EURO FIREPLACES Arlberg, Tatra, Arlberg Aqua, Mt Blanc 970, Mt Blanc 970 tunnel Installation Manual

...

Designer InBuilt Wood Heaters

INSTALLATION GUIDE

Thank you for your purchase of a

Designer Inbuilt Wood heater.

Euro Fireplaces oers a large range of designer InBuilt wood heaters.

While these heaters are best suited to new houses or renovation

projects, installation into an existing replace is also possible with

smaller inserts.

When considering a Euro Fireplace InBuilt, please note that following

the correct installation guidelines is essential to achieve both maximum

eciency as well as safety. Due to the high heat output of these

heaters, an enclosed hotbox is required as well as heat-proong on

any combustible wall (plasterboard, timber, etc...).

All Euro Fireplaces heaters utilize a natural convection system, as well

as radiant heat. Convection allows warm air to travel through your

house, constantly replacing and converting the cold air. It is the most

ecient way to heat an insulated home. No fans or electric components

are required, however intake and outtake vents must be installed to

facilitate this system. Those vents are particularly important in high

convection installations such as Skamol.

Designer InBuilt heaters can be installed with more or less heat bank

depending on the type of installation and the materials used. Heat

bank allows the heater to hold on to heat long after the re has gone

out, storing it in dense building materials such as re bricks, stone or

concrete, heat bank will also prolong the burn time.

High convection installations such as Skamol allow the heater to

distribute hot air almost immediately in to large areas. In most cases a

combination of methods is used to produce the most eective heat for

your home.

Some Euro Fireplaces heaters have a hydronic option, allowing the

In Built unit to provide heat to a series of radiators, oor heaters and

domestic hot water systems. Those heaters have portion of the kw

output dedicated to water and a portion to air.

Content

I Things to Consider 4

I FAQ 6

I How to Burn Guide 8

I Inbuilt Methods 10

I Hot Box Finish 12

I Ducting 13

I Fresh Air Intake 14

I Hydronic 15

I Convection 16

I Skamol Construction 18

I Construction Methods 20

I Step by Step Guide 24

I Alternative Methods 30

I Tunnel Heaters 32

I Insert Construction 34

I Heater Range 40

When considering a Euro Fireplace In Built,

p lease consider the following requirements:

I In Built heaters are designed for maximum eciency and the lowest

possible emissions; therefore only a small amount of rewood is

required for a high heat output.

I Wood size is important; smaller logs will burn hotter for longer. Logs

100 to 150mm in diameter are the ideal size.

I Overloading your replace will result in over burning, which can

eventually cause damage to your heater and may void the warranty.

The heater only needs around 6-7kg of rewood at any one time to

achieve excellent heat output.

I No treated timber or building materials must be used as fuel.

Firewood should be dry and well seasoned.

I Mt Blanc heaters have a vertical door, however the heater should not

permanently be run as an open replace. A closed door will maintain

an eciency of 80%, whilst an open door will cause the eciency to

drop below 30%.

I The heater will burn slowly for many hours when shut down, however

it is not designed to be loaded with large heavy logs, as this will

result in blackened glass and a heavy creosote build-up. Black glass

is an indication of incorrect burning practices.

I Heaters with traditional lateral doors such as the Arlberg have a

tighter seal, and can therefore retain ambers longer.

I The choice of what inbuilt material is used will result in either strong

convection (Skamol) or large amounts of heat storage (Fire Bricks). A

combination of these materials is also an option however.

I No timber or combustible material can be used in any part of the

installation or must be protected against. Any materials used must

withstand temperatures up to 350°C.

I Placing the vents in the correct location is essential for both

eciency and safety

I High convection installations such as Skamol need double the

venting of a brick installation

I A 50mm thick Skamol base with 3mm steel sheet for strength is

required inside the hot box and for 500mm in front of the heater.

4

I The hotbox may require future maintenance; this should be done

through the top or through a side service hatch. Construct the lid

out of Skamol in order to heat proof, facilitate convection and ensure

ease of access

I If the heater sits against any combustible surface, it must be heat

proofed accordingly.

