Eubank TH Series, TH36-42-48-60 Installation & Operation Manual

Heat Pump Product Manual

Vertical Wall-Mount Heat Pumps

Installation & Operation Manual

TH Series 10 EER Vertical Wall-Mount Heat Pumps

MODELS:

TH36-42-48-60

This manual may include information for options and features which may not be

included on the unit being installed. Refer to the unit data label or Model Identication

to determine which features and options this unit is equipped with.

INSTALLER: Afx the instructions on the inside of the building adjacent to the thermostat.

END USER: Retain this manual for future reference.

A Division of the AIRXCEL® Commercial/Industrial Group

P.O. Box 400 • Cordele, Georgia 31010 • 156 Seedling Drive • Cordele, Georgia 31015

E-mail: eubanksales@airxcel.com • Internet: www.EubankWallmount.com

The most current version of this manual can be found at www.EubankWallmount.com.

IMPORTANT

Manufactured By:

(229) 273-3636 • Fax (229) 273-5154

1

Eubank TH Series Heat Pump I&O Manual 09/2018 Rev.10

Eubank TH Series Heat Pump I&O Manual

Part #03698

09/2018 Rev. 10

How To Use This Manual

This manual is intended to be a comprehensive guide to the installation of the Eubank® TH Series family of

vertical packaged heat pumps. It contains installation, troubleshooting, maintenance, warranty, and application

information. The information contained in this manual is to be used by the installer as a guide only. This manual

does not supersede or circumvent any applicable national or local codes. For information on the efciency,

cooling and heating performance, please refer to the TH Series Product Data Sheets. The most current version

of all literature can be found on our website at www.EubankWallMount.com.

If you are installing the heat pump unit, rst read Chapter 1 and scan the entire manual before beginning the

installation as described in Chapter 2. Chapter 1 contains general, descriptive information and provides an

overview which can speed up the installation process and simplify troubleshooting.

If a malfunction occurs, follow this troubleshooting sequence:

1. Make sure you understand how the heat pump unit works (Chapters 1 & 3).

2. Identify and correct installation errors (Chapter 2).

3. Refer to the troubleshooting information in Chapter 4.

4. Identify defective part(s). (Chapter 5).

If you are still unable to correct the problem, contact the Factory at 1-800-841-7854 for additional assistance.

Please read the following “Important Safety Precautions” before beginning any work. Failure to follow

these rules may result in death, serious bodily harm, property damage and damage to the equipment.

Important Safety Precautions

1. USE CARE when LIFTING or TRANSPORTING equipment.

2. TRANSPORT the UNIT UPRIGHT. Laying it down on its side may cause oil to leave the compressor and

breakage or damage to other components.

3. TURN ELECTRICAL POWER OFF AT THE breaker or fuse box BEFORE installing or working on the

equipment. LINE VOLTAGES ARE HAZARDOUS or LETHAL.

4. OBSERVE and COMPLY with ALL applicable PLUMBING, ELECTRICAL, and BUILDING CODES and

ordinances.

5. SERVICE may be performed ONLY by QUALIFIED and EXPERIENCED PERSONS.

* Wear safety goggles when servicing the refrigeration circuit

* Beware of hot surfaces on refrigerant circuit components

* Beware of sharp edges on sheet metal components

* Use care when recovering or adding refrigerant

6. Use COMMON SENSE - BE SAFETY-CONSCIOUS

This is the safety alert symbol . When you see this symbol on the unit and in the instruction manuals be

alert to the potential for personal injury. Understand the signal word DANGER, WARNING, CAUTION and

IMPORTANT. These words are used to identify levels of the seriousness of the hazard.

DANGER Failure to comply will result in death or severe personal injury and/or property damage.

WARNING

Failure to comply could result in death or severe personal injury and/or property damage.

CAUTION Failure to comply could result in minor personal injury and/or property damage.

IMPORTANT

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

Used to point out helpful suggestions that will result in improved installation, reliability

or operation.

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE.

© 09/2018 Airxcel Commercial/Industrial Group

2

Your equipment is covered by a LIMITED WARRANTY against

defects in material and workmanship.

This is a vertical, wallmount unit designed for many different

applications in both residential and commercial settings. It is

self-contained and arrives completely assembled, factorycharged and wired. The unit is 100% run-tested at the factory

to ensure proper operation. Your unit is supplied with highquality copper tubing and enhanced aluminum-finned coils for

high heat transfer efficiency and long life. The unit cabinet is

constructed of G-90 galvanized steel. All exterior surfaces are

finished with a baked-on polyester coating. This will provide

excellent corrosion protection in most applications. However,

if the unit is installed in an area with a corrosive atmosphere,

such as near an industrial plant or on the seacoast, additional

coating should be considered to extend the life of the coils

and cabinet.

This unit was designed for up to 105ºF of ambient temperature

for the cooling mode; for heating mode, this unit was designed

for up to 78ºF of room temperature and minimum 15ºF ambient

temperature.

INSPECTION AND UNPACKING

A thorough inspection of the shipping container should

be made immediately upon receiving your unit. Look for

any punctures or openings. If it appears as if damage has

occurred, it should be noted on the freight bill before signing.

