Eubank R410A Installation Manual

Installation, Operation and Maintenance

V SERIES

Wallmount Air Conditioners

R410A Series

REV. 9/23/13

678629-V-C

Your equipment is covered by a LIMITED WARRANTY against

defects in material and workmanship.

This is a vertical, wallmount unit designed for many different

applications in both residential and commercial settings. It is selfcontained and arrives completely assembled, factory-charged and

wired. The unit is 100% run-tested at the factory to ensure proper

operation. Your unit is supplied with high-quality copper tubing and

enhanced aluminum-finned coils for high heat transfer efficiency

and long life. The unit cabinet is constructed of G-90 galvanized

steel. All exterior surfaces are finished with a baked-on polyester

coating. This will provide excellent corrosion protection in most

applications. However, if the unit is installed in an area with a

corrosive atmosphere, such as near an industrial plant or on the

seacoast, additional coating should be considered to extend the life

of the coils and cabinet.

This unit was designed for up to 105ºF of ambient temperature.

INSPECTION AND UNPACKING

A thorough inspection of the shipping container should be made

immediately upon receiving your unit. Look for any punctures or

openings. If it appears as if damage has occurred, it should be

noted on the freight bill before signing. The delivering carrier should

be contacted immediately to inspect damage, and no installation

work should begin until this inspection is completed.

WARNING:

DAMAGE EQUIPMENT, CAN CREATE A HAZARD, AND

!

WILL VOID THE WARRANTY.

IMPROPER INSTALLATION MAY

OPERATING INSTRUCTIONS

If heating and cooling functions are controlled by separate

thermostats, turn the furnace thermostat to the “OFF” position

during the cooling season to prevent simultaneous operation of

the heating and cooling systems. Reverse the procedure during

the heating season.

If the same thermostat controls both heating and cooling

functions, set the thermostat to either HEAT or COOL as desired.

Set the desired temperature on your thermostat dial and set the

fan switch to “ON” (for continuous air circulation) or to

“AUTOMATIC” (for air circulation only when the air conditioning

system is operating).

IMPORTANT: Wait at least three (3) minutes after turning the

air conditioner off before trying to restart. If an attempt is made to

start the compressor before the refrigerant pressures are

equalized, the compressor motor may trip on its overload. An

additional waiting period will be required before restarting.

DANGER:

!

THIS EQUIPMENT, POWER SUPPLY MUST BE

TURNED OFF AT THE HOUSEHOLD SERVICE BOX TO

AVOID THE POSSIBILITY OF SHOCK, INJURY, DEATH OR

DAMAGE TO EQUIPMENT.

BEFORE PERFORMING ANY WORK ON

SAFETY RULES

WARNING:

AND INSTRUCTIONS COULD CAUSE A MAL-

!

FUNCTION OR DESTRUCTION OF THE

EQUIPMENT WHICH COULD RESULT IN PROPERTY

DAMAGE, SERIOUS BODILY INJURY, OR DEATH.

1. Installation and repair MUST be done by a qualified person.

The equipment should be inspected before use and at least

once annually by a professional service person.

2. AVOID ELECTRICAL SHOCK! Turn power OFF when

servicing. There may be more than one disconnect switch to

de-energize unit.

3. Close cover(s) before returning breaker(s) to “ON” position.

4. Please observe good safety practices by wearing personal

protective equipment such as gloves and safety glasses to

avoid injury.

5. Installation MUST conform to local codes. In the absence of

local codes, refer to the National Electrical Code (NEC),

ANS/NFPA No. 70-1993 and recommendations made by the

National Board of Fire Underwriters.

In our continuing effort to improve our product, specifications may

change without notice. If there are any questions, please see the

contact information on the last page of this manual.

In all cases, the equipment MUST be installed in accordance with

the installation instructions described in this manual.

FAILURE TO FOLLOW THESE RULES

MAINTENANCE

1. Always install and keep filters clean. Check filters every 2 weeks.

Clean or replace if necessary. The factory-installed filter is

located behind the center front access panel.

TO CHANGE SYSTEM FILTER:

A. Turn the power to the unit off at the unit disconnect. The

disconnect is located on the front of the V Series unit behind

a small access door.

B. Remove the front center access door from the unit.

C. Remove and replace the filters with the type and size

indicated in the table below.

D. Replace the access door and turn on the power to the unit.

NOTE: If your system has a filter grille installed in the return air

opening, the unit filter should have been discarded during

installation.

The filter installed into the return air grille assembly should be

replaced with the same size and type provided with the grille.

If your system is equipped with a fresh air intake, the filter for the

fresh air assembly is accessed through the front center panel. The

filter is a permanent washable type.