I The rst 500mm above the hotbox must be void of any timber

components.

I Basic insulation within your home is essential to ensure the heater

runs correctly.

FAQ

Q: The heaters are made in Europe; are they made for soft wood only?

A: Even in Europe the most commonly used rewood is Buche (Beech)

Buche is a kind of hardwood; soft wood such as pine actually burns

hotter ( but quicker) than hardwood. The most important aspect of

wood is:

I Well-seasoned with a moisture condense of no more than 20%

I Never use treated timber

I Only the correct size will give you the best heat

Q: What are the burn times?

A: This is depending on the installation method, heat bank installation

will result in long retention of ambers for up to around 7 hours, however

it is important the heater is used correctly. Never shut the air control

fully while there are still visible ames in the re box. A high convection

installation will result in a shorter burn time of around 5 to 6 hours but

will provide immediate heat when lighting the re

Q: Who can do the installation?

A: Installation can be done by your builder; we usually consult with the

builder to make sure he understands the building process.

Q: How well do those heaters work without a fan?

A: The heaters work by natural convection. Cold air from your house is

drawn in to the lower part of the hot box through vents. That air gets

heated and expelled out through the vents on top. This is the most

ecient way of wood heating. It is important the heater is not allowed

to draw cold air from the outside; this may happen through gaps under

doors

6

Q: What is the fresh air intake?

A: The fresh air intake is an option most Euro Fireplaces have, the fresh

air intake connects a pipe from the back of the heater to the outside;

now the heater will draw air it needs for combustion from the outside

instead of reusing air and oxygen needed for combustion from inside

the house and diminishing air quality.

Q: Where are the heaters made?

A: Euro Fireplaces deals mostly with German and Austrian based

companies such as Thorma, Haas + Sohn and Kobok with the

manufacturing plants located in Austria, Germany, Slovakia and the

Czech Republic

Q: What is the warranty on Euro replaces?

A: Euro Fireplaces have a standard European warranty of 2 years,

however an extra 2 years can be obtained by simply lling out a warranty

card and submitting that to Euro Fireplaces. Designer InBuilt units have

the lifespan of a house, however correct installation and operation are

essential to this.

Q: Are Euro Fireplaces tested for the Australian market?

A: All of our Fireplaces are tested for the Australian market except in

some cases exemption for testings apply such as for kitchen stoves or

central wood heating appliances

Q: How do the test result compare to traditional Australian Wood

heaters?

A: Euro Fireplaces have some of the lowest emissions (as low as 0.4g

per kg wood burned) and highest eciency wood heaters available on

the Australian market

Operation

Move air regulator fully to the left

and stack softwood kindling on

top of two pieces of hardwood.

Make sure air can move freely

from the grate around the stack.

Place a relighter (circled) near

the top of the stack, and light it.

Leave the air regulator fully open.

IMPORTANT:

I Do Not burn anything other than

clean, dry rewood.

I Switch o any exhaust fans in

the house when starting the re.

Move air regulator to the middle.

This will stop the primary air

(from the bottom grate), causing

secondary air to enter from the

top grate and allowing the heater

to build a good bed of coals.

8

The start up cycle is complete

when there are no longer any

visible ames. Open the door

slowly and spread the remaining

coals.

IMPORTANT:

Avoid opening the door and

reloading while ames are still

visible.

Place up to 4 similarly sized logs

(approx. 50cm long, 12cm thick) on

to the bed of hot coals.

Keep the air regulator at the middle.

Using properly dried rewood, and

following the above steps, the logs

will ignite within 60 seconds.

For further information please refer to our burning guide or contact your

local Euro Fireplaces dealer.

