Page 1

Model 2090 Series

Multi-Device

Controller

MANUAL

©ETS-Lindgren, April, 2006 Revision G – P# 399199

Page 2

Model 2090 Multi-Device Controller

ETS-Lindgren reserves the right to make changes to any products herein to improve functioning

or design. Although the information in this document has been carefully reviewed and is believed

to be reliable, ETS-Lindgren does not assume any liability arising out of the application or use of

any product or circuit described herein; nor does it convey any license under its patent rights nor

the rights of others.

©Copyright 2006 by ETS-Lindgren L.P. All Rights Reserved.

No part of this document may be copied by any means

without written permission from ETS-Lindgren L.P.

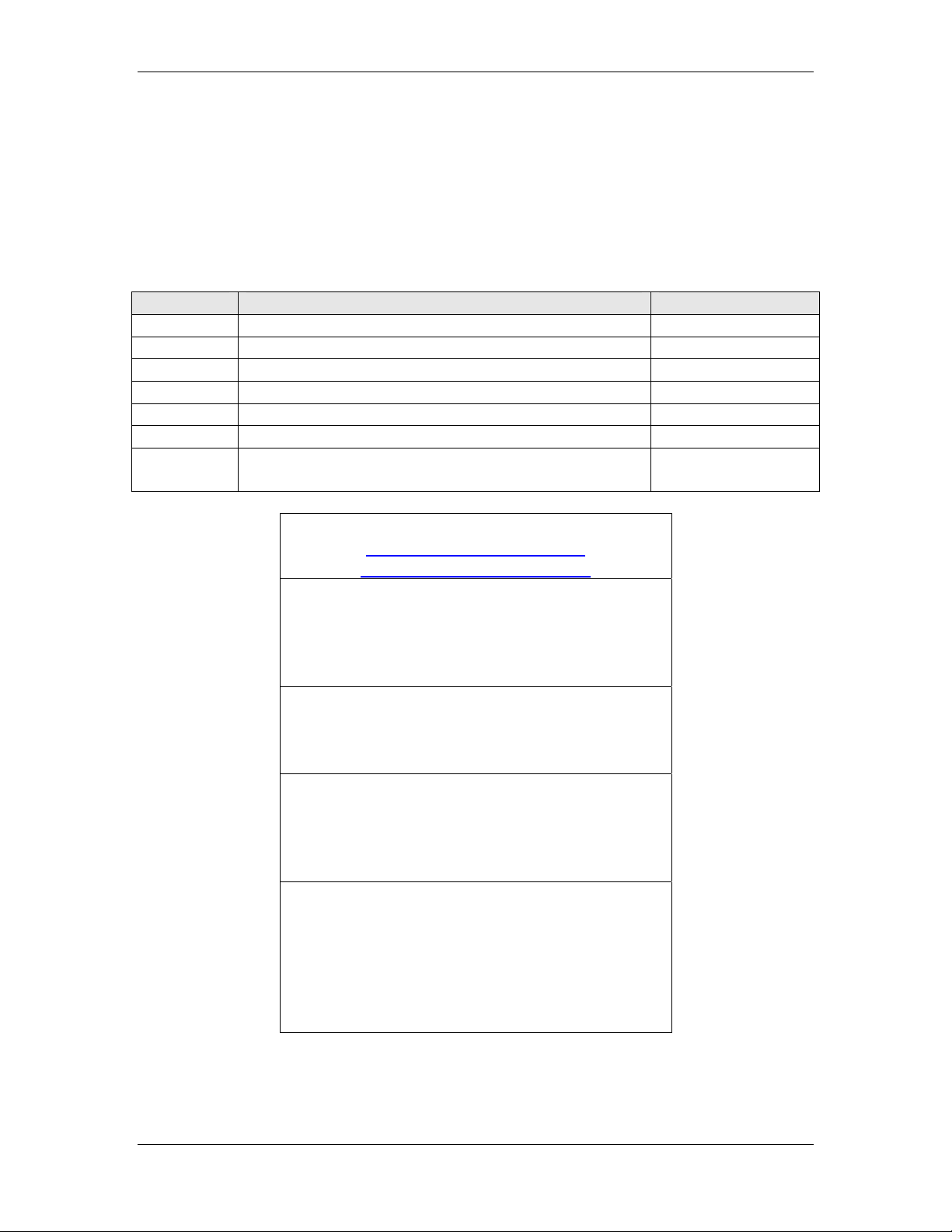

Revision Description Date

A Initial Release December, 1995

B Revision February, 1996

C Revision April, 1997

D Revision October, 1997

E Revision January, 1998

F Revision April, 2001

G Add Option 1 Section. Update warranty and

April, 2006

template to current standards.

E-Mail & Internet Addresses

support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Drive

Cedar Park, TX 78613 USA

Tel. +1.512.531.6400

Fax +1.512.531-6500

Finland

Mekaanikontie 1, 27510, Eura, Finland

Tel. +358.2.838.330

Fax +358.2.865.1233

Japan

4-2-6, Kohinata

Bunkyo-ku, Tokyo 112-0006 Japan

Tel. +81.3.3813.7100

Fax +81.3.3813.8068

China

1917-1918 Xue Zhixuan Building

No. 16 Xue Qing Road

Haidian District

Beijing Postcode: 100083 China

Tel. +86.010.827.55304

Fax +86.010.827.55307

© ETS-Lindgren, April 2006

Revision G– P#399199

Page 3

Model 2090 Multi-Device Controller

TABLE OF CONTENTS

ODEL 2090 QUICK REFERENCE.................................................................................................................... 7

M

KEYBOARD NAVIGATION................................................................................................................................9

INTRODUCTION.............................................................................................................................................. 11

APPLICATIONS........................................................................................................................................... 12

FEATURES ................................................................................................................................................. 13

STANDARD CONFIGURATION..................................................................................................................... 16

OPTIONAL FEATURES......................................................................................................................... 17

PREPARATION FOR USE ................................................................................................................................. 19

UNPACKING THE CONTROLLER ................................................................................................................. 19

FRONT PANEL DESCRIPTION...................................................................................................................... 20

STANDARD BACK PANEL DESCRIPTION .................................................................................................... 29

OPTIONAL BACK PANEL DESCRIPTION...................................................................................................... 31

POWER REQUIREMENTS ............................................................................................................................ 32

RACK MOUNTING...................................................................................................................................... 33

DEVICE CONNECTIONS.............................................................................................................................. 33

OPTIONAL DEVICE CONNECTIONS............................................................................................................. 35

GPIB INTERCONNECTIONS........................................................................................................................ 36

INITIALIZATION ............................................................................................................................................. 37

STARTUP ................................................................................................................................................... 37

EDITING PARAMETERS .............................................................................................................................. 40

CONFIGURING FOR USE............................................................................................................................. 43

MODEL 2090 PARAMETER LIST .................................................................................................................... 45

OPERATION ................................................................................................................................................... 55

MANUAL OPERATIONS .............................................................................................................................. 55

USING LOCAL FUNCTIONS ...................................................................................................................... 56

USING POSITION FUNCTIONS ................................................................................................................. 56

USING LIMIT FUNCTIONS ........................................................................................................................ 58

USING THE SCAN FUNCTION.................................................................................................................... 59

USING THE STEP FUNCTIONS ................................................................................................................... 60

CHANGING POLARIZATION........................................................................................................................ 60

POLARIZATION VIOLATION AND LIMITS.................................................................................................... 63

CHANGING SPEEDS.................................................................................................................................... 63

USING AUXILIARY CONTROL FUNCTIONS ................................................................................................. 66

USING A BORE SIGHT TOWER.................................................................................................................... 67

USING AN AIR FLOTATION TURNTABLE .................................................................................................... 69

USING A REVERBERATION PADDLE........................................................................................................... 69

USING A MULTI-AXIS POSITIONER............................................................................................................ 70

REMOTE OPERATIONS ............................................................................................................................... 71

USING THE GPIB COMMAND SET WITH THE MODEL 2090............................................................................ 73

BACKWARD COMPATIBILITY..................................................................................................................... 73

GETTING STARTED WITH THE GPIB .......................................................................................................... 74

TYPICAL FLOW OF CODE:.......................................................................................................................... 75

CODE SAMPLE 1........................................................................................................................................ 76

CODE SAMPLE 2........................................................................................................................................ 77

GPIB STATUS REPORTING ........................................................................................................................ 82

APPENDIX A: MODEL 2090 GPIB COMMAND REFERENCE .......................................................................... 97

LIST OF MODEL 2090 GPIB COMMANDS................................................................................................ 98

ALPHABETICAL LIST OF MODEL 2090 GPIB COMMANDS .................................................................... 101

APPENDIX B: MAINTENANCE ..................................................................................................................... 137

NVRAM BATTERY BACKUP................................................................................................................... 137

INSTALLING FLASH ROMS...................................................................................................................... 140

