Page 1

Archived 3/18/10

Model 2081

Turntable Series

2081-2.0, 2081-2.5, 2081-3.0,

2081-4.0, 2081-5.0, 2081-6.0

MANUAL

© ETS-LINDGREN L.P. - JANUARY 2003 REV D – PN 399212

Page 2

MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

ETS-Lindgren L.P. reserves the right to make changes to any products herein to improve functioning,

design, or for any other reason. Nothing contained herein shall constitute ETS-Lindgren L.P. assuming any

liability whatsoever arising out of the application or use of any product or circuit described herein. ETSLindgren L.P. does not convey any license under its patent rights or the rights of others.

© Copyright 2003 by ETS-Lindgren L.P. All Rights Reserved.

No part of this document may be copied by any means

without written permission from ETS-Lindgren L.P.

E-MAIL & INTERNET

Support@ets-lindgren.com

http://www.ets-lindgren.com

USA

1301 Arrow Point Dr., Cedar Park, TX 78613

P.O. Box 80589, Austin, TX 78708-0589

Phone 512.531.6400

Fax 512.531.6500

FINLAND

Euroshield OY

Mekaanikontie 1

27510, Eura, Finland

Phone + 358.2.838.3300

Fax + 358.2.865.1233

JAPAN

4-2-6, Kohinata

Bunkyo-ku

Tokyo 112-0006

JAPAN

Phone + 81 3 3813 7100

Fax + 81 3 3813 8068

CHINA

1917-1918 Xue Zhixuan Building

No 16 Xue Qing Road

Haidian District

Beijing Postcode: 100083

CHINA

Phone + 86 010 82755304

Fax + 86 010 82755307

© ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 3

MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

Table of Contents

INTRODUCTION ........................................................................................................................................ 1

STANDARD CONFIGURATION .............................................................................................................. 2

OPTIONS ...................................................................................................................................................... 3

PRECAUTIONS ........................................................................................................................................... 4

TURNTABLE INSTALLATION CONSIDERATIONS........................................................................... 6

POWER AND SIGNAL LINES ......................................................................................................................... 6

OUTDOOR INSTALLATIONS .......................................................................................................................... 6

INSTALLATION ......................................................................................................................................... 7

GROUND RING INSTALLATION .................................................................................................................... 9

ELECTRICAL INSTALLATION ............................................................................................................ 10

CONNECTING THE MODEL 2090 POSITIONING CONTROLLER..................................................................... 11

OPERATION .............................................................................................................................................. 12

RECOMMENDED PARAMETERS FOR THE MODEL 2090 POSITIONING CONTROLLER ................................... 13

EDITING MODEL 2090 POSITIONING CONTROLLER CONFIGURATION PARAMETERS .................................. 14

TURNTABLE ENCODER CALIBRATION ....................................................................................................... 14

TT CALIBRATION EXAMPLE ...................................................................................................................... 15

SETTING CURRENT POSITION ON 2090 ...................................................................................................... 17

CAUTION: ON RESETTING CURRENT POSITION ON 2090 ........................................................................... 17

CHANGING ROTATION SPEED .................................................................................................................... 18

SETTING TRAVEL LIMITS .......................................................................................................................... 19

ALTIVAR MOTOR BASE CONFIGURATION ................................................................................................. 20

HAND CONTROL UNIT .......................................................................................................................... 21

RECOMMENDED MAINTENANCE ...................................................................................................... 22

EVERY SIX MONTHS.................................................................................................................................. 22

EVERY TWELVE MONTHS .......................................................................................................................... 23

SPECIFICATIONS .................................................................................................................................... 24

ELECTRICAL .............................................................................................................................................. 24

PHYSICAL .................................................................................................................................................. 24

WARRANTY STATEMENT .................................................................................................................... 25

ILLUSTRATIONS ..................................................................................................................................... 26

© ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 4

MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

NOTICE: This produc t and related documentation must be r eviewed fo r familiariz ation

with safety markings and instructions before operation.

SAFETY SYMBOL DEFINITIONS

!

OR

CAUTION

WARNING

REFER TO MANUAL

instruction manual for additional information.

HIGH VOLTAGE

could result in severe personal injury or death.

PROTECTIVE EARTH GROU ND (SAF ETY G ROUND)

Indicates protective earth terminal. You should provide uninterruptible safety

ea rth ground from the main power source to the pr o duct input wiring

terminals, power cord, or supplied power cord set.

CAUTION

minor personal i n ju r y and/or propert y damage. Included text gives proper

procedures.

WARNING

SEVERE pe r sonal inju ry and/or proper ty damage. Included text gives pr o per

procedures.

GENERAL SAFETY CONSIDERATIONS

BEFORE POWER IS APPLIED TO THIS INSTRUMENT,

GROUND IT PROPERLY

cable to a power source provided with protective earth contact. Any

interruption of the protective (grounding) conductor , inside or outside the

ins trument, or dis c onnection of the protective ea rth termi nal could result in

personal injury.

When product is marked with this symbol refer to

Indicates presence of hazardous voltage. Unsafe practice

Denotes a hazard. Failure to follow instructions could result in

Denotes a hazard. Failure to follow instructions could result in

through the protective conductor of the AC power

WARRANTY

© ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

BEFORE SERVICING: CONTACT ETS-LINDGREN -

(or modifying) the unit by yourself may void your warranty. I f you attempt to

ser vice the unit by yo urself, disconnect all electrical powe r befor e starting.

There ar e v oltages at many points in the instrument which could, if

contacted, cause personal injury. Only trained service personnel should

perform adjust m ents and/or s ervice proce dures upon thi s inst rument.

Capacitors inside this instrument may still be CHARGE D even when

instrument is disconn ected from its power source.

