Euroheat Harmony 44 Installation & Servicing Instructions Manual

PART NUMBER

SERIAL NUMBER

Installation &

Servicing Instructions

Harmony 44

Conventional Flue Gas Stoves

IN1113 Edition E June 2009

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

1

Manufacturers Identification Plate

The identification plate is located under the gas valve.

To access the plate swing outwards.

The Euroheat Appliance Serial Number

The serial number can be found at 5 locations:

1: On the front page of this manual.

2: On the front page of the operating instructions.

3: On the identification plate located under the gas valve.

4: On the registration form.

5: On the registration certificate returned to the user after successful registration.

Contents

Safety Precautions 2

Technical Data for H44 3

Accessories Supplied with Stove 4

Flue and Chimney Requirements 6

Ventilation 6

Example of Stove Fitted into an Existing Chimney 7

Installation of the Gas Supply 8

Appliance Location 8

Installation of the Stove to the Flue System 9

Changing Flue Outlet Direction 10

Hearth and Fireplace Requirements 11

Minimum Installation Clearances 11

Installation of the Gas Log Effect 12

Placement of the Ember Glow Fibres 13

Gas Connection 16

Low Pressure Adjusting Screw 18

Gas Pressure Test Nipple Locations 18

Fitting the Remote Control 19

Commissioning 20

Information for Users Which must be Advised by the Installer Verbally or in Writing 21

Spare Parts for Servicing H44 Gas Stoves 21

Servicing Instructions 22

Burner Removal and Replacement 23

Thermocouple Replacement 25

Changing Gas Operating Type 28

Primary Air Collar Adjustment 28

Door Handle Adjustment 29

Lower Door Opening and Level Adjustment 29

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

2

Safety Precautions

a) The stove should be visually inspected and if damaged should not be installed.

b) It is a requirement of the Gas Safety (Installation and Use) Regulations that these instructions,

together with the Appliance User Instructions, be left intact with the user.

c) In your own interest, and those of safety, and in accordance with the Gas Safety (Installation

and Use) Regulations, Euroheat stoves must be installed by a suitably qualified Gas Safe

technician using the appropriate fittings for the gas type being used, and the stove must not

be modified in anyway. The gas technician will be responsible for the installation conforming

to all current regulations and standards, during the life of this publication these standards may

be superceded and it is the installer’s responsibility to ensure the installation conforms to

whatever standards are current at the time of installation. Failure to install the appliance

correctly could lead to prosecution.

BS 715 : 1993 Metal Flue Systems

BS 1251 : 1987 Fireplace Components

BS 1289 : PT 1 1986 Flue Block Systems

BS 5440 : PT 1 2000 Flues

BS 5440 : PT 2 2000 Ventilation

BS 5871 : PT 1 2005 Installation of Gas Fires

BS 5482 : PT 1 1994 LPG Installations

BS 6891 : 1998 Pipe Work Installation

d) It is important to ensure that the flue system onto which the appliance is to be installed is

working properly. Products of combustion which enter a room could be a serious health risk. It

is therefore important, in the interests of safety, that these instructions are strictly followed,

together with the legal Statutes and Codes of Practice, current at the time of installation.

e) It is important that the stove is installed so that the clearances specified in these instructions are

complied with.

f) The stove must NOT be run with its door open.

g) It is also important that the occupiers of the property have their attention drawn to the high

temperatures which are normally present on the external surfaces of the stove during operation.

h) Fireguards, in accordance with current British Standards, should be fitted when the appliance is

in the presence of young children, the elderly or infirm.

i) Do not use the stove if any of the ceramic log or coal effect components are damaged or broken

during transportation.

j) Ensure that all transport packaging is removed from inside and outside of the stove.

k) The plastic bags used to protect components of this appliance are a potential hazard to young

children, and should be disposed of immediately.

l) The stove must be serviced annually by a suitably qualified Gas Safe technician.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

3

Harmony 44 Gas Conventional Flue

Model Number H44

Heat Output Maximum

Nat Gas 8.690 kW (29,650 BTU)

L.P.G. 8.05 kW (27,466 BTU)

Gas Input Maximum

Nat. Gas 10.23 kW (35,826 BTU)

L.P.G. 9.55 kW (32,584 BTU)

Heat Control Manual Mertik Maxitrol GV34 Gas Valve

Fuel Types Natural Gas or L. P. G.