FLASH UPGRADING THE MODEL 2090..................................................................................................... 147

©ETS-Lindgren, April, 2006

Revision G – P#399199

Page 4

Model 2090 Multi-Device Controller

FLASH UPGRADING MOTOR BASES ......................................................................................................... 150

APPENDIX C: MODEL 2090 ERROR CODE REFERENCE............................................................................... 157

ERROR CODES......................................................................................................................................... 157

TROUBLESHOOTING ERROR CODES......................................................................................................... 158

APPENDIX D: PARAMETER SETTINGS ......................................................................................................... 165

PARAMETER SETTING FOR AMS-8050 AND 2188 SERIES MAPS............................................................ 165

WARRANTY STATEMENT:................................................................................................................... 167

TECHNICAL SUPPORT .................................................................................................................................. 173

EUROPEAN COMMUNITY DECLARATION OF CONFORMITY .......................................................................... 175

INDEX.......................................................................................................................................................... 177

© ETS-Lindgren, April 2006

Revision G– P#399199

Page 5

Model 2090 Multi-Device Controller

FIGURES

Figure 1 Model 2090 Front Panel...................................................................................................... 20

Figure 2 Model 2090 Device Control Block

Figure 3 Model 2090 Standard Back Panel

Figure 4 Model 2090 Option 1 Back Panel

Figure 5 Bore sight geometry for standard bore sight tower

Figure 6 Status Reporting Model

Figure 7 Model 2090 Motherboard

...................................................................................................... 83

................................................................................................ 139

Figure 8 Universal Device Controller Upgrade Utility

Figure 9 MB-V Flash Upgrade Utility

.................................................................................. 21

..................................................................................... 29

..................................................................................... 31

.................................................... 68

........................................................... 149

.......................................................................................... 153

©ETS-Lindgren, April, 2006

Revision G – P#399199

Page 6

Model 2090 Multi-Device Controller

!

V

NOTICE : This product and related documentation must be reviewed for familiarization

with safety markings and instructions before operation..

SAFETY SYMBOL DEFINITIONS

REFER TO MANUAL

When product is marked with this symbol refer to instruction manual for

additional information.

CAUTION

HIGH VOLTAGE

Indicates the presence of hazardous voltage. Unsafe practices could

result in severe personal injury or death.

PROTECTIVE EARTH GROUND (SAFETY GROUND)

Indicates protective earth terminal. You should provide an uninterruptible

safety earth ground from the main power source to the product input

wiring terminals, power cord, or supplied power cord set.

CAUTION

Denotes a hazard. Failure to follow instructions could result in minor

personal injury and/or property damage. Included text gives proper

procedures.

GENERAL SAFETY CONSIDERATIONS

WARRANTY

S

U

E

F

U

FUSE

2A:250

T

F

E

S

G P I B

G P I B

G P I B

G P I B

BEFORE POWER IS APPLIED TO THIS INSTRUMENT, GROUND IT

PROPERLY through the protective conductor of the AC power cable to a

power source provided with protective earth contact. Any interruption of

the protective (grounding) conductor, inside or outside the instrument, or

disconnection of the protective earth terminal could result in personal

injury.

BEFORE SERVICING: CONTACT EMC TEST SYSTEMS – servicing (or

modifying) the unit by yourself may void your warranty. If you attempt to

service the unity by yourself, disconnect all electrical power before

starting. There are voltages at many points in the instrument which

could, if contacted cause personal injury. Only trained service personnel

should perform adjustments and/or service procedures upon this

instrument. Capacitors inside this instrument may still be CHARGED

even when the instrument is disconnected from its power source.

TO AVOID A SAF ETY HAZARD, replace fuses with the same current

rating and type (normal blow, time delay, etc.). Order any replacement

parts direct from ETS.

TO AVOID UNDUE MECHANICAL STRESS on the GPIB I/O

CONNECTOR, limit connector stacking to no more than three cables on

one connector.

ONLY QUALIFIED PERSONEL should operate (or service) this

equipment.

IN EVENT OF EMERGENCY push the Model 2090 STOP button and

STOP

power unit down.

© ETS-Lindgren, April 2006

Revision G– P#399199

Page 7

Model 2090 Multi-Device Controller

MODEL 2090 QUICK REFERENCE

Error List

E001

E002

E003

E004

E005

E006

E007

E008

E009

E010

E011

E012

E100

E101

E102

E103

E104

E996

E997

E998

E999

Errors less than

cause of the error condition should be corrected before continuing. The remaining errors may indicate th at

the 2090 requires service. If one of these errors occurs, power off the unit for several seconds and power it

back on. If the error recurs, contact EMC Test Systems, L.P. for service.

NVM Initialization Error – Parameters restored to factory defaults due to dead battery.

Motor not moving – Device stalled due to overload, power problems, or failure.

Device will not stop – Device continued moving for too long after motion was disabled.

Device moving wrong direction – Device wired wrong, failing, or reverse delay too short.

Hard Limit hit – Device has reached a mechanical limit.

Polarization limits violation – Tower polarized outside allowed target polarization limits.

Communicat ion lost – No comm. w/ device; power off, fiber disconnected, or failure.

Flotation violation – Attempt to disengage air flotation while turntable is in motion.

Encoder failure – Detected changes in position consistent with an encoder problem.

Trigger failure

Overheat Error – Motor or control board over temperature

Relay Failure – Motor drive control relays not switching properly

ROM test error – ROM has been detected as being corrupt.

RAM test error – RAM has been detected as being corrupt.

NVM test error – NVM has been detected as being corrupt.

Low Power test error – Power test failed.

GPIB test error – GPIB test failed.

BERR Error

Uninitialized Interrupt

Spurious Interrupt

Invalid Interrupt Error

E100 can be cleared by pressing any key on the front panel to acknowledge the error. The

©ETS-Lindgren, April, 2006

Revision G – P#399199

Page 8

Model 2090 Multi-Device Controller

Parameter List

P1

P2

P3

P4 Polarization offset: (±50 cm) -or- Bore Sight separation distance: (3, 10, or 30 m)

P5

P8

P9

B1

C

S0

S1-S8

PCLr

OSCLr

OC

ZERO

BASE

ACC

TEP

SND

Device Type: (0 = rotational positioner, 1 = linear positioner)

Device Sub-Type: (0 = Standard Turntable/Tower, 1 = Air Flotation

Turntable/Bore Sight Tower, 2 = Two Speed Turntable)

SCAN cycle count: (1-999 complete scans, 0 = infinite scan)

Bore sight correction table: (0 = standard, 1 = alternate) -or-

Turntable rotation mode: (0 = Continuous, 1 = Non-continuous)

Motor reverse delay: (0.1 – 99.9 seconds)

GPIB Address: (0-30)

Bit 0, STEP limits – (0 = INC/DEC limited by hard limits, 1 = INC/DEC limited by soft limits)

Bit 1, Quick Stop – (0 = normal deceleration, 1 = fast deceleration (variable speed only))

Encoder calibration: Encoder counts per meter/revolution (1-9999). Typical values are:

Towers: Default = 2000, 2075 = 1620; Turntables: Default = 3600, 2065 = 3665 , 2081 = 3608,

2088 = 4500 (4800*), 5901 = 6000 (6400*), MAPS = 4500. * Early revisions.

STEP speed setting: (-1 = disabled, 0-255 (variable speed devices only)

Speed setting: (0-255 (variable speed devices only)

Clear Parameters: Restores this device to factory default.

Clear Overshoot: Clears overshoot compensation values for this device.

Overshoot Compensation Enable/Disable: (On = enabled, OFF = disabled)

Zero Reference : Initiates a zero pulse reference scan on equipped devices.

Motor base firmware revision: For informational purposes only.

Acceleration: Time in seconds for motorbase to reach full speed (variable speed devices only)

Temperature monitor: Displays motor and control board temperature.

Motorbase sound setting: (0 = No sounds, 1 = remote control only, 2 = errors enabled, 3 = all

sounds enabled).

© ETS-Lindgren, April 2006

Revision G– P#399199

Page 9

Model 2090 Multi-Device Controller

KEYBOARD NAVIGATION

To return to local operation – when RMT indicator lit, pressing LOCAL restores local operation.

To initiate/stop motion – press UP/CW or DOWN/CCW under POSITION to start motion. Press

SCAN to toggle scan mode on or off. Press and hold INC or DEC keys under STEP, when the

display shows the current position, to initiate motion while the key is pressed. Press STOP under

POSITION to stop motion.

To change mast polarization – press the POLARIZATION/FLOAT/SPEED button under

POSITION, while the display shows the current position, to toggle the polarization. Polarizing the

tower while the boom is above or below the limits of the target polarization will cause and error

E006.

To change air flotation turntable flotation – press the POLARIZATION/FLOAT/SPEED button

under POSITION to toggle the flotation. Deflating the table while in motion will cause an error

E008.

