ET Solar ETM53680, ETM572155, ETM53685, ETM53675, ETM572160 Installation And Assembly Instructions

...

warranty.

Installation and Assembly Instructions

for Solar Modules

WARNING!

The photovoltaic module produces el ec tricity when expos ed to the sun or

other light sour ce s. For your saf ety an d t he s afet y of oth e rs, ple ase read

the entire Installation and Assembly Instruction manual carefully prior to

installation. Please carefully read the foll owing installation and safety

instructions. Non-compliance with these instructions may void the module

1. Company Introduction

ET Solar Group is a vertically integrated solar energy equipment manufacturer and

turnkey solutions provider. With local sales and marketing subsidiaries and offices

throughout Asia, Europe, and North America, we provide high quality photovoltaic

modules, world leading solar tracking systems and smart turnkey solutions to our

customers in more than 50 countries and areas. Our products have been delivering strong

operating performance in a large number of residential and utility scaled solar PV

projects around the world.

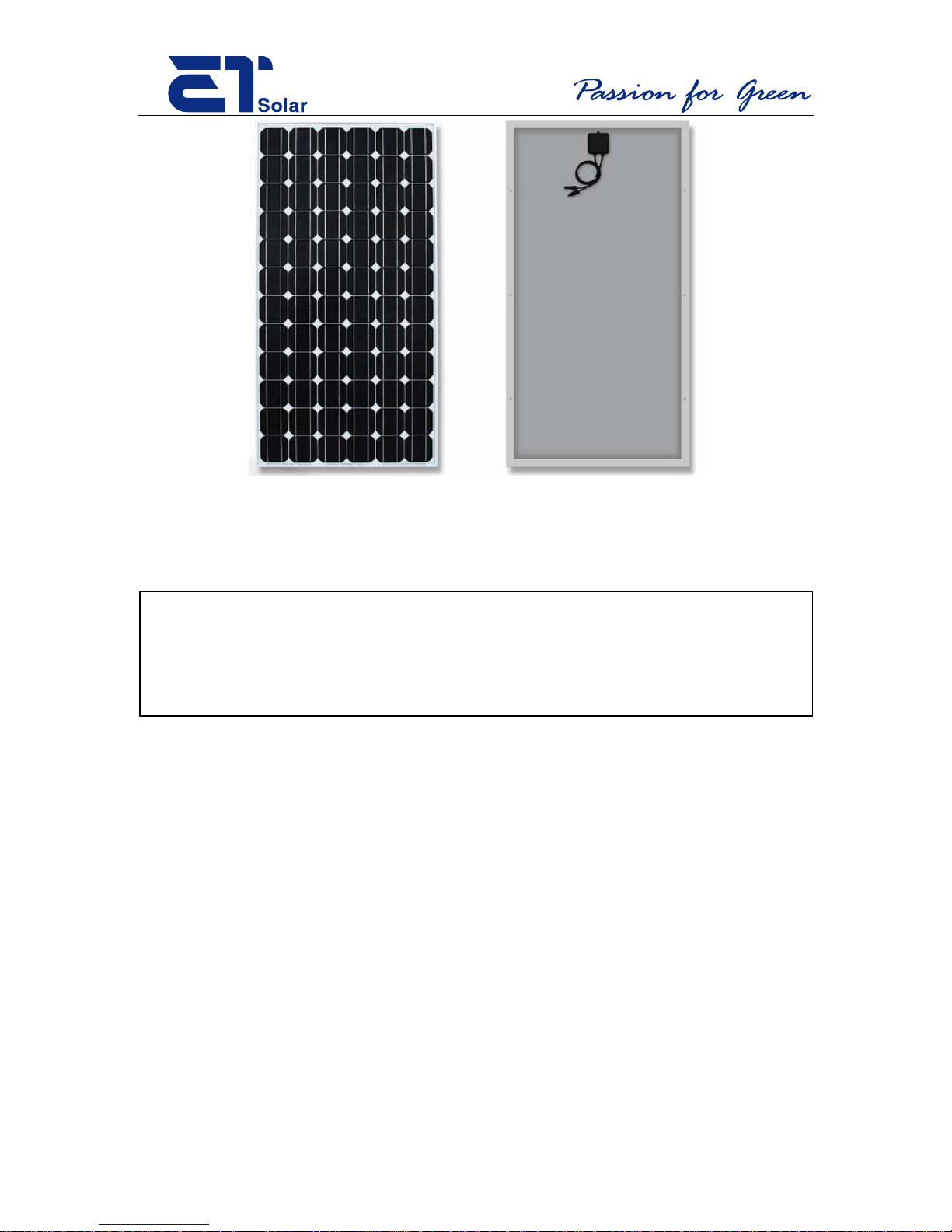

2. Structure of module

ET modules are made by layering low-iron-tempered glass, an EVA sticky membrane,

high conversion-efficient solar cells and a behind-the-membrane multi-layer backsheet.

