Euroheat Harmony evolution H13, Harmony evolution H23, Harmony evolution H33, Harmony evolution H43, Stanford evolution S13 Installation Instructions Manual

...

PART NUMBER

SERIAL NUMBER

Installation Instructions

Harmony evolution

H13,H23,H33,H43

Stanford evolution

S13,S23,S33,SP23,SP33

IN1115 Edition G8 July 2012

This Manual Must Always Be Available To The Stove Operator

This manual must be used in

conjunction with document IN1173.

The Wood and Mutlifuel Chimney

and Installation Guide.

Nestor Martin/Efel

© EUROHEAT DISTRIBUTORS (H.B.S) LTD July 2012 E & OE Instructions Part number IN1115 Edition G7

2

IMPORTANT

.

The installation of this appliance must comply with all local regulations, including those referring to national

and European Standards before it can be operated. The stove is not suitable for a shared flue. However, for England

and Wales, only, the coming into force on 1st April 2002 of SI 2002 No 440 exempts the householder from this legal

requirement for the installation of solid fuel fired appliance whose rated heat output is 50kW or less in a building

having no more than 3 storeys (excluding any basement) if a Competent Engineer is employed who is registered

under the Registration Scheme for Companies and Engineers involved in the Installation and Maintenance of

Domestic Solid Fuel Fired Equipment operated by HETAS Ltd. These registered Competent Engineers may also carry

out associated building work necessary to ensure that the installed appliance complies with Building Regulations

without involving the Local Authority Building Control Department. The installing engineer should refer to BS

8303: Code of practice for installation of domestic heating and cooking appliances burning solid mineral fuels.

Improper adjustment, alteration, maintenance or the fitting of replacement parts not recommended by

the manufacturer can cause injury or property damage. Do not operate the stove with faulty seals or damaged

glass.

Due to the high operating temperatures of this appliance it should be located away from pedestrian traffic

and away from furniture and draperies. Do not store paper or wood near the appliance. Any mats and rugs put

in front of the stove should be fire proof and secured to prevent the possibility of tripping.

Advise all persons as to the stove’s high surface temperatures. If it is possible for children or infirm adults to

come into contact with the stove, fit a suitable fire guard.

It is imperative that all air passageways into, out of, and within the appliance are kept clean. All permanent

ventilation into the room provided for the stove must remain clear and unobstructed at all times. Consideration must

be given to the need for extra ventilation if another heating source needing air is to be operated simultaneously.

If an extraction fan is proposed to be fitted to a connecting area of the house, after the stove has been installed,

professional advice should be sought from a qualified engineer.

The user should be advised that the appliance should be inspected regularly and the chimney cleaned at least

annually.

More frequent cleaning may be required and the advice of a qualified chimney sweep should be sought.

Our range of stoves is capable of operating with outstanding efficiency if the flue system is correct. Because

so little heat is wasted to the flue it is possible that moisture within the products of combustion will condense if

the heat losses within the flue way are too great and allow the flue gases to cool. For this reason we recommend

that the stove is fitted with a suitable flue liner, the same diameter as the flue spigot, to prevent the possibility of

acidic damage to the fabric of the chimney and damage to the stove which will reduce the longevity of the stove.

The flue pipe and chimney flue diameter must at no point be less than the diameter of the stove flue outlet. The

installing engineer should refer to BS EN 15287-1:2007 design, installation and commissioning of chimneys.

When correctly installed, the stove is designed to produce heat, safely. It cannot do so if the installation is

less than absolutely stable, constructed of materials suitable for such an installation and consideration has not

been given to the possibility of people with less than ideal common sense operating it.

Have the existing chimney swept by a chimney sweep. Although you will be lining the chimney, any deposits

left in the chimney will cause problems and may become a fire hazard.

Your attention is drawn to the precautions and responsibilities under the Health and Safety at Work Acts,

and whatever new legislation being introduced during the life of this document. Especially to the possibility of

disturbing asbestos when disturbing structures in older properties. Also the caustic nature of fire cement. The

personal risk of injury when moving heavy items with possible sharp edges.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. July 201s E & OE Instructions Part number IN1115 Edition G8

3

The Model Range Explained

Efel and Euroheat insist on progressive development to produce products which are market leading. Our aims are

to produce stoves with the latest innovations, user friendly operation and highly efficient for lower cost operation.