To change speed selection – on a variable speed device, press the LOCAL key while in local

mode and viewing the current position to display the current speed selection. Press INCRM and

DECRM under LIMIT to scroll up or down through the available speeds. For variable speed

turntables, press the POLARIZATION/FLOAT/SPEED button under POSITION to scroll through

the available speeds. For two-speed turntables, press the POLARIZATION/FLOAT/SPEED

button under POSITION to toggle between high and low speeds.

To view limits – press UP/CW, DOWN/CCW, or CURRENT POSITION under LIMIT to display

the associated value.

To view limits for the opposite polarization – with the desired limit displayed, press the

POLARIZATION/FLOAT/SPEED button under POSITION. The tower will remain at the current

polarization, but the display will change to the limit for the other polarization. The

POLARIZATION indicator will flash to indicate that the display does not represent the actual state

of the device.

To view parameters – press PARAM under CONFIG to display the current parameter.

Repeatedly pressing PARAM will scroll through the parameter list. While a parameter is

displayed, pressing INC or DEC under STEP will scroll up or down through the available

parameters.

To edit limits or parameters – with the desired limit, position, or parameter visible in the display,

press ENTER under LIMIT to enter edit mode. Pressing INCRM or DECRM under LIMIT will also

enter edit mode and immediately change the first digit. The active digit will flash, and pressing

INCRM or DECRM will increase or decrease that value. For values with multiple digits, pressing

the LOCAL key while the display is flashing will shift to the next higher digit in the display. Once

the desired value is entered into the display, press ENTER to store the data. Pressing any other

non-edit key will exit the edit mode, discarding the value, and activate the associated function.

For parameter function calls (PCLr, OSCLr, & ZERO), pressing ENTER will ask for confirmation

(SURE). Pressing enter again will activate the function.

To use auxiliary devices – press the 1-4 button under AUX CONTROL to toggle the associated auxiliary

port on or off.

©ETS-Lindgren, April, 2006

Revision G – P#399199

Page 10

Keyboard Navigation Model 2090 Multi-Device Controller

This page intentionally left blank.

10 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 11

Model 2090 Multi-Device Controller

INTRODUCTION

The Model 2090 Multi-Device Positioning Controller is

designed for use with ETS-Lindgren positioning devices

such as antenna towers, turntables, reverberation paddles,

multi-axis positioners, etc. to accomplish a variety of tests

for EMC compliance, antenna pattern measurements, and

more.

The Controller allows the user to synchronize the

simultaneous, yet independent movement of two primary

devices such as towers or turntables in either manual or

remote GPIB modes while controlling the on/off operation

of up to four auxiliary devices.

Each primary device is interfaced to the Model 2090

through a bi-directional fiber optic interface using a

proprietary command protocol. Auxiliary devices use a

single-pole double-throw RF relay to control simple on/off

operation. The connection type is SMA.

The front panel of the Model 2090 provides the interface

for two separate and complete device controllers, each with

identical displays and function keys. The function keys let

the user configure device specific parameters, adjust limit

and position settings, and control device motion. Numeric

displays and status indicators are provided for each device

interface to show positioning and operational information,

as well as device parameter settings. In addition to the two

primary device interfaces, there is an auxiliary control

interface for four auxiliary devices. This interface provides

©ETS-Lindgren, April 2006 11

Revision G– P#399199

Page 12

Introduction Model 2090 Multi-Device Controller

keys and indicators to allow the user to manually toggle the

auxiliary devices on or off.

Control of all devices may be accomplished either in the

manual or remote modes through the use of the GPIB

(IEEE 488 standard interface bus) port located on the rear

panel. Each primary device is identified by a unique GPIB

address that the controller recognizes, allowing each

positioning device to function as a separate device on the

GPIB bus.

APPLICATIONS

RADIATED EMISSIONS TESTING

The Model 2090 is used to control ETS-Lindgren towers

and turntables during manual or fully automated radiated

emissions testing. The controller is capable of controlling

the tower height scan and antenna polarization functions

and the turntable rotation function from the operator's

station during remotely controlled or manual

measurements. This capability satisfies the technical

measurement requirement to search in azimuth and over a

specified height range to detect the maximum of the signal

sourced in the equipment under test.

SITE ATTENUATION MEASUREMENTS

The Model 2090 allows for the remote control of the height

search of all ETS-Lindgren towers during site attenuation

testing. With this capability, the user can maximize the

signal level detected at each measurement frequency within

the required height search range.

12 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 13

Model 2090 Multi-Device Controller

PATTERN ANALYSIS

With the Model 2090, the user can have manual or

automated control of the turntable rotation function or the

ortho (elevation) and azimuth functions of a Multi-Axis

Positioning System (MAPS) from an operator's station

during antenna pattern measurement.

REVERBERATION CHAMBERS

The Model 2090 can provide precise step control of all

ETS-Lindgren reverberation paddles for mode-tuned

operation, or continuous rotation variable speed control for

mode-stirred operation.

FEATURES

FIBER OPTIC INPUT/OUTPUT LINES

• Eliminate unwanted RF signals generated over wire

cables.

• Each primary device cable contains two fiber optic lines

(transmit/receive).

• Each auxiliary device cable contains one fiber optic line

(transmit only).

• Fiber optic connectors (device and auxiliary) on the

back panel are metal ST connectors that are reliable and

easy to use.

MULTI-DEVICE CONTROL

• Duplicate front panel controls permit simultaneous and

synchronized control of two primary devices and four

auxiliary devices in both manual and remote modes.

©ETS-Lindgren, April 2006 13

Revision G– P#399199

Page 14

Introduction Model 2090 Multi-Device Controller

COMPATIBILITY

• Compatible with the a variety of commercial software

including the following:

Hewlett Packard Commercial Radiated EMI

Measurement Software (HP Part # 85876A).

Rohde & Schwarz ES-K1 Emissions Software

Quantum Change Tile software

• Backward compatible with previous ETS-Lindgren

Models 1050, 1060 and 1090 Controller GPIB

command sets (See Appendix A for settings).

• Compatible with the ETS-Lindgren Model 2190 Virtual

Controller GPIB command set and VCS interface.

SEEK/SCAN FUNCTIONS

• SEEK: Allows for movement of device under control to

a target position (valid through GPIB only).

• SCAN: Allows for movement of device under control

cyclically between pre-programmed limits.

TARGET OVERRUN CORRECTION FEATURE

• Constantly monitors inertia induced target overrun. A

special algorithm continually adjusts subsequent

positioning to minimize overrun, allowing for proper

device positioning during tests.

SPECIAL LIMIT SETTING FEATURE

• When used to control a tower, upper and lower limits

can be set independently for both horizontal and

vertical polarizations.

• Prevents element damage at upper or lower limit due to

a change in polarization.

14 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 15

Model 2090 Multi-Device Controller

GPIB INTERFACE

• Complies with IEEE 488 industry standards (488.1 and

488.2 compatible).

• All front panel functions can be exercised using GPIB

commands while in the remote mode.

• Provides additional capabilities not available from the

front panel, including a variety of SEEK commands.

UNIVERSAL POWER SUPPLY

• Auto ranging - automatically senses supply voltage (no

user selection necessary).

• Accepts any AC power source input within the range of

115/230 VAC, 50/60 Hz.

RACK MOUNTING

• Standard rack width.

• 3 U rack size.

©ETS-Lindgren, April 2006 15

Revision G– P#399199

Page 16

Introduction Model 2090 Multi-Device Controller

STANDARD CONFIGURATION

ELECTRICAL

Voltage

Frequency 44-440 Hz

Fuse 2 A, 250 VAC Time Delay

Power Inlet IEC 320

Interface GPIB (IEE 488)

I/O Ports Fiber Optic, 2 lines each, 2 primary devices

Batteries 3 Size “AAA” 1.5 V DC Alkaline (type

PHYSICAL

Width

Depth 38.0 cm (with handles)

Height 13.3 cm

Weight 4.5 kg

Towers: 1mm ± 1 cm

Turntables: 0.1 degree ± 1 degree

Reverb: 0.1 degree ± 1 degree

MAPS: 0.1 degree ± 1 degree

Position Resolution Positioning Accuracy with

90-250 VAC

Fiber Optic, 1 line each, 4 auxiliary devices

EN92 or equivalent), user replaceable

(for parameter backup)

43.8 cm

17.25 in

13.5 in

5.25 in

10.0 lbs

Overshoot Compensation

16 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 17

Model 2090 Multi-Device Controller

OPTIONAL FEATURES

Option 1 I/O Ports:

RF Switch, SPDT, four auxiliary devices

©ETS-Lindgren, April 2006 17

Revision G– P#399199

Page 18

Introduction Model 2090 Multi-Device Controller

This page intentionally left blank.

