Page 1

2-Hand Safety Relay, Series ESM-2H2..

User Information

Correct Use

Features

Function

The ESM-2H2.. 2-hand safety relay is an extremely

compact, universal safety two-hand control unit. It

complies with EN574, Typ III C, and is intended for use

in safety circuits that are designed in accordance with

EN 60204-1, e.g. on presses, punches and bending

tools. Due to the internal error monitoring, the 2-hand

safety relay can be used, despite very compact dimensions, for all applications up to the highest safety category 4 and PL e according to EN ISO 13849-1, SILCL 3

according to EN 62061 or Typ III C according to EN 574.

•

2 safe, redundant relay outputs

•

Cyclical monitoring of the output contacts

•

Feedback loop for monitoring downstream contactors or

expansion modules

•

Short circuit and earth fault monitoring

•

Extrem compact housing

The EUCHNER 2-hand safety relay ESM-2H2.. is suitable

for setting up and monitoring two-hand circuits and is used

to protect the operators. Dangerous work steps can only be

triggered when both two-hand buttons connected are operated simultaneously, i.e. within 0.5s.

It is to be ensured a single fault or a malfunction does not

result in the loss of the safety function and every fault is

detected by the cyclic self-monitoring at the latest prior to

the next actuation.

When the operating voltage is applied to A1-A2 and the

feedback loop X1-X2 is closed, the ESM-2H2.. is ready for

use. To be able to initiate a switching operation, the output

relays must be de-energized. The output relays only switch

to the energized position when the two-hand buttons T1

and T2 are operated simultaneously, i.e. within 0.5s.

