Page 1

Safety Basic Monitor

User Manual

Revision date: 14.11.11

...supports the requirements for AS-i Safety up to SIL3

Page 2

Subject to modifications without notice.

Generally, this manual refers to products

without mentioning existing patents,

utility models, or trademarks.

The absence of any such references does

not indicate that a product is patent-free.

© Euchner GmbH + Co. KG

Kohlhammerstraße 16

D-70771 Leinfelden-Echterdingen

Page 3

Safety Basic Monitor

Table of Contents

Table of Contents

1 Symbol Catalog ................................. ...................................................7

1.1 Abbreviations................................................................................................... 7

2 General Remarks..................................................................................8

2.1 Product information......................................................................................... 8

2.1.1 Safety Basic Monitor........ ... .................................. .. ... .................................. ... .. ..............8

2.2 Function of this manual ..................................................................................8

2.3 Target group.....................................................................................................8

2.4 AS-i specification 3.0.......................................................................................8

3 Safety.....................................................................................................9

3.1 Experienced staff............................................................................................. 9

3.2 Application area of the device........................................................................ 9

3.3 Correct use....................................................................................................... 9

3.4 AS-i Safety at Work........................................................................................ 10

3.5 Disposal.......................................................................................................... 10

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

3

Page 4

Safety Basic Monitor

Table of Contents

4 Product Description.......................... ... .................................... .......... 11

4.1 Technical data................................................................................................11

4.2 Special characteristics of the Safety Basic Monitor...................................11

4.2.1 Derating by 24 V auxiliary power .......... .................................. ... ... ...............................11

4.3 Safety relevant data.......................................................................................12

4.4 Requirements for the voltage supply +24 VEXT (AUX) ..............................12

4.5 Front view and connections..........................................................................13

4.6 Inputs...............................................................................................................14

4.7 Outputs............................................................................................................14

4.7.1 Push button........... ... .. ................................... .. ... ............................................................14

4.8 LEDs................................................................................................................15

4.8.1 LED flashing sample .....................................................................................................16

4.9 Chip card.........................................................................................................17

4.10 AS-i Power 24 .................................................................................................17

4.11 Decoupling function.......................................................................................18

4.12 AS-i supply options........................................................................................19

4.13 Connecting of an OSSD, supplying of several OSSDs out of the same

connection (S71)20

4.13.1 Additional connection examples .................................................................................21

5 Maintenance .......................................................................................22

5.1 Controlling safe shutdowns..........................................................................22

6 AS-i Diagnostics................................................................................. 23

6.1 Introduction....................................................................................................23

6.1.1 Data of the different diagnostics modes.....................................................................23

6.2 Diagnostics mode "Consortial monitor, for replacement".........................24

6.3 Diagnostics mode "Compatibility mode with additional diagnostics data".

6.3.1 Status codes for the release circuits (OSSD) .............................................................26

6.4 Diagnostics mode "AS-i 3.0 (S-7.5.5), recommended"...............................27

6.4.1 Binary data.......... .. .................................. ... ... .................................. .. ... ..........................27

6.4.2 Transparent input data..................................................................................................27

6.4.2.1 Status codes for the release circuits (OSSD)...............................................................28

6.4.2.2 Transparent output data ...............................................................................................29

6.4.3 Acyclical data.................................................................................................................30

6.4.3.1 Vendor Specific Object 7 - device colors OSSD 1........................................................30

6.4.3.2 Vendor Specific Object 8 - device colors OSSD

6.4.3.3 Vendor Specific Object 9 - device colors at switch off OSSD 1....................................34

6.4.3.4 Vendor Specific Object 10 - device colors at switch off OSSD 1

6.4.3.5 Vendor specific object 11 … 38....................................................................................38

6.4.3.6 Vendor- specific object 110 .............. ... .................................. .. ... ..................................3 9

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

4

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

25

with device index assignment ...................... ... .. ..........................................................32

with device index-assignment ...... ... .................................. ... .. ... ..................................36

Page 5

Safety Basic Monitor

Table of Contents

7 Configuration of the safe inputs.......................................................40

7.1 Configuration possibilities for the safe inputs ........................................... 40

7.2 Assigning the diagnostics outputs.............................................................. 41

7.3 Safe configuration using ASIMON 3 G2....................................................... 42

7.3.1 Replacing a defective AS-i Safety Slave..................................................................... 43

7.3.2 Auto-addressing ................. .. ...... ..... ..... ..... ... ..... ..... ...... ..... ... ..... ..... ..... ... ..... ..... ...... ......44

8 Safety Requirements..........................................................................45

8.1 Safety consideration for selecting OSSD/potential-free contacts............. 45

8.2 Recommendation for improved availability of the function....................... 45

9 Accessories ........................................................................................46

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

5

Page 6

Safety Basic Monitor

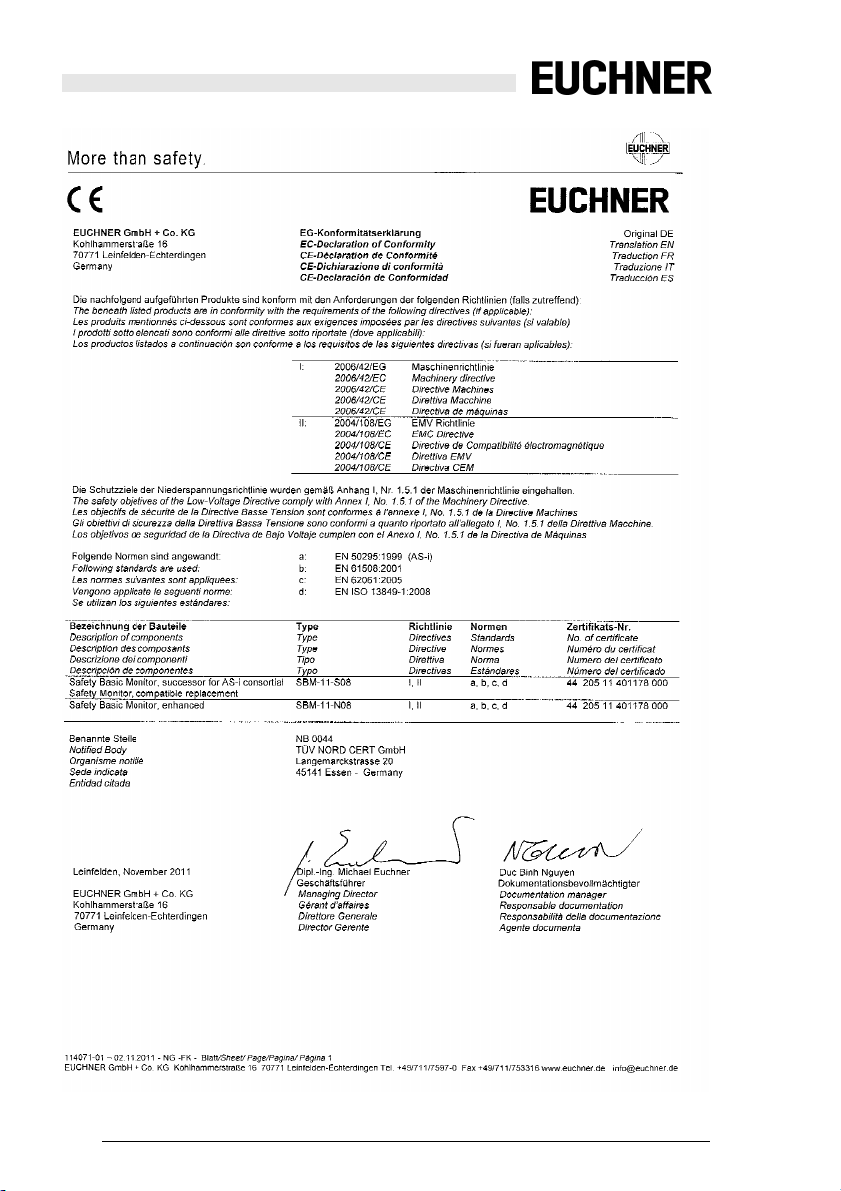

EC Declaration of Conformity

EC Declaration of Conformity

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

6

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 7

Safety Basic Monitor

Symbol Catalog

1. Symbol Catalog

Information!

This symbol indicates important information.

Attention!

This symbol warns of a potential failure. Non-compliance may lead to interruptions of

the device, the connected peri pher al syste ms, or plan t, pote nti ally le adin g to tot al mal functioning.

Warning!

This symbol warns of an imminent danger. Non-compliance may lead to personal injuries that could be fatal or resu lt in material damages and destructi on.

1.1 Abbreviations

AS-i

I/O

EMC

PELV

PFD

SaW

OSSD

AS-interface (actuator sensor interface)

Input/output

Electromagnetic compliance

Protective extra-low voltage

Probability of failure on demand

Safety at Work, safety technic

Output Signal Switching Device, release circuit

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

7

Page 8

Safety Basic Monitor

General Remarks

2. General Remarks

Please read this chapter carefully before working with the documentation and the

Safety Monitor.

2.1 Product information

This user manual is valid for the following Euchner GmbH devices

2.1.1 Safety Basic Monitor

:

Safety Basic Monitor

without Power Supply Decoupling Unit

Safety Basic Monitor

with Power Supply Decoupling Unit

2.2 Function of this manual

This manual instructs for the safe assembly, electrical installation, addressing,

start-up as well as for the operation and for the maintenance of the Safety Monitor.

This manual does not provide instructions for operating machines, on which this

module is built in. Please view the appropriate machine manual for corresponding

information.

Information!

Additional information concerning the technical data as well as the parameterization of

the Safety Monitor can be found at http://www.euchner.de.

2.3 Target group

This manual is intended for designers, developers and operators of systems that

will be safeguarded by one or more Safety Monitors. The manual is also targeted

to people integrating Safety Monitors into machinery, performing the initial startup, or maintaining them.

2.4 AS-i specification 3.0

The AS-i 3.0 devices already fulfil the AS-i specification 3.0.

The previous specifications (2.1 and 2.0) are supported as well.

