EUROIMMUN Medizinische Labordiagnostika AG Sprinter XL Instructions For Use Manual

EUROIMMUN

Medizinische

Labordiagnostika

AG

Instructions for use

Sprinter XL

EUROIMMUN Medizinische Labordiagnostika AG · D-23560 Lübeck · Seekamp 31 · Tel. 0 45 1/58 55-0 · Fax 58 55-591

Medizinische

EUROIMMUN

Knowledge of this manual is required for operation of the instrument. Therefore, please make yourself

familiar with the contents of this manual and pay attention to the notes on the safe operation of the

instrument.

The specifications are subject to change; the manual is not covered by an update service.

© Unless expressly authorised, forwarding and duplication of this document, and the utilisation and

communication of its contents are not permitted. Violation will entail an obligation to pay

compensation. All rights reserved in the event of granting of patents or registration of a utility

model.

Labordiagnostika

AG

Publisher: EUROIMMUN Medizinische Labordiagnostika AG

Seekamp 31

23560 Luebeck, Germany

Phone: +49 (0) 451 5855 0

Fax: +49 (0) 451 5855 591

Internet: www.euroimmun.com

Medizinische

EUROIMMUN

Labordiagnostika

AG

1 Table of contents

1 TABLE OF CONTENTS - 1 -

2 WARNING, SAFETY AND OTHER NOTICES - 3 -

3 INTRODUCTION - 5 -

3.1 Intended use - 5 -

3.2 Validation - 5 -

4 SAFETY NOTES - 6 -

4.1 General - 6 -

4.2 Instrument safety and EMC - 10 -

4.3 Photobiological safety - 10 -

4.4 Position of the safety labels and the nameplate - 10 -

4.5 Maintenance - 11 -

4.6 Disposal - 11 -

4.7 Warranty notes - 12 -

5 GENERAL INFORMATION ON THE INSTRUMENT - 13 -

5.1 Technical data - 13 -

5.2 Instrument description - 16 -

6 INSTALLATION PROCESS - 21 -

6.1 Scope of delivery - 21 -

6.2 Unpacking, transport, storage - 21 -

6.3 Ambient conditions - 22 -

6.4 Installation and commissioning - 22 -

7 OPERATING INSTRUCTIONS - 24 -

7.1 The Sprinter XL software - 24 -

7.2 Before and after each worklist - 27 -

7.2.1 Flushing with the system liquid - 27 -

7.2.2

Decontamination of the pipetting needles - 29 -

7.2.3 Rinsing the washer head - 30 -

7.2.4 Completing a worklist - 31 -

7.3 Creating a worklist - 31 -

7.3.1 Manual creation of a worklist with non-barcoded samples - 31 -

7.3.2 Importing a worklist from lab software - 32 -

7.3.3 Scanning barcoded samples - 32 -

7.3.4 Editing a worklist - 35 -

7.4 Running a test - 37 -

7.4.1 Loading the Sprinter XL for immunofluorescence - 38 -

7.4.2 Optional: Reading of slide ID (2DBarcode) - 45 -

7.4.3 Loading the Sprinter XL for ELISA - 49 -

7.4.4 During the test run (Start, Pause, Stop) - 56 -

1 Table of contents - 1 -

EUROIMMUN

8 RESULT REPORTS - 59 -

9 CLEANING AND MAINTENANCE - 64 -

10 ERROR REMEDIES - 68 -

11 CONSUMABLES AND ACCESSORIES - 70 -

9.1 Maintenance schedule - 64 -

9.1.1 Daily maintenance work - 64 -

9.1.2 Weekly maintenance work - 64 -

9.1.3 Monthly cleaning - 65 -

9.2 Service plan (for service technicians) - 67 -

9.3 Instrument disinfection - 67 -

9.4 Decommissioning the system - 67 -

10.1 Error message: No Liquid found - 68 -

10.2 Error message: Movement of (33) blocked - 68 -

10.3 Error message: Action not startable - 69 -

Medizinische

Labordiagnostika

AG

12 APPENDIX - 73 -

12.1 Customer service - 73 -

12.2 Table of figures - 73 -

- 2 - 1 Table of contents

EUROIMMUN

Medizinische

Labordiagnostika

AG

2 Warning, safety and other notices

The symbols described here are used in this manual, on individual instrument

parts and the packaging. In addition, a specific notation is used to refer to certain

particular elements, e.g. buttons, keys.

NOTES

Notes are indicated with a symbol and printed in bold and italics. The symbols

are as follows:

Read the manual before use!

Information is identified with this symbol. It contains useful information.

Disconnect the plug-in power unit before opening the instrument!

WARNING MESSAGES

Warning messages are displayed using a safety symbol and printed in bold and

italics. The danger symbols are as follows:

Caution, hazard risk! Consult the operating manual!

Bio hazard!

Electrical hazard!

Laser hazard!

Mechanical hazard!

