Page 1

System 5 Control Surface/Frame

Euphonix Inc. 220 Portage Avenue Palo Alto , CA 94306

Tel: (650)855-0400 Fax: (650) 855-0410 Web Page: www.euphonix.com

In the interest of continued product development, Euphonix reserves the right to make improvements in this

manual and the product it describes at any time, without notice or obligation.

System 5, S-5, PatchNet, eMix, EuCon, R-1, Studio Hub, , Digital Studio Controller, DSC, CleaR, GainBall,

SnapShot, SnapShot Automation, SnapShot Recall and Total Automation are trademarks of Euphonix Inc.

Version 1.0

Part# 840-07576-01

Publish date: October 2001

Page 2

TABLE OF CONTENTS

Box Inventory ............................................................................................................. 4

Safety and Precautions.............................................................................................. 4

Power On Sequence ............................................................................................................................ 5

CE/TUV/UL/CSA.......................................................................................................... 5

Component Overview ................................................................................................ 6

Functional Description ........................................................................................................................ 6

FRAME SECTION......................................................................................7

Physical Specifications ....................................................................................................................... 7

Exploded View...................................................................................................................................... 7

Side Panel View.................................................................................................................................... 8

Dimensions and Weight ...................................................................................................................... 9

User Reference - Frame........................................................................................... 10

Assembling the S5 Frame ................................................................................................................. 10

System 5 Ethernet/Power Cable Configuration .............................................................................. 18

System 5 Ethernet Cable Harness ...................................................................................................19

CONTROL MODULES SECTION ............................................................21

Physical Specifications ........................................................................................... 21

Top View - Control Modules ............................................................................................................. 21

Filler Modules..................................................................................................................................... 22

Dimensions and Weight .................................................................................................................... 23

Technical Specifications ......................................................................................... 23

Environmental Requirements ........................................................................................................... 23

Power Requirements ......................................................................................................................... 23

Power Consumption .......................................................................................................................... 23

Control Module Expansion Port ....................................................................................................... 24

General Description ....................................................................................................................... 24

Physical Pinout............................................................................................................................... 24

DB25 Electrical Specification: ........................................................................................................ 26

Typical Usage: ............................................................................................................................... 26

Alternate Usage #1: ....................................................................................................................... 27

Alternate Usage #2: ....................................................................................................................... 28

User Reference – Control Modules......................................................................... 29

Control Module Setup ....................................................................................................................... 29

Overview of Ethernet IP Address Allocation ..................................................................................29

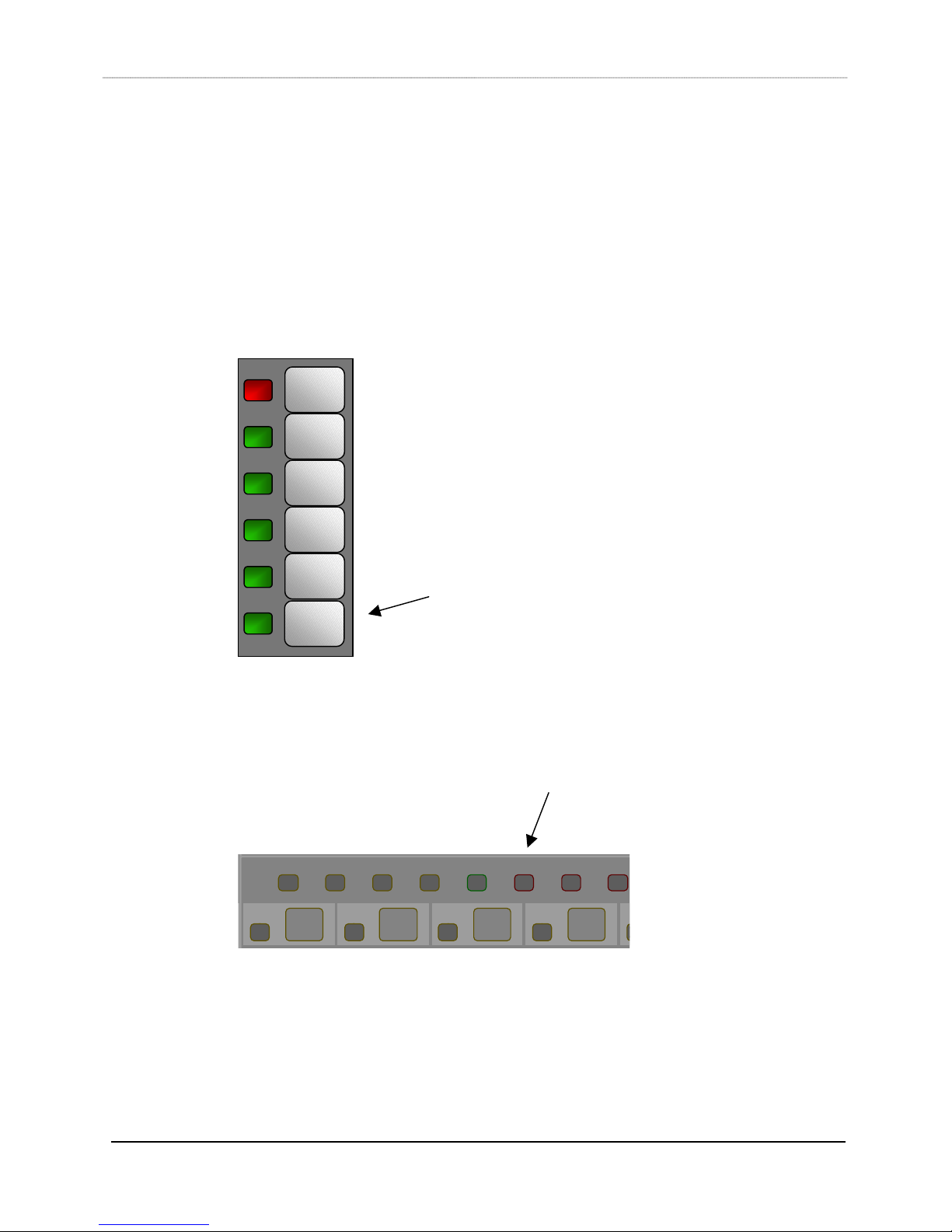

Self Test Procedure for CM401, CM402 and CM408 ....................................................................... 30

Initiating Self Test........................................................................................................................... 31

Self Test Operations ...................................................................................................................... 32

Top Level Test Keys ...................................................................................................................... 33

LED test ......................................................................................................................................... 34

All Switch LEDs Toggle..................................................................................................................35

Color Toggle................................................................................................................................... 35

All Switch and Indicator LEDs Toggle ............................................................................................ 35

Vegas Mode ................................................................................................................................... 35

S5 Control Surface/Frame Manual Page 2 Version 1.0 ©1999 Euphonix, Inc.

Page 3

Switch Test.....................................................................................................................................36

Intelligent Display Test ................................................................................................................... 37

Knob Test ....................................................................................................................................... 38

Knob value display ......................................................................................................................... 39

Halo Test ........................................................................................................................................ 39

Knob meter display ........................................................................................................................ 39

Knob switch test ............................................................................................................................. 39

Expansion port switch test .............................................................................................................39

Fader Test ...................................................................................................................................... 40

Fader Test (continued) ................................................................................................................... 41

All fader up ..................................................................................................................................... 42

All fader down ................................................................................................................................ 42

Fader cycle test with speed control................................................................................................ 42

Fader echo test .............................................................................................................................. 42

Touch Sense Test .......................................................................................................................... 42

Backstop PFL switch test ............................................................................................................... 42

Fader Write value display............................................................................................................... 42

Fader Read value display ..............................................................................................................42

TFT backlight brightness test ......................................................................................................... 42

CPU Test ............................................................................................................................................. 43

RAM Test .......................................................................................................................................43

ROM Test ....................................................................................................................................... 43

PC104 RAM Test ...........................................................................................................................44

APPENDIX 1 ............................................................................................46

Parts Lists................................................................................................................. 46

System 5 Leg Set: Part# 946-07220-01........................................................................................ 46

System 5 Frame Set, 6ft: Part# 946-06425-01 .............................................................................48

System 5 Frame Set, 9ft: Part# 946-06840-01 .............................................................................49

System 5 Frame Set, 12ft: Part# 946-07160-01 ...........................................................................50

S5 Control Surface/Frame Manual Page 3 Version 1.0 ©1999 Euphonix, Inc.

Page 4

Box Inventory

Description Part # Qty

S5 Leg Set

Leg, Left, Finished

Leg, Right, Finished

Keyboard Tray Assembly

Keyboard Palm Rest

S5 Control Surface/Frame Manual

One of the following Frame Kits

Frame, 6ft

Frame, 9ft

Frame, 12ft

The specified number of the following modules:

CM401

CM402

CM408

CM409-HTP

Serial Mouse Extender

CM409-H 946-06650-01

CM409-F 946-06651-01

946-07220-01

726-06398-01

726-06419-01

726-06415-01

726-07216-01

840-07576-01

946-06425-01

946-06840-01

946-07160-01

946-05718-01

946-05719-01

946-05717-01

946-07000-01

032-07169-00

1

1

1

1

1

Safety and Precautions

1) Read Instructions - Read all the safety and operation instructions before

operating the System 5 Control Surface.