•

Up to PL e, SILCL 3, category 4

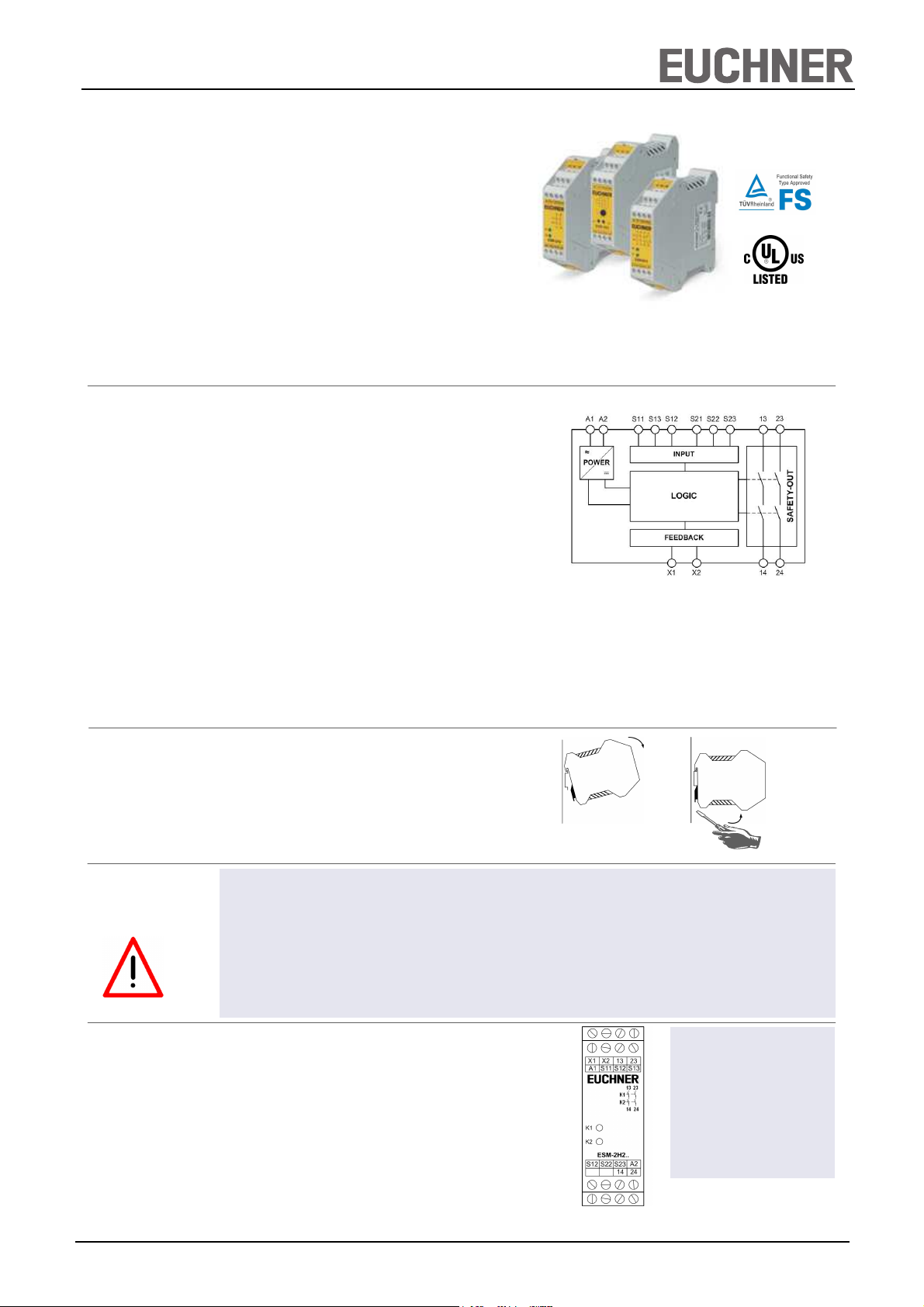

Fig. 1 Block diagram ESM-2H2..

(not dor plug-in terminals)

Installation

Safety Precautions

Electrical Connection

The output relays are not switched if:

•

only one two-hand button is actuated or the time between the actuation of the 2 two-hand buttons is greater than 0.5s,

•

the feedback loop is open (fault in the external contactor),

•

another error (short circuit, cable break, error in the switching device) has occurred.

When T1 and/or T2 are/is released, the output relays opens immediately. In order to trigger a new operation, both two-hand

buttons must first be released and the feedback loop must be closed.

As per DIN EN 60204-1, the device is intended for installation in control cabinets with a minimum degree of protection

of IP54. It is mounted on a 35-mm DIN rail according to

DIN EN 60715 TH35.

Fig. 2 Installation/removal

•

•

Installation an setup are only allowed to be undertaken

by trained personell.

•

The electrical connection is only allowed to be made with

the device and wiring isolated.

•

The wiring must comply with the instructions in this user

information, otherwise there is a risk that the safety

function will be lost.

•

As per EN 60204-1 the device is intended for installation

in control cabinets with a minimum degree of protection

of IP54.

•

When the 24V version is used, a safety transformer

according to EN 61558-2-6 or a power supply unit with

electrical isolation from the mains must be connected.

•

External fusing of the safety contacts (4A slow-blow or

6A quick-action or 10A gG) must be provided.

•

A maximum length of the control lines of 1000 meters

with a line cross section of 0.75 mm2 must not be exceeded.

•

The line cross section must not exceed 2.5 mm2.

•

If the device does not function after commissioning, it

must be returned to the manufacturer unopened. Opening the device will void the warranty.

It is not allowed to open the device, tamper with the device or bypass the safety devices.

•

All relevant sefety regulations and standards are to be

observed.

•

The overall concept for the control system in which the

device is integrated is to be validated.

•

Failure to observe the safety regulations can result in

death, serious injury and serious damage.

A1: Power supply

A2. Power supply

S11: Control line T1

S12: Control line T1

S13: Control line T1

S21: Control line T2

S22: Control line T2

S23: Control line T2

X1; X2: Feedback loop

13-14: Safety contact 1

23-24: Safety contact 2

Fig. 3 Connections

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

1

Page 2

2-Hand Safety Relay, Series ESM-2H2..

User Information

Applications

Feedback loop

Installation

The arrangement of the two-hand buttons must be designed in accordance with the standard EN 574 such that accidental

actuation or simple bypassing of the safety function is excluded.

The ESM-2H2.. unit is provided for the connection of 2-hand push-buttons, with one normally open or one normally colsed

contact.

