient performance.

The vent system must have a damper. If •

roof or wall cap has a damper, DO NOT

use damper (if supplied) on top of the range

hood.

Use silver tape or duct tape to seal all joints •

in the vent system.

Use caulking to seal exterior wall or roof •

opening around the cap.

Maximum* ceiling clearance

110” at 31” hood mounting

height above countertop/stove

(may vary with different

model). Chimney extensions

available for higher ceiling.

Min: 28”

Max: 31”

Max*: 110”

36” base

Mounting

Bracket

Standard

Upper

Chimney

Extension available*

Standard

Lower

Chimney

Extension available*

Range hood

Countertop/Stove

* Due to different ceiling height congurations, rec-

ommended height may not be applicable.

* Higher ceiling requires chim-

ney extension. Available at your

local resellers.

Page 5

IMPORTANT:

A minimum of 6” round (standard for this range hood) or 3-1/4 x 10” rectangular duct (purchased separately) •

must be used to maintain maximum airow efciency.

Flexible 6” round duct provided for convenience, always use rigid type metal/aluminum ducts if available to •

maximize airow when connecting to provided duct.

Please use

• Duct Run Calculation below to compute the total available duct run when using elbows, transitions

and caps.

ALWAYS, when possible, reduce the number or transitions and turns. If long duct run is required, increase •

duct size from 6” to 7” or 8”. If a reducer is used, install a long reducer instead of a pancake reducer. Reducing duct size will restrict airow and decrease airow, thus reduce duct size as far away from opening as pos-

sible.

If turns or transitions are required: Install as far away from opening and as far apart, between 2, as possible.

•

Minimum mount height between stove top to hood bottom should be no less than 28-inch*.•

Maximum mount height between stove top to hood bottom should be no higher than 31-inch*.•

It is important to install the hood at the proper mounting height. Hoods mounted too low could result in heat •

damage and re hazard; while hoods mounted too high will be hard to reach and will loose its performance

and efciency.

If available, also refer to stove top manufacturer’s height clearance requirements and recommended hood

•

mounting height above range.

* Due to different ceiling height congurations, recommended height may not be applicable.

Minimum Duct Size:

Round - 6” minimum•

Rectangular - 3-1/4 x 10” minimum (requires a 6” to 3-1/4x10” adaptor, not supplied)•

