Page 1

t

A

t

Y

φ

INSTRUCTION SHEET

AS-Interface Safety at Work Slave

ES-XA Series

Thank you for purchasing our product. This product is an emergency stop switch compatible with

AS-Interface Safety at Work. Before installing, wiring, operating and performing maintenance and

inspection of this product, please read this manual carefully to use this product correctly.

After reading, keep this instruction sheet handy. Please take care to deliver this manual to the end

user. Note that handling this product requires expert knowledge about electricity.

SAFETY NOTE

This product is manufactured under our tightly controlled production environment. In this

instruction sheet, the dangers expected to occur due to improper handling are described under

the classifications of "Warning" and "Caution." Meanings of the terms are as follows:

Warning notices are used to emphasize that improper operation may cause severe personal

injury or death.

Caution notices are used where inattention might cause personal injury or damage to equipment.

Application

1

This product is an emergency stop switch authorized by TÜV Rheinland according to

IEC60947-5-5 compatible with the AS-Interface Safety at Work. When used in combination with a

safety monitor that is programmed appropriately, this switch operates as an emergency stop

switch applicable to safety category 4 in compliance with EN954-1 and IEC61508 SIL3. For this

purpose, this product generates 8x4-bit code tables defined specifically for the product, and is

scanned in each AS-Interface bus cycle by an AS-Interface master. At the same time, the data is

checked by an AS-Interface safety monitor. The safety loop consists of this product, a safety

monitor, and an actuator connected with the safety monitor.

Laws and Regulations

2

IEC61508 Part1-7 : 2000 EN954-1 : 1996

EN62061 : 2005 IEC60947-5-5: 1997

EN60204-1 : 2005 EN50295 : 1999

EN61000-6-2 : 2005 EN61000-6-4 : 1997

NFPA79: 2002

UL508 CSA C22.2 No, 14 UL/ c-UL

Probability of Failure on Demand (PFD) and Probability

3

of Failure per Hour (PFH)

This product has the following Probability of Failure on Demand (PFD) and Probability of Failure

per Hour (PFH). However, to satisfy SIL requirements, calculation of PFD and PFH is needed for

the all devices comprising the system.

Before using this product, read the manuals for AS-Interface safety

monitor (hereinafter referred to as “safety monitor”) and the safety

monitor setting software carefully. These manuals provide information

about installation, setup, operation, and maintenance of this product.

Be sure to turn off the AS-Interface power supply before installation,

removal, wiring, maintenance or operation of the product. Otherwise it

may cause an electric shock or a fire.

Operations other than those described in this instruction sheet can cause

damage to this product or a connected system, preventing demonstration

of the functions to their full capacities. Do not remodel this product since a

remodeled product is not guaranteed. Use this product according to the

safety standard and related laws and regulations.

Using this product for purposes different from those specified may cause

danger to an operator or damage to the system itself. Installation of this

product must be conducted by the trained personal, following the instructions

in this instruction sheet. When using this product as a slave in a safety

related application, be sure to use it in combination with an AS-Interface

product having an appropriate the safety monitor according to regulations

and standards. Refer to the operation manual for your safety monitor and the

chapter on connection examples in this document. Also, check all safety

functions including safety-related equipment before the normal operation.

Perform a functional test on this product at least once a year. Do not

disassemble, repair, or modify this product. Otherwise, the primary

safety features of this product may be lost.

Standards Organization

PFD 4.38 x 10 -5

PFH 1.00 x 10 -9

TÜV Rheinland

Specifications

4

Electrical specifications

Rated operating voltage Ue 26.5 to 31.6 V (from AS-Interface line)

Rated operating current Ie (when Ue = 30.5V) < 25mA (Not illuminated)

Input specifications

Number of inputs

Output specifications

Number of output points/specifications

AS-Interface specification

Slave type Safety slave

Maximum network length 100 meters in total

Maximum number of slaves in the network

Profile

(I/O . ID . ID2)

Data bit

Parameter bit Not used

Environment

Operating temperature -25 to 55°C(no freezing)

Storage temperature -40 to 70°C(no freezing)

Operating humidity 45 to 85% RH (no condensation)

Structural specifications

Operating force

Minimum operating force of direct break 60 N

Minimum operating distance

for direct circuit breaking

Maximum operating distance 4.5 mm

Insulation resistance 100 MΩ or higher (500 VDC mega)

Pollution degree

Impact resistance

Vibration Resistance

Life time

Protective structure

Recommended tightening torque

for locking ring

Weight 29 type: 35 g

Applicable cable UL2468AIN-F20 AWG×2C

[1] For UL and c-UL , pollution degree is 2.

5

This product is a push-locking, pull- or turn-resetting emergency stop switch. When the button is

pressed, the pressed button is locked. The button is reset by pulling or turning clockwise.

6

Input

Output DO1 to DO3 unused

Reset Operation

Pin Assign

1 2

1: AS-Interface - (Cable color: Blue) 2: AS-Interface + (Cable color: Blown)

When emergency

switch is pressed.

When emergency

switch is not operated.