18 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 19

Model 2090 Multi-Device Controller

PREPARATION FOR USE

UNPACKING THE CONTROLLER

The ETS-Lindgren Model 2090 Multi-Device Controller is

shipped with an instruction manual, power cord, and

appropriate packing material to prevent damage. Carefully

remove the Model 2090 and its accessories from the

shipping container. Save the packing material for storage

and shipping. Check to make sure all contents are intact

and report any missing items to the factory. After verifying

the contents, proceed with the setup process. Before

connecting, configuring, or using the Model 2090, the user

should become familiar with the available controls and

connections. The following sections describe the front and

back panels of the unit.

©ETS-Lindgren, April 2006 19

Revision G– P#399199

Page 20

Preparation for Use Model 2090 Multi-Device Controller

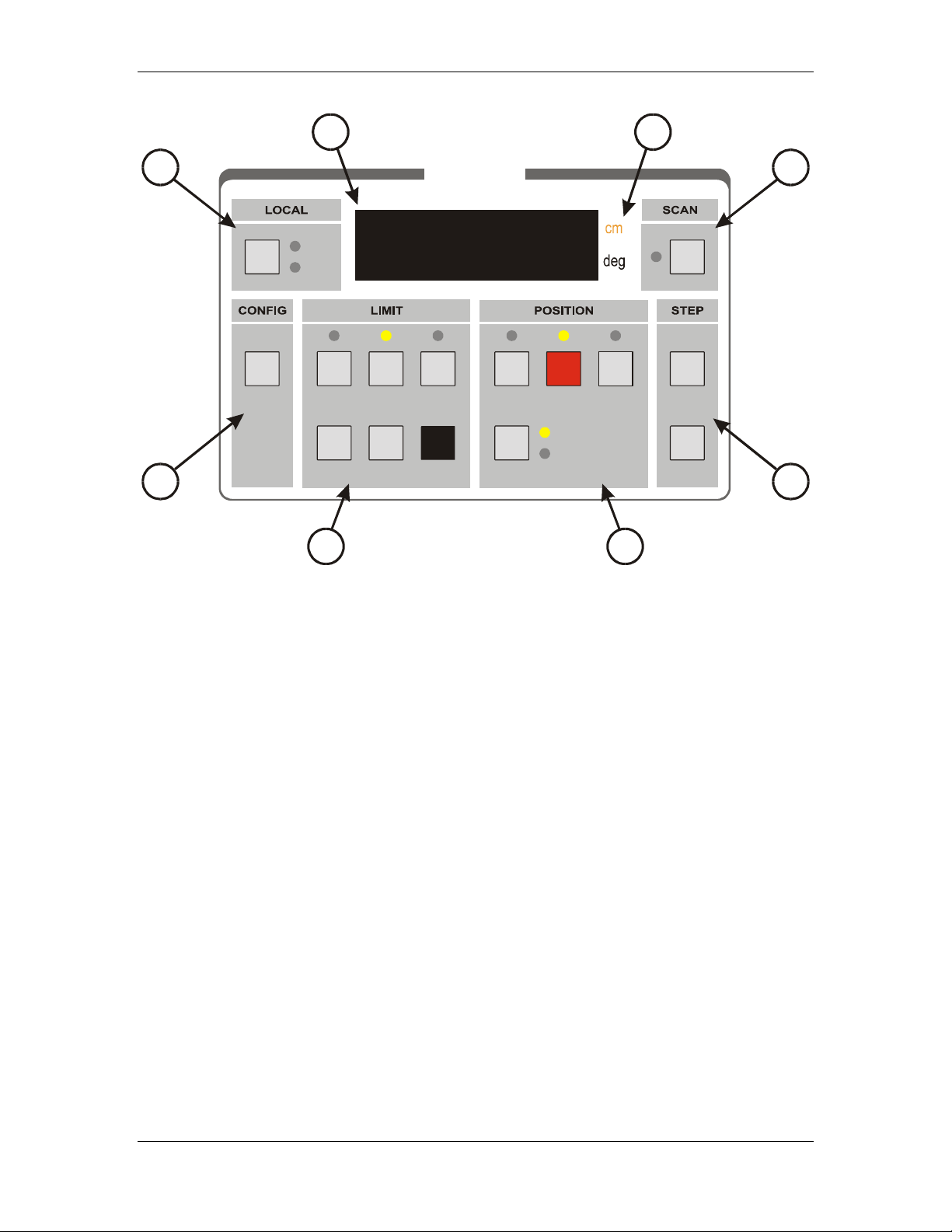

FRONT PANEL DESCRIPTION

CURRENT

POSITION

DEVICE TWO

DOWN

CCW

ENTER

UP

CW

MODEL 2090

MULTI-DEVICE

CONTROLLER

AUX CONTROL

132

4

RMT

8. 8. 8. 8. 8. 8. 8. 8. 8. 8.

ADDR

PARAM DOWN

CURRENT

UP

CW

POSITION

INCRM DECRM

ENTER

DEVICE ONE

CCW

UP

CW

STOP

HOR / UP / FAST

VERT / DN / SLOW

DOWN

RMT

ADDR

INC

PARAM

CCW

DECPOLARIZATION / FLOAT / SPEE D

UP

CW

INCRM DECRM

1 42 3

gure 1 Model 2090 Front Panel Fi

1. CK – Provides input keys

AUXILIARY CONTROL BLO

and indicators for the four auxiliary control ports. Pressing

a key will toggle the corresponding auxiliary output and

indicator on or off.

2. s the user

DEVICE ONE CONTROL BLOCK – Provide

STOP

HOR / UP / FAST

VERT / DN / SLOW

DOWN

POWER

INC

CCW

DECPOLARIZATION / FLOAT / SPEED

interface for Primary Device 1.

3. DEVICE TWO CONTROL BLOCK – Provides the user

interface for Primary Device 2.

4. POWER CONTROL BLOCK – Provides the power

toggle switch and power indicator. Power is enabled with

the switch depressed. The power indicator should light a

few moments after depressing the power switch.

20 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 21

Model 2090 Multi-Device Controller

1

2

PARAM

8

RMT

ADDR

UP

CW

INCRM DECRM

3

DEVICE ONE

8. 8. 8. 8. 8.

CURRENT

POSITION

DOWN

CCW

ENTER

UP

CW

STOP DOWN

HOR / UP / FAST

VERT / DN / SLOW

CCW

4

7

6

INC

DECPOLARIZATION / FLOA T / SPEED

5

Figure 2 Model 2090 Device Control Block

1. LOCAL KEY AND INDICATORS

LOCAL key – The LOCAL key is a multi-function key

which has a different behavior depending on the status of

the Model 2090.

a. Pressing the LOCAL key while the corresponding

primary device is in remote control mode (RMT

indicator lit) will return the controller to local control

mode.

b. For a variable speed device, pressing the LOCAL key

while in local mode and viewing the position displays

will activate the speed selection mode, causing the

current speed selection to be displayed momentarily in

the primary display. The INCRM and DECRM keys

can then be used to adjust the speed selection.

©ETS-Lindgren, April 2006 21

Revision G– P#399199

Page 22

Preparation for Use Model 2090 Multi-Device Controller

c. In edit mode (see below), pressing the LOCAL key

will shift the display digit being edited to the next

higher digit.

RMT (REMOTE) indicator – This indicator will be lit as

long as the corresponding primary device is under remote

GPIB control. The front panel keys (except the LOCAL

key) of this primary device will be disabled while in remote

mode.

NOTE: While user input and control is disabled, the

remaining keys may still be used to acknowledge an error

condition while in remote control mode.

ADDR (ADDRESSED) indicator – This indicator will

strobe to indicate GPIB bus activity while in remote control

mode.

2. CONFIGURATION

PARAM (PARAMETER) key – Pressing this key will

stop all device motion and display the current entry of the

configuration parameter list for this primary device in the

corresponding display window. Repeatedly pressing this

key will advance to the next parameter in the list.

3. LIMIT KEYS AND INDICATORS

UP/CW key – Pressing this key will display the upper limit

for the current polarization of a tower, or the clockwise

limit of a turntable, reverberation paddle, or MAPS in the

corresponding numerical display.

UP/CW indicator – Lights to indicate that the numerical

display represents the upper limit of a tower, or the

clockwise limit of a turntable, reverberation paddle, or

MAPS.

22 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 23

Model 2090 Multi-Device Controller

CURRENT POSITION key – Pressing this key will

display the current position of the primary device in the

corresponding display.

CURRENT POSITION indicator – Lights to indicate that

the numerical display represents the current position of the

primary device. This is the default state.

DOWN/CCW key – Pressing this key will display the

upper limit for the current polarization of a tower, or the

counterclockwise limit of a turntable, reverberation paddle,

or MAPS in the corresponding display.

DOWN/CCW indicator – Lights to indicate that the

numerical display represents the lower limit of a tower, or

the counterclockwise limit of a turntable, reverberation

paddle, or MAPS.

ENTER key – Pressing this key toggles the edit mode on

or off. With the edit mode off, pressing ENTER will

initiate edit mode for the currently displayed limit or

parameter. Pressing ENTER while in edit mode will store

the modified limit or parameter and exit edit mode.