2 Warning, safety and other notices - 3 -

EUROIMMUN

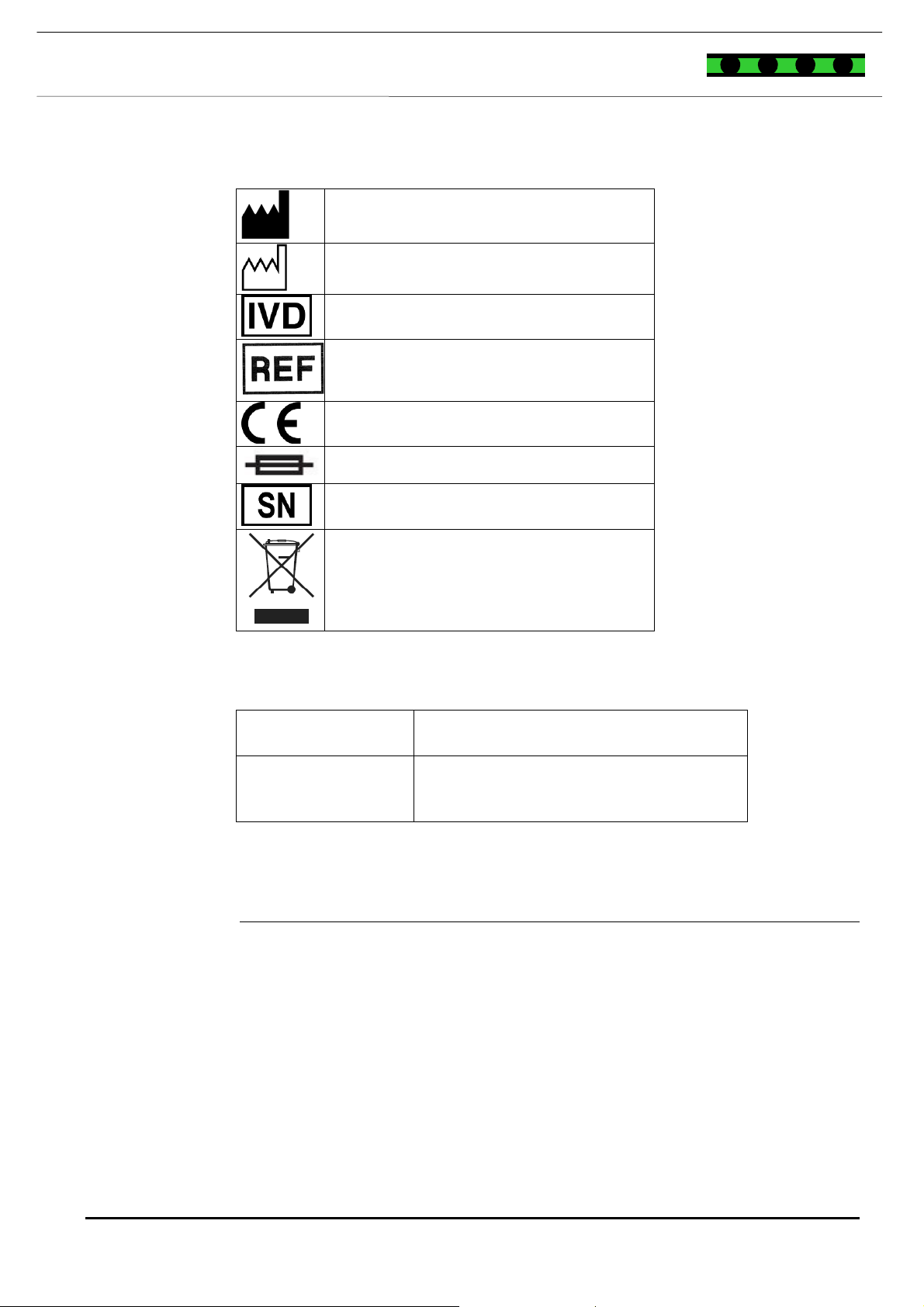

SYMBOLS

Medizinische

Labordiagnostika

AG

Produced by

Completed by

In vitro diagnostic medical device

Order Number

CE label

Fuse

Serial number

The instrument should not be placed in

ordinary domestic waste.

SPECIAL WRITING CONVENTIONS

Menu items

Keys/buttons

Menu items are printed in bold.

Example: Main menu

Keys and buttons are printed in italics or

are shown as a symbol.

Example: Press Enter

ABBREVIATIONS

Abbreviation

°C Celsius

Hz Hertz

IVD In vitro diagnostic medical device

kg Kilogramme

l Litre

ml Millilitre

SN Serial number

- 4 - 2 Warning, safety and other notices

EUROIMMUN

Medizinische

Labordiagnostika

AG

3 Introduction

This document is used to explain the Sprinter XL. After familiarising himself with

this manual, the operator should be able to operate the Sprinter XL safely.

Figures and illustrations may deviate slightly, depending on the configuration of

the instrument.

3.1 Intended use

The Sprinter XL provides fully automated processing of microscope slides for

indirect immunofluorescence, from sample preparation to the final washing step.

ELISA and EUROASSAYS for in vitro determination of human autoantibodies in

serum or plasma in autoimmune diagnostics, infectious serology and allergology

may also be processed with this device. The test systems are provided by

EUROIMMUN AG. The system was developed for use in diagnostic institutions.

