Page 1

Operating instructions for emergency stop switch ES-XW/XN

Projection

SAFETY NOTE

Read this instruction sheet and the catalog for

the ES-XN/XW series emergency stop switches

to make sure of correct operation before starting

installation, wiring, operation, maintenance, and

inspection. Make sure that the instruction sheet

is kept by the end user.

Turn off the power to the ES-XN/XW before

starting installation, wiring, maintenance and

inspection of the ES-XN/XW. Failure to turn power

off may cause electric shock or fire hazard.

Use wires of a proper size to meet voltage and

current requirements. Tighten the M3 terminal

screws to a tightening torque of 0.6 to 0.8 Nm.

Improper wires and loose terminals during operation will cause overheating and fire hazard. Provide

a proper protection against electric shocks.

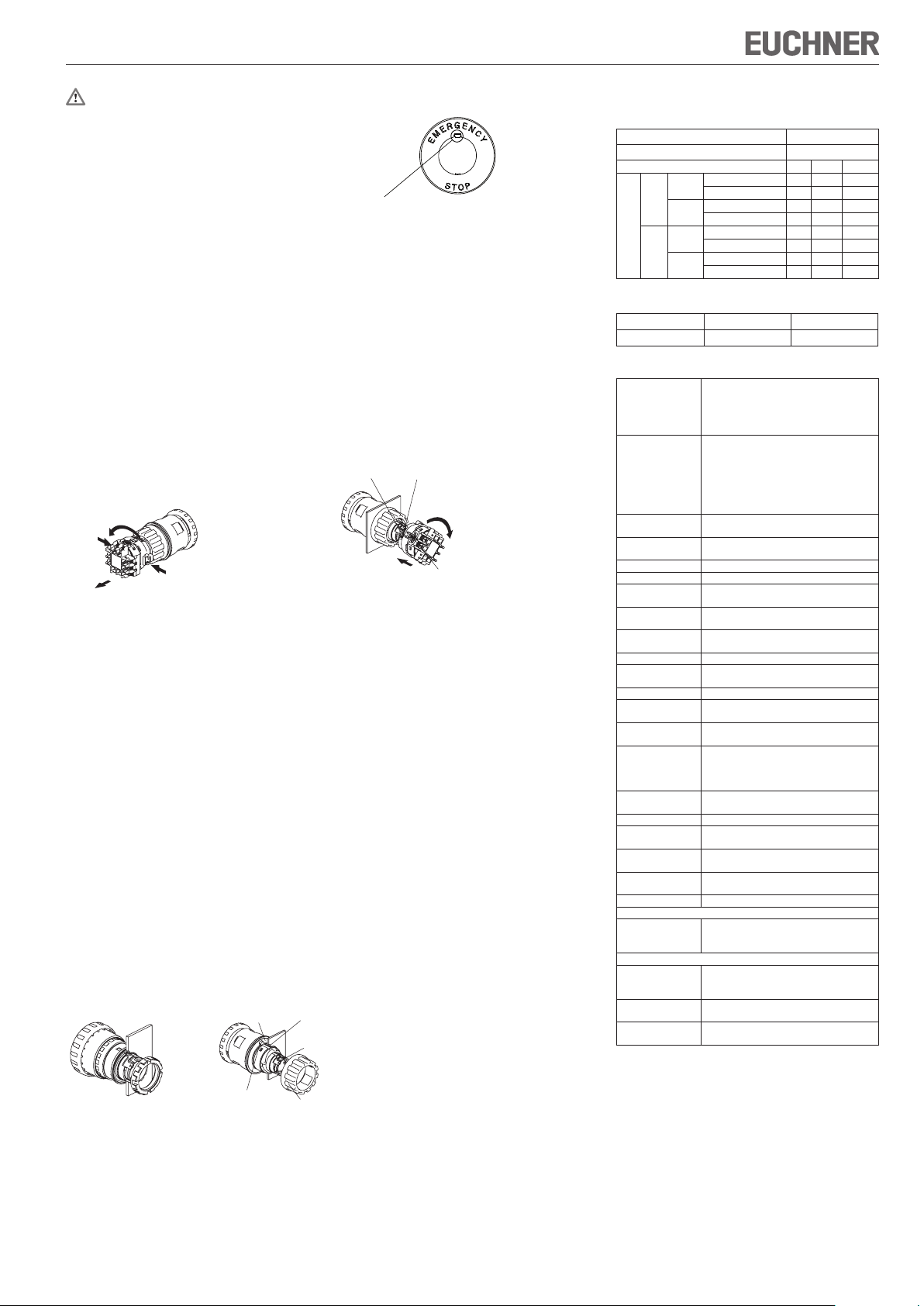

Removing/Installing Contact Block and

Panel Mounting

Removing

First unlock the operator button. Squeeze the latch

lever on the yellow bayonet ring and pull back the

bayonet ring with force until the latch pin clicks,

then turn the contact block counter-clockwise and

pull out.

(Turn counter clockwise)

(Squeeze)

(Pull)

Notes for removing the contact block

1) With the button in the locked position, do not

remove the contact block, otherwise the switch

may be damaged.

2) When the contact block is removed, the monitor

contact (NO contact) is closed.

3) While removing the contact block, do not exert

an excessive force, otherwise the switch may be

damaged.

4) An LED lamp is built into the contact block for

illuminated pushbuttons. When removing the

contact block, pull out the contact block straight

to prevent damage to the LED lamp. If an excessive

force is exerted, the LED lamp may be damaged

and fail to light.

Panel Mounting

Remove the locking ring from the operator and

check that the rubber gasket is in place. Align

the anti-rotation projection on the bezel with the

recess in the panel, insert the operator from panel

front into the panel hole and tighten the locking

ring using ring wrench ES-XN9Z-T1 to a torque

of 2.5Nm. Face the side without thread on the

operator with TOPmarking upward, and tighten

the locking ring using ring wrench ES-MW9Z-T1

to a torque of 2.0Nm.

Bayonet ring

Latch lever

Rubber gasket