2) Heed Warnings – Follow all warnings on the Control Modules and in these

operating instructions.

3) Water and Moisture – Do not use the Control Surface near water.

4) Heat – Locate the Control Surface away from heat sources.

5) Power Sources – Connect the Control Modules only to a power supply of the

type described in these operation instructions or as marked on the Control

Modules.

6) Power Cord Protection – Route power cords so that they are not likely to be

walked upon or pinched by items placed on them.

7) Object and Liquid Entry – Do not drop objects or spill liquids on the Control

Surface.

8) Damage Requiring Service – The Control Modules should be serviced only by

qualified personnel when:

S5 Control Surface/Frame Manual Page 4 Version 1.0 ©1999 Euphonix, Inc.

Page 5

a) Objects have fallen, or liquid has spilled into the Control Modules;

or

b) A Control Module does not appear to operate or exhibits a marked

change in performance; or,

c) A Control Module has been dropped or sustained other physical

damage.

7) Servicing – Do not attempt to service the Control Modules beyond those

means described in this operation manual. All other servicing should be

referred to the Euphonix Tech Support department.

8) Fuse replacement – To prevent electric shock and avoid risk of fire, replace

fuse only with the same type and rating.

9) To prevent electric shock, do not use the Control Modules polarized plug with

an extension cord, receptacle or other outlet unless the blades can be fully

inserted to prevent blade exposure.

10) Grounding or Polarization – Do not defeat the grounding or polarization of

the Control Modules.

Power On Sequence

The Control Surface modules are powered up by a switch on the back of the frame.

The Control Surface should be powered up after the Virtual Mixer is running.

CE/TUV/UL/CSA

CE documentation is available.

S5 Control Surface/Frame Manual Page 5 Version 1.0 ©1999 Euphonix, Inc.

Page 6

Component Overview

Functional Description

The System 5 Console consists of a frame and leg assemblies which house a

configurable number of Control Modules that comprise the Control Surface. The

System 5 Control Surface is the digital control center for all the System 5 component

assemblies. The Control Surface communicates with the System 5 component

assemblies via Ethernet network connections. Control signals are transmitted to the

Euphonix EH224 EuCon Hub and distributed to the various System 5 component

assemblies. No audio passes through the Control Surface.

Available in 6 foot, 9 foot, and 12 foot frame widths, the System 5 Control Surface

is modular in construction. The number and variety of Control Modules are

configurable based on the specific needs of each facility. Control modules are 12

inches wide. Filler modules can be ordered in full or half width.

S5 Control Surface/Frame Manual Page 6 Version 1.0 ©1999 Euphonix, Inc.

Page 7

FRAME SECTION

Physical Specifications

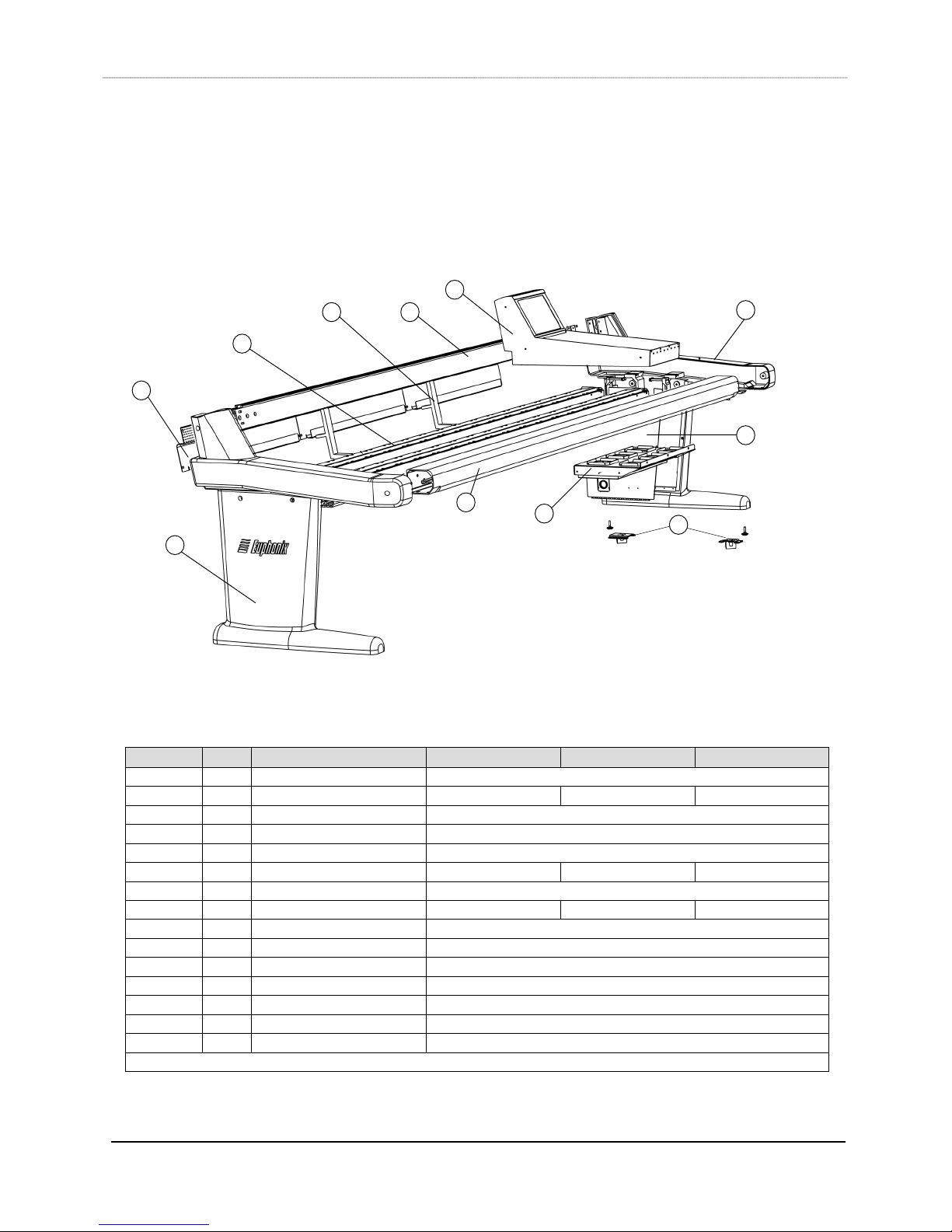

21

15 13

2

16

1

18

7

3

19

10

Exploded View

Item No. Qty Description Part No. 6ft Part No. 9ft Part No. 12ft

1 1 Leg, Right, Finished 726-06419-01

2 2 Box beam 726-06399-01 726-06437-01 726-07164-01

3 1 Leg, Left, Finished 726-06398-01

7 1 Palm beam 726-06415-01

10 4 Caster Brackets

13 1 Back beam-9 726-06408-01 726-06430-01 726-07163-01

15 2 Brace 1 726-06404-01

16 3 Cover, back, 3ft 726-06686-01 (1) 726-06686-01 (2) 726-06686-01 (3)

18 1 Leg panel Left – 726-06394-01 Right – 726-06826-01

19 1 Keyboard Tray Assy 726-06415-01

21 1 CM401 assembly 946-05718-01

21 * CM402 assembly 946-05719-01

21 * CM408 assembly 946-05717-01

21 * CM409F assembly 946-06651-01

21 * CM409H assembly 946-06650-01

* Qty depends on specified configuration

S5 Control Surface/Frame Manual Page 7 Version 1.0 ©1999 Euphonix, Inc.

Page 8

Side Panel View

41”

27

30.5”

13

29.5”

24.2”

21

7

8

19

2

2

6

15

16

39.5”

18

22 12

Item No. Qty Description Part No. 6ft Part No. 9ft Part No. 12ft

2 2 Box Beam 726-06399-01 726-06437-01 726-07164-01

6 1 Plate, compression 726-06402-01

7 2 Palm Beam 726-0403-01 726-07168-01 726-07162-01

8 1 Plate, spread 726-06404-01

12 4 Caster 726-06407-01

13 1 Back beam 726-06408-01 726-06430-01 726-07163-01

15 2 Brace 726-06411-01

16 * Cover, back, 3ft 726-06686-01 (2) 726-06686-01 (3) 726-06686-01 (4)

18 2 Leg Panel 726-06394-01 (Left) 726-06826-01 (Right)

19 1 Keyboard Tray Assy 726-06415-01

21 1 CM401 assembly 946-05718-01

21 * CM402 assembly 946-05719-01

21 * CM408 assembly 946-05717-01

21 * CM409F assembly 946-06651-01

21 * CM409H assembly 946-06650-01

22 4 Foot, level 000-06434-00

27 1 Talk Back Mic 302-07044-00

* Qty depends on specified configuration

S5 Control Surface/Frame Manual Page 8 Version 1.0 ©1999 Euphonix, Inc.

