www.Get2itParts.com

www.Get2itParts.com

ETON America

150cc Service Manual

Covers:

YXL-150, CXL-150, RXL-150R

200028

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

www.Get2itParts.com

Table of Contents

1. Information

2. Maintenance

3. Engine Removal And Installation

4. Engine Lubrication And Cooling System

5. Cylinder Head & Valves

6. Cylinder & Piston

7. Transmission System

8. Front Wheel, Suspension And Steering

9. Rear Wheel System

10. Fenders And Exhaust Pipe

11. Electrical System

12. Trouble Shooting

Information

www.Get2itParts.com

www.Get2itParts.com

1. INFORMATION

1.1 Safety

1.2 Notes

1.3 Specifications

1.4 Serial number

1.5 Torque valve

1.1 Safety

GASOLINE

Gasoline is extremely flammable and is explosive under certain conditions. Do not smoke or allow

sparks or flames in your work area.

CARBON MONOXIDE

Never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas that

may cause loss of consciousness and lead to death.

BATTERY ELECTROLYTE

The battery electrolyte contains sulfuric acid. Protect your eyes, skin, and clothing. If you come into

contact with the electrolyte, flush the area thoroughly with water. If you get the electrolyte in your eyes,

flush with water and contact a doctor immediately.

HOT PARTS

The engine and exhaust pipe become very hot and remain hot for one hour after the engine is

run. Wear insulated gloves before handling these parts.

USED ENGINE / GEAR OIL

Used engine oil and gear oil may cause damage after prolonged exposure to the skin. Keep out of

reach of children.

1.2 NOTES

All information, illustrations, directions and specifications included in this publication are base on the

latest product information available at the time of approval for printing.

ETON America, LLC reserves the right to make changes at any time without notice and without

incurring any obligation whatever.

No part of this publication may be reproduced without written permission.

1-2

Information

www.Get2itParts.com

www.Get2itParts.com

1.3 SPECIFICATION

ENGINE Type Air-Cooled 4-Stroke

with Oil Cooler

Displacement 149.56 cc

Bore and Stroke 57.4x57.8mm

Compression 9.7:1

Maximum Torque 10.6 ps@7500rpm

Carburetor Kei-Hin / Electric choke

Air Cleaner Oil Bathed element type

Transmission Automatic (C.T.V. V-belt)

CHASSIS Overall Length 1730mm/68.1 inches

Overall Width 980mm/38.6 inches

Overall Height 1070mm/42.1 inches

Wheel base 1115mm/43.9 inches

Ground Clearance 140mm/5.5 inches

Dry Weight 172kg / 379lbs

Fuel Tank Capacity 6.5 liters/1.7 gal

SUSPENSION

Front

Rear

BRAKES

Front

Rear

TIRES

Front

Rear

COLOR

* Specifications subject to change without notice.

Dual A-arm

Swing Arm

Dual Mechanical Drum

Mechanical Drum

(YXL only)

Hydraulic Disc

(CXL & RXL-150R only)

21” x 7” - 8”

22” x 10”

Red/Black & Silver/Black

(YXL-150 only)

Red, Blue, Green, Silver

(CXL-150 only)

Black/Yellow

(RXL-150R only)

1-3

Information

www.Get2itParts.com

www.Get2itParts.com

1.4 SERIAL NUMBERS

The frame serial number is stamped on the front frame just above the oil cooler. The

engine number is stamped on the left side of the crankcase.

Frame Number

Engine Number

1-4

Information

A

(

www.Get2itParts.com

www.Get2itParts.com

1.5 TORQUE VALUES

STANDARD

5 mm bolt and nut 5 N-m(3.7 ft-lbs)

6 mm bolt and nut 10 N-m( 7.4 ft-lbs)

8 mm bolt and nut 22 N-m ( 16 ft-lbs)

10 mm bolt and nut 35 N-m ( 26 ft-lbs)

12 mm bolt and nut 55 N-m ( 41 ft-lbs)

ENGINE

Cylinder head nut 28 N-m(20.7 ft-lbs)

Spark plug 12 N-m (8.9 ft-lbs)

Cylinder head bolt 20 N-m (14.8 ft-lbs)

lternator bolt 8 N-m (5.9 ft-lbs)

FRAME

Handlebar upper holder bolt 24 N-m( 17.7 ft-lbs)

Throttle housing cover screw 4 N-m ( 2.9 ft-lbs)

Steering shaft nut 50 N-m( 36.9 ft-lbs)

Steering shaft holder bolt 33 N-m ( 24 ft-lbs)

Wheel rim bolt 18 N-m ( 13.3 ft-lbs)

Tie rod lock nut 35 N-m ( 25.8 ft-lbs)

King pin nut 40 N-m ( 29 ft-lbs)

Handlebar lower holder nut 40 N-m ( 29.5 ft-lbs)

Front wheel bolt 24 N-m ( 17.7 ft-lbs)

Front axle nut 60 N-m ( 44 ft-lbs)

Front brake arm nut 4 N-m ( 3.0 ft-lbs)

Rear brake arm nut 7 N-m ( 5.2 ft-lbs)

Rear axle nut 60 N-m

Rear wheel bolt 24 N-m ( 17.7 ft-lbs)

Exhaust muffler mounting bolt 30 N-m ( 22.1 ft-lbs)

Engine hanger bolt 30 N-m ( 22 ft-lbs)

Rear axle holder bolt 90 N-m ( 65 ft-lbs)

Swingarm pivot nut 90 N-m ( 65 ft-lbs)

Rear shock absorber mounting nut 45 N-m ( 33 ft-lbs)

44.3 ft-lbs)

1-5

www.Get2itParts.com

www.Get2itParts.com

Maintenance

2. Maintenance

2.1 Maintenance data

2.2 Maintenance schedule

2.3 Fuel tube

2.4 Throttle operation

2.5 Throttle cable adjustment

2.6 Air cleaner

2.7 Spark plug

2.8 Idle speed

2.9 Drive chain

2.10 Brake system

2.11 Wheels and tires

2.12 Steering system

2.13 Toe-in

2.14 Gear oil

2.1 MAINTENANCE DATA

SPECIFICATION

SPARK PLUG:

Spark plug gap:

Recommended spark plugs:

Throttle lever free play:

Idle speed:

Brake lever free play:

Drive chain slack

Front/rear tire size

Front/rear tire pressure

Toe-in

TORQUE VALUES

SPARK PLUG

TIE-ROD LOCK NUT

ENGINE OIL

Viscosity :

API service classification

GEAR LUBRICATION OIL

Viscosity:

0.6-0.7 mm / 0.024 – 0.028”

NGK CR7HSA

5-10 mm / 0.2-0.4”

1600±100rpm

15-25 mm / 0.6-1.0”

10-25 mm / 0.4-1.0”

20*7-8 / 22*10-8

2.2± 0.3 psi (0.15 kgf/cm2)

5±10 mm / 0.2±0.4”

12-19 N-m / 9-14 ft-lbs

35-43 N-m / 26-32 ft-lbs

SAE 40 (10W-40)

SF or SG

SAE 90 (80/90 weight gear oil)