SBM-11-S08

SBM-11-N08

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

8

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 9

Safety Basic Monitor

Safety

3. Safety

This chapter contains user safety information.

Warning!

Please read this chapter carefull y before using th e Safety Basic Monitor in combination with other machine safeguarding components on protected machinery.

3.1 Experienced staff

The Safety Basic Monitor must only be installed, operated, and maintained by

qualified staff.

Qualified is a person who

• has a suitable technical education

• has been instructed in operating the machinery and has been informed about

the valid safety guidelines by the machinery operator

• has access to the user manual.

3.2 Application area of the device

The Safety Monitor combines a SaW I/O module and a Safety Monitor in one

IP20 enclosure.

Special characteristics:

• Safety Monitor in IP20

• up to 8 / 4 local safe inputs

optionally the safe inputs will be used as well as standard inputs and signal

outputs

• 2 (4) local electronical safe outputs

• safe AS-i outputs are supported

max. 8 independent AS-i outputs

multiple safe AS-i outputs possible via a single address

• chip card for storage of configuration data

The module is certified according to EN 62 061, SIL 3, and EN 13 849, performance level "e".

3.3 Correct use

The Safety Basic Monitor must only be used as defined in chap. <Application

area of the device>. The Safety Basic Monitor must only be used on the system,

at which it was installed in accordance with this manual by adept personnel.

Information!

If used in a way differing from this description or if the device has been changed in any

way – even during installation – any war ranty claims with respect to Euchner GmbH

are invalid.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

9

Page 10

Safety Basic Monitor

Safety

3.4 AS-i Safety at Work

AS-i Safety at Work combines safe and non-safe data on a bus system. The classification AS-i Safety at Work identifies the safe data transfer that enables the integration of safety procedures in an AS-i network.

The components of AS-i Safety at Work conform to EN 50295 and are compatible

with all other AS-i components. Therefore, existing AS-i applications can easily

be extended with safety-relevant functions.

AS-i Safety at Work always requires a Safety Monitor (as a stand-alone device or

integrated into a Gateway), that evaluates the safe signals on the bus, and a safe

AS-Interface bus connection, that enables the transfer of safe signals from safety-relevant components (AS-i SaW input).

Additionally, decentralized safe AS-I SaW outputs can be added. Controlled by

the Safety Monitor these outputs can be used to safely switch off safe actuators.

Several Safety Monitors and safe input and output slaves can be used on an

AS-i system. At the same time, the Safety Monitors can be parameterized and,

thus, be checked through AS-i and the configuration software.

Information!

By utilizing AS-i Safety at Work safety requirements up to category 4 according to

EN 954-1 and additionally performance level "e" according to EN 13 849 as well as SIL

3 according to EN 62 061 can be satisfied.

In order to satisfy the requirements of these safety categories, all peripheral components, for instance the Safety Monitors, all safe bus connections, and all connected sensors must satisfy these standards.

3.5 Disposal

Information!

Electronic waste is hazardous waste. Please comply with all local ordinances wh en

disposing this product!

The device does not contain batteries that need to be removed before disp osing it.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

10

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 11

Safety Basic Monitor

Product Description

4. Product Description

This chapter is intended to inform the reader about the special characteristics of

the Safety Monitor. It describes the design and the functionality of the devices.

Warning!

This chapter must be read before installation and operation of the device in conjunction

with other safety components on protected machinery.

4.1 Technical data

The technical data are placed in the data sheet. Please view the current version

on the web page: www.euchner.de

4.2 Special characteristics of the Safety Basic Monitor

• The module uses only the necessary AS-i addresses.

• Various configuration possibilities for the safe inputs (see chap. <Configuration possibilities for the safe inputs>).

• No limitation of cable length at safe inputs (the maximum loop resistance is

150 Ohm).

• A safe signal exchange of 2 signals between Safety Monitor and AS-i Safety

Module as well as between two AS-i Safety Modules are possible.

• LED displays acc. to other Safety Slaves or to the Monitor.

• Simple configuration of the AS-i-Slaves using ASIMON.

• Chipcard for the simple exchange.

• Micro-USB port for configuring with AS-i-Control-Tools and ASIMON.

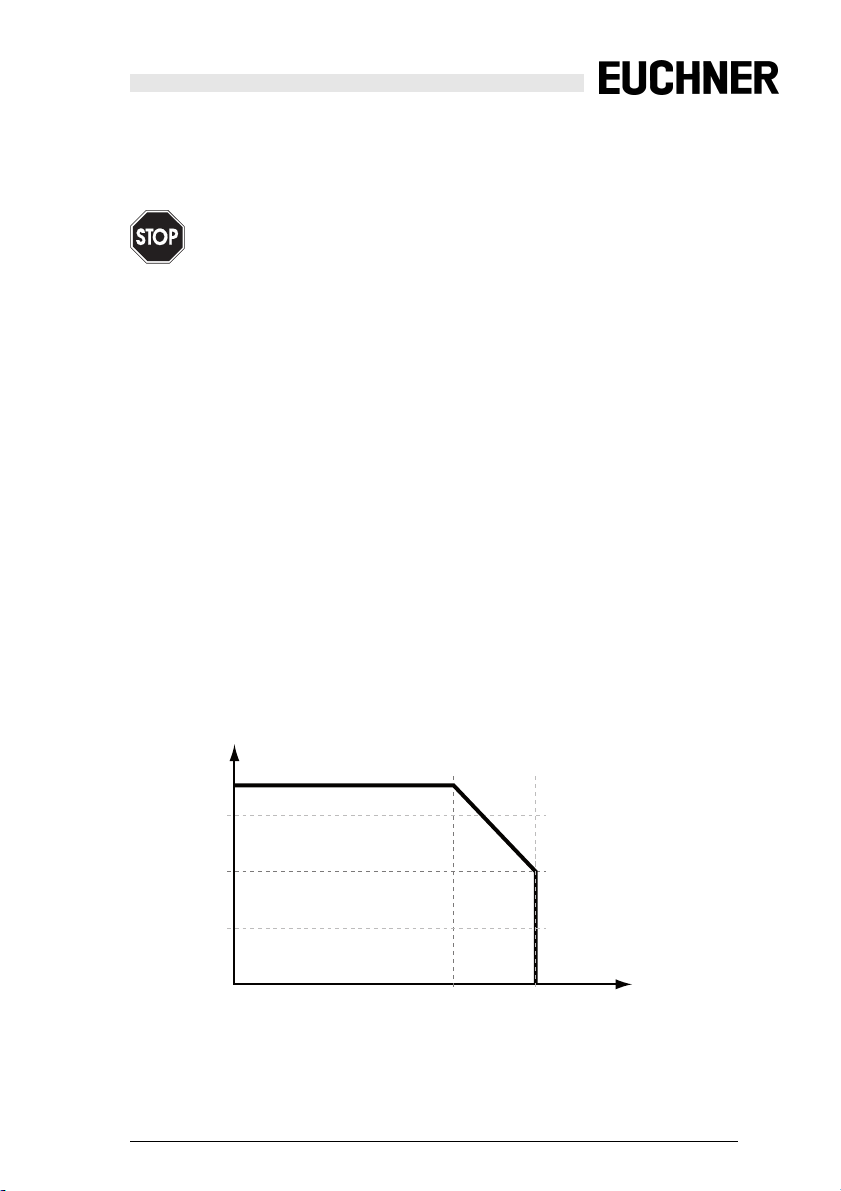

4.2.1 Derating by 24 V auxiliary power

I

AUX, max [A]

3,5

3

2

1

T

[°C]

