Page 1

Emergency Stop Safety Relay ESM-BA7..

User Information

Correct Use The ESM-BA7.. is a universal emergency stop safety switching

device with seven safe relay outputs that can quickly and safely

stop the moving parts of a machine or system in case of danger.

Applications for the ESM-BA7.. include single or dual-channel

emergency stop circuits and guard monitoring on machines and

systems. This safety relay can be delivered with fixed screw

terminals or plug-in terminals.

•

Features

Function

7 safe, redundant relay outputs

•

4 auxiliary relay outputs; 2 auxiliary transistor outputs

•

Connection of:

•

- Emergency stop buttons

- Safety switches

- Non-contact safety switches

- OSSD-Outputs

•

Single or dual-channel operation possible

•

Feedback loop for monitoring downstream contactors or

expansion modules

•

Cyclical monitoring of the output contacts

•

Indication of the swiching state via LED

The emergency stop safety switching device ESM-BA7.. is

designed for safe isolation of safety circuits according to EN

60204-1 and can be used up to safety category 4, PL e

according to EN ISO 13849-1.

The internal logical system closes the safety contacts when

the start button is pressed.

If the safety switch is opened, the positively driven safety

contacts are opened and safely switch the machine off. It is

ensured that a single fault does not lead to a loss of the

safety function and that every fault is detected by cyclical

self-monitoring no later than when the system is switched

off and switched on again.

The operating status of the device is indicate by the

auxiliary transistor outputs O1 and O2

O1: Ready. PWR is connected.

O2: Both relay channel K1, K2 are switched on.

•

2 start behavior possible:

- Monitored manual start

- Automatic start

•

Up to PL e, SILCL 3, category 4

•

STOP-category: 0

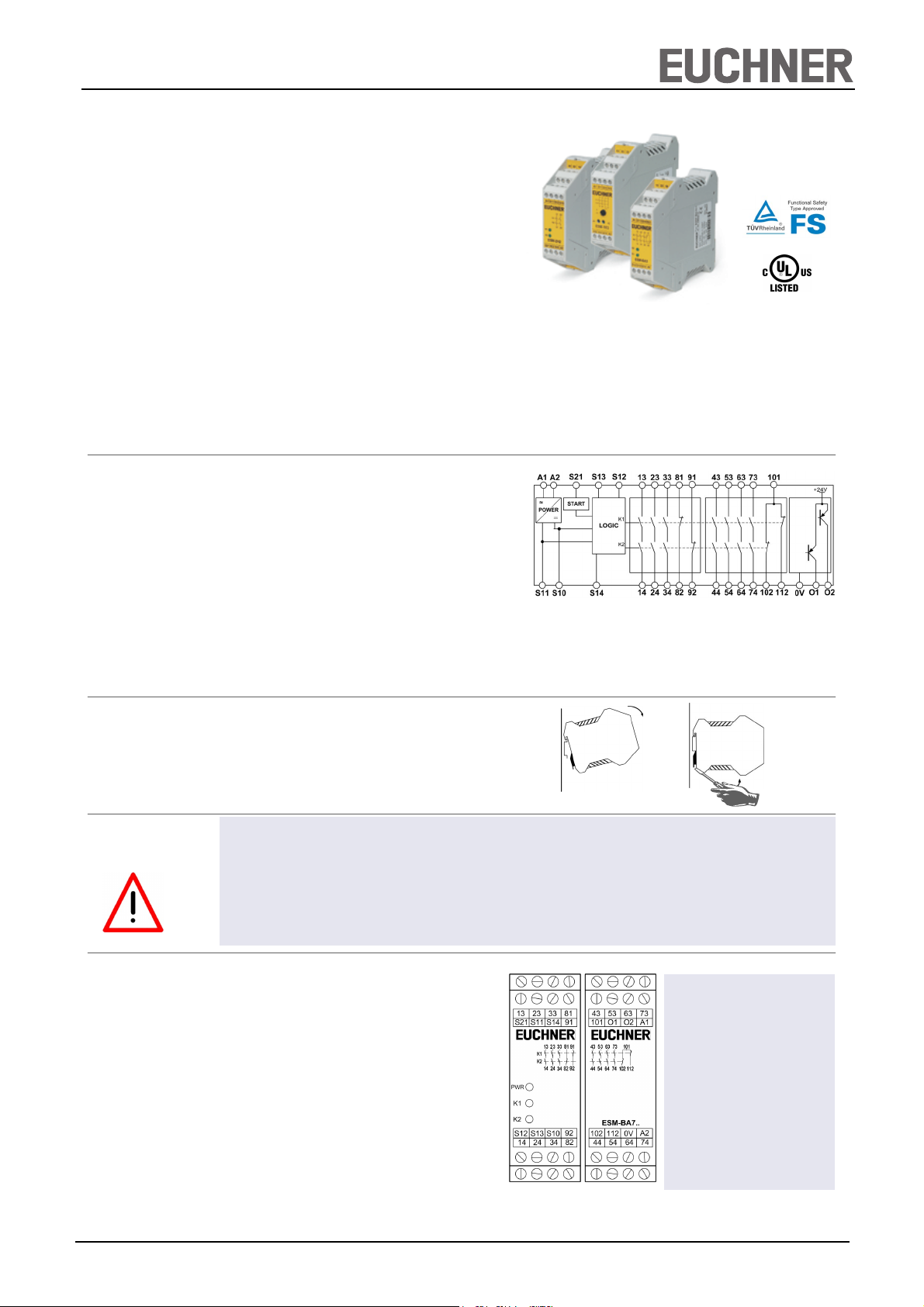

Fig. 1 Block diagramm ESM-BA7..

UL pending

Installation

Safety

Precautions

Electrical

Connection

As per EN 60204-1, the device is intended for installation in

control cabinets with a minimum degree of protection of

IP54. It is mounted on a 35-mm DIN rail according to

DIN EN 60715 TH35.

•

Installation and commissioning of the device must be

performed only by authorized personnel.

•

Observe the country-specific regulations when installing

the device.

•

The electrical connection of the device is only allowed to

be made with the device isolated.

•

The wiring of the device must comply with the instructions in this user information, otherwise there is a risk

•

•

•

•

that the safety function will be lost.

•

A safety transformer according to IEC 61558-2-6 or a

power supply unit with electrical isolation from the

mains must be connected.

•

External fusing of the safety contacts (6A slow-blow or

8A quick-action or 10 A gG) must be provided.

•

A maximum length of the control lines of 1000 meters

with a line cross section of 0.75 mm

2

must not be ex-

ceeded.

•

The line cross section must not exceed 2.5 mm2.

•

If the device does not function after commissioning, it

must be returned to the manufacturer unopened. Opening the device will void the warranty.

Fig. 2 Installation / removal

It is not allowed to open the device, tamper with the device or bypass the safety devices.

All relevant safety regulations and standards are to be

observed.

The overall concept of the control system in which the

device is incorporated must be validated by the user.

Failure to observe the safety regulations can result in

death, serious injury and serious damage.

A1: Power Supply

A2 : Power Supplay

S11: DC 24V control voltage

S10: Control line

S12: Control line

S13: Control line

S14: Control line

S21: Start, Control line

O1;O2: Aux transistor outputs

0V: Reference common O1, O2

81-82: Auxiliary Contact

91-92: Auxiliary Contact

101-102: Auxiliary Contact

101-112: Auxiliary Contact

13-14 to 73-74:

Safety Out1-7

Fig. 3 Connections

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

1

Page 2

Emergency Stop Safety Relay ESM-BA7..

