Page 1

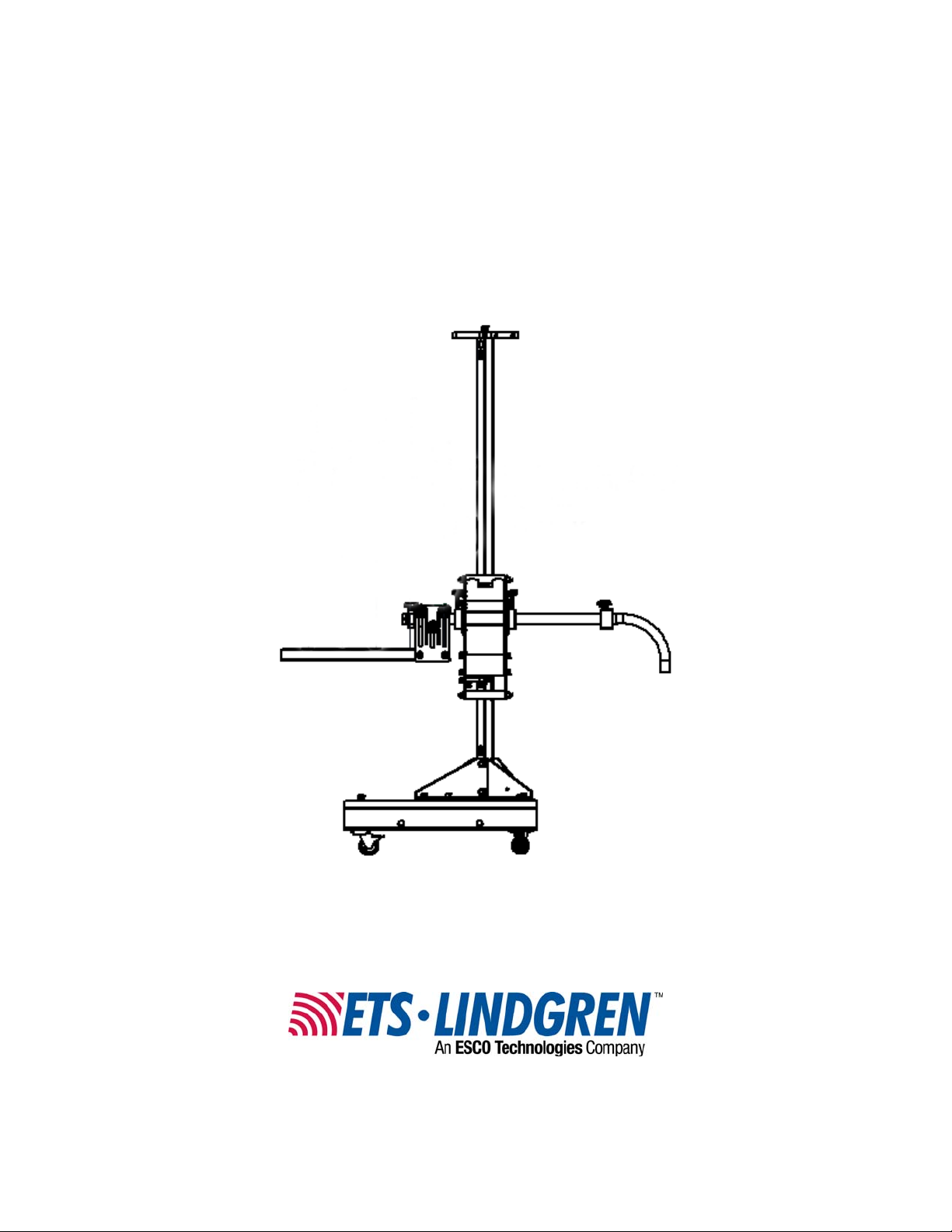

Model 2175 MiniMast™

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any products herein to improve

functioning or design. Although the information in this document has been carefully reviewed and

is believed to be reliable, ETS-Lindgren does not assume any liability arising out of the

application or use of any product or circuit described herein; nor does it convey any license under

its patent rights nor the rights of others. All trademarks are the property of their respective

owners.

© Copyright 2005–2008 by ETS-Lindgren L.P. All Rights Reserved. No part of this

document may be copied by any means without written permission from ETS-Lindgren

L.P.

Trademarks used in this document: The ETS-Lindgren logo and MiniMast are trademarks of

ETS-Lindgren L.P.

