Page 1

Model 7605 / Model 7606

Radiating Loop

&

Loop Sensor

User Manual

For MIL-STD-461D Tests

In Accordance With

Method RS101 of MIL-STD-462D

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren L.P. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren L.P. does not convey any license under its

patent rights or the rights of others.

© Copyright 1999–2010 by ETS-Lindgren L.P. All Rights Reserved. No part

of this document may be copied by any means without written permission

from ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo is a trademark of

ETS-Lindgren L.P.

Revision Record

MANUAL MODEL 7605/7606 MILSTD 461D RS101 | Part # 399222, Rev. B

Revision Description Date

A Initial Release April, 1999

B Rebrand July, 2010

ii |

Page 3

Table of Contents

Notes, Cautions, and Warnings ................................................ v

About This Manual ................................................................... vii

1.0 Introduction .......................................................................... 9

About Model 7605 ........................................................................................ 10

About Model 7606 ........................................................................................ 10

References .................................................................................................. 11

ETS-Lindgren Product Information Bulletin ................................................. 12

2.0 Maintenance ....................................................................... 13

Annual Calibration ....................................................................................... 13

Service Procedures ..................................................................................... 13

3.0 Specifications ..................................................................... 15

Electrical Specifications ............................................................................... 15

Physical Specifications ................................................................................ 15

4.0 Theory of Operation ........................................................... 17

Schematic of 7605/7606 in Calibration Configuration .................................. 17

Model 7605 .................................................................................................. 18

Equation 1 ............................................................................................ 18

Equation 2 ............................................................................................ 18

Model 7606 .................................................................................................. 19

Equation 3 ............................................................................................ 19

Equation 4 ............................................................................................ 19

Equation 5 ............................................................................................ 20

Equation 6 ............................................................................................ 20

Equation 7 ............................................................................................ 20

Conversion Factors for Model 7606..................................................... 21

Equation 8 ............................................................................................ 22

5.0 MIL-STD-462D Method RS101 Testing ............................. 23

Operational Cautions ................................................................................... 23

Assembly for Calibration .............................................................................. 24

Method RS101 Calibration ........................................................................... 25

Required instrumentation ..................................................................... 25

| iii

Page 4

About the Signal Source ...................................................................... 26

About the Measuring Instruments ........................................................ 27

About the Current Probe ...................................................................... 27

Calibration Steps ................................................................................. 28

Disassembly for Method RS101 Testing ..................................................... 29

Method RS101 Testing ................................................................................ 30

Start the EUT ....................................................................................... 31

Select Test Frequencies ...................................................................... 31

Equation 9 ................................................................................... 33

Testing the EUT ................................................................................... 34

Equation 10 ................................................................................. 34

Model 7606 Calibration Calculations ........................................................... 34

Calibration by Calculation .................................................................... 35

Equation 11 ................................................................................. 35

Equation 12 ................................................................................. 35

Equation 13 ................................................................................. 36

Equation 14 ................................................................................. 36

Traceability to NIST ............................................................................. 37

Appendix A: Warranty ............................................................. 39

