Page 1

Turntable

Model 2188

1.2m, 1.5m and 2.0m

Users Manual

©ETS-Lindgren—January, 2006 Rev. B—Part#399771

Page 2

Model 2188 Turntable

ETS-Lindgren reserves the right to make changes to any products herein to improve functioning

or design. Although the information in this document has been carefully reviewed and is believed

to be reliable, ETS-Lindgren does not assume any liability arising out of the application or use of

any product or circuit described herein; nor does it convey any license under its patent rights nor

the rights of others.

©Copyright 2006 by ETS-Lindgren L.P. All Rights Reserved. No part of this document may be

copied by any means without written permission from ETS-Lindgren L.P.

Revision Description Date

A Initial Release November, 2005

B Added two meter turntable information, updated

January, 2006

illustrations and drawings

E-Mail & Internet Addresses

support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Drive, Cedar Park, TX 78613 USA

P O Box 80589, Austin, TX 78708-0589 USA

Tel. +512.531.6400

Fax +512.531.6500

Finland

Mekaanikontie 1, 27510, Eura, Finland

Tel. +358.2.838.330

Fax +358.2.865.1233

Japan

4-2-6, Kohinata

Bunkyo-ku, Tokyo 112-0006 Japan

Tel. +81.3.3813.7100

Fax +81.3.3813.8068

China

1917-1918 Xue Zhixuan Building

No. 16 Xue Qing Road

Haidian District

Beijing Postcode: 100083 China

Tel. +86.010.827.55304

Fax +86.010.827.55307

2

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 3

Model 2188 Turntable

Table of Contents

1. Introduction.................................................................................................................................. 7

1.1. Standard Configuration......................................................................................................... 7

1.2. Model 2188 Options..............................................................................................................8

1.2.1. Model 2090 Series Positioning Controller...................................................................... 8

1.2.2. Additional Fiber Optic Cable .......................................................................................... 9

2. Getting Started........................................................................................................................... 11

2.1. Unpacking and Acceptance................................................................................................ 11

2.2. Electrical Specifications......................................................................................................11

2.2.1........................................................................................................................................ 11

2.2.2. Mechanical ...................................................................................................................12

2.3. Turntable Installation Considerations ................................................................................. 12

2.3.1. Conduit......................................................................................................................... 12

2.3.2. Electrical Considerations.............................................................................................. 12

2.3.3. Access.......................................................................................................................... 12

3. Installation.................................................................................................................................. 13

3.1. Tools Required.................................................................................................................... 13

3.2. Unpacking........................................................................................................................... 14

3.3. Positioning the Turntable.................................................................................................... 14

3.4. Installing Anchor Plates ...................................................................................................... 16

3.5. Raised Panel Floor Flange Installation............................................................................... 17

3.6. Floor Flange Mounting in a Concrete Pit............................................................................ 18

3.7. Motorbase Attachment........................................................................................................19

3.8. Final Leveling of the Table.................................................................................................. 20

3.9. Application of Conductive Grease ...................................................................................... 20

4. Electrical Installation.................................................................................................................. 21

5. Operation................................................................................................................................... 23

5.1. Editing Positioning Controller Configuration Parameters ................................................... 23

5.2. Setting Travel Limits ........................................................................................................... 24

5.3. Turntable Encoder Calibration............................................................................................ 25

5.3.2. Turntable Calibration Example..................................................................................... 26

5.4. Changing Rotation Speed................................................................................................... 27

5.5. Variable Speed Settings ..................................................................................................... 27

5.6. Speed Selection..................................................................................................................28

5.7. GPIB Commands................................................................................................................ 29

6. Infrared Controller...................................................................................................................... 31

7. Recommended Maintenance..................................................................................................... 33

7.1. Routine Maintenance.......................................................................................................... 33

7.2. Bi-Annual Maintenance.......................................................................................................33

7.3. Annual Maintenance........................................................................................................... 34

8. Warranty.................................................................................................................................... 37

9. Addendum A: Drawings............................................................................................................39

©ETS-Lindgren—January, 2006

Rev. B—P#399771

3

Page 4

Model 2188 Turntable

SAFETY SYMBOL DEFINITIONS

NOTICE: This product and related documentation must be reviewed for familiarization

with safety markings and instructions prior to operation of the product.

REFER TO MANUAL—When the product is marked with

this symbol refer to the instruction manual for additional

!

OR

OR

CAUTION

WARNING

information. If the instruction manual has been misplaced,

go to www.ets-lindgren.com

contact ETS-Lindgren customer service.

HIGH VOLTAGE—Indicates the presence of hazardous

voltage. Unsafe practice could result in several personal

injury or death.

PROTECTIVE EARTH GROUND (SAFETY GROUND)—

Indicates protective earth terminal. Uninterruptible safety

earth ground from the main power source to the product

input wiring terminals, power cord or supplied power cord

set shall be provided.

CAUTION—Denotes a hazard. Failure to follow

instructions could result in minor personal injury and/or

property damage. Text that follows the symbol will provide

proper procedures.

WARNING—Denotes a hazard. Failure to follow instruction

could result in SEVERE personal injury and/or property

damage. Text that follows the symbol will provide proper

procedures.

for downloadable files or

GENERAL SAFETY CONSIDERATIONS/PRECAUTIONS

Read this manual completely before beginning the

installation of the turntable. Refer to drawings at the rear of

the manual and the “Tools Required” list included prior to

4

beginning installation. This equipment should be installed

and operated only by qualified personnel.

The electrical installation of this product should be

accomplished by an individual who is authorized to so do by

the appropriate local authority. The installation should be in

compliance with local electrical safety codes.

BEFORE POWER IS APPLIED TO THIS INSTRUMENT,

GROUND IT PROPERLY through the protective conductor

of the AC power cable to a power source provided with

protective earth contact. Any interruption of the protective

(grounding) conductor, inside or outside of the instrument,

or disconnection of the protective earth terminal could result

in personal injury.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 5

Model 2188 Turntable

GENERAL SAFETY CONSIDERATIONS/PRECAUTIONS (continued)

BEFORE SERVICING: CONTACT ETS-LINDGREN

(+1.512.531.6400)—servicing or modifying the unit without

ETS-Lindgren authorization may void your warranty. If an

WARRAN TY

attempt to service the unit must be made, disconnect all

electrical power prior to beginning. Voltages exist at many

points within the instrument that could, if contacted, cause

personal injury. Only trained service personnel should

perform adjustments and/or service procedures upon this

instrument. Capacitors inside this instrument may still be

CHARGED even when the instrument is disconnected from

the power source.

WARRAN TY

Do not make any modifications to this unit without

consulting the factory directly.

ONLY QUALIFIED PERSONNEL should operate or service

this equipment.

