Eurogalan Ochag-2, Ochag-3, Ochag-5, Ochag-6, Geyser-9 Operation Manual

...

“OCHAG”, “GEYSER”, “VULKAN”

ELECTRODE BOILERS

OPERATION MANUAL

2

Contents

3

The given Operation manual contains basic information relating to the practical use of

the electrode boilers for the heating systems. By the aggregative technical and economic

indices of effectiveness, including the boiler efficiency, simplicity of installation and repairing,

cost of heating of one square meter of the apartment, specific consumption of materials per

1 kW of the boiler capacity, etc. the electrode boilers cannot be compared with any other type

of the electric boilers. The areas of application of the electrode boilers continue to extend

confidently.

This Operation manual is intended for the electrode boiler installation specialists,

experts in the installation of the automatic control systems for the electrode boilers, startingup and adjustment specialists, experts in maintenance and repairing, and owners of the

boilers.

We thank in advance those who will send remarks and proposals to the address of the

“Firma “GALAN” Joint-Stock Company.

All rights reserved. None of the parts of the given Operation manual can be reproduced

in any form without written permission of the “Firma “GALAN” Joint-Stock Company which is

a copyright owner.

Introduction

Invention of the electrode boiler is a one of the highest achievements in the area of

creation of the multipurpose heating equipment. A long-term experience of successful

operation shows that electrode boilers are easy operating, reliable, and safety devices. The

boiler efficiency reaches 98%. This is a result of application of one of the best achievements

of the domestic defensive industry in peace purposes. Throughout many years the boilers of

the “Firma “GALAN” Joint-Stock Company are successfully applied in almost all regions of the

Russian Federation, Post-Soviet republics and other foreign countries.

Dear customer!

To use a complete set of advantages of our boilers and to avoid possible annoying

errors in the process of installation of the heating system and boilers and in the course of

starting, further operation, and usage of the electric boilers, we convincingly ask you to

familiarize yourself attentively with the given Operation manual which contains information

relating to the characteristics, construction, operating principle, application, and rules of

installation of the electrode boilers. Also this Operation manual contains basic requirements

imposed on the safety measures, installation, operation, and repairing of the heating system,

registration and maintaining of the working documentation, etc.

The boilers are intended for heating of apartment houses, including country houses,

cottages, multistory apartment houses, garages, baths, premises and buildings of the

domestic, household, trading, public, industrial, and agricultural purpose, and also other

constructions in absence or inefficiency of the centralized heating.

The “Ochag”, “Geyser”, and “Vulkan” instantaneous electrode heating boilers produced

by the “Firma “Galan” Joint-Stock Company (hereinafter referred to as “boilers”) are used

only in the looped heating systems working without extraction of hot water for household,

industrial or any other purposes. These heating systems work on the basis of the compulsory

circulation of the heat-transfer agent (by means of the circulation pump). According to the

recommended most economic mode the temperature on an inlet of the boiler should lie in the

range +35 ÷ +45° С, and the temperature on an outlet of the boiler should fall in the range

+65 ÷ +75° C.

These boilers are made only in Russia.

The specified temperature in the heated premises is supported by the automatics (by

means of the temperature regulator).

The boilers have a long operating mode.

For normal operation of the boiler the following conditions are necessary:

* Operation air temperature of the premises in which the boiler is installed

should lie in the range between +10 to +35° С; ultimate air temperature of

the premises in which the boiler is installed should fall in the range between

4

+10 to +40º C (under condition of absence of other requirements);

* Relative humidity of an air at the temperature of +20° С should be no more

than 75%;

* Non-explosive environment; the environment should not contain aggressive

gases and steams destroying metal and isolation; the environment should not

contain an industrial dust in quantities adversely affecting the boiler

operation.

There are no combustible materials in the construction of the boilers, therefore our

boilers are fireproof.

Boilers meet the requirements of the Technical Specifications (TS) No. 346800117289826-02.

Order designations: “Galan – XXX-№” electrode boiler (“XXX” is a name of the boiler).

Annotation: “№” is a power of the boiler in accordance with the Table 1. Example:

“Galan – Ochag-6” electrode boiler.

All of the “Ochag”, “Geyser”, and “Vulkan” electrode boilers described in the Table

1 are certified.

Number of the certificate of conformity: РОСС RU.ME71.H00072 dated 29.03.05.

The Certification authority: The Electrical Products Certification Authority of the

Independent Noncommercial Organization on Certification of the Electrical

Products, 109052, Moscow, ul. Nizhegorodskaya, 29. Voluntary certification.

