Euroheat Harmony 5 Installation Instructions Manual

© Euroheat Distributors (H.B.S) Ltd. 2000 Instructions Part number IN10111 Edition C

1

Serial Number

Part No.

Technical Help Line

For Installation and Service Advice

Telephone 01885 491117

8.30-12.30 and 1.30-5.30 Week days

Fax 01885 491105 Anytime.

Sales 01885 491111

Euroheat Distributors (H.B.S.) Ltd.,

Unit 2, Court Farm Business Park,

Bishops Frome,

Worcestershire,

WR6 5AY.

01885 490474

Installation Instructions for

Harmony 5

Wood and Coal Stove

© Euroheat Distributors (H.B.S) Ltd. 2000 Instructions Part number IN10111 Edition C

2

INTRODUCTION

The purpose of this technical document is to present, on the basis of the laws of physics involved, the importance

of the drawing power of chimneys and other factors on which the satisfactory functioning of wood & coal heating

equipment depends.

Modern building trends: small-sized rooms, sealed windows and door frames, high thermal output equipment, the

observance of health regulations and clean air fuel products require the whole problem to be reconsidered in its

entirety.

We manufacture a complete heating appliance which has to be connected to a chimney for normal operation. That

chimney when being hot must be capable of providing the air necessary for combustion and fully evacuating the

combustion products.

The installer is responsible under the Health and Safety at Work Act 1974 vi the caustic nature of fire cement and

the possibility of disturbing asbestos in existing installations and to suggest appropriate protection to be given to

the person(s) carrying out the installation.

1) This appliance must be installed by a fully qualified heating engineer. He is responsible to ensure that the

installation is in accordance with all currently accepted British Standards and Codes of Practice, particularly BS6461,

CP403 and BS5449, relating to the installation of solid fuel appliances.

2) The stove must be placed at least 40cm away from any combustible materials. If necessary, any adjoining walls

should be protected from the effects of heat.

© Euroheat Distributors (H.B.S) Ltd. 2000 Instructions Part number IN10111 Edition C

