Page 1

Model 2165

LoPro™ Turntable

1.2-Meter

User Manual

Page 2

ETS-Lindgren L.P. reserves the right to make changes to any products herein to improve

functioning or design. Although the information in this document has been carefully reviewed and

is believed to be reliable, ETS-Lindgren does not assume any liability arising out of the

application or use of any product or circuit described herein; nor does it convey any license under

its patent rights nor the rights of others. All trademarks are the property of their respective

owners.

©Copyright 2007–2008 by ETS-Lindgren L.P. All Rights Reserved. No part of this

document may be copied by any means without written permission from

ETS-Lindgren L.P.

Trademarks used in this document: The ETS-Lindgren logo and LoPro are trademarks of

ETS-Lindgren L.P.

Revision Record

MANUAL,INSTAL,MODEL 2165 LoPro TURNTABLE | Part #399791, Rev. C

Revision Description Date

A Initial Release January, 2007

B

• Updated Turntable Encoder Calibration

February, 2007

• Added Waste Electrical and Electronic

Equipment (WEEE) Directive

C Rebrand July, 2008

ii |

Page 3

Table of Contents

Notes, Cautions, and Warnings ......................................................................... v

1.0 Introduction ................................................................................................... 7

Standard Configuration ....................................................................................................... 7

Turntable Assembly ............................................................................................... 7

Optional Items..................................................................................................................... 8

Infrared Remote Controller .................................................................................... 8

Shaft Kit ................................................................................................................. 9

ETS-Lindgren Product Information Bulletin ........................................................................ 9

2.0 Maintenance ................................................................................................ 11

Recommended Maintenance Schedule ........................................................................... 11

Monthly ................................................................................................................ 11

6-Month Service .................................................................................................. 12

12-Month Service ................................................................................................ 12

Cleaning the Bearing Races ............................................................................................. 12

Replacement and Optional Parts...................................................................................... 13

Service Procedures .......................................................................................................... 13

3.0 Specifications .............................................................................................. 15

Electrical Specifications .................................................................................................... 15

Physical Specifications ..................................................................................................... 15

4.0 Turntable Installation Considerations ....................................................... 17

Before You Begin—Precautions ....................................................................................... 17

5.0 Electrical Installation .................................................................................. 19

6.0 Assembly and Installation .......................................................................... 21

Required Tools ................................................................................................................. 21

Assembly Instructions ....................................................................................................... 21

7.0 Optional Shaft Kit Installation Instructions .............................................. 23

Components ..................................................................................................................... 23

Required Tools ................................................................................................................. 24

Determine Shaft Length .................................................................................................... 24

Assemble Drive Shaft ....................................................................................................... 24

Install Shaft Housing ......................................................................................................... 25

Install Drive Shaft ............................................................................................................. 25

Connect Shaft to Motor Drive ........................................................................................... 26

| iii

Page 4

Cut Drive Shaft Assembly ................................................................................................. 27

Cut Shaft Housing ............................................................................................................ 28

8.0 Operation ..................................................................................................... 29

Appendix A: Warranty ...................................................................................... 31

Appendix B: Drawings ...................................................................................... 33

Appendix C: EC Declaration of Conformity .................................................... 35