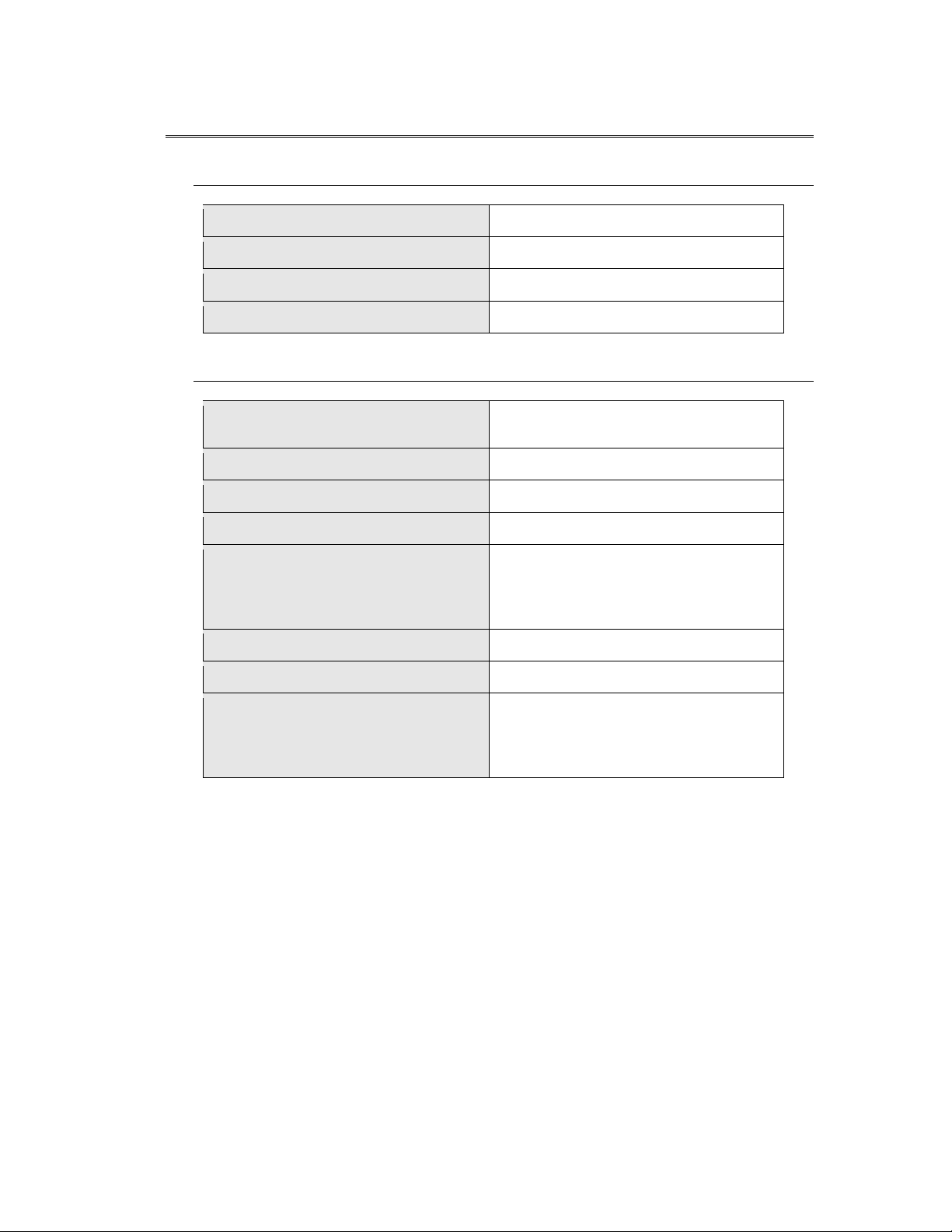

Revision Record | Model 2175 MiniMast, MANUAL | Part #399770, Rev. C

Revision Description Date

A

B

C

Initial Release April, 2005

Updates November, 2005

Design updates; rebrand September, 2008

ii |

Page 3

Table of Contents

Notes, Cautions, and Warnings ......................................................................... v

1.0 Introduction ................................................................................................... 7

Standard Configuration ............................................................................................................. 8

Optional Items ........................................................................................................................... 9

ETS-Lindgren Product Information Bulletin .............................................................................. 9

2.0 Maintenance ................................................................................................ 11

Maintenance Recommendations ............................................................................................ 11

Routine Check .................................................................................................................. 11

Six-Month Check .............................................................................................................. 12

Replacement and Optional Parts ............................................................................................ 12

Service Procedures ................................................................................................................. 12

3.0 Specifications .............................................................................................. 13

Electrical Specifications .......................................................................................................... 13

Physical Specifications ............................................................................................................ 13

4.0 Assembly and Installation .......................................................................... 15

Product Assembly ................................................................................................................... 16

Electrical Installation ............................................................................................................... 23

Connecting the Controller ....................................................................................................... 24

Carrier Safety Brake ................................................................................................................ 25

5.0 Operation ..................................................................................................... 27

Editing the Controller Configuration Parameters .................................................................... 27

MiniMast Encoder Calibration ................................................................................................. 27

Antenna Mounting Instructions ............................................................................................... 28

Pre-Operational Checks .......................................................................................................... 30

Start-Up and Safe Shutdown .................................................................................................. 30

Infrared (IR) Controller ............................................................................................................ 30

Appendix A: Warranty ...................................................................................... 33

Appendix B: Drawings ...................................................................................... 35

Appendix C: EC Declaration of Conformity .................................................... 37

| iii

Page 4

This page intentionally left blank.

iv |

Page 5

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to provide tips for

better use of the product.

Caution: Denotes a hazard. Failure to follow instructions

could result in minor personal injury and/or property

damage. Included text gives proper procedures.

Warning: Denotes a hazard. Failure to follow instructions

could result in SEVERE personal injury and/or property

damage. Included text gives proper procedures.