2-1

WP-0027

www.Get2itParts.com

www.Get2itParts.com

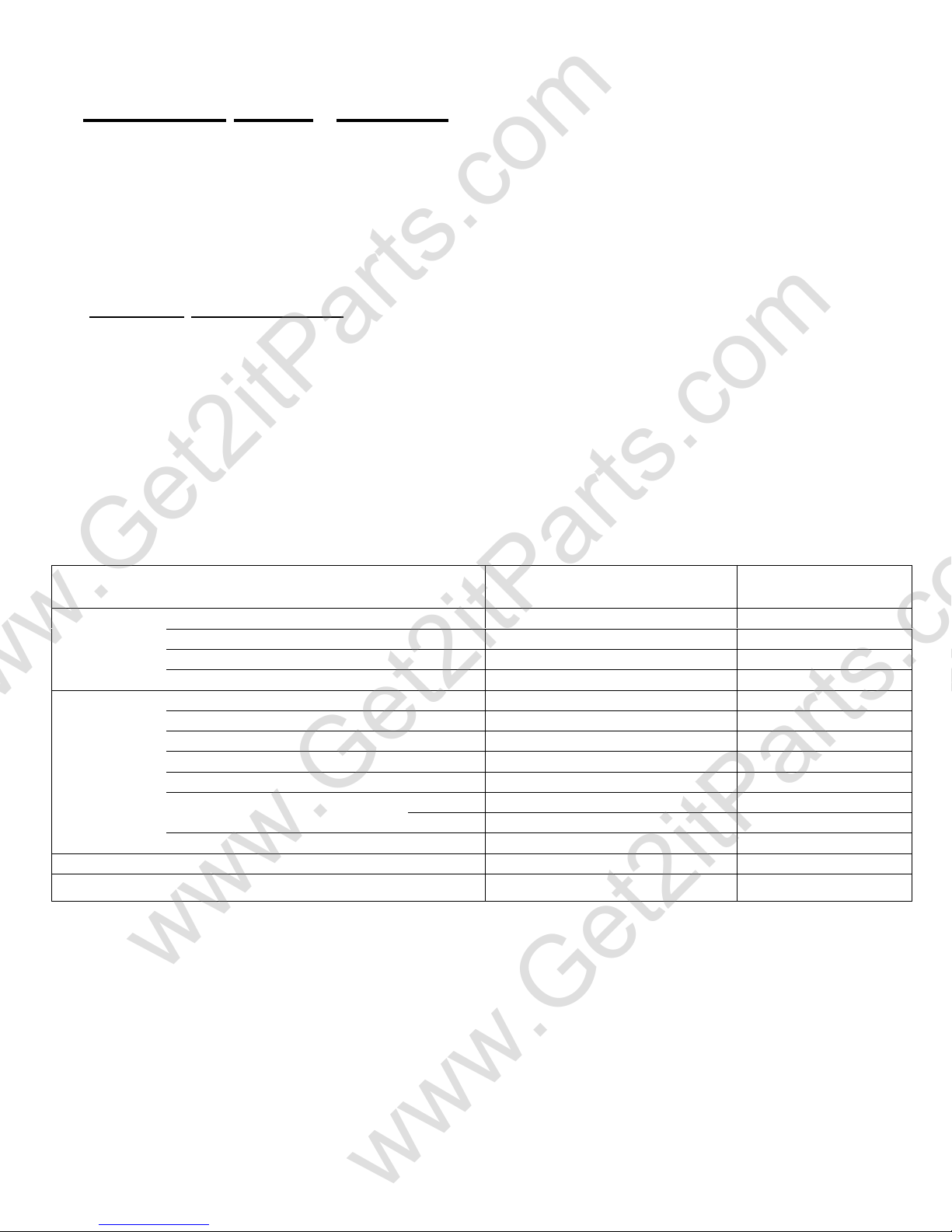

Maintenance Schedule

Four Stroke Vehicles

Scheduled

Maintenance

1 Aircleanerelement

2 Aircleaner

3 Oilfilter(Screen)

4 Engineoil

5 Tire,pressure

6 Battery

7 Sparkplug

8 Carburetor(idlespeed)

9 Steeringbearingandhandles

Checktransmissionforleak‐

10

age

11 Checkcrankcaseforleakage

12 Transmissionoil

13 Drivebelt/roller

14 Fueltankswitchandlines

Throttlevalveoperationand

15

cable

16 Engineboltsandnuts

Cylinderhead,cylinder,and

17

piston

Exhaustsystem/cleaning

18

carbon

19 CamChain/ignitiontime

20 Valveclearance

21 Shockabsorbers

22 Front/Rearsuspension

23 Main/Sidestands

24 Crankcase(PCV)Valve

Brakemechanism/brakelin‐

25

ing(pad)

300KM Every1000KM Every3000KM Every6000KM Every12000KM

200Miles 600Miles 2000Miles 3700Miles 7500Miles

NEW 1Month 3Months 6Months 1Year

I* C* R(paper) R(sponge)

I

C C

Change I Change

I I

I I

I I R

I I

I I

I I

I I

Change Change

I R

I I

I I

I I

I

I

I I

I I I I I

I I

I I

I I/L

I I

I I

TightenallBolts/Nuts&Fas‐

26

teners

Code:

I=Inspection,clean,andadjust

R=Replace

C=Clean(replacedifnecessary)

L=Lubricate

I I

*=Cleanorreplacetheaircleanerelementmoreoftenwhenthevehicleisoperatedondusty

roadsorinaheavilypollutedenvironment.

#=Maintenanceshouldbeperformedmoreoftenifthevehicleisfrequentlyoperatedathigh

speedforprolongedtimeandafterthevehiclehasaccumulated50,000miles.

www.Get2itParts.com

www.Get2itParts.com

Maintenance

2.2 MAINTENANCE SCHEDULE

The maintenance intervals in the follow table are based upon average riding conditions. Riding in

unusually dusty areas requires more frequent servicing. E-TON recommends that all maintenance

and inspections be performed ONLY by a qualified and fully trained technician.

(First Week)_________ (30 Operating days) _____ (Once each Year)

FUEL LINE X X

THROTTLE OPERATION X X

AIR CLEANER C

SPARK PLUG X

CARBURETOR IDLE SPEED X X

DRIVE CHAIN X,L X,L

BRAKE SHOE WEAR X

BRAKE SYSTEM X X

NUT, BOLT, FASTENER X X

WH EEL/TIRES X X

STEERING SYSTEM X

SUSPENSION SYSTEM X

GEAR OIL R

ENGINE OIL R X R

ENGINE OIL FILTER C C

Initial Service Regular Service Yearly Service

Note - X: Inspect and Clean, Adjust, Lubricate or Replace, if necessary

C: Clean

L: Lubricate

R: Replace

2.3 FUEL TUBE

Inspect the fuel lines for deterioration,

damage, or leaks, and replace if

necessary.

ETON 150cc models are equipped with

a vacuum fuel valve. Fuel is

transferred into the carburetor when a

vacuum is created from the engine.

Fuel should not flow if engine is not

running or if vacuum is not applied.

2-2

Vacuum

control line

Maintenance

www.Get2itParts.com

www.Get2itParts.com

2.4 THROTTLE OPERATION

Inspect for smooth lever operation, full opening, and automatic

full closing in all steering positions.

Inspect for deterioration, damage, cuts and nicks, or kink in

the throttle cable, replace it if necessary.

Check the throttle lever; free play should be no more than

5-10 mm / 0.2-0.4” at the tip of the throttle lever.

Disconnect the throttle cable at the upper end. Lubricate the

cable with commercially lubricant to prevent premature wear.

2.5 THROTTLE CABLE ADJUSTMENT

Slide the rubber cap of the adjuster off the throttle

housing, loosen the lock nut, and adjust the free

play of the throttle lever by turning the adjuster on

the throttle housing. Inspect the free play of the

throttle lever.

Throttle cable adjuster

2-3

Maintenance

www.Get2itParts.com

www.Get2itParts.com

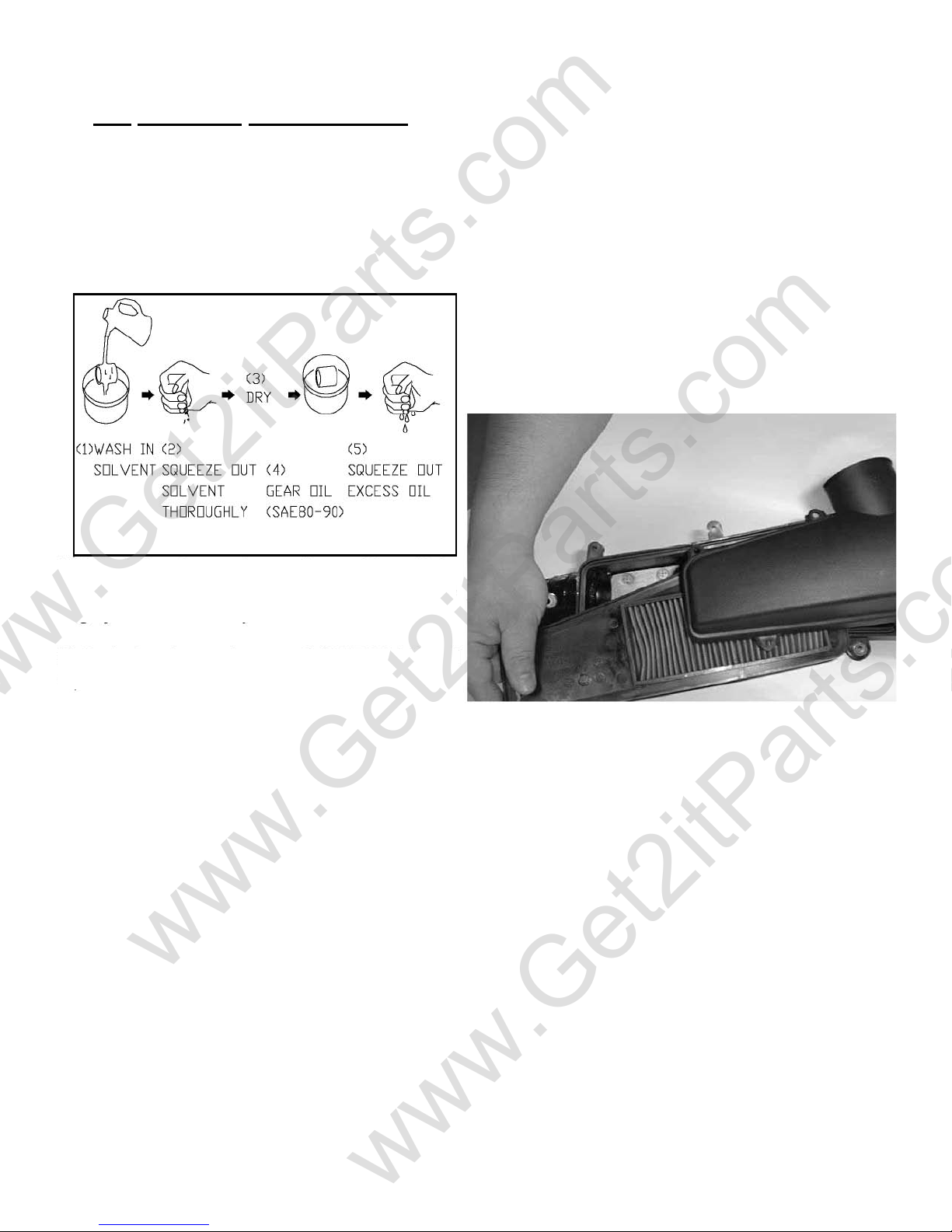

2.6 AIR CLEANER MAINTENANCE

(1) Loosen the screws and remove the air cleaner from carburetor.

(2) Disassemble the air cleaner cover and body.

(3) Clean the air cleaner element and screen. (See Figure below)

(4) Wash the element in non-flammable or high

flash point solvent squeeze out the solvent thoroughly and allow it to dry.

(5) Soak the element in gear oil (SAE 80-90) and

squeeze out the excess.

(6) Install the air cleaner element and screen in

the body.

(7) Assemble the air cleaner body and cover and

attach to the carburetor with the screw.