The results should always be checked for correctness by medically qualified

personnel. For diagnosis, the clinical symptoms of the patient should always be

taken into account along with the serological findings.

The instrument should be operated in a fixed place under laboratory conditions

and can be used several times a day. The instrument should only be used by

trained personnel.

For IVD compliant use of the Sprinter XL, all test methods and kits must be

validated by the user in conjunction with the device. Here the usual clinical

laboratory practice, locally applicable laws and the current state of the art are to

be observed.

3.2 Validation

Proper functioning of the instrument was tested using representative test systems

from EUROIMMUN AG.

Changes of any kind to the Sprinter XL, the software or the firmware

invalidate the warranty for the instrument and result in the loss of IVD

conformity.

Only CE-labelled test kits may be used for clinical diagnostic applications.

3 Introduction - 5 -

EUROIMMUN

Medizinische

Labordiagnostika

AG

4 Safety notes

4.1 General

Heed all warnings and follow all instructions listed on the instrument and in

the operating manual.

The instrument should only be used by trained personnel.

It is very strongly recommended that all first-time users familiarise themselves

with the manual before using the instrument.

The instrument should only be used according to its intended use.

Only the consumables and accessories (e.g. dilution plates etc., see Chapter 11)

described in the manual should be used. The manufacturer is not liable for

damages which result through negligence or improper operation of the

instrument.

The user should perform exclusively the service described in the

corresponding chapter.

Only parts approved by the manufacturer may be used for procedures carried out

on the device.

The tests and service prescribed by the manufacturer should be performed to

ensure the safety of the user and the proper function of the instrument.

Procedures and service to the instrument listed in this manual may only be

performed by trained, qualified and authorised service personnel.

The system was developed and tested according to the provisions of the

IVD directive.

Unauthorised procedures invalidate all claims against the warranty. Unauthorised

procedures performed on the instrument result in the invalidity of the

manufacturer’s conformity statement. In this case, the responsibility to meet the

applicable regulations lies solely with the customer.

The instrument should only be opened, serviced and repaired by trained,

qualified and authorised personnel.

ELECTRICAL SAFETY

Applicable laws must be followed for the safe electrical operation of the

instrument.

The Sprinter XL may only be operated with the voltage source which is noted on

the nameplate. If you are unsure whether the voltage is suitable, please contact

an authorised seller or your local energy utility.

A 3-pin cable must be used to connect the instrument to the mains network.

Only use an extension cable with a protective conductor and an earth connection.

You must ensure that the system and its peripheral devices are equally earthed.

Earth contacts may never be interrupted.

If the protective conductor inside or outside of the instrument is interrupted or the

connection is broken, there is a risk of an electrical shock.

- 6 - 4 Safety notes

EUROIMMUN

The instrument must be connected to the power supply with the included

connection cable.

For the international market only: Please note that the cables provided with

this device are adapted for the German market. In some countries it may

therefore be necessary to use other cables instead.

Do not place anything on the mains connection cable.

If safe work can no longer be assured, the instrument is to be switched off

and disconnected from the power supply.

If liquid gets into the instrument, the instrument should be switched off and

disconnected from the power supply. The corresponding parts are to be

cleaned and dried.

Surfaces (floors, work surfaces) must be dry when working with the

instrument.

Medizinische

Labordiagnostika

AG

Only use bottles, tubes and accessories which are explicitly intended for the

storage of liquids and for the system.

Replacement fuses must meet the specifications (nominal voltage, nominal

current strength, type) of the manufacturer.

Always replace burnt-out fuses, never repair.

Never short-circuit fuse sockets.

The instrument is to be switched off and disconnected from the power

supply before service jobs.

Only connect the instrument to the mains supply if this is expressly required. If

the instrument is connected, procedures performed on components with an open

cover should only be carried out with the greatest care.

Never remove safety devices or safety components.

Electrical connection parts (sockets, jacks etc.) can be live (carry current).

Some electrical components like condensers can still be under voltage even

when the instrument has been shut off. All parts which are live can trigger

electrical shocks and are therefore a potential source of danger.

During installation of the instrument you should ensure that it can easily be

disconnected from the power supply in the event of an emergency.

The instrument meets all requirements of standard IEC 61326.

4 Safety notes - 7 -

EUROIMMUN

MECHANICAL SAFETY

Never place the instrument on an instable table, carriage or similar item. The

instrument can fall and suffer considerable damage as a result or injure the user.

Please comply with the section in the service manual on instructions regarding

lifting and transporting the instrument.

Never open the hood while the instrument is running and never reach into

Medizinische

Labordiagnostika

AG

the work area.

There is always a potential risk of injury through mechanically moving parts with

all automated machines in operation. The instrument is constructed for automatic

processing without any required intervention by the user during operation. The

cover must always remain closed during operation.

By default, a sensor is activated which detects when the cover is open so that the

instrument is automatically paused.

If no sensor is activated, ensure that the pipetting unit is idle when opening

the flap or cover before you reach into the work area.

There is a risk of limbs being crushed or pinched while the robotic arm is in

motion. There is also a potential risk of injury from the pipette tip.