STAY CLEAR of moving components during operation of

equipment. Do not operate the turntable while someone is

physically on the turntable top.

Do not, at any time, place hands or feet in the vicinity of the

drive pinion on the turntable.

Regularly inspect all equipment and conduct scheduled

maintenance in accordance with the factory

WARRAN TY

recommendations provided.

Only use replacement parts and fasteners ordered directly

from the factory.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

5

Page 6

Model 2188 Turntable

This page intentionally left blank.

6

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 7

Model 2188 Turntable

1. Introduction

The ETS-Lindgren Model 2188 is an electric-powered, variable-speed

turntable platform system designed for use with an EMCO Model 2090

series positioning controller to perform EMI compliance testing. The Model

2188 is available in 1.2-meter, 1.5-meter and 2.0-meter diameters. The

turntable is ideal for installations in new or existing test locations where pit

excavation is not an option or must be shallow.

The top of the turntable is conductive with a continuous ground brush to

electrically couple it to the ground plane. The ground brushes are attached

directly to the chamber floor via the floor flange and are in continuous

contact with the turntable top. The brushes point downward from the floor

flange. .

The drive motor and gearing are located beneath the platform. The Model

2188 turntable is powered by an electric motor through a worm gear box

with a chain and sprocket final drive. The top of the turntable is removable

to provide easy access in the event that service is required. The

electronics are located in a shielded enclosure. Signal I/O is via fiber-optic

cable.

To prevent over-travel of the turntable in either direction of movement,

“hard” limits are provided in the form of pins that actuate switches located

below the tabletop. These pins allow limits to be set and allow as much as

two full rotations. Rotation speed can be varied from the front panel of the

controller or through the IEEE-488 interface bus.

1.1. Standard Configuration

• Turntable Assembly

• Single-phase electric drive (208-230 VAC 50/60 Hz)

• Variable speed drive

• Conductive top

• Continuous rotation

• One (1) ten meter fiber-optic control cable

• Fiber optic shield penetration kit

• Two (2) fiber optic feed-thrus

• One (1) three meter fiber optic control cable

©ETS-Lindgren—January, 2006

Rev. B—P#399771

7

Page 8

Model 2188 Turntable

1.2. Model 2188 Options

1.2.1. Model 2090 Series Positioning Controller

The Model 2090 Series Multi-Device Positioning Controller is

designed for use with ETS-Lindgren positioning devices

such as antenna towers, turntables, reverberation paddles,

multi-axis positioners, etc. to accomplish a variety of tests for

EMC compliance, antenna pattern measurements, and

more.

The Controller allows the user to synchronize the

simultaneous, yet independent movement of two primary

devices such as towers or turntables in either manual or

remote GPIB modes while controlling the on/off operation of

up to four auxiliary devices. The unit includes a GPIB bus

and is compatible with most popular software. Firmware

revision 3.11 or higher required.

Each primary device is interfaced to the controller through a

bi-directional fiber optic interface using a proprietary

command protocol. Auxiliary devices use a single fiber optic

signal to control simple on/off operation. The fiber optic

control lines that attach devices to the unit eliminate

extraneous RF interference signals that can normally be

conducted through wire signal cables.

The front panel of the Model 2090 provides the interface for

two separate and complete device controllers, each with

identical displays and function keys. The function keys let

the user configure device specific parameters, adjust limit

and position settings and control device motion. Numeric

displays and status indicators are provided for each device

interface to show positioning and operational information as

well as device parameter settings. In addition to the two

primary device interfaces, an auxiliary control interface for

four auxiliary devices is present. This interface provides

keys and indicators to allow the user to manually toggle the

auxiliary devices on or off.

8

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 9

Model 2188 Turntable

Control of all devices may be accomplished either in the

manual or remote modes through the use of the GPIB (IEEE

488 standard interface bus) port located on the rear panel.

Each primary device is identified by a unique GPIB address

that the controller recognizes, allowing each positioning

device to function as a separate device on the GPIB bus.

1.2.2. Additional Fiber Optic Cable

Various lengths of fiber optic cable may be ordered. Specify

additional cable lengths at the time of order placement.

Cables are terminated with type ST connectors.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

9

Page 10

Model 2188 Turntable

This page intentionally left blank.

10

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 11

Model 2188 Turntable

2. Getting Started

2.1. Unpacking and Acceptance

Step 1. Upon delivery of your order, inspect the shipping

container(s) for evidence of damage. Record any damage on the

delivery receipt before signing. In case of concealed damage or

loss, retain the packing materials for inspection by the carrier.

Step 2. Once all of the materials are removed from the container

by a qualified installer, check all materials against the packing list to

verify that the equipment received matches what was ordered. If

you find any discrepancies, note them and call ETS-Lindgren

Customer Service (+1.512.531.6400) for further instructions.

Ensure that you are satisfied with the contents of your order and

the condition of your equipment prior to installation.

Pre-planning is essential for a successful installation. Be sure to

discuss your requirements with your sales representative and

request dimensional drawings prior to construction of your site.