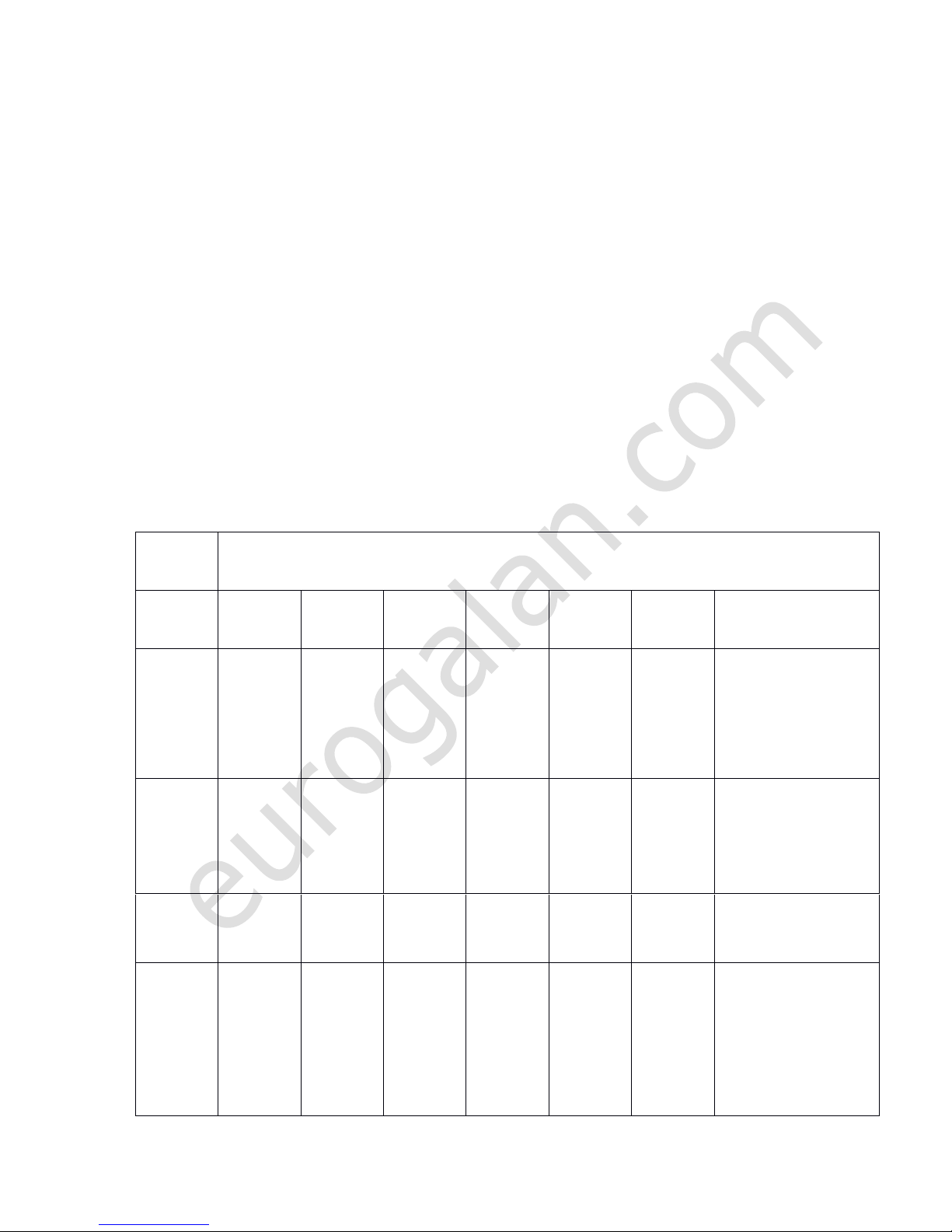

Technical characteristics of the boilers produced by the “Firma “Galan” Joint-Stock

Company Table 1

Name of the boiler

Boiler

characteris

tics

Ochag-2

Ochag-3

Ochag-5

Ochag-6

Geyser-9

Geyser15

Vulkan-25

1. S

ize of

the

heated

space

(cubic

meter

s)

80

120

175

200

340

550

850

2. N

ominal

power

consu

mptio

n

(kW)

2 3 5 6 9

15

25

3. N

ominal

voltag

e (V)