See data table for smoke control exempt and HETAS approved models.

This manual offers installation information for the Evolution range of HARMONY H13, H23, H33, H43. STANFORD

S13, S23, S33, SP23, SP33. In some cases you find references in this document to the model size rather than

the models exterior design. There are four sizes of appliances, 13, 23, 33, 43. The 13 is the smallest and the 43

the largest. Although the exterior clothes change between model ranges, for example the Harmony 23 and the

Stanford 23, the internal workings are the same. Exceptions: The SP models are fitted with a top hot plate for

warming operations.

Model Identification

You will see on the front page of this document a label which confirms which model you have. This label also

advises you of the stoves unique serial number. This information is also attached to your stove for reference.

Important

Please ensure the warranty registration form is completed if you are the installer and confirm with the user that it

is there responsibility to return it to Euroheat. In this way the model and its history will be recorded for reference

in the future.

For the latest versions of manuals, technical information, accessories and spare parts visit the Euroheat web

site.

Stoves supplied through Euroheat authorized retailers.

For England, Wales, Scotland and Northern Ireland

Euroheat Distributors (H.B.S). Ltd.

Unit 2,

Court Farm Business Park,

Bishops Frome,

Worcestershire. WR6 5AY.

www.euroheat.co.uk

info@euroheat.co.uk

Whilst Euroheat are always happy to assist, please ensure you have read this manual and the chimney and

installation guide IN1173.

First contact your supplying retailer for assistance. If you find this not successful contact the Euroheat Technical

support team. Technical support telephone Number 01885 491117. E-mail tech@euroheat.co.uk.

Before telephoning ensure you have the stoves serial number to hand and that you are a Registered Competent

Engineer. If you are not a registered engineer seek one for assistance. A list of engineers can be obtained from

HETAS.

Euroheat unfortunately are not able to offer support for appliances which where not supplied by Euroheat.

Stoves supplied through Eireheat authorized retailers.

For Eire

Sean Murphy Heating Ltd

Kinvara

Co Galway

Eire

www.eireheat.com

sales@eireheat.com

(091)637701 Fax: (091)637797

International +353 91637701

For support for appliances supplied through Eireheat in Ireland please contact using the

details listed above.

Thermic Distribution Europe Sa

11 Rue De Lion

B-5660

Frasnes Les Couvin, Belgium.

www.nestormartin.com

© EUROHEAT DISTRIBUTORS (H.B.S) LTD July 2012 E & OE Instructions Part number IN1115 Edition G7