40

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

55

amb

11

Page 12

Safety Basic Monitor

Product Description

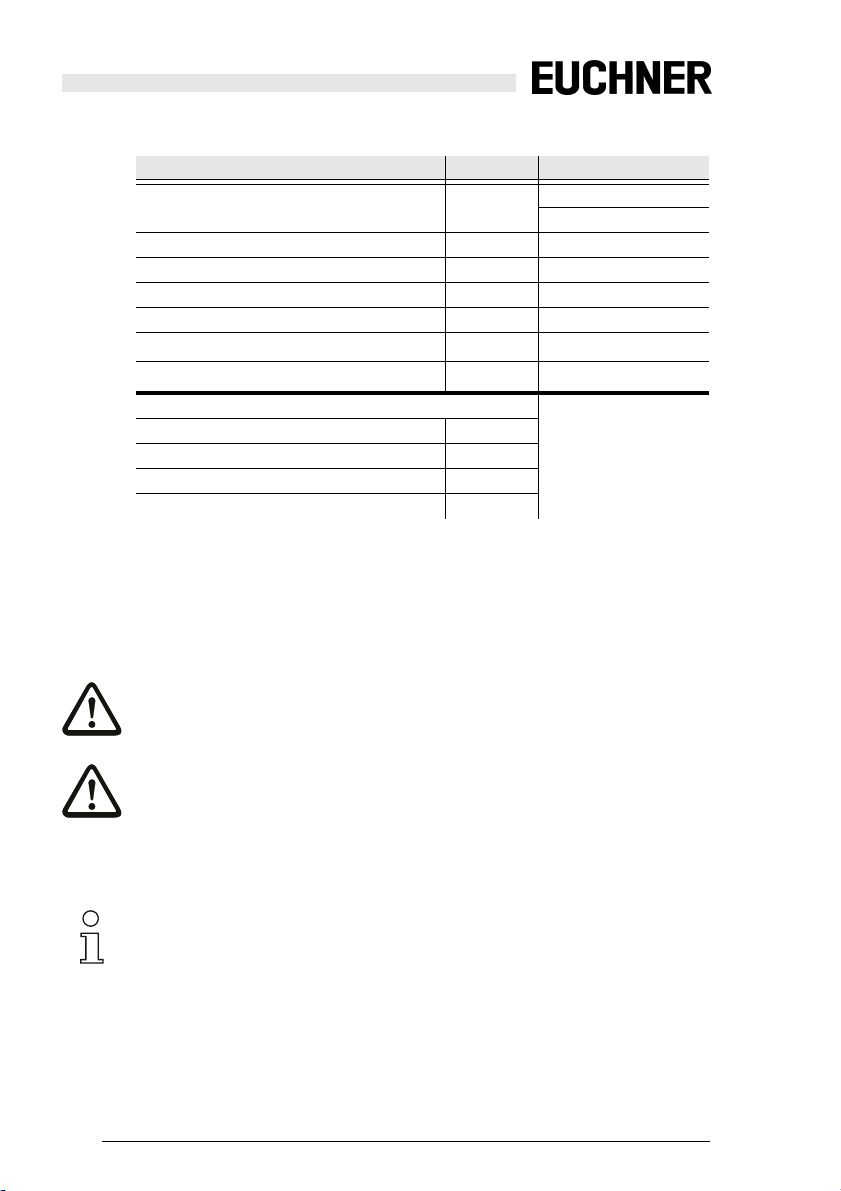

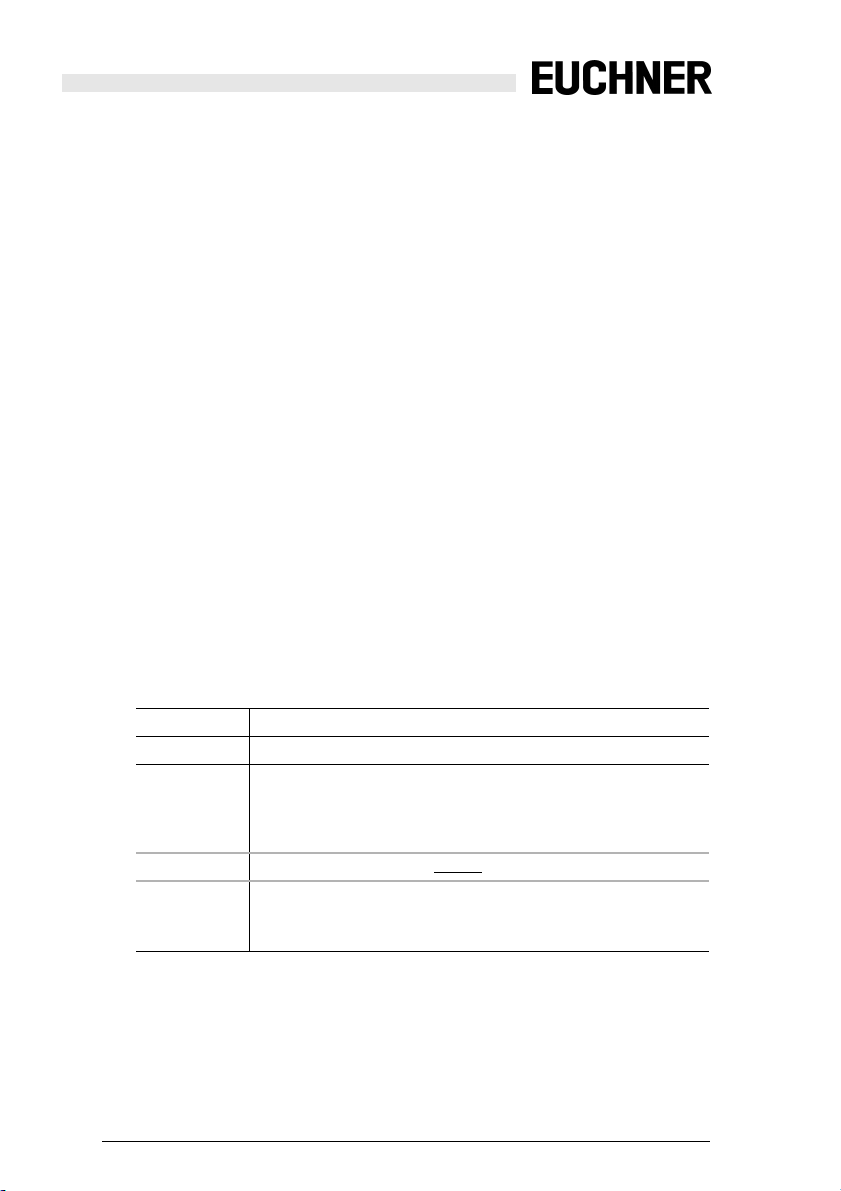

4.3 Safety relevant data

Characteristics Value Standard

Safety category 4 EN 954-1

Performance Level (PL) e EN 13 849-1:2008

Safety Integrity Level (SIL) 3 IEC 61 508, EN 62 061

Service life (TM) [year] 20 EN 13 849-1:2008

Maximal power-on time (month) 12 IEC 61 508

PFD

1

PFH

D

Max. reaction time [ms]

AS-i input slave → local output 40

local input → local output 20

local input → AS-i code sequenc e 26

AS-i input slave → AS-i code sequence 45

1. Probability of a dangerous loss per hour.

To determine the safety characteristics (PFD and PFH), the values of all components using this function are to be considered. The module provides no significant

contribution to the PFD or PFH values of the complete system. For the values of

other components, please refer to relevant documentation.

9,58 x 10

5,08 x 10

EN 13 849-1:2008

-7

EN 62 061

-9

IEC 61 508, EN 62 061

IEC 61 508

Tab. 4-1.

Attention!

If the option „augmented reliability“ is selected the response time can extend.

Attention!

Error states of the remote o utput s used in the safe conf igurat ion can be elimin ated by

starting and stopping the monitor.

4.4 Requirements for the voltage supply +24 V

EXT

(AUX)

Information!

The externally connectable c ircui ts are to be sepa rated f rom the net absol utely re liabl e!

The power supply +24 V

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

12

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

may only occur via SELV or PELV networks.

EXT

Page 13

Safety Basic Monitor

Product Description

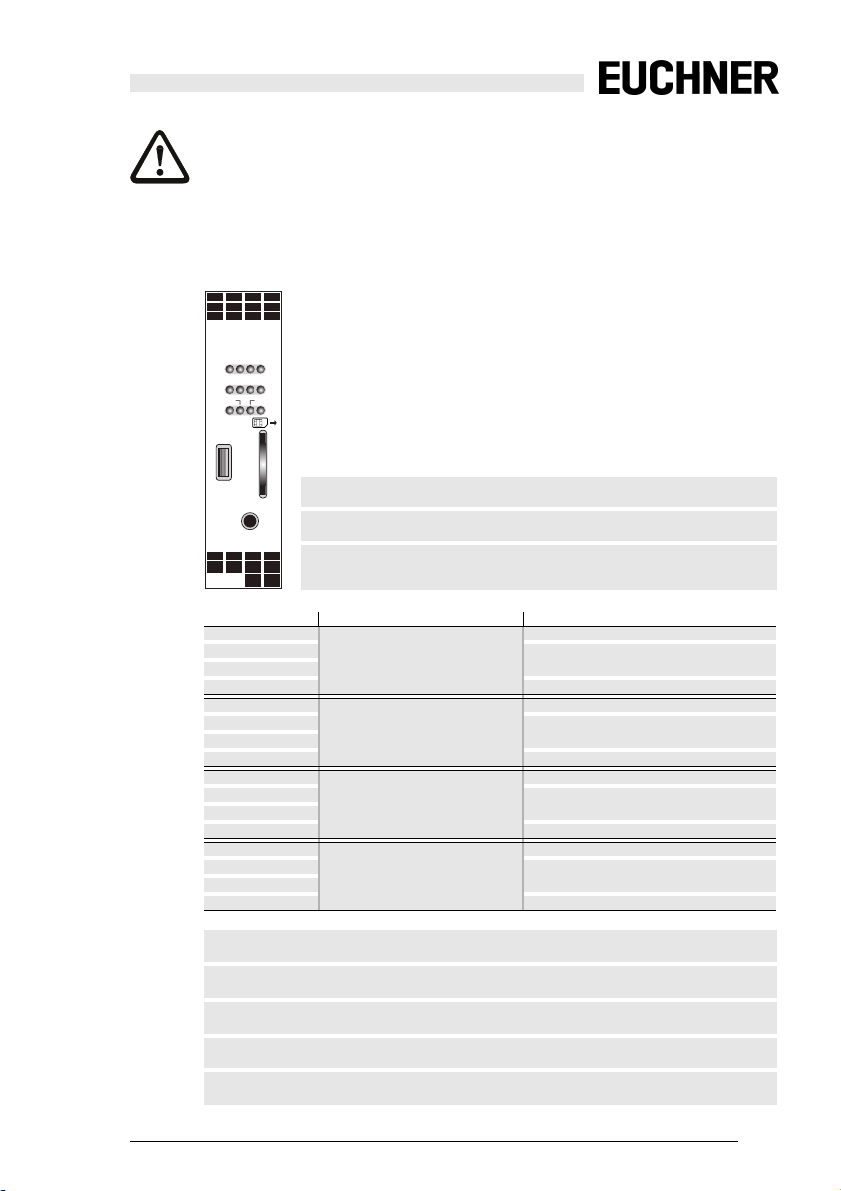

Attention!

The power supply for the 24 V supply mu st also hav e iso la tio n pe r IEC 60 74 2 an d be

able to handle momentary power interr uptions of up to 20 ms. The maximum outp ut

voltage of the power supply must also be less than 42 V in case of a fault.

4.5 Front view and connections

22 S 21 S 12 S 11

S

S

42 S 41 S 32 S 31

62 S 61 S 52 S 51

S

S4S3S2

S1

S8S7S6

S5

AS-i M

O1

O2

SM

CHIP CARD

MICRO USB

S 71 S 72 S 81 S 82

1.14

0 V

1

ext. out

ext. out

–

+

ASI

ASI

connection 2-channel direction

S11

S12

S21

S22 output

S31

S32

S41

S42 output

S51

S52

S61

S62 output

S71

S72

S81

S82 output

Micro USB

Micro USB interface

SET

SET

service button // bouton service // compasse service // botón servicio

Chip Card

0 V

2

2.14

chip card

ext. out

ext. out

–

AUX

AUX+

ext. in

ext. in

2-channel safety input 1

2-channel safety input 2

2-channel safety input 3

2-channel safety input 4

output

input

output

input

output

input

output

input

1.14

ext.out

Safe semiconductor output 1

2.14

ext.out

Safe semiconductor output 2

0V

ext.out

ground connection for semiconductor output

ASI+, ASI–

AS-i connection

AUX+, AUX–

connection to ext. 24 VDC

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

13

Page 14

Safety Basic Monitor

Product Description

4.6 Inputs

The inputs are powered by the 24 V auxiliary power supply. Each input consists of

two terminals: a passive input pin and an active test pulse output. A switch connects the two pins together.