ONLY QUALIFIED PERSONNEL

STAY CLEAR

of moving components during operat i o n of equipment.

shou ld ope rate (or s ervice) this equi pm e nt.

servicing

Page 5

MODEL 2081 TURNTABLE SERIES Introduction

Archived 3/18/10

INTRODUCTION

The ETS-Lindgren Model 2081 is an electric powered turntable

platform system designed to be used with the Model 2090

Positioning Controller for EMI compliance testing. Two meter and

larger tables utilize a pinion and gear drive with a gear reducer and

electric motor. The conductive metal top is outfitted with a

continuous ground brush to electrically couple the turntable to the

ground plane. The drive motor and gearing are located beneath the

platform. The sectional turntable top provides easy access in the

event that service is required. A shielded enclosure contains the

electronics for the system. Signal I/O from the turntable to the

Model 2090 controller is via fiber optic cable.

The bearing on which the turntable rotates has the drive teeth cut

directly on the outside and will easily support most heavily

weighed equipment under test (EUT). Casters underneath the table

surface aid in the support of a cantilevered load. Leveling screws

are located at each caster, between the casters and in the center

section of the assembly for ease in matching height on an uneven

ground plane.

To prevent over-travel of the turntable in either direction of

movement, mechanical limits can be set using dial knobs on the

outside of the encoder enclosure located in the center of the main

pivot bearing. The knobs can be accessed by removing the center

section of the turntable. Soft limits can be set within the

mechanical limits, using the Model 2090 Positioning Controller.

Ground brushes attached directly to the top of the table are in

continual contact with the floor flange supplied with the ground

ring option. The brushes point downward from the top of the table.

To extend the life of the ground brush, a one-piece stainless steel

liner is attached to the inside edge of the stationary floor flange.

© ETS-LINDGREN L.P. – JANUARY 2003 1

REV D – PN 399212

Page 6

Standard Configuration MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

STANDARD CONFIGURATION

• Three-phase electric motor unit (standard)

• Heavy duty two-speed drive system (standard)

• Conductive sectional top

• Convenient rotational limit adjust switches

• Limit override feature

• Ten meter fiber-optic control cables (standard)

• Overall height 400 mm (15.75 in)

• Sectional top for easy service access

• Full supporting leveling screws

2 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 7

MODEL 2081 TURNTABLE SERIES Options

Archived 3/18/10

OPTIONS

Model 2090 Positioning Controller: This controller provides

control for two separate devices (towers and turntables) in any

combination, plus the control of four auxiliary devices via a fiber

optic interface. The unit includes a GPIB connection and is

compatible with most popular EMI measurement software.

Hand Control Unit: This sturdy, hand-held controller will allow

the user to manually operate the table remotely and independently

from the Model 2090 Positioning Controller. This controller

attaches conveniently to the electrical enclosure located on the

base of the turntable. Functions include: Clockwise (CW),

Counterclockwise (CCW) and Hand/Main Control selection.

Slip Ring: This option allows continuous rotation of the turntable

through the use of the latest technology in mercury slip-rings. The

slip ring option is typically supplied with Schuko or NEMA

connectors. Specify part #103441 for NEMA connectors, and part

#103351 for Schuko connectors. The amperage rating for the

standard electrical assembly is 20 amps. Consult the factory for all

custom requirements on slip-rings.

Shield Room Feed-through: This option allows the customer to

take the fiber optic control cable from the control room to the

shield room while maintaining shielding attenuation. The unit is

made of brass for conductivity and provides attenuation of greater

that 100 dB at 10 GHz. A single 22.25 mm (.875 inch) hole is

required to mount this option.

Additional Fiber Optic Cable: Various lengths of fiber optic

cable are available by customer order. The standard length

provided is 10 m (32.8 ft).

Variable Speed Drive: An optional variable speed drive package

is available with the Model 2081 Turntable. Speed adjustment is

electronically controlled by the Model 2090 via the front panel or

through the GPIB interface.

© ETS-LINDGREN L.P. – JANUARY 2003 3

REV D – PN 399212

Page 8

Precautions MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

EUT Power Outlets: Receptacles are usually mounted on the base

of the turntable at its center axis point. These receptacles can be

custom mounted, flush with the tabletop on some turntables.

Consult the factory for more details.

Mounted LISNs: LISNs can be mounted to the underside of some

turntables. This option is only practical on larger turntables with

sufficient clearance.

PRECAUTIONS

Read this manual completely before starting installation. This

equipment should be installed and operated only by qualified

personnel.

Ensure correct voltage setting is selected on the Motor Base unit

(when applicable).

The fiber optic cable must be looped through the “P” clip installed

on the front panel of the motor base. Failure to do so will increase

the chance of the cable being accidentally pulled, thus breaking the

fiber optic connectors.

Do not attempt to service unless qualified to do so. As with any

electrical equipment, ensure unit electrical power has been

disconnected and secured when performing scheduled maintenance

or adjustments.

WARRANTY

Do not make any modifications to this unit without consulting the

factory directly.

Stay clear of all moving components on this equipment.

Do not, at any time, place hands or feet in the vicinity of the drive

pinion on the turntable.

Do not operate the turntable while someone is physically on the

turntable top.

4 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 9

MODEL 2081 TURNTABLE SERIES Precautions

Archived 3/18/10

Regularly inspect the equipment for loose fasteners and wear.

Conduct scheduled maintenance in accordance with the factory

recommendations provided.

Only use replacement parts and fasteners ordered directly from the

factory or specified by ETS-Lindgren.

The access plate(s) above the pinion gear should remain firmly

attached with the screws provided at all times. When the plate is

removed for servicing, the electrical breaker located on the

electrical control enclosure should be in the OFF position.

© ETS-LINDGREN L.P. – JANUARY 2003 5

REV D – PN 399212

Page 10

Turntable Installation Considerations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

TURNTABLE INSTALLATION

CONSIDERATIONS

Pre-planning is essential for a successful installation. Be sure to

discuss your requirements with your sales representative and

request dimensional drawings prior to construction of your site.