The delivering carrier should be contacted immediately to

inspect damage, and no installation work should begin until

this inspection is completed.

DANGER

BEFORE PERFORMING ANY WORK ON THIS EQUIPMENT,

POWER SUPPLY MUST BE TURNED OFF AT THE HOUSEHOLD

SERVICE BOX TO AVOID THE POSSIBILITY OF SHOCK,

INJURY, DEATH, OR DAMAGE TO EQUIPMENT.

SAFETY RULES

WARNING

FAILURE TO FOLLOW THESE RULES AND INSTRUCTIONS

COULD CAUSE A MALFUNCTION DESTRUCTION OF

EQUIPMENT WHICH COULD RESULT IN PROPERTY DAMAGE,

SERIOUS BODILY INJURY, OR DEATH.

1. Installation and repair MUST be done by a qualified person.

The equipment should be inspected before use and at least

once annually by a professional service person.

2. AVOID ELECTRICAL SHOCK! Turn power OFF when

servicing. There may be more than one disconnect switch

to de-energize unit.

3. Close cover(s) before returning breaker(s) to “ON” position.

4. Please observe good safety practices by wearing personal

protective equipment such as gloves and safety glasses

to avoid injury.

5. Installation MUST conform to local codes. In the absence

of local codes, refer to the National Electrical Code (NEC),

ANS/NFPA No. 70-1993 and recommendations made by

the National Board of Fire Underwriters.

In all cases, the equipment MUST be installed in accordance

with the installation instructions described in this manual.

WARNING

IMPROPER INSTALLATION MAY DAMAGE EQUIPMENT, CAN

CREATE HAZARD, AND WILL VOID THE WARRANTY

OPERATING INSTRUCTIONS

If heating and cooling functions are controlled by separate

thermostats, turn the furnace thermostat to the “OFF” position

during the cooling season to prevent simultaneous operation

of the heating and cooling systems. Reverse the procedure

during the heating season.

If the same thermostat controls both heating and cooling

functions, set the thermostat to either HEAT or COOL as

desired.

Set the desired temperature on your thermostat and set

the fan switch to “ON” (for continuous air circulation) or to

“AUTOMATIC” (for air circulation only when the heat pump

system is operating).

IMPORTANT

Wait at least three (3) minutes after turning the air conditioner

off before trying to restart. If an attempt is made to start the

compressor before the refrigerant pressures are equalized,

the compressor motor may trip on its overload. An additional

waiting period will be required before restarting.

MAINTENANCE

1. Always install and keep filters clean. Check filters every 2

weeks. Clean or replace if necessary. The factory-installed

filter is located behind the center front access panel.

TO CHANGE SYSTEM FILTER:

A. Turn the power to the unit off at the unit disconnect. The

disconnect is located on the front of the unit behind a

small access door.

B. Remove the front center access door from the unit.

C. Remove and replace the filter with the type and size

indicated in the table below.

D. Replace the access door and turn on the power to the unit

NOTE: If your system has a filter grille installed in the return

air opening, the unit filter should have been discarded during

installation.

The filter installed into the return air grille assembly should be

replaced with the same size and type provided with the grille.

If your system is equipped with a fresh air intake, the filter for

the fresh air assembly is accessed through the front center

panel. The filter is a permanent washable type.

Unit Model QTY Filter Size - In (mm) Type

36 1 16 x 30 x 1 (406 x 762 x 25) (Standard) Disposable

36 1 16 x 30 x 2 (406 x 762 x 51) (Optional) Pleated

42,48,60 1 20 x 30 x 1 (508 x 762 x 25) (Standard) Disposable

42,48,60 1 20 x 30 x 2 (508 x 762 x 51) (Optional) Pleated

WARNING

SERIOUS INJURY MAY RESULT IF WATER SPRAY IS

DIRECTED TOWARD LIVE ELECTRICAL CONNECTIONS OR

POWER SOURCE.

3

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

TO CLEAN FRESH AIR INTAKE FILTER:

A. Follow steps A and B at left

“TO CHANGE SYSTEM FILTER”.

B. Gently pull out the filter from the

bottom.

C. Wash the filter with water.

D. Reinstall the filter, by sliding it into the

retaining rail.

E. Replace the access door and turn the

power on to the unit.

2. Keep the outdoor coil clean. Wash it down with a garden

hose if necessary.

BE SURE THE UNIT DISCONNECT IS IN THE “OFF”

POSITION AND THAT ALL ELECTRICAL POWER TO

THE UNIT IS TURNED OFF BEFORE CLEANING THE

SYSTEM.

3. Since the heat pump is located outdoors, it is exposed to

all weather elements. Treat it with a good automobile paste

wax twice a year (in the spring and fall).

Check with your contractor if you have any questions regarding

the maintenance or operation of your unit.

INSTALLATION (A: CODES)

The installer SHALL comply with all local, state, and federal

codes and/or regulations pertaining to this type of equipment

and its installation. Such codes and/or regulations should take

precedence over any recommendations contained herein.

Installations SHALL be made in accordance with the National

Electrical Code, local codes, and recommendations made by

the National Board of Fire Underwriters.