4

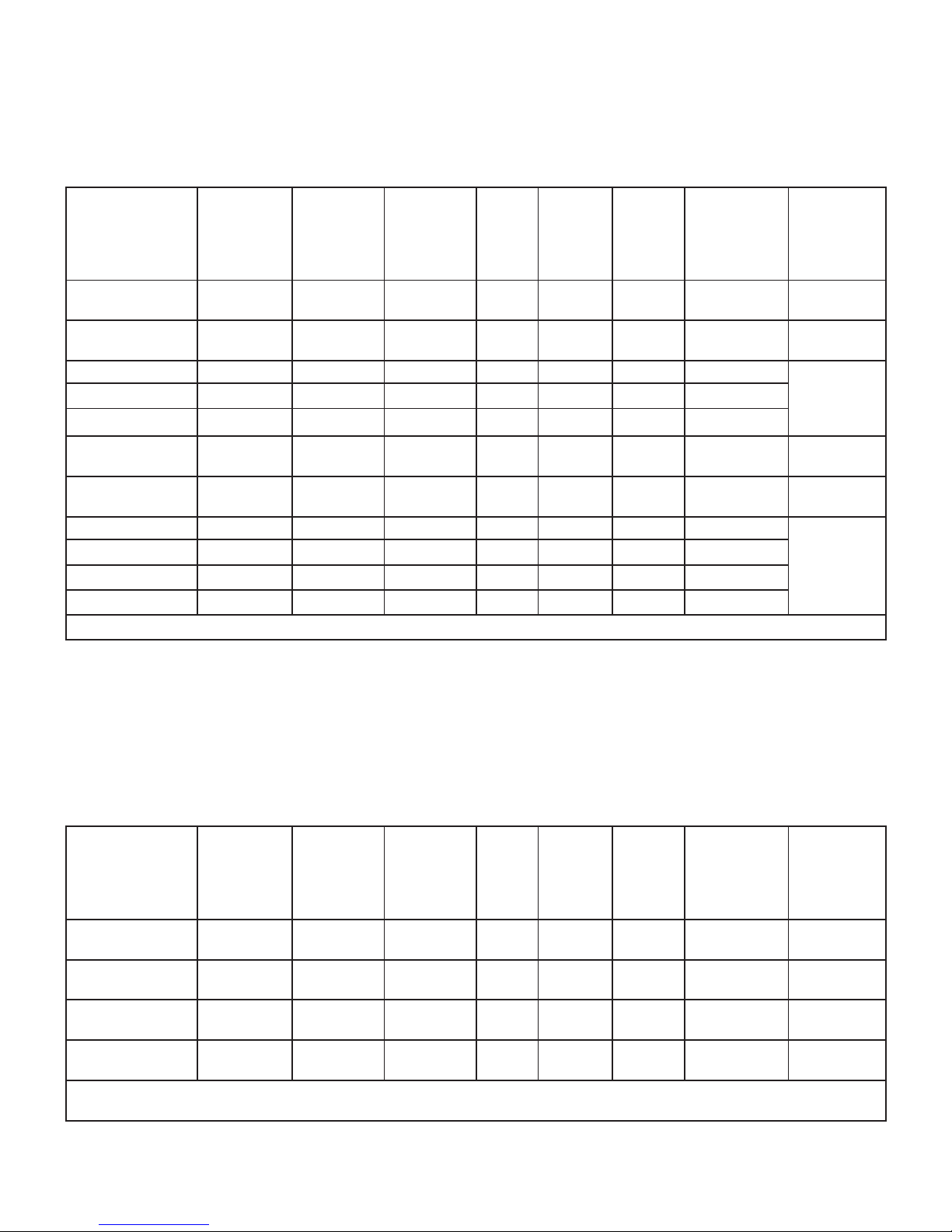

Technical Details Intermittent Operation

Intermittent operation is when the appliance is used for short firing periods for example 45 minutes to 2 hours.

This is a common operation in warmer weather such as cold spring evenings. The information provided below

where indicated as HETAS approved is from the current CE standards EN 13240:2001 and EN 13240 A2:2004. The

test fuel for wood burning, Beech, for Coal burning Anthracite.