iv |

Page 5

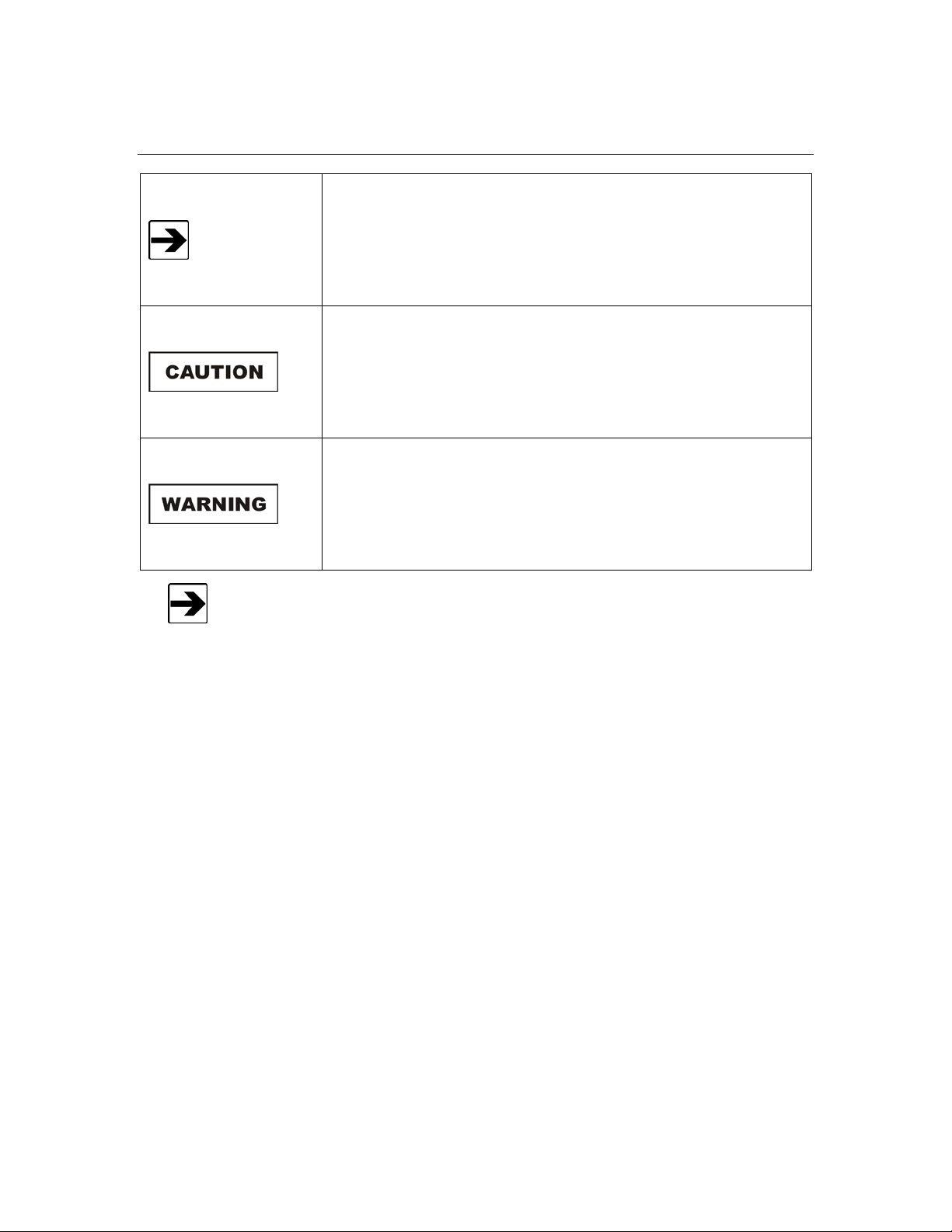

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to provide tips for

See the ETS-Lindgren Product Information Bulletin for safety, regulatory, and

other product marking information.

better use of the product.

Caution: Denotes a hazard. Failure to follow instructions

could result in minor personal injury and/or property

damage. Included text gives proper procedures.

Warning: Denotes a hazard. Failure to follow instructions

could result in SEVERE personal injury and/or property

damage. Included text gives proper procedures.

| v

Page 6

This page intentionally left blank.

vi |

Page 7

1.0 Introduction

The ETS-Lindgren Model 2165 LoPro™ Turntable is an electric-powered,

variable-speed turntable platform system designed for use with the

Model 2090 Multi-Device Controller (or next generation ETS-Lindgren controller,

if applicable) for EMI compliance testing. The Model 2165 is a low-profile design

constructed of PVC plate with a textured ABS top and other non-metallic

components. The 1.2-meter diameter turntable is an easily assembled system

that can be disassembled for service or to be moved. The mechanical assembly,

motor drive unit, and shaft kit (optional) comprise the three basic subassemblies

of the turntable.

The mechanical assembly is shipped assembled with the top, base, gearbox,

support bearings, and drive belt. The bearings on which the turntable rotates are

integral to the top and bottom of the table. Three independent bearing races

provide support for the inner and outer portions of the turntable top. These

bearings are of a completely non-metallic construction. There are four keepers

located on the outside of the turntable top that prohibit the bearings from shifting

out of position during shipment. When the table is in place and ready to begin

testing, the keepers should be removed.

The motor drive, encoder, and limit switch assemblies are located in a shielded

enclosure with state-of-the-art I/O provided by a fiber optic interface. The

motor drive is coupled to the drive shaft with a flexible hose coupling. The other

end of the shaft connects to the turntable gearbox with a keyed coupling that

clamps between the two shafts. The shaft assembly transmits torque from the

motor drive to the gearbox at the table. The drive belt runs around the underside

of the turntable at its perimeter, and is driven by a pulley in the gearbox.

Turntable rotation is limited by the soft, or electrical, limits that are set on the

front panel of the controller.

There is a 1 cm (0.40 in) vertical x 2.54 cm (1.0 in) horizontal slot on the bottom

side of the turntable base that can be used to run 3/8-in maximum diameter cable

from the side and up through the center opening of the turntable.

Standard Configuration

TURNTABLE ASSEMBLY

Featuring continuous or non-continuous operation, the turntable assembly

includes:

• Single-phase electric drive (208-230 VAC 50/60 Hz)

• Variable-speed drive

Introduction | 7

Page 8

• Conductive top

• Continuous rotation

• 10-meter fiber optic control cable

• Fiber optic shield penetration kit

Additionally, the turntable is infrared compatible, and can be used with an

optional ETS-Lindgren Infrared Remote Controller (IR remote). For more

information on using an IR remote, see Infrared Remote Controller on page 8.