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

| v

Page 6

This page intentionally left blank.

vi |

Page 7

1.0 Introduction

The ETS-Lindgren Model 2175 MiniMast™ is a portable, electric-powered mast

and platform system designed to be used with the Model 2090 Multi-Device

Controller (or next generation ETS-Lindgren controller, if applicable) for EMI

compliance testing. The MiniMast is designed for antenna scanning from 1 meter

to 4 meters. The mast, carrier, platform, lifting rope, and guying system are

non-conductive and non-magnetic. The mast section is constructed of square

fiberglass tubing for strength, rigidity, and “weatherability”.

The MiniMast may also be manufactured in custom mast heights. Contact your

local sales representative for additional information regarding custom height.

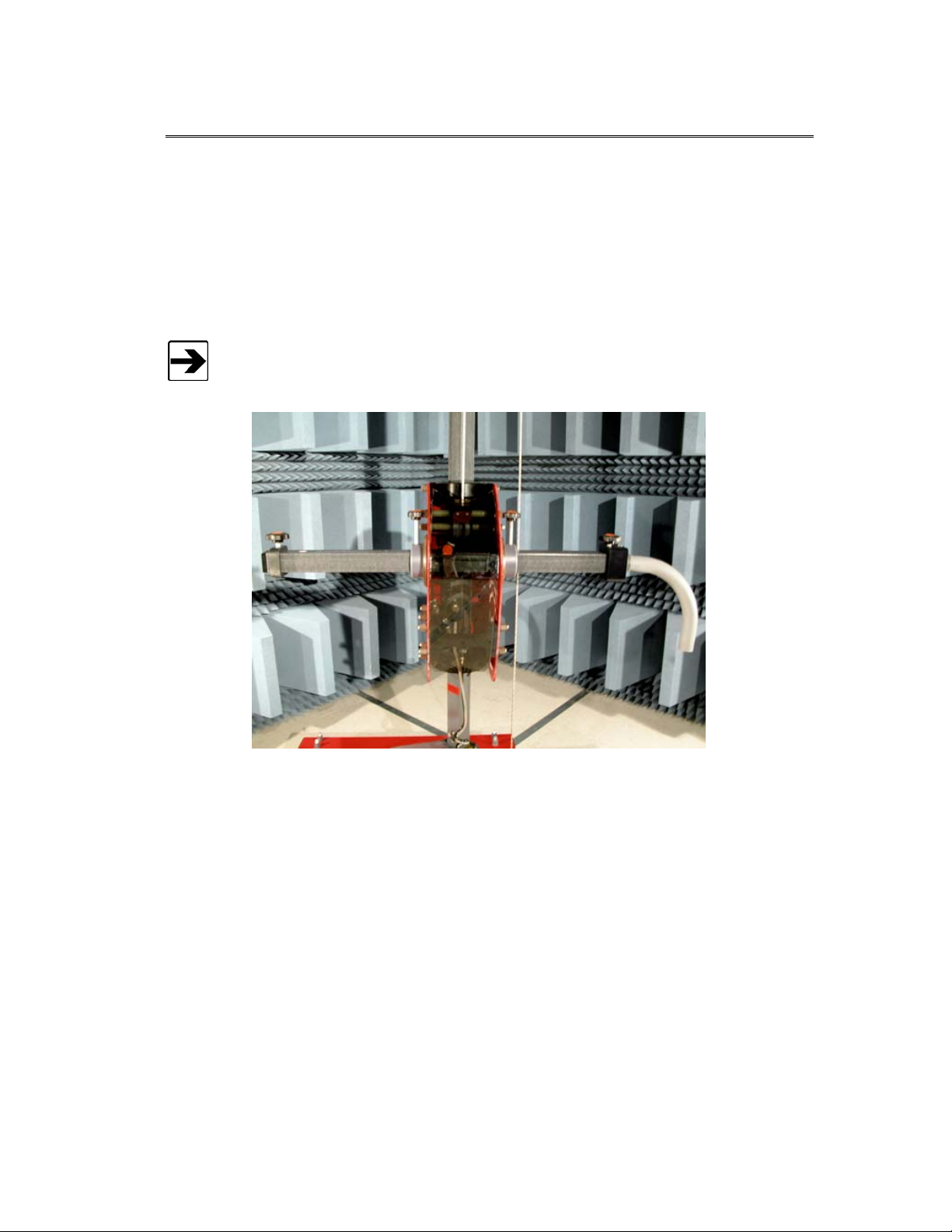

The MiniMast features an offset boom that maintains a constant rotational axis

along the centerline when the antenna is rotated from horizontal to vertical

polarization. A cable guide at the back end of the boom feeds the coaxial cable to

the antenna while maintaining the appropriate bending radius.

The air polarization feature allows for remote polarization of the antenna using

the controller or the infrared remote control.

For antennas with a stinger mount, the offset boom can be removed. The

antenna stinger is then clamped into the mounting block using the hand knob.