Page 9

Dimensions and Weight

Height: 39.5 inches

Width: Frame size + 10”

Depth: 41 inches

Weight: Frame without modules

6ft Frame: 245lbs (111kg)

9ft Frame: 300lbs (136kg)

12ft Frame: 380lbs (172kg)

Approximately 14 inches of depth should be left behind the System 5 Control

Surface for cable connections.

S5 Control Surface/Frame Manual Page 9 Version 1.0 ©1999 Euphonix, Inc.

Page 10

User Reference - Frame

Assembling the S5 Frame

Tools required:

• Hex drivers, 1/8”, 3/16”, 7/32”, ¼”, 5/32”

• Flat-bladed screwdriver, ¼”

• Socket wrench, ½”

• Silicon grease for bolts (Finish Line bicycle grease works great)

• Aux leg (item 20, not shown on some frame drawings)

• Bus wire, two 24” pieces

• Tap set for 3/8” 24 (3/8” 16 for newer box beams) and 5/16 18 threads

Minimum number of people required: 2. For a 12-foot frame, 3 people are

required.

Refer to the System 5 Frame drawings (pages 7-8) and the Parts Lists at the end

of this manual to help with parts identification and visualization of the steps set

forth in this procedure.

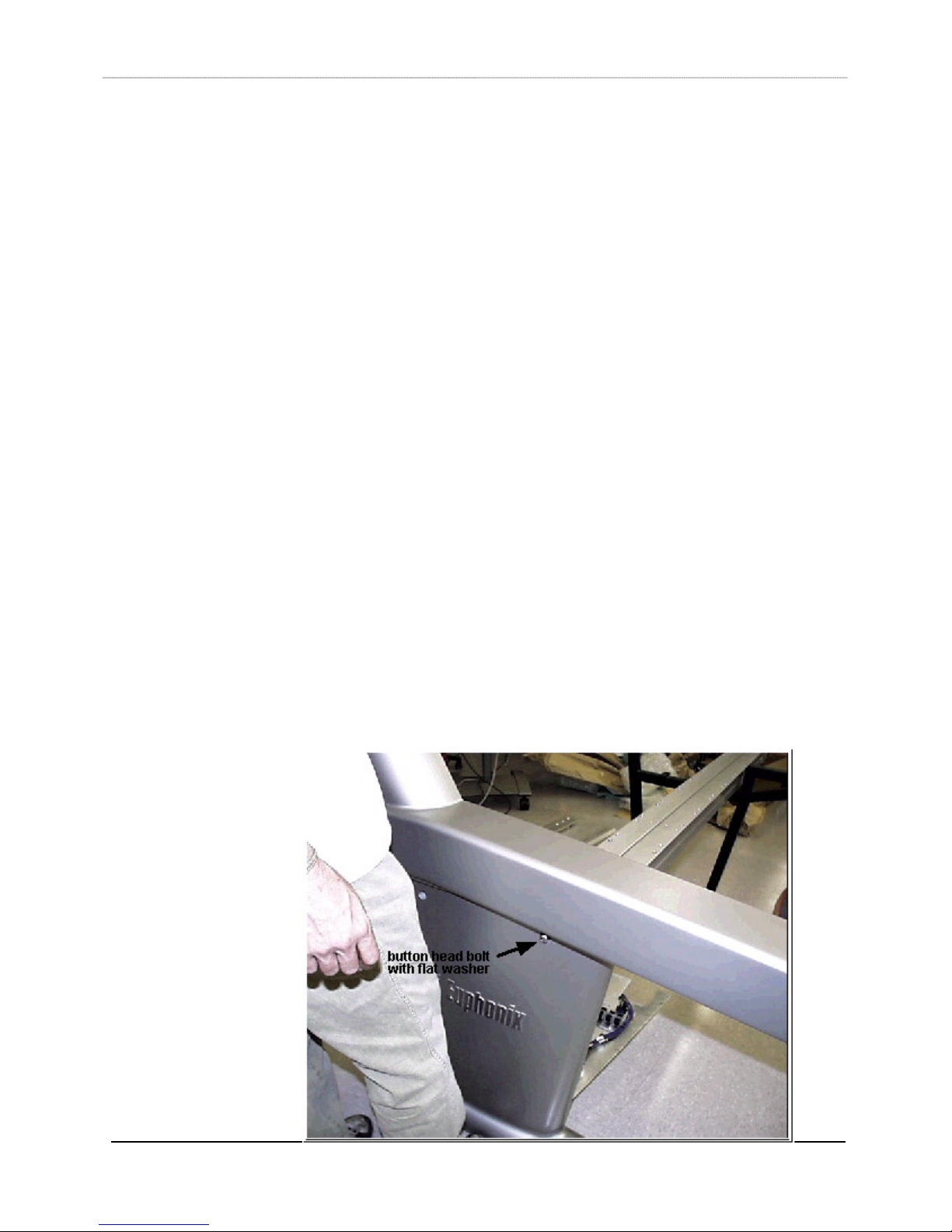

1) Verify that all screws and bolts have been greased. If they aren’t greased, apply

silicon grease to all of them.

2) Start with inserting the middle box beam (item 2) in the left leg (item 3, Leg Left).

You may have to drop the leg panel (item 18, legpnl) to get it in easily. Two people

need to hold up the beam, while the third person holds up the leg. Guide the beam

into the leg (flat side up). Insert a 3/8” 24x1.5 button head bolt (046-06421-00)

with a 3/8” flat washer (081-07193-00) through the leg hole and into the beam,

being careful not to strip the threads. Tighten the bolt fully, using a 7/32” hex

S5 Control Surface/Frame Manual Page 10 Version 1.0 ©1999 Euphonix, Inc.

Page 11

driver.

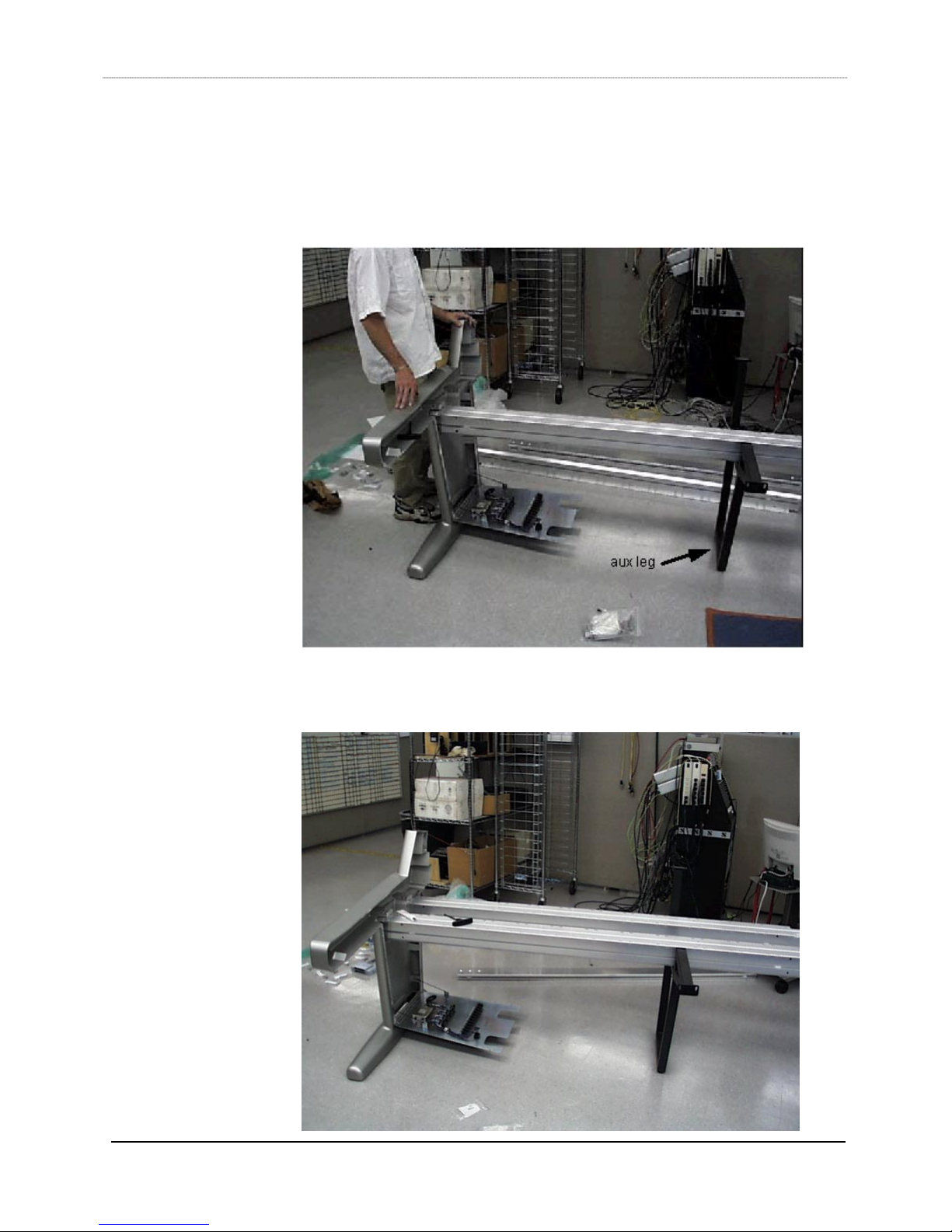

3) After the beam is attached to the leg, the auxiliary leg (12 ft frame only, item 20)

can be put underneath the beam near the center to hold it up. Secure the auxiliary

leg to the beam by inserting a “T” nut (000-06690-00) into the beam, and thread a