(Specify at time of order)

Efficiency Natural Gas 85%

Efficiency L.P.G 84.3%

Ignition Type Piezo

Pilot Flame Yes

Flame Failure Yes

Flue Spillage Sensor Thermocouple Interrupter (TTB)

Fuel Effect Type Wood

Fuel Outlet Options Top or rear

Flue Size 4” (100mm) Internal Diameter

Free Air Requirement

Nat. Gas 1776 sq mm

L.P.G. 1402 sq mm

Gas Fitting Size 1/2” BSP or 3/8” BSP

Colour Options Cast Black, Satin Black Enamel, Bottle Green Enamel

Decorative Plinth Optional extra

Cast Black 88802001

Satin Black Enamel 88802002

Green Enamel 88802006

Remote control Optional extra MS9252

Technical Data for H44

Gas

Type

System

Pressure

Main

Burner

Nozzle

Nominal Output

(Maximum operation)

Minimum Output

(low operation)

Pilot

Nozzle

Size

Hourly

Input

Burner

Operating

Pressure

Hourly

Input

Burner

Operating

Pressure

G20

Na tu ra l

Gas

20mbar

1 jet

4 x 1.4

1.08

m³/h

10.6mbar

0.77

m³/h

5.6mbar 51

G31

Propane 37mbar

1 jet

4 x 0.81 0.76kg 27.8mbar 0.6kg 15mbar 22

Seasonal Efficiency

The efficiency of this appliance has been measured as specified in BS EN 613:2001 and the result is 76.6%

Nat Gas and 77.83% LPG. The gross calorific value of the fuel has been used for this efficiency calculation, the

Net Efficiency being 85% Nat Gas and 84.3% LPG. The test data from which it has been calculated has been

certified by BELTEST. The efficiency value may be used in the Governments Standard Assessment Procedure

(SAP) for energy rating of dwellings.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