220

220

220

220

380

380

380

4. A

pproxi

mate

energ

y

consu

mptio

n

(kW/h

) (with

0,5

0,75

1,25

1,5

2,5 4 6,6

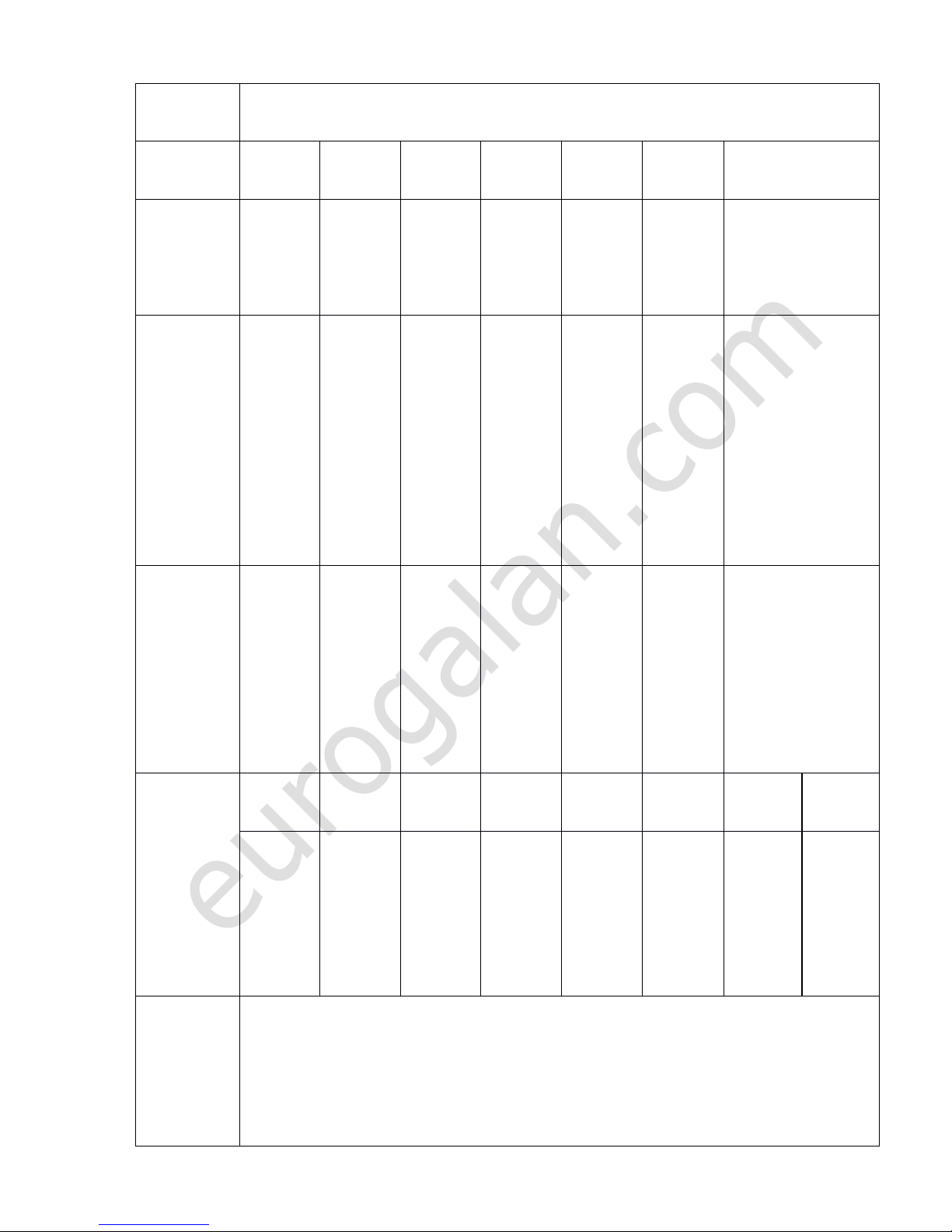

5

Name of the boiler

Boiler

characteris tics

Ochag-2

Ochag-3

Ochag-5

Ochag-6

Geyser-9

Geyser15

Vulkan-25

norma

l

therm

al

protec tion

of premis

es)

5. M ax.

curren

t

streng th

of the

boiler on

each phase

(A) (curre

nt freque

ncy – 50

Hz)

9,1

13,7

22,7

27,3

13,7

22,7

37,5

6. N

ominal

curren

t

streng th of

the

autom

atics (A),

electro

mecha

nical

model

10

16

25

32

3x16

3x25

3x40

7. C

ross sectio

n of

curren

tcarryi ng

copper

conne

ction cable

core (sq.

