Page 1

Operating Instructions for Rope Pull Switches

RPS...

Safety rope pull switch RPS

Correct use

In accordance with EN 60947-5-5, EN ISO 13850, it must be ensured that parts of or complete industrial

machines or installations can be stopped as quickly as possible by generation of an emergency stop signal.

The purpose of these regulations is to prevent any danger for persons or damage to machines.

The following applicable standards must be taken into account for this purpose:

Regulations on installation and operation: EN ISO 13849-1 Safety of machinery. Safety related parts of

control systems

Risk assessment on the machine: EN ISO 12100, Safety of machinery – Basic concepts –

General principles for design – Risk assessment and risk

reduction.

The safety rope pull switches of the series RPS have been designed and tested in accordance with the

standards EN 60947-5-5 and EN ISO 13850. They must be used only in control circuits.

Safety rope pull switches are used on the accessible sides of conveyor systems or machines. In contrast to

emergency stop switches (e.g. mushroom-head pushbuttons) located at certain intervals that allow the

emergency stop signal to be generated only at the devices themselves, rope pull switches allow signal

generation at any point along the rope length.

The safety rope pull switches of the type RPS are intended for use only in closed areas.

Design

The safety rope pull switches of the type RPS consist of a polyamide housing, those of the type RPS-M of a

die-cast aluminum housing. They achieve the specified degree of protection IP67 if the cover is properly closed

and if a cable gland is used that offers at least equivalent protection. The RPS has three cable entries M20x1.5.

The switches comply with the international requirements according to EN 60947-5-5 and EN ISO 13850, i.e.

after actuation or a rope tear, the emergency stop switch latches automatically, and the switch can then be

reset to its initial state only by means of the resetting device on the switch.

Depending on the switch version, it is possible to achieve a rope length of 75 m. It must be taken into account

here that the friction in the overall system can become so high due to the rope guides that this makes it difficult

or impossible to reset the system (see section Installation).

This can be avoided by choosing different system components.

The user is responsible for ensuring that the system functions properly.

Page 2

Operating Instructions for Rope Pull Switches

RPS...