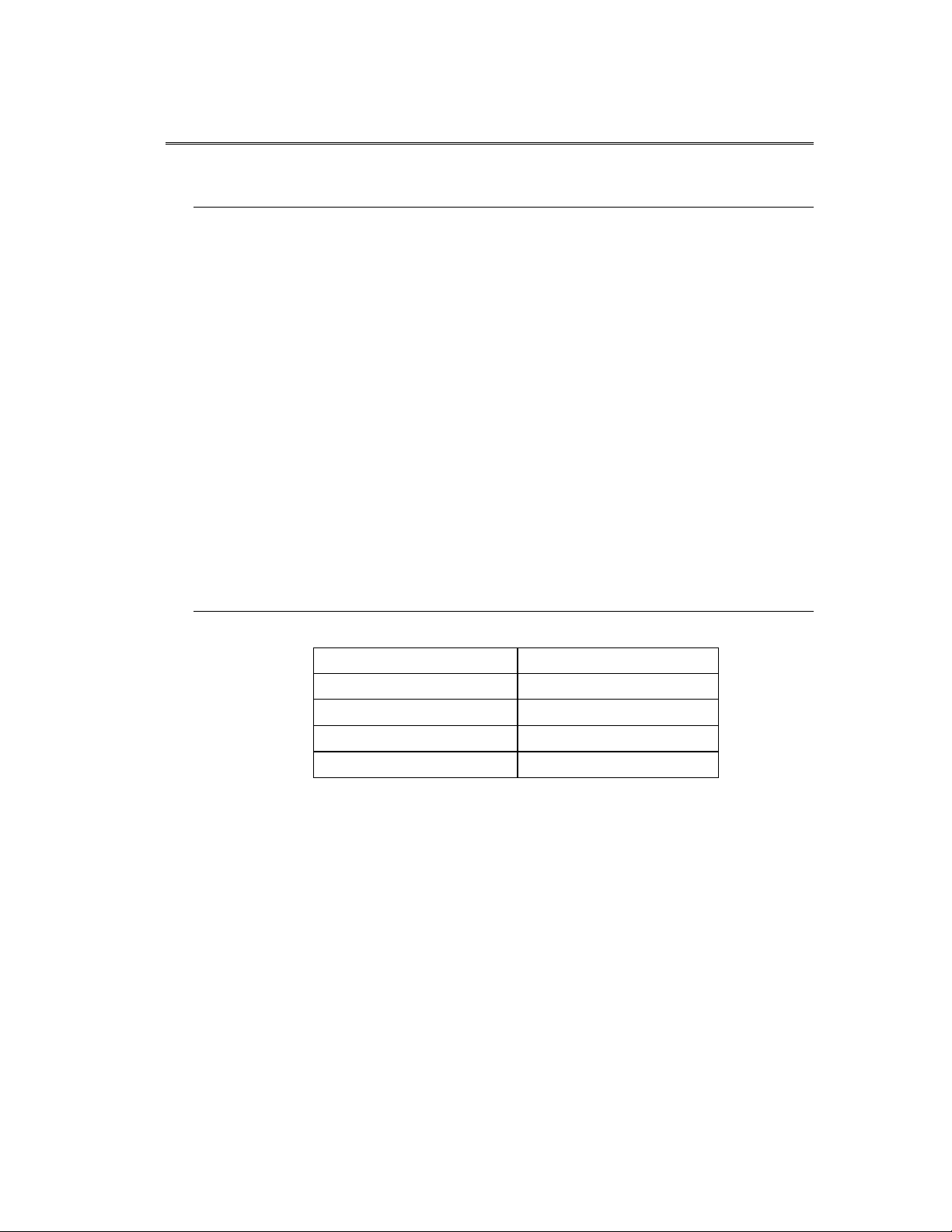

2.2. Electrical Specifications

Nominal AC Voltage 230 VAC

Input Frequency 50/60 Hz

Phase Single Phase

AMP 2.0

RPM 0.5/2.0 variable

Table 1: Electrical Specifications

©ETS-Lindgren—January, 2006

Rev. B—P#399771

11

Page 12

Model 2188 Turntable

2.2.1. Mechanical

Diameter 1.2 meter 1.5 meter 2.0 meter

Height

(Minimum)

Distributed

Load

Rating*

*Distributed Load Rating is based on an evenly distributed

load to each section. Point loads under 0.37 sq. m

(4 sq. ft) should not exceed 500 kg (1,100 lb.). Nothing over

400 kg (882 lb.) may be applied to a 45-degree segment

outboard of the casters.

16.51 cm

(6.12 in.)

500 kg

(1,100 lb)

Table 2: Mechanical Parameters

16.51 cm

(6.12 in.)

1,000 kg

(2,200 lb)

16.51 cm

(6.12 in.)

1,000 kg

(2,200 lb)

2.3. Turntable Installation Considerations

2.3.1. Conduit

Power and signal line paths must be planned in advance.

Power and signal lines must never run through the same

conduit. Conduit must be in place before pouring concrete

or installing the ground plane. Consider the size of the cable

bundle when selecting conduit diameter.

2.3.2. Electrical Considerations

A qualified and licensed electrical contractor must be used to

install power lines, and the installation should comply with all

applicable regulatory agencies. A dedicated circuit is

required with the shortest distance possible between the

power source and the turntable.

2.3.3. Access

12

An access area underneath the turntable is advisable for

large diameter installations. A service switch is necessary to

deactivate the turntable during service.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 13

Model 2188 Turntable

3. Installation

The turntable installation will vary based on the host location. Several

installation options may be presented in the steps that follow. Please

select the option that applies to your location.

The installation of turntables must be performed by a factory installation

specialist or by individuals who have been authorized by ETS-Lindgren to

do such work. Proper installation of the turntable directly affects

performance. The following installation information is provided to

familiarize the user of the turntable with the installation process.

CAUTION: Ensure power is off and secured before proceeding further.

3.1. Tools Required

• 3/16” Allen wrench

• ¼” Allen wrench

• 3/8” Allen wrenches, qty 3

• 6 mm Allen wrench

• 3/8” ratchet wrench

• 12” crescent wrench

• 15 mm, 12 point socket for

½” square head screws

• 7/16” open/box end wrench

• ½” open/box end wrench

• ¾” open/box end wrench

• 0.120 drill bit for 6-32 self

tapping screws

• #7 Drill bit for ¼-20 tap

3/8” hand drill

•

•

9/32 drill bit

• #2 Phillips screw bit

• #3 Phillips screw bit

• Measuring tape

• Pry bar

• Level

• Square

• Hacksaw

• Black marker

• File

• WD 40

• ¾” pipe clamp ends

• ¾” pipe (length depends on table

size 6 ft. will cover most tables)

• 1 – ½” C-clamps, qty 8

• Cutting Oil

• Syringe for applying conductive

grease

• Grease Gun

• Vacuum

• ½” Hammer Drill

CAUTION: Only qualified personnel must perform lifting of the

turntable assembly using a forklift or other lifting machinery.

Damage to the turntable or serious injury to the personnel may

occur.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

13

Page 14

Model 2188 Turntable

3.2. Unpacking

A qualified installer will perform the following steps in preparation for

installation of the turntable. Please pull the drawings from the back pocket

of this manual to assist in the installation directions that follow.

1. Uncrate all parts. Check all parts for any shipping damage. Ensure

a clear area is available to assemble the turntable unit safely.

NOTE: Do not discard any packing material or parts until the

turntable is fully assembled.

2. Verify that that fiber optic cable is long enough to reach from the

turntable to the control room. When working around the table,

avoid stepping on the fiber optic connectors located on the motor

base.

3. If the turntable is to be installed in a pit, check pit depth and inside

diameter and compare measurements with the drawings for your

turntable size at the back of this manual. The inner diameter of the

receptacle pit should be as follows:

• 1.2 meter turntable = 49.00” (+/-0.25”)

• 1.5 meter turntable = 60.00” (+/-0.25”)

• 2.0 meter turntable = 79.75” (+/-0.25”)

4. Remove the bolts that attach the top onto the turntable drive

assembly. These are the six flathead bolts closest to center of the

tabletop. Remove top and place in position as not to damage any

components on the top. Refer to the assembly drawing 2188-1.2,

2188-1.5 or 2188-2.0 included at the rear of this manual for more

details.

3.3. Positioning the Turntable

5. Using a forklift or other appropriate lifting device, place the turntable

bottom into position. The motorbase with the fiber optic connectors

should point in the direction that the fiber optic cable will be

installed. This position will reduce the chance of the cable being

kinked or twisted.