UNIT MODEL QTY. FILTER SIZE TYPE

18, 24, 30, 36 1 16 x 25 x 1 (standard) Disposable

18, 24, 30, 36 1 16 x 25 x 2 (optional) Disposable

48, 60 1 20 x 30 x 1 (standard) Disposable

48, 60 1 20 x 30 x 2 (optional) Disposable

2

WARNING:

WATER SPRAY IS D IRECTED TOWARD LIVE

!

SERIOUS INJURY MAY RESULT IF

ELECTR I CAL CONNE C TION S OR POWER

SOURCES.

TO CLEAN FRESH AIR INTAKE FILTER:

A. Follow steps A and B at left

“TO CHANGE SYSTEM FILTER”.

B. Gently pull out the filter from the

bottom.

C. Wash the filter with water.

D. Reinstall the filter, by sliding it into

the retaining rail.

E. Replace the access door and turn

the power on to the unit.

2. Keep the outdoor coil clean. Wash it down with a garden hose if

necessary. BE SURE THE UNIT DISCONNEC T IS IN T HE

“OFF” POSITION AND THAT ALL ELECTRICAL POWER TO

THE UNIT IS T URNE D OFF B EFOR E C LEANING THE

SYSTEM.

Remove any loose grass, leaves, papers, etc., from the area

around the condenser coil. These could reduce the air

supply through the coil and reduce the amount of cooling

capacity.

3. Since the air conditioner is located outdoors, it is exposed to all

weather elements. Treat it with a good

twice a year (in the spring and fall).

Check with your contractor if you have any questions regarding

the maintenance or operation of your unit.

DAMPER

DOOR

INSULATION

2

1

CLOSED

SCREW

FILTER

automobile paste wax

INSTALLATION

A. CODES

The installer SHALL comply with all local, state, and federal codes

and/or regulation s pertaining to this type of equipment and its

installation. Such codes and/or regulations should take precedence

over any recommendations contained herein in lieu of local codes.

Installations SHALL be made in accordance with the National

Electrical Code, local codes, and recommendations made by the

National Board of Fire Underwriters.

B. UNIT SITE LOCATION

1. To e limina te n oise f rom being t ransmi t ted i nto noise-

sensitive areas, the unit should NOT be installed on walls

adjoining be drooms, sleeping qua rters, o r adjacent to

windows.

2. Locating the unit as close a s possible to the main duct

ystem or area to be conditioned, will prevent lengthy duct

s

runs and unnecessary thermal and air-pressure losses.

3. The clearance to combustibles is 0

the first three (3) feet of supply duct.

4. The condenser air inlets (left, right and bottom inlets) SHALL

be located at least 8

for unrestricted airflow.

5. The condenser air outlet should be located at least 6’ away

from any obstructions to prevent recirculation of condenser

air.

6. Bottom of the unit SHALL be located at least 12" away from

the ground or other obstructions for unrestricted airflow.

14"

" away from walls or other obstructions

" on all sides, and

1

/4" for

7. Service clearance is 28" from the electrical box access panel

located on the fron t of th e unit and 28

upper, and lower front access panels.

8. The wall selected for unit installation MUST be able to or be

made to safely support the weight of the unit.

9. Do NOT locate where heat, lint or exhaust fumes will be

discharged on the unit (as from dryer vents).

" from the center,

C. UNIT PREPARATION

1. The V Series model units have top rain flashing built onto the

unit. The bottom-mounting flange for all models is shipped

sep a rately and in plac e . (Refer to “Se ction J. Unit

Installation” for the recommended use of the bottom flange.)

2. Electrical entrances are located on the right side, left side,

and back of all V Series units. Refer to “Section H. Electrical

Hook-up” for details.

3. Bend the lids of return and supply openi

and supply air collars and install air gaskets.

The supply and return air ducts should be checked to be sure they:

4.

a. Match the openings on the unit to be installed.

b. Have the same distance between them vertically as the

openings on the unit to be installed.

5. If th e factory-installed filter is used on your ins tallation ,

access to the filter is made through the center panel on the

front of the unit. IF A REMOTE FILTER IS USED, SUCH AS

A FILTER GRILLE, THE FACTORY-INSTALLED FILTER

MUST BE REMOVED AND DISCARDED.

ng to form a return

D. DUCTWORK

1. Properly-sized duct systems are critical for satisfactory

operation of any air conditioning system. All ductwork MUST

be correctly sized for the design air flow requirement of the

equipment.