These elements are laminated into a plate by being heated in a vacuum. After installing

the aluminum alloy frame and wiring compartment, a module is born (see Fig. 1)

.

1

Fig.1: Front and back sides of ET-M572170 module

3. Installation of modules

WARNING!

Do not attempt to clean a module with a broken glass cover or a

perforated backsheet . Such a module can present a serious shock

hazard.

3.1 Installation

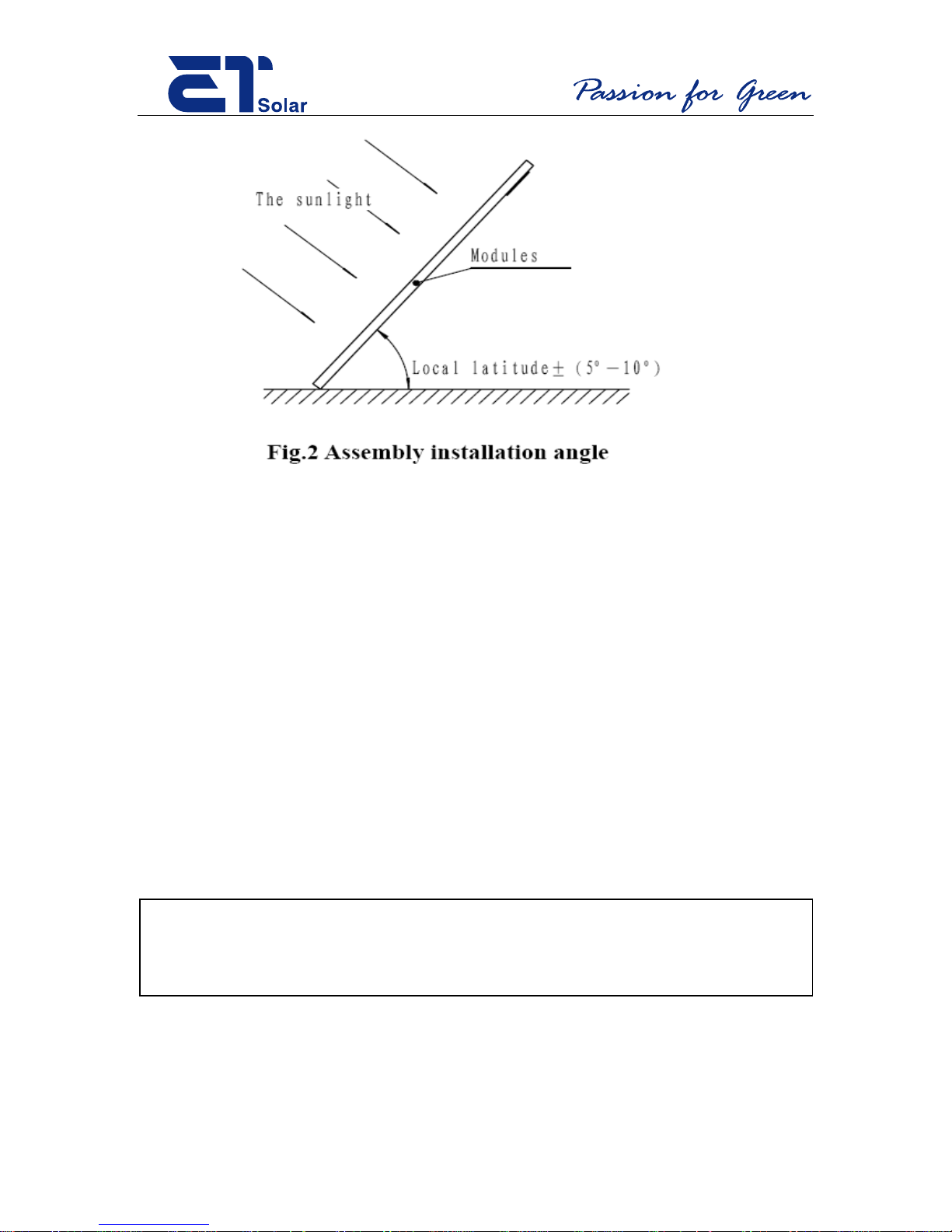

When installing the modules, the face of the units should be placed where they are highly

exposed to the sun. It is recommended that the modules usually face the equator; thus, i n

the Northern Hemisphere the surface should be oriented towards the south, and in the

Southern Hemisphere, towards the north. Usually the angle between modules and the

ground should be local latitude ± (5°~10°) as show in Fig.2.

2

The recommended standoff height is 5 in. (127mm), if other mounting means are

employed this may affect the UL Listing.

The specific angle depends on the sunlight condition, local climate and the actual

application requirements. The appropriate angle of evaluation has a very important

relationship to the output power of the modules and the cost of the construction. The

surface of the modules should avoid shadows and be kept clean from foreign materials

such as dirt.