4

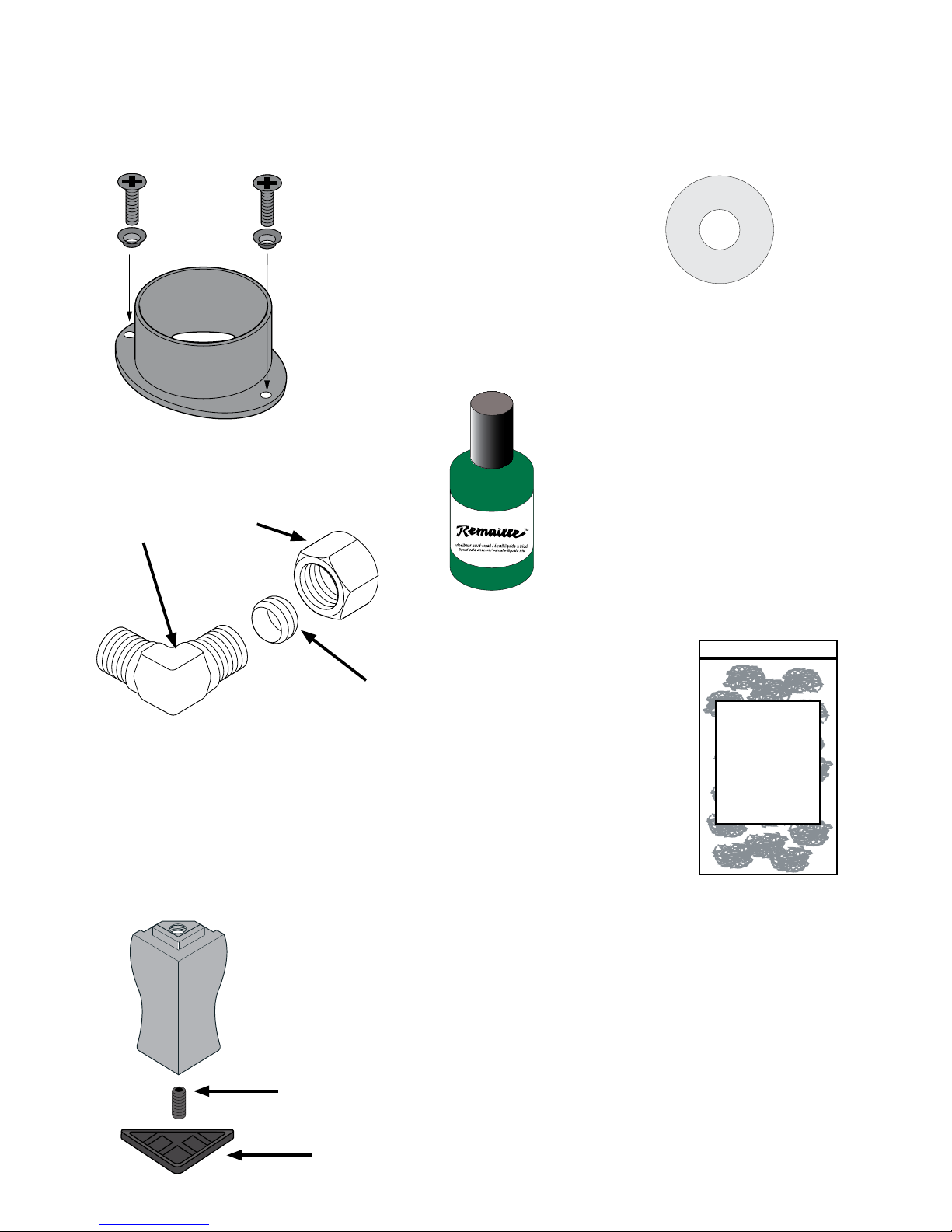

Flue Spigot (Collar) and Choke Plate

The flue spigot (collar) may be

found either screwed to the pallet

on which the stove is delivered or

within the body of the stove.

In the plastic bag within the stove

there will be 2 cup washers and 2

M5 x 20mm screws.

Elbow for Gas Fitting

Accessories Supplied with Stove

Supplied with the conventional flued gas stoves are a number of installation accessories and instruction

manuals.

Nut

Olive

Elbow

Foot Levelling Screws and Triangular Hearth Protectors

In the plastic bag within the stove there will be 4 foot

levelling grub screws and 4 plastic triangular hearth

protectors. The grub screws should be fitted to the feet

prior to installation to allow for levelling the stove on an

uneven hearth.

The plastic hearth protectors can be put under the feet to

protect the hearth when sliding the stove into position,

but should be removed unless required to help level the

stove.

Enamel Repair Touch Up

(Enamel Stoves Only)

In the plastic bag within the stove there

will be a bottle or tube of enamel touch

up which will match the enamel finish

on the stove. This can be used to repair

any minor chips on the enamel surface

of the stove.

Grub Screw

Plastic Hearth Protector

EMBERGLOW

Platinum

Bright

Embers

Emberglow

Small squares of platinum

embers which when teased

out give an ash effect with

the ceramic log or coal effect

(see page 13).