iv |

Page 5

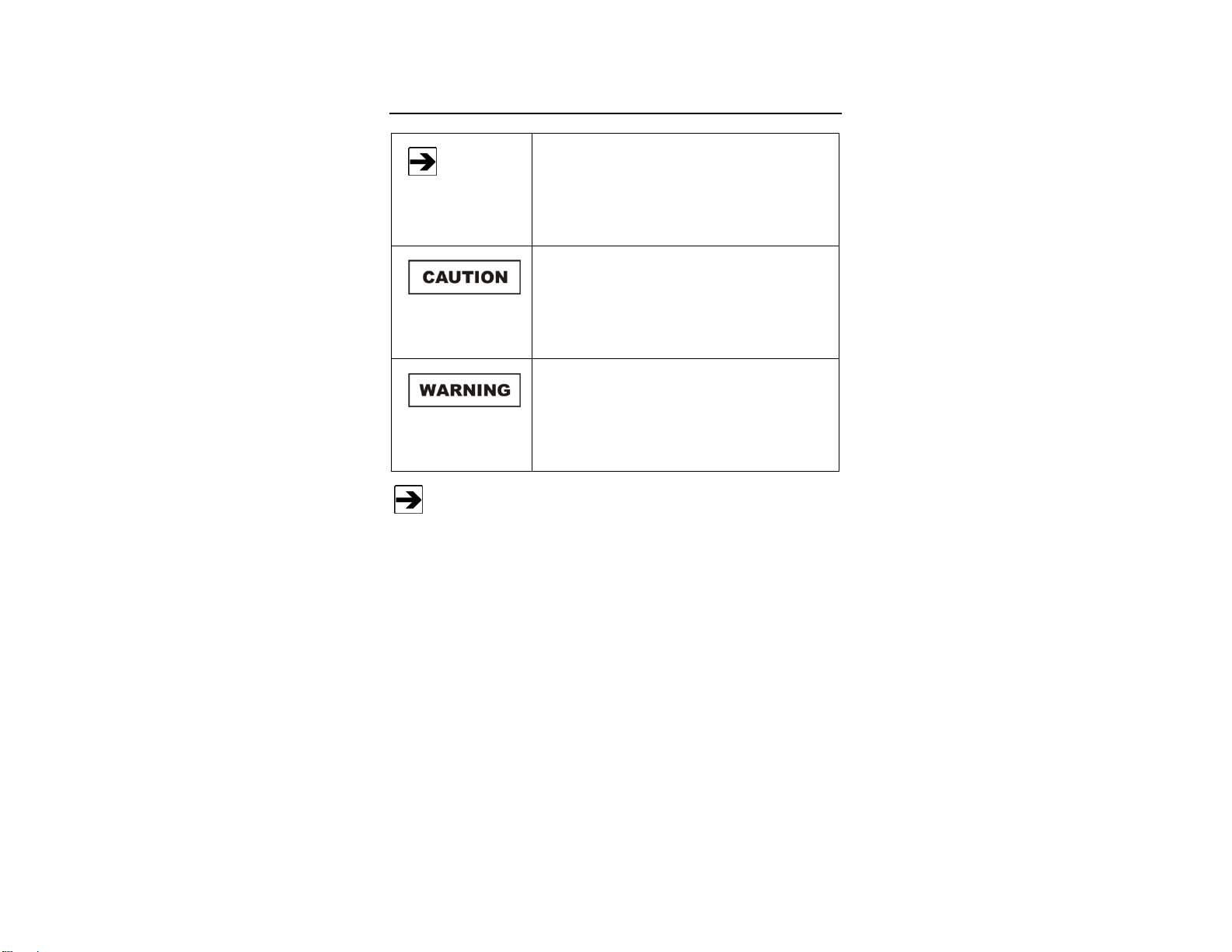

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

| v

Page 6

This page intentionally left blank.

vi |

Page 7

About This Manual

Numbers enclosed in square brackets correspond to the references

listed in References on page 11.

• This manual explains the theory of operation of the Model 7605

Radiating Loop and Model 7606 Radiating Sensor, and the use of the

set for MIL-STD-462D [1] electromagnetic interference (EMI) testing.

• The scope of this manual includes only the theory of operation,

calibration, and use of Model 7605 and Model 7606 for EMI testing in

accordance with Method RS101 [2] of MIL-STD-462D.

• The use of Model 7605 and Model 7606 for other purposes in

electromagnetic compatibility (EMC) testing is limited only by the

ingenuity of the user, but uses in addition to MIL-STD-462,

Method RS101 EMI testing are not included.

• The international system of units (SI) is used throughout this manual.

Refer to IEEE Std 268 [3] for correct abbreviations and their proper

use, and IEEE Std 260 [4] for the proper use of units with the decibel

symbol (dB).