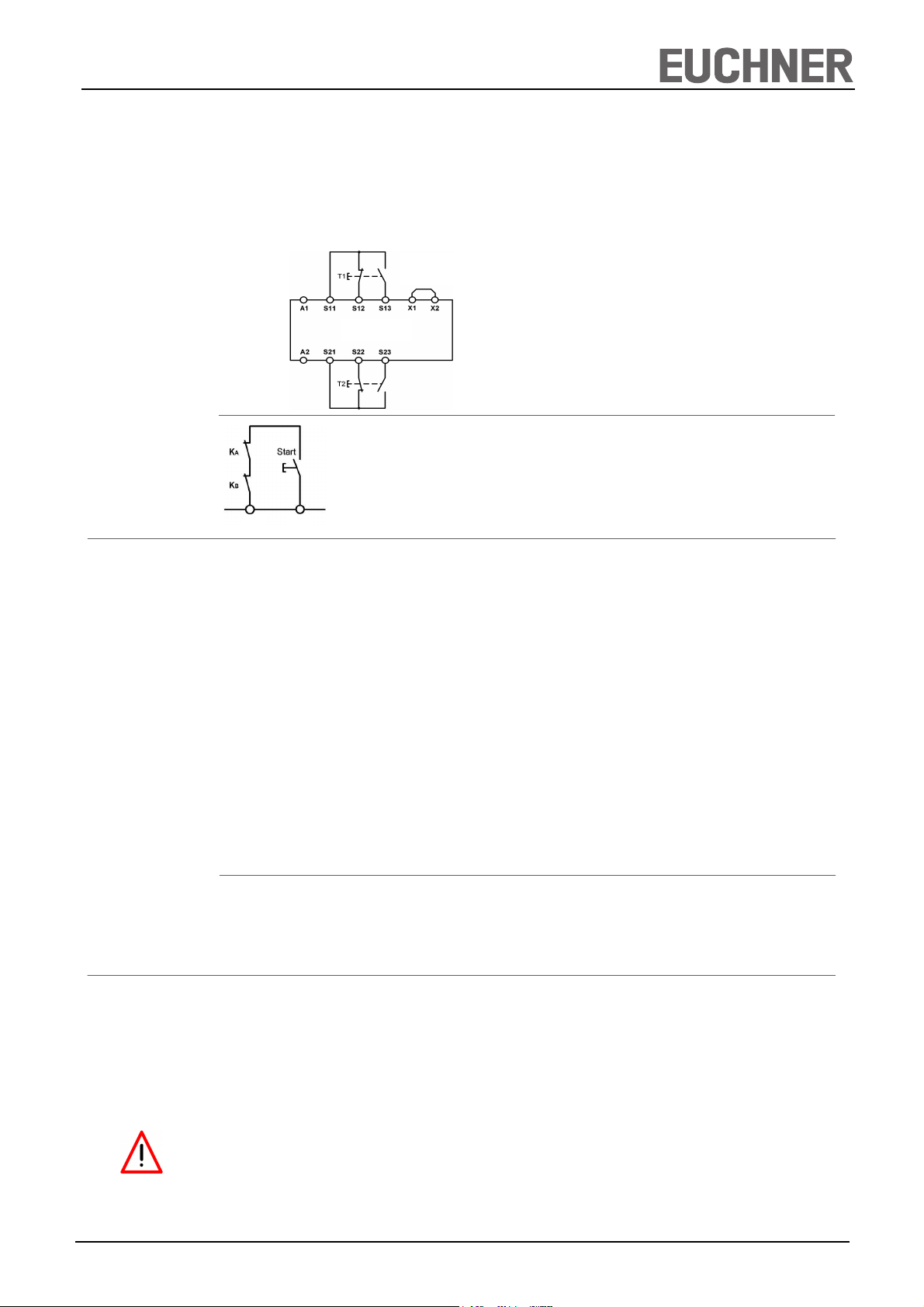

Figur 1 shows the wiring of the ESM-2H2.. with a 2-hand push-buttons:

Jumper X1-X2:

See description

ESM-2H2..

Fig. 1:

Wiring of the ESM-2H2.. with a 2-hand push

-buttons

Fig. 2: Feedback loop

Contactors connected to the ESM-2H2.. or the basic devices

are monitored via the feedback loop of the basic device. KA

and KB are the positively driven contacts of the connected

contactor or expansion module.

X1

Avoiding unintentional actuation or bypassing of the safety device

The arrangement of the two-hand buttons must be designed in accordance with the standard EN 574 such that accidental

actuation or simple bypassing of the safety function is excluded.

The operation of both buttons using one hand must be prevented by an adequate distance (at least 260mm) or by a separating wall. Actuation using forearm, elbow, knee, hip or other parts of the body can be effectively prevented by a further increase in the distance between the two buttons, adequate distance from the floor and/or covers and/or separating walls.

X2

Example

Commissioning

Procedure

Distance from the two-hand buttons to the danger area

It is necessary to maintain a minimum distance between the buttons for the two-hand circuit and the danger area on the

machine or plant so that, after the release of one or both buttons, the machine or plant can only be reached once the dange-

rous movement has been interrupted or completed. According to the standard EN 999, the distance is calculated with the

following equation:

S = (K · T) + C

S: Minimum distance from the nearest pushbutton (two-hand button) to the danger area.

K: Parameter in mm/s, derived from data on the approach speeds of the body or parts of the body, for two-hand circuits

1600mm/s.

T: The overtravel of the overall system in seconds, that is the time from releasing the two-hand button to the end of the dan

gerous movement.

C: Additional distance in mm that based on entry into the danger area prior to the triggering of the safety device. For twohand

circuits this is 250mm, this distance can also be set to 0mm given an adequate cover on the buttons, however then S

must be at least 100mm.