Only reach into the instrument when it is paused and a dialogue window

prompts you to do so. Reaching into the instrument while it is running can

result in injuries and/or affect incubation.

Read all software error messages attentively in the event of an error and perform

the next action carefully.

Avoid coming into contact with the pipette and other moveable parts while the

instrument is in operation. Improper handling can result in damage to the

instrument or injure the user.

BIOLOGICAL SAFETY

- 8 - 4 Safety notes

Infection risk!

Handling of samples and reagents:

Avoid skin/mucous membrane contact with samples/test reagents or instrument

parts which come into contact with samples/test reagents. The aforementioned

items should be handled as potentially infectious material.

Direct contact with reagents can result in irritations of the skin and mucous

membrane.

Wear appropriate gloves, a lab coat and eye protection (e.g. safety

glasses)!

The safety equipment provides protection from contamination with patient sera

when loading and unloading the machine.

Follow the instructions in the test kit enclosure to ensure correct usage of the

reagents.

EUROIMMUN

If sample material is spilled in the system, the instrument should be

disinfected and cleaned immediately.

No guarantee can be made regarding the resistance of reagent vessels and tube

materials (system liquid and waste) to organic solvents. Therefore organic

solvents should only be used if they are explicitly allowed.

Containers for liquids and waste cannot be autoclaved!

SAFETY MEASURES

It is important that the work area of the Sprinter XL is constructed as described in

the manual. Ensure that there are no unnecessary items in the work area.

The liquid waste container should be emptied on a daily basis to avoid an

overflow of the washing station when rinsing the needles. This results in the

contamination of the instrument and can have a negative effect on following

incubations. Ensure that the tube leads directly from the needle washing station

straight down into the waste tank, pointing downward, without loops and kinks.

Always ensure that all other tubes are free of kinks and links.

Medizinische

Labordiagnostika

AG

Always ensure that the system liquid container is adequately filled with system

fluid. The minimum is a litre. Always also ensure that the container is at the same

height as the instrument.

The Sprinter XL must be positioned in such a way that the user can hear

the alarm generated by the PC in the event of an error and can act

accordingly.

The Sprinter XL must be connected to an uninterrupted power supply system

(UPS). In the event of a power outage, this ensures that the instrument can still

work for an additional 30 minutes. It also ensures that the voltage peaks are

filtered and any potential danger to the instrument from voltage fluctuations is

minimised.

The computer keyboard must be placed within reach of the instrument in order to

ensure fast access to the escape key in the event of an emergency stop.

The continuous worklist cannot be reconstructed following a power outage.

Local accident prevention regulations and the national industrial safety

regulations apply in addition to the instructions in this manual.

4 Safety notes - 9 -

EUROIMMUN

4.2 Instrument safety and EMC

The Sprinter XL was constructed, manufactured and inspected according to

standard EN 61010-1. The system has left the factory in flawless condition in

terms of safety.

The Sprinter XL meets the requirements of the IVD directive 98/79/EC “In vitro

diagnostics directive” of the European Union.

Conformity with the above EC directive is documented by the CE label.

4.3 Photobiological safety

The Sprinter XL includes a barcode reader for reading of samples. The barcode

reader works with a LASER. The LASER is assigned to class 2 according to

EN 60825-1:A2:2000.

Optional a 2D-Barcode reader for reading the Slide ID can be ordered. The 2Dbarcode reader works with a LED, The LED is assigned to class “exempt risk

group” according to EN 62471.

The light emitted from this LASER/LED can cause damage to the eyes.

Medizinische

Labordiagnostika

AG

Do not look directly into the light path of the barcode readers!

4.4 Position of the safety labels and the nameplate

If one of the safety labels gets lost, it should be replaced by a comparable

one!

GENERAL DANGER LABELS

General danger labels are located on:

o the moveable robotic arm

o the rear panel next to the power connection

“BIOHAZARD” LABELS

“Biohazard” labels are located on:

o the moveable robotic arm with the pipetting needles

o the waste container

“LASER HAZARD” LABELS

“Laser hazard” labels are located on:

o the integrated barcode reader on the left side panel

o barcode reader for Slide ID on 2D barcode reader, if installed

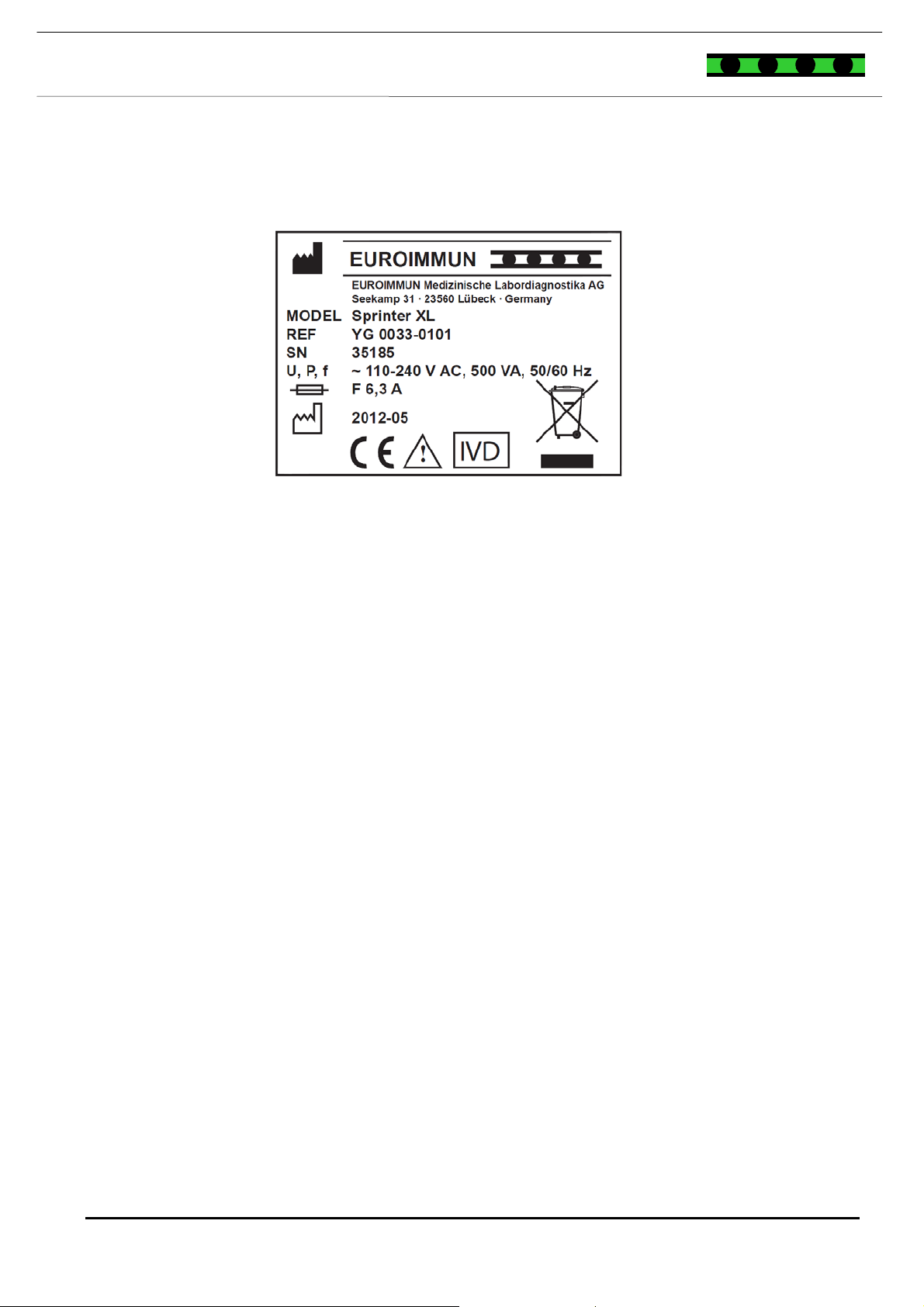

NAMEPLATE

- 10 - 4 Safety notes

EUROIMMUN

The nameplate is located on the left side panel of the instrument next to the

integrated barcode scanner.

The manual should be kept near the instrument and must be accessible to

the user at all times.

4.5 Maintenance

The instrument is to be switched off and disconnected from the power

Medizinische

Labordiagnostika

AG

supply for cleaning or disinfection.

Liquid detergents or disinfectants may neither be shaken nor sprayed into

the instrument.

Use a cloth dipped into a detergent for cleaning or disinfection. Only use

approved detergents or disinfectants. The applicable regulations are to be

followed for cleaning or disinfection.

4.6 Disposal

Potentially infectious material and all parts which can come into contact

with potentially infectious material must be disposed of according to the

applicable legal provisions.

All parts which are replaced must be disposed of according to applicable laws.

The instrument must be disposed of according to applicable laws. The packaging

material must be disposed of according to applicable laws.

Do not reuse dilution blocks.

4 Safety notes - 11 -

EUROIMMUN

4.7 Warranty notes

The Sprinter XL, including its original accessories, may only be used for the

analytical methods described in this manual. Please observe the following

warranty notes for the Sprinter XL:

- The manufacturer guarantees that the instrument has no material and

- The warranty period is 12 months following the installation date.

- You must inform us of any defects immediately and do everything

- If EUROIMMUN AG is informed of such a defect, it is obligated to remove

- No guarantee is provided for defects caused by natural wear (wearing

EUROIMMUN AG is not liable for damages which result from:

- Failure to follow this manual,

- Improper operation or negligence,

- Improper usage,

- Usage by non-qualified personnel,

- Usage of non-approved spare parts,

- Self-made retrofits or interventions by the user,

- Non-approved deactivations of safety devices.

Medizinische

Labordiagnostika

AG

production defects when delivered.

possible to minimise the damage.

it; it is EUROIMMUN’s decision whether it does this by repairing the

instrument or by delivering an instrument free of any defect.

parts in particular) or improper use.