• In general, definitions of EMC terms are contained in ANSI C63.14 [5]

and other electrical terms in IEEE Std 100 [6].

| vii

Page 8

This page intentionally left blank.

viii |

Page 9

1.0 Introduction

The ETS-Lindgren Model 7605 Radiating Loop and Model 7606 Radiating

Sensor are provided as a set, and are used together for the test equipment

calibration described in Method RS101 of MIL-STD-462D. Model 7605 is used

separately during susceptibility (immunity) testing of Equipment Under

Test (EUT).

Use the included nylon bolt to connect the Model 7605 and

Model 7606 together. Do not use a metallic bolt or calibration will be

inaccurate.

Shown unassembled Shown assembled

Introduction | 9

Page 10

About Model 7605

• Model 7605 is a 20-turn coil of AWG-12 enamel-insulated copper wire.

It is wound in a groove on a coil form made of a polytetrafluoroethylene

(PTFE) material. The average diameter of the coil is 12 cm (120 mm).

• The coil form is extended to provide a built-in 5-cm spacer to keep the

coil at the required distance from the EUT. A slot with a threaded

screw hole is cut into the end of the spacer to attach the Model 7606.

• The coil is used to expose EUT to magnetic fields in the range of 30 Hz

to 100 kHz. It produces a magnetic field that has a flux density of

7

9.5 x 10

distance of 5 cm (50 mm) from the center. In decibels, this is

160 dB(pT/A). The coil can carry 15 A rms (root mean square) of

alternating current with only ambient cooling.

About Model 7606

• Model 7606 is a 4-cm (40-mm) diameter, electrostatically-shielded loop

antenna with 51 turns of 7-strand AWG-41 litz wire.

• The Model 7606 is used to calibrate the Model 7605 and associated

instrumentation. It has a phenolic holder which mounts to the

Model 7605 to hold both windings parallel and coaxial to each other

with their centers precisely 5 cm apart. The holder of the Model 7606

has a 1/4–20 threaded hole to mount to a standard tripod.

picotesla per ampere (pT/A) of current flowing in it at an axial

• The Model 7606 is terminated in a BNC connector near the end of the

holder. For test setup calibration, the Model 7605 and Model 7606 are

fastened together with a 3/8–16 nylon bolt.

10 | Introduction

Page 11

References

[1] MIL-STD-462D, 11 January 1993, Military Standard Measurements of

Electromagnetic Interference Characteristics.

[2] Method RS101, "Radiated Susceptibility, Magnetic Field, 30 Hz to

100 kHz," MIL-STD-462D, 11 January 1993, pp 103–108.

[3] IEEE Std 268–1992, American National Standard for Metric Practice.

(ANSI)

[4] IEEE Std 260–1978 (Reaffirmed 1985), IEEE Standard Letter Symbols

for Units of Measurement. (ANSI)

[5] ANSI C63.14–1992, American National Standard Dictionary for

Technologies of Electromagnetic Compatibility (EMC), Electromagnetic

Pulse (EMP), and Electrostatic Discharge (ESD).

[6] IEEE Std 100–1992, Standard Dictionary of Electrical and Electronics

Terms. (ANSI)

[7] Ramo, Simon, and John R. Whinnery, Fields and Waves in Modem

Radio, Second Edition, John Wiley & Sons, Inc. NY, 1953, (©General

Electric Company 1944, 1953), pp 90–91.

[8] Jasik, Henry, Editor, Antenna Engineering Handbook. McGraw-Hill, 1961,

p 6–2.

[9] MIL-STD-461D, 11 January 1993, Military Standard Requirements for the

Control of Electromagnetic Interference Emissions and Susceptibility,

pp 40–41.

[10] MRP-P 1990:8, Testing Visual Display Units, Draft, National Council for

Metrology and Testing, Sweden.