Function

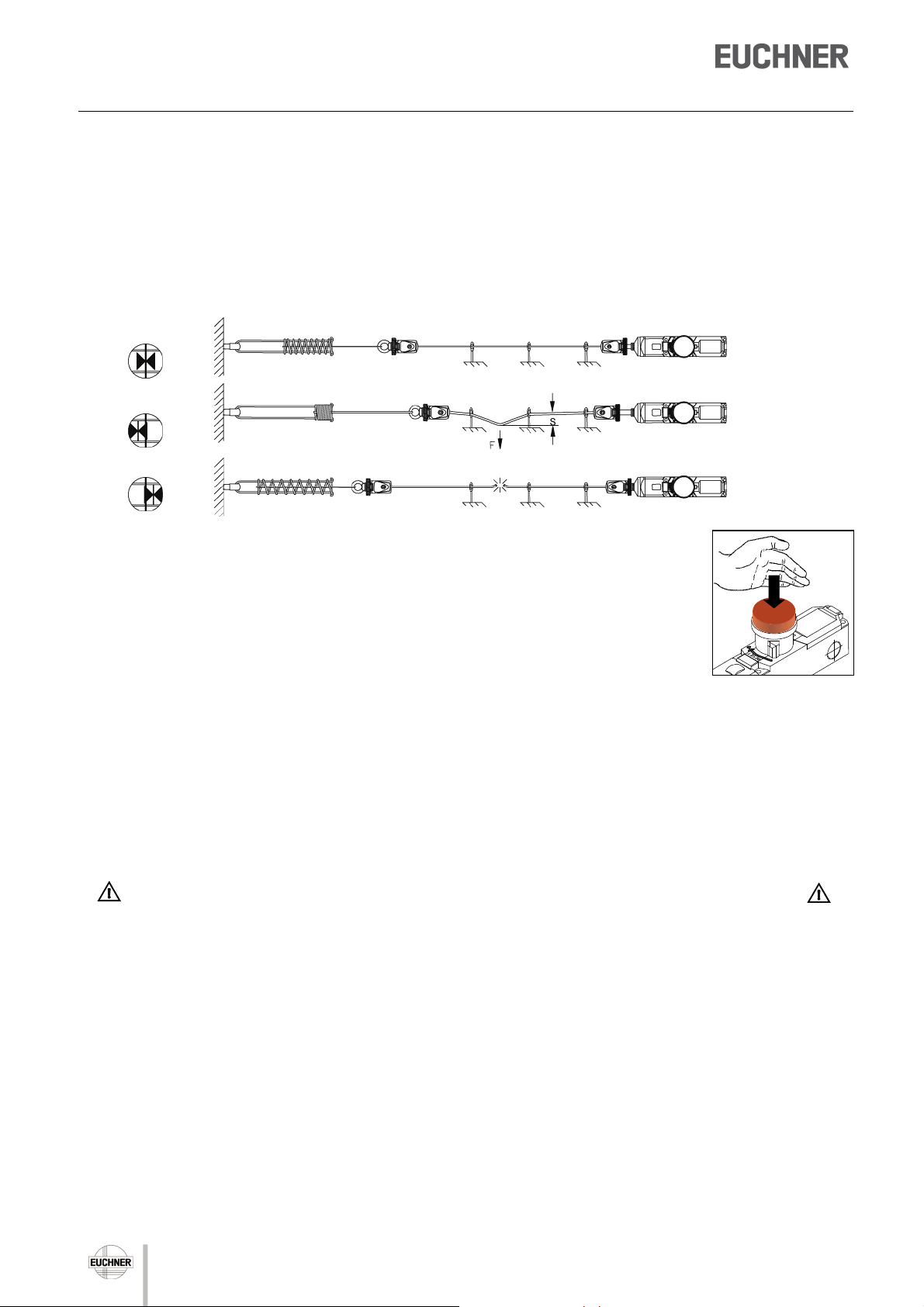

The system consists of the switching device, a red pull rope, supports and a counterspring.

The pull device of the rope pull switch is connected with a pull rope. The emergency stop function can be

tripped by pulling this rope. Since the rope pull system is pretensioned by an integrated spring, switch latching

and the emergency stop function are tripped immediately if the rope tears. The safety contacts remain latched

after tripping. After the hazardous situation has been remedied and after examination of the entire pull rope

length, the system may be reset to operationally ready state again by manual operation of the reset button.

System operating

position

Triggering/

latching

Rope tear

“RESET”

by the operator

“STOP” triggering

by operator/

automatic latching

“STOP” triggering

automatic

latching automatic

RPS...S

The RPS...SC... switch types have an integrated red emergency stop slam button that

can be actuated by pressing it if a hazardous situation occurs. Analogously to operation

of the pull rope, the safety contacts are then opened and the switch is latched. After

rectification of the hazardous situation, the system can be reset manually to operationally

ready state by turning the actuating cylinder 90° in clockwise direction.

Please also refer to item 3 of the section Installation sequence!

RPS...P

After remedying the dangerous situation and with the rope system tensioned, the rope pull switch

can be unlocked and so made operational again by turning the Reset knob.

Pre-failure monitoring (optional)

The safety rope pull switches of the type RPS-M-E-…have a remote display for monitoring the rope tension. It