Pull reset

Do not expose the switch to excessive shock and vibration, otherwise

the switch may be deformed or damaged, causing malfunction or

operation failure.

Connector Body

Use the end connector when installing at the end of the cable.

< 35mA (I

lluminated)

2 channel inputs

(positive opening mechanism)

1 / illuminating red LED

(only illuminated slave)

31 (When any safety slaves are

connected)

S-0.B.E (Non-LED type)

S-7.B.E (LED type)

DI0 DI1 DI2 DI3

0 0 0 0

DI0 DI1 DI2 DI3

X X X X

X: 0,1 (Indefinite)

DO0 = 1 Indicator ON

DO0 = 0 Indicator OFF

Push lock: 10.5 N

Pull reset: 10 N

Turn reset: 0.16 N·m

4.0 mm

[1]

3(operator unit)

2(AS-Interface communication unit)

Normal operation: 15G, 11ms

Not destroyed: 100G

Operating extremes: 10 to 500Hz,

amplitude 0.35mm, acceleration 50m/s

2 hours per axis on each of XYZ axes

Mechanical / Electrical:

250000 times or more

IP65 (operator unit),

IP20 (AS-Interface communication unit)

0.88 N·m

Turn reset

1

2

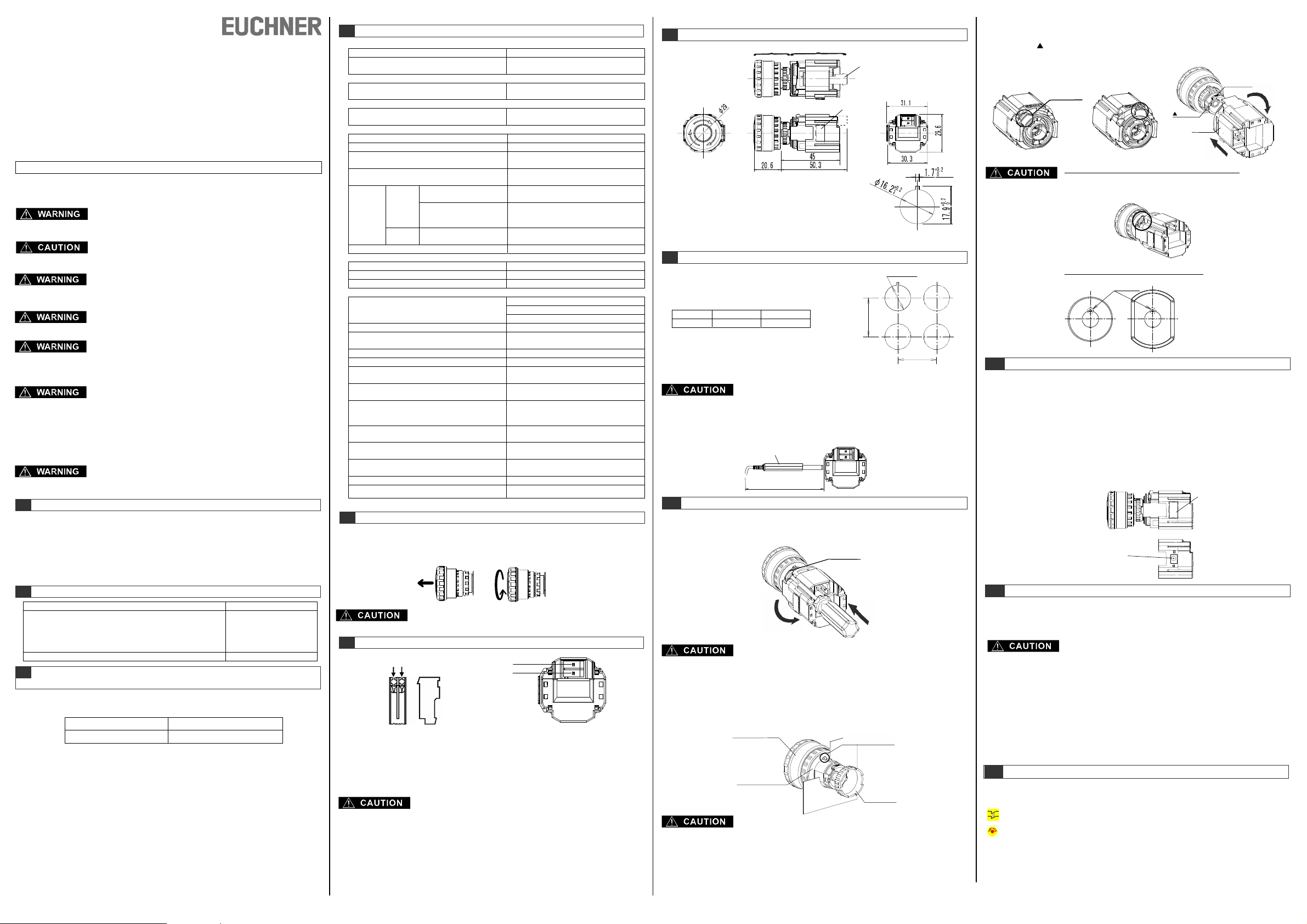

Dimensions

7

Operator uni

AS-Interface communication unit

AS-Interface communication c onnector

Addressing port

Mounting Hole Layout

8

Operator X axis Yaxis

Ø29 Min 40mm Min 40mm

·The values shown above are the minimum dimensions for

mounting with other Ø16mm pushbuttons. For other control

units of different sizes and styles, determine the values

according to the dimensions, operation, and wiring

convenience.