Choke Plate

This MUST be fitted to top

or rear flue applications,

see page 10.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

5

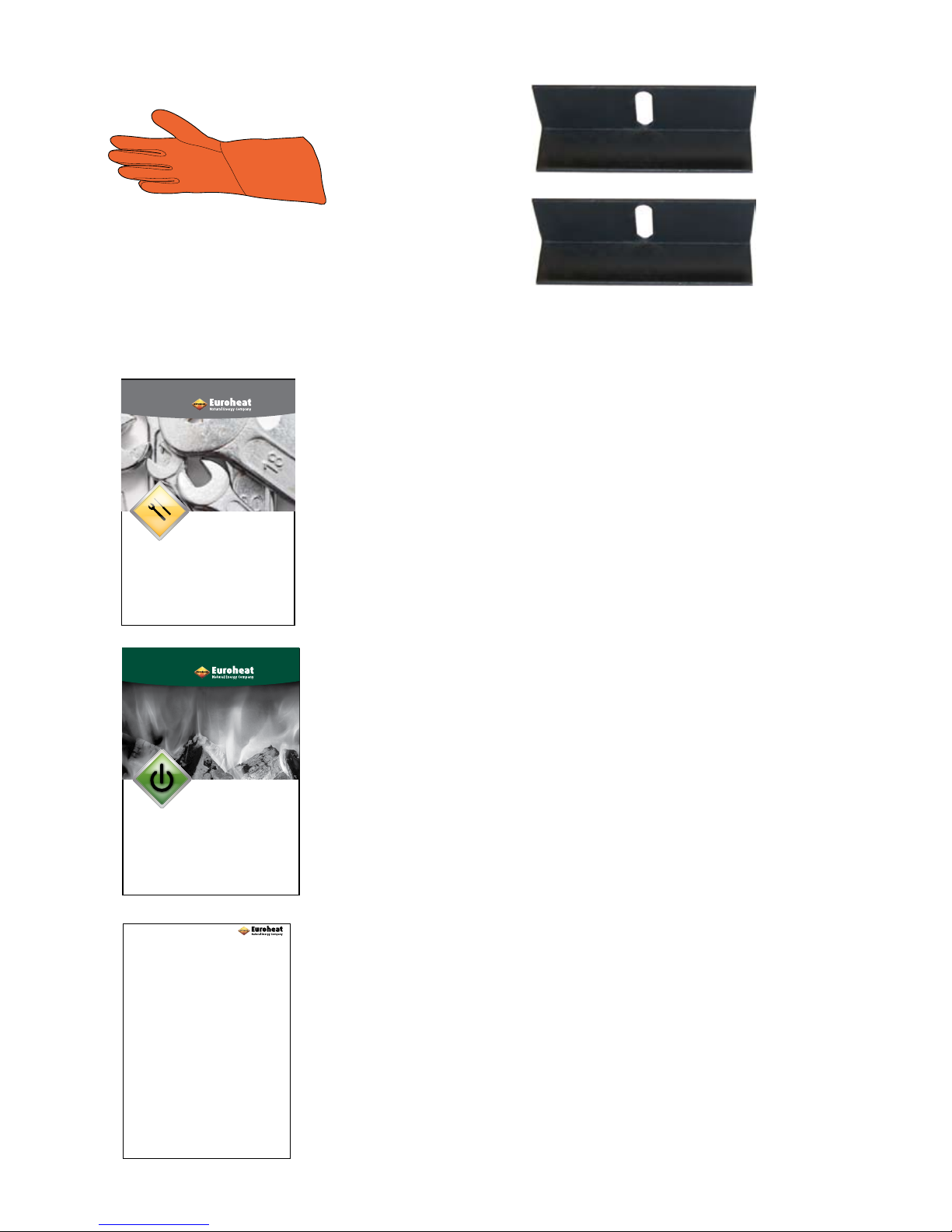

Glove

A heat proof glove is also supplied

with the stove. This is for use by the

installing and servicing engineer if

they have to open the main firebox

door when hot.

Burner Brackets

The two burner brackets are fitted inside the fire box on

the left and right inner walls. They are used to locate the

ceramic burner in place. They are supplied with 2 self tapping

screws.

If there are any of the above documents missing from your

stove upon delivery please contact Euroheat with the serial

number of the stove and we will immediately despatch a

replacement.

Installation Instructions

For the use of the suitably qualified engineer for the

installation and servicing of the stove.

It MUST be handed to the owner of the stove.

Operating Instructions

For the use of the person for the safe operation of the stove.

It MUST be handed to the owner of the stove.

PART NUMBER

SERIAL NUMBER

Installation &

Servicing Instructions

Harmony 44

Conventional Flue Gas Stoves

IN1113 Edition E June 2009

PART NUMBER

SERIAL NUMBER

Operating Instructions

Harmony

Stanford

Conventional Flue Gas Stoves

IN1123 Edition 02 June 2009

GAS STOVE REGISTRATION

Please complete the form on pages 3 and 4 and return it with a

copy of your sales receipt from your Euroheat approved supplier

to obtain your

THREE GOOD REASONS

Why you should have your stove commissioned.