Introduction | 7

Page 8

The antenna carrier is raised and lowered by a fractional horsepower, electric,

variable speed motor. A worm-type gearbox driven by the motor provides the

adequate torque needed to raise and lower the carrier and prevents the carri er

from back-driving the motor. The motor and associated electronics are contained

in a shielded enclosure mounted beneath the platform of the unit. Under

command of the controller, the motor typically positions the carrier within

one centimeter of the desired location. To prevent over travel of the carrier in

either direction of movement, the mast system has integral fiber optic limits. Soft

limits may be set within the travel range provided by the mechanical limits using

the controller.

The motor base is connected to the controller through a twin fiber optic cable

assembly. This fiber optic cable transmits both directional control and position

information. Power to the motor base is provided locally to the motor through a

detachable, grounded power cable.

A carrier brake is mounted on the carrier assembly. In the event that the carrier is

released from the rope suspension, a spring-loaded cam locks the brake into

position against the mast and locks the carrier so that further vertical movement

is restricted.

The carrier brake is intended to provide some protection to the

carrier and the antenna; it is not a fail-safe brake for protection

to personnel. Personnel operating this equipment should be

instructed to stay clear of the carrier and boom at all times

whether or not the carrier is moving.

Polypropylene braided rope guy lines are provided for installations requiring the

mast to be guyed and must be firmly anchored for vertical stability. Use of the

guy lines is recommended in all applications to provide maximum stability.

Standard Configuration

• Motor, 220 VAC, nominal

• Input frequency 50 or 60 Hz

• Tower platform casters for movement of the unit

• Offset antenna mount

• Stinger antenna mount

• 10-meter fiber optic control cable for inside chamber

8 | Introduction

Page 9

• 3-meter fiber optic control cable for connection to Model 2090 controller (or

next generation ETS-Lindgren controller, if applicable) outside chamber

• Two ST-to-ST bulkhead feedthroughs provide a means to penetrate a shield

wall and maintain the integrity of the shielded enclosure

• Air polarization (adjustable speed)

• Infrared (IR) Remote

Optional Items

• Model 2090 Multi-Device Controller (or next generation ETS-Lindgren

controller, if applicable): This controller provides control for two separate

devices (for example, towers and turntables) in any combination, plus the

control of four auxiliary devices through a fiber optic interface. The unit

includes a GPIB connection and is compatible with most popular EMI

measurement software.

• Universal Antenna Mount: This option is a versatile and sturdy mount for

most common antennas.

• Additional Fiber Optic Cable: Various lengths of fiber optic cable are

available by custom order.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS Lindgren calibration service

• ETS Lindgren contact information

Introduction | 9

Page 10

This page intentionally left blank.

10 | Introduction

Page 11

2.0 Maintenance

Maintenance of the Model 2175 MiniMast™ is limited to external components

such as cables or connectors. If you have any questions concerning

maintenance, contact ETS-Lindgren Customer Service.

Maintenance Recommendations

Regular maintenance will prolong the service of your mast assembly. If excessive

wear or damage is found during any of the recommended checks, the system

must be taken out of service and repaired before proceeding. Pneumatic tubing

that appears to be brittle and worn from the effects of UV radiation and inclement

weather should be replaced. Lubricant may be purchased from ETS-Lindgren;

contact the Sales Department at +1-512-531-6400 and request item #890437.

Before performing any maintenance, follow the safety

information in the ETS-Lindgren Product Information Bulletin

included with your shipment. Warranty may be void if

maintenance is performed incorrectly.

Before performing any maintenance, disconnect the unit and

turn off power.

ROUTINE CHECK

• Prior to beginning normal operation of the mast, check the mast and

lift system for any signs of damage or excessive wear.

• Checks the lift rope for excessive wear.

• Check the mast and carrier for any signs of damage or excessive

wear.

• Check the guy line(s) to ensure safe and secure and check for

excessive wear.

• Verify the height readout of the controller and the physical position of

the mast are the same.

• Verify the antenna is secure.

• Check routing of all cables to make sure they do not interfere with

the operation of the mast.

Maintenance | 11

Page 12

SIX-MONTH CHECK

• Check the lift rope and guy line for signs of wear.

• Inspect the components and tubing of the pneumatic polarization

mechanism for signs of corrosion, excessive moisture, and wear.

• Lubricate the air cylinder O-rings to prevent excessive wear.

• Check all cabling to the motor base for frayed and worn insulation.

Replacement and Optional Parts

See the drawings located in the back pocket of this manual for the part numbers

to order replacement or optional parts for the MiniMast.

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

12 | Maintenance

Page 13

3.0 Specifications

Electrical Specifications

Nominal AC Voltage

Input Frequency

Current Rating

Phase

Physical Specifications

Base Dimensions

Weight

Overall Height

Mast Height

Scan Range

Required Air Pressure

220 VAC

50/60 Hz

10 Amp service

Single

0.90 m x 0.90 m

2.95 ft x 2.95 ft

81.2 kg (179.0 lb)

4.61 m (15.1 ft)

Nominal 4.5 meters

4 meters standard

Custom height may be specified upon

placement of order

60-80 psi (410-550 kPa)

Carrier Load Rating

Maximum Loading

Not to exceed 18 kg (40 ft lb)

10 kg (22 lb)

See Operation on page 27 for additional

information

Specifications | 13

Page 14

This page intentionally left blank.