POWER AND SIGNAL LINES

Conduit

Power and signal line paths should be planned in advance. Conduit

should be in place before pouring concrete or installing the ground

plane. Be sure to consider the size of the cable bundle when

selecting conduit diameter.

Electrical Considerations

A qualified and licensed electrical contractor should be used to

install power lines, and the installation should comply with all

applicable regulatory agencies. A dedicated circuit should be used,

with the shortest distance possible between the power source and

the turntable.

Access

An access area underneath the turntable is advisable for large

diameter installations. A service switch should be installed to

deactivate the turntable during service.

OUTDOOR INSTALLATIONS

Drainage

A centerline drain of at least 15cm (6in) must be installed to

provide proper drainage during rain storms, etc.

Cold Climate Conditioning

Oil used in the gear assemblies will congeal at 2

Turntables operated in these temperatures should include a heat

source and/or dehumidifier.

6 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

o

C (28o F).

Page 11

MODEL 2081 TURNTABLE SERIES Installation

Archived 3/18/10

INSTALLATION

The installation of turntables 2 meters and larger will be performed

by a factory installation specialist or by individuals who have been

authorized by ETS-Lindgren to do such work. Proper installation

of the turntable directly affects performance. The following

installation information is provided to familiarize the user of the

turntable with the installation process.

1. Uncrate all parts. NOTE: Do not discard any packing material

until unit is fully assembled. Check all parts for any shipping

damage. Ensure a clear area is available to assemble the

turntable unit safely.

2. After removing three ½-13 flat head screws from the center of

the turntable, install three eye-bolts (provided) for lifting the

turntable center drive section.

3. Attach lifting chains or slings though the eye-bolts.

CAUTION Lifting and placement of turntable center drive unit

into a pit should only be performed by qualified personnel.

4. Safely lift the turntable into the pit using a forklift or other

appropriate lifting device, place the turntable bottom or bearing

support section into position.

5. Remove the drive pinion so the turntable may be rotated

manually.

6. If the turntable is to be installed into a pit or floor cut-out,

center and level the assembly. The drawings at the back of this

manual illustrate the placement of floor plates and leveling

screws that will take place in order to anchor and level the

turntable. Your installation specialist may have to make slight

adjustments to accommodate the conditions at your site. After

installing the floor plates and leveling screws the installer will

level the entire turntable by adjusting all the leveling screws.

CAUTION Ensure power is OFF and secured before proceeding

further.

© ETS-LINDGREN L.P. – JANUARY 2003 7

REV D – PN 399212

Page 12

Installation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

7. After the turntable is level the installation specialist will tighten

all lock-nuts accompanying the leveling screws to lock the

height of the turntable into place.

8. Anchor the turntable through the anchor holes with the

appropriate bolts (provided).

9. With the electrical breaker still in the OFF position, re-install

the drive pinion.

CAUTION Electrical connection should only be performed by a

qualified electrician and in compliance with all applicable

regulatory agencies.

10. Connect the fiber optic control cable and install the power

connection. The “Electrical Installation” section provides

guidelines for the installation of the electrical connection.

11. Return the breaker in the center of the turntable to the ON

position.

CAUTION Keep all body parts away from the drive pinion when

the turntable in energized.

12. Rotate the turntable using the controller to verify proper

operation.

13. Set the travel limits, if desired, by following the instructions in

the section titled “Setting Travel Limits”.

14. Install the ground ring flange provided around the turntable

with flat head screws (not provided). Install the stainless steel

wear strip and apply conductive grease according to the

“Ground Ring Installation” section.

15. With the key provided, adjust the speed of the turntable while it

is running on the CW or CCW direction until the desired speed

is obtained.

16. Install the top sections of the turntable to complete the

assembly.

8 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 13

MODEL 2081 TURNTABLE SERIES Installation

Archived 3/18/10

GROUND RING INSTALLATION

The ground ring assembly includes a floor flange which interfaces

with the brush ring located on the perimeter of the turntable. The

floor flange provides constant electrical contact with the user’s

ground plane and is usually installed with the turntable.

Mounting methods vary according to user specifications. Clearance

holes are provided along the outside perimeter of the ground ring

as a means of attaching the ring to a customer supplied ground

plane. These mounting holes are provided at evenly spaced

intervals.

1. When attaching the ground ring, first center and level the

turntable assembly into the turntable pit. The cutout diameter in

the floor needs to be per the Dimensional Drawing for the

table.

2. Install the floor flange around the turntable. A gap of 5/16” to

7/16” should be maintained around the turntable. Trim flange

to length by match drilling with floor and installing ¼-20

flathead screws.

3. Install wear strip on inside of floor flange by aligning with top

of turntable flange.

4. Make sure that pre-drilled mounting holes in wear strip are

aligned to 2.54cm (1.00”) from bottom of flange.

5. Trim wear strip to size after ensuring that the full

circumference of the flange is covered by the strip.

6. Using pre-drilled holes on wear strip as a template, drill holes

through the flange.

7. Secure wear strip to floor flange using 6-32 x 3/8” hex head

stainless steel thread cutting screws (furnished with turntable).

8. Apply conductive grease (furnished with turntable) on wear

strip along the brush contact area (approximately 1” to 2” from

the top of the strip).

© ETS-LINDGREN L.P. – JANUARY 2003 9

REV D – PN 399212

Page 14

Electrical Installation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

ELECTRICAL INSTALLATION

CAUTION It is important that this procedure be performed by a

qualified electrician prior to energizing the unit.

The Model 2081 is designed to operate using either 208-230 VAC

three–phase 60 Hz or 400 VAC three phase 50 Hz power. The

appropriate power requirements are determined when the order is

placed. Other power ratings are available on a special order basis.

1. The branch circuit supplying power to the motor base should

be protected from excess current according to local electrical

codes. ETS-Lindgren has provided a three pole circuit breaker

integral to the relay control enclosure. This circuit breaker also

serves as a service switch and removes motor power from both

the control enclosure assembly and the motor.