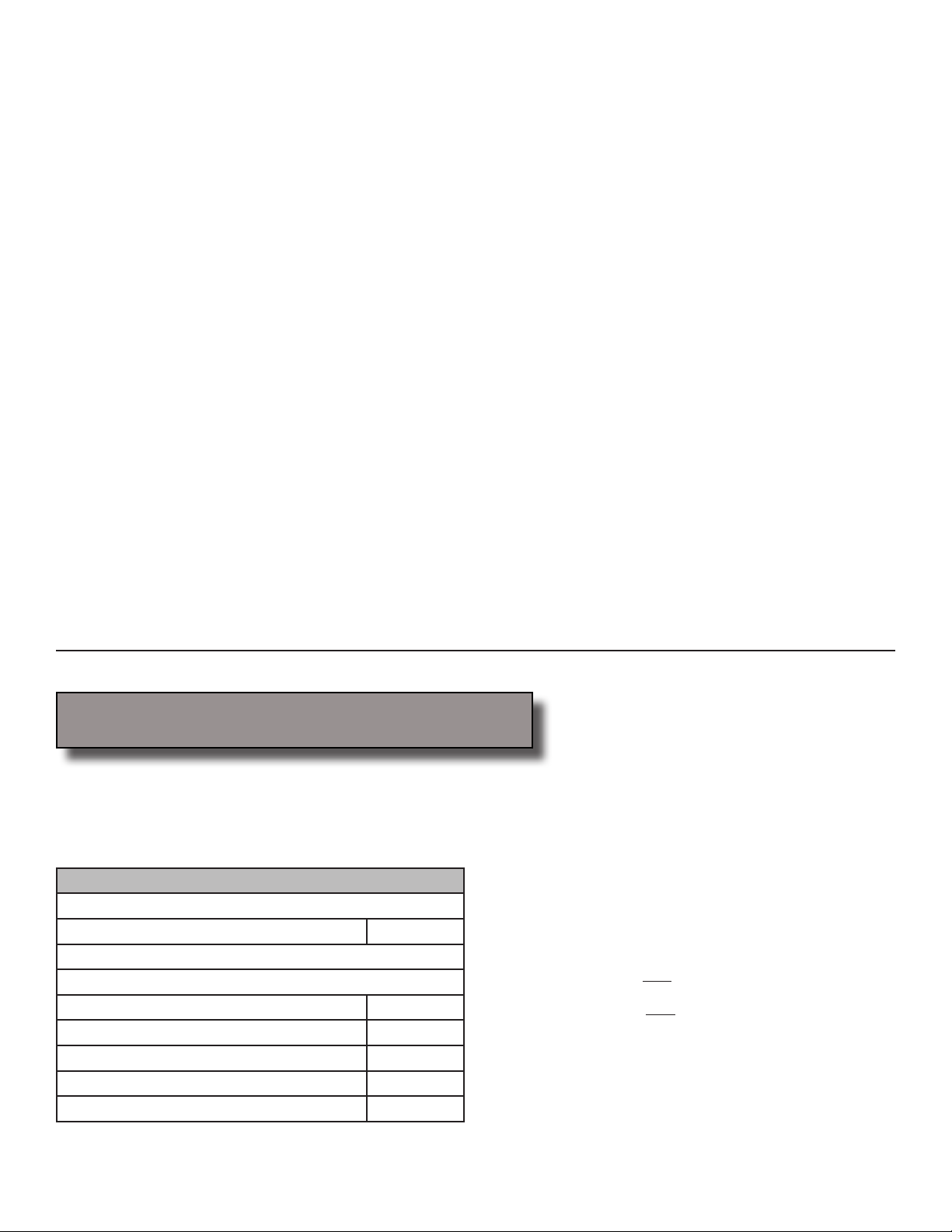

Calculating Vent System Length

To calculate the length of the system you need, deduct the equivalent feet for each vent piece used in the system

from the recommended maximum duct run.

Duct Run Calculation:

Recommended maximum run

6” or 3-1/4 x 10” duct 50 ft

Vent piece deduction

Each 90º elbow used 9 ft

Each 45º elbow used 5 ft

Each 6” to 3/14 x 10” transition used 7 ft

Side wall cap with damper 0 ft

Roof cap 0 ft

Duct Run Calcuation example:

One roof cap, two 90º elbow, and one 45º elbow used:

0ft + 9ft + 9ft + 5ft = 23ft used.

Deduct 23ft from 50ft, 27ft maximum available for

straight duct run.