INSTALLATION (B: UNIT SITE SELECTION)

1. To eliminate noise from being transmitted into noise

sensitive areas, the unit should NOT be installed on walls

adjoining bedrooms, sleeping quarters, or adjacent to

windows.

2. Locating the unit as close as possible to the main duct

system or area to be conditioned, will prevent lengthy duct

runs and unnecessary thermal and air-pressure losses.

3. The clearance to combustibles is 0” on all sides, and 1/4”

for the first three (3) feet of supply duct.

4. The condenser air inlets (left, right and bottom inlets)

SHALL be located at least 8” away from walls or other

obstructions for unrestricted airflow.

5. The condenser air outlet should be located at least 6’

away from any obstructions to prevent recirculation of

condenser air.

6. Bottom of the unit SHALL be located at least 12” away from

the ground or other obstructions for unrestricted airflow.

7. Service clearance is 28” from the electrical box access

panel located on the front of the unit and 28” from the

center, upper, and lower front access panels.

8. The wall selected for unit installation MUST be able to or

be made to safely support the weight of the unit.

9. Do NOT locate where heat, lint or exhaust fumes will be

discharged on the unit (as from dryer vents).

INSTALLATION (C: UNIT PREPARATION)

1. TH Series model units have top rain flashing built onto

the unit. The bottom-mounting flange for all models is

shipped separately and in place. (Refer to “Section J. Unit

Installation” for the recommended use of the bottom flange.)

2. Electrical entrances are located on the right side and left

side of all TH Series units. Refer to “Section H. Electrical

Hook-up” for details.

3. Bend the lids of return and supply opening to form a return

and supply air collars and install air gaskets.

4. The supply and return air ducts should be checked to be

sure they:

e. Match the openings on the unit to be installed.

f. Have the same distance between them vertically as

the openings on the unit to be installed.

5. Return and supply grilles must be used when the return

and supply are not ducted. When a supply grille is used

in the installation, the louver spacing must be no greater

than 5/8 inch.

6. If the factory-installed filter is used on your installation,

access to the filter is made through the center panel on

the front of the unit.

IF A REMOTE FILTER IS USED, SUCH AS A FILTER

GRILLE, THE FACTORY-INSTALLED FILTER MUST BE

REMOVED AND DISCARDED.

INSTALLATION (D: DUCTWORK)

1. Properly-sized duct systems are critical for satisfactory

operation of any air conditioning system. All ductwork

MUST be correctly sized for the design air flow requirement

of the equipment.

2. The recommended operation duct static is to deduct 0.07”

W.C. for any size of heater 5 kW to 20 kW on factory or

field-installed heaters.

3. Ductwork routed through wall cavities, as well as any duct

not in conditioned space, MUST be insulated. Supply

ducting routed through exterior walls MUST be insulated

with 1” insulation to the back of the unit.

4. Supply and return air ducts should be flush with the exterior

wall and sized to fit over the unit duct collars in order to

compress the collar air gasket.

5. If supply duct is flashed to the exterior of a building

constructed with combustible material, the flashing MUST

be insulated in order to maintain the required clearances

to combustible materials. Required clearance is 1/4” for

the first three (3) feet of supply duct.

INSTALLATION (E: FILTERS)

1. One-inch disposable filters are supplied standard in each

unit. Two-inch disposable filters can also be used and

are available as an option. The filter rack is adjustable

to accommodate 2” filters. The filter rack on this series is

adapted by removing the 1” filter brackets. Refer to the

Maintenance section for the procedures for changing the

filters.

2. If a filter grille is used in the installation, the filter should be

properly sized to allow a maximum velocity of 400 FPM.

WHEN A FILTER IS USED, THE FACTORY-INSTALLED

FILTER MUST BE REMOVED.

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

4

INSTALLATION (F: ELECTRICAL POWER)

The installer MUST check available power to make certain

it matches the unit nameplate rating and that constant

voltage can be maintained to the unit. Unsatisfactory and

unsafe performance could otherwise result. The local power

company should be contacted about questions concerning

power supply.