WARNING With the circuit breaker in the off position some parts

with AC hazards still present a potentially lethal shock hazard.

2. Check that the conductor size is adequate for the motor load

and the distance from the mains source. Improperly sized

conductors will lead to a high voltage drop in the power

conductors and cause reduced starting torque and premature

motor failure.

3. The motor base assembly is provided with an unterminated

flexible conduit with input power leads exposed. This flexible

conduit is to be terminated into a junction box fitted on or near

the motor base. Terminate the power leads of the motor base

assembly according to local electrical code requirements.

2081 Electrical

Wiring Color

Code

Line Conductors

(3 each)

Neutral N/A Blue

Protective Earth Green with yellow

208-230 VAC

60 Hz 3 phase

Brown Brown

stripe

380-410 VAC

50 Hz 3phase

Green with yellow

stripe

10 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 15

MODEL 2081 TURNTABLE SERIES Electrical Installation

Archived 3/18/10

CONNECTING THE MODEL 2090

POSITIONING CONTROLLER

Any combination of primary devices (towers, turntables,

reverberation paddles, MAPS, etc.) can be connected to the two

Device Interface ports located on the rear panel of the Model 2090

controller. For easy set up of an EMC facility, it is recommended

that the turntable be connected to the Device 2 interface port. The

controllers default settings are for a tower connected to the Device

1 interface port and a turntable connected to the Device 2 port.

Primary device connection is accomplished by way of a dual fiberoptic cable included with the device. This cable terminates into

two ST connectors that are identical at both ends. The cable is

symmetrical; either end can be connected to the controller. A fiber

optic cable that is connect to the IN port of a device should, at the

other end, be connected to the primary OUT port of the motorbase.

A fiber connected to the OUT port of the device should, at the

other end, be connected to the primary IN port of the motorbase.

Older motor base designs have only one fiber optic connector pair,

while the newest motor base interface provides a secondary

interface reserved for future expansion.

NOTE: Fiber optic cabling for each device should not be allowed

to hang unsupported from the rear panel of the controller. The

fibers and connectors are easily broken if twisted or bent. Keep the

fiber optic cables as straight as possible from the connector to the

protective sheath.

Using the Model 2090 Position Controller (or hand controller),

rotate the motor base shaft to verify proper operation. Run the

motorbase down to the lower limit CCW and then back it off from

the lower limit just a bit. This step will help after the turntable is

attached to the motorbase and it is time to set the rotation limits for

the turntable.

CAUTION The soft rotational limits in the Model 2090 controller

must be set. Ensure the travel limit settings will not cause damage

to user installed cables and equipment mounted on the table.

© ETS-LINDGREN L.P. – JANUARY 2003 11

REV D – PN 399212

Page 16

Operation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

OPERATION

Please refer to the Model 2090 Positioning Controller manual if

you are unfamiliar with the operation of the unit. A manual is

included with each 2090 shipment and is also available for

download from our website.

With the assembly complete, the Model 2090 controller will need

to be connected to the unit and power applied to both the motor

base and controller in order to continue. Refer to the section titled

“Connection the Model 2090 Positioning Controller” if you have

questions about how to connect the fiber optic cables.

Using the Model 2090 Positioning Controller check the CW and

CCW rotation in both directions by a few degrees. The position in

degrees increases (+) in the CW direction and decreases (-) in

CCW direction.

The turntable is calibrated at the factory to read out 360 degrees (+

or - 1 degree) for one complete revolution. If the table is not within

this accuracy, the unit can be re-calibrated per the instructions in

the “Turntable Encoder Calibration” section.