Introduction | 11

Page 12

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS-Lindgren calibration service

• ETS-Lindgren contact information

12 | Introduction

Page 13

2.0 Maintenance

Before performing any maintenance,

Maintenance of the Model 7605 and Model 7606 is limited to external

components such as cables or connectors. If you have any questions concerning

maintenance, contact ETS-Lindgren Customer Service.

Annual Calibration

See the Product Information Bulletin included with your shipment for information

on ETS-Lindgren calibration services.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

follow the safety information in the

ETS-Lindgren Product Information

Bulletin included with your shipment.

Maintenance | 13

Page 14

This page intentionally left blank.

14 | Maintenance

Page 15

3.0 Specifications

Electrical Specifications

Model 7605 Model 7606

Frequency Range: 30 Hz–100 kHz 30 Hz–100 kHz

Wire: AWG-12

Enameled Copper

Number of Turns: 20 51

Maximum Input Current: 15 A Continuous NA

Connector: Banana Jack (Pair) Type BNC Female

Resistance of Winding

(Approximate):

Inductance

(Approximate):

40 mΩ 3.9 Ω

71.8 µH 175 µH

7-41

Litz Copper

Physical Specifications

The windings on both models have square cross sections with dimensions of

approximately 12 mm for the Model 7605 Radiating Loop and approximately

3.175 mm for the Model 7606 Radiating Sensor.

Height: 5.89 cm (2.32 in) 13.46 cm (5.30 in)

Base Width: NA 5.08 cm (2.00 in)

Base Depth: NA 1.90 cm (0.75 in)

Model 7605 Model 7606

Mean Loop Diameter: 12.0 cm 4.0 cm

Specifications | 15

Page 16

This page intentionally left blank.

16 | Specifications

Page 17

4.0 Theory of Operation

Schematic of 7605/7606 in Calibration Configuration

The following illustration shows the Model 7605 Radiating Loop and the

Model 7606 Radiating Sensor as loops or coils separated by a calibration

distance of 5 cm.

Theory of Operation | 17

Page 18

Model 7605

Model 7605 is used alone to produce an AC magnetic field to test Equipment

Under Test (EUT) for susceptibility (immunity) to magnetic fields in the frequency

range from 30 Hz to 100 kHz. It consists of 20 turns of AWG-12 enamel-insulated

copper wire close-wound with an average diameter of 12 cm. It is capable of

carrying 15 A rms, but if this level of coil current is sustained for long periods, the

coil will become warm. It has a coil resistance of approximately 40 mΩ and an

inductance of approximately 71.8 µH.

EQUATION 1

Equation 1 derived from [7] gives the relationship between coil current and

magnetic flux density.

Equation 1 may be simplified for computation as shown in equation 2.

EQUATION 2

18 | Theory of Operation

Page 19

Model 7606

Model 7606 is used with Model 7605 to calibrate the 7605 and other

instrumentation used in tests. With 51 turns of wire in a 4-cm diameter loop, it

has an effective area of 640 cm

the sensitivity of measurements with a given instrument by more than 30 dB over

a small, single-turn loop. The response is tabulated in the Conversion Factors for

Model 7606 table on page 21 (and is proportional to the frequency shown in

Figure RS101-1 in Method RS101 of MIL-STD-462D).

2

(an effective diameter of 28.6 cm), improving

The voltage induced in the loop, e

number of turns, the frequency, and the average flux density within the area of

the loop. Equation 3 derived from [8] gives this relationship.

, is proportional to the area of the loop, the

i

EQUATION 3

For the Model 7606, the open-circuit loop-terminal induced voltage in microvolts

for a magnetic flux density in picotesla is given in equation 4.

EQUATION 4

The general equation for the conversion factor is given by equation 5 and

equation 6, and includes the effects of loop impedance and load impedance.

Theory of Operation | 19

Page 20

EQUATION 5

EQUATION 6

For the Model 7606, equation 6 becomes equation 7.

EQUATION 7

The values in the following table were calculated from equation 5 and equation 7

using a 50 Ω load and a 600 Ω load. (These values are the same as in

Figure RS101-1 in MIL-STD-462D.)