Two of the safe inputs are also usable as inputs for OSSDs, and the others for potential-free contacts only.

Each safe input can also be configured as two standard inputs. The test pulse

outputs can also be switched as diagnostics outputs (non safety).

For additional information see chap. <Additional connection examples>.

4.7 Outputs

The outputs must be powered by a PELV power supply.

The maximum output current is 700 mA per output, and the outputs are suitable

for DC13 loads.

The plus side of the output load is at 1.14 or 2.14. The minus side of the output

load must be connected to the 0Vext out.

The lines between the module and the load must be routed so that no extraneous

voltages caused by damaged insulation can inadvertently switch the load.

4.7.1 Push button

The Teach/Service button (SET) has the following functions:

• Error acknowledgement

• PC-less substitution of Safety Slaves

Keystroke Description

< 1s Error acknowledgement

> 1s Changing to projecting mode

The master goes into projecting mode and the safety unit is ready to

learn a code sequence (analogous to learning using the Set key on

standard monitors).

< 1s

Projecting mode is exited without ch anges.

> 1s Saving the actual configuration in the master

Teaching the individual code sequence of a newly safety-configured

slave when exactly one safety-configured slave is replaced.

For additional information see Tab.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

14

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

<LEDs>.

Page 15

Safety Basic Monitor

Product Description

4.8 LEDs

LEDs Status Signal // Description

S1, S2,

S3, S4,

S5, S6,

S7, S8

(yellow)

1

SM

(green)

contact (S1 … S8) open

1 Hz

cross circuit //

contact (S1 … S8) closed

AS-i supply power not OK

1 Hz

’protective mode’ and ASIMON active

(red)

1 Hz

’configuration mode’ and ASIMON active //

’configuration mode’ active

2 Hz

(yellow)

at least 1 device in state ’red flashing’ or ’yellow flashing’

2 Hz

1 Hz

service button, state: ’teach-error’

service button, state: ’ready’

2

AS-i M

(red)

off-line, monitor mode

1 Hz

’peripheral fault’ without ’config error’

’config error’, auto addressing not possible

1 Hz

(green)

’config error’, auto addressing possible

2 Hz

master: ’protective mode’, no error //

1 Hz

master: ’configuration mode’, no error //

3

O1, O2

(yellow)

output (O1, O2) off

1 Hz

restart inhibit

8 Hz

correctable error codition

output (O1, O2) on

(red)

SM,

AS-i M,

O1, O2

no auxiliary voltage

competing master active

1 Hz

1. ’yellow’ has higher priority than ’red’ and ’green’ and will displayed preferentially.

Tab. 4-2. LEDs

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

15

Page 16

Safety Basic Monitor

Product Description

2. If ’config-error’ and ’p eripheral fault’ occur simultaneously, only ’config-error’ is displayed.

3. ’red’ has higher priority than ’yellow’

4.8.1 LED flashing sample

operation LEDs frequency Status

chip card will be written

(yellow)

S1-S4 2 x 1 Hz

S5-S8

internal error

(red)

data on the chip card + device different

(yellow)

chip card defect

(yellow)

legend

flashing in common mode

flashing in push-pull mode

off

on

SM, AS-i M,

O1, O2

S1-S4 —

S5-S8 —

SM, AS-i M,

O1, O2

S1-S4 1 Hz

S5-S8

SM, AS-i M,

O1, O2

S1-S4 1 Hz

S5-S8

SM, AS-i M,

O1, O2

table 4-2

table 4-2

table 4-2

8Hz

Tab. 4-3.

standard view acc. to table 4-2

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

16

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Tab. 4-4.

Page 17

Safety Basic Monitor

Product Description

4.9 Chip card

The chip card stores the addresses of the slaves. All programming operations are

stored both in the module and on the chip card.

• The device can operate both with and without a chip card.

• If a blank chip card is plugged into a programmed module, the configuration

of the module is stored on the chip card.

• If a non-blank chip card is plugged into an non-programmed module, the configuration of the chip card is transmitted to the module. The changes do not

become effective until the module is restarted.

• If a non-blank chip card is plugged into a different programmed module, the

configurations do not agree and an error message is displayed.

4.10 AS-i Power 24

only

SBM-11-N08 !

• internal decoupling network / AS-i voltage is generated out of 24 V

• no external AS-i power supply, no external decoupling unit required!

• maximum 0,5 A for AS-i available using internal decoupling network

• switching between internal and external decoupling.

directly

ext

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

17

Page 18

Safety Basic Monitor

Product Description

4.11 Decoupling function

only

SBM-11-N08 !

Bei activating the option "Operation without AS-i power supply" you can use the

AS-i Power24V data decoupling network instead of an external AS-i power supply.

Information!

The internal decoupling unit can supply a maximum current of 500 mA.

Simply open the ‘Monitor/-Bus Information’ window in ASIMON, select the tab

’Safety Basis Monitor’ and activate the check box "Operation without AS-i power

supply".

ASIMON 3 G2 Software

Information!

Please note additional information in the manual for the ASIMON software.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

18

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 19

Safety Basic Monitor

Product Description

4.12 AS-i supply options

SBM-11-N08 SBM-11-S08 +

internal decoupling external decoupling

SBM-11-N08

AS-i -

AS-i +

Ground

AS-i Power Supply

–

–

+

AUX

ASI

ASI

AUX+

ext. in

ext. in

Safety Basis Monitor

–

+

AUX

(24 VDC)

PELV

AS-i Power Supply

AS-i -

AS-i +

Ground

–

–

+

AUX

ASI

ASI

AUX+

ext. in

ext. in

Safety Basis Monitor

–

+

AUX

(24 VDC)

PELV

Tab. 4-5.

Attention!

The AS-I power supply for the AS- I components must have iso lation per IEC 60 742

and be able to handle momentary power interruptions of up to 20 ms. The power supply for the 24 V supply must also ha ve is olat ion pe r I EC 60 742 a nd be a ble to ha nd le

momentary power interruptions of up to 20 ms. The maximum output voltage of the

power supply must also be less than 42 V in case of a fault.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

19

Page 20

Safety Basic Monitor

Product Description

4.13 Connecting of an OSSD, supplying of several OSSDs out of the same connection (S71)

22 S 21 S 12 S 11

S

S

42 S 41 S 32 S 31

S

62 S 61 S 52 S 51

S52S61

OSSD2

OSSD1

24V

0V

Receiver

Transmitter

24V

0V

FE

FE

S71

S72

S81

S 71 S 72 S 81 S 82

0

2.14

1.14

V

ext. out

ext. out

ext. out

–

AUX+

+

ASI

ASI

ext. in

–

+

+

ASI

AUX

PELV

0 V

ext. out

–

AUX

ext. in

–

(24 VDC)

24V

OSSD1

OSSD2

0V

Receiver

Transmitter

24V

0V

FEFE

0V

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

20

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 21

Safety Basic Monitor

Product Description

4.13.1 Additional connection examples

safety input standard inputs message outputs

22 S 21 S 12 S 11

22 S 21 S 12 S 11

S

S

42 S 41 S 32 S 31

62 S 61 S 52 S 51

S

S

S

42 S 41 S 32 S 31

S

62 S 61 S 52 S 51

S52S61

22 S 21 S 12 S 11

S

42 S 41 S 32 S 31

S

S

62 S 61 S 52 S 51

S62

S51

I

max

= 10mA

SPS

PLC

IN

IN

0V

S 71 S 72 S 81 S 82

1.14

ext. out

+

ASI

–

+

ASI

contactor

22 S 21 S 12 S 11

S

42 S 41 S 32 S 31

S

S

62 S 61 S 52 S 51

ext.out

1.14

0Vext.out

S 71 S 72 S 81 S 82

2.14

0

1.14

V

ext. out

ext. out

ext. out

–

AUX+

+

ASI

ASI

ext. in

–

+

+

ASI

0

V

ext. out

–

ASI

–

AUX

(PELV)

ext. out

AUX

0 V

ext. in

2.14

ext. out

AUX+

ext. in

+

–

0 V

ext. out

AUX

ext. in

–

AUX

(PELV)

(24 VDC)

–

(24 VDC)

S32

AUX+

K1

K2

+

L1 L2 L3

Motor

ext. in

S 71 S 72 S 81 S 82

2.14

0

1.14

V

ext. out

ext. out

ext. out

–

AUX+

+

ASI

ASI

ext. in

–

+

AUX

ASI

0 V

ext. out

–

AUX

ext. in

–

(24 VDC)

(PELV)

ASIMON

ext. in

AUX+

S 71 S 72 S 81 S 82

1.14

ext. out

ASI

+

+

ASI

0 V

2.14

0

V

ext. out

ext. out

ext. out

–

–

AUX

AUX+

ASI

ext. in

ext. in

–

–

+

AUX

(24 VDC)

(PELV)

Tab. 4-6. Additional connection examples

ext. in

AUX-

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

21

Page 22

Safety Basic Monitor

Maintenance

5. Maintenance

5.1 Controlling safe shutdowns

The plant safety engineer is responsible for verifying that the Safety Basic Monitor works correctly as part of the safety system.

At least once a year it is necessary to verify the safe shutdown by initiating associated safety-related sensors or switchs:

Attention!

Press each safety-related AS-i slave and watch the reaction of the output circuits of the

AS-i Safety Monitor.

Attention!