12 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 17

MODEL 2081 TURNTABLE SERIES Operation

Archived 3/18/10

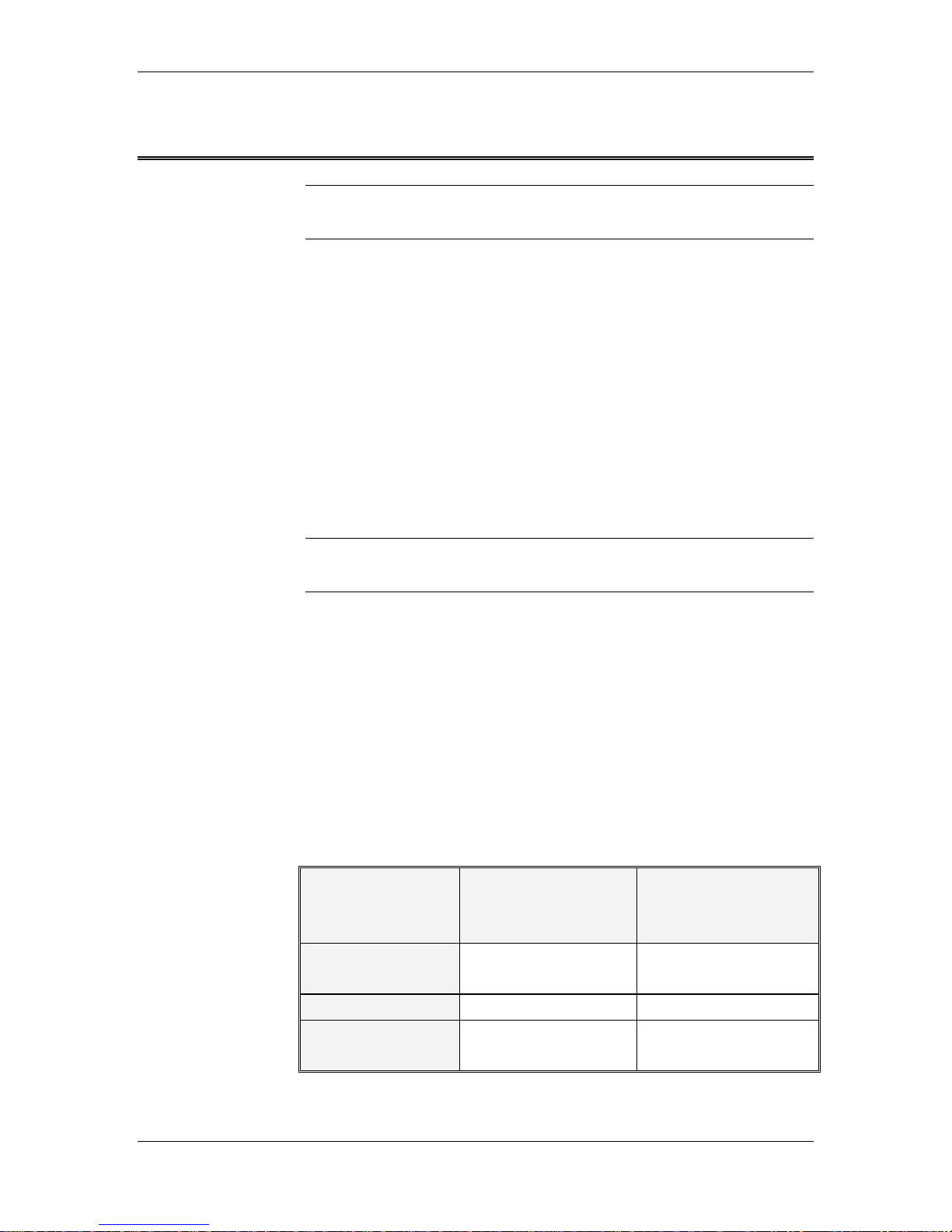

RECOMMENDED PARAMETERS FOR THE

MODEL 2090 POSITIONING

CONTROLLER

DEVICE 2

Parameter Value Description

P1 0 Turntable

P2 2 Standard Turntable

P3 000 Infinite Scan Count

P5 1 Non-continuous rotation

P8 2.5 2.5 Second reverse delay

P9 9 Primary GPIB address 9

b1 000 User options disabled

c 3608 3600 encoder counts per meter

S0 -1 Step speed = run speed

S1 31 Speed 1 ~12.5% of max speed

S2 63 Speed 2 ~25% of max speed

S3 95 Speed 3 ~37.5% of max speed

S4 127 Speed 4 ~50% of max speed

S5 159 Speed 5 ~62.5% of max speed

S6 191 Speed 6 ~75% of max speed

S7 223 Speed 7 ~87.5% of max speed

S8 255 Speed 8 = max speed

Oc On Overshoot compensation enabled

© ETS-LINDGREN L.P. – JANUARY 2003 13

REV D – PN 399212

Page 18

Operation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

EDITING MODEL 2090 POSITIONING

CONTROLLER CONFIGURATION

PARAMETERS

To edit a configuration parameter, press the PARAM key to

display the current parameter. Pressing the PARAM key

repeatedly will scroll down through the parameter list, showing

each parameter in turn. While viewing a parameter, the STEP

keys (INC/DEC) may be used to scroll up or down the parameter

list. This reduces the effort necessary to scan through a long

parameter list using the PARAM key. Pressing any of the

LIMIT/POSITION selection keys will return the display to that

selection. Pressing any of the remaining motion keys will return

the display to the current position and execute that motion.

Pressing the PARAM key again will return to the last displayed

parameter in the list, allowing easy transition between parameter

adjustment and device operation.

Once the desired limit, position or parameter is visible in the

display window, pressing INCRM, DECRM, or ENTER will

toggle into edit mode. The lowest adjustable digit will flash on

and off. Pressing the LOCAL key for that device will switch the

flashing digit to the next higher digit. In this way, it is possible to

rapidly adjust any digit of a multi-digit parameter or limit.

TURNTABLE ENCODER CALIBRATION

The display symbol C refers to the encoder calibration parameter.

This setting is used to convert the encoder count values returned

from a motor base into the corresponding centimeter or degree

position reading. For turntables, this represents the number of

encoder counts per revolution. The setting for the Model 2081

Turntable Series is: 3608

If the given value does not appear to work correctly, the encoder

calibration value can be determined using the following procedure:

1. Set the encoder calibration value to 3600.

14 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 19

MODEL 2081 TURNTABLE SERIES Operation

Archived 3/18/10

2. Insure that the turntable is positioned to allow more than a full

revolution of travel in the clockwise direction and use the

STEP keys to run the turntable clockwise a few degrees to

remove any play in the table.

3. Mark the current location of the turntable against the ground

ring (masking tape works well), and set the current position

reading to 000.0.

4. Using the STEP keys, rotate the turntable clockwise until it is

again aligned with the mark on the ground ring. For best

results, the last motion should always be in the clockwise

direction to insure that any play in the gearing between the

motor and encoder is accounted for.

5. Record the reading of the display, ignoring the decimal point

(i.e. 360.0 would be 3600). This is the encoder calibration

value. NOTE: If the value is below 3600, the resolution of the

encoder is low and thus the 2090 will not provide 0.1 degree

resolution, even though the display shows that digit. If the

value has gone past 9999, the encoder has too many counts per

meter and the 2090 can not correct for it. In this case, contact

ETS-Lindgren for assistance.

6. Enter this value for the encoder calibration value and reset the

limits and position information.

7. Test the turntable by moving it a complete revolution and

comparing the alignment marks. It may be necessary to adjust

the encoder calibration value up or down slightly depending on

the result. NOTE: When scanning between limits, it is not

uncommon to have a small discrepancy between the absolute

position of the table and the display on the 2090. This is

because reversing the direction of rotation reverses any gear

play between the encoder and the table top, allowing that play

to be visible in the positioning accuracy.

TT CALIBRATION EXAMPLE

The table is set at the 0 degree position. A piece of tape is placed

on the edge of the TT to line up with the edge of the gearbox

cover. The table is stopped when the tape travels exactly 360

© ETS-LINDGREN L.P. – JANUARY 2003 15

REV D – PN 399212

Page 20

Operation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

degrees around. The display on the 2090 now reads 356.3 degrees

which is recorded.