14

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 15

Model 2188 Turntable

Figure 1: Turntable Interior Design

Figure 2: Turntable Pit Locator Detail

©ETS-Lindgren—January, 2006

Rev. B—P#399771

15

Page 16

Model 2188 Turntable

6. Position the table as close as possible to the center. Attach the

measuring bar provided to the brass spacers mounted onto the

bearing. Note the appropriate hole-mount locations in reference to

the size of the turntable to be installed. Rotate the bearing and

ensure approximately

7/8” to 1” spacing exists between the edge of

the outer measuring bar and the diameter of hole cut into the pit.

Adjust if necessary.

7. Once the center is located, using a marker, mark around the

perimeter of the table base or outer floor plates. These marks may

be used for reference if the assembly moves during placement of

the floor shims or anchor plates.

NOTE: When installing the turntable on modular shielding, attempt

to make as many anchor holes miss the floor joint strips as possible

when positioning the table. Use the shim plates provided for this

application.

8. The Model 2188 turntable includes curved floor anchor plates that

are under the base unit. The 1.5m and 2.0m model includes an

outer ring of floor plates to support additional casters. Place

between the base unit and outer plates, the four connector strips

included to ensure proper spacing. Please refer to drawing number

2188-1.2, 2188-1.5 or 2188-2.0 included at the back of this manual

and figure two for the placement and securing of floor plates. If the

turntable is to be installed in a welded chamber with a steel pit and

steel raised floor, please refer to step 12.

3.4. Installing Anchor Plates

9. The anchor plates are held in place by ¼-20 screws and set collars.

Screw the anchor plates to the floor using #14x1” #3 square socket

flat head screws. Drill

up shavings so that you have good contact with the floor. Continue

mounting the rest of the plates.

10. Once all anchor plates are securely mounted, remove the ¼ -20

screws that hold the anchor plates to the base and discard.

11. Proceed to level the table to the raised floor.

1/8” pilot holes for these screws and vacuum

16

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 17

Model 2188 Turntable

12. When mounting to a steel pit and steel raised floor, a #7 drill bit for

tapping or a 9/32 drill bit to create “through holes” is required when

mounting anchor plates to the steel raised floor. Locate and mark

holes in each group of anchor plates. Drill and tap or drill through

each hole and then screw in ¼-20 hardware so that the table does

not move as you go around each location. Proceed with leveling

instructions.

CAUTION: Before leveling make sure all ½-13 flange nuts and

clamp collars are backed off all the way to avoid pulling plates off

the floor. Refer to drawings at the back of this manual.

13. Raise the table by turning the ½-13 square head screws clockwise

until the measuring bar top is 3/16” above the raised floor; this is

just a rough finish height. Check height with a leveling instrument

(torpedo laser level or some other device).

Once the table is leveled, tighten flange nuts on the square head

screws and secure set collars on the torque pins down onto the

base top surface and outer plate if applicable. Remove the

measuring bar. Refer to figure three and drawing 2188-1.2 at the

rear of the manual for more details.

3.5. Raised Panel Floor Flange Installation

Figure 3: Turntable Elevation View

The ground ring assembly includes a floor flange with a mounted

brush ring that interfaces with the contact ring mounted underneath

the turntable top. The floor flange provides constant electrical

contact with the ground plane.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

17

Page 18

Model 2188 Turntable

Mounting methods vary according to user specifications.

Clearance holes are provided, at evenly spaced intervals, along the

outside perimeter of the ground ring as a means of attaching the

ring to a customer supplied ground plane. These instructions cover

installation for a paneled floor; please see the section on “Floor

Flange Mounting in Concrete Pit” for further instructions regarding

mounting in a concrete pit.

For this step you will need three ¼” spacers i.e. bolts, drill bits, etc.

A hand drill, 5/32” drill bit, #3 Phillips drive bit, a small square, #14 x

1 wood/metal screws are also required at this time.

The turntables described in this manual each have two floor flange

pieces. All of the flanges are pre-cut at the factory for drop in fit.

Lay the floor flange into the opening of the raised floor and push

outward to the diameter of the opening. Attach the turntable top

onto the brass spacers with the hardware provided.

14. Using a pipe clamp and ¼” Allen wrenches or ¼” pin, place a

spacer between the turntable and flange starting in three places in

the center or on the flange. Once tension exists on all three

wrenches, drill a 5/32” hole through the counter-sunk holes in the

floor flange. Drill completely through the panel and place screws

into the holes. Continue working around the flange completing two

or three holes at a time. Refer to the 2188 1.2 drawing included for

details

NOTE: It is very important that a ¼” gap between turntable top and

ground brush flange mounted on floor flange be held as close as

possible so that the grounding brushes seat properly. Also, it is

important to ensure the flange ends are flush with each other.

15. Continue mounting as stated above until all screws have been

installed. Some screws may fall between the floor panel joints. Try

to position the flanges, ensuring as few screws hit these points as

possible, and making certain that the first or last hole in the flange

is not too close to one of these joints. Also, the top floor joint strips

will need to be trimmed to fit up against the flange.

3.6. Floor Flange Mounting in a Concrete Pit

Mounting to concrete is the same with the exception of the

mounting hardware. Instead of the #14 x 1” square socket flat head

screws, you will use ¼ x 1 3/4” Phillips flat head TAPCON screws.

18

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 19

Model 2188 Turntable

Figure 4:Turntable Motorbase

A ½” hammer drill, 3/16 x 3 ½” min. hammer drill bit, and a vacuum

to clean in holes drilled for maximum thread engagement will be

required for this stage of the installation.

NOTE: When drilling holes, watch out for buried conduit and pit

drainpipes. Drill 3/16” holes 2” min. depth.

3.7. Motorbase Attachment

Locate the box that contains the motorbase. The box also includes

the hardware needed to attach the motorbase to the turntable.

Refer to figure four above to locate the drive chain and bolts to

secure the motorbase. Slide the motorbase between the two rails

provided.

Attach three bolts, flat and lock washers provided on each side of

the motorbase, do not tighten them completely at this time.

Attach the chain around the bearing sprocket and the drive

sprocket. Adjust the mortorbase using the two pusher bolts

provided. Allow only ¼ inch maximum side-to-side motion for

proper chain tension on the motor. Finally, tighten the six securing

bolts.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

19

Page 20

Model 2188 Turntable

3.8. Final Leveling of the Table

Once the table is in place with the floor flange and wear strip

mounted, check that the table is level. Ensure that it is level and all

screws, nuts, and collars have been tightened.

3.9. Application of Conductive Grease

Before placing the turntable into operation, apply conductive grease

to the ground brush. Apply the contents of one tube of GC

Electronics conductive grease to the brush. Apply one tube per

meter size of the diameter of the table.