Model Name

Model

Number

Heat Output

Nominal

Wood

Heat Output

Nominal

Coal*

Weight KGFlue

Draught

Nominal

Flue Gas

Mass

Flow g/s

Flue Gas

Temperature

Down Stream

of Flue Spigot

deg C

Efficiency

with

Top Flue

Connection

Harmony 13 Wood

H13* 5.0kW 96 12pa 4.9 350

77.1% Net

70.2% Gross

Harmony 13 Coal

H13* 3.5kW 96 12pa 3.8 210

82.8% Net

75.4% Gross

Harmony 23 H23* 7.7kW 7.7kW 124 12pa 7.7 326 See smoke

control

exempted

table

Harmony 33

H33**

9.2kW 9.2kW 143 12pa 6.5 305

Harmony 43

H43* 10.5 10.5kW 186 12pa 6.5 357

Stanford 13 Wood

S13* 5.0kW 96 12pa 4.9 350

77.1% Net

70.2% Gross

Stanford 13 Coal

S13* 3.5kW 96 12pa 3.8 210

82.8% Net

75.4% Gross

Stanford 23 S23* 7.7kW 7.7kW 124 12pa 7.7 326

See smoke

control

exempted

table

Stanford SP23 HP

SP23 HP* 7.7kW 7.7kW 132 12pa 7.7 326

Stanford 33

S33**

9.2Kw 9.2kW 146 12pa 6.5 305

Stanford SP33 HP

SP33 HP**

9.2kW 9.2kW 153 12pa 6.5 305

* HETAS Approved ** Awaiting HETAS Approval

Model Name

Model

Number

Heat Output

Nominal

Wood

Heat Output

Nominal

Coal*

Weight KGFlue

Draught

Nominal

Flue Gas

Mass

Flow g/s

Flue Gas

Temperature

Down Stream

of Flue Spigot

deg C

Efficiency

with

Top Flue

Connection

Harmony 13 Wood*

H13 5.4kW 96 12pa 4.9 350

83.4% Net

75.9% Gross

Harmony 13 Coal*

H13 3.5kW 96 12pa 3.8 210

78.3% Net

71.2% Gross

Stanford 13 Wood*

S13 5.4kW 96 12pa 4.9 350

83.4% Net

75.9% Gross

Stanford 13 Coal*

S13 3.5kW 96 12pa 3.8 210

78.3% Net

71.2% Gross

* HETAS Approved

Technical Details Continuous Operation

Continuous operation is when the appliance is used for long firing periods for example several hours and for

overnight operation. This is a common operation in cold weather as experienced in deep winter. The information

provided below is from the current CE standards EN 13240:2001 and EN 13240 A2:2004. The test fuel for wood

burning, Beech, for Coal burning Anthracite.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. July 201s E & OE Instructions Part number IN1115 Edition G8