- 12 - 4 Safety notes

EUROIMMUN

Medizinische

Labordiagnostika

AG

5 General information on the instrument

The Sprinter XL is a system with a modular structure which allows the automatic

processing of IFA microscope slides and ELISA microplates, from sample

preparation to the final washing or measuring step.

The system is able to detect and identify sample barcodes.

An archiving function of the results is present and is managed with the

RepExplorer program.

5.1 Technical data

System

Max. load

Accessories 8/12 sample racks (each with 20 positions Ø 10-16 mm)

Pipetting unit

Needle system 4 washable needle (ceramic-coated)

Level detection

Clot detection Yes

Needle volume 5-1000 µl increments of 1 µl

Precision CV < 1% with a volume > 20 µl

Wash unit

160/240 samples (depending on device configuration)

Capacitive, sensitivity 200 µl

162 screening dilutions, individually configurable

192 titer dilutions, individually configurable

30 microscope slides/6 microplates (depending on device

configuration)

64/49 standards/controls (depending on device configuration)

20/12 secondary reagents (depending on device configuration)

6/9 sample buffer (depending on device configuration)

4 wash buffer

(depending on device configuration)

4/1 control/standard racks (each with 16/49 positions Ø 18 mm)

(depending on device configuration)

2/1 reagent racks (each with 10/12 positions Ø 30 mm)

(depending on device configuration)

1 sample buffer rack (with 6/9 positions Ø 45 mm)

(depending on device configuration)

2 containers for wash buffer 2 l and 4 l

1 container for liquid waste 10 l

1 container for system liquid 5 l

Station for system liquid

(NaCl solution in 16 mm tubes)

2% with a volume of 10 µl

5 General information on the instrument - 13 -

EUROIMMUN

Wash method Flooding the microscope slides in a 5-slide tray/strip-by-strip

Washer head 8-channel washer head

Reader

Software

Number of saved tests Unlimited

Number of steps in a test Unlimited

Duration of the incubation step 1-1000 minutes in increments of 1 min each

Combinability Unlimited (depending on device configuration)

Dilutions 13 freely definable dilutions per test

Processing steps Dilution and transfer

Miscellaneous

Barcode scanner CCD camera (semi-aut omatic)

Pump Highly precise micro-gear pump

Optional accessories Covers for microscope slide racks

System

Operating system Microsoft Windows XP SP2/Windows 7 (32 Bit)

Hardware Dual core processor with 1.6 GHz or higher

Connection CAN bus on USB 2.0 port

Bidirectional communication ASCII, XML, optional HL7

Current/Voltage

Current supply 110-240 V AC

Power consumption

Medizinische

Labordiagnostika

AG

washing of ELISA plates

8-channel photometer. Measurable wavelength range 400-800 nm.

4 filters (405, 450, 492, 620 nm)

Incubation, shaking, heating,

Washing

Dispensing

Measuring step

Heating plate, shaker,

Manual and integrated 2D-Barcode-Scanner,

ELISA reader, instrument cover

1 GB RAM

15’’ monitor (resolution > 1280 x 1024 pixels)

50/60 Hz

max. 2 A

max. 500 Watt

- 14 - 5 General information on the instrument

EUROIMMUN

Physical

External dimensions 112 cm (B) x 85 cm (T) x 55 cm (H)

Weight Approx. 150 kg

Temperature 15°C to 30°C

Relative humidity

Noise emission 56 dB (max.)