20

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 21

Model 2188 Turntable

4. Electrical Installation

CAUTION: Electrical connection should only be performed by a qualified

electrician and subject to local electrical codes.

The Model 2188 is designed to operate using 208-230 VAC single-phase

50 or 60Hz power.

The branch circuit supplying power to the motor base should be protected

from excess current according to local electrical codes. ETS-Lindgren has

provided integral circuit protection in the motor base assembly.

Check that the conductor size is adequate for the motor load and the

distance from the mains source. Improperly sized conductors will lead to

a high voltage drop in the power conductors and cause reduced starting

torque and premature motor failure.

The motor base assembly is provided with an IEC-320 power inlet for

connecting to the mains. Prior to servicing the turntable or the turntable

motor base, remove the power connection for safety.

Connect the fiber-optic control cable and install the power connection per

local electrical code. Please refer to the Model 2090 series positioning

controller manual for instructions on connecting the fiber optic cable. After

the fiber optic cable is installed secure it with a wire tie to one of the

leveling screws.

In order to feed the fiber optic connectors through the waveguide in a

chamber it may be necessary to remove part of the protective sheath.

The removal of a portion of the sheath will allow the connectors to fit

through the hole without bending or kinking the fiber optic cable

excessively. Find the spot in which you will need to remove the sheath

and mark. A very sharp knife is needed to make the splice. Being very

careful, cut around the outside of the sheath at each end of the area

needing to be cut, cut very lightly so as to not cut into the fiber cables.

You should then be able to bend the sheath back and forth until you can

see the fiber cables.

Next, you will need to make a cut down the length of sheath area, being

careful not to cut into fiber cable. You will see two pieces of white string

inside the sheath. Find the string and use it to split the sheath open. Now

insert the cable into the waveguide.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

21

Page 22

Model 2188 Turntable

This page intentionally left blank.

22

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 23

Model 2188 Turntable

5. Operation

Please refer to the Model 2090 series positioning controller manual if you

are unfamiliar with the operation of the unit. A manual is included with

each positioning controller shipment and is also available for download

from our website, www.ets-lindgren.com.

With the assembly of the turntable complete the Model 2090 series

controller must be connected to the unit and power applied to both the

motor base and controller in order to continue. Refer to the electrical

installation section if you have questions about how to connect the fiber

optic cables.

Using the Model 2090 series positioning controller check the CW

(clockwise) and CCW (counter clockwise) rotation in both directions by a

few degrees. The position in degrees increases (+) in the CW direction

and decreases (-) in CCW direction.

The turntable is calibrated in the factory to read out 360 degrees

(+ or - 1 degree) for one complete revolution. If the table is not within this

accuracy, the unit can be re-calibrated per the instructions in the

“Turntable Encoder Calibration” section below.

5.1. Editing Positioning Controller Configuration Parameters

To edit a configuration parameter, press the PARAM key to display

the current parameter. Pressing the PARAM key repeatedly will

scroll down through the parameter list, showing each parameter in

turn. While viewing a parameter, the STEP keys (INC/DEC) may

be used to scroll up or down the parameter list. This reduces the

effort necessary to scan through a long parameter list using the

PARAM key. Pressing any of the LIMIT/POSITION selection keys

will return the display to that selection. Pressing any of the

remaining motion keys will return the display to the current position

and execute that motion. Pressing the PARAM key again will

return to the last displayed parameter in the list, allowing easy

transition between parameter adjustment and device operation.

Once the desired limit, position or parameter is visible in the display

window, pressing INCRM, DECRM, or ENTER will toggle into edit

mode. The lowest adjustable digit will flash on and off. Pressing

the LOCAL key for that device will switch the flashing digit to the

next higher digit. In this way, it is possible to rapidly adjust any digit

of a multi-digit parameter or limit.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

23

Page 24

Model 2188 Turntable

5.2. Setting Travel Limits

Figure 5: Turntable Limit Switch

The Model 2188 is fitted with mechanically actuated or “hard” limit

switches. These switches are adjustable to allow for limited travel

beyond zero and 360 degrees. Actuation pins are placed in the

turntable top to engage the limit switch mechanism. The limit

switch mechanism is designed so that the amount of travel is

dictated by the pin position in the turntable top.

The default configuration allows for travel between –45 degrees

and +405 degrees. Remove all pins and the access panel. Move

the turntable so that the access hatch is directly above the limit

switch mechanism (shown in Figure five above). Set the

mechanism to the CCW armed position and insert actuations pins

in the holes on either side of the mechanism 45 degrees away.

Now, set the current position displayed by the controller to 000.0

degrees. Test the lower limit by holding down the DEC key, which

allows the turntable to travel past the soft limit. The turntable

should engage the lower hard limit between -35 and -55 degrees.

You can also test the upper limit by holding down the INC key until

the upper limit is engaged between 395 and 415 degrees.

It is also advised that the user properly set the “soft” limits in the

controller should non-continuous operation be desired.

24

To set the counterclockwise rotational limit for the turntable, press

the DOWN/CCW key under LIMIT. The indicator above this key will

light. Set the limit by pressing the INCRM and DECRM keys under

LIMIT until the desired limit is shown on the display. Then, press

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 25

Model 2188 Turntable

the ENTER key. To set the clockwise rotational limit for the

turntable, press the UP/CW key under LIMIT. The indicator light

above this key will light. Set the limit by pressing the INCRM and

DECRM keys under LIMIT until the desired limit is shown on the

display. Press the ENTER key.

WARNING: Ensure the current travel limit settings will not cause

damage to existing cables and equipment located underneath the

turntable.

Should continuous operation be desired, the Model 2090 series

controller permits easy configuration to this type of operation from

the front panel or through the IEEE-488 interface bus. Refer to the

positioning controller manual for more information. The limit pins

should also be removed form the turntable top to allow for

continuous operation.

5.3. Turntable Encoder Calibration

Parameter C, which calibrates the encoder counts to the rotation of

the turntable, must be set to the value 3600. Parameter C Refers to

the encoder calibration parameter. This setting is used to convert

the encoder count values returned from a motor base into the

corresponding centimeter or degree position reading. For

turntables, this represents the number of encoder counts per

revolution. The setting for the Model 2188 turntable series is 3600.

If the given value does not appear to work correctly, the encoder

calibration value can be determined using the following procedure:

1. Set the encoder calibration value to 3600.

2. Ensure that the turntable is positioned to allow more than a full

revolution of travel in the clockwise direction and use the STEP

keys to run the turntable clockwise a few degrees to remove any

play in the table.

3. Mark the current location of the turntable against the ground ring

(masking tape works well for marking), and set the current

position reading to 000.0.