2

,

Installation

9

-Removing AS-Interface communication unit

First unlock the operator button. While pushing up the white bayonet ring with force, using a small

screwdriver (width: 2.5 to 3mm) if necessary, turn the AS-Interface communication unit

counterclockwise and pull out.

-Panel Mounting

Remove the locking ring from the operator and check that the rubber gasket is in place. Insert the

operator from panel front into the panel hole. Face the side with the anti-rotation protrusion on the

operator upward, and tighten the locking ring.

To set an address while mounting this product on the panel, more than

60mm space is necessary on the left side in terms of the AS-Interface

communication unit. Note that adequate space cannot be allocated by

the distance specified with minimum mounting pitch. If adequate space

cannot be allocated, set the address before installing the product on the

panel or set the address after removing the AS-Interface communication

unit from the operation section.

Programming cable

60.0

(2) Turn counterclockwise

Notes for removing an AS-Interface communication unit

(1) Do not exert excessive force when using a screwdriver, otherwise

the bayonet ring may be damaged.

(2) When removing the AS-Interface communication unit, avoid rough

handling of the unit. Rough handling may damage the switch.

Operator unit

Rubber Gasket

Notes for Panel Mounting

The panel thickness should be within the range from 0.8 to 3.7 mm. To

mount the ES-XA emergency stop switches onto a panel, tighten the

locking ring to a tightening torque of 0.88 N·m maximum using ring

wrench ES-MT-001. Do not use pliers. Do not exert excessive force,

otherwise the locking ring may be damaged.

Bayonet ring

Anti-rotation protr usion

Subject to technical modifications; no responsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG 105027-04-02/10

Mounting hole dimension

16.2

(1) Push

Locking ring

+0.2_

0

-Installing the AS-Interface communication unit

First turn the bayonet ring to the unlocked position.

Align the small marking on the edge of the operator boss with the TOP marking on the

AS-Interface Communication unit onto the operator and turn the AS-Interface communication unit

clockwise until the bayonet ring clicks.

TOP marking

Bayonet Ring

Mark

TOP

Unlocked Locked

Notes for Installing the AS-Interface communication unit

Check that the AS-Interface communication unit is securely installed on

the operator. When the emergency stop switch is properly assembled,

the bayonet ring is in place as shown below.

Notes for using nameplate and switch guard

Remove the projection from the nameplate or switch guard using pliers.

X

Addressing

10

Turn off the power and then remove the lid of the address setting section. Connect the

programming cable to the address setting device and insert the device in the address setting

section. Then specify the address settings according to the setting procedures. After specifying

settings, be sure to replace the lid of the address setting section. Specifying address settings on

an AS-Interface slave is also possible using an AS-Interface master. Refer to the manual for the

AS-Interface master for details. Setting addresses 1 through 31 is allowed. The address specified

upon shipment is "0".

Refer to the address setting device instruction sheet for the operation of the address setting device.

-Connecting the programming cable for ES-XA address setting device

The lid of the address setting device on the side of the unit can be removed by prying it out. Take

care not to lose the lid, which comes off completely. By removing the lid of the address setting

section, you are able to see the terminals for connecting a programming cable. Connect the

programming cable to the terminals.

Projection

ddressing port for connecting

he programing cable is under the lid

Wiring

11

For cabling of this product, mount the connector sold separately to the compatible cable and

connect the main unit with the cable through the connector. A special tool is necessary to connect

the connector to the cable. When mounting a connector at the end of the cable, use a connector

for termination.

A maximum of 31 units can be connected to a network. Addresses must be assigned to avoid overlaps.

This product allows connecting safety slaves with safety equipment, and normal slaves without

safety equipment at the same time. Do not connect safety related signals to a normal slave.

The normal slaves for AS-Interface are divided into two types: A/B slaves with expanded

addresses and standard slaves without expanded addresses. If A/B slaves and standard slaves

are connected simultaneously, the maximum number of slaves connectable to a network may

exceed 31.

Setting Safety Monitor

12

When using this product in combination with a safety monitor, use a “2-channel forced” monitor

device with the “Emergency shutdown” icon.

2-channel forced

Emergency shutdown

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen

Notes for setting up wiring

The network length is a maximum of 100 meters, including all wires.

However, the maximum possible length of the wires may actually be shorter

than 100 meters depending on the type of master and composition of slaves.

Consider the lengths of cables and wiring topology so that voltage drops in

transmission lines are no higher than 3V.

Use the applicable two-wire flat cables for wiring.

Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

(1) Press

Lid of addressing port

(2) Turn

Loading...

Loading...