It is vital for the longevity and efficient and safe operation of the stove to have the stove installed and

commissioned by a competent qualified heating engineer.

1. Installation

The stove should be installed by a competent qualified heating engineer, who will be conversant with the

Building Regulations and Codes of Practice current at the time of installation. Installation instructions are

supplied with the stove which contain instructions specific to the appliance.

Incorrect installation may lead to poor performance of the stove and ultimately damage to the appliance.

2. Operating

The operation of the stove should be demonstrated by a competent person, so you, as the operator, are

conversant with the operation of the controls. Instructions on the use of the controls can be found in the

operating instructions supplied with the stove.

Incorrect operation of the controls of the stove may lead to poor performance from the stove and ultimately

damage the appliance.

3. Maintenance

Routine maintenance as described in the operating instructions, supplied with the stove, should be

undertaken by a competent person.

Failure to perform the routine maintenance may adversely effect the performance of the stove and

ultimately damage the appliance.

Registration Form

To be completed by both the owner of the stove and the installing/

commissioning engineer.

It MUST be returned to Euroheat for the registration to be completed.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

6

Flue and Chimney Requirements

BS 5440 : PART 1

Before installation of the appliance, the chimney or flue system must be inspected and passed as suitable.

In particular, the following should be checked:

a) This appliance is suitable for installation onto the following flue types:

A suitable sized diameter flexible or fabricated steel flue system (See appliance data for

flue size), or a precast flue system (See Technical Bulletin TB118).

b) We would strongly recommend that a flue liner is also fitted if being installed into an existing

chimney built with an integral clay liner.

c) If being installed into an existing masonry flue which has NOT been built with an

integral clay liner, a flexible flue liner MUST always be used to line the entire chimney.

NOTE:

Any steel flue systems used should be manufactured in line with the requirements of BS 715, and

installed with due regard to the manufacturers recommendations.

d) The chimney should be thoroughly swept prior to installation of the flue liner. However,

if the flue is clean and unobstructed throughout its entire length, it need not be swept.

e) The chimney or flue must be free from any obstruction. Any flue damper or restrictor

must be removed or permanently fixed in the fully open position.

f) The minimum effective height of the chimney or flue must be 10ft (3 metres) measured

from the hearth to the termination of the flue (chimney pot). If the flue has any non

vertical sections the height should be increased in line with BS 5440 : Part 1.

For further information see the Euroheat Flue Guide IN1087.

g) An approved gas flue terminal MUST be fitted in accordance to the manufacturers

recommendations.

h) Where required a closure plate, of a suitable non-combustible material should be fitted. This

should have an infill panel so as to facilitate removal of any debris that may fall down

the chimney. Even after sweeping soot or debris may continue to fall down the chimney.

Ventilation

BS 5440 : PART 2

Before proceeding further, the following ventilation requirements must be satisfied.

a) If the stove is installed in a builder’s opening or fireplace recess that has an air supply entering from below

floor level, or within the opening or recess, this must be completely sealed off.

b) If there is another gas appliance fitted in the same room, or adjacent area, or extractor fan system, air

conditioning, etc., it will be necessary to refer to BS 6714 and BS 5440 : Part 2 to ascertain the additional

precautions necessary.

If any of the pre-installation checks reveal inadequacies, the installation should not proceed until they are

rectified.

Do not fit the appliance, seek expert advice.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