4. Using the STEP keys, rotate the turntable clockwise until it is

again aligned with the mark on the ground ring. For best

results, the last motion should always be in the clockwise

direction to ensure that any play in the gearing between the

motor and encoder is accounted for.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

25

Page 26

Model 2188 Turntable

5. Record the reading of the display, ignoring the decimal point

(i.e. 360.0 would be 3600). This is the encoder calibration

value.

NOTE: If the value is below 3600, the resolution of the encoder

is low and consequently the controller will not provide 0.1degree resolution, even though the display shows that digit. If

the value has gone past 9999, the encoder has too many counts

per meter and the controller cannot correct for it. In this case,

contact ETS-Lindgren for assistance.

6. Enter the encoder calibration value and reset the limits and

position information.

7. Test the turntable by moving it a complete revolution and

comparing the alignment marks. It may be necessary to adjust

the encoder calibration value up or down slightly depending on

the result.

NOTE: When scanning between limits, it is not uncommon to

have a small discrepancy between the absolute position of the

table and the display on the controller. This is because

reversing the direction of rotation reverses any gear play

between the encoder and the table top, allowing that play to be

visible in the positioning accuracy.

5.3.2. Turntable Calibration Example

• The table is set at the “0” degree position. A piece of tape is

placed on the edge of the turntable to line up with the edge

of the gearbox cover. The table is stopped when the tape

travels exactly 360 degrees around. The display on the

controller now reads 356.3 degrees, which is recorded.

• The table is rotated CCW back to zero. The parameter

button is set on the “C” setting. The “C” digits display 3430.

A new “C” setting is now calculated:

• New “C” = (356.3 divided into 360) times 3430 = 3395

(rounded off).

• The decrement the C parameter to 3395 and “ENTER” is

pressed. The “current position” button is pressed to get back

to operation mode.

26

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 27

Model 2188 Turntable

• The table is rotated from 0 to 360 and the mark is now within

one degree of being one full turntable revolution. Calibration

is complete.

5.4. Changing Rotation Speed

The Model 2188 turntable is equipped with a variable speed drive.

Firmware Revision 3.11 (or higher) must be installed in the Model

2090 series controller for proper operation of the Model 2188. The

revision level is displayed on the front panel LED display during

startup of the Model 2090 series controller. If the controller does

not have this or a later revision installed, consult the factory for an

upgrade.

To select one of the four speeds, use the POLAR/SPEED button to

toggle through the speed options. It is necessary to set the

controller parameters to configure the controller to properly control

the motor base. Refer to the controller manual to the section that

describes setting the parameters.

Specifically, parameter two must be set to the value three, which is

for variable speed control. Parameter C, which calibrates the

encoder counts to the rotation of the turntable, should be set to the

value 5440. This will insure that the position display will properly

report the full 360 degrees of travel.

5.5. Variable Speed Settings

The Model 2090 series controller parameters S1-S4 control the

variable speed settings for the turntable. These parameters are the

continuous variable speed settings for each of the four speed

selections described below. Each of these parameters can be set

to any value from 1 to 255, with the resulting turntable speed being

roughly an S/255 fraction of the maximum speed. Note that it is the

nature of variable speed drives that there is a minimum speed at

which the motor will operate. For the Model 2188 this minimum

speed setting will be somewhere between 30-75 and should

correspond to a value of 0.5 RPM or less. Below this setting, the

motor will not be able to cause rotation, but will be active until a

Motor Not Moving error (E002) occurs.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

27

Page 28

Model 2188 Turntable

WARNING: Do not operate the turntable in a stalled condition.

Doing so may cause damage to the drive unit and will nullify your

warranty. Always insure that the minimum speed setting specified

in the S1-S4 parameters is above the minimum value at which your

table will turn under normal load.

5.6. Speed Selection

For the Variable Speed Turntable, the Polarization/Flotation button

provides the ability to cycle between the eight preset speeds

described above. For each press of the button, the turntable will

change to the next speed setting. The polarization LEDs will light

to indicate the speed selection in a binary fashion as shown below:

• Speed 1: Both off

• Speed 2: Top on, bottom off

• Speed 3: Top off, bottom on

• Speed 4: Both on

• Speed 5: Both off

• Speed 6: Top on, bottom off

• Speed 7: Top off, bottom on

• Speed 8: Both on

Each speed setting has its own individual overshoot compensation

value to provide proper overshoot correction for each speed

selection.

28

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 29

Model 2188 Turntable

5.7. GPIB Commands

The following GPIB commands have been added or modified:

• Sn: Select Speed, where n is 1 or 2 for a two-speed turntable

and 1-4 for a variable speed turntable.

• S?: Query speed selection. Returns 1 or 2 for a two-speed

turntable and 1-4 for a variable speed turntable.

• SSn: Set Speed Value, where “n” is 1-4. This command is valid

only for a variable speed turntable. Valid speed values are from

1 to 255.

Command Usage: SSn <Speed>

Example: Output 708, "SS1 196;"

• Query Speed Value, where “n” is 1-4. This command is valid

only for a variable speed turntable. Returns a speed value from

1 to 255.

Command Usage: SSn?

Example: Output 708, "SS2?;"

5.8. Controller Interface

©ETS-Lindgren—January, 2006

Rev. B—P#399771

29

Page 30

Model 2188 Turntable

This page intentionally left blank.