2-4

Maintenance

www.Get2itParts.com

www.Get2itParts.com

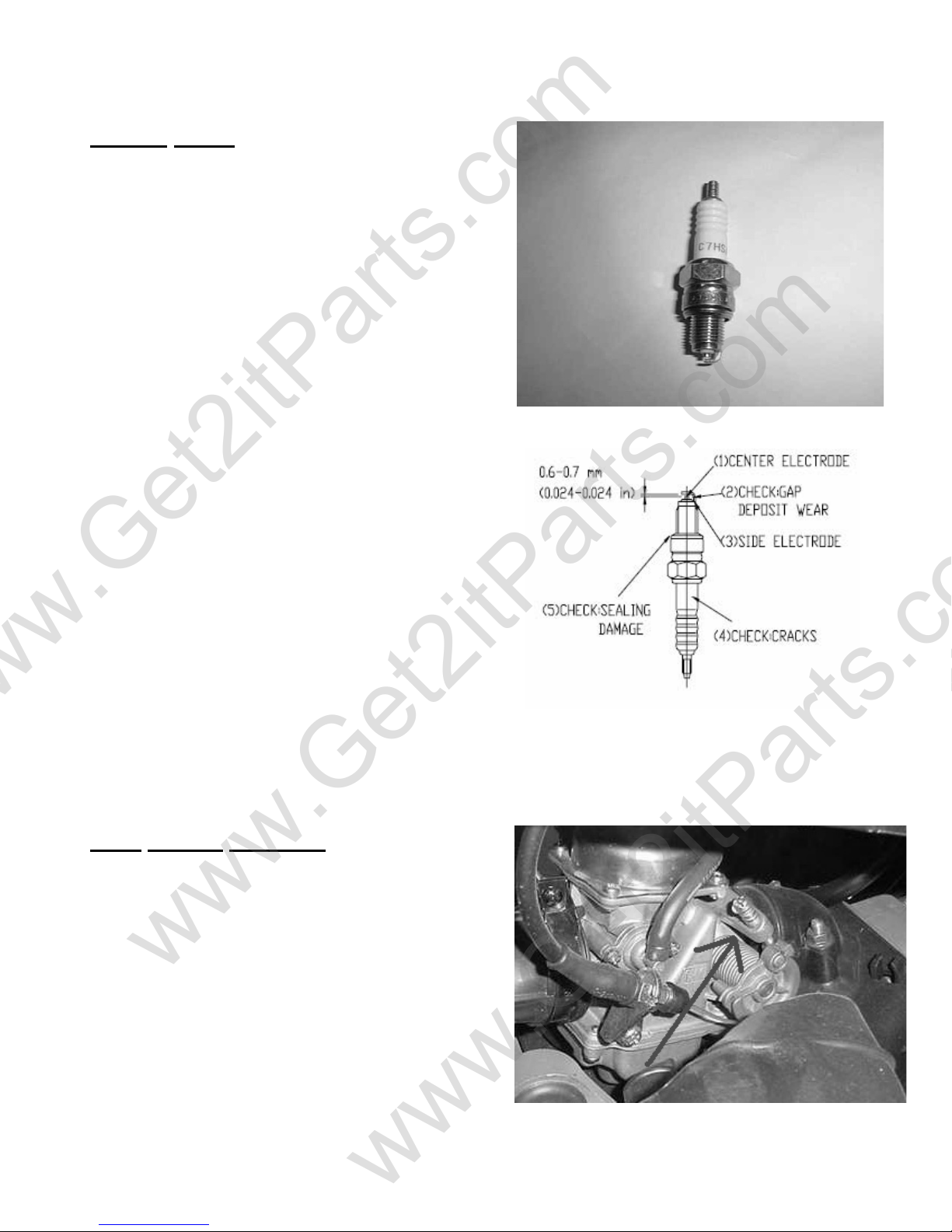

2.7 SPARK PLUG

The spark plug is located at the front of the engine.

(1) Disconnect the spark plug cap and remove the

spark plug.

(2) Visually inspect the spark plug electrodes for

wear or cracks in insulator. Replace if

needed.

(3) The center electrode should have square edges

and the side electrode should have a

constant thickness.

(4) Discard the spark plug if there is apparent wear

or if the insulator is cracked or chipped.

(5) Measure the gap with a wire-type feeler gauge and

adjust if necessary by carefully bending the

side electrode.

SPARK PLUG GAP : 0.6-0.7 mm

Recommended replacement plug: NGK CR7HSA

(6) Check the sealing washer and replace with a new

one if damaged.

(7) With the sealing washer attached thread the spark

plug in by hand to prevent cross threading.

Tighten the spark plug.

TORQUE : 12-19 N-m / 9-14 ft-lbs

2.8 IDLE SPEED SETTING

(1) Inspect and adjust the idle speed after all other

engine maintenance has been performed and is within

specifications. The engine must be warm for accurate

idle speed inspection and adjustment.

(2) Warm up the engine for about ten minutes and

connect a tachometer.

(3) Turn the throttle stop screw as required to obtain

the specified idle speed.

IDLE SPEED : 1700 ± 100 rpm

2-5

Maintenance

www.Get2itParts.com

www.Get2itParts.com

2.9 DRIVE CHAIN ADJUSTMENT

Stop the ATV and shift transmission into

neutral. Inspect the chain slack midway

between the sprockets. The standard is

10-25mm (5/8 – 1”).

If needed, remove the chain protective

cover and adjust the chain slack.

Loosen the axle holder lock nuts then

adjust the drive chain slack by turning the

adjusting nut. Tighten the axle holder lock

nuts.

Torque = 90N-m (65 ft-lbs)

When the drive chain becomes very dirty, it

should be removed, cleaned, and lubricated with

commercially available lubricant.

Clean the drive chain with kerosene and wipe it

dry.

Inspect the drive chain for possible wear or

damage.

Replace the chain if it is worn excessively or

damaged.

Inspect the sprocket teeth; if there is

excessive wear or damage, replace.

Use a commercial chain lubricant to lubricate the

drive chain; replace and adjust the slack as

described above.

2-6

Maintenance

www.Get2itParts.com

www.Get2itParts.com

2.10 BRAKE SYSTEM ADJUSTMENT

Inspect the front brake lever and cable for excessive play

or damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end of the

lever. The standard is 15-25 mm / 0.59-0.98”.

Adjust the free play of the front brake lever by turning the

adjuster on the brake lever assembly.

Inspect the rear brake lever and cable for excessive play or

damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end of the

lever.

The standard is 10-20 mm / 0.39-0.78”.

Adjust the free play of the rear brake lever by turning the

adjuster on the rear axle.

BRAKE SHOE WEAR

Front Brake

Loosen the front brake cable and inspect the brake lining

thickness.

Service Limit: 2.0mm (0.08”)

If either lining is worn beyond the service limit, replace both

brakes shoes.

Rear Brake

Replace the brake shoes if there is uneven wear or if the

lining is worn beyond the service limit.

2-7

Maintenance

www.Get2itParts.com

www.Get2itParts.com

2.11 WHEELS AND TIRES

Inspect the tire surfaces for cuts or sharp

objects.

Check the tire pressure at cold tire conditions.

The standard tire pressure is 2.2±0.3 psi (0.15

kgf/cm

2.12 STEERING SYSTEM

Check the free play of the steering shaft with the

front wheels turned straight ahead. If there is

excessive play, inspect the tie-rod, kingpin bushing,

and ball joint.

2

).

Steering Shaft Holder Bushing

Remove the front fender.

Remove the steering shaft holder and check the

steering shaft bushing for wears or damage.

If the bushing is worn or damaged, replace.

Grease the steering shaft bushing and install the

parts in the reverse order of removal.

Torque steering shaft holder bolt: 33 N-m (24 ft-lbs)

2-8

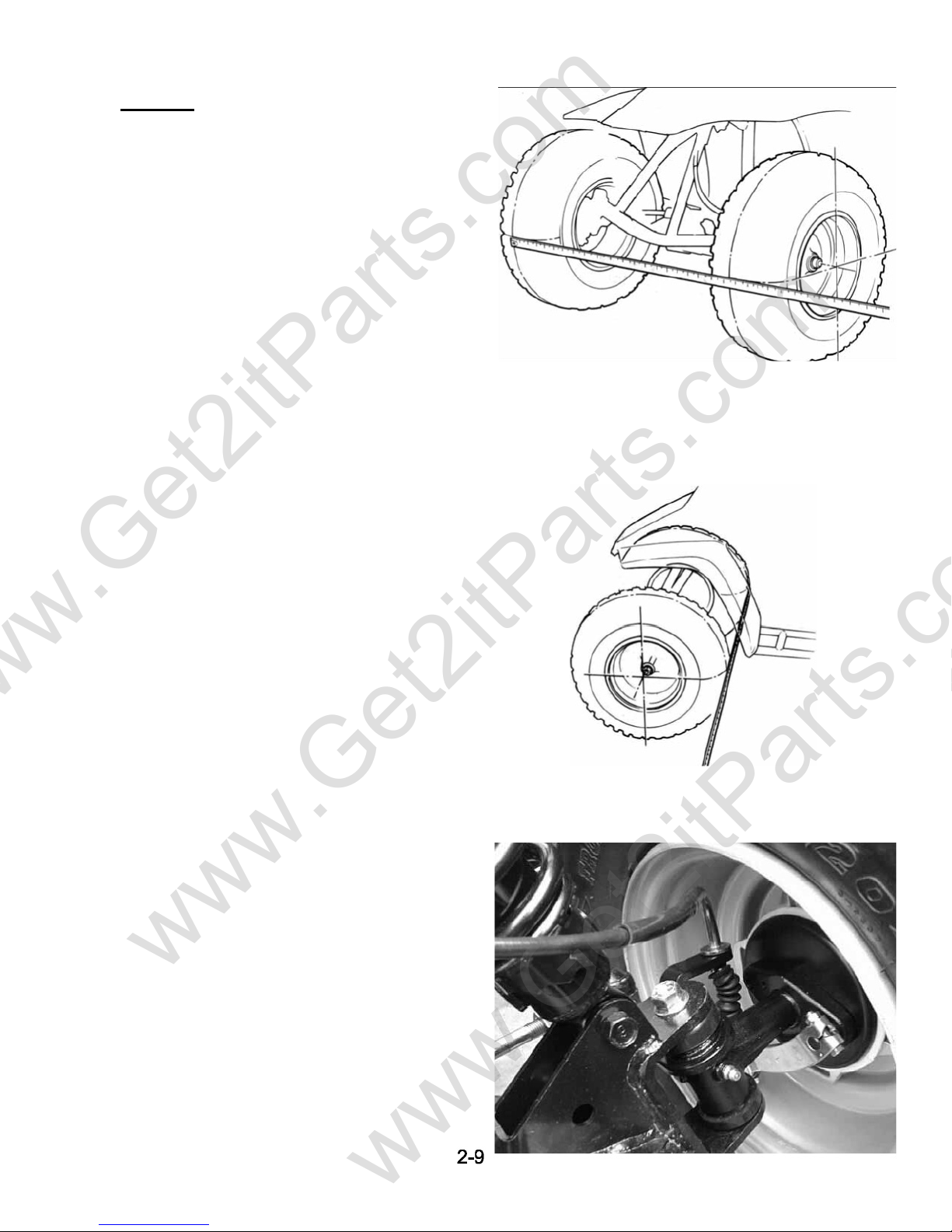

2.13 TOE-IN

www.Get2itParts.com

www.Get2itParts.com

Park the vehicle on level ground with the front

wheels facing straight ahead.