Optional Items

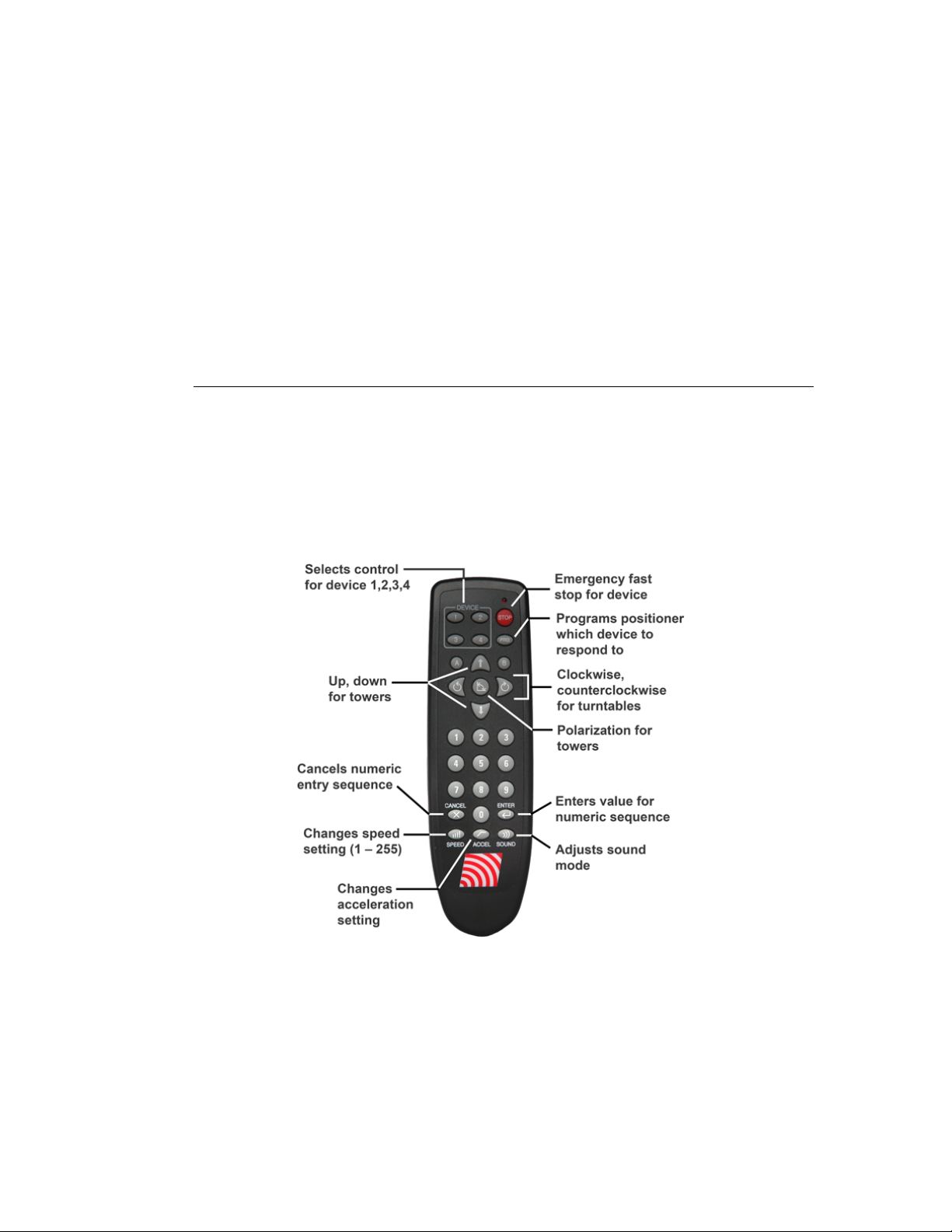

INFRARED REMOTE CONTROLLER

The Model 2165 is infrared compatible, and can be used with a universal remote

control programmed to a specific protocol, such as the ETS-Lindgren Infrared

Remote Controller (IR remote).

8 | Introduction

Page 9

SHAFT KIT

This option allows the electric drive motor to be positioned farther from the

turntable. The extension shaft separates the turntable and the drive motor by as

much as 5 m (16.4 ft). Steps to cut it to a custom length are included in Optional

Shaft Kit Installation Instructions on page 23.

The shaft kit option must be specified at the time the turntable order is placed.

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

• Warranty information

• Safety, regulatory, and other product marking information

• Steps to receive your shipment

• Steps to return a component for service

• ETS Lindgren calibration service

• ETS Lindgren contact information

Introduction | 9

Page 10

This page intentionally left blank.

10 | Introduction

Page 11

2.0 Maintenance

WARRANT Y

Before performing any maintenance, follow the safety

information in the ETS-Lindgren Product Information

Bulletin included with your shipment.

Regularly inspect all equipment and conduct scheduled

maintenance in accordance with the factory recommendations

provided.

BEFORE SERVICING: CONTACT ETS-LINDGREN

(+1.512.531.6400)—Servicing or modifying the unit without

ETS-Lindgren authorization may void your warranty. If an

attempt to service the unit must be made, disconnect all

electrical power prior to beginning. Voltages exist at many points

within the instrument that could, if contacted, cause personal

injury. Only trained service personnel should perform

adjustments and/or service procedures upon this instrument.

Capacitors inside this instrument may still be charged even

when the instrument is disconnected from the power source.

Recommended Maintenance Schedule

Regular maintenance will prolong the effective operation and reliability of your

turntable. Follow the recommended schedule for monthly, 6-month, and

12-month service.