14 | Specifications

Page 15

4.0 Assembly and Installation

Before connecting any components, follow the safety information

in the ETS-Lindgren Product Information Bulletin included with

your shipment.

The Model 2175 MiniMast™ is shipped partially assembled; the assembly

process will take approximately one hour. Ensure that a clear area is available to

unpack and assemble the MiniMast. Prior to starting the assembly process, open

the shipping container and check all parts for any shipping damage.

Do not discard any packing material until the MiniMast is fully installed and

operation. During this assembly procedure, refer to the illustrations provided

for each step.

Tools needed for assembly (included with shipment):

• Adjustable open-end wrench

• Phillips head #2 screwdriver

Figure 1: Tools shipped with MiniMast

Assembly and Installation | 15

Page 16

Product Assembly

1. Attaching the motor is the first step of the assembly process. Locate the motor in the

packaging under the positioner base. Lay the motor with the winch drum facing the

direction of the slot provided in the base. Roll the platform over the top of the motor

and find the brackets under the platform that pin the motor into position.

Tabs on motor slide between the brackets on the platform.

Figure 2: Motor attached to bottom of MiniMast

2. Lift slightly on the motor and insert the pins provided to secure the motor in position.

Once pinned into position, the platform and motor together may be placed on one

side to connect the air hoses from the platform to the motor base. After the air hoses

are connected lay the positioner platform back into position with the casters on the

floor.

16 | Assembly and Installation

Page 17

3. Continuing with the assembly, insert the mast into the support angles on the platform.

An axle bushing with stud and nuts for securing in place is on the platform. Carefully

remove the fiber optic cable packed into the lower end of the mast and straighten the

leads. Insert the mast between the two angle supports in approximately the correct

position. Insert the mast axle. After the axle is in place, route the fiber optic limit

cables through the fiber optic hole provided in the platform.

Do not damage the fiber optic cable during this step. Make sure it is out of the

way when inserting the mast axle through the mast.

Figure 3: Fiber Optic Placement

4. Place the carrier and top cap into the position shown on the mast. Verify that the

carrier brake engages the corner of the mast and all components are oriented as

shown in the following picture. The top cap of the mast bolts into place with an axle

nut and a threaded fiberglass stud and nut combination. Securely tighten the nut and

stud to secure the top cap. The stud should be flush with the nut when tightened in

the proper position. Uncoil the guy ropes and let them hang unobstructed.

Assembly and Installation | 17

Page 18

Figure 4: Securing the Mast Cap

5. Unwind the rope from the winch drum and feed it over the pulleys so that the free end

lines up with the clamp on the carrier brake assembly. Feed the rope through the

clamp on the brake assembly and tighten clamp nuts hand tight. Further adjustment

will be necessary once the mast is completely assembled.

Figure 5: Pulley Location

18 | Assembly and Installation

Page 19

Figure 6: Screw Placement

6. The mast brackets should be installed according to the orientation shown in previous

illustrations. Using the #2 Phillips screwdriver provided, tighten the screws through

the large and small mast brackets through the mast and into the nut plate that is

already fitted with inserts.

7. Engage the brakes on the swivel casters of the platform so that they will not roll.

Carefully raise the mast to a vertical position and insert the lock pin provided to hold it

in place.

Do not attempt the next portion of the assembly with less than two people.

Care should be taken to keep the carrier from contacting the platform during

this procedure so that it cannot damage the platform.

8. Leaving approximately one turn of rope on the winch drum, pull the hoisting rope tight

through the clamp block on the brake. Once the clamp is fully tightened onto the

rope, tie a loose half-knot on the mast side of the clamp to make sure the rope does

not slip back through the clamp. Once this is accomplished, wind the excess rope

around the clamp portion of the brake so that the brake still functions correctly and

the rope does not interfere with the carrier working properly.

9. Attach the free end of the guy lines to anchors located on the ground plane or within

the chamber.

Assembly and Installation | 19

Page 20

Outdoor applications require guying to stabilize the mast against wind. For

outdoor applications, engage the lock on the swivel casters at this time.

Figure 7: Boom Placement

10. Pull the coiled hose out of the carrier and insert the primary boom as pictured into the

carrier. Note the position of the knobs on the boom gear and on the boom bearings.

The gear back-up roller should be directly behind the rack gear and the cylinder

should be in a fully compressed state. Incorrect horizontal and vertical polarization

angles will result if the cylinder is not fully compressed. Once the primary boom is

locked in place, install the offset boom and the coaxial cable strain relief.

20 | Assembly and Installation

Page 21

L

OCATION OF CONNECTIONS

Assembly and Installation | 21

Page 22

L

OCATION OF CONNECTIONS, CONTINUED

Figure 8: Location of Connections

11. Coiled hoses that were located inside the carrier should be connected to the fittings

on the platform for the polarization to become operable. All connections to the motor

base should be completed at this time including fiber optic limits and control lines,

along with compressed air and electrical power. Route all connections through the

connection entry on the platform tube so they will exit through the connection exit.

Install the platform end covers by positioning and applying pressure to secure them in

place. Check to see that the controller reads horizontal polarization.