Medizinische

Labordiagnostika

AG

10 to 85% at 30°C

5 General information on the instrument - 15 -

EUROIMMUN

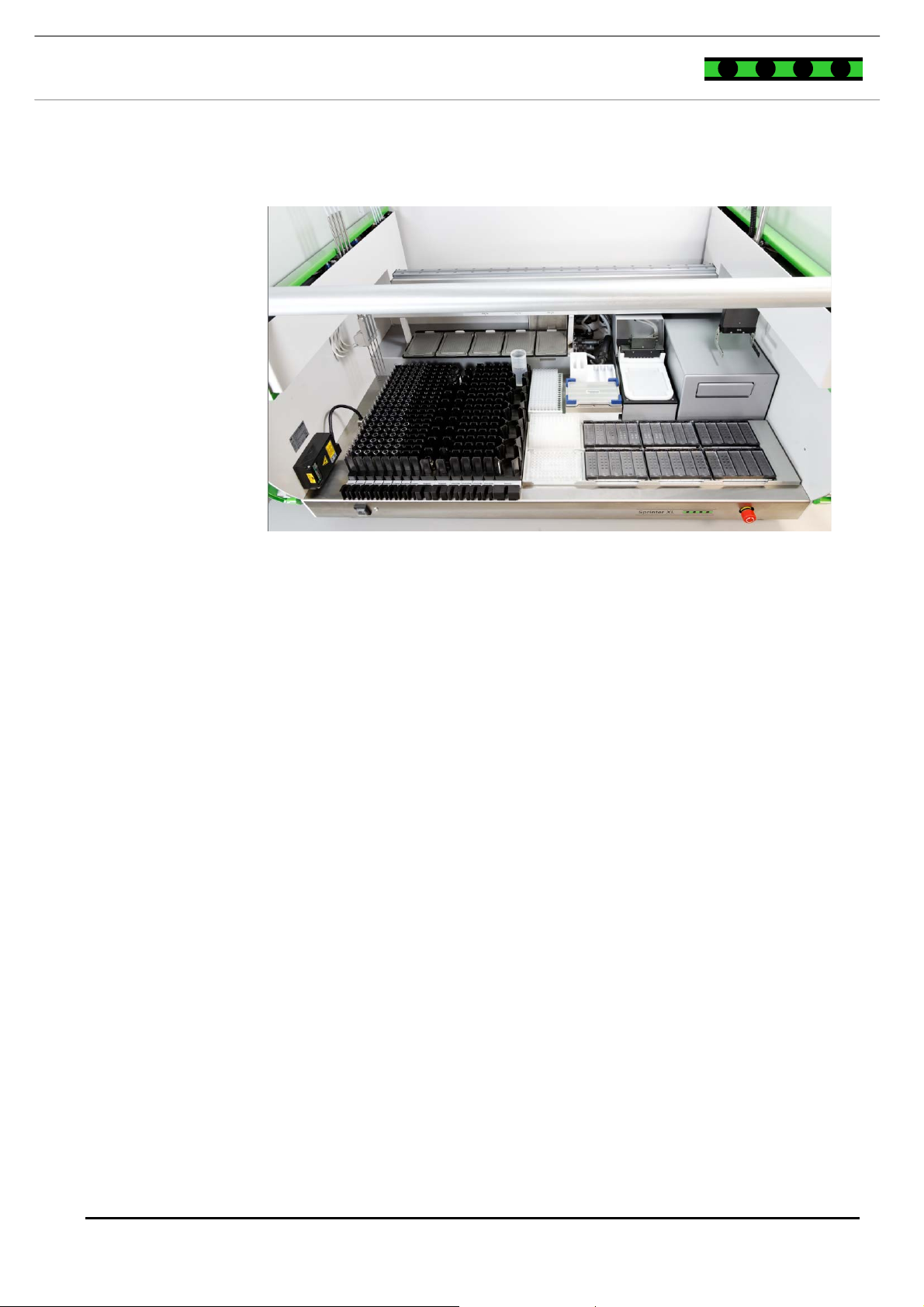

5.2 Instrument description

The moveable robotic arm guides four washable pipetting needles, which pipette

the samples and reagents. The fullness levels of the individual liquids are

determined via a capacitive measurement system.

On the robotic arm there is a gripping system to transport microscope slide

racks/microplates and to guide the washer head.

A barcode scanner system reads and detects the barcodes of the fed samples.

Samples and reagents are loaded into the instrument via slide racks.

Optionally, a manual or integrated 2D-Barcode-Scanner can be used for reading

barcode on slides.

The washing unit consists of 8 coaxial dispensing and aspirating channels and

4 wash buffer feeding channels.

There is also an area to create initial dilutions in a dilution tube (2 ml) and an

area for the creation of serial dilutions in a microplate.

In the middle of the instrument there is a shaker that serves as pipetting station.

Medizinische

Labordiagnostika

AG

There are generally 6 positions for microplates or microscope slide racks, which

can be each equipped with up to 5 standard slides or with a 50 well slide. A

combination of slide racks and microplates is also possible. A cover for standard

slide plates during incubation is optionally available.

The cover flap of the instrument can be conveniently flipped up or down to allow

the user to gain access to the inside of the instrument for handling and service.

A PC with the corresponding software is available to select and edit the tests.

The software allows the user to edit pre-defined tests. The clear structure with

intuitive user prompts makes system operation easy and rapid for daily usage.

A serial cable connects the instrument to the PC via a USB dongle. The power

supply of the instrument is guaranteed via an integrated switch mains adaptor

according to the technical specifications. The supply connection is located at the

back left of the instrument. The power switch is located to the front left of the

instrument. The emergency stop is front right.

In addition, a personal computer, a computer mouse, keyboard, LCD monitor and

a laser printer and, optionally, a device table are part of the equipment.