2. The recommended operation duct static is to d e duct

3. Ductwork routed through wall cavities, as well as any duct

4. Supply and return air ducts should be flush with the exterior

5. If sup ply duc t is fla she d to the e xterior o f a building

" W.C. for any size of heater 5 kW to 20 kW on factory-

0.07

or field-installed heaters.

not in conditioned space, MUST be insulated. Supply ducting

routed through exterior walls MUST be insulated with 1

insulation to the back of the unit.

wall and sized to fit over the unit duct collars in order to

compress the collar air gasket.

constructed with combustible material, the flashing MUST be

insulated in order to maintain the required clearances to

combustible materials. Required clearance is

three (3) feet of supply duct.

1

/4" for the first

E. FILTERS

1. One-inch disposable filters are supplied standard in each

unit. Two-i

available as a n option. The filter rack is adjusta ble to

accommodate 2

adapted by bending the retaini ng brackets. Refer to the

Maintenance section for the procedures for changing the

filters.

2. If a filter grille is used in the installation, the filter should be

properly sized to allow a maximum velocity of 400 FPM.

THE FACTORY-I N STA LLED FILTER MUST BE

REMOVED.

3

nch disposable filters can also be used and are

" f ilte rs. Th e filter rack on this series is

"

F. ELECTRICAL POWER

The installer M UST check a vailable pow er to make certain it

matches the unit nameplate rating and that constant voltage can be

maintained to the unit. Unsatisfactory and unsafe performance

could other wise r esu lt. T he l oca l power company should be

contacted about questions concerning power supply.

G. BREAKER/DISCONNECT ASSEMBLY

These units are standard equipped from the factory with a unit

disconnect. This is in the form of a circuit breaker (230V models) or

a disconnect (460V models). If an optional electric heat kit is to be

installed, follow the instructions included with the heater assembly.

See Figure 1 for reference.

FIGURE 1

Electrical Box

Breaker

Breaker Mount

WARNING:

!

BE IN STA LLED BY A QUALIFIED , LICENSED

ELECTRICAL EQUIPMENT SHOULD

ELECTRICIAN. IMPROPER ELECTRICAL HOOK-UP

MAY DAMAGE EQU IPM ENT, CAN CRE A TE A

HAZARD AND WILL VOID WARRANTY.

H. ELECTRICAL HOOK-UP

The line voltage electrical service can be routed through the right

side panel, the right side of the back panel, or left side panel. Each

area is supplied

1

/4"). Low voltage wiring can be routed through the right side panel.

1

with two line voltage knock-outs (

1

/2" – 3/4" and 1" –

NOTE: When routing line voltage through the return air com-

partment, conduit MUST be used (even though this is a dry area) to

comply with the NEC code. A 1

application. Refer to the ELECTRICAL DATA tables for minimum

wire size and maximum breaker size. All wire sizes listed under the

dual-feed circuit column are based on no more than thr ee (3)

conductors in the same conduit. If two circuits or more than three (3)

conductors are to be routed in the same conduit, the ampacity of the

wire size listed MUST be derated. Refer to Article 310 of the NEC

code for adjustment factors. Be sure to install a g

proper size to the unit’s equipment ground lug.

1

/4" PVC conduit is supplied for this

round wire of the

I. LOW VOLTAGE WIRING

230 volt, 1- and 3-phase units are equipped with dual-primary

voltage transformers for 208/240 volt operation. These models are

factory wired to the 240 volt tap. For 208 volt operation connect the

factory-installed black wires from the 240 volt tap to the 208 volt tap.

The acceptable voltage range of the tap is as follows.

Five ( 5) c ondu ctor thermostat wires shoul d be r u n from th e

thermostat location to the unit. Thermostat wire should be sized as

shown on the table below.

Refer to wiring diagrams for connection details.

Tap Voltage Range

240 Volt 253 - 216

208 Volt 220 - 187

Wire Gauge Maximum Length

20 45'

18 60'

16 100'

14 160'

12 250'

STAGING OF ELECTRIC HEAT

All V Series units with electric heat assemblies above 10 kW may be

wired for single- or two-stage heat. These models come factory wired

for single-stage operation. For two-stage operation, remove the

jumper bar from between the W2 and E terminal. Wire the first-stage

heat to terminal W2. Wire the second-stage heat to terminal E.