5/16x18x0.50 screw (044-07192-00) through the auxiliary leg mounting hole and

into the “T” nut.

4) Insert the rear box beam (item 2) into the left leg next, using the same techniques

outlined in step 2. The auxiliary leg can help to hold up the beam.

S5 Control Surface/Frame Manual Page 11 Version 1.0 ©1999 Euphonix, Inc.

Page 12

5) Prior to inserting the palm beam (item 7) into the left leg, thread the bus wire

through one of the holes of the spread plate (part#726-06404-01, item 8), twistlocking the wire at the spread plate end. Run the other end of the wire through its

matching bolt hole on the left end of the palm beam. The spread plate should mount

inside the end of the palm beam, flat side up. As the palm beam is inserted into the

left leg (rounded side out) guide the bus wire into the matching bolt hole of the leg.

Insert a 3/8” 24x1.5 button head bolt through the leg hole and into the beam, using

the same techniques outlined in step 1. The auxiliary leg can help to hold up the

S5 Control Surface/Frame Manual Page 12 Version 1.0 ©1999 Euphonix, Inc.

Page 13

beam.

6) Insert the back beam (item 13) into the left leg, using the same techniques outlined

in step 1. The auxiliary leg can help to hold up the beam.

7) Insert as many “T” nuts in the beams as required. For example, you will need 3 “T”

nuts for the middle box beam’s inner channel and 3 “T” nuts for the palm beam’s

inner channel in order to install the keyboard tray. You will need 4 “T” nuts for each

back cover brace (item 15, brace 1), 2 for the back beam bottom channel and 2 for

the rear box beam outside channel. You will need 2 “T” nuts for each power strip,

usually mounted on the rear box beam.

8) With the auxiliary leg holding up one end of the S5 frame, insert the four beams into

the right leg (item 1, Leg Right), using the same techniques outlined in step 1.

S5 Control Surface/Frame Manual Page 13 Version 1.0 ©1999 Euphonix, Inc.

Page 14

Also, for the palm beam, use the same technique with the spread plate and bus wire

as outlined in step 4.

9) Install the four box beam braces (item 4) on each end of the box beams. Use four

5/16-18x3.5 bolts (043-06688-00) and four 5/16 lock washers (082-066889-00) for

each box beam brace. Use a ½” socket wrench. Do not tighten down fully until the

frame is fully loaded and its width is checked.

10) To secure the spread plates into the palm beam ends, pull down on the bus wire, and

line up the spread plate screw holes with the leg screw holes. With a 3/16” hex

driver, insert a 5/16-18x1.125 flathead screw (046-06409-00) into spread plate screw

hole sans the bus wire. Once the screw is threaded in and tightened down, remove

the bus wire and insert the other counter-sunk screw in the screw hole that the bus

wire previously occupied. You may have to loosen the other screw a little in order to

remove the bus wire.

11) Using the 3/16” hex driver and 5/16-18x2.25 flathead screws (046-06401-00), install

the spread plates (part# 726-06402-01, items 5 & 6) into the back beam ends. (Like

spread plate pictured in Step 5.)

12) Install all the modules into the frame to ensure that their surfaces are flush. Use the

thumbscrews (936-07240-01, S5 thumbscrew kit, 4 per module) to secure the

modules to the box beams. Before installing the 401 module permanently into the

frame, attach the talkback mic bracket (936-07219-01, S5 talkback mic kit) into the

middle top screw hole of the SBC panel, using the screw and insulating washer

supplied in the S5 talkback mic kit.

13) After verifying that the control surface is acceptable, tighten all loose screws and

bolts in the frame. Tighten the bolts on the box beam braces only until their lock

washers flatten, and no further. You will have to temporarily remove the modules on

each end of the frame to be able to tighten the box beam braces.

S5 Control Surface/Frame Manual Page 14 Version 1.0 ©1999 Euphonix, Inc.

Page 15

14) Using a ¼” hex driver and 5/16x18x0.375 socket head screws (044-06686-00), install

the back cover braces (item 15, brace 1). Determine the position of the braces by

aligning them with the back cover mounting screw holes. Move the slide nuts in the

rear box beam and back beam to the brace locations, and mount the braces to them.

S5 Control Surface/Frame Manual Page 15 Version 1.0 ©1999 Euphonix, Inc.

Page 16

15) Using a 5/32“ hex driver and 1/4x20/3/8 button head screws (044-07236-00), install

the back covers on the braces.

16) Determine where the power strips (part#600-07223-00)) are going to be mounted on

the rear box beam, line up the slide nuts in the box beam to match the mounting

holes of the power strips, and use a ¼” hex driver with 5/16x18x0.375 socket head

screws to mount the power strips into the slide nuts.

17) Determine where the keyboard drawer (item 19, kbd drawer) is going to be located,

then line up the slide nuts in both box beams (the distance between the screw holes

on each box beam end of the keyboard drawer is xx”). Use a ¼” hex driver with

5/16x18x0.375 socket head screws to mount the drawer into the slide nuts.

S5 Control Surface/Frame Manual Page 16 Version 1.0 ©1999 Euphonix, Inc.

Page 17

18) If the network, power, and talkback mic cables are not going to enter the S5 frame

from the bottom of a leg, then the leg panel supporting the cabling will have to have

its knockout plate removed. Remove the leg panel from the leg before punching.

The punch direction should be from the outside to the inside. Support the knockout

hole on the inside of the leg panel with a roll of duct tape, or something similar.

This will alleviate any distortion to the leg panel metal while punching.

S5 Control Surface/Frame Manual Page 17 Version 1.0 ©1999 Euphonix, Inc.

Page 18

System 5 Ethernet/Power Cable Configuration

S5 Control Surface/Frame Manual Page 18 Version 1.0 ©1999 Euphonix, Inc.

Page 19

System 5 Ethernet Cable Harness

1

(TYP 30 PLACES)

LABEL EACH CABLE AS INDICATED

A1-A15

A1

1

2

3

4

5

6

7

8

9

(TYP BOTH ENDS)

(TYP 15 PLACES)

5

31.0'

1

2

3

4

5

6

7

8

9

A16

A16-A30

10

11

12

13

14

15

MACHINE ROOM

1.0' (x15)

(TYP BOTH ENDS)

SEE DETAIL 'A'

A30

5.0'

B1

10

2

A15

CONSOLE

LABEL CABLE AS INDICATED

(TYP BOTH ENDS)

11

12

13

14

15

6

4

POINT B

3

POINT A

2

(TYP BOTH ENDS)

DETAIL 'A'

CONNECTOR

MATING

A1-A16

A2-A17

A3-A18

A4-A19

A5-A20

A6-A21

A7-A22

A8-A23

A9-A24

A10-A25

A11-A26

A12-A27

A13-A28

A14-A29

A15-A30

B1-B2

:

Notes

1. All dimensions are in feet

2. Make sure that all wire ends are flush with "Point A". Typical 30 places

3. Make sure that the insulation jacket of the cable reaches to "Point B" when crimping terminal. Typical 2 places. Cable ends are to be

terminated according toTIA/EIA 568b standards.