The table is rotated CCW back to 0. The parameter button is set on

the “C” setting. The “C” digits display 3430. A new “C” setting is

now calculated:

New “C” = (356.3 divided into 360) times 3430 = 3395 (rounded

off)

Decrement the C parameter to 3395 and “ENTER” is pressed.

Then the “current position” button is pressed to get back to

operation mode.

The table is rotated from 0 to 360 and the mark is now within one

degree of being one full TT revolution. Calibration is complete.

16 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 21

MODEL 2081 TURNTABLE SERIES Operation

Archived 3/18/10

SETTING CURRENT POSITION ON 2090

The total travel between the mechanical limits is typically set

between 370 and 400 degrees at the factory. Set the 0 degree

position on the 2090 so that the 2090 moves the table between the

mechanical limits without engaging them in normal operation.

EXAMPLE (CW - clockwise, CCW - counterclockwise)

The table is rotated CCW until it stops at the mechanical limit. The

table current position is then set at 0. Then it is rotated CW until it

stops at the CW mechanical limit switch. The controller now reads

385 degrees which is the full travel between mechanical limits.

The current position on the 2090 is then reset to 360 about 10-15

degrees from the CW mechanical limit. This will keep it from

hitting both mechanical limits when rotating from 0 to 360 during

operation by the 2090.

CAUTION: ON RESETTING CURRENT

POSITION ON 2090

The 0 degree position of the 2090 controller is fixed with respect to

the mechanical limits described in the “Setting Current Position on

2090” section if they are not disabled per the instructions in the

“Setting Travel Limits” section.

Should it become necessary to reset the current position readout of

the Model 2090 Controller. The platform can be rotated

periodically back to a desired position and the 2090 current

position can be reset to 0 only if the mechanical limits are disabled.

The CW and CCW limits on the 2090 will continue to function

with the mechanical limits disabled. If the mechanical limits

remain in operation, the 360 travel on the 2090 will no longer be

between mechanical limits and normal operation will be

interrupted if they are not disabled per the instructions in the

“Setting Travel Limits” section.

© ETS-LINDGREN L.P. – JANUARY 2003 17

REV D – PN 399212

Page 22

Operation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

CHANGING ROTATION SPEED

The ETS-Lindgren two-speed turntable is designed to shift speeds

at a standstill or during rotation. To change rotational speed,

simply depress the POLAR/SPEED button on the front panel of the

Model 2090 Controller. (Refer to the controller manual for more

information). Changing speed on the turntable is also available

through the IEEE-488 GPIB interface.

The shift from high to low speed as well as from low to high speed

should be a relatively smooth transition. A smooth pole changer is

utilized in the motor control assembly which compensates for

changes in torque when switching speeds. No adjustments are

necessary.

The ETS-Lindgren optional variable speed drive provides smooth

speed adjustment throughout the range of adjustment. A variable

frequency drive provides continuous speed adjustment with high

reliability. Adjustment of the turntable’s speed is facilitated by the

Model 2090 Controller and these operations are discussed in detail

in the Model 2090 Controller manual.

18 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 23

MODEL 2081 TURNTABLE SERIES Operation

Archived 3/18/10

SETTING TRAVEL LIMITS

The mechanical limits of the Model 2081 turntable have been

changed from previous models for user convenience, ease of

operation and safety. These limit adjustments are located outside

the center section of the turntable adjacent to the gearbox. In some

installations, it will be necessary to remove several of the top

sections of the turntable to access the limit switch adjustments.

To increase the amount of travel in either direction turn the knob in

the direction indicated by the positive (+) sign. To decrease the

amount of travel in either direction you must turn the knob in the

minus (-) direction as indicated.

WARNING Ensure the current ravel limit settings will not cause

damage to existing cables and equipment located underneath the

turntable.

You may decide not to use any mechanical limits if you want the

turntable to rotate continuously. To do this, the coupling between

the encoder and threaded shaft must be disengaged. To gain access,

remove the knobs and cover to the encoder. Disengage one side of

the coupling by loosening the set screws that link it to the shaft.

Then slide the coupling ¼ inch on the shaft to disengage the teeth

and retighten the shaft set screws.

CAUTION The limits should be set whether or not the soft limits

present in the controller are used. Failure to do so may cause

damage to occur due to overrun of the table in either direction.

Once limits have been set, return the turntable to its original

position by replacing the top center section removed previously.

© ETS-LINDGREN L.P. – JANUARY 2003 19

REV D – PN 399212

Page 24

Operation MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

ALTIVAR MOTOR BASE CONFIGURATION

The following settings are the defaults for the Altivar motor base

set by ETS-Lindgren:

Altivar

208/230 VAC 60 Hz 400 VAC 50 Hz

Setting

bFr 60 50

ACC

dEC

0.1 0.1

0.1 0.1

LSP 0 0

HSP 75 75

UnS 230 400

FrS 60 60

tFr

90 90

Should you need to change the configuration on the Altivar motor

base supplied with your turntable the Altivar manual is available at

www.SquareD.com.

20 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 25

MODEL 2081 TURNTABLE SERIES Hand Control Unit

Archived 3/18/10

HAND CONTROL UNIT

To connect the Hand Control Unit (HCU), remove the connector

cap on the motor base. Plug the cable receptacle from the hand

control unit into the electrical enclosure and screw connectors

completely together. The HCU is now ready to operate. Be sure to

coordinate use of the unit with the operator of the Model 2090

Positioning Controller.

To allow the HCU to operate, push the control switch from MAIN

to HAND. When the HCU is selected, the Model 2090 Positioning

Controller is overridden until control is returned from the HCU. If

the Model 2090 Positioning Controller is left on while the HCU is

used, all changes in position are recorded by the Model 2090

Device Positioner.