Check the maximum activated time an d the tot al o per ati ng time . These va lu es de pe nd

on the PFD value chosen for the total failure probability. Please refer to the information

in chap. Safety relevant data.

After reaching the projected maximum operating time (three, six, or twelve months) the

entire safety system must be checked for proper operation.

After reaching the projecte d tot al usag e time (2 0 yea rs) t he de vice must be c hec ked b y

the manufacturer concerning it s proper operation.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

22

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 23

Safety Basic Monitor

AS-i Diagnostics

6. AS-i Diagnostics

6.1 Introduction

The device provides two different diagnostics modes:

• Consortial monitor, for replacement (see chap. 6.2)

• Compatibility mode with additional diagnostics data (see chap. 6.3)

• AS-i 3.0 (S-7.5.5), recommended (see chap. 6.4)

The respective diagnostics mode is selected using the ASIMON software.

Simply open the ‘Monitor/-Bus Information’ window in ASIMON

Select the ‘Diagnostics/Service’ tab

There select the required diagnostics mode.

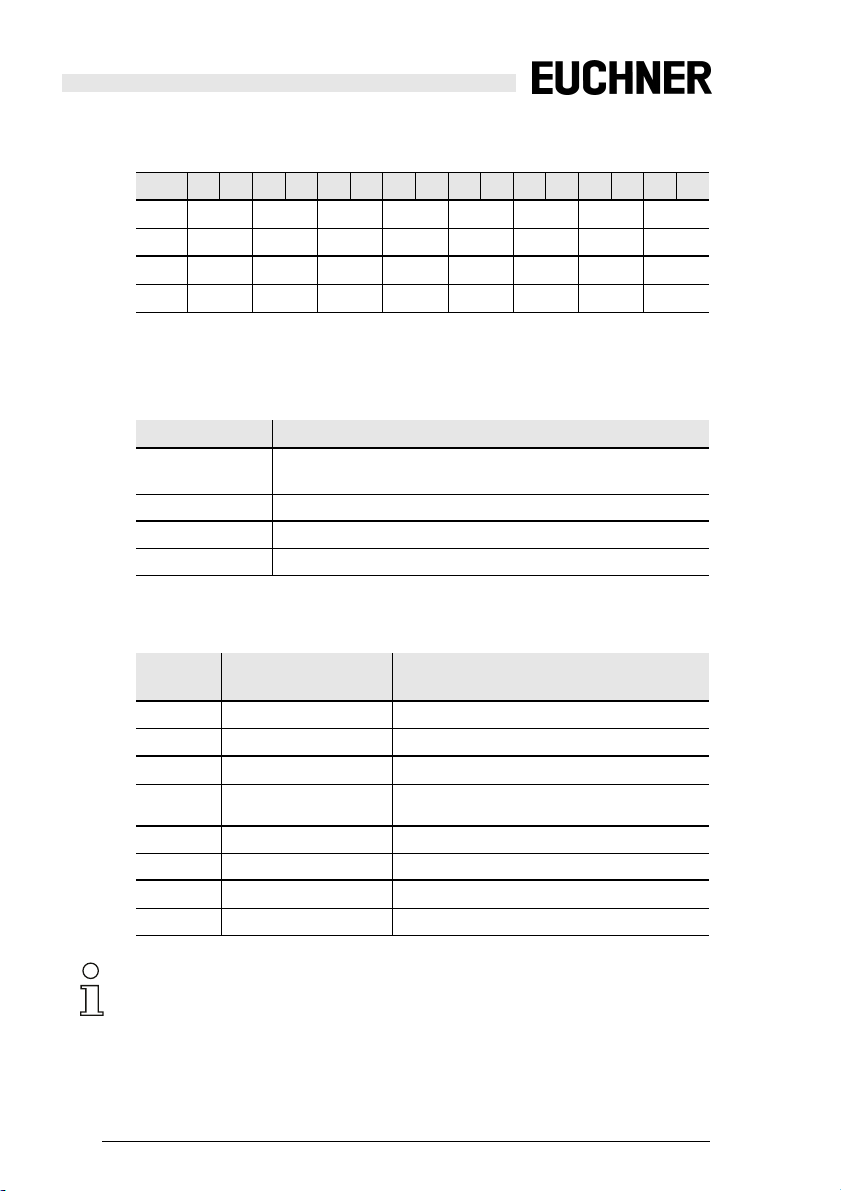

6.1.1 Data of the different diagnostics modes

AS-i 3.0 (S-7.5.5), recommended

(see chap. 6.4)

base address S-7.5 communication

(see chap. 6.4.1 …

6.4.3)

simulate slave 1

state OSSD1+OSSD2 state

base address+1

simulate slave 2

base address+2

simulate slave 3

base address+3

S-7.F slave,

input data = 0

S-7.F slave,

input data = 0

Consortial monitor,

for replacement

(see chap. 6.2)

consortial diagnostics (chap. 7.3.2 …

7.3.6 software manual)

OSSD1+OSSD2

S-7.F slave,

input data = 0

S-7.F slave,

input data = 0

Compatibility mode

with additional diagnostics data

(see chap. 6.3)

consortial diagnostics (chap. 7.3.2 …

7.3.6 software manual)

state

OSSD1+OSSD2

S-7.3.0.C slave (see

chap. 6.3)

S-7.3.1.C slave (see

chap. 6.3)

Tab. 6-7.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

23

Page 24

Safety Basic Monitor

AS-i Diagnostics

6.2 Diagnostics mode "Consortial monitor, for replacement"

Information!

Diagnostics type: compatibility mode for Safety Basic Monitors starting with the SafetyVersion ’SV4.3’.

Consortial diagnostics, with S-7-3 diagnostics added.

Address Meanining

basic address Consortial diagnostics, limited to 48 devices

simulated slave 1 status OSSD 1 and OSSD 2

simulated slave 2 S-7.F slave, input data = 0

simulated slave 3

Simulated slave 1: status OSSD 1 and OSSD 2 (binary data)

Data bit content

D0 status relay output 1

D1 status message output 1

D2 status relay output 2

D3 status message output 2

Tab. 6-8.

Tab. 6-9.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

24

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 25

Safety Basic Monitor

AS-i Diagnostics

6.3 Diagnostics mode "Compatibility mode with additional diagnostics data"

Information!

Diagnostics type: compatibility mode for Safety Basic Monitors starting with the SafetyVersion ’SV4.3’.

Address Meanining

basic address Consortial diagnostics, limited to 48 devices

simulated slave 1 status OSSD 1 and OSSD 2

simulated slave 2 S-7.3 OSSD diagnostics, 4 channel transparent input,

Profil S-7.3.0.C

simulated slave 3 S-7.3 SaW slave diagnostics, 4 channel transparent input,

profile 7.3.1.C

Tab. 6-10.

Simulated slave 1: status OSSD 1 and OSSD 2 (binary data)

Data bit content

D0 status relay output 1

D1 status message output 1

D2 status relay output 2

D3 status message output 2

Tab. 6-11.

Simulated slave 2 (7.3.0.C): OSSD diagnostics

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

CH1 Safety status OSSD 2 Safety status OSSD 1

CH2 Safety status OSSD 4 Safety status OSSD 3

CH3 Safety status OSSD 6 Safety status OSSD 5

CH4 S8 S7 S6 S5 S4 S3 S2 S1 Safety status OSSD 7

When switch S1 … S8 is closed a ‘1’ is entered in the corresponding position.

The Safety Status is defined as follows:

Bit 7 6 5 4 3 2 1 0

1: not less than

one device red

flashing

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

1: not less than one

device yellow flashing

n/a n/a OSSD color

(siehe Tab. Status codes for the

release circuits (OSSD))

Tab. 6-12.

Tab. 6-13.

25

Page 26

Safety Basic Monitor

AS-i Diagnostics

^

Simulated slave 3 (S-7.3.1.C)::SaW slave diagnostics

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Slv 7 Slv 6 Slv 5 Slv 4 Slv 3 Slv 2 Slv 1

CH1

Slv15 Slv14 Slv13 Slv12 Slv11 Slv10 Slv9 Slv8

CH2

Slv 23 Slv 22 Slv 21 Slv 20 Slv 19 Slv 18 Slv 17 Slv 16

CH3

Slv 31 Slv 30 Slv 29 Slv 28 Slv 27 Slv 26 Slv 25 Slv 24

CH4

For each safe slave (ID=B) the status of the code sequence is entered as seen by

the Master. Code sequence errors are not detected here. For non-safe slaves ‘00’

is entered.

Bit-combination meaning

00 Not a safe slave or save slave with zero sequence, both switches

open

01 Safe slave, switch for upper bits open

10 Safe slave, switch for lower bits op en

11 Safe slave, both switches closed

6.3.1 Status codes for the release circuits (OSSD)

Tab. 6-14.

Tab. 6-15.

Code

Status / color Description

bit [3..0]

0 green permanent light in g Output on

1 green flashing

2 continuous yellow

3 yellow flashing

delay time is running at stop category 1

start-up/restart-disable active

External test required / acknowledgement /

Turn-on delay active

4 red permanent lighting Output off

5 red flashing Error

6grey or off

output not projected

7 ... F reserved

Information!

Monitors which support less than 8 release circuits do not set all release circuits

present to “grey".

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

26

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Tab. 6-16.