uses an integrated sensor unit to monitor the permissible rope tension for being exceeded and impending

triggering of the safety rope pull switch.

Required maintenance/adjustment is signaled via an electronic output in good time before unintentional

machine standstills occur. Optionally available signal lamps can also be connected to this output; refer to the

section “Accessories”. This meets the requirements for “preventive maintenance”.

Safety precautions

All system components must be mounted on surfaces that can reliably withstand all the forces that may

occur.

Routing of the rope as straight as possible results in low frictional forces in the system. From a rope length

of 25 m, only rope pulley blocks may be used as rope supports.

Rope pulley blocks and other accessories are optionally available.

Positioning of the support points at irregular intervals prevents rope oscillations that might cause false

tripping.

The red pull rope must have sufficient space between the support points to ensure that secure gripping and

tripping are possible. To improve visibility, marking flags can be attached to the pull rope along its length;

however, these must not interfere with tripping of the emergency stop function!

When a pull rope section is being set up and planned, it is necessary to take into account and comply with

the applicable regulations, as well as the maximum permitted actuating travel of S= 400 mm and maximum

tripping force of F=200 N applied perpendicularly to the rope.

Suitable guide rollers must be used for rope routing at angles.

2

Page 3

Operating Instructions for Rope Pull

Switches RPS...