5

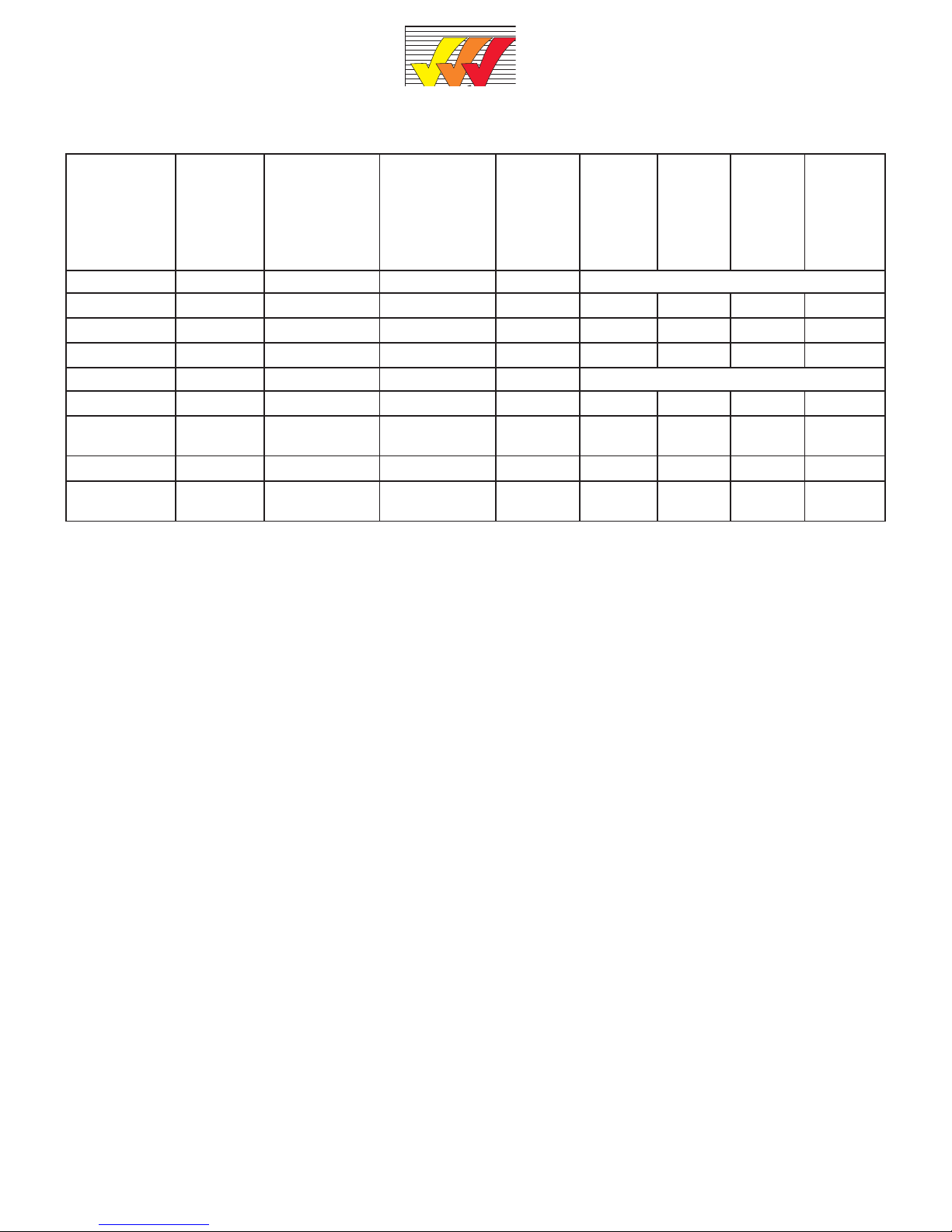

* Free Air Requirement

Air requirement equivalent area. Building regulations Document J, advises that an air supply,permanently open

vents, should be installed for appliances:

If design air permeability >5.0m³/(h.m²) then 550mm²/kW of appliance rated output above 5kW

or

If design air permeability <5.0m³/(h.m²) then 550mm²/kW of appliance rated output

Equivalent air is as measured according to the method in BS EN13141-1:2004

It is unlikely that a dwelling constructed prior to 2008 will have an air permeability of <5.0m³/(h.m²) at 50pa

unless extensive measures have been taken to improve air-tightness.

_

Models indicated above as HETAS approved to a certain flue position are indicated by #

Smoke Control Exempted

Models listed as smoke control exempted have passed the very strict U.K. requirements and can operate in smoke

control zones burning dry seasoned wood.

Model Flue Size

* Free Air

Requirement

Equivalent Area

as Approved

Document J

>5.0m³/(h.m²)

* Free Air

Requirement

Equivalent Area

as Approved

Document J

<5.0m³/(h.m²)

UK Smoke

Control

Exemption

Burning

Wood

Efficiency

Net %

Rear flue

Efficiency

Net %

Top flue

Efficiency

Gross %

Rear flue

Efficiency

Gross %

Top flue

Harmony 13 5” (125mm) Nil* 2750mm

2

Approved See intermittent or continuous operation

Harmony 23 6” (153mm) 1485mm

2

4235mm

2

Approved

78# 72.8#

Harmony 33 6” (153mm) 2310mm

2

5060mm

2

Approved

78

72.8

Harmony 43 7” (180mm) 3025mm

2

5775mm

2 80# 72.8#

Stanford 13 5” (125mm) Nil* 2750mm

2

Approved See intermittent or continuous operation

Stanford 23 6” (153mm) 1485mm

2

4235mm

2

Approved

78# 72.8#

Stanford SP23

HP

6” (153mm) 1485mm

2

4235mm

2

Approved

78# 72.8#

Stanford 33 6” (153mm) 2310mm

2

5060mm

2

Approved

78

72.8

Stanford SP33

HP

6” (153mm) 2310mm

2

5060mm

2

Approved

78

72.8

Carbon Monoxide Alarms

Where a new solid fuel stove is installed in a property a carbon monoxide alarm should be located in the same

room where the appliance is located:

a. on the ceiling at least 300mm from any wall or, if it is located on a wall, as high up as possible (above any

doors and windows) but not within 150mm of the ceiling; and

b. between 1m am 3m horizontally from the appliance.

Carbon monoxide alarms should comply with BS EN 50291:2001 and be powered by a battery designed to

operate for the working life of the alarm. The alarm should incorporate a warning device to alert users when the

working life of the alarm is due to end. Mains-powered BS EN 50291 Type A carbon monoxide alarms with fixed

wiring (not plug in types) may be used as alternative applications provided they are fitted with a sensor failure

warning device.

Loading...

Loading...