7

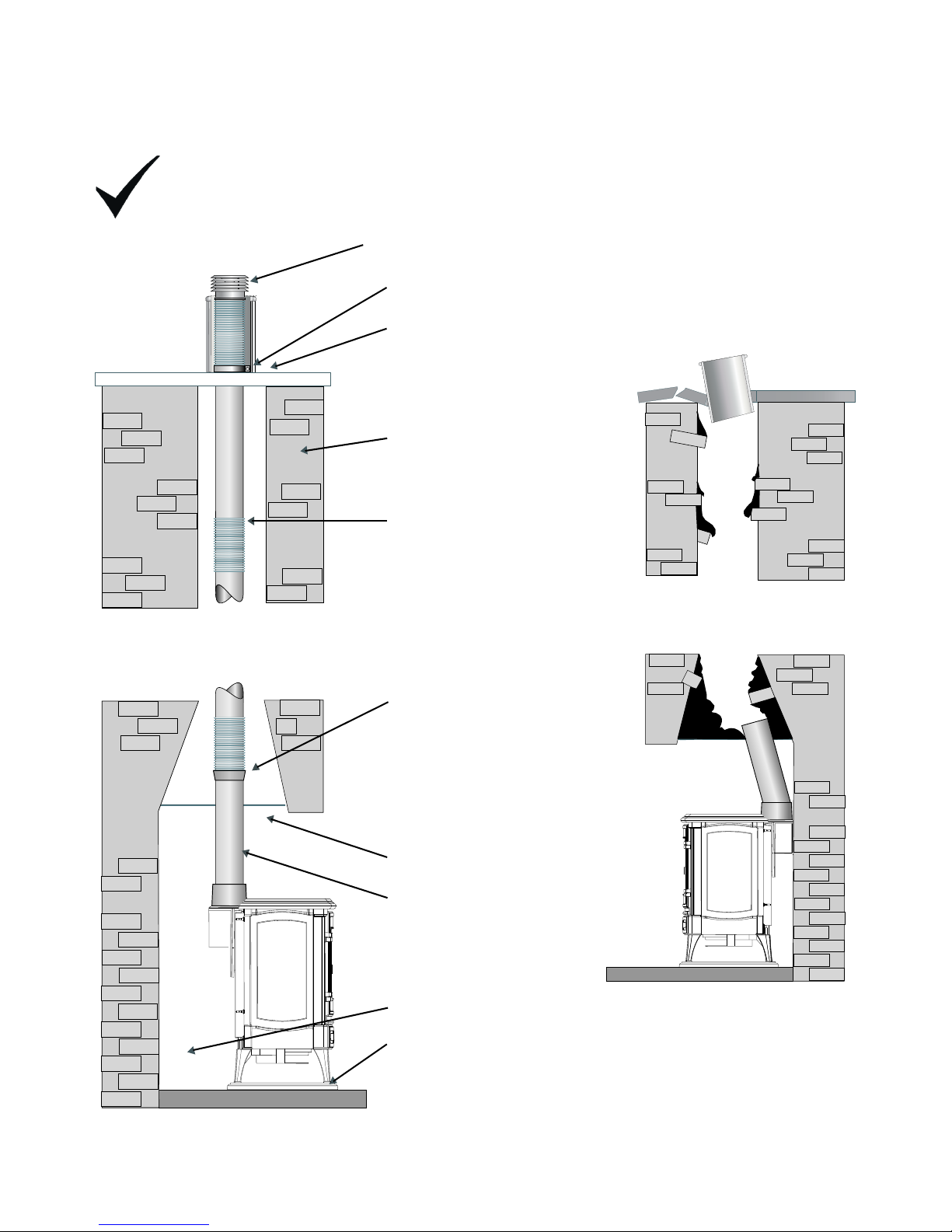

Suitably approved cowl

to prevent ingress of rain,

birds and/or to assist with

flue stabilization

Flue liner support collar

Weatherproof chimney

capping and pot

Sound chimney brick work

Stainless steel liner

Flexible to single wall

adapter

Register plate preventing the

escape of heat, positioned as low

as practicable to aid convection.

There must be an access door

to facilitate debris removal and

inspection.

Sufficient clearance behind

stove for maintenance

Level and stable supporting

hearth

Ridged section of flue pipe

Example of Stove Fitted into an Existing Chimney

For further information on flues ask you retail outlet for Technical Document IN1087 The Flue, or if the

installation is to be into a pre cast flue Technical Bulletin 118.

X

Height of flue less than 3 meters

Height of flue greater than 3 meters

The example above shows an

unacceptable installation into an

unsound and unlined flue. The height

is less than 3 meters and there is no

cowl.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

8

Installation of the Gas Supply

BS 6891

NOTE: Ensure that the gas supply is capable of delivering the required amount of gas, and is in

accordance with the relevant current standards.