Do not perform maintenance while the turntable is operating.

MONTHLY

• Inspect the turntable assembly for loose fasteners, abnormal wear, and oil

leaks.

• Verify the accuracy of the current position setting on the ETS-Lindgren

controller in relation to the turntable. If the turntable always rotates in the

same direction, over time the 0-degree position may drift. To reset the

current position, see the controller manual.

Maintenance | 11

Page 12

6-MONTH SERVICE

• Check all parts for wear.

• The drive belt is furnished fully tensioned, but after usage the belt may need

to be tightened. To remove slack in the belt, loosen the six bolts on the

gearbox, move it outward, and then re-tighten. See Drawing 5 and

Drawing 11 located in the back pocket of this manual.

12-MONTH SERVICE

• Thoroughly inspect the unit for wear.

• Grease the plastic miter gears with a silicone grease lubricant.

• Clean the bearing races to remove any dust or dirt that may have

accumulated. For instructions, see the next section.

Cleaning the Bearing Races

To clean the bearing races, remove the turntable top as follows:

1. Remove the eight bolts at the center ring to remove the center

plate/flange that holds down the turntable.

2. If keepers are installed at the four corners of the assembly, remove the

bolts that hold the four keepers in place, and then remove the keepers.

3. Expose the bearing races by gently lifting the turntable top and placing it

to the side.

4. Remove the bearings. Carefully place them in a secure location.

5. Use a clean rag moistened with water to clean the races. No lubrication

is necessary in the tracks.

6. When complete, replace the bearings. Alternate the delrin bearings

(white) and nylon bearings (tan tint) to improve wear characteristics.

Gently replace the turntable surface. Insert the plate/flange in the center

and tighten the eight bolts that secure it. If desired, reinstall the four

keepers.

12 | Maintenance

Page 13

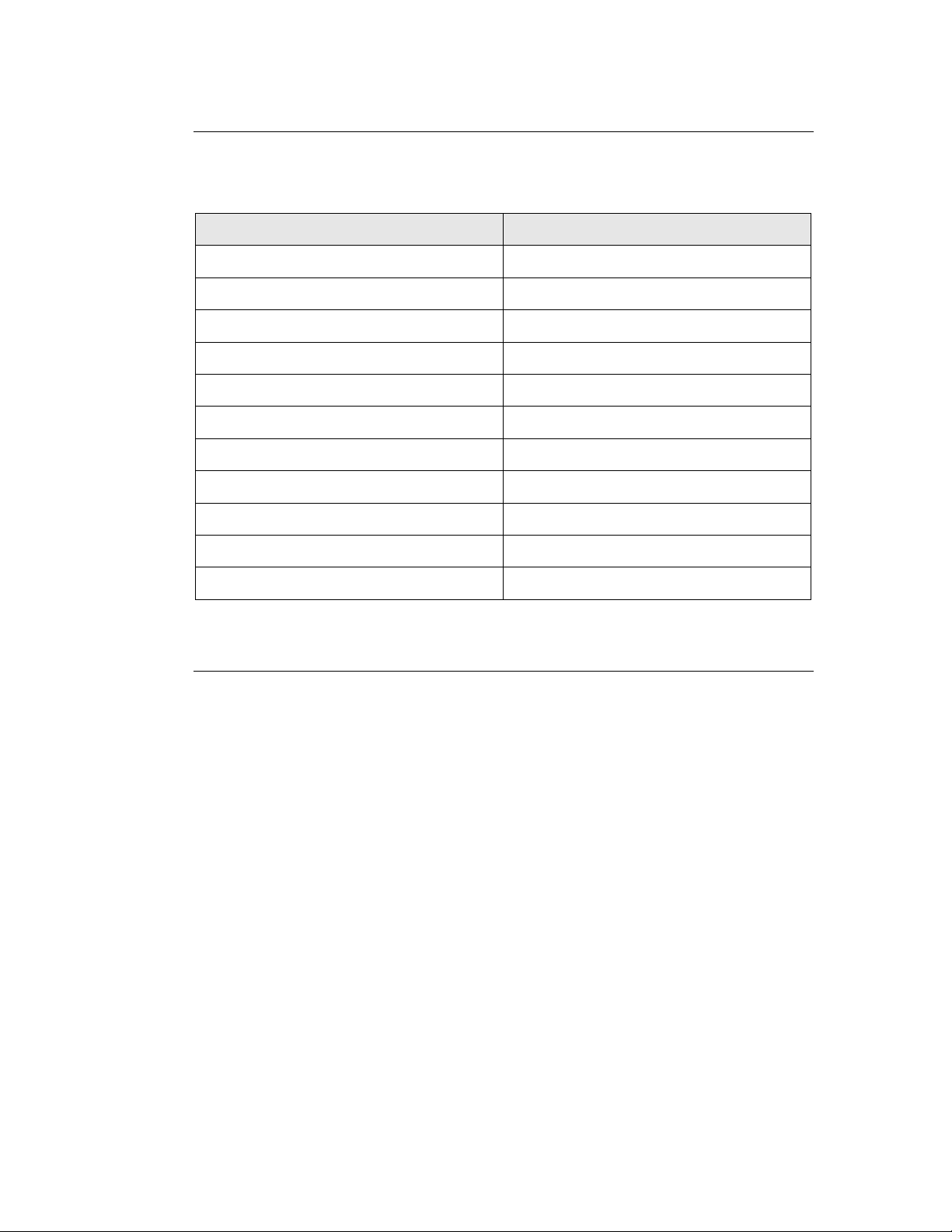

Replacement and Optional Parts

Following are the part numbers for ordering replacement or optional parts for the

Model 2165 LoPro™ Turntable.