The overtravel time for the entire system is 90ms. Then the above equation gives for the minimum distance:

S = (1600 mm/s · 0.09 s) + 250 mm

S = 144 mm + 250 mm = 394 mm

If a suitable cover is used, S can be reduced to 144mm (see above).

Note: The items listed under “Electrical connection” must be observed during commissioning.

1. Wiring ESM-2H2..:

Wire the ESM-2H2.. with the EUCHNER basic device

according to your application (see Fig. 1).

2. Wiring feedback loop:

Wire the feedback loop as shown in Fig. 2.

3. Wiring power supply:

Connect the power supply to terminals A1 and A2.

Warning: Wiring only in de-energized state.

4. Starting the device:

Switch the operating voltage on.

5. Switch to working condition:

Press the two buttons T1 and T2 simultaneously, or within

0.5 seconds.

The positive-guided relay switches.

6. Switch into hibernation:

Release the two buttons T1 and T2.

The positive-guided relay swiches off.

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

2

Page 3

2-Hand Safety Relay, Series ESM-2H2..

User Information

Maintenance

What to Do in

What to Do in

Case of a Fault?

Case of a Fault?

Safety

Characteristics

According to

EN ISO 13849-1

Once per month, the device must be checked for proper

function and for signs of tampering and bypassing of the

safety function (to do this, check the wiring of the device

and activate the emergency stop function. Check the delay

time).

Device does not switch on:

•

Check whether the 2-hand button of correct function.

•

Check whether the wiring.

•

Check the supply voltage on A1 and A2

•

Is the feedback loop closed?

The device is certified according to EN ISO 13849-1 up to a

Performance Level of PL e.

Safety characteristics according to EN ISO 13849-1 for all variants of ESM-2H2..

Load (DC-13; 24V) <= 0,1A <= 1A <= 3A

T10d [years] 20 20 20

Category: 4 4 4

PL e e e

PFHd [1/h]: 1,2E-08 1,2E-08 1,2E-08

The device is otherwise maintenance free, provided that it

was installed properly.

If the fault still exists, perform the steps listed under

“Commissioning Procedure”.

If these steps do not remedy the fault either, return the

device to the manufacturer for examination.

Opening the device is impermissible and will void the

warranty.

Note:

Additional data can be requested from the manufacturer for

applications that deviate from these conditions.

Techn. Data

nop [cycle / year] <= 400.000 <= 100.000 <= 22.500

Operating voltage ESM-2H201 ESM-2H202 ESM-2H203

AC/DC 24V AC 115V AC 230V

Rated supply frequency AC: 50-60Hz

Permissible deviation +/- 10%

Power consumption DC 24V AC 230V

approx. 1.5W approx. 3.7VA

Control voltage at S12-S13 and at S22-S23 DC 24V

Control current (both switches) approx. 2 x 40mA

Release time for the safety relays after release of a button < 20ms

Response delay after actuation of the buttons < 20ms

Syncronization time < 0.5s

Safety contact configuration 2 NO contacts

Max. switching voltage AC 250V

Safety contact breaking capacity AC: 250V, 2000VA, 6A for ohmic load,

230V, 3A for AC-15

DC: 24V, 192W, 6A for ohmic load;

24V, 3A for DC-13

Max. total current through all contacts: 12 A

Minimum contact load 24V, 20mA

Contact fuses 6A slow-blow or 8 A quick-action or 10A gG

Line cross section 0.14 - 2.5mm2

Max. length of control line 1000m with 0.75mm2

Contact material AgSNO

Contact service life mech. approx. 1 x 107, electr. 1 x 105 operating cycles

Test voltage 2.5kV (control voltage/contacts)

Rated impulse withstand voltage, leakage path/air gap 4kV (DIN VDE 0110-1)

Rated insulation voltage 250V

Degree of protection IP20

Degree of contamination 2 (DIN VDE 0110-1)

Overvoltage category 3 (DIN VDE 0110-1)

Temperature range DC 24V: -15°C to +60°C

AC 230V/115V/24V: -15°C to +40°C

Weight ca. 230g

Mounting DIN rail according to EN 60715TH35

2

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

3

Page 4

2-Hand Safety Relay, Series ESM-2H2..

User Information

Dimension

Drawing

99

22,5

114

EUCHNER GmbH + Co. KG Kohlhammerstraße 16 D-70771 Leinfelden-Echterdingen Tel. +49/711/75 97-0 Fax +49/711/75 33 16 www.euchner.de info@euchner.de

Subject to technical modifications, no responsibility is accepted for the accuracy of this information. © EUCHNER GmbH + Co. KG 109071-04-11/13 (Translation of the Original Operating Instructions)

4

Loading...

Loading...