A1-A30 WIRE LIST

A1-A15

CABLE ASSEMBLY PARTS LIST

ITEM QTY MFR MFR P/N DESCRIPTION

1 30 PHYCO 1001-8P8CSR RJ45 PLUG, 8-8, RND SLD

2 1 NEUTRIK NC3FX XLR 3PIN FEMALE CABLE CONNECTOR

3 1 NEUTRIK NC3MX XLR 3PIN MALE CABLE CONNECTOR

4 41' GEPCO MP1022 BLACK 2 LEAD SHIELDED CABLE, 24AWG

5 495' BELDEN MEDIA TWIST 350(1872A)BLUE 4 PAIR UTP CABLE, 24AWG SOLID COPPER

6 31' TECHFLEX CCPT6X EXPANDABLE SLEEVING

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

A16-A30

PIN 1

PIN 2

PIN 3

PIN 4

PIN 5

PIN 6

PIN 7

PIN 8

WIRE COLOR

WHT/ORG

ORG

WHT/GRN

BLU

WHT/BLU

GRN

WHT/BRN

BRN

B1-B2 WIRE LIST

B1

B2

1

1

2

2

3

3

WIRE

DRAIN

WHITE

BLACK

SIGNAL

GND

HOT

COLD

S5 Control Surface/Frame Manual Page 19 Version 1.0 ©1999 Euphonix, Inc.

3

B2

Page 20

CONTROL MODULE SECTION

S5 Control Surface/Frame Manual Page 20 Version 1.0 ©1999 Euphonix, Inc.

Page 21

CONTROL MODULES SECTION

Physical Specifications

Top View - Control Modules

6’10”

5”

41”

12”

D

A B C

1 3 A

Frames are available in 6ft, 9ft, and 12ft sizes. Actual width of Control Surface is

frame size + 10 inches.

Item No. Qty Description Part No.

A * CM408 Control Module 946-05717-01

B * CM402 Control Module 946-05719-01

C 1 CM401 Control Module 946-05718-01

D * TFT Display Inc. in CM Module

1 1 Leg, right 726-06419-01

3 1 Leg, left 726-06398-01

*

Qty depends on specified configuration

S5 Control Surface/Frame Manual Page 21 Version 1.0 ©1999 Euphonix, Inc.

Page 22

Filler Modules

CM409F CM409H CM409HTP

CM409F- This is the full-wide blank module for S5 Control surfaces. It can be

placed anywhere within the control surface to fill up the frame. It provides a working

surface for remote controls, keyboards, etc. Order part# 946-06651-01.

CM409H- This module is a half-wide blank module for S5 Control surfaces. It

module is similar to a CM409F but only half the width. Order part# 946-06650-01.

CM409HTP- This module is a half-wide Track Panner. It is the same width as the

CM409H. The CM409HTP contains a high quality track ball for panning and two

switches for Pan Select/Punch and Channel Pan Function. Order part# 946-07000-01.

S5 Control Surface/Frame Manual Page 22 Version 1.0 ©1999 Euphonix, Inc.

Page 23

Dimensions and Weight

Module Weight Width

CM401: 35lbs (16kg) 12”

CM402: 35lbs (16kg) 12”

CM408: 35lbs (16kg) 12”

CM409F: 16lbs (7kg) 12”

CM409H: 9lbs (4kg) 6”

CM409HTP: 10lbs (4.5kg) 6”

Approximately 14 inches of depth should be left behind the System 5 Control

Surface for cable connections.

Technical Specifications

Environmental Requirements

Environmental requirements for the System 5 Control Modules are as follows:

Operating Temperature: 0 to 40 degrees Celsius (ambient)

Storage Temperature: -10 to 55 degrees Celsius

Humidity: 0 to 90% non-condensing

Power Requirements

90 to 254 Volts AC (rms), 50/60Hz, 150 Watts per module.

Power Consumption

Power consumption of the Control Surface Modules is shown in the table below.

Module US (117V) Europe (230V) Japan (100V)

CM401 1.0A .5A 1.0A

CM402 1.0A .5A 1.0A

CM408 1.0A .5A 1.0A

Individual Module Power Consumption

• Inrush current : 25 Amps

• Fuse Rating: 5Amp Slo-Blo or Time Delay

S5 Control Surface/Frame Manual Page 23 Version 1.0 ©1999 Euphonix, Inc.

Page 24

Control Module Expansion Port

General Description

On the back of each System 5 Control Module (CM401, CM402, and CM408,) is a

DB25 Euphonix Expansion Port. This port is a hardware interface to external devices,

and supports 8 switch inputs and 8 LED/relay drive outputs. This document describes

the pinout and typical usage of this port.

Physical Pinout

The Expansion Port on the module is a DB25 female connector. A DB25 male cable

needs to be built to interface to this port (pictured below). The pinout has been

configured for easy interface to the Euphonix GP132 box, and is as shown on the

following page:

S5 Control Surface/Frame Manual Page 24 Version 1.0 ©1999 Euphonix, Inc.

Page 25

Looking into the FEMALE connector on the module:

13

25

1

14

Looking into a MALE cable connector:

1 13

14 25

Pin # Signal

1 LED 1 output (active low)

2 Switch 1 input (active high)

3 +5V

4 LED 3 output (active low)

5 Switch 3 input (active high)

6 +5V

7 LED 5 output (active low)

8 Switch 5 input (active high)

9 +5V

10 LED 7 output (active low)

11 Switch 7 input (active high)

12 +5V

13 +5V

14 +5V

15 LED 2 output (active low)

16 Switch 2 input (active high)

17 +5V

18 LED 4 output (active low)

19 Switch 4 input (active high)

20 +5V

21 LED 6 output (active low)

22 Switch 6 input (active high)

23 +5V

24 LED 8 output (active low)

25 Switch 8 input (active high)

S5 Control Surface/Frame Manual Page 25 Version 1.0 ©1999 Euphonix, Inc.

Page 26

DB25 Electrical Specification:

The +5V output on the connector is protected internally by a 200mA self-resetting

fuse. If LED drive outputs are used, it is recommended that several +5V connections

be used to drive the anodes of the LED’s (at least one +5V wire per LED used). The

active-low LED drive outputs are current limited by internal 110 ohm series resistors,

and are capable of sinking 20mA each. The active-high switch inputs are TTL-level

inputs with 100K pull-down resistors.

Typical Usage:

Currently, the software supports remote talkback switching and status on Switch

inputs 1-4 and LED outputs 1-4 on the CM401 Expansion Port only. Functionality is

as follows:

Function Triggered by Status shown on

Talkback ! Mon A Switch 1 input

LED 1 output

(momentary)

Talkback ! Mon B Switch 2 input

LED 2 output

(momentary)

Talkback ! Mon C Switch 3 input

LED 3 output

(momentary)

Talkback ! Mon D Switch 4 input

LED 4 output

(momentary)

For example, while Switch 1 is pressed down, the Talkback mic signal will be

routed to the Mon A output, and LED 1 will light during the time that the switch is

pressed down. Also, if Talkback ! Mon A is activated from the console itself, LED 1

will also light, to indicate the status.

Pressing SW1A routes the Talkback signal to Mon A, and the SW1B LED lights to

indicate the Talkback!Mon A status.

PINS 3, 6, 9, 12, 13, 14, 17, 20, 23 (PICK ANY 4)

+5V

3

4

6

SW1A

SW1B

LIGHTED SWITCH

2

1

5

PIN 2 PIN 1

S5 Control Surface/Frame Manual Page 26 Version 1.0 ©1999 Euphonix, Inc.

3

4

6

SW2A

SW2B

2

1

5

PIN 16 PIN 15

LIGHTED SWITCH

4

1

PIN 5 PIN 4

3

6

SW3A

SW3B

LIGHTED SWITCH

2

5

4

1

PIN 19 PIN 18

3

2

SW4A

6

SW4B

LIGHTED SWITCH

5

Page 27

Alternate Usage #1:

Another way of using these talkback inputs/outputs would be to have one switch

activate more than one talkback function. For example, a single switch can route the

Talkback signal to all four monitor outputs:

PINS 2, 16, 5, 19

PINS 3, 6, 9, 12, 13, 14, 17, 20, 23 (PICK ANY 4)

+5V

3

4

SW1A

2

1

PIN 1

D1

LED

PIN 15

D2

LED

PIN 4

D3

LED

PIN 18

D4

LED

Pushing SW1A routes the Talkback signal to all four monitor outputs, and LED’s

D1-D4 indicate the Talkback ! Mon A-D status.

S5 Control Surface/Frame Manual Page 27 Version 1.0 ©1999 Euphonix, Inc.

Page 28

Alternate Usage #2:

Another implementation combines the above two approaches – we have individual

Talkback enable buttons like in the Typical Usage, but we’ve added an ‘OMNI’ switch

that routes the Talkback signal to all four monitor outputs:

4

1

PIN 2

PINS 3, 6, 9, 12, 13, 14, 17, 20, 23 (PICK ANY 4)

+5V

3

D4

1N4148

4

SW1A

2

1

6

3

SW1A

2

SW1B

LIGHTED SWITCH

5

PIN 1

D1

1N4148

3

4

6

SW2A

2

1

PIN 16

SW2B

LIGHTED SWITCH

5

PIN 15

D2

1N4148

3

4

6

SW3A

2

1

PIN 5

SW3B

LIGHTED SWITCH

5

PIN 4

D3

1N4148

3

4

6

SW4A

2

1

SW4B

LIGHTED SWITCH

5

PIN 18

PIN 19

S5 Control Surface/Frame Manual Page 28 Version 1.0 ©1999 Euphonix, Inc.