Part Description Part Number

2165 turntable assembly 2165

Motor base assembly 109896

Tie bracket 105728

Standoff (2) 890508

1/2–13 x 3/4-in hex bolt 910551

1/4-in x 1 1/4-in hex bolt 910449

Hose clamp 890684

Hose coupling 860204

Fiber optic cable 705344-10

Shaft Kit 106555

IR Remote Controller 707030

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

Maintenance | 13

Page 14

This page intentionally left blank.

14 | Maintenance

Page 15

3.0 Specifications

Electrical Specifications

Nominal AC Voltage:

Input Frequency:

Current Rating:

RPM:

Phase:

Motor Horsepower:

Physical Specifications

Turntable Diameter:

Nominal Height:

Nominal Load Capacity:

Nominal Max Diameter:

Top Construction:

Distributed Load Rating:

208–230 VAC

50/60 Hz

3 A

0.5 – 2.5

Single

1/4 HP

1.2 m (3.94 ft)

5 cm (1.97 in)

273 kg (601.86 lb)

1.2 m (3.94 ft)

One-piece PVC

273 kg (600 lb)

Distributed Load Rating applies when:

• Load is evenly distributed on top;

• No point loads under 0.19 sq m (2.0 sq ft) should exceed 100 kg

(220 lb);

• And not over 28.5 kg (62.8 lb) should be applied to a 45-degree

segment at the table outer edge.

Specifications | 15

Page 16

This page intentionally left blank.

16 | Specifications

Page 17

4.0 Turntable Installation Considerations

Before assembling, installing, or connecting any components,

follow the safety information in the ETS-Lindgren

Product Information Bulletin included with your shipment.

Before You Begin—Precautions

Read this manual completely before starting installation. This

equipment should be installed and operated only by qualified

personnel.

Do not attempt to service unless qualified to do so. As with any

electrical equipment, make sure unit electrical power has been

disconnected and secured when performing scheduled

maintenance or adjustments.

WARRAN TY

Do not make any modifications to this unit without consulting

the factory directly.

Regularly inspect all equipment for loose fasteners and wear.

Conduct scheduled maintenance in accordance with the factory

recommendations provided.

Only use replacement parts and fasteners ordered directly from

the factory.

Stay clear of all moving components on this equipment.

Do not operate turntable while someone is physically on the

turntable top.

Do not, at any time, place hands or feet in the vicinity of the

drive pinion on the turntable.

Turntable Installation Considerations | 17

Page 18

The fiber optic cable must be looped through the P-clip

installed on the front panel of the motor base. Failure to

do so increases the chance of the accidentally pulling

cable and breaking the fiber optic connectors.

The keepers on the outside edge of the turntable should

be in place when the turntable is to be moved or

relocated. This will prevent damage to the bearings on

which the turntable top rotates.

18 | Turntable Installation Considerations

Page 19

5.0 Electrical Installation

Determine the mains voltage to be applied to the motor base unit. The branch

circuit supplying power to the motor base should be protected from excess

current according to local electrical codes. Confirm that the conductor size is

adequate for the motor load with respect to the distance from the mains source.

Improperly-sized conductors will lead to a high voltage drop in the power

conductors and cause reduced starting torque. This condition could lead to

premature motor failure.

Before assembling, installing, or connecting any components,

follow the safety information in the ETS-Lindgren

Product Information Bulletin included with your shipment.

Electrical installation must be performed by a qualified

electrician, and in accordance with local and national electrical

standards.

Make sure the power is off and secured before proceeding.

Keep all body parts away from the drive gears and drive belt

when the turntable is energized. Do not operate the turntable

with the protective guards removed.

Electrical Installation | 19

Page 20

This page intentionally left blank.

20 | Electrical Installation

Page 21

6.0 Assembly and Installation

Before assembling, installing, or connecting any components,

follow the safety information in the ETS-Lindgren

Product Information Bulletin included with your shipment.

Prior to assembly and installation, review the drawings located in the back

pocket of this manual.

The Model 2165 LoPro™ Turntable is shipped partially assembled, and

additional assembly is estimated to take a maximum of one hour. Make sure a

clear area is available to unpack, assemble, and install the turntable. Prior to

assembly, open the shipping container and check all parts for any shipping

damage.

Do not discard any packing material until the turntable is fully installed and

operational.

Required Tools

• Level

• Adjustable wrench

• Phillips screwdriver and flat head screwdriver

• Shims, if the floor surface is not level

Assembly Instructions

Make sure power is off and secured before proceeding.