3

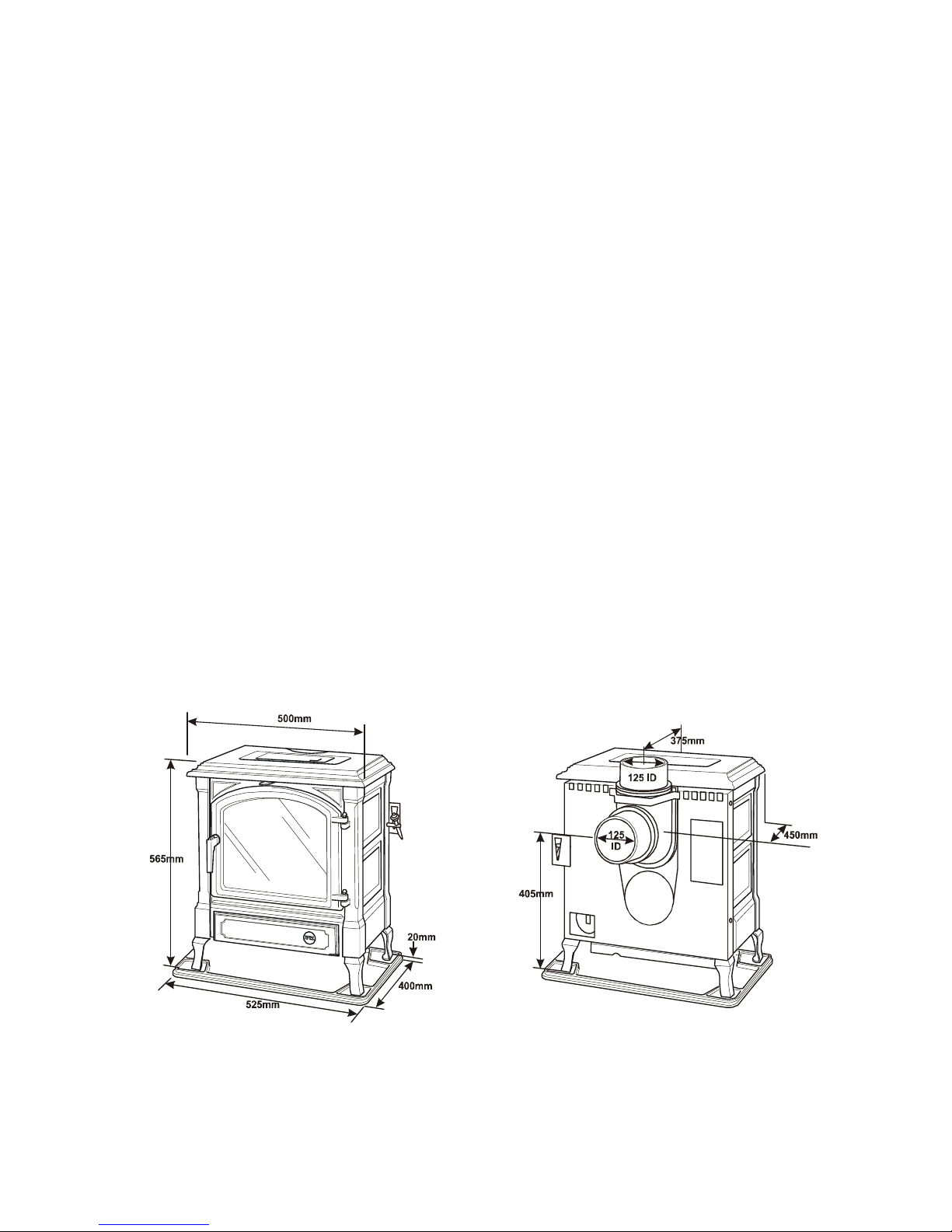

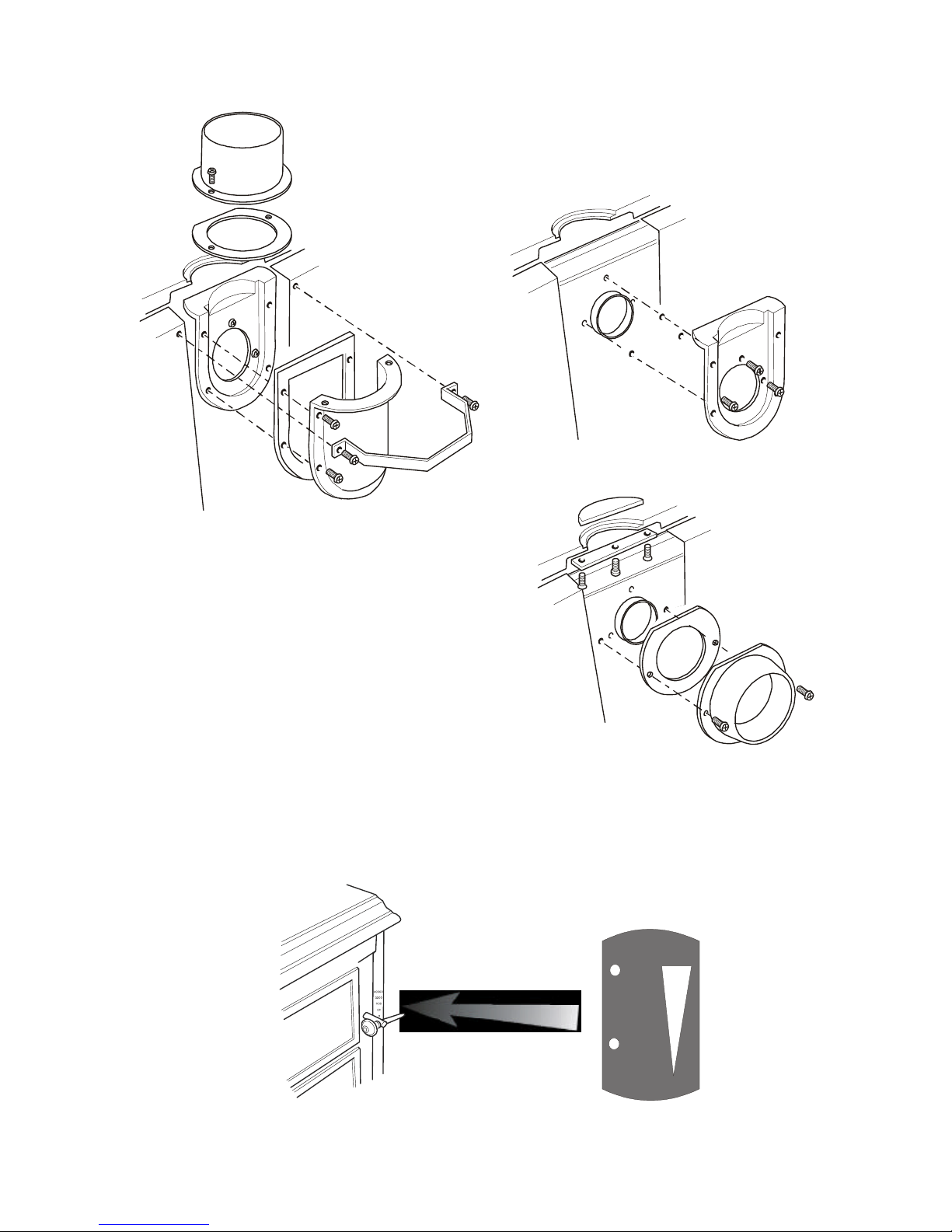

Flue Outlet Options

Optional Front Facing Thermostat Indicator

© Euroheat Distributors (H.B.S) Ltd. 2000 Instructions Part number IN10111 Edition C

4

D. Wind eddies or down-draughts around the top of

the chimney, sometimes due to remote obstacles (hills,

trees, houses, particular architectural arrangements, roof

ridge, etc.) may cause drawing problems.

E. Permanent or temporary excess drawing, also

prejudicial to good combustion (buzzing noise), can be

controlled by a draught regulating flap when excess

draught is experienced at high flow settings. A draught

stabilizer is highly recommended as part of a

standard installation.

F. In all cases the draught of the chimney must be

measured with a draught indicator (gauge) connected to

the flue which runs from the stove to the chimney.

The negative pressure indicated must ideally lie within

the shaded zone on the requirement graph when the

stove is operating smoothly.

Conclusion

Whilst it is obvious that a chimney with adequate drawing

power alone will ensure the satisfactory functioning of

the stove, it should never be forgotten that a large

percentage of problems are caused by faulty drawing

power of chimneys.

CHIMNEY DRAUGHT

For a wood/coal stove to operate normally, it is essential

that the suction of the chimney, which determines the

provision of air to the stove, is continuous and that the

evacuation of the fumes is ensured during combustion.

That is why it is recommended, above all, to check the

state of the chimney to which the stove must be

connected. Once connected it is of the utmost

importance to balance the flue draught to conform the

graph showing draught requirements.

1. THE CHIMNEY

If the chimney is cold, the water in the flue gases will

condense. If it is porous the condensate will appear in

the form of unsightly brown patches on the external

walls of the chimney.

In the event of poor combustion an understanding of

the paragraphs which follow will enable you to solve all