Page 29

User Reference – Control Modules

Control Module Setup

Overview of Ethernet IP Address Allocation

Computers

Computer IP Address Pilot ID Frame ID Module ID

System Computer

Digital Pilot

Interface Pilot

Module IP Address Frame ID Module ID

CM401

CM402

CM408

192.168.0.1 N/A N/A

192.168.0.200 1 N/A 0

192.168.0.201 2 N/A 1

192.168.0.202 3 N/A 2

192.168.0.203 4 N/A 3

192.168.0.215 15 N/A 15

Control Modules

192.168.0.24 IL 15

192.168.0.25 IL 16

192.168.0.10 IL 1

192.168.0.11 IL 2

192.168.0.12 IL 3

192.168.0.13 IL 4

192.168.0.14 IL 5

192.168.0.15 IL 6

192.168.0.16 IL 7

192.168.0.17 IL 8

192.168.0.18 IL 9

S5 Control Surface/Frame Manual Page 29 Version 1.0 ©1999 Euphonix, Inc.

Page 30

Self Test Procedure for CM401, CM402 and CM408

(For CM40x Firmware Rev 1.0S)

The following pages describe the operation of standalone self test software for

System-5 control modules.

The self-test code is designed to be invoked in a module right after power-up and

before the SBC downloads code into the control module 386 board.

The self-test works in a fully assembled module as well as with just the upper

board or just the lower board connected to the CPU board. However, the upper board

must be present to run fader test modes.

All the three types of control modules have the same lower board. Because of this,

the lower board can be tested separately without an upper board connected. The selftest can be invoked from the lower board knobs as well as upper board self test keys.

S5 Control Surface/Frame Manual Page 30 Version 1.0 ©1999 Euphonix, Inc.

Page 31

y

Initiating Self Test

Enter self-test by pressing the self-test enter keys shown below. This must be

done before the SBC code download. If code download from the SBC happens during

self-test, then the module will automatically exit self-test and execute downloaded

code.

G p S L

N o n B

B o o m

P a n R

S u r r

D i v F

F o c F

P a n F

cfg

cpy pst

Insrt In

Dyn In

EQ In

Filts In

Pan to:

G

R

route

P

swap

select

main

N a m e

select

MSL

MSL

12

6

0

6

12

18

24

30

36

42

48

60

72

Enter Self-Test

*

cpy pst

Insrt In

Dyn In

Filts In

Pan to:

M

I

X

G p S L

N o n B

B o o m

P a n R

S u r r

D i v F

F o c F

P a n F

EQ In

G

R

P

swap

select

main

select

MSL

MSL

s

Rec Rec Rec Rec Rec Rec Rec Rec

12345678

G p S L

Rec Rec Rec Rec Rec Rec Rec Rec

17 18 19 20 21 22 23 24

Rec Rec Rec Rec Rec Rec Rec Rec

33 34 35 36 37 38 39 40

N o n B

ABCDEFGH JKMNPQRS

2 4 6 P a n

B o o m

1357 8

P a n R

S u r r

D i v F

x A t k x R l s

F o c F

x R a t

P a n F

cfg

cfg

cpy pst

N a m e

On

*

Input

Dyn

EQ

Filts

Aux

Pan

route

swap

N a m e

solo

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

solo

*

Insrt In

N a m e

Input

On

Dyn In

solo

Dyn

N a m e

EQ In

EQ

On

Filts

solo

Filts In

N a m e

Aux

Pan to:

On

solo

Pan

G

M

M

R

I

I

P

X

X

route

swap

swap

swap

select

select

chan

main

N a m e

select

select

solo

MSL

MSL

MSL

MSL

ON

x

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

cfg

Num

N a m e

All All Record

Repro Input SafeRecord Machine

R - 1

In

A u x

Slct/Pnch

In

D y n

c D p t c G M Ux D p t x H y s

c A t k

c R a t c T h r

x T h r

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Strp

On

Slv

swap

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Assign Knobs

P1 P2 P3 P4 P5 Store P

c R l s

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

Solo

swap

swap

swap

select

chan

N a m e

select

solo

MSL

MSL

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

Rec

Ready

C l a r i n e t

solo

ON

On

solo

On

solo

On

solo

On

solo

Rec Rec Rec Rec Rec Rec Rec Rec

910111213141516

25 26 27 28 29 30 31 32

Rec Rec Rec Rec Rec Rec Rec Rec

Rec Rec Rec Rec Rec Rec Rec Rec

41 42 43 44 45 46 47 48

Grp

Route

F l t s I n s D y n E Q

F 1 t p

L o Q l m Q h m Q H i Q

L o F

L o G

N a m e

N a m e

N a m e

N a m e

swap

select

chan

select

MSL

MSL

12

6

0

6

12

18

24

30

36

42

48

60

72

ClrPstCpyGrp

swap

N a m e

Route

Knob Values

solo

ON

Mix

Route to

Sections

F 1 F F 2 F

l m F

l m G

On

solo

On

solo

On

solo

On

solo

swap

select

chan

select

MSL

MSL

Slct/Pnch

N a m e

N a m e

N a m e

N a m e

12

12

18

24

30

36

42

48

60

72

Pan to:

Grp Buses

f l t s

E Q

Page

swap

N a m e

solo

ON

6

0

6

Press both ke

G p S L

G p S L

G p S L

G p S L

G p S L

N o n B

N o n B

N o n B

N o n B

N o n B

B o o m

B o o m

B o o m

B o o m

B o o m

P a n R

P a n R

P a n R

P a n R

P a n R

S u r r

S u r r

S u r r

S u r r

S u r r

D i v F

D i v F

D i v F

D i v F

D i v F

F o c F

F o c F

F o c F

F o c F

F o c F

P a n F

P a n F

P a n F

P a n F

P a n F

cfg

cfg

cfg

cfg

cfg

cpy pst

*

Insrt In

Input

Dyn In

Dyn

EQ In

EQ

Filts

Filts In

Aux

Pan to:

Pan

G

M

R

I

route

P

X

swap

swap

select

main

N a m e

select

solo

MSL

MSL

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

G

G

M

M

R

R

I

I

route

P

route

P

X

X

swap

swap

swap

swap

select

select

main

main

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Input

Dyn In

Dyn In

Dyn

Dyn

Dyn

EQ In

EQ In

EQ

EQ

EQ

Filts

Aux

Pan

M

I

X

swap

solo

ON

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

G

G

M

R

R

I

route

P

route

P

X

swap

swap

swap

swap

select

select

main

main

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Enter Self-Test

Press both Knob Switches

G p S L

B t y p

N o n B

B o o m

P a n R

S u r r

D i v F

F o c F

P a n F

cfg

cpy pst

Insrt In

Dyn In

EQ In

Filts In

Pan to:

G

R

route

P

swap

select

main

N a m e

select

MSL

MSL

12

6

0

6

12

00000000000000000

18

24

30

36

42

48

60

72

*

Input

Dyn

EQ

Filts

Aux

Pan

M

I

X

swap

solo

ON

B r n g

B t r m

A t y p

A r n g

A t r m

D l y

I n p t

cfg

Aux

Mstrs

Grp

Mstrs

Mix

Mstrs

ALL

Strip

s

Center Strip

III

ON

Grand

Master

0

6

12

18

24

30

36

42

48

54

60

72

84

Pan to:

Reverse

Route

Mix Buses

F 2 t p

In

cfg

In

h m F

H i F

h m G

H i G

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Scroll

swap

mstrs

swap

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

xxxxxxx

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Control Room

Dim Cut

Mix

On

Input

Route

ON

Fader

Strips Only

Preview

Move

Punch

Select

Start

Fill

<--

Undo Redo

Keys

All

LR phase

LLiCRiR

Pass

View

Dyn

EQ

Filts

Aux

Pan

Glide

On

ATO

On

Select

End

Fill

-->

Mon D

Source

Mon C

Source

Mon B

Source

Mon A

Source

L4

Solo

L3

Ctrl

L2

L1

Comms

T2

Ctrl

T1

CR

Output

SlSr B

CR

Source

Main

Spkrs

Main

Panel

Alt 1

Spkrs

Alt 2

Spkrs

Slate / OscTalk ListenComms

ON

Save

Time

Mix

Display

hr min sec / ft fr / ms

+-=

789

456

bar beat tick

locate time

Edit

Cue Recall

Isolate

Read

Write

Abs

Write

Trim

Info

Trim+Trim

Locate

Reg’s

-

Store

Store

Curren

Locate

t

123

.