1. Position the turntable mechanical assembly on the floor. The turntable

mechanical assembly has a 44-in (112-cm) base plate that must rest on

a flat surface. For proper alignment of the drive shaft, the bottom surface

of the turntable mechanical assembly, the drive shaft assembly, and the

motor drive assembly must all be installed at the same level. If the floor

is not flat, it may be necessary to place shims under the base. The

turntable will stay in place due to its own weight, but the base plate

provides four holes used to fasten the unit to the floor with 5/16-in

diameter screws.

Assembly and Installation | 21

Page 22

2. After the turntable is in position, remove the plastic gearbox cover plate

by loosening the four plastic bolts holding it in place.

If you are installing the shaft kit, disregard the remainder of the instructions in

this section and skip to Optional Shaft Kit Installation Instructions on page 23.

3. Install the aluminum shaft adapter onto the black shaft from the turntable

gearbox. Use the 1/4-in phenolic (brown plastic) pin to key it to the black

shaft. A spacer piece fits inside the shaft adapter and between the

adapter and phenolic pin to secure the pin into place.

Two 8–32 set screws lock the adapter into place onto the shaft.

4. Slip the gray hose coupling with the two hose clamps onto the shaft

adapter.

5. An aluminum bracket holds the motor drive to the turntable base. The

bracket attaches to the 3/4-in base plate of the turntable using

two 1/2–13 x 3/4-in bolts. Two standoffs attach the bracket to the

motor base at the correct distance.

6. Position the motor drive so the shaft slips into the hose coupling. The

bracket installed in step 5 should now be in place. Secure the bracket to

the motor base using the provided 1/4-in x 1 1/4-in hex head cap screws.

Tighten both hose clamps to secure the gray hose coupling around the

shafts.

7. Place the gearbox cover on the gearbox, and then insert and tighten the

four bolts.

22 | Assembly and Installation

Page 23

7.0 Optional Shaft Kit Installation Instructions

Before assembling, installing, or connecting any components,

follow the safety information in the ETS-Lindgren

Product Information Bulletin included with your shipment.

If you are not installing the shaft kit, disregard the instructions in this section

and skip to Operation on page 29.

The shaft kit allows the motor base to be positioned up to 5 m (16.4 ft) from the

turntable. The drive shaft assembly includes an inner shaft mounted in an outer

housing supported in the center and at each end by plastic floor supports.

This section provides assembly information for the shaft and instructions to cut

the shaft components if a shorter distance between the motor base and turntable

is required. Following is an overview of steps:

1. Determine shaft length—see page 24.

• Cut drive shaft assembly (may not be required)—see page 27.

• Cut shaft housing (may not be required)—see page 28.

2. Assembly drive shaft—see page 22.

3. Install shaft housing—see page 25.

4. Install drive shaft—see page 25.

5. Connect shaft to motor drive—see page 26.

Components

Part Quantity

Shaft sections 2

Shaft coupler 1

1/4–20 self-tapping screws 4

End floor supports, with a single clamp for a single item 2

Mid-floor support, with a double clamp for two items 1

Shaft housings, 4.5-in diameter 2

White bushings, one for each end of the shaft housing assembly

and one for the center between the two shaft housing components

3

Optional Shaft Kit Installation Instructions | 23

Page 24

Required Tools

In addition to the tools for basic installation, these additional tools are required:

• Tape measure

• Drill

• Assorted bits, including 7/32

• Hand or reciprocating saw

• Marker

• File/sandpaper

Determine Shaft Length

To install the shaft kit, determine the DIM1 dimensions as shown on Drawing 4

located in the back pocket of this manual. This is the distance from the center of

the turntable top to the end of the drive shaft floor support.

If DIM1 needs to be shorter than the standard 5 m (16.4 ft), you must cut the

drive shaft assembly to the proper length before attaching it to the turntable. See

Cut Drive Shaft Assembly on page 27 for complete instructions.

No cutting is required if the standard length is acceptable for installation.

However, the shaft must be the correct length before proceeding.

Assemble Drive Shaft

See Drawing 8 located in the back pocket of this manual.

To assemble the two sections (section A and section B) of the drive shaft using

the provided coupling: Insert the 6.0-cm (2.37-in) diameter plain ends of the shaft

sections into the coupling all the way to the step. Match drill the shaft sections

through the four pre-drilled holes in the coupling and install the

four 1/4–20 self-tapping screws provided.

24 | Optional Shaft Kit Installation Instructions

Page 25

Install Shaft Housing

1. Assemble one of the two PVC outer shaft housings into one of the two

end floor supports. The floor supports are split into a top and bottom half

that clamp together. Loosen the top 1/2–13 hex nuts to separate these

two split pieces. Insert one white bushing followed by the end of one

housing into the floor support. Tighten the two top nuts to clamp the floor

supports around the housing and bushing.

2. Install the housing assembly onto the base plate of the turntable

mechanical assembly using two 1/2–13 x 1.5-in hex bolts inserted

through the tie plate. Make sure the housing is square with the turntable

base for proper shaft alignment.