Page 27

Safety Basic Monitor

AS-i Diagnostics

6.4 Diagnostics mode "AS-i 3.0 (S-7.5.5), recommended"

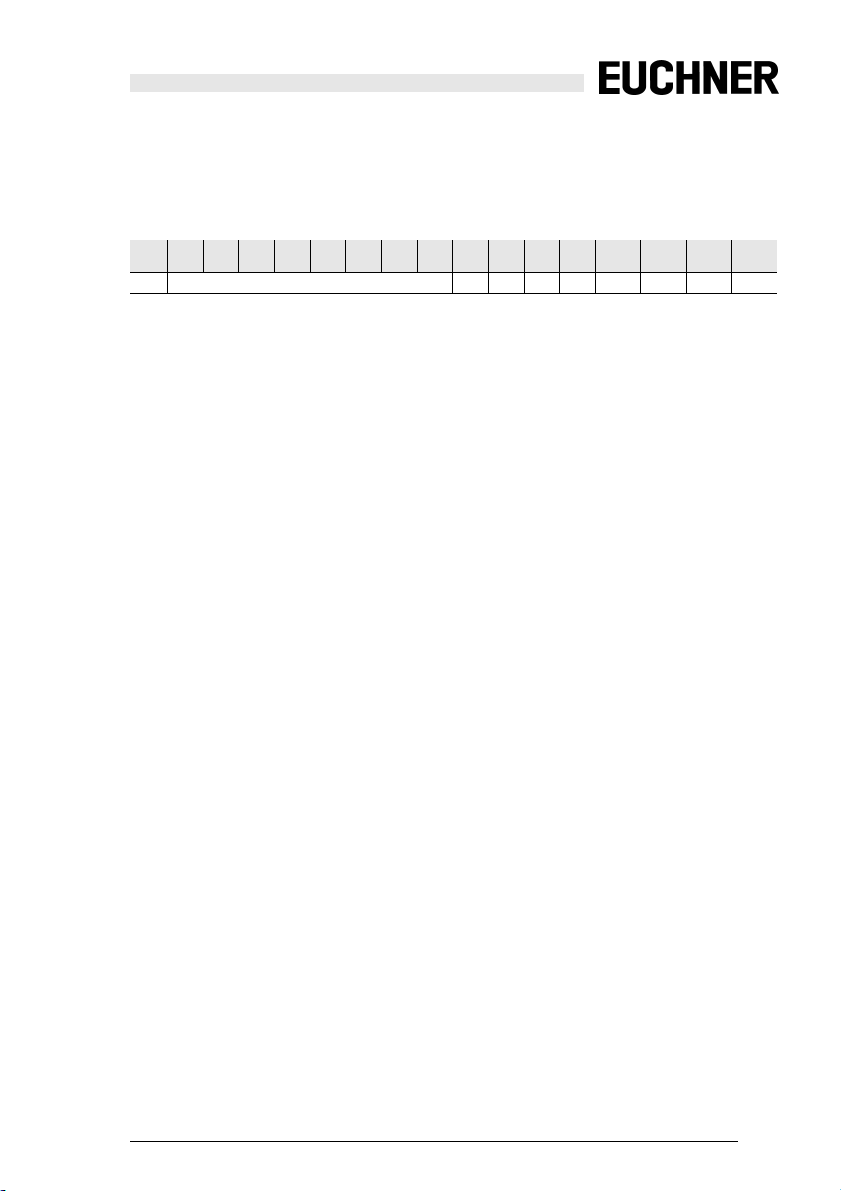

6.4.1 Binary data

D3 D2 D1 D0

input data Serial

output data – – Serial

communication

Serial

communication

1: Output 2

either turned off

or flashing green

communication

6.4.2 Transparent input data

Using profile 7.5.5 it is possible to poll the status of the release circuits (OSSD

Safety Control Status) of the Safety Monitor cyclically (see table below). To do this

you must assign an AS-i address (basic address) to the Safety Monitor and assign an 8-byte analog input slave to the basic address of the Safety Monitor.

These 8 bytes contain the diagnostics data (transparent input data) as shown in

the following table:

1: Output 1

either turned off

or flashing green

Serial

communication

Tab. 6-17.

channel

2152142132122112102928272625242322212

0

CH0 AS-i circuit 2 AS-i circuit 1

AU MO S8 S7 S6 S5 S4 S3 S2 S1 UA1 UA

CH1 Safety status

OSSD 4

CH2 Safety status

OSSD 8

Safety status

OSSD 3

Safety status

OSSD 7

Safety status

OSSD 2

Safety status

OSSD 6

Safety status

OSSD 1

Safety status

OSSD 5

CH3 OSSD 8 OSSD 7 OSSD 6 OSSD 5 OSSD 4 OSSD 3 OSSD 2 OSSD 1

RF YF RF YF RF YF RF YF RF YF RF YF RF YF RF YF

Tab. 6-18.

Channel ‘0’ of the transparent input data describes the status of the two AS-i segments. The upper 8 bits describe the status of AS-i segment 2, the lower 8 the

status of AS-i segment 1.

In Channels 1 and 2 the colors of the release circuits then follow (only two are

used at present).

Channel 3 then indicates combined information for the colors of the devices in the

release circuits.

Then the information is listed individually:

MO Operating

mode

1: Safety Monitor in protected operating mode

0: Safety Monitor in configur ation operation

UA UAS-i AS-i voltage greater than 18 V

1: voltage is sufficient

0: voltage is not sufficient

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

27

Page 28

Safety Basic Monitor

AS-i Diagnostics

AU AUX 24V

The 24 V for supplying the safe outputs is present

1: 24 V for supplying the safe outputs is present

0: 24 V for supplying the safe outputs is not present

UA1 Warning AS-i voltage OK, but less than 22.5 V

1: AS-i voltage greater than 22.5 V

0: AS-i voltage less than 22,5 V

S1-S8Switch S1-S8: for a closed switch S1 … S8 '1' is entered at the correspond-

ing position.

Channels 1 and 2 describe the states of the respective release circuits (OSSD’s)

of the Safety Monitor. For status codes and colors see section Status codes for

the release circuits (OSSD).

Channel 3 contains information as to whether there are warnings or faults in a release circuit for one or more devices assigned to this release circuit. The meanings are as follows:

YF Yellow flashing At least one of the devices associated with this release cir-

cuit is in the yellow flashing state

RF Red flashing At least one of the devices associated with this release cir-

cuit is in the red flashing state

6.4.2.1 Status codes for the release circuits (OSSD)

Code

status / color Description

bit [3..0]

0

1 green flashing

2 yellow permanent light-

green permanent lighting

output on

delay time is running at stop category 1

start-up/restart-disable active

ing

3 yellow flashing

external test necessary / acknowledgement

/ start delay active

4 red permanent lighting

5 red flashing

6grey or off

output off

error

output not projected

7 ... F reserved

Tab. 6-19.

Tab. 6-20.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

28

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 29

Safety Basic Monitor

AS-i Diagnostics

6.4.2.2 Transparent output data

The transparent output data are available there to the safe unit as non-safe additional bits, for example for Start buttons. They are linked with the input bits of the

input configured as non-safe terminals.

Ch

2152142132122112102928272625242322212

0 reserved S8S7S6S5 S4 S3 S2 S1

Tab. 6-21.

0

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

29

Page 30

Safety Basic Monitor

AS-i Diagnostics

6.4.3 Acyclical data

6.4.3.1 Vendor Specific Object 7 - device colors OSSD 1 Read only

This object contains the colors and additional information for all release circuits

for all devices assigned to Release Circuit 1.

Information!

If not all 128 devices are assigned, the Monitor can shorten the S-7.5.5 telegram in

order to save transmission time.

Coding for the states and colors

Byte Meaning

1

bit 0 0=configuration mode, 1=protect ing mode

bit 3 … 1 reserved, 0

bit 4 status S12

bit 5 status S21

bit 6 status S32

bit 7 status S41

2

relay status, output 1+2

bit 3 … 0 status output 1

bit 7 … 4 status output 2

3…8

...

9

relay status output 15+16

bit 3 … 0 status output 15

bit 7 … 4 status output 16

10

bit field for devices which are present. Device 7 … 0

11 ... 40

...

41

bit field for devices which are present. Device 248 … 255

42

color device 1+2

bit 3 … 0 color de vice 1

bit 7 … 4 color de vice 2

43 ... 168

105

...

device 127+128

bit 3 … 0 color de vice 127

bit 7 … 4 color de vice 128

Tab. 6-22.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

30

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 31

Safety Basic Monitor

AS-i Diagnostics

Bit field coding for devices which are present:

The numbers indicate the position of the bit for the corresponding device.

0: Device is not present

1: Device is present

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-23.

Coding of states and colors

Code

State or color

Bit [2 … 0]

0

green permanent lighting

1

green flashing

2

yellow permanent lighting

3

yellow flashing

4

red permanent lighting

5

red flashing

6

grey or off

7

non existent

Bit 3

0: Device is not present in this OSSD

1: Device is present in this OSSD

Tab. 6-24.

0

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

31

Page 32

Safety Basic Monitor

AS-i Diagnostics

6.4.3.2 Vendor Specific Object 8 - device colors OSSD with device index assignment

Read only.

This object contains, for all devices assigned to Release Circuit 1, the colors and

additional information for all release circuits with the module index assignment

from the configuration.

Coding of the states and colors

Byte Meaning

1

bit 0 0=configuration operation, 1=protective operation

bit 3 … 1 reserved, 0

bit 4 st atus S12

bit 5 st atus S21

bit 6 st atus S32

bit 7 st atus S41

2

relay status output 1+2

bit 3 … 0 status output 1

bit 7 … 4 status output 2

3…8

...

9

relay status output 15+16

bit 3 … 0 status output 15

bit 7 … 4 status output 16

10

11 ... 40

41

42

bit field for devices which are present. Device 7 … 0

...

bit field for devices which are present. Device 248 … 255

color device 1+2

bit 3 … 0 color device 1

bit 7 … 4 color device 2

43 ... 168

105

...

device 127+128

bit 3 … 0 color device 127

bit 7 … 4 color device 128

Tab. 6-25.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

32

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 33

Safety Basic Monitor

AS-i Diagnostics

Bit field coding for devices which are present:

The numbers indicate the position of the bit for the corresponding device.

0: Device is not present

1: Device is present

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-26.

Coding of states and colors

Code

State or color

Bit [2 … 0]

0

green permanent lighting

1

green flashing

2

yellow permanent lighting

3

yellow flashing

4

red permanent lighting

5

red flashing

6

grey or off

7

non existent

Bit 3

0: Device is not present in this OSSD

1: Device is present in this OSSD

Tab. 6-27.