mm)

220 V

4 4 4

6

380 V

4 4 6

9. Max.

(operat ing)

temper

ature of

the

heattransfe

r agent on

the

90

6

Name of the boiler

Boiler

characteris tics

Ochag-2

Ochag-3

Ochag-5

Ochag-6

Geyser-9

Geyser15

Vulkan-25

outlet of

the

boiler

(ºC)

10.Recom

mende

d volume

of the

heattransfe

r agent in

the heating

system

(liters)

20-40

25-50

30-60

35-70

50-100

100-200

150-300

11. Nomin

al

diamet

er of

couplin gs

for

connec ting

to the

heating

system

(mm)

25

25

25

25

32

32

32

12. Class of

protect ion

against

electric

shock

hazard

1

13. Constr

uction by

moistu re

proofin g

degree

IP X3 splash-proof

14. Length

(mm)

250

275

320

335

360

410

460

15. Weight

(kg)

0,85

0,9

1,05

1,1

5,0

5,3

5,7

7

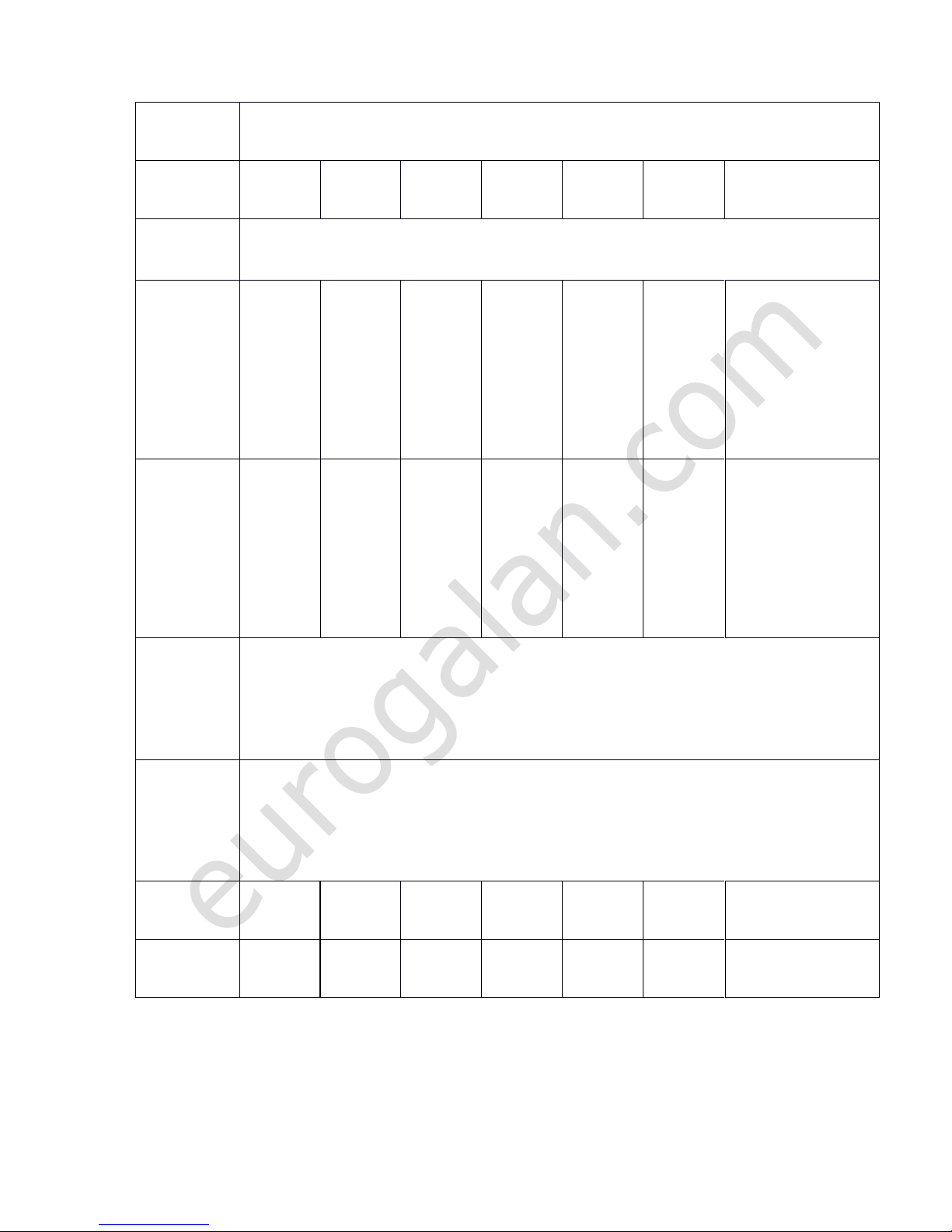

16. It is recommended to use the following types of liquids as heat-transfer agents for all of the “Ochag”, ”Geyser”,

“Vulkan” electrode boilers of the “Firma “Galan” Joint-Stock Company which are listed in this table:

• “Galan-Potok” low-freezing liquid with special rust prevention components and additives against formation of

scale and scum (freezing temperature: -40º C, life expectancy: no less than 5 years, warranty period: 1 year)

(hereinafter referred to as “low-freezing liquid”);

• Potable water (defined by the Sanitary Regulations and Rules No. 2.1.4.559-96), distilled water, snow melt water,

rain water (filtered water) the specific electric resistance (hereinafter referred to as “resistance”) of which is no

less than 1300 Ohm/cm at a temperature of +15º C.

ATTENTION!

It is strictly forbidden to use low-freezing liquids (antifreezes) such as “TOSOL”, “Arktika”, “Tvoy Dom”, etc. as heat-

Name of the boiler

Boiler

characteris tics

Ochag-2

Ochag-3

Ochag-5

Ochag-6

Geyser-9

Geyser15

Vulkan-25

transfer agents since they are not intended for a use by the electrode boilers.

The “Firma “Galan” Joint-Stock Company regularly performs technological

improvements of electric boilers, therefore their technical characteristics can slightly differ

from characteristics resulted in the table above.

Boilers construction

Depending on the boiler power the electrode boilers produced by the “Firma “Galan”

Joint-Stock Company fall into the following categories:

• Single-phase electrode boilers (“Ochag-2”, “Ochag-3”, “Ochag-5”, and “Ochag-

6” electrode boilers);

• Three-phase electrode boilers (“Geyser-9”, “Geyser-15”, and “Vulkan-25”

electrode boilers).

Single-phase electrode boilers consist of the following components:

• Metal case with inlet and outlet connections (a case functions as the second

electrode and ionization chamber);

• Rod electrode with current lead and hermetic electric bushing insulator;

• Two terminal groups with protective housings (phase terminal is located at the

bottom of the single-phase electrode boiler; neutral wire terminal and ground

wire terminal are on the side of the single-phase electrode boiler).

Three-phase electrode boilers consist of the following components:

• Metal case with inlet and outlet connections (a case functions as ionization

chamber);

• Base on which three electrodes with current leads and hermetic electric bushing

insulators are installed;

• Terminal group with protective housing.

The operating principle is the same for all electrode boilers. It is discussed below.

Advantages of the electrode boilers

The electrode boilers of the “Firma “Galan” Joint-Stock Company are 2-3 times cheaper

than the boilers of the same power produced by other manufacturers and have the following

significant advantages:

• Significant energy conservation is achieved by high electrode boilers efficiency

which reaches 98%. By this indicator electrode boilers surpass the existing

heating boilers of other types. This advance has come about through the direct

8

transformation of electric energy to thermal energy in the heat-transfer agent

during the passage of electric current through the heat-transfer agent. Under

these conditions the ionization of the heat-transfer agent takes place. The

temperature and electrical conductance of the heat-transfer agent grow. The

strength of electric current passing from one electrode to another grows too.

The electrode boiler is brought to nominal power quickly.

• The pressure of the heat-transfer agent on the boiler outlet comprises up to 1

atm. without usage of the circulation pump. This advance has come about

through the using of ionization chamber of small size which provides a sharp

heating of the heat-transfer agent and through the using of a standpipe which

is installed at a height of no less than 2 m. above the boiler. The “dy” value of

the standpipe depends on the power of the boiler. For example, for the boiler

the power of which is equal to 25 kW, the “dy” value of the standpipe should

be no less than 40 mm. A possibility of working without circulation pump

depends on the floor on which the heated space is located and on the

configuration of the heating system. Therefore our electrode boiler is at once a

heating device and a circulation pump. This results in considerable savings of

customer expenses.

• The saving of power consumption ranges from 40% to 60%. This advance has

come about through the using of automatics which includes the “Navigator”,

“Istopnik 103” electronic temperature regulators, “Istopnik 203” electronic

programmable temperature regulator, “Galan GSM” cellular monitoring system

of the heating equipment, and electromechanical model of the automatics. Also

this advance has come about through the high performance of the electrode

boilers.