If DIM1 is 3035 mm (9.9 ft) or less, the mid-floor support is not required. Skip

to Install Drive Shaft on page 25.

If DIM1 is more than 3035 mm (9.9 ft), the mid-floor support is required.

3. If the mid-floor support is required, assemble the mid-floor support with a

white bushing onto the end of the shaft housing. Make sure the housing

is square with the turntable base for proper drive-shaft alignment after

final assembly.

Install Drive Shaft

The drive shaft has two reduced ends. Make sure the 2.69-cm (1.06-in) diameter

end with the groove goes toward the turntable. The knurled 2.54-cm (1.0-in)

diameter end should point toward the motor drive.

The coupling on the drive shaft will not fit through the white bushing if a

mid-floor support is used. The coupling should be on the motor drive side of

the mid-floor support when the drive shaft is installed into the housing.

1. Insert the turntable end of the drive shaft through the housing assembly

and into the clamp coupling on the gearbox. A 1/4-in diameter x 1-in long

dowel pin is furnished to key the shaft to the coupling and prevent

slipping.

Optional Shaft Kit Installation Instructions | 25

Page 26

2. Loosen the three 3/8–16 hex head screws on the gearbox coupling

before insertion. Place the 1/4-in diameter x 1-in long dowel pin into the

groove of the drive shaft, and line the shaft and pin up with the groove in

the coupling. With everything aligned, push the shaft and pin into the

coupling. Leave approximately a 1/4-in gap between the 6.01-cm

(2.37-in) diameter shaft shoulder and the end of the coupling. Slowly

tighten the three screws on the coupling.

3. If the mid-floor support was not required because DIM1 was less than

3035 mm (9.9 ft), skip to step 5. Otherwise, continue to the next step.

4. If the second shaft housing is required, slip it around the shaft, into the

mid-floor support, and then clamp it in place. Only the one bushing that

was installed previously is needed in this support. There should be one

remaining bushing, and that will be used in the next step.

5. Install the remaining bushing and mid-floor support onto the motor drive

end of the shaft housing. Guide the 2.54-cm (1-in) diameter end of the

shaft through the white bushing. The end of the shaft should stick out of

the bushing approximately 5.08 cm (2.0 in). Make sure the housing

extends out square with the base of the table for proper alignment.

Connect Shaft to Motor Drive

1. Install the hose coupling onto the steel shaft of the motor drive unit. The

two hose clamps provided should rest loosely around the hose.

2. Position the motor drive on the floor and slide the unit into place with the

hose coupling connecting both shafts. Bolt the aluminum tie bracket into

place, and install one hose clamp onto the steel drive shaft and one onto

the plastic shaft.

3. Fasten the floor supports and motor drive unit to the floor using 5/16-in

diameter screws through the mounting holes in the bottom base of the

shaft supports and motor drive.

4. Reinstall the gearbox cover using four 3/8-16 x 1-in hex screws. Be

careful not to over-tighten the plastic bolts.

5. If desired, cables can be run along a slot under the base of the turntable,

up and through the opening at the center of the table. The slot is 1 cm

(0.40 in) deep and 2.54 cm (1 in) wide. It should accept a cable up to

3/8-in diameter.

26 | Optional Shaft Kit Installation Instructions

Page 27

Cut Drive Shaft Assembly

The inner drive shaft is shipped separate from the turntable and consists of the

following:

• Drive shaft section (A)—2.37-in diameter x 82 in long, with a grooved

1.06-in diameter end for the turntable side

• Drive shaft section (B)—2.37-in diameter x 72 in long, with a knurled 1.0-in

diameter end for the motor drive side

• Shaft coupling—with 1/4–20 self-tapping screws for joining the two shaft

sections

Follow these steps to cut the shaft to the desired length. The material is PVC and

can be cut with a hand or reciprocating saw with a 6-in blade length.

1. Determine the distance DIM1 from the center of the turntable to the

mounting holes in the floor support next to the motor drive unit. This

DIM1 dimension is critical in determining the length of the drive shaft and

shaft housing. See Determine Shaft Length on page 24 for more

information.

2. Determine the required total length of the drive shaft after section A and

section B are connected with the coupling.

3. Subtract 978 mm (38.5 in) from DIM1 in step 1 for the total overall length

of the shaft.

4. Subtract 6.3 mm (0.25 in) for the total combined cut length of section A

and section B. The coupling will add 6.3 mm (0.25 in) to the shaft length

after the two sections are assembled.

5. Divide the total cut length in step 4 in half. Cut shaft B longer than

shaft A as described:

• Add three inches to the half length, and mark shaft A to this length.

Measure from the 1.0-in diameter end.

• Subtract three inches from the half length, and mark shaft B to this

length. Measure from the 1.06-in diameter end.

This will offset the coupling three inches from the center after it is

assembled.

Optional Shaft Kit Installation Instructions | 27

Page 28

Make sure to measure and mark each section from the small end, not the plain

Cut Shaft Housing

end. The length of section A (on the turntable side) should be at least 150 mm

(6 in) longer than section B (on the motor side).

6. Place the shaft sections side by side to double check the length from

small end to small end. Offset the cut marks 6.35 mm (0.25 in) for the

coupling. If the length is accurate, cut the shaft pieces to length at the

marks.