20 | Theory of Operation

Page 21

CONVERSION FACTORS FOR MODEL 7606

This table shows that below 15 kHz there is less than 1 dB difference between

the values of the conversion factors for the loop loaded in 50 Ω and in 600 Ω

(open circuit), and over most of the range the difference is less than 0.6 dB. To

find values of the correction factor between these values, use the interpolation in

equation 8.

Frequency (kHz)

0.03 99.01 98.41

0.1 88.56 87.96

1 68.56 67.96

3 59.03 58.42

7 51.41 51.06

10 48.73 47.96

13 46.57 45.68

15 45.42 44.44

17 44.44 43.35

20 43.20 41.94

23 42.18 40.73

27 41.07 39.34

30 40.39 38.43

35 39.46 37.09

Conversion Factor, dB(pT/µV)

50 Ω 600 Ω

40 38.72 35.94

45 38.13 34.92

50 37.66 34.01

70 36.46 31.13

100 35.66 28.10

Theory of Operation | 21

Page 22

EQUATION 8

22 | Theory of Operation

Page 23

5.0 MIL-STD-462D Method RS101 Testing

Before connecting any components, follow the

safety information in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

The normal design application of the Model 7605 Radiating Loop and

Model 7606 Radiating Sensor is the MIL-STD-462D Method RS101 EMI testing.

Additional applications are possible, but only the application to Method RS101 is

discussed here.

Method RS101 requires two distinct activities: test setup calibration and exposure

of the Equipment Under Test (EUT) to specified magnetic flux densities.

Operational Cautions

Large magnetic fields are produced during

testing, particularly at low frequencies. They are

capable of affecting calculators and watches,

and at the RS101 worst-case limits, they exceed

the levels which the Swedish government [10]

has set for video display terminals. Therefore,

take these precautions:

• Keep all calculators, watches, rings, and

other metallic objects at least one meter

from the Model 7605 during testing.

• Keep your head and torso at least 90 cm

from the Model 7605 during testing below

400 Hz.

The Model 7606 may be damaged by large

currents, so do not connect it to the

signal source, and do not leave it in place

during testing.

MIL-STD-462D Method RS101 Testing | 23

Page 24

Assembly for Calibration

For test setup calibration, Model 7605 and Model 7606 are assembled together.

When assembled, the two loops are parallel to each other and coaxial with their

centers precisely 5 cm apart.

Do not over tighten the nylon bolt. Tighten it to

only finger tight; do not use a wrench.

Over tightening may cause the bolt to break,

blocking the bolt hole and making calibration

impossible.

1. Place the Model 7606 into the slot

in the body of the Model 7605, with

the BNC connector positioned

outside Model 7605 and pointing

upward.

2. Insert the 3/8–16 nylon bolt. Tighten

to finger tight.

24 | MIL-STD-462D Method RS101 Testing

Page 25

Method RS101 Calibration

Mount the Model 7605/Model 7606 assembly on a non-metallic tripod. This helps

prevent interaction between the assembly and the surroundings, and allows the

operator to be hands-free near the instrumentation.

Block Diagram – Calibration Test Setup

During calibration, keep the assembly several diameters away from metal

objects. Space the current probe and other instrumentation at least one meter

from the assembly to keep it from the influence of the Model 7605.

REQUIRED INSTRUMENTATION

• Model 7605/Model 7606 assembly

• Signal source—see page 26 for more information

• Two measuring instruments—see page 27 for more information

• Current probe—see page 27 for more information

MIL-STD-462D Method RS101 Testing | 25

Page 26

ABOUT THE SIGNAL SOURCE

The signal source may be a signal generator followed by a power amplifier or

current amplifier. The signal generator may be a manual signal generator, a

tracking generator (part of a spectrum analyzer or EMI meter), or a

computer-controlled signal generator. A 30 W power amplifier with an output

impedance of 0.5 Ω will drive the Model 7605 to about 15 A and produce up to

183 dB(pT) at the end of the built-in 5 cm spacer. When the amplifier is set to the

30 W output level, it produces a current of almost 15 A in the Model 7605, but the

actual amplifier power output is only about 9 W; the 30 W amplifier is needed to

be able to provide enough current from a 0.5 Ω source.