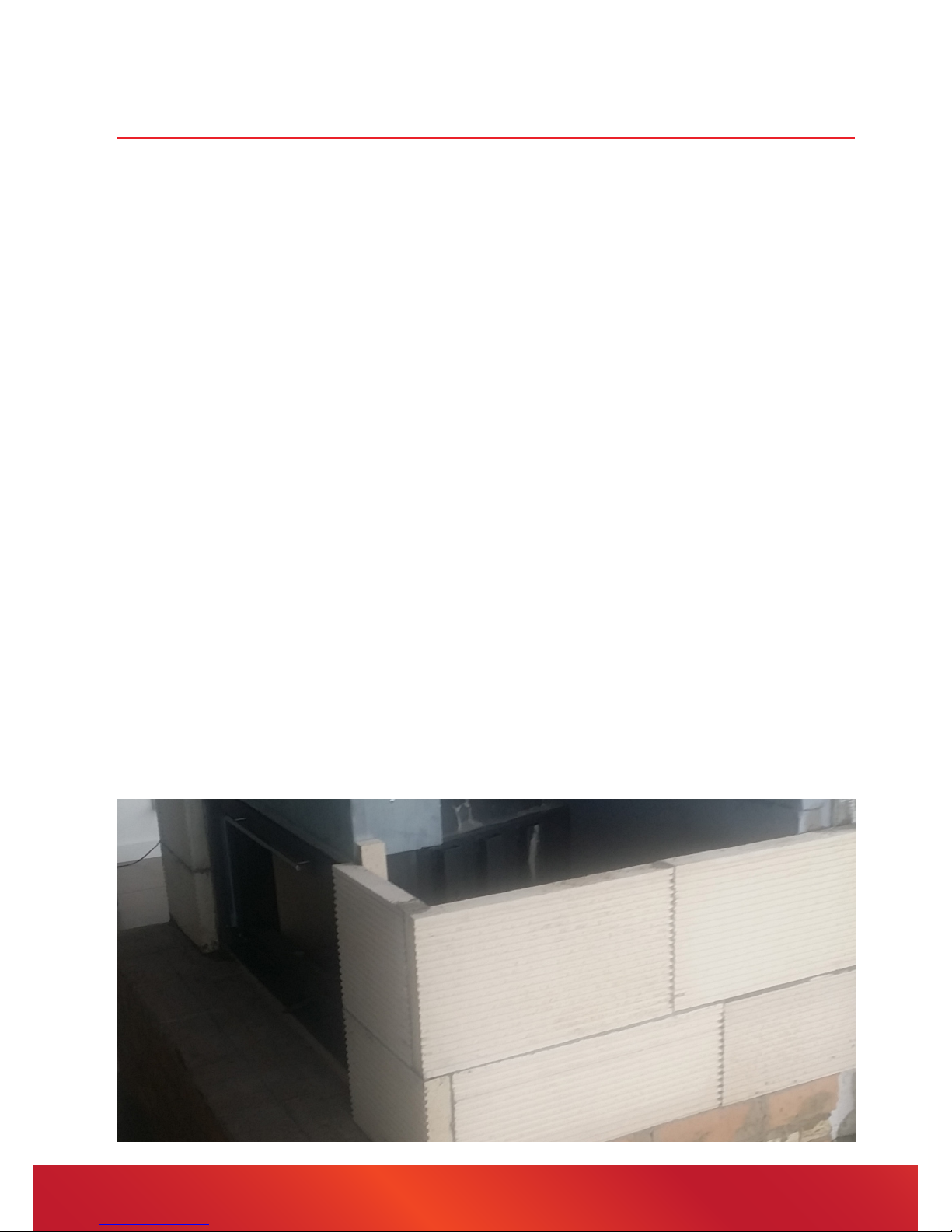

InBuilt Methods

In order to achieve maximum eciency from your inbuilt replace,

Euro Fireplaces recommends the following installation methods.

The aim of these methods is to create a Hot Box that will enhance the

convection of the replace and maintain heat that would otherwise

be lost through the ue. This Hot Box should be 1.8m to 2m tall, and

leave a gap of at least 150mm around the replace unit. There are three

dierent materials the structure can be made from: Fire bricks such

as Akumol, building bricks or Skamol. The most ecient installation

is with re bricks; a material used in the construction of pizza ovens.