Improper installation or manipulation of the rope pull switch will lead to loss of the personal protection

function and can cause serious or fatal injuries.

Safety rope pull switches must not be bypassed (bridging of contacts), turned away, removed or otherwise

rendered ineffective.

The switching procedure may be triggered only by a pretensioned rope system when it is pulled or the rope

is severed.

If damage or wear is found, the complete switch must be replaced. Replacement of individual parts or

assemblies is not permitted!

Identification of the safety pull rope switch

Identification by designation

RPS-M-E-3131-SC-300M...

RPS safety rope pull switch (switch series)

- without

E pre-failure monitoring

- plastic housing

M metal housing

3131 switching function depends on the type used (standard 3131); see section

Switching elements

R with ring

C quick fastener and fast-action tensioning device

P without emergency stop pushbutton, reset by pull knob

S emergency stop pushbutton, reset by rotary actuating cylinder

e.g. 300 N max. spring force to tension the rope

Identification by item number

The item number of the switch is located beneath the switch designation on the switch label. Please state this

number in correspondence and orders to EUCHNER GmbH & Co. KG.

RPS3131SC300M

088884

...

...

...

3

Page 4

Operating Instructions for Rope Pull Switches

RPS...

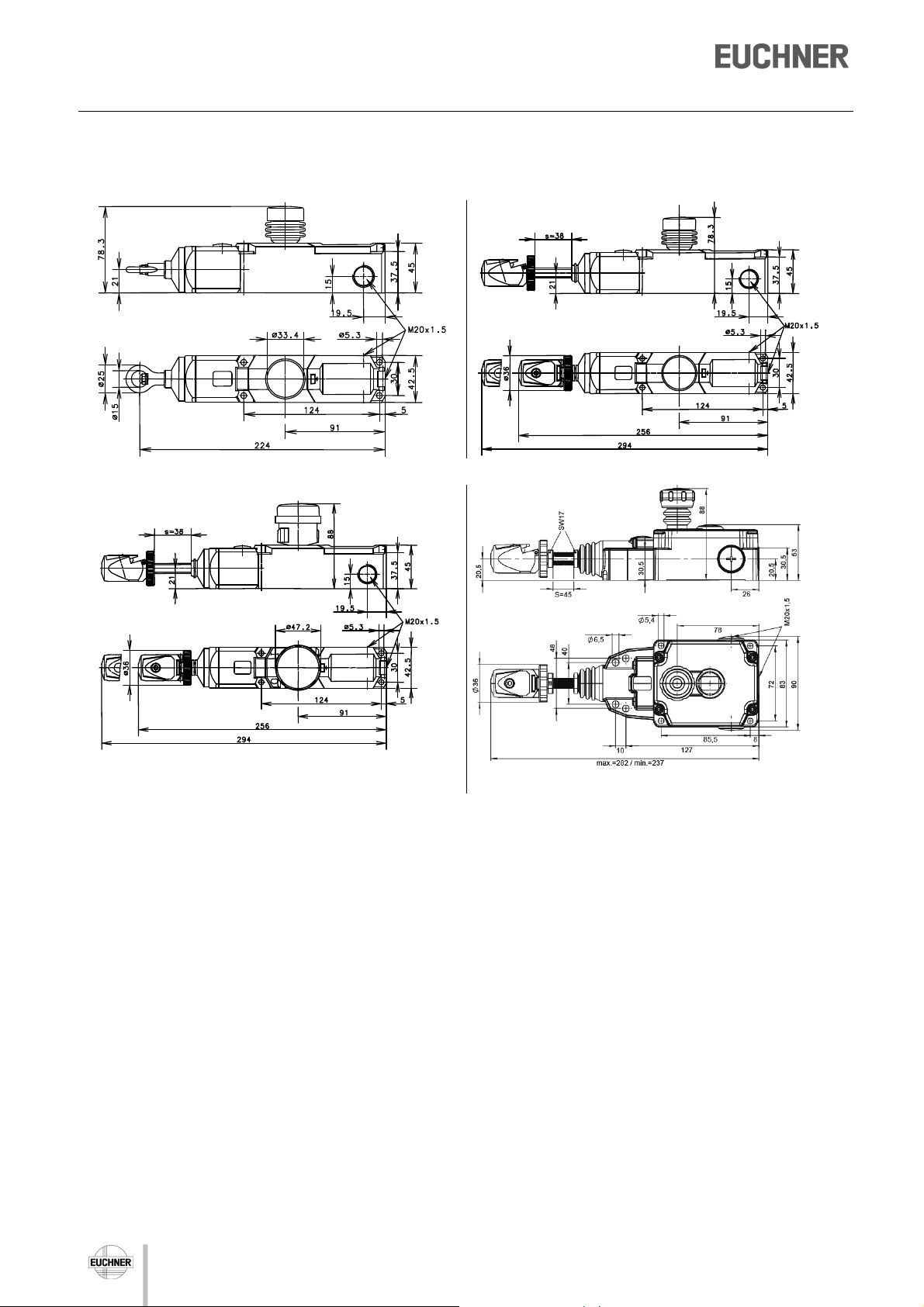

Dimensions

RPS...PR... RPS...PC...

RPS...SC... RPS-M...SC...

All dimensions in millimeters

4

Page 5

Operating Instructions for Rope Pull

Switches RPS...

Mounting

Note

Under ideal installation conditions it is possible to achieve a maximum rope tension length of 75 m.

Depending on the actual situation, there may be increased friction in the system. This friction may be so high

that automatic resetting is no longer possible as described above. However, tripping in the event of a rope tear

must be guaranteed in all cases.

The amount of friction depends on:

- Number of eyebolts used

- Number of contact angles and deflections

- Number and size of guide rollers

- Alignment of rollers and eyebolts with respect to each other.

The friction can be reduced by using guide rollers with a larger diameter. The system should be divided up if

there is too much friction. The user is responsible for component selection and correct functioning of the

system.