(Squeeze)

TOP marking

Rubber gasket

Recess

TOP

marking

When using the ES-XN emergency stop nameplate

(ES-HNAV-27).

Before installing the emergency stop nameplate,

break the projection on the nameplate using pliers.

Installing

First unlock the operator button. Align the small

▼ marking on the edge of the operator sleeve

with the small ▲ marking on the yellow bayonet

ring. Hold the contact block, not the bayonet ring.

Press the contact block onto the operator and turn

the contact block clockwise until the bayonet ring

clicks.

Notes for installing the contact block

1) With the button in the locked position, do not

install the contact block, otherwise the switch

may be damaged.

2) Make sure that the bayonet ring is secured in the

locked position.

▼ ▲

(Push)

making making

(Turn

clockwise)

TOP making

Notes for Operation

When using the emergency stop switch for safetyrelated equipment in a control system, refer to the

safety satandards and regulations in each country

and region depending on the application purpose of

the actual machines and installations to make sure

of correct operation. Before using the emergency

stop switch, perform risk assessment to make

sure of safety.

Wiring

Tighten the terminal screws to a torque of 0.6 to 0.8 Nm.

Contact Bouncing

When the button is reset by pulling or turning, the NC

main contacts cause bouncing. When pressing the

button, the NO monitor contacts cause bouncing.

When designing a control circuit, take the bouncing

into consideration (reference value: 20 ms).

LED Illuminated Switches

The LED lamp is built into the contact block and

cannot be replaced.

Handling

Do not expose the switch to excessive shocks and

vibrations, otherwise the switch may be deformed

or damaged, causing malfunction or operation

failure.

Padlock Emergency Stop (ES-XN)

The padlockable emergency stop switches can

be reset by turning only, and cannot be pulled to

reset. Do not attempt to pull to reset, otherwise

damage or malfunction may result.

Contact Ratings [Main Contact (NC) and

Monitor Contact (NO)]

Rated Insulation Voltage (Ui) 250V

Conventional Free Air Thermal Current (Ith) 5A

Rated Operational Voltage (Ue) 30V 125V 250V

AC

50/60Hz

Main

DC

Contact

AC

Current

50/60Hz

Rated Operational

DC

Monitor

Contact

Resistive Load (AC-12)