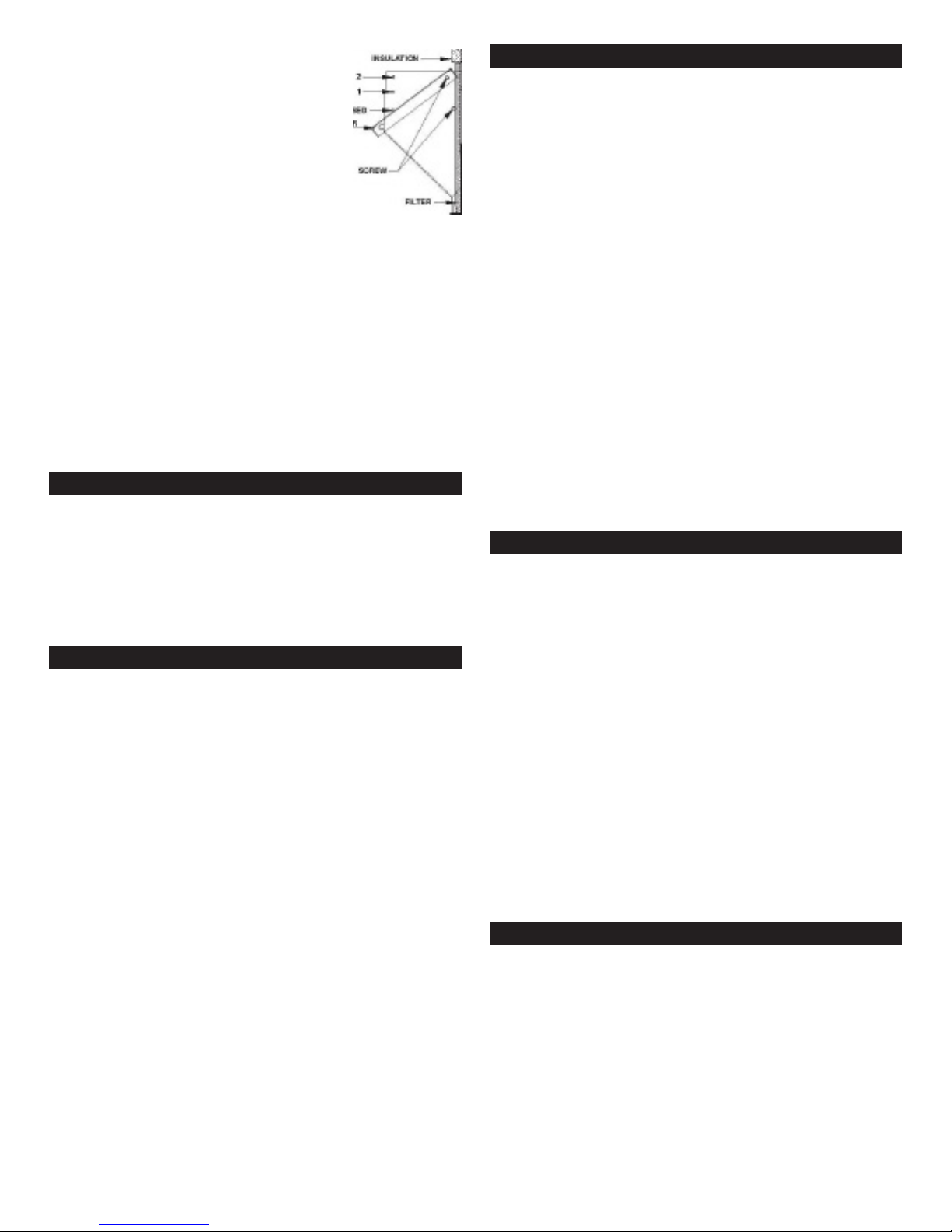

INSTALLATION (G: BREAKER/DISCONNECT)

These units are standard equipped from the factory with a

unit disconnect. This is in the form of a circuit breaker (230V

models) or disconnect (460V models). If an optional electric

heat kit is to be installed, follow the instructions included with

the heater assembly. See Figure 1 for reference.

WARNING

ELECTRICAL EQUIPMENT SHOULD BE INSTALLED BY

A QUALIFIED, LICENSED ELECTRICIAN. IMPROPER

ELECTRICAL HOOK-UP MAY DAMAGE EQUIPMENT, CAN

CREATE A HAZARD AND WILL VOID WARRANTY.

INSTALLATION (H: ELECTRICAL HOOKUP)

The line voltage electrical service can be routed through the

right side panel or left side panel. Each area is supplied with

two line voltage knock-outs (1/2” – 3/4” and 1” – 1 1/4”). Low

voltage wiring can be routed through the right side panel.

NOTE: When routing line voltage through the return air

compartment, conduit MUST be used (even though this is a dry

area) to comply with the NEC code. Refer to the ELECTRICAL

DATA tables for minimum wire size and maximum breaker

size. All wire sizes listed under the dual-feed circuit column

are based on no more than three (3) conductors in the same

conduit. If two circuits or more than three (3) conductors are

to be routed in the same conduit, the ampacity of the wire size

listed MUST be derated. Refer to Article 310 of the NEC code

for adjustment factors. Be sure to install a ground wire of the

proper size to the unit’s equipment ground lug.

The blower motor must be powered by 240V or 277V supply.

If the unit is supplied by 460V power, and a neutral connection

is unavailable, the motor may be powered by a 460V to 277V

or 240V transformer.

powered fresh air option, seven (7) conductor thermostat wires

should be run to the unit. Thermostat wire should be sized as

shown on the table below.

Wire Gauge Maximum Length - Ft (meters)

20 45 (13.7)

18 60 (18.3)

16 100 (30.5)

14 160 (48.8)

12 250 (76.2)

Refer to wiring diagrams for connection details.

STAGING OF ELECTRIC HEAT

Units with electric heat assemblies are wired for two stage

heat in normal operation. The first stage is refrigerant heat

(Y and G terminals are energized and the O terminal is deenergized). The second stage is auxiliary resistance heat (W is

energized). TH Series units are equipped with an emergency

heat lock-out relay. This will disable the compressor when the

E terminal is energized. Do not install a jumper between the W

and E terminals; this would keep the compressor contacts from

being energized and prevent the compressor from operating.