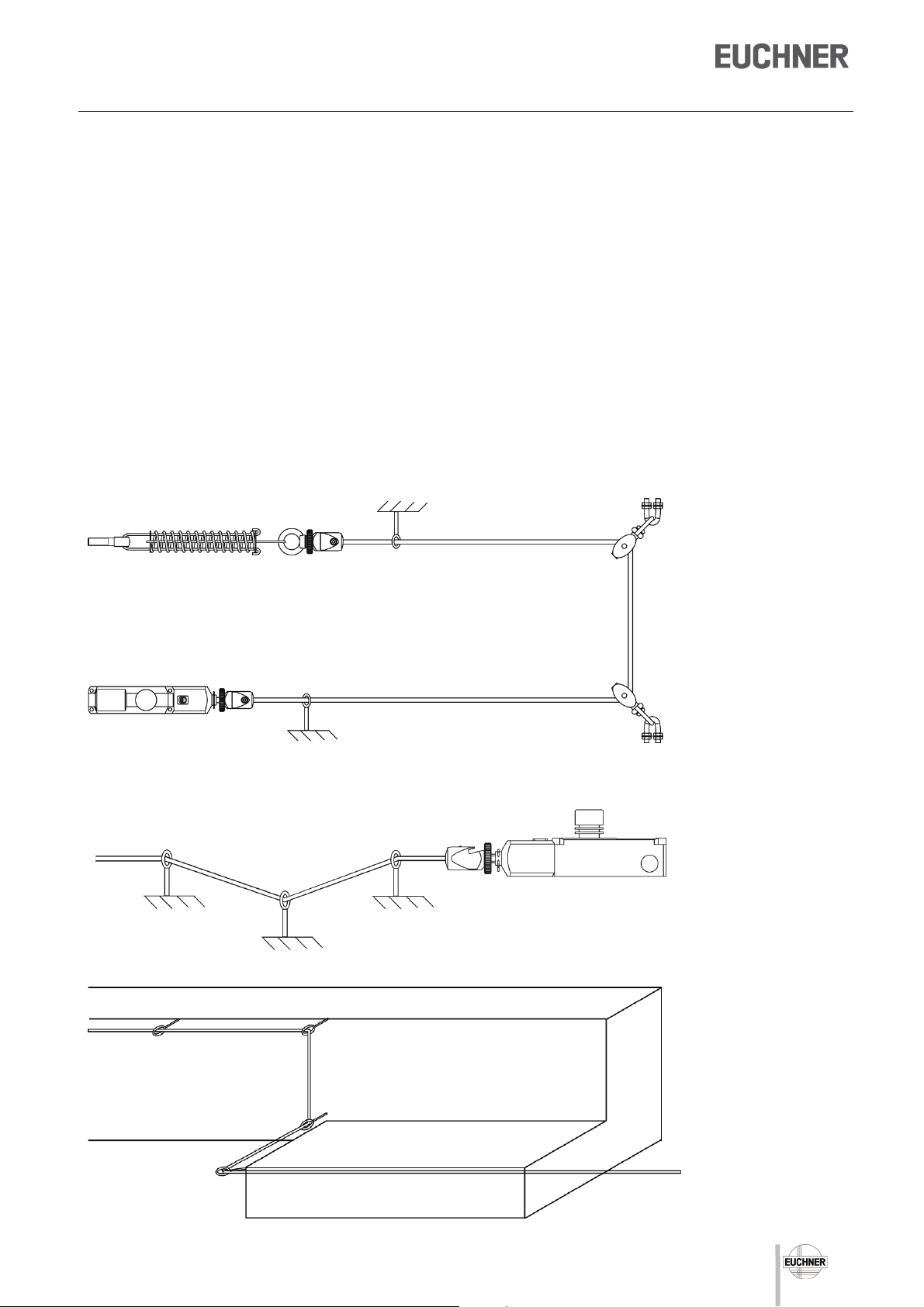

Example of proper installation

Example of improper installation

5

Page 6

Operating Instructions for Rope Pull Switches

RPS...

Selection of system components

A tensioner spring must be installed on the thrust bearing in order to ensure proper and safety-compliant

implementation of the pull rope system. This is a precondition for direction-independent tripping at any point

along the rope length. In order to achieve fast and simple compliance with this requirement, we recommend the

use of EUCHNER tensioner springs with integrated overstretch protection (see Table 1). Additional fixing and

installation materials as well as ropes are also optionally available. A detailed overview is provided in the

section Accessories.

Tensioner spring

Table 1

RPS type RPS...100/175 RPS...300

Item number 092136 092138

L

[mm] 383 483

0 min.

L

[mm] 487 653

max.

ØD [mm] 39 48

Tensioner springs are supplied with quick fastener and an eyebolt DIN 444 - M12 x 50

6

Page 7

Operating Instructions for Rope Pull

Switches RPS...