CAUTION Do not plug the hand control unit into the motor base

while that device is operational. Coordinate with the operator of

the Model 2090 Positioning Controller before plugging in, using,

or unplugging. Do not push the CD and CCW buttons at the same

time. Be sure that the motor is completely stopped before reversing

direction with the unit.

When you are ready to change to automated testing, toggle the

control switch from HAND to MAIN.

© ETS-LINDGREN L.P. – JANUARY 2003 21

REV D – PN 399212

Page 26

Recommended Maintenance MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

RECOMMENDED MAINTENANCE

CAUTION Do not perform maintenance while turntable is

operating.

Regular maintenance will prolong the serviceable life of your

turntable. Follow this recommended schedule.

EVERY SIX MONTHS

Adjust the encoder chain. The chain should have no more than 20

mm (1/8”) looseness when flexed to a point halfway between the

two sprockets. Adjust the chain by loosening the two screws

holding the encoder assembly. Move the encoder in or out to the

desired tension.

Lubricate the encoder chain. Use a good quality grease to lubricate

the chain.

Grease the casters. Use a good quality bearing grease to lubricate

the casters.

Check the gearbox for fluid leakage. A slight film that collects is

normal. You should not have puddles of fluid. The gearbox is

lubricated and sealed at the factory. Under normal conditions, it

should not require servicing during its life.

Apply conductive grease on the ground brush along the wear strip

contact area (approximately 1 to 2” from the top of the strip).

Inspect the ground brush for wear. A well maintained ground brush

should have a long serviceable life. Should it need to be replaced,

replacement ground brushes for turntables are available in standard

lengths that are straight and not trimmed. They are assembled at

the factory into the predrilled aluminum extrusion that is attached

around the edge of the turntable. During replacement the brush

assembly is clamped in place using a pipe clamp in order to bend

the brushes to conform to the edge of the turntable top. The

22 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 27

MODEL 2081 TURNTABLE SERIES Recommended Maintenance

Archived 3/18/10

replacement brushes have hole spacing that is machined exactly

the same as the original.

EVERY TWELVE MONTHS

Lubricate the main bearing race. Use a grease gun with a good

quality bearing grease. The grease fittings are located inside the

race, 90 degrees apart, underneath the top. Three discharges from

the grease gun in each fitting are adequate.

Grease the gear teeth with a good quality grease.