0

Clear

Enter

Hold

On

Fill to

Punch

Pass

Record

Shuttle

Loc

Trim

Roll

Back

Jog Return

Reh

Auto

Punch

Rec

CM408 CM402 CM401

S5 Control Surface/Frame Manual Page 31 Version 1.0 ©1999 Euphonix, Inc.

Page 32

Self Test Operations

The operation of each key on the upper and lower board is described in this

document.

G p S L

N o n B

B o o m

P a n R

S u r r

D i v F

F o c F

P a n F

cfg

cpy pst

Insrt In

Input

Dyn In

EQ In

Filts In

Pan to:

G

R

P

route

swap

swap

select

main

N a m e

select

MSL

MSL

12

6

0

6

12

18

24

30

36

42

48

60

72

Rec Rec Rec Rec Rec Rec Rec Rec

G p S L

G p S L

G p S L

G p S L

G p S L

G p S L

N o n B

N o n B

N o n B

N o n B

N o n B

N o n B

B o o m

B o o m

B o o m

B o o m

B o o m

B o o m

P a n R

P a n R

P a n R

P a n R

P a n R

P a n R

S u r r

S u r r

S u r r

S u r r

S u r r

S u r r

D i v F

D i v F

D i v F

D i v F

D i v F

D i v F

F o c F

F o c F

F o c F

F o c F

F o c F

F o c F

P a n F

P a n F

P a n F

P a n F

P a n F

P a n F

cfg

cfg

cfg

cfg

cfg

cfg

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

M

G

G

R

R

I

I

P

P

X

X

route

route

swap

swap

swap

select

select

main

main

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

M

G

G

R

R

I

I

P

P

X

X

route

route

swap

swap

swap

swap

select

select

main

main

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

cpy pst

cpy pst

*

Insrt In

Input

Dyn In

Dyn

EQ In

EQ

Filts

Filts In

Aux

Pan to:

Pan

M

G

R

I

P

X

route

swap

swap

select

main

N a m e

select

solo

MSL

MSL

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

M

G

R

I

I

P

X

X

route

swap

swap

swap

select

main

N a m e

select

solo

solo

MSL

MSL

MSL

ON

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

12345678

G p S L

Rec Rec Rec Rec Rec Rec Rec Rec

17 18 19 20 21 22 23 24

Rec Rec Rec Rec Rec Rec Rec Rec

33 34 35 36 37 38 39 40

N o n B

ABCDEFGH JKMNPQRS

2 4 6 P a n

B o o m

1357 8

P a n R

S u r r

D i v F

x A t k x R l s

F o c F

x R a t

P a n F

cfg

N a m e

On

solo

*

N a m e

Input

On

solo

Dyn

N a m e

EQ

On

Filts

solo

N a m e

Aux

On

solo

Pan

G

M

R

I

P

route

X

swap

swap

swap

select

select

chan

main

N a m e

select

select

solo

MSL

MSL

MSL

ON

x

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Num

cfg

N a m e

All All Record

Repro Input SafeRecord Machine

R - 1

In

A u x

Slct/Pnch

In

D y n

c D p t c G M Ux D p t x H y s

c A t k

c R a t c T h r

x T h r

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Strp

On

Slv

swap

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Rec Rec Rec Rec Rec Rec Rec Rec

Rec Rec Rec Rec Rec Rec Rec Rec

Rec Rec Rec Rec Rec Rec Rec Rec

Rec

Ready

F 1 t p

Assign Knobs

C l a r i n e t

P1 P2 P3 P4 P5 Store P

L o Q l m Q h m Q H i Q

L o F

c R l s

L o G

N a m e

On

On

solo

solo

N a m e

On

On

solo

solo

N a m e

On

On

solo

solo

N a m e

On

On

solo

solo

Solo

swap

swap

swap

swap

select

select

chan

chan

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

910111213141516

25 26 27 28 29 30 31 32

41 42 43 44 45 46 47 48

Grp

Mix

Route

Route

F l t s I n s D y n E Q

Knob Values

N a m e

N a m e

N a m e

N a m e

ClrPstCpyGrp

swap

N a m e

solo

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

Route to

Sections

F 1 F F 2 F

Slct/Pnch

l m F

l m G

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

Page

swap

swap

select

chan

N a m e

select

solo

MSL

MSL

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

Pan to:

Reverse

Pan to:

Route

Mix Buses

Grp Buses

F 2 t p

In

f l t s

cfg

In

E Q

h m F

H i F

h m G

H i G

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Scroll

swap

mstrs

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

MSL

MSL

MSL

MSL

ON

xxxxxxx

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

G p S L

B t y p

N o n B

B r n g

B o o m

B t r m

P a n R

A t y p

S u r r

A r n g

D i v F

A t r m

F o c F

D l y

P a n F

I n p t

cfg

cfg

cpy pst

Aux

Mstrs

*

Insrt In

Grp

Input

Mstrs

Dyn In

Mix

Dyn

Mstrs

EQ In

EQ

Filts

Filts In

Aux

Pan to:

Pan

ALL

Strip

M

G

R

s

I

P

X

route

swap

swap

solo

ON

swap

select

main

select

MSL

MSL

12

12

18

00000000000000000

24

30

36

42

48

60

72

N a m e

solo

ON

6

0

6

Center Strip

III

ON

Grand

Master

0

6

12

18

24

30

36

42

48

54

60

72

84

Control Room

Dim Cut

Mix

Input

Route

Fader

Strips Only

Preview

Move

Punch

Select

Start

Undo Redo

Mon D

Source

Mon C

Source

Mon B

Source

Mon A

Source

L4

Solo

L3

Ctrl

L2

L1

Comms

T2

Ctrl

T1

CR

LR phase

Output

LLiCRiR

SlSr B

CR

Source

Main

Spkrs

Main

Panel

Alt 1

Spkrs

Alt 2

Spkrs

Slate / OscTalk ListenComms

ON

Pass

Save

Time

View

Mix

On

All

Keys

ON

Fill

<--

Display

hr min sec / ft fr / ms

+-=

789

456

123

.

0

Clear

Enter

Loc

Trim

Roll

Back

bar beat tick

locate time

Edit

Cue Recall

Shuttle

Dyn

Isolate

EQ

Read

Filts

Aux

Write

Abs

Pan

Write

Trim

Glide

On

ATO

On

Hold

Select

End

On

Fill

Fill to

Punch

-->

Pass

Record

-

Store

Curren

t

Jog Return

Info

Trim+Trim

Locate

Reg’s

Store

Locate

Reh

Auto

Punch

Rec

CM408

Upper Board

Test Keys

S5 Control Surface/Frame Manual Page 32 Version 1.0 ©1999 Euphonix, Inc.

CM402

CM401

Lower Board

Test Keys

Page 33

C

gg

Top Level Test Keys

To enter the 6 different tests, use the keys shown below. After entering the test,

use the detailed description of each test on the following pages to navigate through

different test modes within a test.

CPU Board tests

cfg

cpy pst

CPU

test

Switch

test

Knob

test

Exit

Test

Insrt In

*

Input

Dyn In

Dyn

EQ In

EQ

Filts

Filts In

Aux

Pan to:

Pan

CM401/CM408

Knob Test

LED test

Switch Test

Display Test

Knob Test

Fader Test

Exit Test /Exit to

main

LoF

LED

test

On On On On

solo solo solo solo

Grp On

Display

Slv

test

Strp SoloNum

Fader

test

CM402

LoQ

LED Test

All LEDs

To

le

S5 Control Surface/Frame Manual Page 33 Version 1.0 ©1999 Euphonix, Inc.

LoF

LoF

LoQ

Halo LEDs

Cycle Test

LoQ

Press Together

to Exit Test/Exit

to top-level

tests

Lower Board

Page 34

A

A

LED test

The LED test has the following modes;

• Toggle upper board LEDs

• Toggle all LEDs

• LED color test

• Vegas mode

*

Input

Dyn

EQ

Aux

Pan

CM401/CM408

ll Switch LEDs

toggle

Color Toggle

All Switch and Indicator

LEDs toggle

Vegas Mode/Vegas

Mode fader cycle

toggle

Exit Test Key/Exit to

main

LoF

LoQ

ll Upper

LEDS

toggle

Color

toggle

Grp

CM402

All Upper

& Lower

LEDs

toggle

Slv

Vegas

Mode

Strp SoloNum

LED Color

Toggle Test

On

swapswapswap

Exit

Test

All LEDs

Toggle

S5 Control Surface/Frame Manual Page 34 Version 1.0 ©1999 Euphonix, Inc.

LoF

LoF

LoQ

Halo LEDs

Cycle Test

LoQ

Press Together

to Exit Test/Exit

to top-level

tests

Lower Board

Page 35

All Switch LEDs Toggle

This switch toggles all the upper board LEDs on and off. This mode times out after

5 mins if all LEDs are left ON and goes into Vegas mode.