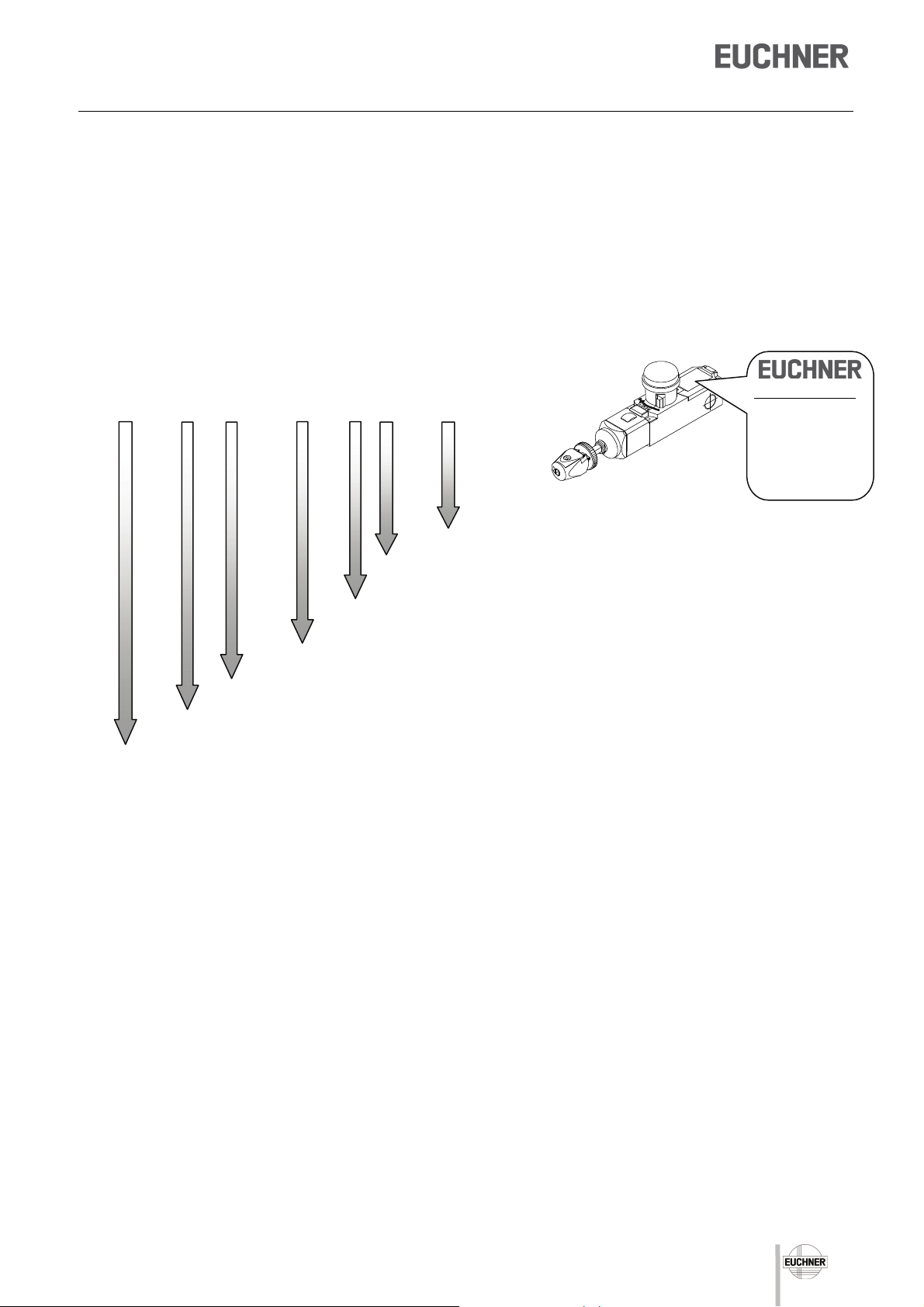

When installing and adjusting the rope pull switch, it is necessary to take into account the physical changes in

the rope length as a result of variations in temperature.

Table 3 shows the permitted rope tension lengths as a function of the expected temperature difference.

The diagram also shows the maximum permitted rope tension length for the different spring forces of the

respective switch types. It also permits selection of the appropriate switch corresponding to the expected

temperature variations.

Table 3

Max. temperature

RPS...100 Rope tension length max. 25 m

RPS...175 Rope tension length max. 37.5 m

RPS...300 Rope tension length max. 75 m

1 2 3 4 5 6 7 8 9

+/-40 K

+/-35 K

+/-30 K

Kelvin

fluctuation in

+/-25 K

+/-20 K

10

11

+/-15 K

+/-10 K

Rope tension length Lmax. in meters [m]

12

13

14

15

16

17

18

19

20

22

24

26

28

30

32

34

36

38

40

42

44

46

48

50

55

+/-5 K

+/-3.5 K

60

65

Rope supports must be provided at intervals of 2–5 m when planning and installing the system. Refer also to

the section Safety precautions.

70

75

7

Page 8

Operating Instructions for Rope Pull Switches

RPS...

Installation sequence

Installation must be performed only by authorized personnel.

1

A

1.1A

1.2A

Attach bearing element with tensioner spring; fit pull rope: sheathing must be removed in clamping area; insert rope

in the fast-action clamping head as shown and secure.

B

Attach bearing element with counterspring; fit pull rope: secure rope as shown with thimble and rope clamp, attach

rope bridge to limit travel of counterspring with thimbles and rope clamps.

2

1.1B

1.2B

1.3A

2 - 5 m La = 150 mm

rope tension

Observe distance to the 1st support point. The 1st rope support next to the switch must be installed after La =150

mm.

Install supports at intervals of 2 – 5 m.

Fasten the RPS switch with four M5 screws

3

(also M6 for RPS-M) .

Maximum tightening torque M = 2 Nm.

Display

The emergency stop switches must be

positioned so that the rope or emergency stop

slam button can be reached without obstacles

in hazardous situations.

17

Display

48

40

10

85,5

72

8

Page 9

Operating Instructions for Rope Pull

Switches RPS...

A

4

Connect pull rope fast-action clamping head (see Item 1).

Pre-tension pull rope.

B

Connect pull rope with turnbuckle as shown (3x rope clamp with thimble)

Basic setting should take place at a temperature corresponding to the prevailing operating conditions.

5

The length of the pull rope changes if there is a large change in the ambient temperature. Under these conditions,

long rope lengths mean a frequent change in the basic setting.