At the lower end of the frequency range, it would be better to use an amplifier

with output impedance lower than 0.5 Ω. For example, if the amplifier had a

source impedance of only 0.125 Ω, the power output capability would need to be

only 9.5 W. However, amplifiers and matching transformers to provide an output

impedance of 0.125 Ω are not readily available in the EMC test equipment

marketplace, but those providing 0.5 Ω are; they are typically found in an

EMC laboratory equipped for MIL-STD-462 testing.

The power amplifier and coupling transformer used for Method CS101 tests may

be used for RS101 tests, but the amplifier does not need as much power for

RS101 tests. Higher impedance amplifiers may be practical at the higher

frequencies where much less current is needed to produce the flux densities

required in the RS101 EMI susceptibility tests.

26 | MIL-STD-462D Method RS101 Testing

Page 27

ABOUT THE MEASURING INSTRUMENTS

The measuring instruments can be radio-noise or EMI meters, calibrated

receivers, spectrum analyzers, or other tunable (narrowband) voltmeters. These

instruments must be accurately calibrated with appropriate correction factors

available across the frequency range. A number of possible instruments are

available. Some instruments, for example, certain automatic spectrum analyzers,

may require no correction factors, since they self-calibrate and internally

generate and apply a correction factor at each frequency.

A single instrument can be used for both Measuring Instrument A and

Measuring Instrument B indicated in the illustration on page 25. If this is done:

• The Model 7606 should be loaded by a 50 Ω dummy load while the

output of the current probe is being measured.

• More importantly, the output of the current probe must be loaded by a

50 Ω dummy load when the output of the Model 7606 is being

measured.

Failure to load the current probe in 50 Ω while the measuring

instrument is not connected to it may result in unpredictable changes

in the impedance inserted into the line by the current probe. This may

then cause an unknown change in the current flowing in the

Model 7605.

For convenience during the susceptibility testing of the EUT, a spectrum analyzer

with a tracking generator may be used for measuring instrument A.

ABOUT THE CURRENT PROBE

The current probe may be a low-frequency EMI measuring clamp-on

current probe designed to cover the frequency range from 30 Hz to 100 kHz;

several manufacturers offer this type of probe. The accuracy of the individual

calibration is important because it is a key element in setting the test current

during EMI measurements.

The transfer admittance (or impedance) should be individually calibrated over the

frequency range. Usually, the probe calibration by the manufacturer is adequate,

but do not rely on a probe that has a calibration reported at a single frequency or

has a single conversion factor that is to be applied across the entire frequency

range.

MIL-STD-462D Method RS101 Testing | 27

Page 28

CALIBRATION STEPS

1. Set the signal source to a frequency of 1 kHz and adjust the output to

provide a magnetic flux density of 110 dB(pT) as determined by the

reading obtained on instrument A and the relationship

B = 160 dB(pT/A). This requires a current of -50 dB(A) or 3.16 mA.

To determine the current, algebraically add the current probe

correction factor in dB(S) to the reading in dB(mV) on instrument A; for

example:

2. Measure the voltage output in dB(µV) from the Model 7606 on

instrument B.

3. Verify that the output from the Model 7606 is 42 dB(µV) ±3 dB, and

record this value.

If the output from Model 7606 is not within ±3 dB of 42 dB(µV), verify the source

current is set correctly, and then look for other causes. Some possible causes

are:

• Inaccuracy in either or both measuring instruments.

• Malfunction of either or both measuring instruments.

• Inaccuracy in the current probe.

• Loose clamping or other malfunction of the current probe.

• Damage to the current probe.

• Magnetic-field coupling between Model 7605 and the current probe or

measuring instruments.