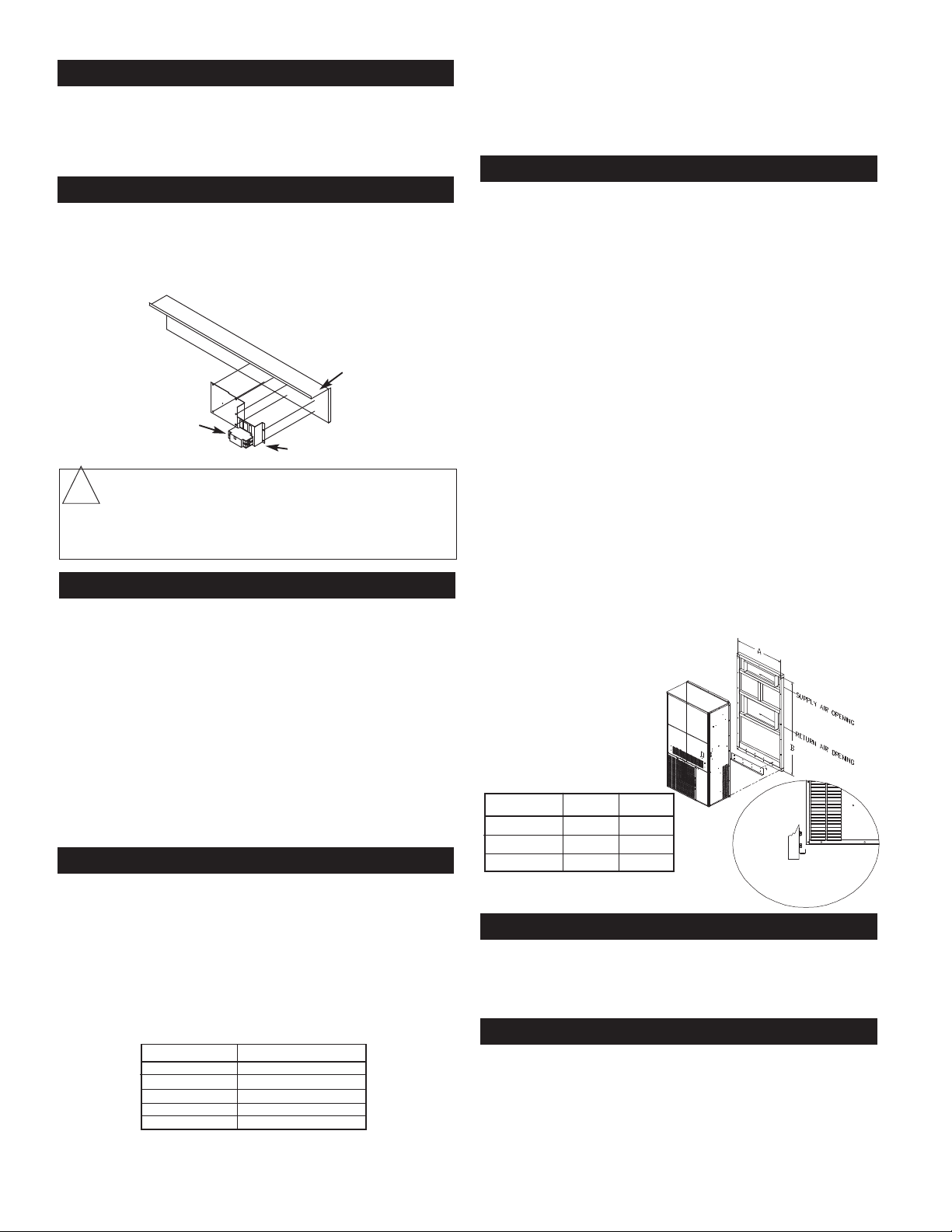

J. UNIT INSTALLATION

V SERIES UNITS ARE FOR USE IN

SINGLE-STORY BUILDINGS ONLY

1. As previously stated, the wall that the unit is to be installed

onto MUST be strong enough to support the unit under the

condition for which it will be used. For example, a unit to be

installed on a building that is intended to be transported will

req u ire m o re w a ll stre n gth than a unit installed at a

perma n ent site. Existing walls m a y n

reinforcement. NEVER RELY ON EXTERIOR SIDING OR

PLYWOOD TO SUPPOR T T HE UNIT. Fi gure 2 below

represents a typical installation of a single-story stud wall at a

permanent site. Since building materials and techniques vary

with regions and intended use, a building contractor and/or

local building code official MUST be consulted for suitable

construction methods.

2. Locate and attach the lower mounting bracket in the desired

location on the building.

3. Apply a suitable caulk across the entire length of the top rain

flashing and side mounting flanges.

4. Remove the flanges on both ends of the pallet and slide the

unit approximately 2” off the rear of pallet. Lift unit gently into

location with fork truck, taking care to align unit with lower

mounting bracket.

5. While allowing a small portion of weight on the lower bracket,

push the unit against the wall and fasten appropriately.A

drain hose is located on

may be extended for condensate removal to comply with

local codes (use fitting size or larger). Install a condensate

trap on this line.