the problems.

A. In naturally aspirated wood/coal stoves the air

necessary for combustion is drawn into the combustion

chamber by the negative pressure of the chimney. The

negative pressure is uniquely due to the fact that the

combustion gases present in the chimney are hot and

lighter than the air outside it. If the chimney is cold,

either because it has not been used for a long time or

because it has no heat insulation or is too short (minimum

4 m), the slow air movement will prevent the flame

burning cleanly. It is always necessary to wait for a while

when there is difficulty in operating until the chimney

has warmed, before deciding that it is the chimney which

is at fault.

B. If inside the house, the stove chimney which is the

natural moving force of the combustion, is competing

with another stronger moving force (the entry of

secondary air into the chimney, another higher or better

insulated chimney, an extractor hood in the kitchen, a

water-heater or a clothes dryer,...) combustion will be

difficult and in the most serious cases smoke and fumes

will even be drawn back into the house. If the house is

too well sealed and the air necessary for combustion

cannot reach the stove, the same malfunction will occur.

In this case, it is not the chimney which is at fault, but

the fact that the room is too well sealed. This is easily

observed by the following symptoms: the flame is weak,

flickers or produces excess smoke. (responds slowly)

The remedy consists of ensuring normal ventilation of

the room in which the appliance is fitted.

This problem can be resolved, in particular, by bringing

in the air necessary for combustion through a pipe of

adequate dimensions leading from outside the premises

close to the stove. Like humans a stove has to breathe.

C. Any obstacle to the easy passage of the combustion

gases through the chimney will be prejudicial to good

drawing and therefore to satisfactory operation. Bends,

turbulence, foreign bodies, dirt, nests, cold walls, etc.see the cases shown in the appended diagrams.