Mark the centers of the tires to indicate the axle

center height.

Measure the distance between the marks.

Carefully moving the vehicle backward, let the

wheels turn 180° so the marks on the tires are

aligned with the axle center height.

Maintenance

Measure the distance between the marks.

Calculate the difference in the front and rear

measurements.

Toe-in: 5±10mm / 0.2±0.4”

If the toe-in is out of standard, adjust it by

changing the length of the tie-rods equally by

turning the tie-rod while holding the ball joint.

Tighten the lock nuts.

Torque: 35-43 N-m / 26-32 ft-lbs

2.14 GEAR OIL MAINTENANCE

www.Get2itParts.com

www.Get2itParts.com

Maintenance

Gear oil needs to be changed every year.

There is a gear oil drain hole bolt at the rear of

engine.

(STEP 1)

Unscrew this drain hole bolt and let the dirty oil

flow out; catch the oil in a proper container for

later disposal.

Oil Fill Plug

Drain bolt

(STEP 2)

Reinsert the drain hole bolt and tighten.

(STEP 3)

Fill with 26oz of 80/90 weight gear oil through

the oil fill hole located on the engine case

beside the gear box.

NOTE: for best results, change the oil while the

engine is warm.

2-10

www.Get2itParts.com

www.Get2itParts.com

ENGINE REMOVAL AND REPLACEMENT

3.1 ENGINE

ENGINE SHOULD ONLY BE REMOVED IN THE CONDITIONS OF NECESSARY REPAIRS OR

ADJUSTMENT TO THE TRANSMISSION AND COMBUSTION SYSTEM!

3.2 ENGINE REMOVAL

Remove the seat, front and rear fender.

(See Chapter 10 )

Remove the footrest.

Remove the spark plug cap from the spark plug.

Remove the exhaust muffler.

Disconnect the carburetor cable by unscrewing

the two screws on top of the carburetor.

Disconnect the carburetor auto-choke (if

equipped), starter motor, generator, the neutral

safety switch, CDI box, and the ignition coil wire.

Remove the drive chain cover.

Remove the drive chain retaining clip and master

link, and remove the drive chain.

Remove the engine hanger bolts under the engine.

REMOVAL AND INSTALLATION

Remove the engine and air cleaner together

3.2 ENGINE REPLACEMENT

Engine installation is essentially the reverse order

of removal.

The torque of the engine hanger bolt is 30 N-m / 22

ft-lbs.

Route the wires and cable properly in reverse

order of removal.

3-1

www.Get2itParts.com

www.Get2itParts.com

LUBRICATION

4. Lubrication

4.1 Service Information

4.2 Trouble Shooting

4.3 Engine Oil Level

4.4 Engine Oil & Filter Change

4.5 Oil Pump Removal / Installation

4.1 SERVICE INFORMATION

GENERAL

1. This section describes cylinder head, valves, camshaft, and other parts maintenance.

2. The engine must be removed from the frame to service the cylinder head.

3. Camshaft lubrication oil is fed to the cylinder head through an oil hole in the engine case.

4. Before installing the cylinder head, be sure the hole is not clogged and the gasket, O-ring,

and dowel pins are in place

SPECIFICATIONS

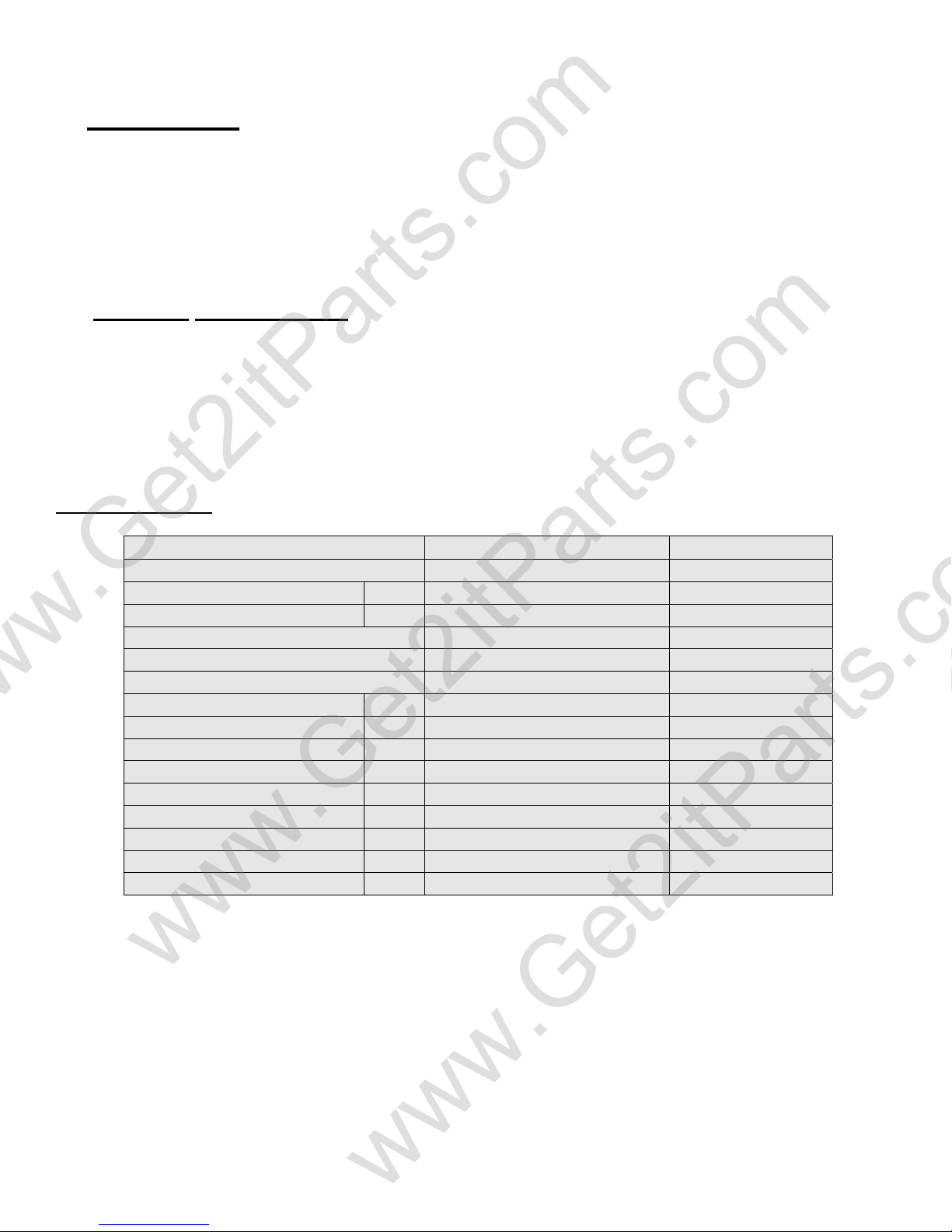

ITEM STANDARD SERVICE LIMIT

Cylinder compression

Cam lobe height IN

EX

Rocker arm I.D.

Rocker arm shaft O.D.

Cylinder head warp

Valve spring free length IN

EX

Valve stem O.D. IN

EX

Valve guide I.D. IN/EX

Stem-to-guide clearance IN

EX

Valve seat width IN

EX

TORQUE VALUES

Cylinder head bolts

Camshaft holder flange nuts

Tappet adjusting nut

Oil Drain Bolt

12±0.5 kg/cm2 --------

29.795mm / 1.180” 29.395mm / 1.157”

29.560mm / 1.16” 29.160mm / 1.148”

10.000-10.018mm / 0.394” 10.10mm / 0.398”

9.972-9.987mm / 0.393 “ 9.91mm / 0.390”

-------- 0.05mm

32.3mm / 1.27” 31.2mm / 1.23”

35.0mm / 1.38” 34.1mm / 1.34”

4.975-4.990mm / 0.196” 4.90mm / 0.193”

4.955-4.970mm / 0.195” 4.90mm / 0.193”

5.000-5.012mm / 0.197” 5.30mm / 0.209”

0.010-0.037mm 0.08mm

0.030-0.057mm 0.10mm

1.0mm 1.80mm

1.0mm 1.80mm

8 - 12 N-m (6-9 ft-lbs)

20 - 24 N-m (15-18 ft-lbs)

9 - 12 N-m (7-9 ft-lbs)

20-30 N-m (15-22 ft-lbs)

4-1

www.Get2itParts.com

www.Get2itParts.com

LUBRICATION

4.2 TROUBLE SHOOTING

Engine top-end problems often affect engine performance. These problems can be diagnosed by a

compression test, or by tracing engine noise to the top end with a sounding rod or stethoscope.

Low compression (Valve)

-Incorrect valve adjustment.

-Worn or damaged valve seats.

-Burned or bent valve.

-Incorrect valve timing.

-Weak valve spring.

Cylinder head

-Leaking or damaged head gasket.

-Warped or cracked cylinder head.

-Faulty cylinder or piston.

Excessive noise

-Incorrect valve adjustment.

-Sticking valve or broken valve spring.

-Worn or damaged rocker arm or camshaft.

-Worn or damaged cam chain.

-Worn or damaged cam chain tensioner.

-Worn cam sprocket teeth.

Excessive smoke

-Damaged valve stem seal.

-Faulty cylinder or piston rings.

4.3 ENGINE OIL LEVEL

Place the engine on the level plane.