NOTE: This key only works when the device is not in

motion.

INCRM (INCREMENT) key – Pressing this key will

increment the currently highlighted digit of the limit,

position, parameter, or speed selection in the display

window. For limits, position, and parameters, if the Model

2090 is not already in edit mode, it will automatically

switch to edit mode.

NOTE: With the exception of changing the speed selection,

this key only works when the device is not in motion.

DECRM (DECREMENT) key – Pressing this key will

decrement the currently highlighted digit of the limit,

©ETS-Lindgren, April 2006 23

Revision G– P#399199

Page 24

Preparation for Use Model 2090 Multi-Device Controller

position, parameter, or speed selection in the display

window. For limits, position, and parameters, if the Model

2090 is not already in edit mode, it will automatically

switch to edit mode.

NOTE: With the exception of changing the speed selection,

this key only works when the device is not in motion.

4. POSITION KEYS AND INDICATORS

UP/CW key – Pressing this key will command the

associated primary device to move in the UP or

CLOCKWISE direction. Actual motion will depend on the

current state of the device and the controller.

UP/CW indicator – Lights solid to indicate that the device

is moving in the UP or CLOCKWISE direction. Flashes to

acknowledge user key-press of the UP/CW key and to

indicate that the target motion is in the UP or

CLOCKWISE direction during reverse delay operations.

STOP key – Pressing this key will command the

associated primary device to stop motion. Variable speed

devices will decelerate to their minimum speed before

disabling the drive.

STOP indicator – Lights solid to indicate that the device

is stopped. Flashes to acknowledge user key-press of the

STOP key and during deceleration of variable speed

devices.

DOWN/CCW key – Pressing this key will command the

associated primary device to move in the DOWN or

COUNTERCLOCKWISE direction. Actual motion will

depend on the current state of the device and the controller.

DOWN/CCW indicator – Lights solid to indicate that the

device is moving in the DOWN or COUNTER-

24 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 25

Model 2090 Multi-Device Controller

CLOCKWISE direction. Flashes to acknowledge user keypress of the DOWN/CCW key and to indicate that the

target motion is in the DOWN or COUNTERCLOCKWISE direction during reverse delay operations.

POLARIZATION/FLOAT/SPEED key – This key has a

variety of behaviors depending on the attached primary

device type:

a. For towers, pressing this key toggles the tower boom

between horizontal and vertical polarization when the

display shows the current position; and toggles the

display between horizontal and vertical limit displays

when showing an upper or lower limit.

b. For air-flotation turntables, pressing this key floats or

lowers the turntable on its air cushions. The turntable

cannot be dropped while in motion.

c. For two speed turntables, pressing this key toggles the

turntable between fast and slow speed.

d. For standard variable speed turntables, pressing this key

advances the selected speed setting to the next preset

speed selection.

HOR/UP/FAST indicator – This indicator has a variety of

behaviors depending on the attached primary device type:

a. For towers, this indicator lights solid to indicate that the

tower is polarized horizontally. This indicates the

status of the polarization solenoid only, and may or may

not reflect the actual position of the tower’s cross boom

at any given instant. This indicator flashes to indicate

that the display is showing the upper or lower limit for

the horizontal polarization, while the tower is still

polarized vertically.

©ETS-Lindgren, April 2006 25

Revision G– P#399199

Page 26

Preparation for Use Model 2090 Multi-Device Controller

b. For air-flotation turntables, this indicator lights solid to

show that the air flotation solenoid has been activated.

c. For two speed turntables, this indicator lights solid to

show that the turntable motor is set to high speed.

d. For standard variable speed turntables, this indicator

lights in a binary fashion with the VERT/DN/SLOW

indicator to represent the least significant bits of the

current speed selection. See the section on

“OPERATION” for more information on this display.

VERT/DN/SLOW indicator – This indicator has a variety

of behaviors depending on the attached primary device

type:

e. For towers, this indicator lights solid to indicate that the

tower is polarized vertically. This indicates the status

of the polarization solenoid only, and may or may not

reflect the actual position of the tower’s cross boom at

any given instant. This indicator flashes to indicate that

the display is showing the upper or lower limit for the

vertical polarization, while the tower is still polarized

horizontally.

f. For air-flotation turntables, this indicator lights solid to

show that the air flotation solenoid has been deactivated.

g. For two speed turntables, this indicator lights solid to

show that the turntable motor is set to low speed.

h. For standard variable speed turntables, this indicator

lights in a binary fashion with the HOR/UP/FAST

indicator to represent the least significant bits of the

current speed selection. See the section on

“OPERATION” for more information on this display.

26 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 27

Model 2090 Multi-Device Controller

5. STEP KEYS

INC (INCREASE) key – This key has two functions:

a. Pressing this key while viewing position information

will command the associated primary device to move

in the UP or CLOCKWISE direction until the key is

released. Actual motion will depend on the current

state of the device and the controller.

b. Pressing this key while viewing the parameter list will

move up the parameter list by one entry, allowing the

user to scroll back through the parameter list.

DEC (DECREASE) key – This key has two functions:

a. Pressing this key while viewing position information

will command the associated primary device to move in

the DOWN or COUNTERCLOCKWISE direction until

the key is released. Actual motion will depend on the

current state of the device and the controller.

b. Pressing this key while viewing the parameter list will

move down the parameter list by one entry, allowing

the user to scroll forward through the parameter list

(same as pressing the PARAM key).

6. SCAN KEY AND INDICATOR

SCAN key – This key toggles the scan mode on or off.

When activated, the associated primary device will move

between the upper/clockwise and lower/counterclockwise

limits for the number of cycles specified by the scan cycle

parameter,

P3. See the “MODEL 2090 PARAMETER

LIST” for more information.

SCAN indicator – This indicator is lit as long as the scan

mode is activated.

©ETS-Lindgren, April 2006 27

Revision G– P#399199

Page 28

Preparation for Use Model 2090 Multi-Device Controller

7. UNIT INDICATORS

cm indicator – This indicator is lit for devices configured

as towers, to indicate that the position and limit information

is displayed in centimeters.

deg indicator – This indicator is lit for devices configured

as turntables, to indicate that the position and limit

information is displayed in degrees.

8. PRIMARY DISPLAY

This five digit, seven-segment display provides the primary

feedback for the user interface. It is used to display current

position information, limit settings, parameter settings,

speed selection, error messages, and other alphanumeric

messages.

28 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 29

Model 2090 Multi-Device Controller Model 2090 Multi-Device Controller

STANDARD BACK PANEL DESCRIPTION

LINE INPUT

FUSE

2 A: 250 V T

115/230 V

50/ 60 Hz

100 VA MAX.

IEEE 488

-

GPIB

CAUTION

For laborator y use by

qualified per sonnel.

ATTENT ION

Pour emploi par le

personnel de labora toire.

AUXILIARY CONTROL

AUX 1 AUX 2

AUX 3 AUX 4

DEVICE INTERFACE

DEVICE 2

IN IN

OUT OUT

DEVICE 1

1

2

Figure

3 4 5 6

3 Model 2090 Standard Back Panel

1. AC POWER FUSE – This is the AC power fuse holder.

Replace the fuse with the power off and the power cord

disconnected from the unit, and only with a fuse of the

same rating. Failure to do so may cause personal injury or

instrument damage and will void the warranty.

2. ER INLET – This is the IEC 320 power inlet.

IEC POW

Attach an appropriate power cord between this inlet and the

power mains. This is a grounded outlet and provides the

safety earth ground for the instrument. Never attempt to

defeat the safety features of the device. Doing so may cause

personal injury or instrument damage and will void the

warranty.

3.

GPIB PORT – This is the IEEE 488 GPIB interface port.

It is used to connect the Model 2090 to a PC

or other GPIB

bus controlling device using a standard GPIB cable.

4.

AUXILIARY CONTROL – These are the ST-type fiber

optic output connectors for the four auxiliary device

©ETS-Lindgren, April 2006 29

©ETS-Lindgren, April 2006 29

Revision G– P#399199

Revision G– P#399199

Page 30

Preparation for Use Model 2090 Multi-Device Controller

controls. They provide simple on/off control for remote

devices fitted with an auxiliary device input.

5.

6.

DEVICE 2 INTERFACE – These are the ST-type fiber

optic I/O co

nnectors for primary device number two. One

channel of a duplex fiber optic cable connects from the

OUT connector of the controller to the IN connector of the

primary interface of a device (tower, turntable, e

cond channel connects from the OUT connector of the

se

tc.). The

primary interface of the device to the IN connector of the

controller.

NOTE: Older motor base designs do not have a secondary

fiber optic interface. The secondary interface on newer

devices is currently reserved for future expansion.