FIGURE 2

the bottom side of the unit. The drain

eed additional

Unit Model A B

18/24 35 71

30/36 39 71

48/60 42 86

MOUNTING FLANGE BOLT

PATTERN DIMENSIONS

1

/2

K. CONDENSATE DRAIN

A3/4” drain hose is located on the bottom side of the unit. The drain

may be extended for condensate removal to comply with local

codes (use fitting size or larger). Install a condensate trap on this

line.

L. ELECTRICAL HEAT INSTALLATION

Electric heat is an option on V Series units and can be field-installed

on either single- or three-phase models.

Re fer to t he individual insta llation instructions fo r insta lling

heater kits on page 14.

4

3

/4”

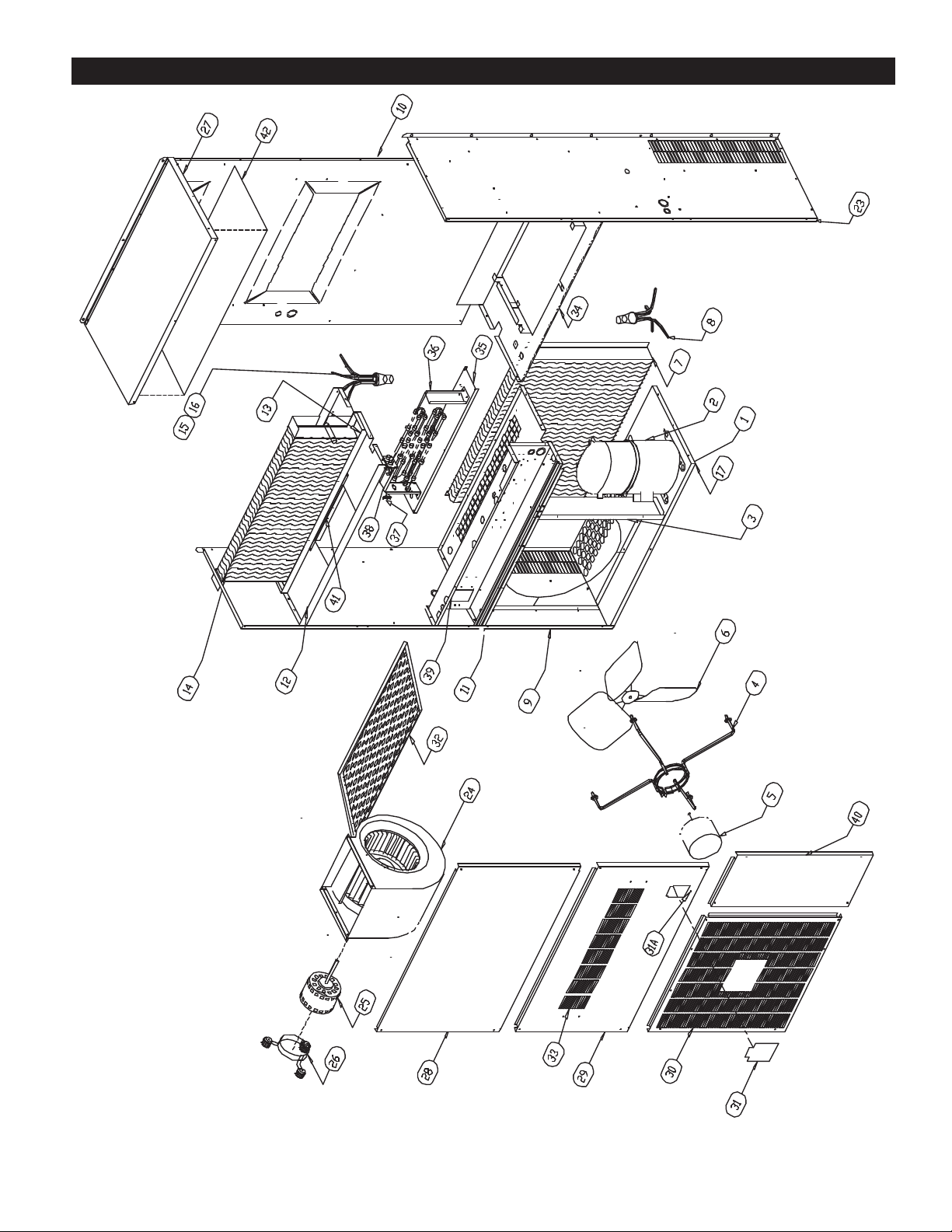

EXPLODED PARTS DRAWING — 18 / 24 / 30 / 36

5

Loading...

Loading...