30

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 31

Model 2188 Turntable

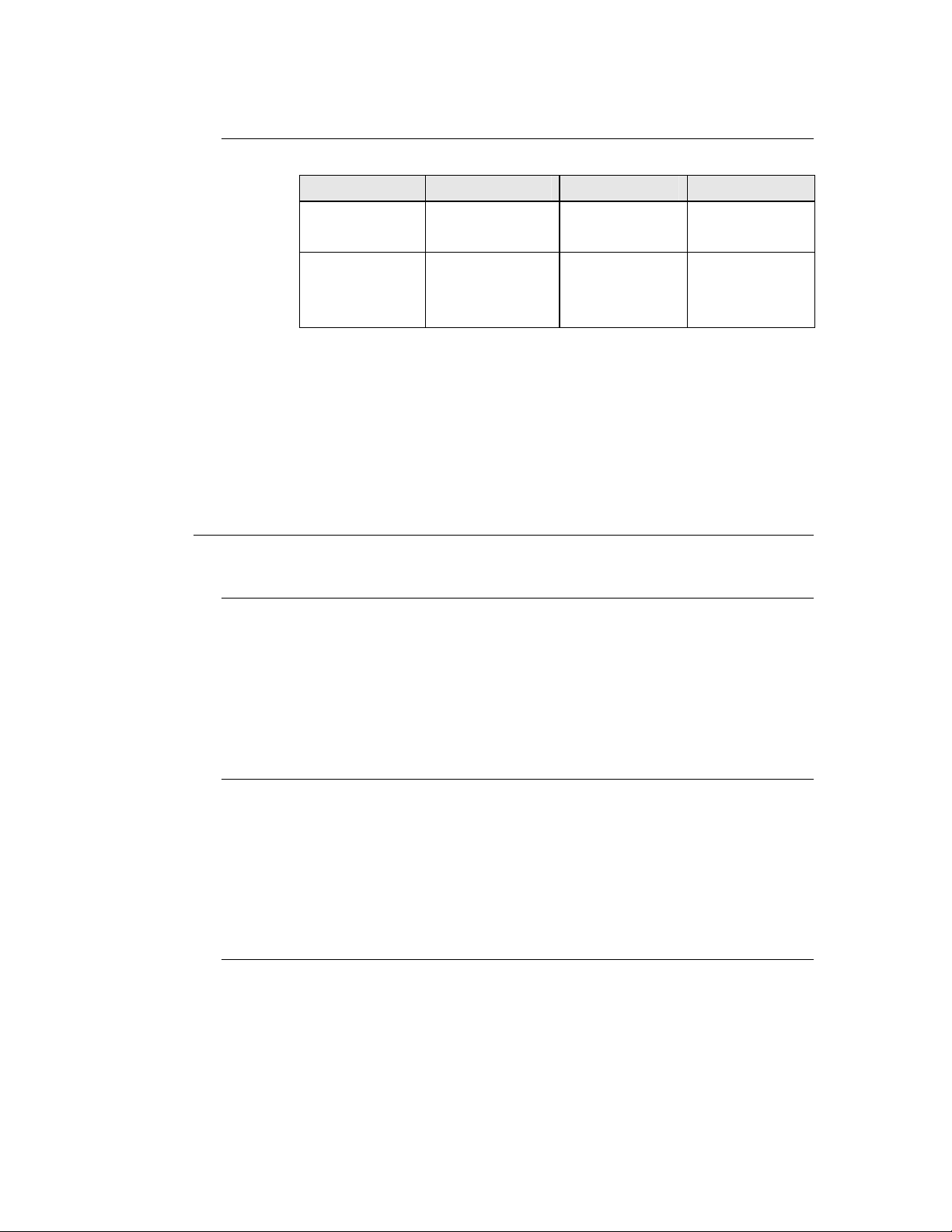

6. Infrared Controller

The motor base features an infrared receiver that will respond to a

universal remote control programmed to a specific protocol. Any remote

that continuously transmits and contains the proper TV protocol can be

used.

The basic functions supported are as follows:

Button Command

Power Emergency Stop

Channel Up Up for linear positioner

Channel Down Down for linear positioner

Volume Left Counterclockwise for rotational

positioner

Volume Right Clockwise for rotational

positioner

Mode Polarization for linear positioners

Table 3: Controller Functions

State 1 2 3 4

Power

Init

Up/CW

Down/CCW

Polar

Upper Limit

Lower Limit

Any Any Any Any

Cycling Amber

Green

Green

Green

Red

Red

Table 4: Motorbase Status Indicators

©ETS-Lindgren—January, 2006

Rev. B—P#399771

31

Page 32

Model 2188 Turntable

This page intentionally left blank.

32

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 33

Model 2188 Turntable

7. Recommended Maintenance

CAUTION: Do not perform maintenance while turntable is operating.

Disconnect the power connection for safety. Only qualified individuals

should conduct these maintenance inspections.

Regular maintenance will prolong the serviceable life of your turntable.

Follow this recommended schedule. Use the inspection log that follows to

maintain a record of maintenance described below.

7.1. Routine Maintenance

Routine maintenance should be conducted prior to each use of the

turntable.

• Visually inspect the turntable prior to use. Look for foreign

objects in the gap between the turntable top and the floor

flange. If possible, remove the objects to eliminate damage to

the turntable.

• Attempt to rotate the top by hand. Excessive rotation may

indicate a loose drive component.

• Listen for excessive or unusual noise during turntable operation.

7.2. Bi-Annual Maintenance

These maintenance items should occur every six months once the

turntable is put into operation. Prior to conducting any of the

following items, remove the turntable top.

• Grease the casters. Use a good quality bearing grease to

lubricate the casters. Using synthetic grease, grease all

casters. Mobil 1 synthetic and a standard SAE grease gun is

recommended; do not use lithium grease.

• Inspect the ground brush for contaminates. Vacuum the brush

to remove unwanted debris. Add a small amount of conductive

lubricant to the brush interface if required.

• Inspect the ground brush for wear. A well maintained ground

brush should have a long serviceable life.

• Replace the ground brush.

©ETS-Lindgren—January, 2006

Rev. B—P#399771

33

Page 34

Model 2188 Turntable

7.3. Annual Maintenance

These maintenance items should occur every twelve months after

the turntable is put into service.

• Lubricate the main bearing race. Use a grease gun with a good

quality bearing grease. The grease fittings are located inside

the race, 90 degrees apart, underneath the top. Three

discharges from the grease gun in each fitting are adequate.

Using synthetic grease, grease all casters. Mobil 1 synthetic is

recommended; do not use lithium grease.

• Lubricate the chain and sprocket of the chain drive. Apply good

quality grease to the chain and sprocket; do not use lithium

grease.

34

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 35

Model 2188 Turntable

EMCO Model 2188 Turntable Maintenance Log

Routine Bi-Annual Annual Routine Bi-Annual Annual Routine Bi-Annual Annual

Routine Check

Remove foreign

objects between

turntable top and

floor flange

Check for

excessive rotation

by hand

Listen for

excessive noise

Bi-Annual Check

Grease the casters

Inspect the ground

brush for

contaminates

Inspect the ground

brush for wear,

replace if

necessary

Annual Check

Lubricate the main

bearing race

Lubricate chain

and sprocket of the

chain drive

Table 6: Turntable Maintenance Log

©ETS-Lindgren—January, 2006

Rev. B—P#399771

35

Page 36

EMCO Model 2188 Turntable

This page intentionally left blank.

36

©ETS-Lindgren—October, 2005

Rev. A—Part#399771

Page 37

8. Warranty

SCOPE AND DURATION OF WARRANTIES

Seller warrants to Buyer that the Standard EMCO Brand Products Excluding 5211 & 5220 be (1) free

from defects in material, manufacturing workmanship, and title, and (2) conform to the Seller’s

applicable product descriptions and specifications, if any, contained in or attached to Seller’s quotation.

If no product descriptions or specifications are contained in or attached to the quotation, Seller ’s

applicable product descriptions and specifications in effect on the date of shipment shall appl y. The

criteria for all testing shall be Seller’s applicable product specifications utilizing factory-specified

calibration and test procedures and instruments.