22 | Assembly and Installation

Page 23

12. Slightly engage the air lines onto the fittings and note the position of the boom.

Energize the air line supply to the motor base. If the boom is in horizontal polarization

(holes in the boom are on top), fully engage the hoses onto the fittings provided. If

the boom is in vertical polarization, turn the air off and reverse the air lines and then

fully engage them on the fittings provided in the platform.

Air line pressure should be between 60–80 psi (4.14–5.52 bar). Do not

exceed 80 psi (5.52 bar).

Keep hands away from any portion of the carrier while

performing this task. Failure to do so may result in

personal injury.

Do not perform any service on the carrier with the air lines

energized.

13. When the MiniMast is in the position where testing will occur, lock the brakes

provided on the swivel casters to prevent movement of the platform.

Electrical Installation

The motor base is provided with a three-conductor AC power cord that is

approximately 2.45m (8 ft) long. Power to the motor base is 220 VAC. The

motor base should be wired to a circuit capable of providing 10 amps of service.

The power cord is to be terminated into an outlet near the motor base. The power

cord is suitable for portable or indoor applications without modification. Ideally,

the power cord would exit the motor base and terminate into an outlet with as

short a cord as possible as the start and stop actions of the motor base create a

small amount of RF noise through the power cord.

If this equipment is to be operated outdoors, precautions must be taken to

protect the MiniMast from the weather. In the event that modifications are

required, the installation should be compliant with all local and national

electrical safety codes.

As with all electrical devices, disconnect the power prior to

servicing the equipment.

A fuse is mounted on the side of the motor enclosure. This fuse provides

protection for the motor and the associated electronics. An additional fuse

provides protection for the DC power supply inside the motor base.

Assembly and Installation | 23

Page 24

The branch circuit supplying power to the motor base should be protected from

excess current according to local electrical codes. Whenever possible the motor

should be powered from a separate branch circuit of adequate current capacity to

keep voltage drop to a minimum during startup and running.

Check that the conductor size is adequate for the motor load and the distance

from the mains source. Improperly sized conductors will lead to a high voltage

drop in the power conductors and cause reduced starting torque an d premature

motor failure. For longer runs, increase the wire size in accordance with the wire

selection guide shown below. When considering what gauge of wi re to use,

never use smaller than 14 AWG for any installation.

Length of wire

@220V

Wire gauge

required

Connecting the Controller

Any combination of devices may be connected to the two device interface ports

located on the rear panel of the Model 2090 Multi-Device Controller (or next

generation ETS-Lindgren controller, if applicable). The default settings are for a

tower connected to the Device 1 interface port and a turntable connected to the

Device 2 port.

Fiber optic cabling for each device should not be allowed to hang unsupported

from the rear panel of the controller. The fibers and connectors are easily

broken if twisted or bent. Keep the fiber optic cables as straight as possible

from the connector to the protective sheath.

Device connection is accomplished with a dual fiber optic cable included with the

device. This cable terminates into two ST connectors that are identical at both

ends. The cable is symmetrical; either end can be connected to the controller. A

fiber optic cable that connects to the IN port of a controller should, at the other

end, be connected to the OUT port of the motor base. A fiber optic cable

connected to the OUT port of the controller should, at the other end, be

connected to the IN port of the motor base.

0–15.24 m

(0–50 ft)

15.24–30.48 m

(50–100 ft)

30.45–60.96 m

(100–200 ft)

14 AWG 14 AWG 14 AWG

The fiber optic mechanical limits must be set before the carrier is able to move.

24 | Assembly and Installation

Page 25

Carrier Safety Brake

A safety brake is mounted on the carrier assembly. In the event that the carrier is

released from the rope suspension, a spring-loaded cam jams the brake into

position against the mast and slows the vertical movement of the carrier.

The safety brake is not intended to completely restrict

movement of the carrier. Always exercise extreme caution

when the safety brake is engaged.

To release the carrier safety brake, support the carrier and release the brake

roller. Slide the carrier down to the base of the mast. Replace the carrier rope if

necessary. Reset the current position using the controller before resuming use of

the mast.

Assembly and Installation | 25

Page 26

This page intentionally left blank.

26 | Assembly and Installation

Page 27

5.0 Operation

Editing the Controller Configuration Parameters

MiniMast Encoder Calibration

Before connecting any components, follow the safety information

in the ETS-Lindgren Product Information Bulletin included with

your shipment.

See the Model 2090 Multi-Device Controller (or next generation ETS-Lindgren

controller, if applicable) manual if you are unfamiliar with the operation of the

unit. A manual is included with each controller shipment and is also available

for download from www.ets-lindgren.com

.

See the Model 2090 Multi-Device Controller (or next generation ETS-Lindgren

controller, if applicable) manual for steps to edit the configuration parameters.

The display symbol C refers to the encoder calibration parameter. This setting is

used to convert the encoder count values returned from a motor base into the

corresponding centimeter or degree position reading. For towe rs, the number

represents the number of encoder counts per meter. Using this parameter, a

variety of standard, retrofit, and custom devices can be used. The setting for the

Model 2175 MiniMast™ is 2000.

If the given value does not appear to work correctly, the encoder calibration value

can be determined using the following procedure:

1. Set the encoder calibration value to 1000.

2. Ensure that the MiniMast is positioned to allow at least one meter of

travel in the upward direction at an easily measurable height, then set

the current position reading to 000.0.