Page 6

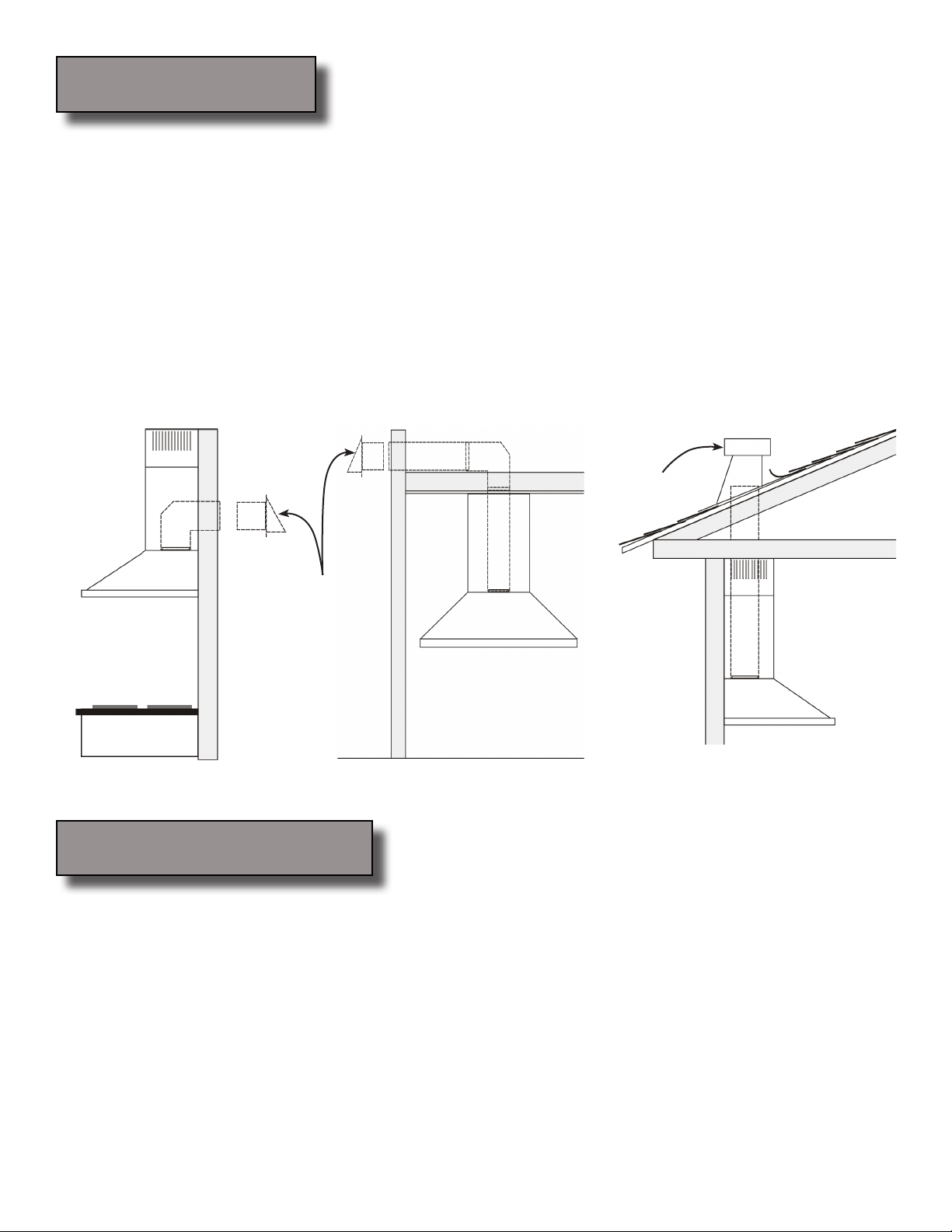

Venting Methods

This range hood is factory set for venting through the roof or wall. For non-vented (re-circulating) installa-•

tions, see Recirculating (Non-Vented) Kit on Page 11.

Vent work can terminate either through the roof or wall. To vent through a wall, a 90° elbow is needed.•

IMPORTANT:

NEVER exhaust air or terminate duct work into spaces between walls, crawl spaces, ceiling, attics or garages. •

All exhaust must be ducted to the outside.

Use metal/aluminum duct work only. •

Fasten all connections with sheet metal screws and tape all joints with certied Silver Tape or Duct Tape.•

Use caulking to seal exterior wall or roof opening around the cap.•

Option 1:

Horizontal wall venting

Side wall cap

Vertical roof venting

Option 2:

Roof cap

Ductless Conversion

Ductless conversion is intended for applications where an exhaust duct work is not possible to be installed.

•

When converted, the hood functions as a purifying hood rather than an exhaust hood. Fumes and exhaust

from cooking is drawn and ltered by a set of charcoal lters. The air is then puried and re-circulated back

within the home.

We recommend to ALWAYS exhaust air outside of the home by employing existing or installing new duct •

work, if possible. Only when the exhaust option is not possible should you recourse to converting the hood

into a purifying unit.

When converted to be a “purifying” unit, a set of charcoal lters and an air-diverter are required in addition to •

its standard aluminum lter set. Available at your local resellers. The standard aluminum lters are intended

to capture residue from cooking, the optional charcoal lters help to purify fumes exhausted from cooking,

and the optional air-diverter redirects ltered clean air back to the house.

Page 7

Charcoal Filter Installation

NOTE: The charcoal lters are preinstalled if you purchased the range hood with re-circulating kit from us.

Remove aluminum lters on hood.1.

Remove the safety lter under the aluminum lter by unscrewing two screws, then position the charcoal lter 2.

and align the screw holes, reinstall and fasten two screws.

Reinstall the aluminum lters back to the hood.3.

Charcoal lters must be replaced after 120 hours of use (or approximately every 2 to 3 months based on the 4.

average of 1 to 2 hours of daily cooking time). Available at your local reseller.

Electrical Requirements

IMPORTANT: Observe all governing codes and ordinances.

(Please consult with a qualied electrician for 220-Volt 50 Hz voltage)

It is the customer’s responsibility:

To contact a qualied electrical installer.

To assure that the electrical installation is adequate and in conformance with National Electrical Code, ANSI/

NFPA 70 — latest edition*, or CSA Standards C22. 1-94, Canadian Electrical Code, Part 1 and C22. 2 No. 0-M91

- latest edition** and all local codes and ordinances.