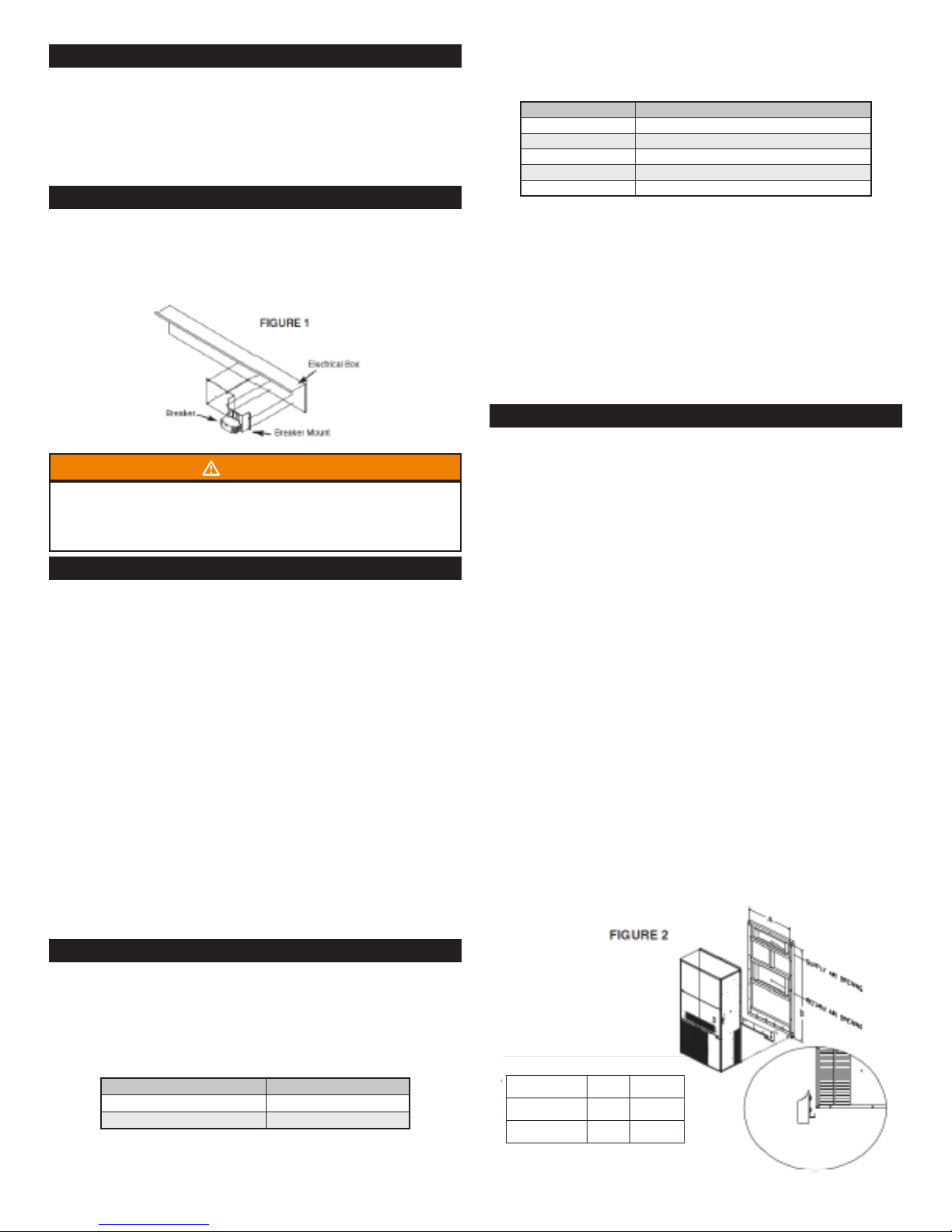

INSTALLATION (J: UNIT INSTALLATION)

TH UNITS ARE FOR USE IN 1-STORY BUILDINGS ONLY.

1. As previously stated, the wall that the unit is to be installed

onto MUST be strong enough to support the unit under the

condition for which it will be used. For example, a unit to

be installed on a building that is intended to be transported

will require more wall strength than a unit installed at

a permanent site. Existing walls may need additional

reinforcement. NEVER RELY ON EXTERIOR SIDING

OR PLYWOOD TO SUPPORT THE UNIT. Figure 2 below

represents a typical installation of a single-story stud wall at

a permanent site. Since building materials and techniques

vary with regions and intended use, a building contractor

and/or local building code official MUST be consulted for

suitable construction methods.

2. Locate and attach the lower mounting bracket in the desired

location on the building.

3. Apply a suitable amount of caulk or silicone across the

entire length of the top rain flashing and side mounting

flanges.

4. Remove the flanges on both ends of the pallet and slide the

unit approximately 2” off the rear of pallet. Lift unit gently

into location with fork truck, taking care to align unit with

lower mounting bracket.

5. While allowing a small portion of weight on the lower

bracket, push the unit against the wall and fasten

appropriately.

INSTALLATION (I: LOW VOLTAGE WIRING)

230 volt, 1- and 3-phase units are equipped with dual-primary

voltage transformers for 208/240 volt operation. These models

are factory wired to the 240 volt tap. For 208 volt operation

connect the factory-installed black wires from the 240 volt tap

to the 208 volt tap. The acceptable voltage range of the tap

is as follows.