This can be remedied by re-adjustment (Item 5) or shortening the rope length (Table 3).

A

Adjust the setting ring until the arrow tips of the

display are aligned with the marking.

Hold the fast-action clamping head tight when

doing this to prevent the pull rope from twisting

Display:

B

Adjust the turnbuckle until the arrow tips of the display are flush with the marking.

Mechanical function test

RPS...PR/PC

A

6

Pull up the blue RESET knob:

- safety contacts closed.

Actuate the pull rope:

- safety contacts open.

S max. 400 mm

max. 200 N

RPS...SC...

B

Turn yellow actuating cylinder at the

RESET contact areas (blue) by 90° up

to the marking, then release.

Cylinder returns to initial position.

Operate the EMERGENCY STOP

button or the pull rope for each test

procedure.

S max. 400 mm

Display:

max. 200 N

Operate the pull rope forcefully several times in order to settle the pull rope section.

If necessary, carry out re-adjustment by means of the adjusting screw/turnbuckle.

9

Page 10

Operating Instructions for Rope Pull Switches

RPS...

Electrical connection

Electrical connection must be performed only by authorized personnel.

Connection of RPS…

1. Release cover using a screwdriver

2. Open break-out wall by screwing in the cable

gland, remove the plastic part

3. Tighten cable gland

4. Connection to cage pull spring

5. Insert screwdriver (2.5 mm blade width) (1) into

bottom opening

6. Turn screwdriver by 45 (2)

7. Insert flexible cable with a cross-section of 0.08 ...

1.5 mm² in the upper opening (3)

The cable end must be fitted with a wire end

ferrule.

8. Remove screwdriver

9. Press on cover

Connection of RPS-M…

1. Remove cover. To do this, unscrew the cover

screws with a screwdriver and remove the cover.

2. Electrical connection. The electrical contacts of

the switches have M3.5 screw terminals. For the

terminal assignment, see section “Circuit symbol

and switching diagram”.

The connection must be made as stranded wire

with wire end ferrule or as a single wire with the

conductor cross sections 0.5 … 1.5 mm².

3. Close cover. Place the cover on the housing as

shown and tighten the cover screws with a

torque of 2 Nm.

10

Page 11

Operating Instructions for Rope Pull

Switches RPS...

Connection example

The following connection example shows a possible circuit structure with redundant design at the cable level as

well.

The signals of the emergency stop chain are evaluated by a safety relay (ESM from EUCHNER).

The overall control concept into which the pull rope switch RPS is integrated must be evaluated by the end

consumer/machine designer in accordance with EN ISO 13849-2.

24V

RPS

S3

S2

S1

K1

A1A2S11

24VDC

21

22

ESM-BA301

S10

S13

41

42

EUCHNER

EUCHNER

131433

RPS3131SC....

34

23

24

23

24

21

K1B

22

23

21

K1A

24

22

S21

S12 S14 13142324333441

+

K1

+

K2

42

A1

K1A K1B

A2

24V

A1

A2

PE

GND

21 22 .2 21 22 .2

Setup

Mechanical function test

It must be possible to actuate the pull rope easily at every point of the cabling rope pull system. As a check,

actuate the pull rope several times.

Electrical function test

Activate the rope pull system by means of the RESET actuating cylinder.

Start the installation/machine.

Actuate the pull rope / EMERGENCY STOP button: this results in the safety contacts opening immediately.

The safety contacts close only after renewed operation of the RESET actuating cylinder.

GND

11

Page 12

Operating Instructions for Rope Pull Switches

App

g

App

g

RPS...

Technical data

Version RPS… RPS-M…

Electrical data (refers to the switch without plug connector)

Rated insulation voltage Ui 250 V

Rated operating voltage Ue 240 V

Rated impulse withstand voltage U

Continuous thermal current I

Utilization category AC 15; 230 V/ 3 A AC 15; 240 V/ 3 A

Short circuit protection 6 A gG acc. to IEC 60269-1

Safety class II I

Positively driven NC contacts

Pre-failure monitoring RPS-M-E…

Rated operating voltage Ue 10-30 V/DC

Rated operating current Ie 50 mA

Utilization category DC 13

Short circuit protection Yes

Reverse polarity protection Yes

Connection Screw terminal, 3-pin

Mechanical data

Housing/cover PA 6 GV (UL94-VO) die-cast aluminum

Emergency stop PA, glass-fiber reinforced

Actuation Die-cast zinc/steel

Ambient temperature -25°C to +70°C -30°C to +80°C

Contact opening gap > 2 x 2 mm

Mechanical life acc. to IEC 60947-5-5 1 x 105 operating cycles

Switching frequency ≤ 20/min.