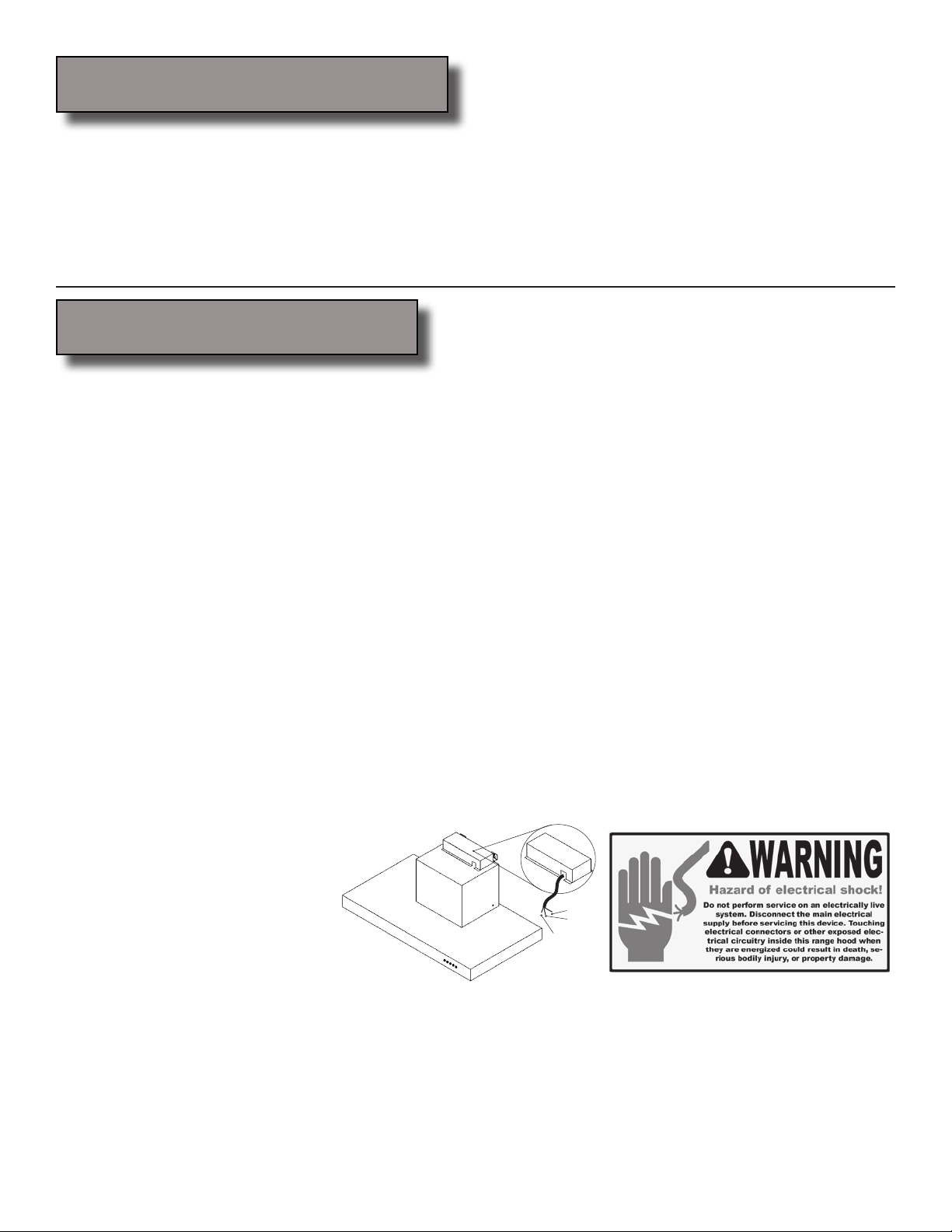

If codes permit and a separate ground wire is used, it is recommended that a qualied electrician determine •

that the ground path is adequate.

A 120-volt, 60 Hz, AC-only, fused electrical supply is required on a separate 15-amp circuit, fused on both •

sides of the line.

Do not ground to a gas pipe.•

Do not have a fuse in the neutral or ground circuit.•

RISK OF ELECTRICAL SHOCK. This range hood must be properly grounded. Check with a qualied elec-•

trician if you are not sure whether the range hood is properly grounded.

The range hood should be connected directly to the fused disconnect (or circuit breaker) box through exible •

armored or non-metallic sheathed copper cable. A U.L. - or C.S.A. - listed strain relief must be provided at

each end of the power supply cable. Do not use extension cord or adapter plug with this appliance.

The range hood must be connected with copper wire/plug only.•

Always use plug provided. If not •

possible, connect three wires ac-

cording to its color (black to hot,

white to neutral, and green to

ground) to house wires and cap

White

Green

Black

with wire connectors:

Wire sizes (copper wire only) and connections must conform with the rating of the appliance as specied on

the model/serial rating label. Wire sizes must conform to the requirements of the National Electrical Code

ANSI/NFPA 70 — latest edition*, or CSA Standards C22. 1-94, Canadian Electrical Code Part 1 and C22.

2 No. 0-M91 - latest edition** and all local codes and ordinances. A U.L. - or C.S.A. - listed conduit connector must be provided at each end of the power supply cable (at the range hood and at the junction box).

Copies of the standards listed may be obtained from:

* National Fire Protection Association ** CSA International

Batterymarch Park 8501 East Pleasant Valley Road

Quincy, Massachusetts 02269 Cleveland, Ohio 44131-5575

Page 8

Loading...

Loading...