Tap Voltage Range

240 Volt 253 - 216

208 Volt 220 - 187

Six (6) conductor thermostat wires should be run from the

thermostat location to the unit. If the unit is equipped with a

Unit Model A B

36 39 71

42/48/60 42 86 1/2

MOUNTING FLANGE BOLT

PATTERN DIMENSIONS

5

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

SPECIAL NOTES FOR UNIT INSTALLATION

1. Minimum 12” clearance at the bottom of the unit for

unrestricted airflow

2. Ensure the ambient temperature uniformity around unit

3. Intake and discharge of the outdoor air flow must not be

restricted or altered

4. All insulation and sealing related to the installation must

be completed properly

5. External Static pressure should not exceed the minimum

value in the AHRI Standard 390

INSTALLATION (K: CONDENSATE DRAIN)

A 3/4” drain hose is located on the bottom side of the unit. The

drain may be extended for condensate removal to comply with

local codes (use fitting size or larger). Install a condensate

trap on this line.

INSTALLATION (L: OPTIONS)

Eubank wallmount air conditioners and heat pumps have the

ability to equip a variety of options:

• Electric Heat 5-20kW

• Sound Attenuation Module

• Powered Ventilation Damper

• Low Ambient Packages

• Economizer

• Lead Lag Controllers

Option kits must be installed according to the respective

installation manual to ensure safe and reliable operation.

Installation manuals are included with the option kit or can be

found on the Eubank website, www.EubankWallMount.com.

INSTALLATION (M: SEQUENCE OF OPERATION)

COOLING MODE

Low-voltage thermostat terminal R is connected to Y, O, and

G, at the unit low-voltage terminal board.

The system reversing valve is energized during the cooling

mode. Power is supplied to the reversing valve solenoid

through the low-voltage O terminal. The low-voltage Y terminal

to the control will energize the contactor latch coil (causing

the contactor to energize the compressor). The low-voltage

Y terminal to the control will also energize the control’s timer.

During the cooling mode, the defrost thermostat is open (coil

temperature is above 30°F) and will not allow the time to be

accumulated to initiate the defrost mode. The outdoor fan is

wired through the N/C points of the control’s relay and the

N/O points of the contactor. The fan motor will be energized

whenever the contactor is energized (except during defrost).

HEATING MODE

Low-voltage terminal R is connected to Y and G, at the unit

low-voltage terminal board.

The system reversing valve is not powered during the heating

mode. With the thermostat system switch turned to heat. The

Y terminal will energize the compressor, outdoor fan, and the

indoor blower.

DEFROST MODE

To prevent ice build-up on the coil during the heating mode, as

the outdoor coil temperature falls below 30°F ±5°F, an outdoor

defrost thermostat closes. (This thermostat is located on a coil

tube.) When the thermostat closes, the timer on the defrost

control starts accumulating the compressor run time. After the

selected time (30, 60,or 90 minutes) has been accumulated,

the controller will start the defrost cycle regardless of the

outside temperature. During the defrost cycle, the system

is switched back into the cooling mode by the control deenergizing the reversing valve solenoid. The N/C pole of the

control fan relay is opened, turning off the outdoor fan to allow

the outdoor coil to be warmed (defrosted) faster. The defrost

control energizes the indoor auxiliary heat relays through the

E terminal to temper the indoor supply air. This terminal should

be connected to E (second-stage heat) on the thermostat.

After the defrost thermostat reaches 65°F ±5°F, the defrost

cycle will end. The control will not allow the defrost to continue

longer than 10 minutes.

DEFROST TIME SELECTION

The defrost control has three selectable time intervals: 30, 60

and 90 minutes. The timing is factory set at 60 minutes. This

timing has been determined by testing to provide the best

operating efficiency. In areas where the humidity is lower than

normal, the timer may be set to a higher time (90 minutes). To

change the time, move the timer jumper to the postmarked

30 for 30 minutes, 60 for 60 minutes, or 90 for 90 minutes.

DEFROST TEST POST

The defrost control has test posts to speed up the defrost time

setting by a factor of 256.

If you want to initiate a defrost without waiting for the time to

accumulate, you can jumper the two test pins (marked test).

If the coil temperature is above 30°F you will need to jumper

the DFT (defrost thermostat) terminals to simulate a closed

thermostat. The defrost cycle should occur in 7 seconds for

a 30-minute setting, 14 seconds for a 60-minute setting, and

17 seconds for an 90-minute setting. If the jumper is removed

immediately when the defrost cycle starts, the cycle will end if

the defrost thermostat is opened (coil above 65°F). If the test

pins remain jumped, and the defrost thermostat is closed, the

defrost will end in 2.3 seconds, which is the 10-minute default.

DURING THE ABOVE TEST, DO NOT CONTACT OR SHORT

ANY OTHER PIN. THIS MAY DAMAGE THE CONTROL.

INSTALLATION (N: HIGH-PRESSURE LOCKOUT)

FIELD CHARGING

Compared to a cooling-only unit, a heat pump is difficult to

field charge correctly without the use of charging scales. It

is recommended the charge be weighed in with an accurate

charging scale. The correct charge weight can be found on

the unit name plate.