Latching device acc. to EN 60947-5-5, DIN EN 418

Emergency stop reset RPS...SC : By turning the RESET actuating cylinder

RPS...PR/PC: By pulling the blue RESET button

Rope length acc. to type L

Rope D = 2 - 5 mm

Rope attachment

Connection

Cable entry 3 x M20x1.5

Mounting 4 x M5 4 x M5 or 4 x M6

Weight

Degree of protection IP67 acc. to EN 60529

Regulations

EC conformity

Approvals

2.5 kV

imp

10 A

the

DC 13; 250 V/ 0.27 A

IEC/ EN 60947-5-1, Appendix K

= 1.5 mm²

= 75 m / 37.5 m / 25 m (observe Table 3)

max

RPS...SC/PC... Fast-action clamping device / PR... by

means of ring

8 x x cage pull springs 0.08

... 1.5 mm² flex.

rox. 0.65 k

EN 60947-1, EN 60947-5-1, EN 60947-5-5, EN ISO 13850

See enclosed Declaration of Conformity

c CSA us / BG

8 screw terminals (М3.5)

rox. 1.0 k

12

Page 13

Operating Instructions for Rope Pull

Switches RPS...

Switching elements

The values for the tensile force depend on the switch type used. (RPS...100/RPS...175/RPS...300)

Tolerance: tensile force ± 15%

3131 (standard) 2131

Detent

Detent

3131 RPS-M (optionally with pre-failure monitoring)

S1

Detent

Detent

S2

ON OFF

Maintenance/service

In order to ensure trouble-free, long-term operation, it is necessary to perform regular, documented inspection

of the following:

- smooth actuation

- correct switching function

- Correct rope tension

- secure mounting of components

- dirt and wear

- sealing of cable entry

- loose cable connections or plug connectors.

After servicing or repair, correct functioning of the system should be checked by actuating the pull rope several

times. It must be ensured that the switch latches properly after actuation.

In the event of a fault in the switching system or latching device, the switch must be replaced and can be sent

to EUCHNER GmbH + Co. KG for inspection.

Exclusion of liability

If the instructions (incorrect use, safety regulations, mounting and connection by trained personnel, check for

safe function) are violated, this renders the manufacturer’s liability null and void.

13

Page 14

Operating Instructions for Rope Pull Switches

RPS...

Accessories

Designation Description/version

Eyebolt

Rope set

RPS roller set

Tensioning rope

Built-in LED

Turnbuckle

Tensioner spring

Thread M8

Consisting of thimble and rope clamp

Rope pulley block with swiveling lug (roller Ø 6 mm) and fastening clamp

Rope pulley block (roller Ø 14 mm) and fastening clamp

Length 50 m

Length 100 m

Light radiation to side

Light radiation to front

M6 x 60

M6 x 110

for RPS 100, 175

for RPS 300

Packaging

unit

5 ea.

5 ea.

5 ea.

1 ea.

1 ea.

1 ea.

1 ea.

1 ea.

5 ea.

1 ea.

1 ea.

1 ea.

Order no./item

092495

092496

092501

096251

RPS-P/V1

092813

092814

087423

095510

092498

092500

092136

092138

RPS-O-8-50/V5

RPS-RS/V5

RPS-PS/V5

RPS-I-3-4/50M

RPS-I-3-4/100M

LED M20x1.5

LED M20x1.5

RPS-B-6-60/V5

RPS-B-6-110

RPS-W-100-175

RPS-W-300

14

Page 15

Operating Instructions for Rope Pull

Switches RPS...

15

Page 16

Euchner GmbH + Co. KG

Kohlhammerstraße 16

D-70771 Leinfelden-Echterdingen

info@euchner.de

www.euchner.de

Edition:

090276-06-08/12

Title: Operating Instructions for Rope Pull

Switches RPS

Copyright:

© EUCHNER GmbH + Co. KG, 08/2012

Subject to technical modifications;

no responsibility is accepted for the accuracy of

this information

0800000388

0800000606

Loading...

Loading...