A stable chimney draught within the

required parameters is always required.

© Euroheat Distributors (H.B.S) Ltd. 2000 Instructions Part number IN10111 Edition C

5

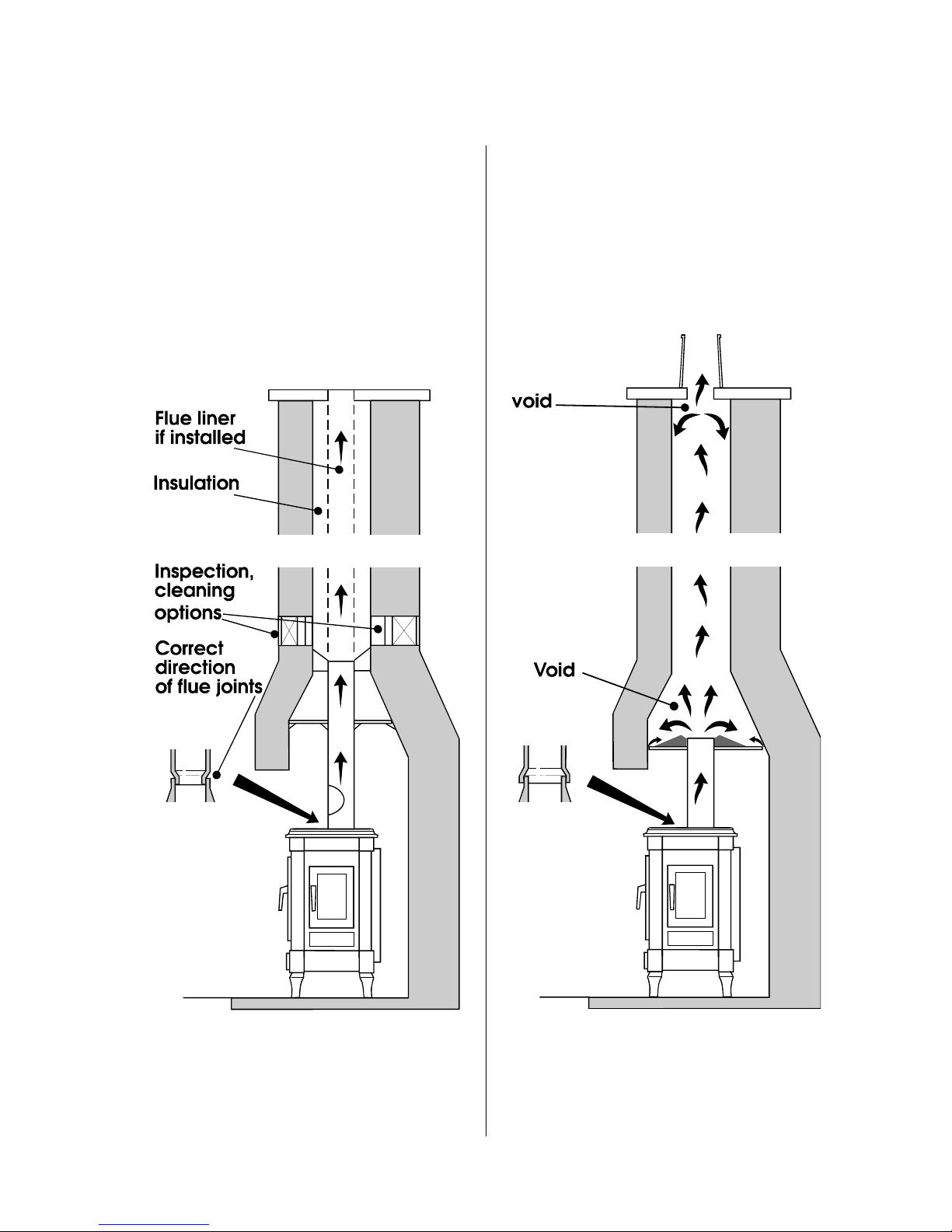

Planning the chimney

A. The ideal chimney should be vertical, smooth, free

of cracks or foreign bodies. The chimney must be swept

before lining or connection.

Good

Poor

B. To prevent throttling, suction cowls (chimney pots),

or anti-down draught devices must not have a smaller

connecting section than the chimney.

2. The chimney and connection

Loading...

Loading...