TH Series units may be equipped with a high-pressure switch.

This switch is wired through a lockout relay to lock out the

system if the high side pressure exceeds 650 psi. The high

side pressure MUST be below 450 psi before the system can

be reset.

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

6

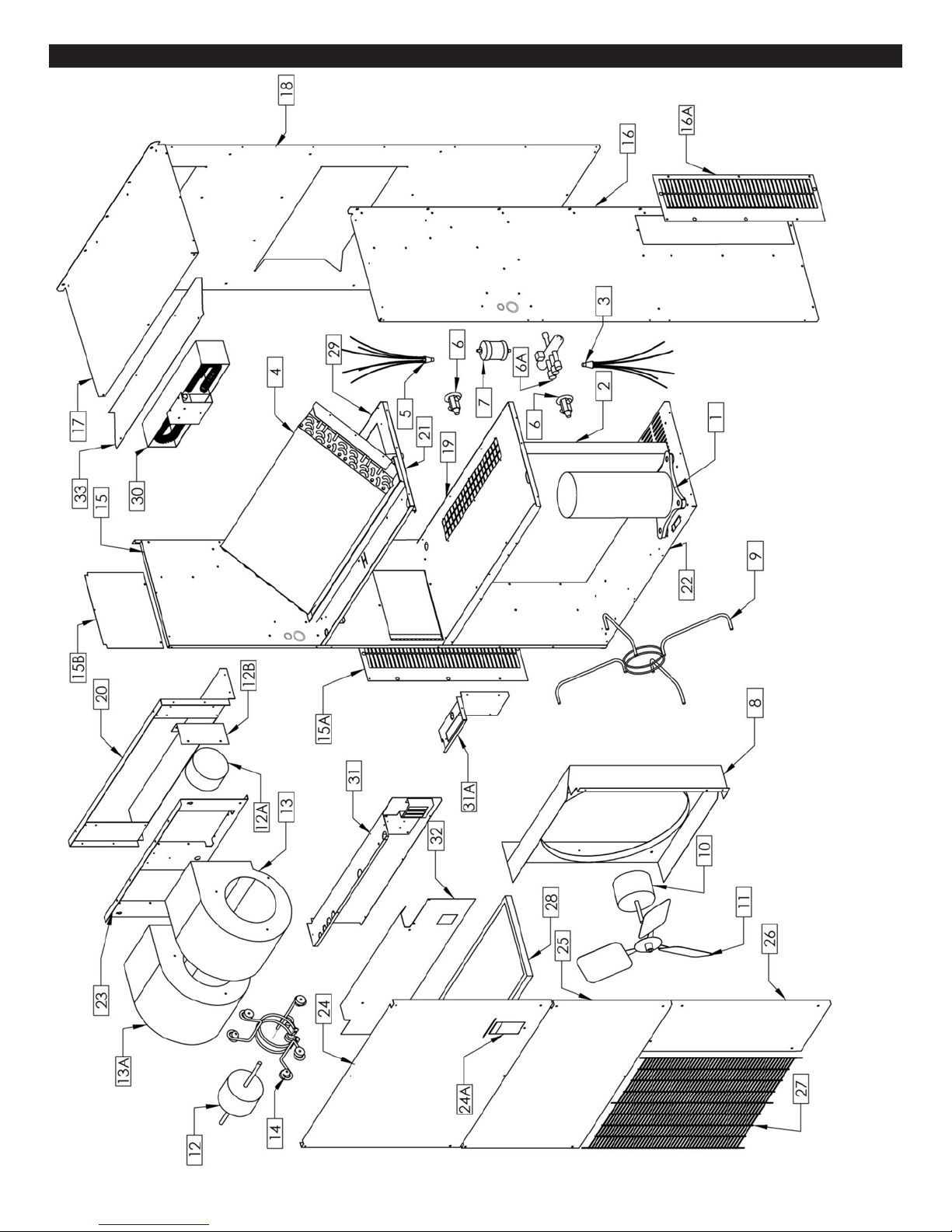

EXPLODED PARTS DRAWING - 36/42/48/60

7

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

PART NUMBER

DESCRIPTION

1

COMP-BZP31-001

ZP31K5EPFV130

X

1

3020004

ZP31K5ETF5130

X

1

3020005

ZP31K5ETFD130

X

1

COMP-BZP44-001

ZP44K5EPFV130

X

1

COMP-BZP44-003

ZP44K5ETF5130

X

1

COMP-BZP44-004

ZP44K5ETFD130

X

1

COMP-BZP54-001

ZP54K5EPFV130

X

1

COMP-BZP54-003

ZP54K5ETF5130

X

1

COMP-BZP54-004

ZP54K5ETFD130

X

2

COND-H436

OUTDOOR COIL

XXX

2

3070001

OUTDOOR COIL

XXXXX

X

3

550505

DISTRIBUTOR 3 CIRCUIT-OD COIL

XXX

3

550517

DISTRIBUTOR 6 CIRCUIT-OD COIL

XXXXX

X

4

T36-EVAP

EVAP COIL

XXX

4

3070002

EVAP COIL

XXXXX

X

5

550517

DISTRIBUTOR 6 CIRCUIT-EVAP

XXX

5

550521

DISTIBUTOR 9 CIRCUIT-EVAP

XXXXX

X

6

TXV410-E3

TXV VALVE

XXX

6

TXV410-E5-HP

TXV VALVE

XXXXX

X

6A

550792

REVERSING VALVE

7

61508

BI-FLOW FILTER DRIER

XXXXXXXXX

8

T36-0008

FAN SHROUD HV36

XXX

8

T60-0008

FAN SHROUD HV48-60

XXXXX

X

9

421508

MOTOR MOUNT OD FAN

XXX

9

259109

MOTOR MOUNT OD FAN

XXXXX

X

10

025015/3010014

MOTOR OD 230V 825 RPM

X

X

10

025018

MOTOR OD 460V 1/4 HP 825 RPM

X

10

351145

MOTOR OD 230V 1075 RPM 1/2 HP

XXX

X

10

351146

MOTOR OD 460V 1/2 HP

X

X

11

259114

OD FAN BLADE 22" HV36-60

XXXXXXXXX

12

359104

1/3 HP ECM BLOWER MTR 230V/277V

XXX

12A

3010020

1/3 HP ECM MODULE

XXX

12

359105

1/2 HP ECM BLOWER MTR 230V/277V

XXXXX

X

12A

3010021

1/2 HP ECM MODULE

XXXXX

X

12B

T36-0131

ECM MODULE BRACKET

XXXXXXXXX

13

050001

R.BLOWER WHEEL 98-7T CW

XXX

13A

050000

L.BLOWER WHEEL 98-7T CCW

XXX

13

3020002

R.BLOWER WHEEL 100-9T CW

XXXXX

X

13A