All product warranties, except the warranty of title, and all remedies for warranty failures are limited in

time as shown in the table below.

Product Warranted Duration of Warranty Period

Standard EMCO Brand Products Excluding

5211 & 5220

Any product or part furnished to Buyer during the warranty period to correct a warranty failure shall be

warranted to the extent of the unexpired term of the warranty applicable to the repaired or replaced

product.

The warranty period shall commence on the date the product is delivered to Buyer; however, if Seller

assembles the product, or provides technical direction of such assembly, the warranty period for such

product shall commence on the date the assembly of the product is complete. Notwithstanding the

foregoing, in the event that the assembly is delayed for a total of thirty (30) days or more from the date

of delivery for any reason or reasons for which Seller is not responsible, the warranty period for such

product may, at Seller’s options, commence on the thirtieth (30th) day from the date such product is

delivered to Buyer. Buyer shall promptly inspect all products upon delivery. No claims for shortages will

be allowed unless shortages are reported to Seller in writing within ten (10) days after delivery. No other

claims against Seller will be allowed unless asserted in writing within thirty (30) days after delivery (or

assembly if the products are to be assembled by Seller) or, in the case of alleged breach of warranty,

within the applicable warranty period.

WARRANTY EXCLUSIONS

Except as set forth in any applicable patent indemnity, the foregoing warranties are exclus ive and in lieu

of all other warranties, whether written, oral, express, implied, or statutory. EXCEPT AS EXPRESSLY

STATED ABOVE, SELLER MAKES NO WARRANTY, EXPRESS OR IMPLIED, BY STATUTE OR

OTHERWISE, WHETHER OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE

OR USE OR OTHERWISE ON THE PRODUCTS, OR ON ANY PARTS OR LABOR FURNISHED

DURING THE SALE, DELIVERY OR SERVICING OF THE PRODUCTS. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

Warranty coverage does not include any defect or performance deficiency (including failure to conform

to product descriptions or specifications) which results, in whole or in part, from (1) negligent storage or

handling of the product by Buyer, its employees, agents, or contractors, (2) failure of Buyer to prepare

the site or provide an operating environmental condition in compliance with any applicable instructions

or recommendations of Seller, (3) absence of any product, component, or accessory recommended by

Seller but omitted at Buyer’s direction, (4) any design, specification, or instruction furnished by Buyer, its

employees, agents or contractors, (5) any alteration of the product by persons other than Seller, (6)

combining Seller’s product with any product furnished by others, (7) combining incompatible products of

Seller, (8) interference with the radio frequency fields due to conditions or causes o utsid e the product as

furnished by Seller, (9) improper or extraordinary use of the product, or failure to comply with any

applicable instructions or recommendations of Seller, or (10) acts of God, acts of civil or military

authority, fires, floods, strikes or other labor disturbances, war, riot, or any other causes beyond the

reasonable control of Seller. This warranty does not cover (1) contact fingers or replacements unless

loss is caused by a defect in material or manufacturing workmanship within the scope of this warranty

(2) items designed to be consumable and (3) removal and reconstruction of walls, partitions, ceilings

and other facility costs arising from repair or replacement of the product or parts thereof by Seller under

the warranty. Seller does not warranty products of others which are not included in Seller’s published

price lists for shielding products and systems supplies and accessories.

2 Years

©ETS-Lindgren—January, 2006

Rev. B—P#399771

37

Page 38

Model 2188 Turntable

BUYER’S REMEDIES

If Seller determines that any product fails to meet any warranty during the applicable warranty period,

Seller shall correct any such failure by either, at its option, repairing, adjusting, or replacing without

charge to Buyer any defective or nonconforming product, or part or parts of the product. Seller shall

have the option to furnish either new or exchange replacement parts or assemblies.

Warranty service during the applicable warranty period will be performed wit ho ut charge to Buyer within

the contiguous 48 United States during Seller’s normal business hours. After the warranty period,

service will be performed at Seller’s prevailing service rates. Subject to the availability of personnel,

after-hours service is available upon request at an additional charge. For service outside the contiguous

48 United States, travel and per diem expenses, when required, shall be the responsibility of the Buyer,

or End User, whichever is applicable.

The remedies set forth herein are conditioned upon Buyer promptly notifying Seller within the applicable

warranty period of any defect or nonconformance and making the product availab le for correction.

The preceding paragraphs set forth Buyer’s exclusive remedies and Seller’s sole liability for claims

based on failure of the products to meet any warranty, whether the claim is in contract, warranty, tort

(including negligence and strict liability) or otherwise, and however i nstituted, and, upon the expiration

of the applicable warranty period, all such liability shall terminate. IN NO EVENT SHALL SELLER BE

LIABLE TO BUYER FOR ANY SPECIAL INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES

OF ANY KIND ARISING OUT OF, OR AS A RESULT OF, THE SALE, DELIVERY, NON-DELIVERY,

SERVICING, ASSEMBLING, USE OR LOSS OF USE OF THE PRODUCTS OR ANY PART

THEREOF, OR FOR ANY CHARGES OR EXPENSES OF ANY NATURE INCURRED WITHOUT

SELLER’S WRITTEN CONSENT DESPITE ANY NEGLIGENCE ON BEHALF OF THE SELLER. IN NO

EVENT SHALL SELLER’S LIABILITIES UNDER ANY CLAIM MADE BY BUYER EXCEED THE

PURCHASE PRICE OF THE PRODUCT IN RESPECT OF WHICH DAMAGES ARE CLAIMED. This

agreement shall be construed in accordance with laws of the State of Illinois. In the event that any

provision hereof shall violate any applicable statute, ordinance, or rule of law, such provision shall be

ineffective to the extent of such violation without invalidating any other provision hereof.

Any controversy or claim arising out of or relating to the sale, delivery, nondelivery, servicing,

assembling, use or loss of use of the products or any part thereof or for any charges or expenses in

connection therewith shall be settled in Austin, Texas by arbitration in accordance with the Rules of the

American Arbitration Association, and judgment upon the award rendered by the Arbitrator ma y be

entered in either the Federal District Court for the Western District of Texas or the State District Court in

Austin, Texas, all of the parties hereto consenting to personal jurisdiction of the venue of such court and

hereby waive the right to demand a jury trial under any of these actions.

38

©ETS-Lindgren—January, 2006

Rev. B—P#399771

Page 39

9. Addendum A: Drawings

Please locate the drawings placed in pocket of the back cover of this

manual. Drawings include ETS-Lindgren drawing numbers:

• 2188-1.23B

• 2188-1.53 rev. 2

• 2188-2.03 rev. 1

• 108912C

• 110053B

• 110277 rev. 2

• 110406 rev. 2

• 398790

©ETS-Lindgren—January, 2006

Rev. B—P#399771

39

Loading...

Loading...