Check the oil level with the oil level

dipstick, but do not screw it in when

making this check.

4.3.1 TROUBLESHOOTING

Oil level too low-high oil consumption

-Typical oil consumption.

-External oil leaks.

-Oil not changed often enough.

-Worn piston rings.

Oil contamination

-Worn piston rings.

-Oil or filter not changed often enough.

4-2

Engine

Oil

Dipstick

LUBRICATION

www.Get2itParts.com

www.Get2itParts.com

4.3 ENGINE OIL LEVEL (continued)

Add the recommended oil up to the upper

level if the oil level is below or near lower level

line on the gauge.

4.4 ENGINE

Remove the oil drain plug.

NOTE: Drain the oil while the engine is warm to

ensure complete draining.

Remove the oil drain plug, spring, and oil filter

screen.

Check the O-ring for damage or wear.

Install a new oil filter screen and spring; then,

install the plug.

OIL & FILTER CHANGE

LOWER LEVEL

Oil drain plug

OIL DRAIN PLUG

O-RING

4-3

www.Get2itParts.com

www.Get2itParts.com

4.4 ENGINE OIL & FILTER CHANGE

(continued)

Install the oil drain bolt with sealing washer.

TORQUE: 20-30 N-m (15-22 ft-lbs)

Fill the crankcase with the SAE 10w40 oil.

OIL CAPACITY: 0.8 liter / 0.2 gal at draining.

Install the oil drain plug.

Install the oil level gauge.

Start the engine and let it idle for 2 - 3 minutes.

Stop the engine and check that the oil level is

at the upper line on the gauge. Make sure there

are no oil leaks.

Oil drain plug

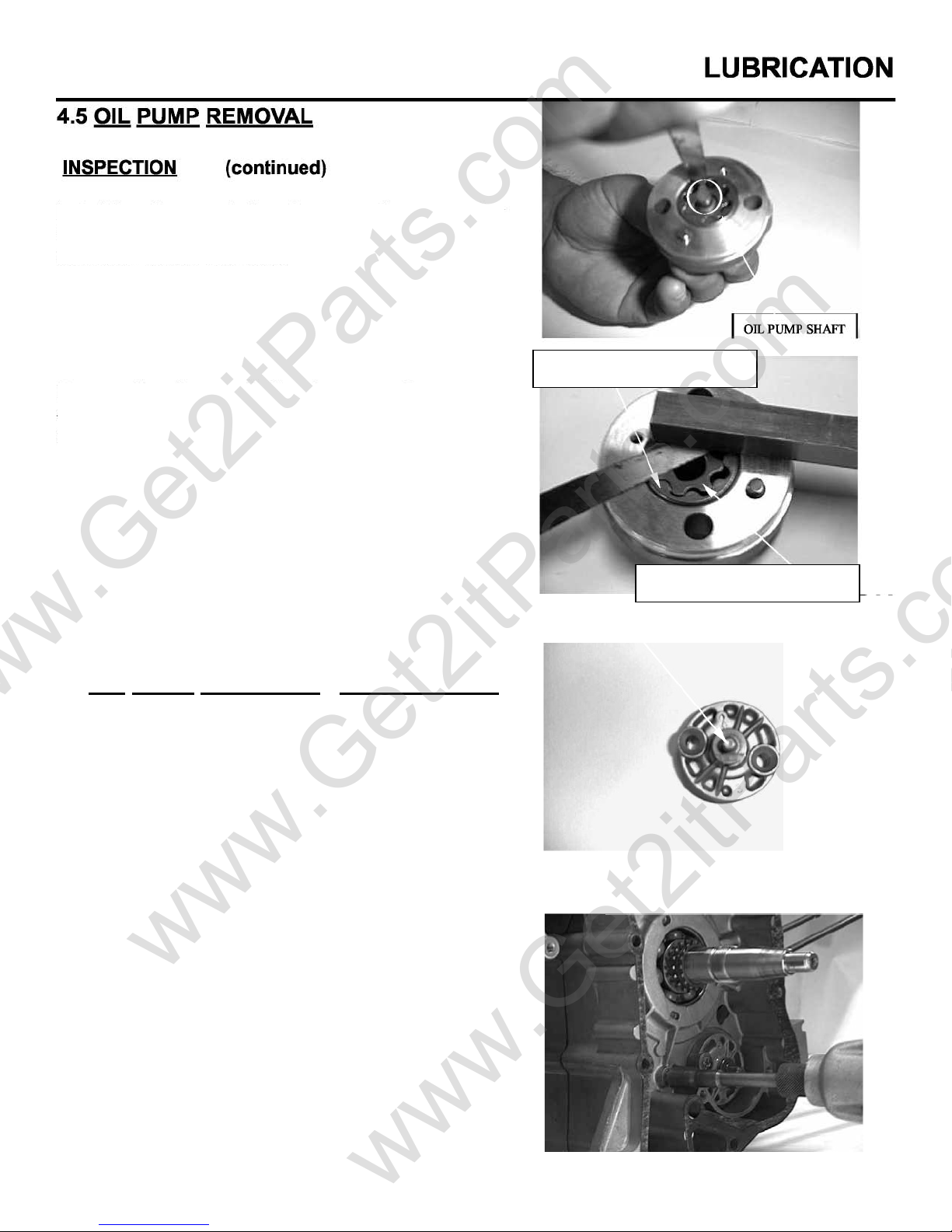

4.5 OIL PUMP REMOVAL

Remove the fan cover assembly.

Remove the cooling fan assembly.

OIL DRAIN PLUG

4-21

www.Get2itParts.com

www.Get2itParts.com

FLYWHEEL

Remove the flywheel and the AC Generator

assembly. Flywheel pullers are available

from the ETON Parts Department.

Remove the starting clutch outer and gear

assembly.

Remove the flange bolts and oil separator.

4-5

www.Get2itParts.com

www.Get2itParts.com

Disassemble the oil pump.

INSPECTION

Measure the oil pump rotor-to-body clearance.

SERVICE LIMIT: 0.12 mm / 0.005”

4-6

www.Get2itParts.com

www.Get2itParts.com

Install the oil pump shaft and measure the pump rotor

tip clearance.

Remove the oil pump shaft and measure the pump

end clearance.

SERVICE LIMIT: 0.2 mm / 0.008”

OIL PUMP OUTER ROTOR

4.5 OIL PUMP ASSEMBLY / INSTALLATION

Install the outer rotor, inner rotor and oil pump shaft

onto the body.

NOTE: Pour a drop of clean engine oil inside

the oil pump.

Install the oil pump assembly.

OIL PUMP INNER ROTOR

4-7

www.Get2itParts.com

www.Get2itParts.com

4.5 OIL PUMP ASSEMBLY / INSTALLATION

(continued)

Install the oil pump driven sprocket and oil pump

chain.

Install the oil separator.

LUBRICATION

Install the starting clutch outer and gear assembly.

Install the new gasket, dowel pins, and right crankcase

cover.

4-8

www.Get2itParts.com

www.Get2itParts.com

LUBRICATION

4.5 OIL PUMP ASSEMBLY / INSTALLATION

(continued)

Install the AC Generator and then the outer flywheel.

Install the cooling fan.

FLYWHEEL

Install fan housing cover.

4-9

www.Get2itParts.com

www.Get2itParts.com

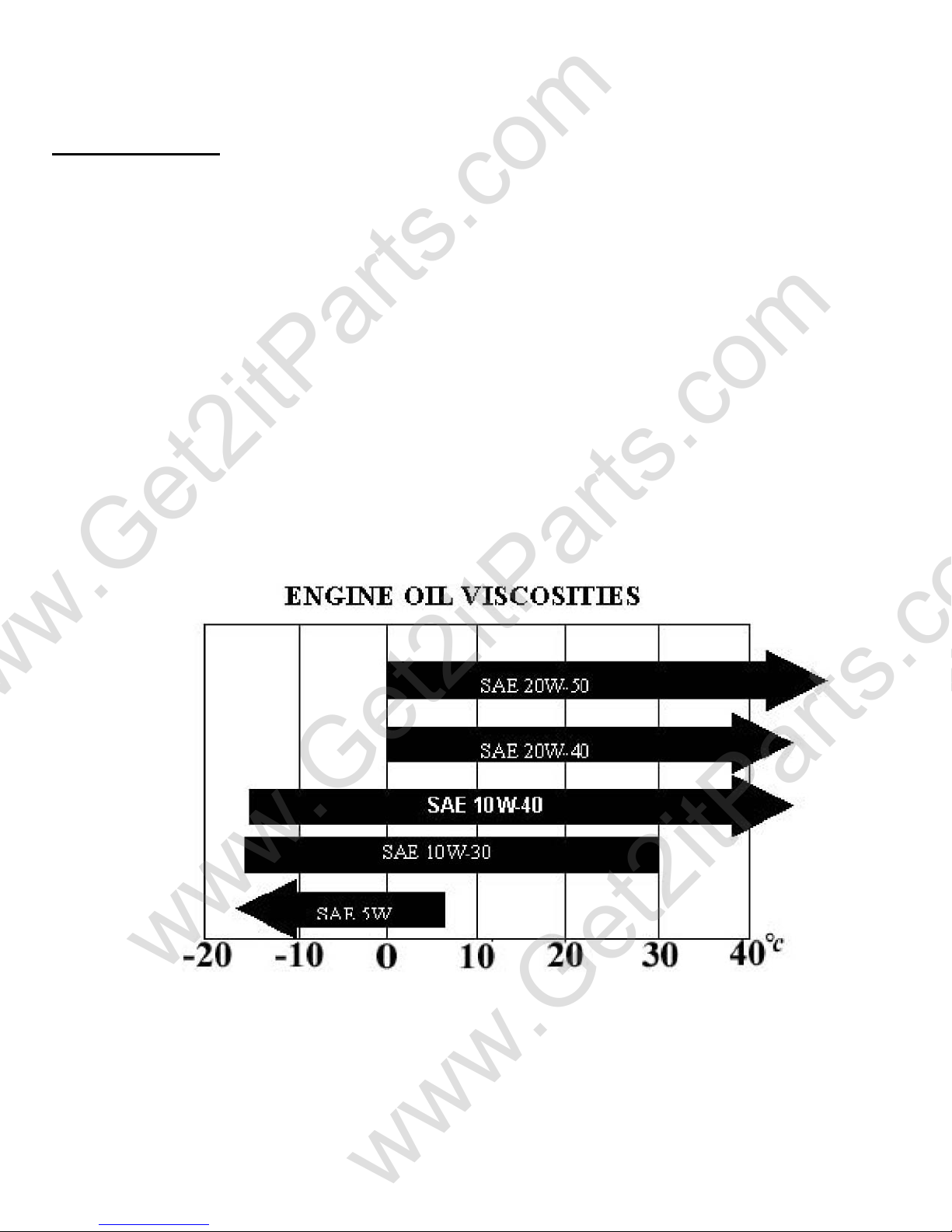

4.6 ENGINE OIL

This section describes inspection and replacement of the engine oil, oil filter screen, and

assembly of the oil pump.