© ETS-LINDGREN L.P. – JANUARY 2003 23

REV D – PN 399212

Page 28

Specifications MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

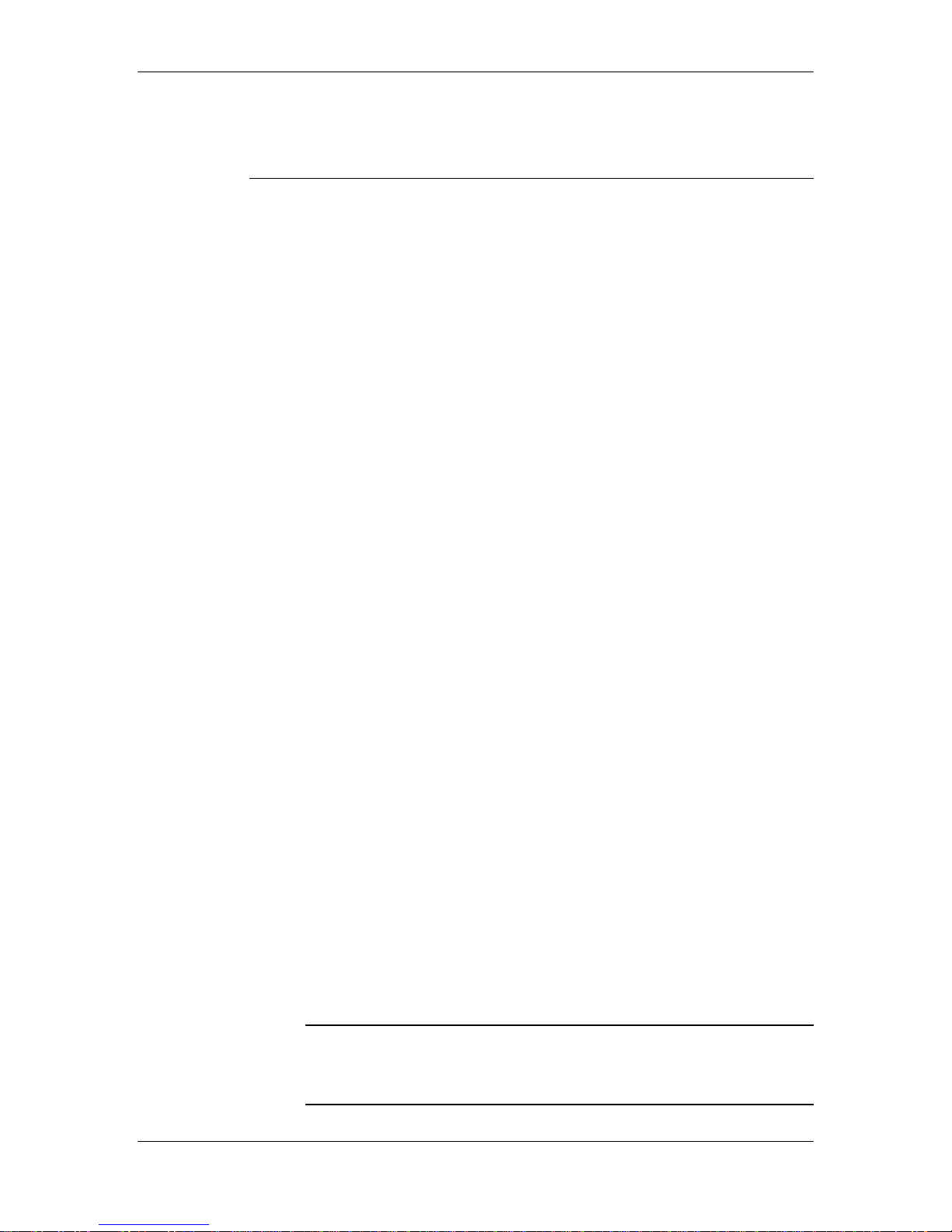

SPECIFICATIONS

ELECTRICAL

Model Drive Speeds RPM Voltage Line

2081-2.0 Series

2081-3.0 Series

2081-4.0 Series

2081-5.0 Series

2081-6.0 Series

Frequency

Dual .5/2.0 208-230 60 8 3

Dual .5/2.0 380 50 5 3

Variable .5/2.0 208-230 60 18 3

Variable .5/2.0 380 50 7 3

Dual .5/2.0 208-230 60 8 3

Dual .5/2.0 380 50 5 3

Variable .5/2.0 208-230 60 18 3

Variable .5/2.0 380 50 7 3

Variable .5/2.0 208-230 50/60 15 Single

Dual .5/2.0 208-230 60 8 3

Dual .5/2.0 380 50 5 3

Variable .5/2.0 208-230 60 18 3

Variable .5/2.0 380 50 7 3

Variable .5/2.0 208-230 50/60 15 Single

Dual .5/2.0 208-230 60 13 3

Dual .5/2.0 380 50 8 3

Variable .5/2.0 208-230 60 20 3

Variable .5/2.0 380 50 14 3

Dual .5/2.0 208-230 60 13 3

Dual .5/2.0 380 50 8 3

Variable .5/2.0 208-230 60 20 3

Variable .5/2.0 380 50 14 3

AMP Phase

PHYSICAL

Model Diameter Nominal Height Distributed Load

Rating*

2081-2.0 Series

2081-3.0 Series

2081-4.0 Series

2081-5.0 Series

2081-6.0 Series

*Distributed Load Rating is based on load being evenly distributed to each section. No point loads under

.37 sq. m (4 sq. ft) should exceed 500kg (1100 lb); and not over 500 kg should be applied to a 45 degree

segment outboard of the casters.

2.0 m

6.56 ft

3.0 m

9.84 ft

4.0 m

13.12 ft

5.0 m

16.40 ft

6.0 m

19.69 ft

40.0 cm

15.75 in

40.0 cm

15.75 in

40.0 cm

15.75 in

40.0 cm

15.75 in

40.0 cm

15.75 in

1,500 kg

3,300 lb

4,000 kg

8,800 lb

6,000 kg

13,200 lb

6,800 kg

15,000 lb

9,000 kg

20,000 lb

24 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Top Construction

Sectional

Aluminum

Sectional

Aluminum

Sectional

Aluminum

Sectional

Aluminum

Sectional

Aluminum

Page 29

MODEL 2081 TURNTABLE SERIES Warranty Statement

Archived 3/18/10

WARRANTY STATEMENT

ETS-Lindgren L.P., hereinafter referred to as the Seller, warrants that standard EMCO products

are free from defect in materials and workmanship for a period of two (2) years from date of

shipment. Standard EMCO Products include the following:

Antennas, Loops, Horns

GTEM cells, TEM cells, Helmholtz Coils

LISNs, PLISNs, Rejection cavities & Networks

Towers, Turntables, Tripods, & Controllers

Field Probes, Current Probes, Injection Probes

If the Buyer notifies the Seller of a defect within the warranty period, the Seller will, at the Seller’s

option, either repair and/or replace those products that prove to be defective.

There will be no charge for warranty services performed at the location the Seller designates.

The Buyer must, however, prepay inbound shipping costs and any duties or taxes. The Seller will

pay outbound shipping cost for a carrier of the Seller’s choice, exclusive of any duties or taxes. If

the Seller determines that warranty service can only be performed at the Buyer’s location, the

Buyer will not be charged for the Seller’s travel related costs.

This warranty does not apply to:

Normal wear and tear of materials

Consumable items such as fuses, batteries, etc.

Products that have been improperly installed, maintained or used

Products which have been operated outside the specifications

Products which have been modified without authorization

Calibration of products, unless necessitated by defects

THIS WARRANTY IS EXCLUSIVE. NO OTHER WARRANTY, WRITTEN OR ORAL, IS

EXPRESSED OR IMPLIED, INCLUDING BUT NOT LMITED TO, THE IMPLIED WARRANTIES

OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE. THE REMEDIES

PROVIDED BY THIS WARRANTY ARE THE BUYER’S SOLE AND EXCLUSIVE REMEDIES.

IN NO EVENT IS THE SELLER LIABLE FOR ANY DAMAGES WHATSOEVER, INCLUDING

BUT NOT LIMITED TO, DIRECT, INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES, WHETHER BASED ON CONTRACT, TORT, OR ANY OTHER LEGAL THEORY.

Note: Please contact the Seller’s sales department for a Return Materials Authorization (RMA)

number before shipping equipment to us.

© ETS-LINDGREN L.P. – JANUARY 2003 25

REV D – PN 399212

Page 30

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

ILLUSTRATIONS

26 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 31

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 27

REV D – PN 399212

Page 32

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

28 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 33

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 29

REV D – PN 399212

Page 34

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

30 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 35

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 31

REV D – PN 399212

Page 36

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

32 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 37

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 33

REV D – PN 399212

Page 38

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

34 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 39

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 35

REV D – PN 399212

Page 40

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

36 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 41

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 37

REV D – PN 399212

Page 42

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

38 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 43

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 39

REV D – PN 399212

Page 44

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

40 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 45

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 41

REV D – PN 399212

Page 46

Illustrations MODEL 2081 TURNTABLE SERIES

Archived 3/18/10

42 © ETS-LINDGREN L.P. – JANUARY 2003

REV D – PN 399212

Page 47

MODEL 2081 TURNTABLE SERIES Illustrations

Archived 3/18/10

© ETS-LINDGREN L.P. – JANUARY 2003 43

REV D – PN 399212

Loading...

Loading...