Inductive Load (AC-15) - 3A 1.5A

Resistive Load (DC-12) 2A 0.4A 0.2A

Inductive Load (DC-13) 1A 0.22A 0.1A

Resistive Load (AC-12) - 1.2A 0.6A

Inductive Load (AC-14) - 0.6A 0.3A

Resistive Load (DC-12) 2A 0.4A 0.2A

Inductive Load (DC-13) 1A 0.22A 0.1A

-

5A 3A

Built-in LED Ratings

Rated Voltage Operating Voltage Operating Current

24V AC/DC 24V AC/DC±10% 15 mA

Specifications

Applicable Standard IEC 60947-5-1, EN 60947-5-1

Standard Operating

Conditions

Minimum Direct

Opening Force

Minimum Direct

Opening Travel

Maximum Travel 4.5 mm

Contact Resistance 50 mΩ maximum (initial value)

Insulation Resistance

Over voltage

Category

Impulse Withstand

Voltage

Pollution Degree 3

Operating Frequency

Mechanical Life 250,000 operations min

Electrical Life 100,000 operations min

Shock Resistance Operating extremes : 150 m/s²

Vibration Resistance Operating extremes :10 to 500 Hz, amplitu-

Degree of Protection

Terminal Protection IP20

Short-circuit Protective Device

Conditional Shortcircuit Current

Applicable Tightening Torque

Applicable Wire 0.75 to 1.25 mm² (AWG18 to 16)

ES-XW

Recommended

Tightening Torque of

Locking Ring

ES-XN

Recommended

Tightening Torque of

Locking Ring

Total Weight of

Padlock and Hasp

Reinforced Insulation (IEC 60664-1)

IEC 60947-5-5, EN 60947-5-5

JIS C8201-5-1, JIS C8201-5-5, UL508,

UL991, NFPA79, CSA C22.2 No.14,

GB14048-5

Operating temperature

Non illuminated : -25 to +60 °C (no freezing)

LED illuminated : -25 to +55 °C (no freezing)

Relative humidity : 45 to 85 % RH (no

condensation)

Storage temperature : -45 to +80 °C (no

freezing)

80 N

4.0 mm

100 MΩ minimum (500V DC megger)

II

2.5 kV

900 operations/hour

250,000 operations min (24V AC/DC, 100mA)

Damage limits : 1,000 m/s²

de 0.35mm, acceleration 50 m/s²

Damage limits:10 to 500 Hz, amplitude

0.35mm, acceleration 50 m/s²

IP65 (panel front)

250V/10A fuse (Type aM IEC60269-1/

IEC60269-2)

1,000 A

0.6 to 0.8 Nm

2.0 Nm

2.5 Nm

1500g maximum

Between live parts and Bezel

Sleeve

without threed

ES-XW... ES-XN

About anti-rotation

Locking ring

Anti-rotation

projection

Locking ring

To prevent the ES-XW emergency stop switch from

rotating when resetting from the latched position with

excessive force, use of a nameplate (ES-HWAV-27) is

recommended. Align the side without thread on the

operator with TOP marking, the small ▲ marking

on the projection on the nameplate, and the recess

on the mounting panel.