Fill the oil pump with clean oil when reassembling the pump.

SPECIFICATION

ENGINE OIL CAPACITY 0.8-1.0 liter / 0.2-0.3 gal

API service classification: SF or SG Viscosity: SAE 20w-40

When the average temperature in your riding area is within the indicated range,

you should use the other engine oil viscosity that's shown in the chart.

LUBRICATION

4-10

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

5. CYLINDER

5.1 SERVICE INFORMATION

5.2 TROUBLESHOOTING

5.3 CAMSHAFT ASSEMBLY REMOVAL

5.4 CYLINDER HEAD REMOVAL

5.5 CYLINDER HEAD INSTALLATION

5.1 SERVICE INFORMATION

GENERAL

This section describes the maintenance of cylinder head, valves, camshaft, and the other parts.

The engine must be removed from the frame to service the cylinder head.

Camshaft lubrication oil is fed to the cylinder head through an oil hole in the engine case. Before

installing the cylinder head, be sure the hole is not clogged and the gasket, O-ring, and dowel

pins are in place.

SPECIFICATIONS

HEAD / VALVES

Cylinder I.D. 57.400 - 57.410mm / ~2.260” 57.50mm / 2.263”

Piston PISTON O.D. 57.3075 - 57.3095mm / ~2.256” 56.5mm / 2.22”

Piston pin PISTON PIN BORE 15.002 - 15.008mm / ~0.0510” 15.04mm / 0.592”

Piston rings PISTON PIN O.D. 14.994 – 15.000mm / ~0.590” 14.960mm / 0.589””

CYLINDER-TO-PISTON CLEARANCE

CONNECTING ROD SMALL END I.D. 15.010 – 15.028mm / ~0.591” 15.06mm / 0.593”

TORQUE VALUES

Cylinder head bolts

Camshaft holder flange nuts

Tapper adjusting nut

TAPER ------------ 0.10mm / 0.004”

OUT OF ROUND ------------ 0.10mm / 0.004”

WARPAGE ACROSS TOP ------------ 0.10mm / 0.004”

PISTON-TO-PIN CLEARANCE

PISTON-TO-PIN CLEARANCE TOP 0.015 – 0.050mm/0.0006-0.002” 0.12mm/0.005”

PISTON RING-TO-RING SECOND 0.015 – 0.050mm/0.0006-0.002” 0.12mm0.005”

GROOVE CLEARANCE TOP/SEC 0.10 – 0.25mm/0.004-0.01” 0.5mm/0.02”

PISTON RING END GAP OIL 0.2 –0.7mm/0.008-0.03” -----------

ITEM STANDARD SERVICE LIMIT

0.002 – 0.014mm/7.8x10-5-0.0006”

0.0005 – 0.1025mm/2.0x10-6-0.004”

20-24 N-m / 15-18 ft-lbs

0.02mm/0.0008”

0.1mm/0.004”

8-12 N-m / 6-9ft-lbs

9-12 N-m / 7-9 ft-lbs

5-1

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

5.2 TROUBLE SHOOTING

Engine top-end problems often affect engine performance. These problems can be diagnosed by a

compression test, or by tracing engine noise to the top end with a sounding rod or stethoscope.

Low compression Valve

-Incorrect valve adjustment.

-Worn or damaged valve seats.

-Burned or bent valve.

-Incorrect valve timing.

-Weak valve spring.

Cylinder head

-Leaking or damaged head gasket.

-Warped or cracked cylinder head.

-Faulty cylinder or piston.

Excessive noise

-Incorrect valve adjustment.

-Sticking valve or broken valve spring.

-Worn or damaged rocker arm or camshaft.

-Worn or damaged cam chain.

-Worn or damaged cam chain tensioner.

-Worn cam sprocket teeth.

Excessive smoke

-Damaged valve stem seal.

-Faulty cylinder or piston rings

5-2

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

5.3 CAM SHAFT ASSEMBLY REMOVAL

Remove the rubber gas waste recovery tube.

Remove the cylinder head cover.

Remove the air cleaner and carburetor.

Remove the inlet pipe assembly.

Remove the engine shroud.

Loosen the cam chain adjuster screw.

ENGINE SHROUD

5-3

www.Get2itParts.com

www.Get2itParts.com

5.3 CAM SHAFT ASSEMBLY REMOVAL

(continued)

Remove the screw and O-ring and tighten the cam

chain-adjusting bolt by turning in the clockwise

direction.

Remove the nuts and washers.

Remove the camshaft holder and dowel pins.

CYLINDER HEAD / VALVES

Loosen the camshaft gear from cam chain and remove

the camshaft.

INSPECTION

Inspect the cam lobes surface and height of cam lobes

for wear or damage.

SERVICE LIMIT: IN 29.395 mm / 1.157”

EX 29.160 mm / 1.148”

r

www.Get2itParts.com

www.Get2itParts.com

5.3 CAM SHAFT ASSEMBLY REMOVAL

(continued)

Inspect the camshaft and bearings for wear or damage and replace them if necessary.

Screw a 5mm bolt into the rocker arm shaft threaded

end. Pull on the bolt to remove the shafts and rocke

arms.

CYLINDER HEAD / VALVES

Inspect the camshaft holder, rocker arms, and rocker

arm shafts for wear or damage.

Measure the I.D. of each rocker arm.

SERVICE LIMIT: 10.10 mm / 0.3976”

Measure the O.D. of each rocker arm shaft.

SERVICE LIMIT: 9.91 mm / 0.390”

5-5

5.4 CYLINDER HEAD REMOVAL CYLINDER HEAD / VALVES

www.Get2itParts.com

www.Get2itParts.com

Remove the flange bolts and cylinder head.

Remove the cylinder head gasket and dowel pins.

Remove the cam chain guide.

CYLINDER HEAD DISASSEMBLY

Remove the valve cotters, spring retainers, and

valve springs with a valve spring compressor.

5.4 CYLINDER HEAD REMOVAL CYLINDER HEAD / VALVES

www.Get2itParts.com

www.Get2itParts.com

(continued)

INSPECTION

Clean off all carbon deposits from the combustion and check the spark plug hole and

valve area for cracks.

Measure the cylinder head diagonally for warping

with a straight edge and feeler gauge.

SERVICE LIMIT: 0.05 mm / 0.002”

Measure the free length of the inner and outer

valve springs.

SERVICE LIMITS: Inner 31.2 mm / 1.23”

Outer 34.1 mm / 1.34”

Inspect each valve for turning, burning,

scratches, or abnormal stem wear. Check

the valve movement in the guide.

OUTER VALVE SPRING

INNER VALVE SPRING

5-7

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

Measure and record each valve stem O.D.

SERVICE LIMITS: 4.90 mm / 0.19”

Measure and record the valve guide I.D.

SERVICE LIMITS: IN / EX 5.30 mm / 0.209”

Calculate the stem-to-guide clearance.

SERVICE LIMITS: IN 0.08 mm / 0.003”

EX 0.10 mm / 0.004”

NOTE: If the stem-to-guide clearance exceeds the service

limits, determine if a new guide with standard dimensions

would bring the clearance within tolerance.

If so, replace guides as necessary and ream to fit. If the valve guide is replaced, the valve seat

must be refaced.

5.5 CYLINDER

HEAD ASSEMBLY

Lubricate each valve stem with oil.

Insert the valves into the guides.

Install the valve springs, retainers, and the cotters.

NOTE: To prevent loss of tension, do not

compress the valve springs more than

necessary.

INSTALLATION

Install the new gasket and dowel pins.

5-8

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

www.Get2itParts.com

www.Get2itParts.com

Install the cam chain guide.

Install the cylinder head.

5.6 CAMSHAFT ASSEMBLY INSTALLATION

Install the rocker arms and rocker arm shafts into the

camshaft holder.

Align the "T" mark (as shown in picture) on the flywheel

with the index mark on the alternator cover by turning the

flywheel counter-clockwise.

5-9

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

Position the camshaft gear with cam chain so that its

"I" mark aligns with the cylinder head surface and the

circle hole towards the front.

Install the dowel pins and camshaft holder. Tighten

the washers and nuts.

TORQUE: 20 N-m (15 ft-lbs)

I MARK

Adjust the clearance between the rocker arm and

valve stem by applying a feeler gauge.

STANDARD VALVE: 0.08 – 0.12 mm / 0.003-0.005”

Loosen the cam chain-adjusting bolt by turning in a

counterclockwise direction. Install the O-ring and screw.

5-10

www.Get2itParts.com

www.Get2itParts.com

CYLINDER HEAD / VALVES

Install the cylinder head cover.

5-11

www.Get2itParts.com

www.Get2itParts.com

CYLINDER & PISTON

6. CYLINDER

6.1 SERVICE INFORMATION

6.2 TROUBLESHOOTING

6.3 CYLINDER REMOVAL

6.4 PISTON REMOVAL

6.5 CYLINDER INSTALLATION

AND PISTON

6.1 SERVICE INFORMATION

GENERAL

Camshaft lubrication oil is fed to the cylinder head through an oil hole in the cylinder head and

engine case. Before installing the cylinder head, be sure the hole is not clogged and the gasket, Oring and dowel pins are in place.