The assembly is to be mounted over a fire resistant roof covering material when roof

mounting is intended for the modules, the fire resistance of roof covering or wall should

be rated for the application.

WARNING!

The local shadowing of modules may cause se rious hot-spots and

damage the modules.

A torsion and corrosion-resistant anodized aluminum frame ensures dependable

performance, even under harsh weather conditions. Eight pre-drilled mounting holes,

3

located on the aluminum alloy frame, are provided for ease of installation. They are

designed to be used with metric M6×1(Torque 12 Lb-in) stainless steel screws.

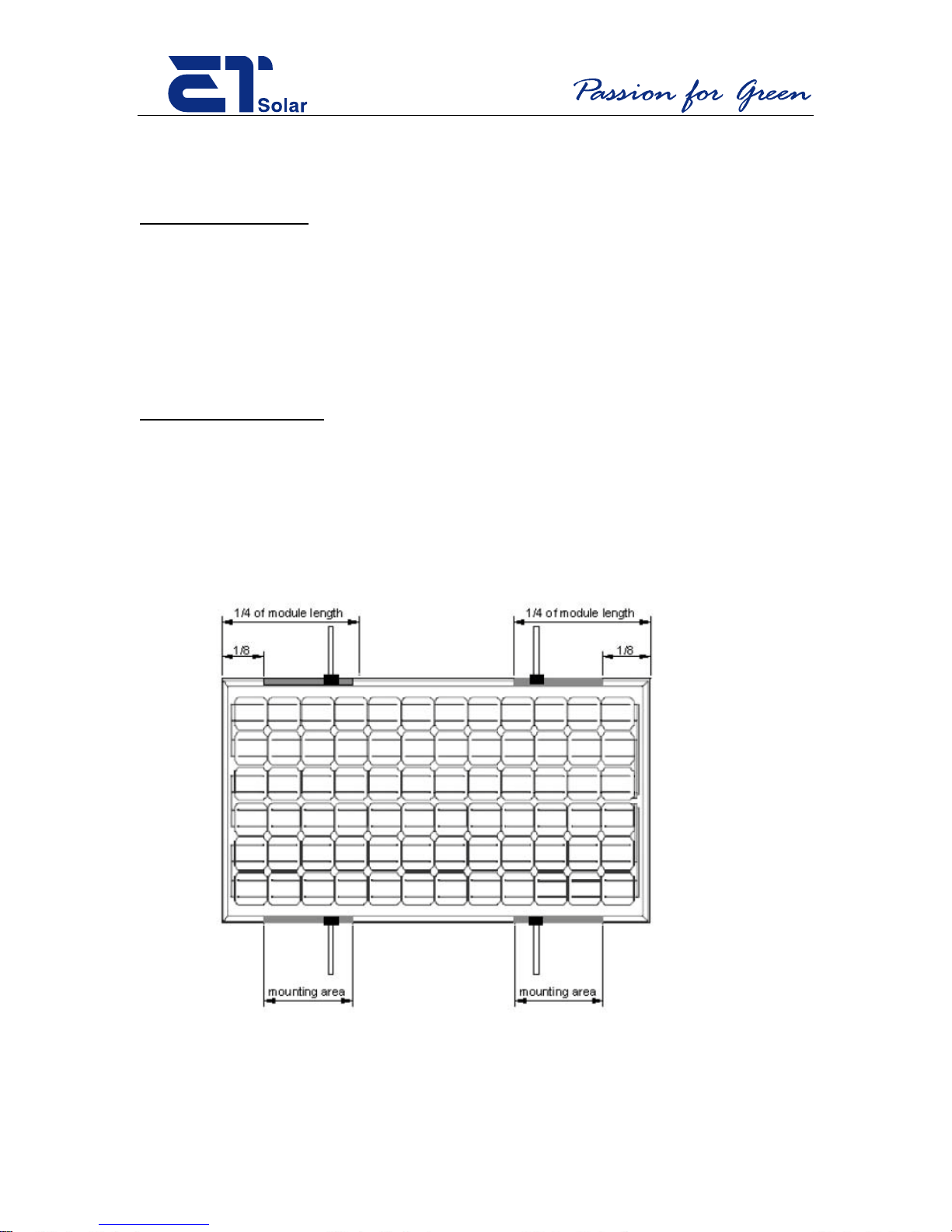

Mounting with Bolts

• The module must be attached and supported by at least four bolts through the

indicated mounting holes.

• Most installations will use the four inner mounting holes on the module frame.

• Depending on the local wind and snow loads, additional mounting points may be

required.

Mounting with Clamps

• If module clamps are used to secure the module, the torque on the clamp bolt

should be around 8–10 Nm.

• A minimum of four module clamps should be used, two on each long frame side,

in the general clamping areas denoted by the wide arrows on the drawing.

• Depending on the local wind and snow loads, additional module clamps may be

required.

4

Loading...

Loading...