• Loose fit between Model 7605 and Model 7606, or other incorrect

assembly.

• Damage to Model 7605 or Model 7606.

• Metallic objects, particularly magnetic materials, in close proximity to

Model 7605 and Model 7606.

28 | MIL-STD-462D Method RS101 Testing

Page 29

If all instrumentation is operating properly and is accurately calibrated, readjust

the source to produce the correct output from the Model 7606. Use the ratio (or

difference in dB) between the initial setting of the source to the corrected setting

of the source as a correction factor in the later EMI susceptibility measurements.

Disassembly for Method RS101 Testing

Before disassembling Model 7605 and Model 7606, verify that the test signal

source is turned off or the output is reduced to zero.

1. Remove the 7605/7606 assembly from the tripod.

2. Unscrew the nylon bolt.

3. Remove the Model 7606 from the Model 7605.

MIL-STD-462D Method RS101 Testing | 29

Page 30

Method RS101 Testing

Block Diagram – RS101 Test Setup

This diagram shows EUT and these items of instrumentation:

• Model 7605

• Test signal source

• Current probe

• Measuring instrument

• Line Impedance Stabilization Network (LISN) in the EUT power line

• One or more pieces of input/output stimulating and monitoring

equipment for exercising the EUT and monitoring performance

All instrumentation, including the current probe, must be outside of the

influence of the Model 7605 magnetic field. A spacing of one meter

should be adequate.

30 | MIL-STD-462D Method RS101 Testing

Page 31

Testing EUT for susceptibility (immunity) consists of three processes: starting the

EUT, selecting test frequencies (may be done semi automatically), and testing

the EUT at the selected frequencies (done manually).

START THE EUT

Turn on the EUT, allow it to stabilize, and then verify it is operating properly.

Make sure the input/output stimulation and monitoring equipment is operating

satisfactorily.

SELECT TEST FREQUENCIES

Testing – Showing Application of Model 7605

1. Position the Model 7605 so that the built-in spacer is flat against one

surface of the EUT. This places it parallel to and 5 cm from the EUT.

MIL-STD-462D Method RS101 Testing | 31

Page 32

2. Drive the Model 7605 with sufficient current to produce a magnetic flux

density 10 dB greater than the applicable limit in MIL-STD-46ID [9], but

do not exceed 15 A; for example, 183 dB(pT). The following chart

shows the Model 7605 coil current at the RS101 limits.

3. Scan the frequency range from 30 Hz to 100 kHz. The scan rate may

be three times faster than the rates specified in Table III of

MIL-STD-462D.

In the 30 Hz to 100 kHz range the specified rates are 0.02f

per second for analog scans and 0.01f

steps (1% steps) for stepped

0

scans; so for these frequency selecting scans, the scan rates can be

per second for analog scans and 3% steps for stepped scans.

0.06f

0

32 | MIL-STD-462D Method RS101 Testing

0

Page 33

Stepped scans must dwell at each frequency for one second. f

tuned frequency, not the starting frequency. Usually, for analog scans,

the frequency range is broken into octave or decade bands and the

scan rate is changed at each band. The following table shows

suggested bands and analog scan rates. For stepped scans, the

frequencies may be computed using equation 9.

Frequency Band Analog Scan Rate Total Scan Time

30 Hz–100 Hz 2 Hz/s 35 s

100 Hz–200 Hz 8 Hz/s 12.5 s

200 Hz–400 Hz 17 Hz/s 11.8 s

400 Hz–700 Hz 32 Hz/s 9.3 s

700 Hz–1.5 kHz 61 Hz/s 13.1 s

1.5 kHz–3 kHz 127 Hz/s 11.8 s

3 kHz–6 kHz 250 Hz/s 12 s

6 kHz–10 kHz 460 Hz/s 8.7 s

10 kHz–20 kHz 850 Hz/s 11.8 s

20 kHz–40 kHz 1.7 kHz/s 11.8 s

is the

0

40 kHz–100 kHz 3.8 kHz/s 15.9 s

Suggested Scan Rates for Analog Scanning

EQUATION 9

4. If susceptibility is noted, select three or more test frequencies per

octave at frequencies where susceptibilities are present. For example,

if five frequencies within an octave show susceptible responses, select

at least three of them for further testing. The three selected should be

those with the maximum indication of susceptibility.