User Information

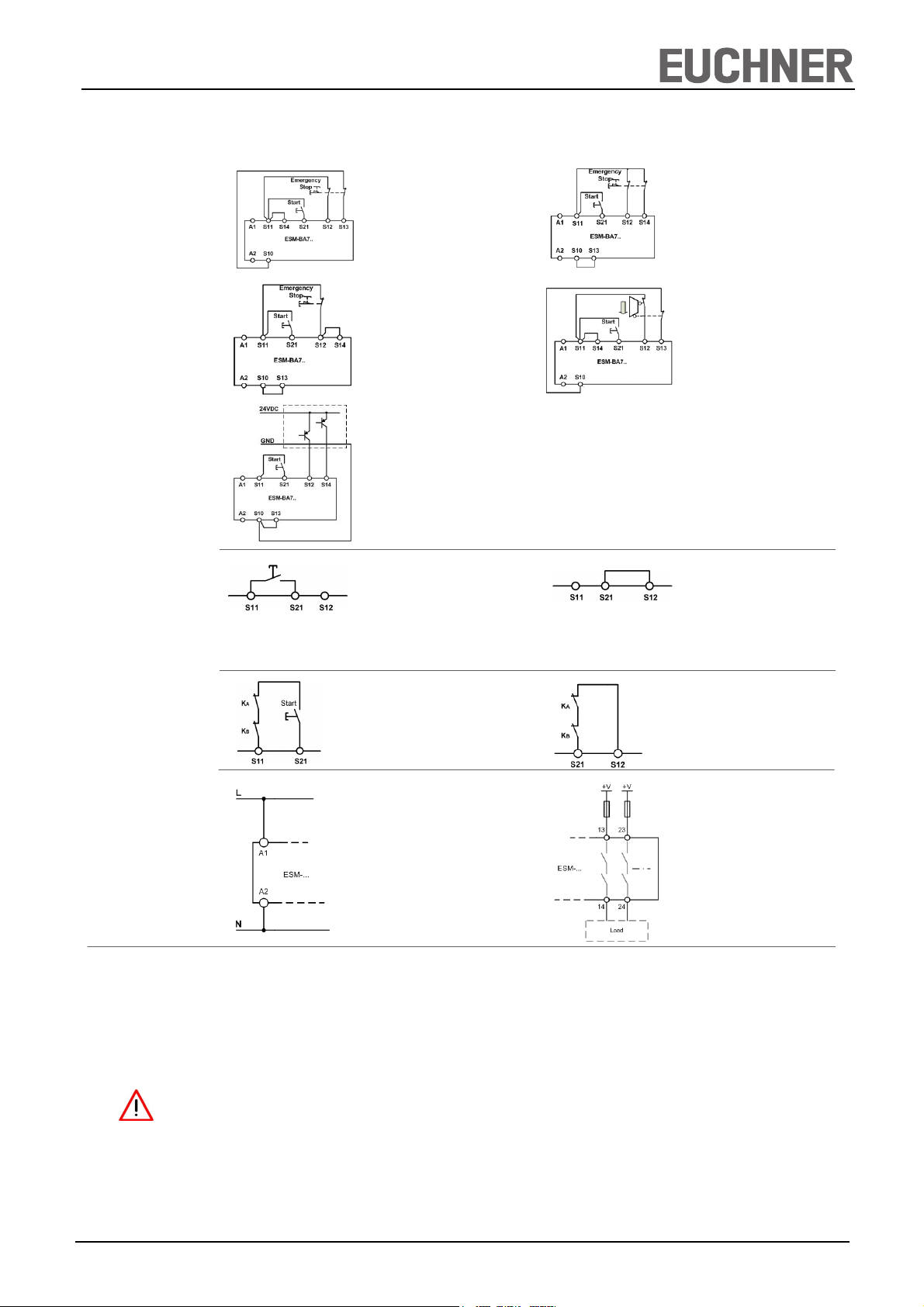

Applications

Emergency Stop

Circuit

Depending on the application or the result of the risk assessment according to EN ISO 13849-1, the device must be wired as

shown in Fig. 1 to Fig. 11.

Fig. 1:

Two-channel emergency stop

circuit with short circuit and earth

fault monitoring.

(category 4, up to PL e)

Fig. 2:

Two-channel emergency stop

circuit with earth fault monitoring.

(category 3, up to PL d)

Starting Behavior

Feedback Loop

Fig. 3:

Single-channel emergency stop

circuit with earth fault monitoring.

(category 1, up to PL c)

Fig. 5:

Two-channel emergency stop

with pnp-outputs/OSSD-outputs

with short circuit monitoring.

(category 4, up to PL e)

Fig. 6:

Monitored manual start.

It is monitored that the start button was

opened before the emergency stop

button closes. (Prerequisite: operating

voltage must not be interrupted.)

Fig. 8:

Feedback loop for monitored manual

start:

The feedback loop monitors contactors

or the expansion modules .

Fig. 4:

Two-channel sliding guard

monitoring with short circuit and

earth fault monitoring.

(category 4, up to PL e)

Warning only for 24V-version:

In order to activate earth fault monitoring, the PE must be

connected only to the power supply unit in accordance with

EN60204-1.

Fig. 7:

Automatic start.

Warning:

Safety contacts switch

immediately when the

power supply is connected.

Max. permitted delay during

closing of the safety switches on

S12 and S13:

S12 before S13: 300 ms

S13 before S12: any

Fig. 9:

Feedback loop for automatic start:

The feedback loop monitors contac-

tors or the expansion modules .

Power supply

and

Safety contacts

Commissioning

Procedure

Fig. 10:

Power supply A1 and A2.

(Power supply according to techn.

data )

Note: The items listed under “Electrical connection” must be observed during commissioning.

1. Wiring emergency stop circuit:

Wire the emergency stop circuit according to the required

Performance Level determined (see Fig. 1 to Fig. 5).

2. Wiring start circuit:

Wire the start circuit according to Fig. 6 or Fig. 7 to set the

starting behavior.

Warning:

If “Automatic start” is set, bear in mind that the safety con-

tacts will switch immediately after the power supply is

connected. If “monitored manual start” is set, the start

button must be opened after wiring.

3. Wiring feedback loop:

If your application provides for external contactors or expansion modules, connect them to the device according to

Fig. 8 or Fig. 9.