3020003

L.BLOWER WHEEL 100-9T CCW

XXXXX

X

14

421506

BLWR MTR BRKT

XXXXXXXXX

14A

454280

BLWR MTR BRKT GROMMET TUBE

XXXXXXXXX

14B

454282

BLWR MTR BRKT WASHER TUBE

XXXXXXXXX

14C

454284

BLWR MTR BRKT MOUNTING SLEEVE

XXXXXXXXX

14D

454236

BLWR MTR BRKT WASHER

XXXXXXXXX

14E

750058

BLWR MTR BRKT BOLT(1/4-20)

XXXXXXXXX

15

T36-0000B

ASSEMBLY LEFT SIDE PANEL HV36

XXX

15A

T36-0135

OD.GRILL INLET LEFT SIDE HV36

XXX

15

T60-0008

ASSEMBLY LEFT SIDE PANEL HV48-60

XXXXX

X

15A

T60-0091

OD.GRILL INLET LEFT SIDE HV48-60

XXXXX

X

15B

T36-0126

ERV INTAKE AIR PANEL

XXXXXXXXX

16

T36-0001B

ASSEMBLY RIGHT SIDE PANEL HV36

XXX

16A

T36-0134

OD.GRILLINLET RIGHT SIDE HV36

XXX

16

T60-0001B

ASSEMBLY RIGHT SIDE PANEL HV48-60

XXXXX

X

16A

T60-0081

OD.GRILL INLET RIGHT SIDE HV48-60

XXXXX

X

17

T36-0007B

TOP HV36

XXX

17

T60-0007B

TOP HV48-60

XXXXX

X

18

T36-0012

ASSEMBLY REAR PANEL HV-36

XXX

18

T60-0012

ASSEMBLY REAR PANEL HV48-60

XXXXX

X

19

T36-0003

ASSEMBLY DIVIDER DECK HV-36

XXX

19

T60-0003

ASSEMBLY DIVIDER DECK HV48-60

XXXXX

X

20

T36-0005

ASSEMBLY BLOWER DECK HV36

XXX

20

T60-0005

ASSEMBLY BLOWER DECK HV48-60

XXXXX

X

21

2022-0006P

ASSEMBLY DRAIN PAN HV36

XXX

21

2023-0006P

ASSEMBLY DRAIN PAN HV48-60

XXXXX

X

22

T36-0098

BASE PAN ASSEMBLY HV36

XXX

22

T60-0098

BASE PAN ASSEMBLY HV48-60

XXXXX

X

23

T36-0018

BLOWER FLANGE HV36

XXX

23

T60-0018

BLOWER FLANGE HV60

XXXXX

X

24

T36-0010B

UPPER FRONT PANEL HV36

XXX

24

T60-0010B

UPPER FRONT PANEL HV48-60

XXXXX

X

24A

2022-5062

DISCONNECT ACCESS DOOR HV36-60

XXXXXXXXX

24B

70518

DISCONNECT ACCESS DOOR LATCH HV36-60

XXXXXXXXX

25

T36-0011B

MIDDLE FRONT PANEL (no fresh air) HV36

XXX

25

T36-0011EB

MIDDLE FRONT PANEL (economizer f/a) HV36

XXX

25

T36-0011FB

MIDDLE FRONT PANEL (barometric f/a) HV36

XXX

36S

36T

36D

42/48S

42/48T

42/48D

60S

60T

60D

Eubank TH Series Heat Pump I&O Manual

09/2018 Rev. 10

8

Loading...

Loading...