You must adjust the lower limit setting to allow at least one meter of travel.

3. Using the STEP keys of the controller, adjust the height of the carrier

until it is one meter above the start point.

4. Record the reading of the display, ignoring the decimal point (for

example, 200.0 would be 2000). This is the encoder calibration value.

Operation | 27

Page 28

If the value is below 1000, the resolution of the encoder is low and the

Antenna Mounting Instructions

controller will not provide 0.1 cm resolution, even though the display shows

that digit. If the value has gone past 9999, the encoder has too many counts

per meter and the controller cannot correct for it. In this case, contact

ETS-Lindgren for assistance.

5. Enter this value for the encoder calibration value and reset the limits and

position information.

6. Test the MiniMast by moving it to a known distance and comparing the

display to the measured distance traveled. It may be necessary to adjust

the encoder calibration value up or down slightly depending on the result.

Antennas may be mounted to the assembly using either the 7/8–14 thread which

is common on ETS-Lindgren brand antennas, or the 1/4–20 thread which is

another common size. The antenna should be mounted on the boom as close to

the carrier as possible. Insert the mounting knobs through the holes on the boom

and align the mounting holes on the antenna with the threaded end of the

mounting knobs. Secure the antenna in place by tightening the threaded knobs

into the receptacle mounting holes on the antenna.

Antennas may also be mounted using the stinger mount adapter included with

the assembly.

28 | Operation

Page 29

Figure 9: Boom Load Limitations

Operation | 29

Page 30

Pre-Operational Checks

• Verify that the power lines are connected to the motor base for the MiniMast,

controller, and any other equipment that will be used to test.

• Verify the fiber optic cables are connected to the motor base.

• Verify the limit fibers are connected to the motor base.

• Verify the antenna connected to the boom is securely mounted in place.

• Connect the feed cable to the antenna.

• Verify the load of the antenna is within the operating specifications.

Before moving the carrier on the mast up or down using the

controller or the IR remote, make sure no one is standing near

the boom.

Start-Up and Safe Shutdown

After completing the pre-operational checks, the controller may be turned on by

pressing the power button. See the Model 2090 Multi-Device Controller (or next

generation ETS-Lindgren controller, if applicable) manual for operating

instructions.

Prior to shutting the MiniMast down, move the carrier to an accessible height for

the removal of the antenna. Make sure the unit has come to a complete stop.

Press the power button on the controller to turn it off. Finally, remove power from

the MiniMast.

Infrared (IR) Controller

The motor base features an infrared receiver that will respond to a universal

remote control programmed to a specific protocol. Any remote that continuously

transmits and contains the proper TV protocol can be used.

The basic functions supported are as follows:

Button Command

Power Emergency Stop

Channel Up Up for linear positioner

Channel Down Down for linear positioner

30 | Operation

Page 31

Button Command

Volume Left Counterclockwise for rotational

positioner

Volume Right Clockwise for rotational positioner

Mode Polarization for linear positioner

Operation | 31

Page 32

This page intentionally left blank.

32 | Operation

Page 33

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for the

D

URATION OF WARRANTIES FOR THE MINIMAST

complete ETS-Lindgren warranty for your Model 2175 MiniMast™.

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to two years.

Product Warranted Duration of Warranty Period

Model 2175 MiniMast 2 Years

Warranty | 33

Page 34

This page intentionally left blank.

34 | Warranty

Page 35

Appendix B: Drawings

These drawings are included in the pocket located on the back cover of the

manual:

• 108983, Crossboom

• 109276, 2175 Carrier

• 109356, 2175 Positioner (2 pages)

Drawings | 35

Page 36

This page intentionally left blank.

36 | Drawings

Page 37

Appendix C: EC Declaration of Conformity

EC Declaration of Conformity | 37

Page 38

Page 39

Page 40

REF DRAWING

REVISIONS

NOTES:

1) CUT ROPE

1 EA. 29.5 FT. BURN ENDS

AND INSTALL ON WINCH

DRUM. TAPE TO HOLD IN

PLACE FOR SHIPPING.

2) CUT ROPE 3 EA.

18 FEET. BURN ENDS AND

INSTALL IN HOLES PROVIDED

IN MAST CAP FOR GUYING.

34.50

34.25

17

ECO#

5120

6

41

920300

REV

B

DESCRIPTION

CHANGED ROPE

TAPE,RECLOSABLE,250 STEMS/IN, I IN. WIDTH

DATE

09/14/06

APPROVED

SRK

8

2X APPLY TAPE TO FULL

WIDTH OF BASE AND THEN

40

910899

NUT,5/8-11,FG,BROWN

1

APPLY 1" LENGHTS EQUALLY

SPACED, 6" ON CENTER TO

39

910686

SCREW,10-32 X 1/2,PHIL,FLAT,SS

4

CLOSURE.