Akumol functions as a heat bank as well as aiding convection. A Skamol

installation will create a powerful convection, yet cannot function as a

heat bank. Normal building bricks will provide re proong as well as

some heat bank and convection.

Each type of construction must be built on a concrete slab, and a hearth

must be installed in front of the rebox. If built onto wood oors 50mm

Skamol will suce.

A combination of these materials can also be used, with a Skamol lining

on the back for convection and bricks on the sides and front for heat

storage and possible heat transfer on to a tile or stone nish.

10

If you choose standard building bricks for the installation, ensure the

bricks are of good quality. Lesser quality bricks may crack with time due

to being exposed to the heat inside the hotbox. Heat tolerant mortar

must be used. Standard building bricks provide moderate heat storage

and reection of heat. You may also choose to line a standard brick

installation with Skamol.

In many cases a combination of inbuilt material is used. You may choose

to have a brick installation while lining the back of the hotbox with

Skamol; this will give you eective convection as well as reproong

the back of the hotbox, while the brick sides and front act as a heat

bank. You can increase convection or heat bank depending on how

many sides within the hot box are lined with Skamol and how many

sides are bricks.

If you choose to use Hebel for a hot box installation it must be lined

with Skamol as Hebel by itself is not ecient and eective enough to

absorb heat or reect heat. Hebel by itself may also break down in time

due to the high heat inside the hotbox.

I Heat proong against timber: if the hotbox is built in to a timber

framed house 100mm thick Skamol panels with a 30mm air gap must

be used. Alternatively 70mm brick and 50mm sheet of Skamol with a

30mm air gap. This will provide more heatbank.

I Hotbox lid: The hot box lid should be constructed of 2 x 50 mm thick

Skamol.

I Venting in a Skamol installation is crucial and double the venting

(oppose to a heat bank installation) is needed for this type of

installation.

I Heat bank also can be attached on to the heater even with a Skamol

installation.

Finish of the hot box

If you plan to choose a stone or tile nish we recommend you use a

brick installation. heat will then be absorbed in to the bricks as well as

in to the stone or tile. Heavier installation (more thermal mass) will result

in less convection but more heat bank . If you plan to nish a Skamol

installation with tile or stone please be aware the tile or stone will not

be able to store heat as heat will not be able to penetrate the Skamol

hot box. If you choose to paint or render a brick or Skamol installation

please make sure heat tolerant paint and heat tolerant render is used

Building the hot box up to the ceiling or only at 2 m height: If you choose

to build the hot box installation up to the ceiling, a hot box lid will be

installed at 2 m height and continued from there all the way up to the

ceiling, the space from the hot box lid must be vented! (Usually in to the

roof cavity) If the hot box is built to 2 m only (popular with tunnel heater,

when used as a room divider) you will have a painted ue from the hot

box going in to a standard triple ue conguration through the ceiling

(similar to a standard freestanding heater installation)

12

Ducting

Euro Fireplaces Designer InBuilt units can be ducted via a hot air transfer

kit from the hot box in to other areas of the house (central wood heating

appliances) Those ducting kits are available from your local Euro Fireplaces

distributer. Only approved ducting kits must be used

Fresh Air Intake

Euro Fireplaces models rely on surrounding air to achieve a high

standard of combustion. As such, an adequate intake of air is essential.

In an energy ecient room (eg. tight windows and doors), air intake

may be low and aect the re. Quality of the air in the room may also be

aected, however this can be aided with the installation of an external

air supply. For large inbuilt units this air intake is necessary due to the

high oxygen requirement of the re.