Color Toggle

This switch cycles between the same color LEDs in the following order

• Green

• Red

• Yellow

• Orange

• Blue

All Switch and Indicator LEDs Toggle

This toggles all the upper and lower board LEDs including the daughter board

LEDs.

Vegas Mode

For thermal reasons, the module should not be left with all LEDs On. Use

NOTE:

Vegas mode for burn-in. For protection, the module will time out into Vegas mode if

all LEDs are left ON for more than 5 minutes.

Flashes alternate LEDs on and off. The default Vegas mode also puts the fader into

cycle test. Repeated presses of this key toggles the fader cycle on/off. If left

running, the fader cycle will time out after 5 minutes.

S5 Control Surface/Frame Manual Page 35 Version 1.0 ©1999 Euphonix, Inc.

Page 36

Switch Test

Switch test has the following modes;

Momentary switch press - This tests lights up the switch LED of a switch while it

is pressed.

*

Input

Dyn

EQ

Aux

Pan

CM402/CM408

Slv

CM402

Exit Test

Key/Exit to main

Strp SoloNum

On

Exit Test

PstCpyGrp

swapswapswapswap

S5 Control Surface/Frame Manual Page 36 Version 1.0 ©1999 Euphonix, Inc.

Page 37

Intelligent Display Test

Display bit test – This test lights up the whole of the intelligent display. It dims

the displays for the duration of this test to protect them from overheating and

burnout.

Display text - This test shows a text on each intelligent display, which happens

to be the hexadecimal display number in the software map.

This test is not accessible from the lower board.

Display bits test

*

Display text test

Input

Dyn

EQ

Aux

Pan

CM402/CM408

Display

Bits Test

Display

Text Test

Slv

Exit Test

Key/Exit to main

Strp SoloNum

On

Exit Test

PstCpyGrp

S5 Control Surface/Frame Manual Page 37 Version 1.0 ©1999 Euphonix, Inc.

swapswapswapswap

CM402

Page 38

Knob Test

• Halo Test

• Knob value display

• Knob meter display

• Knob switch test

• Expansion port switch test

*

Input

Dyn

EQ

Aux

Pan

CM401/CM408

Knob Test

Knob Halo

Test/Halo Test

Setup

Knob Meters

Knob Test

Exit Test Key/Exit to

main

LoF

LoQ

Knob

Halo

test

Knob

Value

Display

Grp

CM402

Knob

Meters

Display

Slv

Exit

Strp SoloNum

On

swapswapswap

Test

S5 Control Surface/Frame Manual Page 38 Version 1.0 ©1999 Euphonix, Inc.

LoF

LoF

LoQ

Halo LEDs

Cycle Test/LED

Cycle Step

LoQ

Press Together

to Exit Test/Exit

to top-level

tests

Lower Board

Page 39

Knob value display

Displays the hex 0 through FF value of the knob being currently moved on an

intelligent display. This mode is useful for testing the CM401 spin knob.

Halo Test

This cycles through all the knob halo and center LEDs by turning one LED on at a

time on each key press.

Knob meter display

Shows the knob value as a bar on the meter board (fader daughter board).

Knob switch test

All the knobs halo orange LEDs light up while the knob center switch is pressed.

The Expansion port switches are also tested in this mode. Pressing one of the eight

switches will light up its LED for as long as the key is pressed.

Expansion port switch test

See the Knob switch test section.

S5 Control Surface/Frame Manual Page 39 Version 1.0 ©1999 Euphonix, Inc.

Page 40

Fader Test

• All fader up

• All fader down

• Fader cycle test with speed control

• Fader echo test

• Touch Sense Test

• Backstop PFL switch test

• Fader Write value display

• Fader Read value display

• TFT backlight brightness test

This test is not accessible from the lower board.

All Fader Up

*

Input

Dyn

EQ

Aux

Pan

CM401/CM408

All Fader Down

Fader Cycle

Fader Echo

Exit Test Key/Exit to

main

All

Fader

Up

All

Fader

Down

Slv

Fader

Cycle

Strp SoloNum

Fader

Echo

On

Exit

Test

PstCpyGrp

S5 Control Surface/Frame Manual Page 40 Version 1.0 ©1999 Euphonix, Inc.

swapswapswapswap

CM402

Page 41

Fader Test (continued)

G p S L

N o n B

B o o m

P a n R

S u r r

D i v F

F o c F

P a n F

cfg

cpy pst

Insrt In

Dyn In

EQ In

Filts In

Pan to:

G

R

P

route

swap

select

main

N a m e

select

MSL

MSL

12

6

0

6

12

18

24

30

36

42

48

60

72

Fader Cycle

Speed

12345678

G p S L

N o n B

B o o m

P a n R

cpy pst

Insrt In

Dyn In

EQ In

Filts In

Pan to:

M

G

I

R

X

P

swap

select

main

select

MSL

MSL

S u r r

D i v F

F o c F

P a n F

cfg

On

solo

*

Input

On

solo

Dyn

EQ

On

Filts

solo

Aux

On

solo

Pan

M

I

route

X

swap

N a m e

solo

ON

12

6

0

6

12

18

24

30

36

42

48

60

72

Rec Rec Rec Rec Rec Rec Rec Rec

Rec Rec Rec Rec Rec Rec Rec Rec

17 18 19 20 21 22 23 24

Rec Rec Rec Rec Rec Rec Rec Rec

33 34 35 36 37 38 39 40

ABCDEFGH JKMNPQRS

2 4 6 P a n

All All Record

Repro Input SafeRecord Machine

R - 1

1357 8

In

A u x

Slct/Pnch

cfg

In

D y n

c D p t c G M Ux D p t x H y s

x A t k x R l s

x R a t

N a m e

N a m e

N a m e

N a m e

Num

swap

swap

select

chan

N a m e

select

MSL

MSL

x

12

6

0

6

12

18

24

30

36

42

48

60

72

c A t k

c R a t c T h r

x T h r

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Strp

On

Slv

swap

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

solo

solo

MSL

MSL

MSL

MSL

ON

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

G p S L

G p S L

G p S L

G p S L

G p S L

G p S L

N o n B

N o n B

N o n B

N o n B

N o n B

N o n B

B o o m

B o o m

B o o m

B o o m

B o o m

B o o m

P a n R

P a n R

P a n R

P a n R

P a n R

P a n R

S u r r

S u r r

S u r r

S u r r

S u r r

S u r r

D i v F

D i v F

D i v F

D i v F

D i v F

D i v F

F o c F

F o c F

F o c F

F o c F

F o c F

F o c F

P a n F

P a n F

P a n F

P a n F

P a n F

P a n F

cfg

cfg

cfg

cfg

cfg

cfg

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

M

G

G

R

R

I

I

P

P

X

X

route

route

swap

swap

swap

swap

select

select

main

main

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

N a m e

cpy pst

cpy pst

*

*

Insrt In

Insrt In

Input

Input

Dyn In

Dyn In

Dyn

Dyn

EQ In

EQ In

EQ

EQ

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

M

G

G

R

R

I

I

P

P

X

X

route

route

swap

swap

swap

swap

select

select

main

main

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

N a m e

cpy pst

cpy pst

*

*

*

Insrt In

Insrt In

Input

Input

Input

Dyn In

Dyn In

Dyn

Dyn

Dyn

EQ In

EQ In

EQ

EQ

EQ

Filts

Aux

Pan

M

I

X

swap

solo

ON

Filts

Filts

Filts In

Filts In

Aux

Aux

Pan to:

Pan to:

Pan

Pan

M

G

G

R

R

I

P

P

X

route

route

swap

swap

swap

swap

select

select

main

main

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

910111213141516

Rec Rec Rec Rec Rec Rec Rec Rec

25 26 27 28 29 30 31 32

Rec Rec Rec Rec Rec Rec Rec Rec

41 42 43 44 45 46 47 48

Rec Rec Rec Rec Rec Rec Rec Rec

Rec

Grp

Ready

Route

Route

F l t s I n s D y n E Q

F 1 t p

Assign Knobs

Knob Values

C l a r i n e t

P1 P2 P3 P4 P5 Store P

L o Q l m Q h m Q H i Q

L o F

c R l s

L o G

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

N a m e

N a m e

On

On

solo

solo

Solo

ClrPstCpyGrp

swap

swap

swap

swap

select

select

chan

chan

N a m e

N a m e

select

select

solo

solo

MSL

MSL

MSL

MSL

ON

ON

12

12

6

6

0

0

6

6

12

12

18

18

24

24

30

30

36

36

42

42

48

48

60

60

72

72

Mix

Route to

Sections

On

solo

On

solo

On

solo

On

solo

swap

select

chan

select

MSL

MSL

Pan to:

Grp Buses

F 1 F F 2 F

f l t s

Slct/Pnch

E Q

l m F

l m G

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

N a m e

On

solo

Page

swap

swap

select

chan

N a m e

select