SPECIFICATIONS

ITEM

Cylinder I.D. 57.400 - 57.410 / 2.26” 57.50 / 2.26”

Taper ------------ 0.10 / 0.004”

Out of round ------------ 0.10 / 0.004”

Warp across top ------------ 0.10 / 0.004

Piston Piston O.D. 57.3075 - 57.3095 / ~2.26” 56.500 / 2.22”

Piston pin Piston pin bore 15.002 - 15.008 / ~0.59” 15.04 / 0.59”

Piston rings Piston pin O.D.

Piston-to-pin clearance

Piston ring TOP

SECOND

Groove Clearance TOP/SEC 0.10 - 0.25 / ~0.004” 0.5 / 0.02”

Piston ring end gap OIL 0.2 -0.7 / ~0.008” -----------Cylinder-to-piston clearance

Connecting rod small end I.D. 15.010 - 15.028 / ~0.56” 15.06 / 0.59”

TORQUE VALUES

STANDARD (mm / in) SERVICE LIMIT (mm / in)

14.994 - 15.000 / ~0.58”

0.002 - 0.014 / ~7.2x10-5”

0.015 - 0.050 / ~0.0006”

0.015 - 0.050 / ~0.0006”

0.0005 - 0.1025 / ~2x10-5”

14.960 / 0.58”

0.02 / 0.0008”

0.12 / 0.005”

0.12 / 0.005”

0.1 / 0.004”

Cylinder head bolts

Camshaft holder flange nuts 20-24 N-m / 15-18 ft-lb s

Tappet adjusting nut 9-12 N-m / 7-9 ft-lbs

6-1

8-12 N-m / 6-9 ft-lbs

www.Get2itParts.com

www.Get2itParts.com

6.2 TROUBLESHOOTING

Low or unstable compression

-Worn cylinder or piston rings.

Overheating

-Excessive carbon build-up on piston or combustion chamber wall.

Knocking or abnormal noise

-Worn piston and cylinder.

-Excessive carbon build-up.

Excessive smoke

-Worn cylinder, piston, or piston rings.

-Improper installation of piston rings.

-Scored or scratched piston or cylinder wall.

-Damaged valve stem seal.

CYLINDER & PISTON

6-2

www.Get2itParts.com

www.Get2itParts.com

6.3 CYLINDER REMOVAL

Remove the cylinder head.

Remove the cylinder.

CYLINDER HEAD

CYLINDER

Remove the cylinder gasket and dowel pins.

Clean off any gasket materials from the cylinder

surface.

NOTE: Be careful not to damage the gasket surface

BASE GASKET DOWEL PINS

CRANKCASE SURFACE

6-3

www.Get2itParts.com

www.Get2itParts.com

6.4 PISTON REMOVAL

Stuff a shop towel into the crankcase.

Remove the piston pin clip with needle nose pliers.

NOTE: Do not allow the clip fall into the crankcase.

Remove the piston pin from the piston. Remove the piston.

C-CLIPS

Spread each piston ring and remove it by lifting up at a point

opposite the gap.

INSPECTION

Inspect the cylinder walls for scratches or wear.

PISTON PISTON PIN

PISTON

6-4

www.Get2itParts.com

www.Get2itParts.com

Measure and record the cylinder I.D. at three levels in both

the X and Y axis. Take the maximum reading to determine

the cylinder wear.

SERVICE LIMIT: 57.50 mm / 2.264”

Calculate the piston-to-cylinder clearance.

Take the maximum reading to determine the clearance.

SERVICE LIMIT: 0.10 mm / 0.004”

Calculate cylinder taper at three levels in the X and

Y-axis. Take the maximum reading to determine the taper.

SERVICE LIMIT: 0.10 mm / 0.004”

Calculate the cylinder out-of-round at three levels in the X and

Y-axis. Take the maximum reading to determine the out-of round.

SERVICE LIMIT: 0.10 mm / 0.004”

Inspect the top of the cylinder for warp.

SERVICE LIMIT: 0.10 mm / 0.004”

PISTON / PISTON RING INSPECTION

Measure the piston ring-to-groove clearance.

SERVICE LIMITS: TOP 0.12 mm / 0.005”

SECOND 0.12 mm / 0.005”

6-5

www.Get2itParts.com

www.Get2itParts.com

Inspect the piston for wear or damage.

Insert each piston ring into the cylinder and measure

the ring end gap.

NOTE: Push the rings into the cylinder with the top of

the piston to be sure they are squarely set in the

cylinder.

SERVICE LIMITS: TOP 0.5 mm / 0.02”

SECOND 0.5 mm / 0.02”

CYLINDER & PISTON

PISTON

Measure the piston pin O.D.

SERVICE LIMIT: 14.960 mm / 0.589”

Measure the piston pin bore.

SERVICE LIMIT: 15.04 mm / 0.592”

PISTON PIN

6-6

www.Get2itParts.com

www.Get2itParts.com

Calculate the piston-to-piston pin clearance.

SERVICE LIMIT: 0.02 mm / 0.0008”

Measure the connecting rod small end I.D.

SERVICE LIMIT: 15.06 mm / 0.59”

CYLINDER & PISTON

CONNECTING ROD

6.5 PISTON & PISTON RING INSTALLATION

Clean the piston ring grooves thoroughly and install the

piston ring with the marks facing up.

NOTE: Don't interchange the top and second rings.

Avoid piston and piston ring damage during installation.

Space the piston ring end gaps 120 degrees apart.

6-7

www.Get2itParts.com

www.Get2itParts.com

PISTON INSTALLATION

Install the piston with its "IN" mark pointing up toward

the intake valve side.

Install the piston pin with new pin clips.

Do not align the piston pin clip end gap with the piston

cutout.

NOTE: Do not allow the clip to fall into the crankcase.

“IN” MARK

6.6 CYLINDER INSTALLATION

Clean any gasket material from the crankcase surface.

NOTE: Be careful not to damage the gasket surface.

Install the dowel pins and a new gasket.

PISTON PIN

6-8

BASE GASKET

www.Get2itParts.com

www.Get2itParts.com

Coat the cylinder bore and piston rings with engine oil

and install the cylinder.

NOTE: Avoid piston rings damage cylinder bore during

installation. Do not allow the cam chain fall into the

crankcase.

CYLINDER & PISTON

Install the cylinder head.

CYLINDER

6-9

www.Get2itParts.com

www.Get2itParts.com

TRANSMISSION & KICK STARTER

7. TRANSMISSION

7.1 SERVICE INFORMATION

7.2 TROUBLE SHOOTING

7.3 CVT DISASSEMBLY

7.4 KICK STARTER DISASSEMBLY

7.5 KICK STARTER ASSEMBLY

7.6 CVT ASSEMBLY

7.7 TRANSMISSION SYSTEM

7.1 SERVICE INFORMATION

If the drain tube assembly fills with water, the tube should be drained.

& KICK STARTER

SPECIFICATIONS

ITEM STANDARD SERVICE LIMIT

Driven belt width 19.8 - 20.2mm / ~0.780” 19.0mm / 0.75”

Weight roller O.D. 17.9 - 18.1mm / ~0.705” 17.40mm / 0.685”

Movable drive face I.D. 27.98 - 28.0mm / ~1.101” 28.03mm / 1.104”

Drive face collar I.D. 24.06 - 24.09mm / ~0.945” 24.098mm / 0.9487”

Drive face boss O.D. 23.96 - 23.98mm / ~0.944” 23.92mm / 0.942”

Clutch outer I.D 124.8 - 125.2mm / ~4.90” 125.5mm / 4.941”

Clutch weight lining thickness ------------------ 1.5mm / 0.059”

Driven face spring length 168.4 - 169.4mm / ~6.650” 164.0mm / 6.46”

TORQUE VALUES

Clutch outer nut 55 N-m/ 41 ft-lbs

Drive face nut 55 N-m / 41 ft-lbs

7-1

www.Get2itParts.com

www.Get2itParts.com

7.2 TROUBLE SHOOTING

Engine starts but won’t run

-Worn driven belt.

-Worn clutch lining.

-Damaged driven face spring.

Low engine power

-Worn driven belt.

-Worn weight roller.

-Dirty drive face.

7-2

www.Get2itParts.com

www.Get2itParts.com

7.3 CVT DISASSEMBLY

LH CRANKCASE COVER REMOVAL

Loosen the band screw and remove the CVT inlet

duct.

Loosen the band screw and remove the CVT outlet

duct.

Remove the gas waste recovery unit.

Remove the 8 bolts and the LH crankcase cover.

7-3

www.Get2itParts.com

www.Get2itParts.com

CVT REMOVAL

Remove the flange nut and remove the kick-starter

ratchet. Remove the drive face and primary clutch

sheave.

Remove the flange nut.

Remove the drive pulley assembly and driven belt.

Remove the driven face boss and movable driven face

assembly.

Remove the gasket and dowel pins. Clean off any gasket

material from the left hand crankcase surface. Be sure not

to damage the clutch cover surface.

7-4

www.Get2itParts.com

www.Get2itParts.com

Remove the ramp plate and weight roller set.

Loosen the special nut and remove the driven plate

assembly and driven face spring.

INSPECTION

Inspect the drive belt for wear, tearing, or other damage.

Measure the width of drive belt.

SERVICE LIMIT: 19.0 mm / 0.75”

Inspect the weight rollers for wear or damage and

replace them if necessary.

Measure the O.D. of weight rollers.

SERVICE LIMIT: 17.40 mm / 0.69”

DRIVEN PLATE ASSEMBLY

7-5

www.Get2itParts.com

www.Get2itParts.com

Measure the I.D. of movable driven face.

SERVICE LIMIT: 28.03mm / 1.10”

Inspect the drive face collar for wear or damage.

Measure the I.D. of drive face collar.

SERVICE LIMIT: 24.098 mm / 0.95”

Inspect the drive face boss for wear or damage.

Measure the O.D. of the drive face boss.

SERVICE LIMIT: 23.92 mm / 0.94”

Inspect the clutch outer for wear or damage.