38

37

36

35

910455

910451

910357

910331

WASHER,1/4,FLAT,SS

BOLT,1/4-20 X 1-3/4,HEX,SS

SCREW,10-32 X 3/4,PHIL,BIND,SS

SCREW,10-32 X 1/2,PHIL,BIND,SS

5

5

6

9

D

C

34

33

32

31

30

29

28

27

26

25

24

23

910269

905194

890983

890971

890951

890950

890947

890946

890797

890465

890464

860314

NUT,8-32,HEX,SS

COUPLING,BULKHEAD,1/8 NPT

SLEEVING,SLIT-CONVOLUTED,PE,1/4" ID(NOT SHOWN)

PIN,3/16 X 1" QUICK RELEASE

PIN,1/2 X 5 GRIP LENGTH,SST

FITTING,TUBE,1/8 NPT TO .17 ID,RT ANGLE

HOSE,TWIN,1/8 ID X 1/4 OD,COILED,20 FT

BUSHING,3/8 ID X 5/8 OD X 3/8,GRAPHITE

BUMPER,.75 OD,.5 HT,#8 SCREW

BARB HOSE 11924-1 CLIPPARD

NUT TUBE 5000-2 CLIPPARD

ROPE,3/16,2300 LBS

2

2

23

3

1

2

1

2

2

4

4

83.5

21

20

19

18

17

4

4486.28

16

15

860140

708041

708040

109363

109362

109355

109354

TUBE,1/4 O.D. X .047 W.T.,NYLON,BLK

FIBER OPTIC CABLE LIMIT SWITCH 6.5M(NOT SHOWN)

FIBER OPTIC CABLE LIMIT SWITCH 1.5M(NOT SHOWN)

LENSE,INFARED,1" X 8"

BASE,ASSEMBLED,2175

NUT,MAST CAP,2175

PLATE,NUT,2" MAST

6.5

2

2

1

1

1

1

176.63

14

13

12

11

10

109353

109352

109285

109284

109283

BRKT 2,MINIMAST

BRKT 1,MINIMAST

BRKT,PIN MOUNT

BRKT 2,MOTOR MOUNT

BRKT 1,MOTOR MOUNT

1

1

3

3

3

18

A

B

7

17

ATTACH TWIN HOSE

TO FITTINGS ON AIR

CYLINDER.

9

8

7

6

5

4

3

2

1

ITEM NO.

109282

109277

109276

109274

109272

109271

109252

108963

108962

PART NUMBER

STUD,5/8-11 X 4,FG

MOTORBASE,2175

CARRIER,2175

CLOSURE,BASE,2175

CAP,MAST,2175

MAST,2-1/8" X 4 METER,2175

LIMIT,F.O. ASSEMBLY

AXLE,ROPE PULLEY,3/8 DIA.

PULLEY,2-5/16 MEAN DIA.,3/16 ROPE

DESCRIPTION

TM

1

1

1

2

1

1

2

2

2

Default/QTY.

ETS LINDGREN

E

6

8

22

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

DECIMALS

ANGLES

APPROVALS

DRAWN

SRK

DATE

12/12/04

EMC Test Systems, L.P.

Cedar Park, TX

TITLE

An ESCO Technologies Company

POSITIONER,2175

Lindgren-RF Enclosures

Glendale Hts, IL

X.XX

X.XXX

FINISH

±

.015

±

.005

NONE

±

.5

CHECKED

MATERIAL

RG

SEE BOM

2/4/05

PROPRIETARY INFORMATION

ANY DUPLICATION OF THIS

DOCUMENT, WHOLE OR IN PART,

WITHOUT EXPRESS WRITTEN

PERMISSION OF ETS LINDGREN

IS PROHIBITED.

SIZE

D

DO NOT SCALE DRAWING

SCALE

1:16

DWG. NO.

109356

SHEET

1

REV.

B

OF

2

Page 41

REF DRAWING

REVISIONS

NOTES:

ECO#

5120

3837

10

31

REV

B

DESCRIPTION

CHANGED ROPE

DATE

09/14/06

APPROVED

SRK

TWIN HOSE

ATTACHES

HERE.

24

25

33

11

DETAIL B

SCALE 1 : 2

12

35

40

9

5

1

DETAIL E

SCALE 1 : 1

27

2

29

16

DETAIL C

SCALE 1 : 2

26

13

36

34

14

30

39

DETAIL D

SCALE 1 : 2

3

TM

ETS LINDGREN

UNLESS OTHERWISE SPECIFIED:

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

DECIMALS

ANGLES

APPROVALS

DRAWN

SRK

DATE

12/12/04

EMC Test Systems, L.P.

Cedar Park, TX

TITLE

An ESCO Technologies Company

POSITIONER,2175

Lindgren-RF Enclosures

Glendale Hts, IL

DETAIL A

SCALE 1 : 2

X.XX

X.XXX

FINISH

±

.015

±

.005

NONE

±

.5

CHECKED

MATERIAL

RG

SEE BOM

2/4/05

PROPRIETARY INFORMATION

ANY DUPLICATION OF THIS

DOCUMENT, WHOLE OR IN PART,

WITHOUT EXPRESS WRITTEN

PERMISSION OF ETS LINDGREN

IS PROHIBITED.

SIZE

D

DO NOT SCALE DRAWING

SCALE

1:20

DWG. NO.

109356

SHEET

2

REV.

B

OF

2

Loading...

Loading...