MIL-STD-462D Method RS101 Testing | 33

Page 34

5. Reposition the Model 7605 successively to a location in each 30 cm by

30 cm area on each surface of the EUT and repeat the previous steps.

6. From the total set of data where susceptibility was noticed, select three

frequencies in each octave of the frequency range from 30 Hz to

100 kHz where susceptibility was found.

TESTING THE EUT

At each frequency determined as a result of selecting test frequencies, apply the

current to the Model 7605 that corresponds to the applicable limit in

MIL-STD-461D. For accuracy in this process, calculate the required loop current

using equation 10. Move the loop to search for all possible locations of

susceptibility, including cables, connectors, cabinet seams, vents, and so on.

EQUATION 10

Model 7606 Calibration Calculations

The Model 7606 is designed to conform to MIL-STD-462D. This sensor is

electrically very small, which permits performance calculation based on

geometry. In the table on page 21 the performance is shown in the form of a

conversion factor which is used to convert the output voltage, in dB(µV), to the

magnetic flux density, in dB(pT), of the field in which the coil is immersed.

The tolerances in manufacturing are a maximum of 0.05 mm (0.002 inches).

These tolerances in worst-case combination cause a maximum error of ±0.06 dB.

The best accuracy with which the conversion factor can be measured is ±1 dB,

and larger errors are probable. Therefore, the conversion factor is not measured,

but is instead calculated to provide the best possible accuracy (absolute error

≤0.06 dB).

34 | MIL-STD-462D Method RS101 Testing

Page 35

CALIBRATION BY CALCULATION

Following are the equations used in calculation of Model 7606 performance,

along with a sample calculation.

The absolute value of the ratio of the magnetic flux density to the voltage across

the connected load, BV

EQUATION 11

, is given by equation 11.

L

The coil resistance, R

resistance of the wire; or, it can be measured with a low-resistance bridge. The

length of the wire is the product of the average circumference of the winding and

the number of turns. This is shown in equation 12.

, is found from the length of wire in the coil and the unit

c

EQUATION 12

The coil inductance, L, is found from equation 13.

MIL-STD-462D Method RS101 Testing | 35

Page 36

EQUATION 13

The ratio |B/VL| is put in decibels by equation 14 to become the correction factor,

CF.

EQUATION 14

Sample Calculation:

The maximum uncertainty because of dimensional tolerances is ±0.06 dB;

therefore, this calculated correction factor has a range of 98.95 dB to 99.07 dB.

For ordinary measurement work, such as the measurements for RS101, it is

reasonable to round this correction factor to 99.0 dB.

36 | MIL-STD-462D Method RS101 Testing

Page 37

TRACEABILITY TO NIST

The traceability to NIST is through the mechanical measurements and

mechanical calibration of the tools used to manufacture the Model 7606. It can

be proven mathematically that for such an electrically small sensor, the

performance can be accurately calculated based on the dimensions of the

sensor. Thus, the traceability of the manufacturing tools to NIST provides

traceability of the electrical performance of the sensor to NIST.

MIL-STD-462D Method RS101 Testing | 37

Page 38

This page intentionally left blank.

38 | MIL-STD-462D Method RS101 Testing

Page 39

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for

the complete ETS-Lindgren warranty for your Model 7605 Radiating

Loop and Model 7606 Radiating Sensor.

DURATION OF WARRANTIES FOR MODEL 7605 / MODEL 7606

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to two years.

Product Warranted Duration of Warranty Period

Model 7605 Radiating Loop 2 Years

Model 7606 Radiating Sensor 2 Years

Warranty | 39

Loading...

Loading...