DEVICE 1 INTERFACE – These are the ST-type fiber

optic I/O co

nnectors for primary device number one. One

channel of a duplex fiber optic cable connects from the

OUT connector of the controller to the IN connector of the

primary interface of a device (tower, turntable, e

tc.). The

second channel connects from the OUT connector of the

primary interface of the device to the IN connector of the

controller.

NOTE: Older motor base designs do not have a secondary

fiber optic interface. The secondary interface on newer

devices is currently reserved for future expansion.

30 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 31

Model 2090 Multi-Device Controller

A

OPTIONAL BACK PANEL DESCRIPTION

uxiliary Control

Switches

NC C NO

NC C NO

NC C NO

SW 1

SW 2

SW 3

SW 4

Figure 4 Model 2090 Option 1 Back Panel

AUXILIARY CONTROL – Auxiliary devices use a single-pole double-throw RF relay to control simple

on/off operation. The connection type is SMA.

©ETS-Lindgren, April 2006 31

Revision G– P#399199

Page 32

Preparation for Use Model 2090 Multi-Device Controller

POWER REQUIREMENTS

The Model 2090 accepts any AC power source input within

the range of 115-230 VAC, 50/60 Hz. It is not necessary to

select a voltage. To apply AC power, use the threeconductor power cable that is shipped with the controller.

When connected from the IEC 320 power inlet to an

appropriate AC power source, the instrument chassis will

be connected to the earth ground.

CAUTION: Before switching on, connect the protective

earth terminal of this instrument to the protective conductor

of the power cord. The power cord should only be

connected to a socket outlet provided with a protective

earth contact. Do not use an extension cord without a

protective earth connector. Never attempt to defeat any

safety feature of an electrical device or serious injury may

result.

The Model 2090's configuration and current settings are

backed-up by non-volatile RAM (NVM). The NVM

retains these settings in the event of power loss or power

down. Three (3) AAA alkaline batteries, located internally,

are needed for this memory back up. Refer to the

procedure in the section “NVRAM Battery Backup” in

Appendix B: Maintenance, for more information on

replacing these batteries.

NOTE: It is recommended that the batteries be replaced

annually to reduce the risk of potential memory loss.

32 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 33

Model 2090 Multi-Device Controller

RACK MOUNTING

DEVICE CONNECTIONS

The Model 2090 controller can be ordered with a rack

mount option (Part # 540037). This option can be either

factory or field installed. The rack mount option provides

capability for installing the controller in a universal E. I. A.

48.26 cm (19.0 in) rack. A rack height of 13.34 cm (5.25

in) is required.

Any combination of primary devices (towers, turntables,

reverberation paddles, MAPS, etc.) can be connected to the

two Device Interface ports located on the rear panel of the

controller. For easy set up of an EMC facility, it is

recommended that the tower be connected to the Device 1

interface port and the turntable be connected to the Device

2 interface port, since these are the controller's default

settings. Reverberation paddles and each axis of the MultiAxis Positioner behave similar to turntables, and should be

configured as such. Primary device connection is

accomplished by way of a dual fiber cable included with

the device. This cable terminates into two ST connectors

that are identical at both ends. The cable is symmetrical;

either end can be connected to the controller. A fiber optic

cable that is connected to the IN port of a device should, at

the other end, be connected to the primary OUT port of the

motor base. A fiber connected to the OUT port of the

device should, at the other end, be connected to the primary

IN port of the motor base. Older motor base designs have

only one fiber optic connector pair, while the newest motor

©ETS-Lindgren, April 2006 33

Revision G– P#399199

Page 34

Preparation for Use Model 2090 Multi-Device Controller

base interface provides a secondary interface reserved for

future expansion.

Additional devices (for example: Remote Air Polarized

Tripods, LISNs, EUTs, etc.) can be connected in any

sequence to the four Auxiliary Control Ports (located on the

rear panel). If there are less than four auxiliary devices

connected to the controller, it is recommended (not

required) that these devices be connected in numerical

order, starting with the Auxiliary Control Port 1. The

Auxiliary Ports are also standard ST fiber optic connectors.

Auxiliary Port Enabled products, such as air polarized

tripods, are provided with a single fiber cable with ST

connectors at both ends. Either end may be attached to the

2090.

NOTE: Fiber optic cabling for each device should not be

allowed to hang unsupported from the rear panel of this

controller. The fibers and connectors are easily broken if

twisted or bent too much. Keep the fiber optic cables as

straight as possible from the connector to the protective

sheath.

34 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 35

Model 2090 Multi-Device Controller

OPTIONAL DEVICE CONNECTIONS

SW 1

NC C NO

NC C NO

NC C NO

Auxiliary devices use a single-pole, double-throw RF relay to

control simple on/off operation. The connection type is SMA.

SW 2

Additional devices (for example: CMU, Analyzers, dual

polarized horn antennas, etc.).

SW 3

SW 4

©ETS-Lindgren, April 2006 35

Revision G– P#399199

Page 36

Preparation for Use Model 2090 Multi-Device Controller

GPIB INTERCONNECTIONS

The Model 2090 is compatible with the General Purpose

Interface Bus as described in the IEEE 488.1/488.2

standard. A "D" connector has been provided on the 2090

rear panel for connection to a GPIB bus.

NOTE: When making this connection, do not stack more

than three cables on any one connector. This eliminates

undue mechanical stress on the connector and rear panel.

Also, be sure to screw the two-connector lock-screws finger

tight to avoid a loose connection during operation.

NOTE: The controller's talker/listener bus address can be

set through the front panel. Instructions on how to perform

this operation may be found in “Initialization” under the

subsection “Configuring For Use”.

36 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 37

Model 2090 Multi-Device Controller

INITIALIZATION

STARTUP

The devices that will be controlled by the Model 2090 must

be properly connected to the controller before applying

power to the unit. If nothing is connected to the Model

2090 when power is applied the Device One and Device

Two displays will show dashes (-----).

The Model 2090 controller has a power-up diagnostic/selftest to check for internal problems found during

initialization. During this period, the all display indicators

will flash on for several seconds to allow a visual

inspection, and then the firmware revision number will be

displayed in the left-hand (Device One) display window as

r X.XX where X.XX is the version number. If an internal

error is found during the startup sequence, an error message

"EXXX" will appear in the Device One display, where

XXX is the error code.

©ETS-Lindgren, April 2006 37

Revision G– P#399199

Page 38

Initialization Model 2090 Multi-Device Controller

RECOVERABLE ERRORS:

The following errors indicate a recoverable problem that

may require user intervention. These errors can be cleared

by pressing any key on the front panel to acknowledge the

error. These errors can also be cleared remotely through

the GPIB Status reporting structure described in the

section “USING THE GPIB COMMAND SET WITH THE

MODEL 2090” subsection “GPIB Status Reporting”.

E001

E100

E101

E102

E103

E104

NVM Initialization Error. Parameter settings were lost

and restored to factory defaults. This error usually

indicates that the NVM backup batteries are dead and

should be replaced. See the procedure in the section

“NVRAM Battery Backup” in Appendix B:

Maintenance, for more information.

SYSTEM TEST FAILURES:

The following errors are of a more serious nature and may

indicate that service is needed. In the event of such an

error, power off the unit for several seconds and power it

back on. If the error recurs, contact ETS for service.

ROM test error: ROM has been detected as being

corrupt.

RAM test error: RAM has been detected as being

corrupt.

NVM test error: NVM has been detected as being

corrupt.

Low Power Test error: Power test failed.

GPIB Test error: GPIB test failed.

38 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 39

Model 2090 Multi-Device Controller

HARDWARE ERRORS:

The following errors are not limited to the startup process,

and should not occur under normal operation. In the event

of such an error, power off the unit for several seconds and

power it back on. If the error recurs, contact ETS for

service.

E996

E997

E998

E999

BERR Error

Uninitialized Interrupt

Spurious Interrupt

Invalid Interrupt Error

Refer to “Appendix B” for more information on error

conditions and possible causes.

©ETS-Lindgren, April 2006 39

Revision G– P#399199

Page 40

Initialization Model 2090 Multi-Device Controller

EDITING PARAMETERS

The Model 2090 provides a versatile user interface for

editing configuration parameters, limits, and the current

position, by allowing several keys to perform multiple

duties. Prior to editing any settings, all device motion

should be stopped. The Model 2090 will automatically

stop device motion when configuration parameters are

displayed, and prevent the editing of limit and position

values while in motion, but the user should avoid

attempting to modify these values while equiptment is in

motion to avoid unexpected results.

To edit the limits or current position settings, select the

appropriate limit or position by pressing the corresponding

button under the LIMIT key group. The associated

indicator should light and the display will show the

corresponding value. For a tower, the 2090 provides two

sets of limits, one for horizontal polarization and one for

vertical, in order to protect antenna elements from damage

due to accidental polarization at the top or bottom of the

mast. Pressing the POLARIZATION key while the upper

or lower limit is displayed will switch the display to show

the corresponding limit for the opposite polarization,

without changing the tower polarization. To indicate

that the displayed value and polarization is not the current

polarization, the indicator light by the POLARIZATION

key will flash on and off. While in this state, the limit can

be changed using the limit edit keys just the same as any

other parameter.