0

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

33

Page 34

Safety Basic Monitor

AS-i Diagnostics

6.4.3.3 Vendor Specific Object 9 - device colors at switch off OSSD 1 Read only.

This object contains colors and additional information about all release circuits at

the time of the most recent switch-off of release circuit 1. Additionally, information

identifying all devices assigned to release circuit 1 is transferred.

Coding for the states and colors

Byte

Meaning

1

bit 0 0=Configuration mode, 1=protecting mode

bit 3 … 1 reserved, 0

bit 4 st atus S12

bit 5 st atus S21

bit 6 st atus S32

bit 7 st atus S41

2

relay status output 1+2

bit 3 … 0 status output 1

bit 7 … 4 status output 2

3 ... 8

...

9

relay status output 15+16

bit 3..0 status output 15

bit 7..4 status output 16

10

11 ... 40

41

42

43 ... 72

73

74

bit field for devices which are pr esent. Device 7 ... 0

...

bit field for devices which are present. Device 248 ... 255

bit field for devices which changed in the last step. Device 7 ... 0

...

bit field for devices which changed in the last step. Device 248..255

color device 1+2

bit 3 … 0 color device 1

bit 7 … 4 color device 2

75 ... 200

137

...

device 127+128

bit 3..0 color device 127

bit 7..4 color device 128

Tab. 6-28.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

34

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 35

Safety Basic Monitor

AS-i Diagnostics

Bit-field for devices that changed during the last step.

These numbers indicate the position of the bits that correspond to a certain device.

0: device not changed during the last step

1: device changed during the last step

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-29.

Bit field coding for devices which are present:

The numbers indicate the position of the bit for the corresponding device.

0: Device is not present

1: Device is present

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-30.

Coding of states and colors

Code

status bzw. color

Bit [2 … 0]

0

green permanent lighting

1

green flashing

2

yellow permanent lighting

3

yellow flashing

4

red permanent lighting

5

red flashing

6

grey or off

7

non existent

Bit 3

0: Device is not present in this OSSD

1: Device is present in this OSSD

Tab. 6-31.

0

2

0

2

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

35

Page 36

Safety Basic Monitor

AS-i Diagnostics

6.4.3.4 Vendor Specific Object 10 - device colors at switch off OSSD 1 with device index-assignment

Read only.

This object contains colors and additional information about all release circuits at

the time of the most recent switch-off of release circuit 1, sorted by the diagnostics index. Additionally, information identifying all devices assigned to release circuit 1 is transferred.

Coding of states and colors

Byte Meaning

1

bit 0 0=configuration mode, 1=protective operation

bit 3 … 1 reserved, 0

bit 4 st atus S12

bit 5 st atus S21

bit 6 st atus S32

bit 7 st atus S41

2

relay status output 1+2

bit 3 … 0 status output 1

bit 7 … 4 status output 2

3 ... 8

...

9

relay status output 15+16

bit 3..0 status output 15

bit 7..4 status output 16

10

11 ... 40

41

42

43 ... 72

73

74

bit field for devices which are pr esent. Device 7 ... 0

...

bit field for devices which are present. Device 248 ... 255

bit field for devices which changed in the last step. Device 7 ... 0

...

bit field for devices which changed in the last step. Device 248 … 255

color device 1+2

bit 3 … 0 color device 1

bit 7 … 4 color device 2

75 ... 200 ...

137 device 127+128

bit 3..0 color device 127

bit 7..4 color device 128

Tab. 6-32.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

36

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 37

Safety Basic Monitor

AS-i Diagnostics

Bit field coding for devices which changed in the last step:

The numbers indicate the position of the bit for the corresponding device.

0: Device did not change in the last step

1: Device changed in the last step

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-33.

Bit field coding for devices which are present:

The numbers indicate the position of the bit for the corresponding device.

0: Device is not present

1: Device is present

Byte

7

2

6

2

5

2

4

2

3

2

2

2

1

2

176543210

2 151413121110 9 8

……

32 255 254 253 252 251 250 249 248

Tab. 6-34.

Coding of states and colors

Code

State or color

Bit [2 … 0]

0

green permanent lighting

1

green flashing

2

yellow permanent lighting

3

yellow flashing

4

red permanent lighting

5

red flashing

6

grey or off

7

non existent

Bit 3

0: Device is not present in this OSSD

1: Device is present in this OSSD

Tab. 6-35.

0

2

0

2

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

37

Page 38

Safety Basic Monitor

AS-i Diagnostics

6.4.3.5 Vendor specific object 11 … 38

Objects 11 … 38 correspond to Objects 7 … 10, but do not refer to the following

release circuits. The table shows the relationship:

OSSD device

colors

device colors with

device index

device col-

ors at switch

off

device colors at

switch off mit

device index

Vorverarb. object 3 object 4 - -

1 object 7 object 8 object 9 object 10

2 object 11 object 12 object 13 object 14

3 object 15 object 16 object 17 object 18

4 object 19 object 20 object 21 object 22

5 object 23 object 24 object 25 object 26

6 object 27 object 28 object 29 object 30

7 object 31 object 32 object 33 object 34

8 object 35 object 36 object 37 object 38

9 object 39 object 40 object 41 object 42

10 object 43 object 44 object 45 object 46

11 object 47 object 48 object 49 object 50

12 object 51 object 52 object 53 object 54

13 object 55 object 56 object 57 object 58

14 object 59 object 60 object 61 object 62

15 object 63 object 64 object 65 object 66

16 object 67 object 68 object 69 object 70

Tab. 6-36.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

38

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 39

Safety Basic Monitor

AS-i Diagnostics

6.4.3.6 Vendor- specific object 110

Vendor specific object 110 describes the SaW slave diagnostics.

^

15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Slv 7 Slv 6 Slv 5 Slv 4 Slv 3 Slv 2 Slv 1

CH1

Slv 15 Slv 14 Slv 13 Slv 12 Slv 11 Slv 10 Slv 9 Slv 8

CH2

Slv 23 Slv 22 Slv 21 Slv 20 Slv 19 Slv 18 Slv 17 Slv 16

CH3

Slv 31 Slv 30 Slv 29 Slv 28 Slv 27 Slv 26 Slv 25 Slv 24

CH4

For each safe slave (ID=B) the status of the code sequence is entered as seen by

the Master. Code sequence errors are not detected here. For non-safe slaves ‘00’

is entered.

Bit-combination meaning

00 Not a safe slave or save slave with zero sequence, both switches

open

01 Safe slave, switch for upper bits open

10 Safe slave, switch for lower bits open

11 Safe slave, both switches closed

Information!

Please note additional informat ion in the manual for the ASIMON software.

Tab. 6-37.

Tab. 6-38.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

39

Page 40

Safety Basic Monitor

Configuration of the safe inputs

7. Configuration of the safe inputs

The unit is configured and diagnosed using the ASIMON software.

Communication takes place over the USB interface.

7.1 Configuration possibilities for the safe inputs

The safe inputs on the unit can be configured variously:

• Safe inputs for floating contacts

Two inputs act together on one sub-device which can serve as the source for

a safety device. Test pulses are used to check the inputs for cross-wire short.

• Safe inputs for self-testing OSSDs (only on contacts S5-S8).

Two inputs act together on one sub-device which can serve as the source for

a safety device. The unit does not check the inputs for cross-wire short, since

this is done by the OSSDs themselves.

• Standard inputs

.

Each channel operates independently. The values can be used like the familiar monitor inputs.

• Diagnostics outputs

.

The test pulse outputs of the input terminals (i.e. terminals S11, S22, S31,

S42, S51, S62, S71, S82) can be used as diagnostics outputs (approx. 10mA

max. output current). A safety device can be assigned to each input, where

the status of the device is represented on the diagnostics output. The diagnostics output turns on when the device is “green”.

Configuration is done in ASIMON, in the ‘Monitor/Bus Information’ window using

the ‘Safety Basis Monitor’ tab.

.

The ASIMON Control logic prevents invalid combinations.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