14

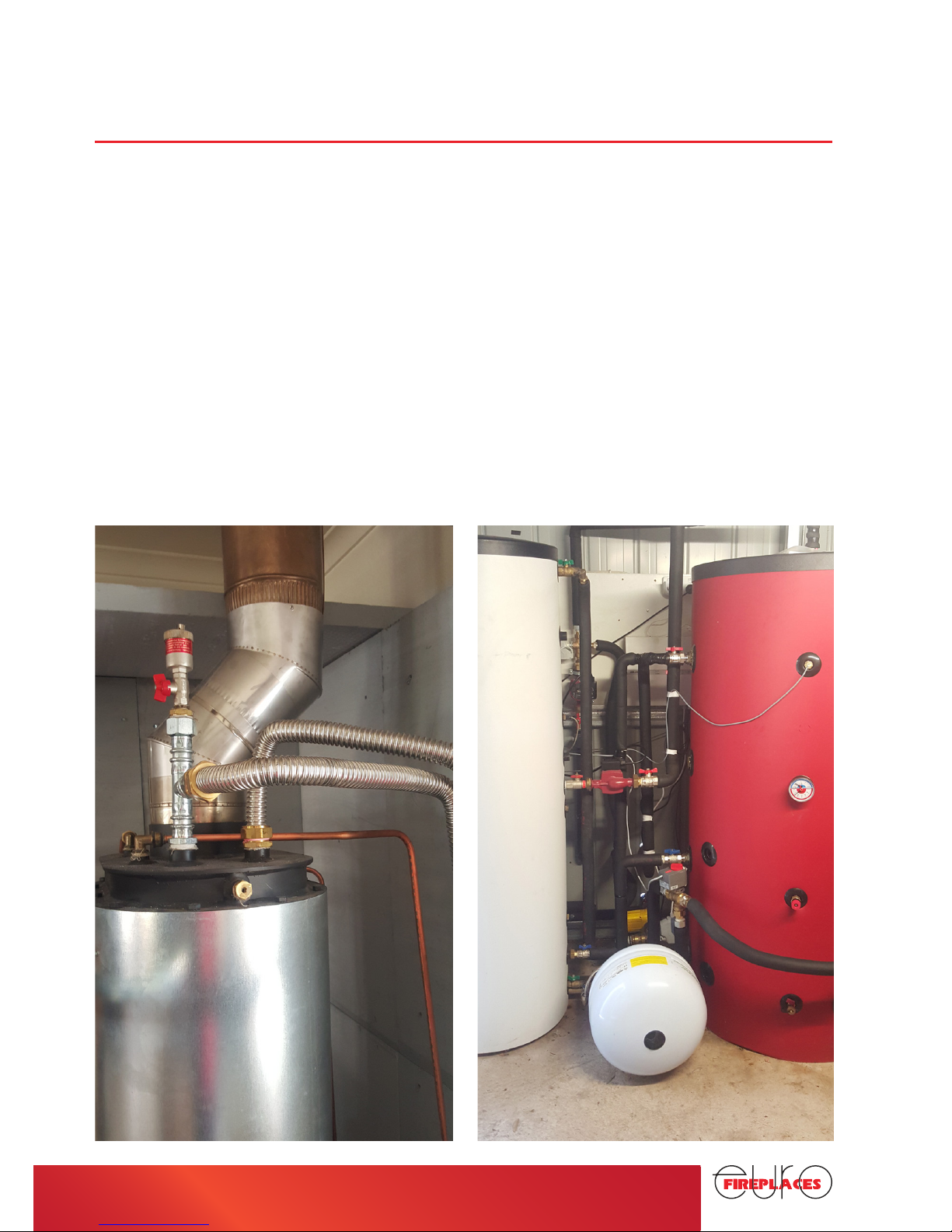

Hydronic options

Some of Euro Fireplaces Designer InBuilt have a hydronic option where

a certain portion of the heat output is dedicated to heating water.

Depending on your needs heaters have between a 40/50 to 30/70

distribution of heat into air. Water installations are usually done with a

buer tank domestic hot water and radiators or oor heating. Heat can

also be ducted via the roof cavity with an Euro Fireplaces approved

ducting kit.

Due to the complex nature of hydronic heating installations we

recommend contacting your local Euro Fireplaces dealer or hydronic

specilist for more detailed information as to the pricing and requirements

of these systems.

Loading...

Loading...