7. De-burr the cut ends before installing them in the coupling.

8. Install the plain end of each shaft into the coupling all the way to the

step. The total overall length should be close to the length calculated in

step 3.

9. Cut the shaft housing(s) next:

• If DIM1 in step 1 on page 27 was 3035 mm (9.9 ft) or less, then the

mid-floor support is not required. One housing is required. Continue

to step 10.

• If DIM1 is more than 3035 mm (9.9 ft), then the mid-floor support is

required. Two housings are required. Continue to step 11.

10. Determine the total length of the shaft housing. One housing is required.

Subtract 4.75 inches from the overall length of the assembled shaft in

step 3 on page 27. Cut one of the two housings to this length, ±1/16 inch.

Discard the unused housing and mid-floor support, and skip to step 12.

11. Determine the total combined length of the two shaft housings. Two

housings are required with the mid-floor support. Subtract 5.75 in from

the overall length of the assembled shaft to get the combined length of

the housings. Cut each housing to one-half this length, ±1/16 inch. After

cutting the first housing, determine the required length for the second to

equal the total combined length.

12. The shaft housing pieces should now be ready to assemble. See

Assemble Drive Shaft on page 24.

28 | Optional Shaft Kit Installation Instructions

Page 29

8.0 Operation

Before placing into operation, follow the safety information in the

ETS-Lindgren Product Information Bulletin included with your

shipment.

With the assembly of the turntable complete, the Model 2090 Multi-Device

Controller (or next generation ETS Lindgren controller, if applicable) must be

connected to the unit and power applied to both the motor base and controller.

See the controller manual for complete information on connecting the fiber optic

cable and operating the controller. A manual is included with each controller and

is also available for download from www.ets-lindgren.com

.

Operation | 29

Page 30

This page intentionally left blank.

30 | Operation

Page 31

Appendix A: Warranty

See the Product Information Bulletin included with your shipment for the

D

URATION OF WARRANTIES FOR MODEL 2165

complete ETS-Lindgren warranty for your ETS-Lindgren Model 2165 LoPro™

Turntable.

All product warranties, except the warranty of title, and all remedies for warranty

failures are limited to two years.

Product Warranted Duration of Warranty Period

ETS-Lindgren Model 2165 LoPro™ Turntable 2 Years

Warranty | 31

Page 32

This page intentionally left blank.

32 | Warranty

Page 33

Appendix B: Drawings

Your Model 2165 LoPro™ Turntable may vary slightly from the following

drawings.

See these drawings located in the back pocket of this manual:

• Drawing 1

• Drawing 2

• Drawing 3

• Drawing 4

• Drawing 5

• Drawing 6

• Drawing 7

• Drawing 8

• Drawing 9

• Drawing 10

• Drawing 11

Drawings | 33

Page 34

This page intentionally left blank.

34 | Drawings

Page 35

Appendix C: EC Declaration of Conformity

The EC Declaration of Conformity is the method by which ETS-Lindgren L.P. declares that the equipment listed on

this document complies with the EMC Directive and Low Voltage Directive.

Issued by

Factory

ETS-Lindgren, L.P. ETS-Lindgren, L.P.

P.O. Box 80589 P.O. Box 80589

Austin, Texas USA 78708-0589 Austin, Texas USA 78708-0589

The products listed below are eligible to bear the CE mark:

– Model 2165 Turntable with 2165-style motor base

APPLICABLE REQUIREMENTS

Standard Criteria

EN 55011 Group 1, Class B

EN 61000-4-2:1995 Level 2/3 (4/8 kV)

EN 61000-4-3:1997 Level 2 (3 V/m)

EN 61000-4-4 Level 2 (1/0.5k V)

ENV 50204:1996 Level 2 (3 V/m)

EN 61000-4-5:1995 Level 3 (2/1 kV)

EN 61000-4-11:1994 2 kV

EN 61010-1

Safety requirements for electrical equipment for measurement, control and

laboratory use

AUTHORIZED SIGNATORIES

The authorizing signatures on the EC Declaration of Conformity document authorize ETS-Lindgren, L.P. to affix the

CE mark to the indicated product. CE marks placed on these products will be distinct and visible. Other marks or

inscriptions liable to be confused with the CE mark will not be affixed to these products. ETS-Lindgren, L.P. has ensured

that appropriate documentation shall remain available on premises for inspection and validation purposes for a period of

no less than 10 years.

EC Declaration of Conformity | 35

Page 36

10

11

Drawing 1

Page 37

10 11

12

Drawing 2

Page 38

10 11 12

Drawing 3

(optional shaft kit shown)

Page 39

Drawing 4

(optional shaft kit shown)

Page 40

Drawing 5

(optional shaft kit shown)

Page 41

Drawing 6

(optional shaft kit shown)

Page 42

Drawing 7

Page 43

Drawing 8

(optional shaft kit shown)

Page 44

Drawing 9

(optional shaft kit shown)

Page 45

Drawing 10

(optional shaft kit shown)

Page 46

Drawing 11

Loading...

Loading...