40 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 41

Model 2090 Multi-Device Controller

NOTE: In order to toggle the polarization of the tower from

the front panel, the display must be showing the current

position, and not either limit.

To edit a configuration parameter, press the PARAM key

to display the current parameter. Pressing the PARAM key

repeatedly will scroll down through the parameter list,

showing each parameter in turn. While viewing a

parameter, the STEP keys (INC/DEC) may be used to

scroll up or down the parameter list. This reduces the effort

necessary to scan through a long parameter list using the

PARAM key. Pressing any of the LIMIT/POSITION

selection keys will return the display to that selection.

Pressing any of the remaining motion keys will return the

display to the current position and execute that motion.

Pressing the PARAM key again will return to the last

displayed parameter in the list, allowing easy transition

between parameter adjustment and device operation.

Once the desired limit, position or parameter is visible in

the display window, pressing INCRM, DECRM, or

ENTER will toggle into edit mode. The lowest adjustable

digit will flash on and off. Pressing the LOCAL key for

that device will switch the flashing digit to the next higher

digit. In this way, it is possible to rapidly adjust any digit

of a multi-digit parameter or limit.

NOTE: Some parameters only have one digit, or a fixed

range of selections. For those parameters, such as bore

sight separation distance, the whole entry to be changed

will flash. Other parameters consist of single on/off toggles

©ETS-Lindgren, April 2006 41

Revision G– P#399199

Page 42

Initialization Model 2090 Multi-Device Controller

or activate specific controller functions. The edit behavior

of these parameters is described in the parameter table.

Using the LOCAL key to select the appropriate digit and

the INCRM and DECRM key to adjust the setting, any

value can be entered quickly. Once the desired value is

shown in the display, pressing ENTER will store the new

value. Pressing any key other than LOCAL, INCRM,

DECRM, or ENTER will exit the edit mode without

saving the value and perform the action associated with that

key.

When editing limits or the current position setting, the 2090

will not allow the current position to be set outside the

software limits, nor can the upper or lower limits be

adjusted below or above, respectively, the current position

or each other.

42 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 43

Model 2090 Multi-Device Controller

CONFIGURING FOR USE

Before using the Model 2090, it must be configured to

match the primary devices connected to it. To the Model

2090, all primary devices are generic motor bases, with the

ability to move in two directions, report an encoder

position, and perform a few other basic functions. To

activate behavior specific to a certain type of device, i.e. a

bore sight tower or a two-speed turntable, it is necessary to

enter additional information into the Model 2090’s

configuration parameters table. The previous section

describes the process for entering these parameters. This

section describes each parameter and their typical settings.

The default factory preset configuration is given below.

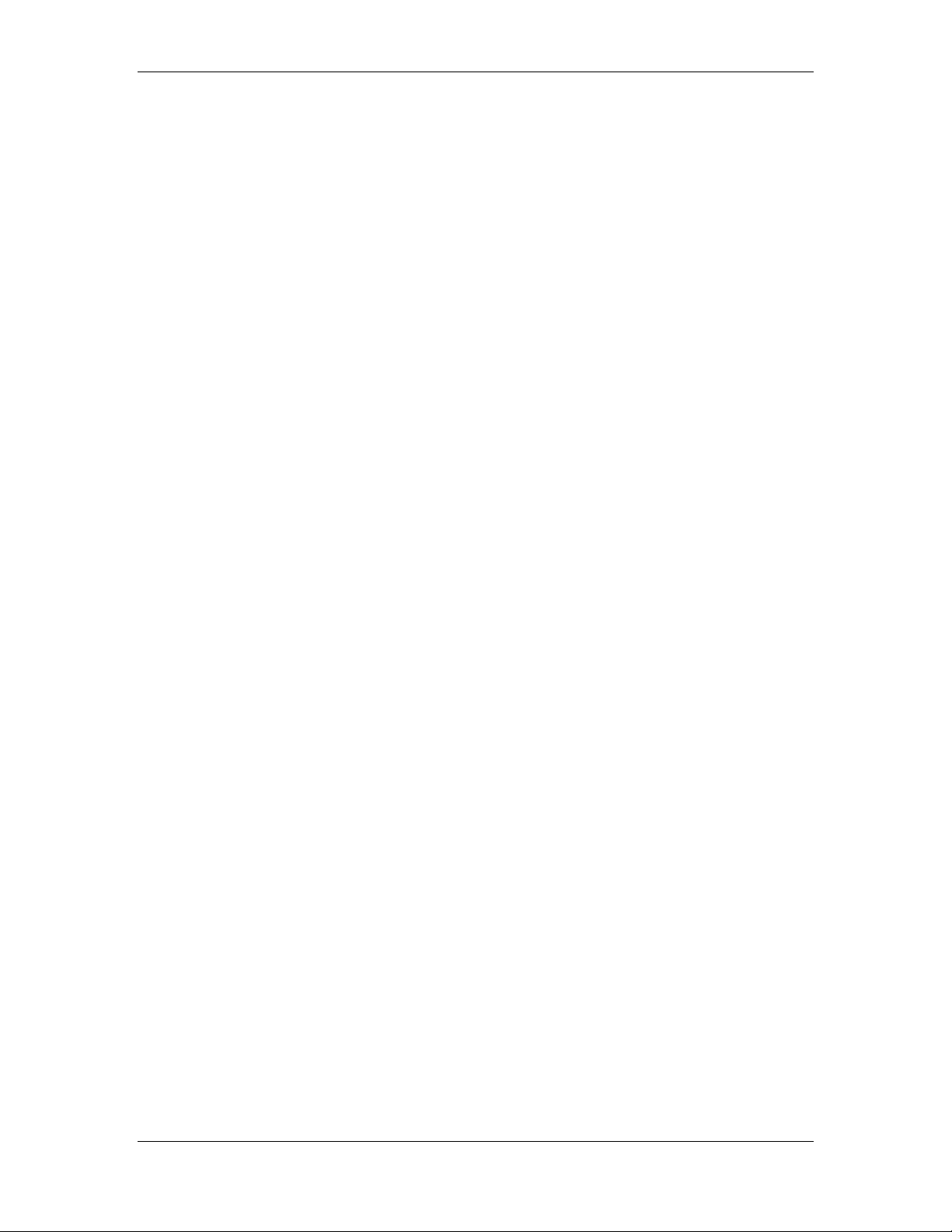

2090 Default Configuration:

Parameter Value Description

P1

P2

P3

P4

P5

P8

P9

B1

S0

S1

S2

S3

S4

S5

S6

S7

S8

Oc

ACC

c

1

0

000

00

0

0.5

8

000

2000

-1

31

63

95

127

159

191

223

255

On

2.0

Tower

Standard (non-bore sight) tower

Infinite scan count

0 cm polarization offset

Standard bore sight correction

0.5 second reverse delay

Primary GPIB address 8

User options disabled

2000 encoder counts per meter

Step speed = run speed

Speed 1 ~12.5% of max speed

Speed 2 ~25% of max speed

Speed 3 ~37.5% of max speed

Speed 4 ~50% of max speed

Speed 5 ~62.5% of max speed

Speed 6 ~75% of max speed

Speed 7 ~87.5% of max speed

Speed 8 = max speed

Overshoot compensation enabled

Acceleration = 2 seconds

©ETS-Lindgren, April 2006 43

Revision G– P#399199

Page 44

Initialization Model 2090 Multi-Device Controller

SND

1

Remote sounds enabled

Lower Limit: 050.0 cm

Upper Limit: 400.0 cm

Current Position: 100.0 cm

Parameter Value Description

P1

P2

P3

P5

P8

P9

b1

S0

S1

S2

S3

S4

S5

S6

S7

S8

Oc

ACC

SND

c

0

0

000

1

2.5

9

000

3600

-1

31

63

95

127

159

191

223

255

On

2.0

1

Turntable

Standard turntable

Infinite scan count

Non-continuous rotation

2.5 second reverse delay

Primary GPIB address 9

User options disabled

3600 encoder counts per meter

Step speed = run speed

Speed 1 ~12.5% of max speed

Speed 2 ~25% of max speed

Speed 3 ~37.5% of max speed

Speed 4 ~50% of max speed

Speed 5 ~62.5% of max speed

Speed 6 ~75% of max speed

Speed 7 ~87.5% of max speed

Speed 8 = max speed

Overshoot compensation enabled

Acceleration = 2 seconds

Remote sounds enabled

CCW Limit: 000.0 degrees

CW Limit: 360.0 degrees

Current Position: 180.0 degrees

44 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 45

Model 2090 Multi-Device Controller

MODEL 2090 PARAMETER LIST

The following table describes each parameter and the

available settings. In general, the term “tower” will be used

to refer to any linear positioning device, and the term

“turntable” will refer to any rotational positioner.