40

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 41

Safety Basic Monitor

Configuration of the safe inputs

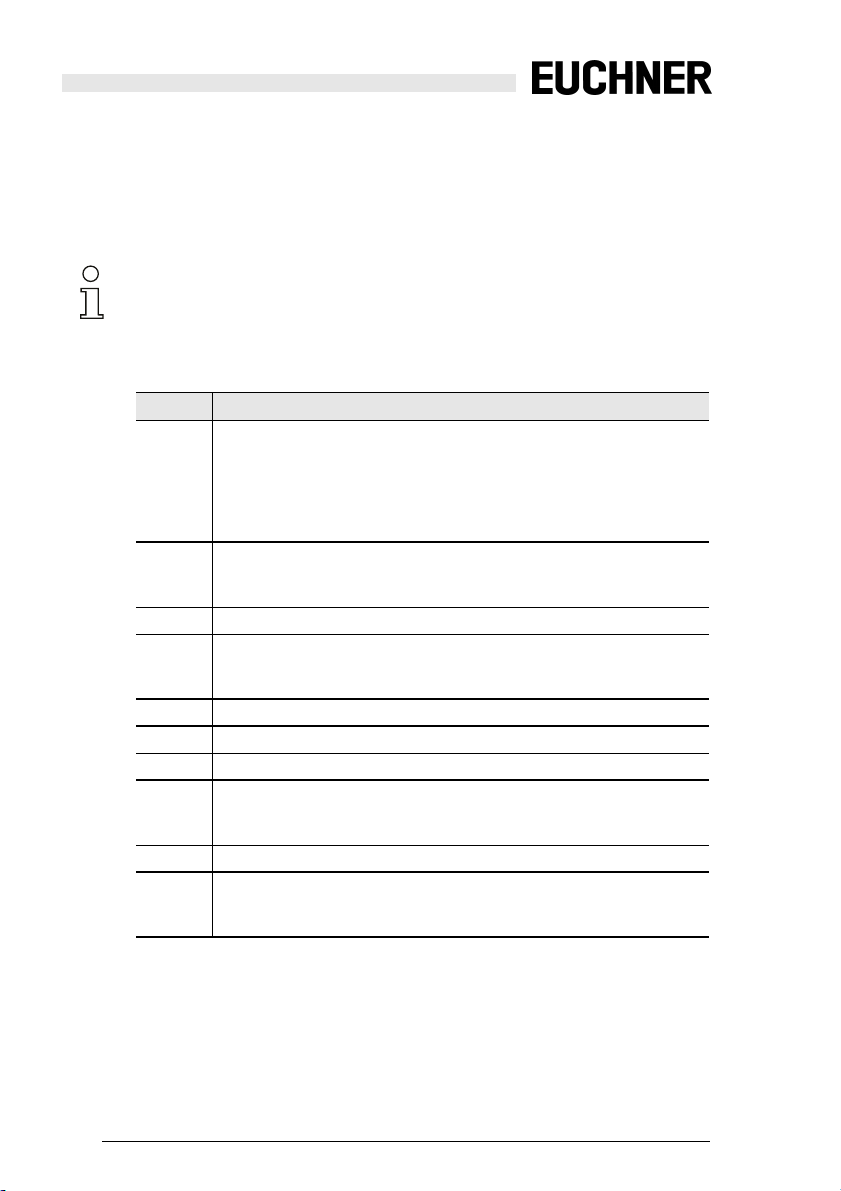

Safety Input Dry Contacts Safety Input OSSD Std Input Diag Out

S1

S2

S3

√

S4

S5

S6

S7

√

S8

7.2 Assigning the diagnostics outputs

Diagnostics outputs represent the status of the selected safety devices. Outputs

are assigned using the ‘Diagnostics Output’ column in the ‘Module Index Assignment’ field.

√√

√√

√

Tab. 7-39.

There the selected diagnostics outputs can be assigned to the module indices.

Each diagnostics output can be assigned to just one safety device.

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

41

Page 42

Safety Basic Monitor

Configuration of the safe inputs

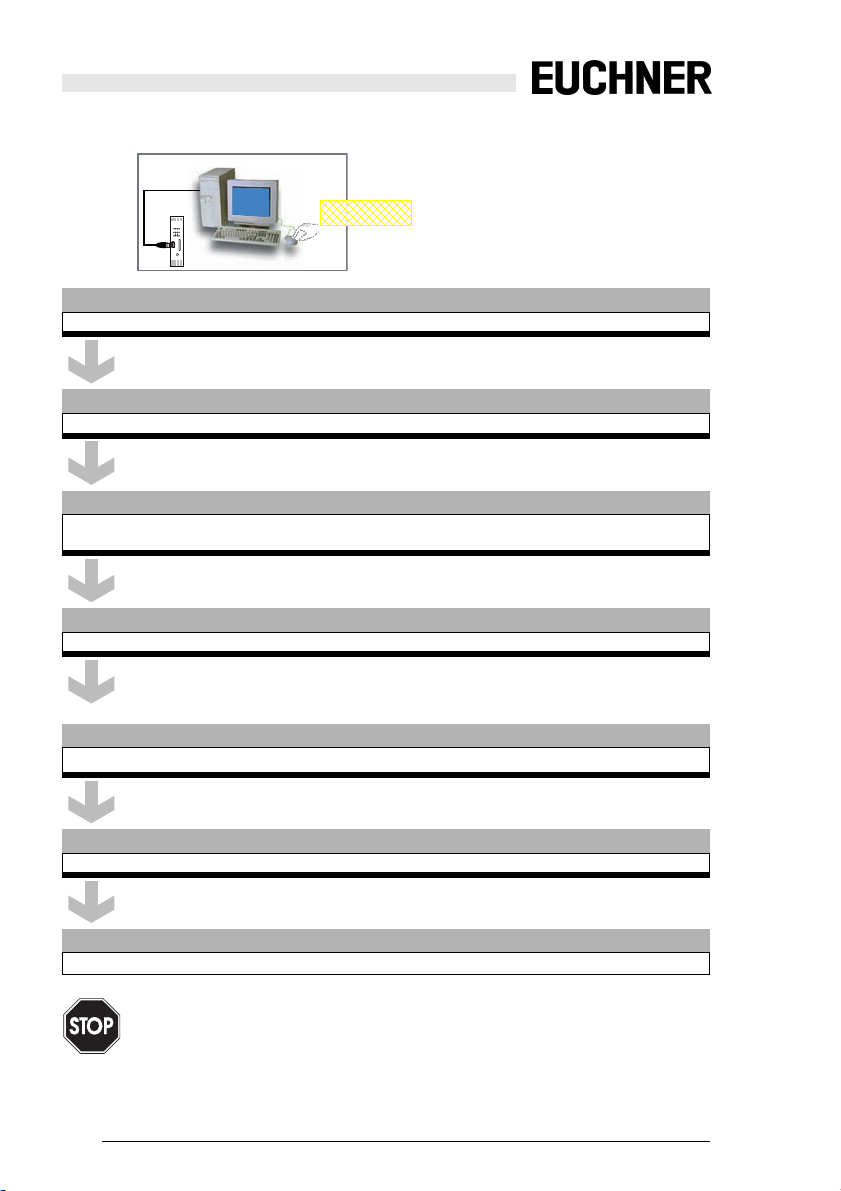

7.3 Safe configuration using ASIMON 3 G2

ASIMON

USB

ASIMON 3 G2 Software

Change the preset password during the first use of the device (Monitor/change password)!

ASIMON 3 G2 Software

Create the desired configuration.

ASIMON 3 G2 Software

Download the configuration with MONITOR / PC-> MONITOR into the device. Enter the password for

this purpose.

ASIMON 3 G2 Software

Acknowledge the request TEACH CODE SEQUENCES? selecting "Yes".

Start

ASIMON 3 G2 Software

Check the configuration log (respect instructions in <chap. 5.8> of the ASIMON manual!).

ASIMON 3 G2 Software

Validate the configuration with MONITOR –> VALIDATION.

ASIMON 3 G2 Software

Start the monitor with MONITOR–> START.

The correct safety function of the device must be verified once installed within the protected machinery!

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

42

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 43

Safety Basic Monitor

Configuration of the safe inputs

7.3.1 Replacing a defective AS-i Safety Slave

[1]

Safety In

Adr. 2

[2]

alt

[3]

AS-i network

AS-i network

Safety

Basic Device

Power

Supply

Safety

Basic Device

Power

Supply

Safety In

Adr. 1

Safety In

Adr. 2

Safety In

Adr. 1

neu*

Analog Out

Adr. 6

Analog Out

Adr. 5

Analog Out

Adr. 6

Analog Out

Adr. 5

Safety Output

Module

Slave

Adr. 9/8a

Safety Output

Module

Slave

Adr. 9/8a

[4] [5]

Safety

Basic Device

AS-i network

Power

Supply

* ’new’ (address ’0’ or ’2’)

Safety In

Adr. 2

Safety In

Adr. 1

Analog Out

Adr. 6

Analog Out

Adr. 5

Safety Output

Module

Slave

Adr. 9/8a

SET

> 1s

SET

> 1s

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

43

Page 44

Safety Basic Monitor

Configuration of the safe inputs

7.3.2 Auto-addressing

[1]

Safety

Basic Device

AS-i network

Power

Supply

[2]

Safety

Basic Device

AS-i network

Power

Supply

* ’new’ (address ’0’ or ’2’)

alt

Analog In

Adr. 2

Safety In

Adr. 1

Analog In

Adr. 2

Safety In

Adr. 1

Analog In

Adr. 2

neu*

Analog Out

Adr. 6

Analog Out

Adr. 5

Analog Out

Adr. 6

Analog Out

Adr. 5

Safety Output

Module

Slave

Adr. 9/8a

Safety Output

Module

Slave

Adr. 9/8a

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

44

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Page 45

Safety Basic Monitor

Safety Requirements

8. Safety Requirements

8.1 Safety consideration for selecting OSSD/potential-free contacts

Potential-free contacts are cross-circuit monitored by the module. OSSD outputs

test themselves and only require that the module tolerate the test pulses.

If the module is incorrectly configured so that OSSDs are connected but potentialfree contacts are configured, a cross-circuit is detected, since the test pulses

which the module sends out on S82 and S62 do not correlate with the test pulses

on S81 and S61. The error is thus detected.

If the module is incorrect configured so that potential-free contacts are connected

by OSSDs are configured, Contact S81 / S82 is never seen as turned on, since

S82 is not turned on as a supply pin for the OSSD module. The error is thus detected. The same applies by analogy to Contact S61 / S62.

8.2 Recommendation for improved availability of the function

The switching contacts should be turned off for at least 41 ms, since the safety

monitor (depending on the set monitoring component) must recognize the INPUT

OFF for a minimum number of AS-i telegrams. IF the minimum off time of 41 ms

(depending on the number of slaves on the AS-i bus and the set monitoring component) is maintained, correct recognition of the input state is assured. Non-observance of this time may limit the availability of the AS-i Safety Monitor as follows:

• A setting of TWO-CHANNEL POSITIVE OPENING can cause the Safety

Monitor to go into the error state; to eliminate the error state, the supply voltage for the Safety Monitor must be disconnected.

• A setting of TWO-CHANNEL DEPENDENT means the Safety Monitor allows

release only after a sufficient off-time; the release can be achieved if the

switching contacts are turned off for at least 41 ms .

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

45

Page 46

Safety Basic Monitor

Accessories

9. Accessories

• SBM-ZB-PGK (Ident-Nr. 113832)

USB connector cable for Safety Basic Monitor

• ZMO-ZB-MB10 (Ident-Nr. 100875)

Chip card for GMOX/SMOX 32kByte

• ESM-F-KK4 (Ident-Nr. 097195)

Connecting kit ESM-F (Phoenix clamps 4 unit)

Subject to reasonable modifications due to technical advances Id.-No.: 114013 Issue date: 14.11.2011 EUCHNER GmbH + Co. KG

46

Kohlhammerstraße 16, D-70771 Leinfelden-Echterdingen Tel. +49/711/7597-0, Fax +49/711/753316

Loading...

Loading...