Page 2

Operating instructions for emergency stop switch ES-XW/XN

32

31

21

22

4

1

4

2

11 12

LED 24V

4

2

4

122

21

X233

34X1

11 12

L R

32

31

21

22

4

1

4

2

11 12

LED 24V

X2

X1

L R

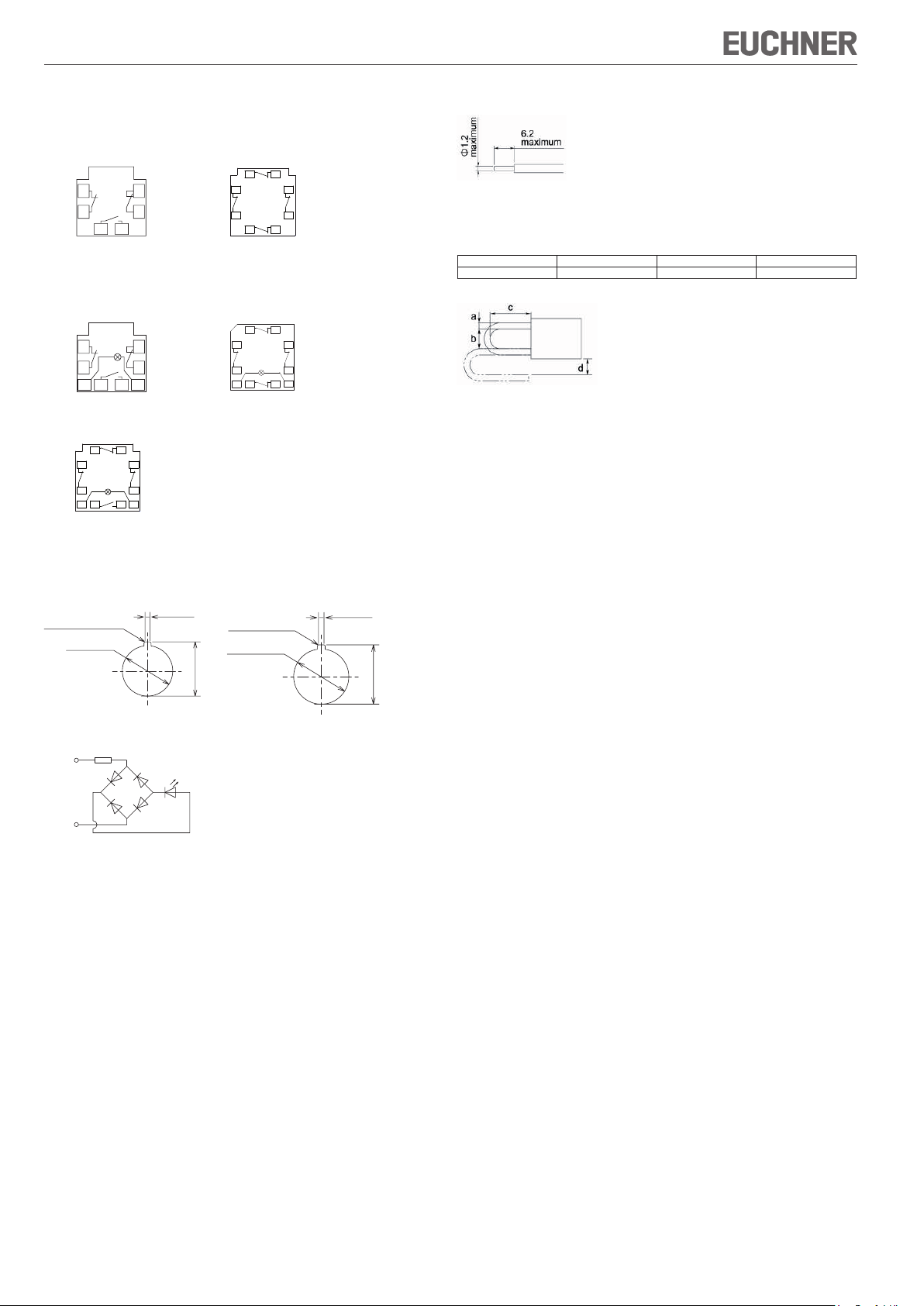

Contact Arrangements (Bottom View)

Non-illuminated

ES-XW1E-BV412MFR/ ES-XW1E-BV404MFR

ES-XN4E-BL412MFRH

L R

11 12

24 23

Illuminated

ES-XW1E-LV412Q4MFR/ ES-XW1E-LV404Q4MFR

ES-XN4E-LL412Q4MFR

L R

11 12

X1

24 23

ES-XW1E-LV413Q4MFR

32 31

32 31

X2

Applicable Wire

Padlock and Hasp

Applicable padlock and hasp are shown below.

Padlock size

a b c d

7 mm maximum 19 mm minimum 39 mm minimum 15 mm minimum*)

*) Dimension d is 6 mm or more when attaching a padlock from the side of a switch.

Since various from and sizes are available, make sure of applicability using the

actual padlock and hasp before use.

The total weight of the padlock and hasp can be a maximum of 1500g. When

the total weight exceeds this limit, the switch may malfunction or fail.

Mounting Hole Dimensions

ES-XW ES-XN

R0.8 maximum

+0.4

φ

22.3

0

3.2

+0.2

0

R0.8

maximum

Φ

30.5

0

+0.4

24.1

LED Unit Internal Circuit

X1

X2

R

LED

+0.5

+0.2

4.8

0

0

0

+0.5

33.0

Subject to technical modifications; no responsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG 105026-07-06/12

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49 711 7597-0 Fax +49 711 7533-16 www.euchner.de info@euchner.de

Loading...

Loading...