• Simplicity of installation, compact size, and light weight. For example, the

weight of the boiler the power of which is equal to 6 kW comprises 1,1 kg, and

the weight of the boiler the power of which is equal to 25 kW comprises 5,7 kg.

• It is possible to build our electrode boilers in earlier installed heating systems

(also as secondary reserve boilers by using parallel connection) under the

condition of obligatory performance of our recommendations (Fig. 3). The

power of the reserve boiler should correspond to the size of the heated space,

quality of the thermal protection, and volume of the heat-transfer agent in the

heating system (Table 1). In case of installing of the reserve boiler in running

heating system it is necessary to perform the following tasks:

o To wash the heating system carefully by means of the “Galan-

Protektor” rust inhibitor; o To

filter the heat-transfer agent;

o To take measures for preventing ingress of contamination from the

heating system to the boiler and to install the filters.

It is necessary to replace some meters of the ingoing (into the boiler) and

outgoing (out of the boiler) plastic pipes with not zinc-coated (“black”) pipes.

• It is possible to increase the power of the heating system repeatedly by using

parallel connection of number of the electric boilers. For example, the

connection of 8 boilers the power of which is equal to 25 kW increases the total

power of the heating system to 200 kW (Fig. 2).

It is forbidden to use electrode boilers:

• For the “direct” water heating (the heating system is filled directly with water

which is taken from basin, well, water-well hole, water-supply line or river).

Our boilers are used only in the looped heating systems working without

extraction of hot water. The characteristics of water which is used as a

heattransfer agent should meet the requirements specified in the boiler’s

Operation manual. Non-observance of these requirements results in the boiler

breakage.

9

• For “warm floors” construction. The temperatures required for the “warm

floors” construction are considerably lower than the optimal operating

temperatures of the electrode boilers. For this reason a boiler is not brought to

nominal power. We recommend you to use highly reliable modern tubular

electric heating boilers produced by the “Firma “Galan” Joint-Stock Company

for “warm floors” construction.

It is not recommended to use electrode boilers in the heating systems in which large

heating radiators (radiators which use pipes of big diameter, cast-iron radiators, etc.) are

installed. In this case we also recommend you to use tubular electric heating boilers produced

by the “Firma “Galan” Joint-Stock Company.

If you need to use electrode boiler by force of circumstances, it is necessary to provide

the conformity of volume of the heat-transfer agent filled in the heating system to the boiler

power (Table 1). Besides, in case of using cast-iron radiators it is necessary to install a strainer

or mud settler in the return pipe to prevent the situation in which the remaining volume of

the core sand with the heat-transfer agent is brought into the boiler from the cast-iron

radiators resulting in the boiler breakage. With that end in view it is necessary to wash castiron radiators carefully before installing them into the heating system.

Recommended complete set of delivery

• Boiler as an assembly – 1 item.

• The electrode boiler operation manual and reference guide – 1 item.

• Automatics* – 1 complement.

• Automatics operation manual** – 1 item.

• Package – 1 item.

Note:

* - One of the models of the automatic control units produced by the “Firma “Galan”

Joint-Stock Company is chosen.

The warranty is not applied to the boiler which is purchased without this automatic

control system.

The electrode boiler cost does not include a cost of the automatic control unit.

** - With the exception of the operation manual for electromechanical model of the

automatics which is a part of this Operation manual.

The contents of this offered model of the automatics can be altered.

Installation of the electrode boiler into the heating system

The heating systems designing, boilers and automatics installation tasks, power

network and grounding connection tasks, putting into operation and repairing tasks,

equipment examination and testing tasks should be performed by the organization (firm)

having the corresponding license for performing these tasks.

On performing the tasks listed above the provisions of the following documents should

be observed:

• “Inter-branch rules for electric installations”.

• “User rules for operating electrical equipment”.

• “Safety rules for operating electrical equipment”.

• “User and safety rules for operating electric boilers and boiler-houses”.

• The given Operation manual.

Also it is necessary to observe the provisions of the corresponding Construction

Regulations and Rules and the Fire prevention rules of the Russian Federation.

It is necessary to employ the electricians or control equipment and automatics

specialists of the corresponding qualification for connecting the boiler, installing the automatic

control systems for the heating equipment, and performing the servicing and repairing tasks.

Loading...

Loading...