- 16 - 5 General information on the instrument

8

15

12

EUROIMMUN

FRONT VIEW IMMUNOFLUORESCENCE

Medizinische

Labordiagnostika

AG

16

6

5

4

2

1

14

1 Integrated barcode scanner

2 Sample racks 8x

3 Reagent racks 2x

4 Control racks 4x

5 Buffer rack 1x

6 Initial dilution plate

7 Titer dilution plate 2x

8 Shaker/Pipetting station

9 Incubation positions for microscope slide plates 6x

10 Washing module

11 Photometer module

12 Needle washing station

13 Emergency stop

14 On/Off switch

15 Accessory module with 5 incubation positions

16 Moveable arm with 4 pipetting needles

17 Moveable arm with gripper

3

7

Figure 5-1: Sprinter XL – Standard configuration IFA

10

9

17

11

13

5 General information on the instrument - 17 -

EUROIMMUN

4

17

FRONT VIEW ELISA

Medizinische

Labordiagnostika

AG

16

2

1

1 Integrated barcode scanner

2 Sample racks 8x

3 Reagent racks 2x

4 Standard/Control rack 4x

5 Sample buffer rack 1x

6 Dilution area 1

7 Dilution area 2

8 Needle washing station

9 Shaker/Pipetting station

10 Microplate incubation positions 6x

11 Washing module

12 ELISA photometer

13 More microplate incubation positions/37°C

14 Emergency stop

15 On/Off switch

16 Moveable arm with 4 pipetting needles

17 Moveable arm with gripper

14

13

6

3

Figure 5-2: Sprinter XL – Standard configuration ELISA

5

4

8

7

11

9

10

12

15

- 18 - 5 General information on the instrument

6

13

15

EUROIMMUN

FRONT VIEW ELISA/IFA COMBINATION

Medizinische

Labordiagnostika

AG

13

8

9

5

4

2

1

1 Integrated barcode scanner

2 Sample racks 8x

3 Reagent racks 2x

4 Standard/Control racks 4x

5 Sample buffer rack 1x

6 Initial dilution area

7 Serial dilution area

8 Needle washing station

9 Shaker/Pipetting station

10 Microplate incubation positions 6x

11 Washing module

12 ELISA photometer

13 Incubation positions for microscope slide plates 5x

14 On/Off switch

15 Emergency stop

14

Figure 5-3: Sprinter XL – Standard configuration ELISA/IFA

3

7

11

12

10

5 General information on the instrument - 19 -

EUROIMMUN

NAMEPLATE

Medizinische

Labordiagnostika

AG

Figure 5-4: Nameplate

- 20 - 5 General information on the instrument

EUROIMMUN

Medizinische

Labordiagnostika

AG

6 Installation process

This chapter provides the information required for instrument installation.

6.1 Scope of delivery

The scope of delivery of the Sprinter XL includes:

o Sprinter XL, microscope slide racks with a cover

o Slide racks for samples and reagents

o PCAN bus system, USB dongle, network cable

o Container for wash buffer 2 l and 4 l

o Waste container 10 l

o Container for system liquid 5 l and matching station

o Tweezers, cleaning brush, reagent vessels

o Sprinter XL manual, maintenance manual and quick-start manual

o Personal computer with monitor, mouse, keyboard and printer

o Speaker

o Optional: ELISA reader, 37°C incubation module

If parts are damaged, please contact the relevant field service employee or

EUROIMMUN AG.

6.2 Unpacking, transport, storage

Please observe the following safety notes when unpacking, transporting and

storing the Sprinter XL:

o The Sprinter XL is supplied in a wooden case on a pallet. Check the

container for damage before opening.

o When unpacking, use the delivery note to ensure that all system

components are present.

o Ensure transport and storage temperatures in accordance with the

technical data.

o Place the system onto a stable work surface.

o Compare the serial number of the instrument on the nameplate to the

side with the serial number on the delivery note.

o Check the instrument for visibly loose, bent or broken parts.

o Retain the packaging for longer storage periods or to return the

instrument to the manufacturer.

When unpacking, use the scope of delivery described in section 6.1 to

6 Installation process - 21 -

ensure that all system components are present.

EUROIMMUN

6.3 Ambient conditions

The instrument is intended for use in closed rooms. Select the installation

location in such a way that the instrument is protected from dust, vibrations,

strong magnetic fields, direct sunlight, a high level of moisture and large

temperature fluctuations.

Operating temperature +15°C to +30°C

Warehouse temperature 15°C to 30°C

Max. installation height for

operation

Max. relative moisture

Medizinische

Labordiagnostika

AG

10% to 85% at 30°C, no condensing moisture

NOTE: If the instrument was subjected to temperatures outside of

this area, it may only be operated again once the prescribed

temperature range has been reached. Premature commissioning

can damage the instrument.

Up to 2000 m over sea level

6.4 Installation and commissioning

Commissioning and installation of the Sprinter XL may only be performed

by an authorised service technician of EUROIMMUN AG.

o Place the instrument on the work surface in such a way that the main

switch and the emergency stop are easily accessible. The instrument

should be as free-standing as possible to ensure the installation and

other handling of the system for system liquids and the wash buffer

container. Also enough space is required to flip the instrument cover up.

o Remove all packaging materials and clean the instrument.

o Align the instrument horizontally using a spirit level. The instrument can

be adjusted with the bottom adjustable feet.

o Connect the system liquid tube to the pipetting needles and attach them

with the headless screw. Ensure the correct orientation of the pin on the

needle!

o Insert the shaker module and connect it to the instrument connections

using the black connecting cables. Pass the cables under the needle

washing station.

o The waste tubes of the needle washing station and the washing module

exit the instrument on the right. Lead both tubes to the waste container.

The tubes should not be too long or droop!

o Place the station for system liquid to the right next to the instrument.

Use the inserts and the end of the system tube with the filter, fill the

container with system liquid and place it on the station. Connect the

station with the mains adapter to the power supply and turn it on.

Connect the system tubes to the station.

o The containers for the wash buffers are placed to the side and the wash

buffer tubes are inserted.

o Only connect the instrument with the USB dongle to the PC once the

required software and the driver have been installed.

- 22 - 6 Installation process

Loading...

Loading...