It is generally preferred to conceal the gas supply by bringing it under the hearth, or through masonry to

the side of the fireplace. Any pipe work in 8mm tube connecting the stove to the main pipe work should be

kept as short as possible with as few fittings as possible to prevent restrictions.

a) Whenever a gas pipe passes through any masonry it must have a sleeve of non

combustible material sealed at both ends to prevent the gas supply from coming in

contact with masonry or lime based mortars.

b) The gas pipe should be adequately supported over longer lengths.

c) Soft copper tubing and soft soldered joints are suitable, providing the tube is not closer than

150mm to the stove casing, i.e., the temperature must not exceed 100°C.

d) A means of isolating the gas supply to the appliance must be provided, unless the

appliance is supplied with its own isolation valve, independent of any appliance control

(gas control valve). This may be a gas cock, ideally of the nursery type to prevent

children interfering with the gas supply.

e) Any gas tubing that has been passed through masonry, should be purged to expel

any foreign materials that may have entered the supply.

Care should be taken to ensure that pipe work brought through metal structures has been secured to prevent

chaffing, but allow for thermal expansion.

Appliance Location

a) In a fireplace recess the stove can be mounted on a 12mm thick decorative hearth or plinth, if

a constructional hearth of the correct dimensions is in place. In a free standing situation, as the

hearth temperature does not exceed 100ºC, a constructional hearth is not required. The stove

can be mounted on a 12mm thick non-combustible decorative hearth of the correct size i.e. a

cast iron plinth, provided that the floor can support the weight.

b) The stove is not suitable for installation into a rear combustible wall, any combustible

material must be removed from an area of 300mm around the installation of the appliance.

c) There must be a minimum of 300mm (see page11) from the top of the stove to the

underside of any combustible shelf. Note that for every 50mm increase on clearance, the

shelf may project by a further 50mm.

d) The appliance must not be installed in a room or space which contains a bath or shower, or if the

room is used as sleeping quarters.

e) Ensure that the stove fits neatly into its intended location.

f) Any manufactured surround used with this stove should comply with the appropriate British

Standard.

g) Do not place furniture or furnishing within 1 metre of the stove.

h) Do not obstruct the area directly beneath the stove as this may block the passage of air into

the appliance.

If any of these conditions are not fulfilled,

DO NOT FIT THE STOVE until the problem has been rectified.

© EUROHEAT DISTRIBUTORS (H.B.S) LTD. June 2009

E & OE Instructions Part Number IN1113 Ed. E

9

Installation of the Stove to the Flue System

Refer to page 6 to determine which flue systems are suitable for your stove size, having selected a suitable

flue system, please follow the applicable installation method.

Installation to a Flue Pipe System

IMPORTANT: The flue pipe system should be manufactured in line with BS 715, it should be either

a flexible flue liner or a rigid tubular steel construction, and it must be continuous from appliance

outlet spigot to terminal.

IF IT IS INTENDED TO FIT INTO AN EXISTING MASONRY BUILT CHIMNEY SYSTEM A SUITABLE DIAMETER

FLEXIBLE FLUE LINER MUST BE USED.

(See page 4 appliance data for flue size)

If fitting to a pre cast flue system refer to Technical Bulletin 118.

The stove is factory assembled for top flue connection. To choose a rear flue option follow the instructions

on page 10.

The flue system may now be connected to the stove, ensure that all joints are sealed with a suitable fire

resistant sealant we recommend Fraxfill (available from Euroheat Part No: MS9045).

Some so called “Heat Proof” mastiks will only stand a temperature of 300°C before they start breaking down.

In many cases they may give off an obnoxious smell at temperatures much lower than this and therefore

should not be used on this type of installation.

A physical retention method MUST be used at the flue spigot joint with the flue pipe, self tapping screws

being favoured.

Note:

If the flue is to be connected to the rear outlet, there should be no more than 150mm of horizontal

flue run before the flue rises vertically. Under certain circumstances it may be necessary to use a 45

degree bend directly from the top of the stove, this is acceptable as long as it does not compromise

the performance of the flue and the stove passes the necessary flue spillage test.

Loading...

Loading...