Parameter Description

Refers to the principal type of device to be controlled:

P1

P2

P3

0 = Turntable, Reverberation Paddle, MAPS, or other rotational

positioner.

1 = Tower or other linear positioner.

Refers to model specific features of device to be controlled:

0 = Standard Turntable / Tower

1 = Air Flotation Turntable / Bore Sight Tower

2 = Two Speed Turntable

NOTE: Parameter P2 for a turntable no longer supports a setting 3 =

Variable Speed Turntable/Tuner, which was introduced in V 2.25.

Instead, the 2090 now checks what type of motor base is attached and

automatically enables variable speed if it is available.

Refers to SCAN cycle count in full cycles:

1-999 = Number of complete circuits to perform from one limit

to the other and back again.

000 = Infinite scan count; scan mode does not automatically

terminate.

The Model 2090 also supports a half-cycle scan count through the

GPIB interface.

©ETS-Lindgren, April 2006 45

Revision G– P#399199

Page 46

Model 2090 Parameter List Model 2090 Multi-Device Controller

Refers to two different tower corrections, depending on the tower

P4

type:

For a standard tower, this value represents the polarization offset, in

the range of ±50 cm, applied to the tower position reading when the

polarization is changed. This parameter allows for correction of the

antenna height changed caused when centerline rotation is not

available or not in use.

For a bore sight tower, this parameter is used to enter the bore sight

separation distance corresponding to the configuration of the tower.

This value can be 3, 10, or 30 meters, and configures the 2090 to

correct for the difference in height between the carrier position and

the actual antenna position.

For bore sight towers, refers to the bore sight mast height correction:

P5

0 = Standard bore sight towers

1 = Custom or alternate bore sight tower

Currently, all six-meter tall 2070 series bore sight towers use the

default correction table. The alternate selection provides a correction

table for a shorter five-meter tower with a different cam mechanism.

In future revisions, the 2090 may provide support for other bore sight

tower designs either by adding additional tables or by allowing the

user to download the appropriate correction table for the attached

tower.

For turntables, refers to turntable rotation mode:

0 = Continuous

1 = Non-continuous

In the continuous mode of operation a turntable is allowed unlimited

movement. The counter readout is from 0 to 359.9 and the software

limits are ignored in this mode of operation. This is the desired

setting for reverberation paddles.

NOTE: For turntables equipped with hardware limits, they must be

disengaged for this mode to work correctly.

In the non-continuous mode, the turntable motion is restricted

between the upper and lower software limits. These limits are

adjustable between –999.9 to 999.9.

46 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 47

Model 2090 Multi-Device Controller

Refers to the motor reverse delay, in seconds. This parameter allows

P8

setting the reverse delay used between direction changes. This is the

period of time for which the motor must remain off before allowing it

to move in the other direction. For split-phase motors, it is critical

that the motor come to a complete stop prior to reversing direction, or

the motor will continue moving in the same direction and cause a

Moving Wrong Direction error (

damage may be caused to the motor or device from reversing the

motor too quickly. This parameter should be used with care. If in

doubt use the factory default setting.

Refers to the primary GPIB address for each device. Valid values are

P9

in the range from 1 to 30 (0 is normally reserved for the controller in

charge; i.e. the computer). Each device must have a unique GPIB

address.

Refers to bit-wise parameter number one. This parameter provides

b1

selective enabling of several customizable parameters. The bits are

displayed in increasing order from right to left. Unless otherwise

indicated, a value of 0 indicates that the option is disabled and a value

of 1 indicates it is enabled. The two bits currently defined for

Refers to the encoder calibration parameter. This setting is used to

C

convert the encoder count values returned from a motor base into the

corresponding centimeter or degree position reading. For towers, the

number represents the number of encoder counts per meter. For

turntables, it represents the number of counts per revolution. Using

this parameter, a variety of standard, retrofit, and custom devices can

be used. The settings for various products are listed below:

E004). For other motors, physical

b1 are:

Bit 0 – Limits STEP controls (INC/DEC) to only allow motion

within the soft limits instead of the hardware limits of

the motor base.

Bit 1 – Provides a quick stop option for the STEP controls

(INC/DEC) on variable speed devices. Enabling this

bit (setting it to 1) will bypass the deceleration ramp on

variable speed motor bases, stopping them as quickly as

possible. NOTE: This option should be used with

caution, since it is possible to cause damage to the

device or equipment attached to the device.

Model 2075 Mini-Mast: 1620

All other EMCO 2070 series towers: 2000

Model 2065 LoPro Turntable: 3665

©ETS-Lindgren, April 2006 47

Revision G– P#399199

Page 48

Model 2090 Parameter List Model 2090 Multi-Device Controller

g

Model 2081 Turntables: 3608

Model 2088 EuroPro Turntable: 4500*

Model 5901 Mode Tuner: 6000**

Multi-Axis Positioning System: 4500

All other model 2060/2080 series turntables: 3600

All other current ETS-Lindgren rotational devices:3600

*Early revisions of the Model 2088 used 4750 for the Euroshield

versions and 4800 for the U.S. version.

**Early revisions of the Model 5901 Mode Tuner used 6400.

If the device is not listed, or the given value does not appear to work

correctly, the encoder calibration value can be determined using the

following procedure:

FOR TOWERS,

1. Set the encoder calibration value to 1000.

2. Insure that the tower is positioned to allow at least a meter

of travel in the upward direction at an easily measurable

height, and then set the current position reading to 000.0.

NOTE: It will be necessary to adjust the lower limit setting

to allow this.

3. Using the STEP keys, adjust the height of the carrier until it

is one meter above the start point.

4. Record the reading of the display, ignoring the decimal

point (i.e. 200.0 would be 2000). This is the encoder

calibration value. NOTE: If the value is below 1000, the

resolution of the encoder is low and thus the 2090 will not

provide 0.1 cm resolution, even though the display shows

that digit. If the value has gone past 9999, the encoder has

too many counts per meter and the 2090 can not correct for

it. In this case, contact ETS for assistance.

5. Enter this value for the encoder calibration value and reset

the limits and position information.

6. Test the tower by moving it a known distance and

comparing the display to the measured distance traveled. It

may be necessary to adjust the encoder calibration value up

or down slightly depending on the result.

FOR TURNTABLES,

1. Set the encoder calibration value to 3600.

2. Insure that the turntable is positioned to allow more than a

full revolution of travel in the clockwise direction and use

the STEP keys to run the turntable clockwise a few degrees

to remove any play in the table.

3. Mark the current location of the turntable a

ainst the ground

48 © ETS-Lindgren– April, 2006

Revision G– P# 399199

Page 49

Model 2090 Multi-Device Controller

Refers to the speed setting for variable speed devices when the STEP

S0

(INC/DEC) keys are used.

This parameter is only visible for variable speed devices. See the

next entry for more information on speed settings.

ring (masking tape works well), and set the current position

reading to 000.0.

4. Using the STEP keys, rotate the turntable clockwise until it

is again aligned with the mark on the ground ring. For best

results, the last motion should always be in the clockwise

direction to insure that any play in the gearing between the

motor and encoder is accounted for.

5. Record the reading of the display, ignoring the decimal

point (i.e. 360.0 would be 3600). This is the encoder

calibration value. NOTE: If the value is below 3600, the

resolution of the encoder is low and thus the 2090 will not

provide 0.1 degree resolution, even though the display

shows that digit. If the value has gone past 9999, the

encoder has too many counts per meter and the 2090 can

not correct for it. In this case, contact ETS for assistance.

6. Enter this value for the encoder calibration value and reset

the limits and position information.

7. Test the turntable by moving it a complete revolution and

comparing the alignment marks. It may be necessary to

adjust the encoder calibration value up or down slightly

depending on the result. NOTE: When scanning between

limits, it is not uncommon to have a small discrepancy

between the absolute position of the table and the display on

the 2090. This is because reversing the direction of rotation

reverses any gear play between the encoder and the table

top, allowing that play to be visible in the positioning

accuracy.

-1 Disabled. The STEP keys will cause the device to

move at the same speed as the other motion keys.

0-255 Defines the speed setting for motion caused from

the STEP keys. This allows the STEP keys to be

used for fine adjustment at a constant speed, while

having all other motion governed by the selected

speed setting.

©ETS-Lindgren, April 2006 49

Revision G– P#399199

Page 50

Model 2090 Parameter List Model 2090 Multi-Device Controller

Refers to the eight possible preset speed settings for variable speed

S1-S8

devices. Each of these parameters can be set to any value from 0 to

255, with the resulting device speed being given approximately by

the formula:

Speed = N (MaxSpeed – MinSpeed) / 255 + MinSpeed

Where N is the speed setting from 0 to 255.

Each speed setting has its own individual overshoot compensation

value to provide proper overshoot correction for each speed selection.

However, the new ramp control provided by the 2090 and the