4. Wiring power supply:

Connect the power supply to terminals A1 and A2 (Fig. 10).

5. Starting the device:

Switch on the operating voltage.

Warning:

If the “automatic start” starting behavior is set, the safet y

contacts will close immediately.

If the “monitored manual start” starting behavior is set, close

the start button to close the safety contacts.

LEDs K1 and K2 are lit.

6. Triggering safety function:

Open the emergency stop circuit by actuating the connected safety switch. The safety contacts open immediately.

7. Reactivation:

Close the emergency stop circuit. If “automatic start” is

selected, the safety contacts will close immediately.

If the “monitored manual start” starting behavior is set, close

the start button to close the safety contacts.

Warning: Wiring only in de-energized state.

Fig. 11:

Connecting load to safety contacts.

(Figure shows example.

Voltage „+V“ according to techn.

data)

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

2

Page 3

Emergency Stop Safety Relay ESM-BA7..

User Information

Maintenace

The device must be checked once per month for proper

function and for signs of tampering and bypassing of the

safety function.

The device is otherwise maintenance free, provided that it

was installed properly.

What to Do in

Case of a Fault?

Safety

Characteristics

According to

EN ISO 13849-1

Device does not switch on:

•

Check the wiring by comparing it to the wiring diagrams.

•

Check the safety switch used for correct function and

adjustment.

•

Check whether the emergency stop circuit is closed.

•

Check whether the start button (with manual start) is

closed.

•

Check the operating voltage at A1 and A2.

•

Is the feedback loop closed?

The device is certified according to EN ISO 13849-1 up to a

Performance Level of PL e.

Safety characteristics according to EN ISO 13849-1 for all variants of ESM-BA7

Load (DC-13; 24V) <= 0.1A <= 1A <= 2A

T10d [years] 20 20 20

Category: 4 4 4

PL e e e

PFHd [1/h] 2.47E-08 2.47E-08 2.47E-08

nop [cycle / year] <= 500.000 <= 350.000 <= 100.000

Device cannot be switched on again after an emergency

stop:

•

Check whether the emergency stop circuit was closed

again.

•

Was the start button opened before closing of the emergency stop circuit (with manual start)?

•

Is the feedback loop closed?

If the fault still exists, perform the steps listed under

“Commissioning Procedure”.

If these steps do not remedy the fault either, return the

device to the manufacturer for examination.

Opening the device is impermissible and will void the

warranty.

Note:

Additional data can be requested from the manufacturer for

applications that deviate from these conditions.

Techn. Data

Operating voltage AC/DC 24V

Rated supply Voltage 50-60Hz

Permissible deviation + / - 10%

Power consumption DC 24V AC 24V

approx. 4.5 W approx. 8.5 VA

Control voltage at S 11 DC 24V

Control current S11..S14 approx. 250mA

Safety contacts 7 NO contacts

Auxiliary contacts 4 NC contacts

Auxiliary transistor outputs (O1, O2) DC 24V / 30mA, over current protected

Max. switching voltage AC 250V

Safety contact breaking capacity AC: 250V, 2000VA, 8A for ohmic load

(13-14, 23-24, 33-34,43-44, 53-54, 63-64, 73-74) 250V, 3A for AC-15

DC: 50V, 8A for ohmic load

24V, 3A for DC-13

Max. total current through all 7 contacts up to Ta=40°C:

35A 10mm spacing between the devices

20A no spacing between the devices

Auxiliary contacts braking capacity AC: 250V, 2000VA, 8A for ohmic load

(81-82, 91-92, 101-102,101-112)

Minimum contact load 24V, 20mA

Contact fuses 6A slow blow or 8A quick-action or 10A gG

Line cross section 0.14 -2.5mm2

Max. length of control line 1000m at 0.75 mm2

Contact material AgSnO

Contact service life mech. approx. 1 x 107, electr. 1 x 105 operating cycles

Test voltage 2.5kV (control voltage / contacts)

Rated impulse withstand voltage, leakage path/air gap 4kV (DIN VDE 0110-1)

Rated insulation voltage 250V

Degree of protection IP20

Temperature range -15°C bis +40°C

Degree of contamination 2 (DIN VDE 0110-1)

Overvoltage category 3 (DIN VDE 0110-1)

Weight approx. 350g

Mounting DIN rail according to EN 60715TH35

2

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

3

Page 4

Emergency Stop Safety Relay ESM-BA7..

User Information

Dimension

Drawing

9945

4

1

1

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

Subject to technical modifications, no responsibility is accepted for the accurac y of this information. © EUCHNER GmbH + Co. KG 090093-03-04/12 (Translation of the Original Operating Instructions)

4

Loading...

Loading...