Measure the I.D. of clutch outer.

SERVICE LIMIT: 125.5 mm / 4.94”

Inspect the clutch weight set for wear or damage.

Measure the thickness of the clutch weight lining.

SERVICE LIMIT: 1.5mm / 0.06”

7-6

www.Get2itParts.com

www.Get2itParts.com

Measure the length of the driven face spring in its

natural state.

SERVICE LIMIT: 164.0 mm / 6.46”

Inspect the driven face assembly and replace if

necessary.

7.4 KICK STARTER DISASSEMBLY

Remove the LH crankcase cover.

Remove the kick starter.

Remove the external circle-clip and washer from the

kick starter spindle.

7-7

www.Get2itParts.com

www.Get2itParts.com

Rotate the kick-starter spindle assembly to remove

the kick driven gear and spring.

Remove the kick-starter spindle assembly and return

spring.

Remove the kick spindle bush.

INSPECTION

Inspect the kick-starter spindle assembly for wear or

damage.

KICK DRIVEN GEAR

ASSEMBLY

Inspect the kick-starter return spring for wear or

damage.

Inspect the kick-starter spindle bush for wear or damage.

Inspect the kick driven gear and spring for wear or

damage.

7-8

www.Get2itParts.com

www.Get2itParts.com

Inspect the machining surface for wear or damage.

7.5 KICK-STARTER ASSEMBLY

Install the kick spindle bush, return spring, and spindle

assembly.

Install the kick driven gear and spring.

Install the kick-starter.

7.6 CVT ASSEMBLY

Install the dowel pins and gasket.

7-9

www.Get2itParts.com

www.Get2itParts.com

Assemble the driven face assembly, spring, and

driven plate. Assemble the movable driven face,

weight roller set, and drive face.

Install the movable drive face assembly and boss.

Install the drive face and kick starter ratchet.

Install the driven belt and driven pulley assembly

7-10

www.Get2itParts.com

www.Get2itParts.com

Install the LH crankcase cover.

Install the gas waste recovery system and CVT

ducts.

7-11

www.Get2itParts.com

www.Get2itParts.com

7.7 TRANSMISSION SYSTEM

To remove the transmission, we recommend the

motor be removed. The transmission can be serviced

with the motor still in the frame, but this is not

recommended.

Before servicing transmission, drain the gear oil from

the transmission case. First, remove the gear shift

lever and the outside bolts of the transmission

housing. Remove the retaining clip from the

countershaft and remove the transmission cover.

Check the gear shift shaft forward and reverse gears

for end play. Check the countershaft teeth for

damage, as well as the drive shaft. Check the

operation of the shift fork and shift drum.

DRAIN BOLT

All bearings should be checked, and ball bearing

and spring for the shift drum should be removed.

7-12

www.Get2itParts.com

www.Get2itParts.com

7.7 TRANSMISSION SYSTEM

(cont’d)

Installation

Install the shift guide and shift drum. Insert the shift fork

into the slot on the gear shift shaft. Install the gear shift

shaft with the forward gear facing the CVT system.

Install the countershaft and the ball bearing and spring

under the shift drum.

Inspect the bearings in the transmission cover for wear

and replace if necessary. Install the primary shaft in the

transmission cover and hold in place by installing a

retaining clip.

Install the transmission cover on the transmission

housing. Torque the outer bolts (28 N-m / 20 ft-lbs)

and fill the fill plug with 26 oz of 80/90 weight gear

oil.

FILL PLUG

7-13

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8. FRONT

8.1 Parts drawing

8.2 Troubleshooting

8.3 Handlebar

8.4 Throttle housing

8.5 Front wheel

8.6 Front brakes

8.7 Steering system

8.8 Front suspension

8.1 PARTS DRAWING

WHEEL, SUSPENSION, AND STEERING

FRONT WHEELS

STEERING

8-1

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.2 TROUBLESHOOTING

HARD STEERING:

-Faulty tire

-Steering shaft holder too tight

-Insufficient tire pressure

-Faulty steering shaft bushing

-Damaged steering shaft bushing

FRONT WHEEL WOBBLING:

-Faulty tire

-Worn front brake drum bearing Bent rim

-Axle nut not tightened properly

BRAKE DRAG:

-Incorrect brake adjustment

-Sticking brake cable

STEERS TO ONE SIDE:

-Bent tie rods

-Wheel installed incorrectly

-Unequal tire pressure

-Bent frame

-Worn swing arm pivot bushing

-Incorrect wheel alignment

POOR BRAKE PERFORMANCE:

-Brake shoes worn

-Worn brake drum

-Brake lining oily, greasy or dirty

-Improper brake adjustment

FRONT SUSPENSION NOISE:

-Loose front suspension fastener

-Binding suspension link

HARD SUSPENSION:

-Faulty front swing arm bushing

-Improperly installed front swing arms

-Bent front shock absorber swing rod

-Weak front shock absorber springs

-Worn or damage front swing arm bushing

8-2

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.3 HANDLEBAR SYSTEM

Removal

Remove the handlebar cover by unscrewing the two fix

screws.

Remove the throttle lever housing on the right handle

bar.

Remove brake lever bracket assembly.

Remove the handle bar switch on the left handle bar.

Remove rear brake lever bracket assembly.

Remove the bolts attaching the handlebar upper

holder.

Remove the handlebar.

8-3

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.4 HANDLEBAR SYSTEM

Installation

Put the handlebar on the lower holders. Make sure

the handlebar punch marks match with the top

end of the handlebar lower holders. Install the

handlebar upper holders with the L / R marks

facing forward. Tighten the forward bolts first; then,

tighten the rear bolts. Install the handlebar upper

holder's cover.

Install the switch housing, aligning the boss with

the hole. Tighten the upper screw first then tighten

the lower one.

Install the rear brake lever bracket, aligning the

boss with the hole. Tighten the screw securely.

Align the split line of the throttle housing and

holder with the punch mark. Tighten the

screw securely.

8-4

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.5 THROTTLE HOUSING

Disassembly

Unscrew the screws on the throttle housing cover.

Remove the throttle housing cover and gasket.

Disconnect throttle cable from the throttle arm and

remove from the throttle housing.

8.6 FRONT WHEEL

Removal

Raise the front wheels off the ground by placing a

jack or other support under the frame.

Remove the front wheel nuts, washer, and wheels.

Installation

Install and tighten the four-wheel nuts

Torque: 60 N-m (44 ft-lbs)

Remember to put a new cotter pin in the castle nut.

8.7 FRONT BRAKES

Brake Inspection

Front

Remove the front wheel. Remove the brake drum.

.

Measure the brake lining thickness.

Minimum limit: 1.5 mm / 0.06”

If the thickness is thinner than the minimum limit,

replace the brake lining.

8-5

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.7 FRONT BRAKES

(continued)

Measure the brake drum inner diameter. Inspect the

brake drum surface for scoring or uneven surfaces.

Maximum limit: 86 mm / 3.39”

Turn the inner race of each bearing with fingers. The

bearings should turn smoothly and quietly. If the race

does not turn smoothly or quietly, remove and replace

the bearings

.

Brake Panel Removal

Disconnect the brake cable from the brake arm.

Remove the brake panel from the knuckle.

Remove brake arm and cam.

Remove return spring.

Remove indicator plate and felt seal.

8-6

FRONT WHEEL, SUSPENSION AND STEERING

www.Get2itParts.com

www.Get2itParts.com

8.7 FRONT BRAKES (continued)

Install Brake Panel

Apply grease to the brake cam and anchor pin and

install the cam in the brake panel.

Soak the felt seal in engine oil and install the seal

on the brake cam.

Install the brake arm on the cam by aligning the

punch mark and the groove on the cam. Tighten

the brake arm bolt and nut.

Torque: 4-7 N-m / 3-5 ft-lbs.

Install the return spring.

Install the brake panel on the knuckle. Connect the

brake cable to the brake arm.

Install the brake arm cover.

Tighten the screws securely.

Position the brake shoes in their original locations

and install the brake shoe spring.

Install the brake drum and front wheel.

Install the castle nut and cotter pin.

8-7

FRONT WHEEL, SUSPENSION AND STEERING

www.Get2itParts.com

www.Get2itParts.com

8.8 STEERING SYSTEM

Kingpin and Tie-rod Removal

Remove the front wheels and brakes plates.

Remove the two self-lock nuts from the tie-rod

ball joints and remove the two tie-rods.

Remove the cotter pin on the kingpin.

Unscrew the bolt and remove the kingpin.

Tie-rod Inspection

Inspect the tie-rod for damage or bending.

Inspect the ball joint rubbers for damage, wear, or

deterioration.

Turn the ball joints with fingers. The ball joints

should turn smoothly and quietly.

Kingpin Inspection

Inspect the kingpin for damage or cracks.

8-8

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.8 STEERING SYSTEM (continued)

Steering Shaft Removal

Remove the handle bar cover and handle bar.

(See section 8-3)

Remove the front fender. (See section 10-1)

Remove handlebar lower holder.

Unscrew the steering shaft holder bolt.

Remove the steering shaft holder.

Take off the cotter pin below the steering shaft.

Pull the steering shaft carefully.

Steering Shaft Holder Inspection

Remove the steering shaft.

Remove the bushing from the shaft.

Inspect the bushing for damage or wear, replace if

necessary.

Measure the bushing inner diameter.

Maximum limit : 39.5 mm / 1.56”

Steering Shaft Inspection

Inspect the steering shaft for damage or cracks.

Installation of Steering Shaft

Apply grease to the holder. Install the holder and

oil seal. Tighten the nuts.

Torque: 33 N-m / 24 ft-lbs

8-9

www.Get2itParts.com

www.Get2itParts.com

FRONT WHEEL, SUSPENSION AND STEERING

8.8 STEERING SYSTEM (continued)

Installation of Steering Shaft

Apply Blue Lock-Tite and install the

steering shaft nut (under the steering

shaft) and tighten it. Also, install a new

cotter pin.

Torque: 50 N-m / 37 ft-lbs

Installation of Tie-rod

Install the ball joint with the “L” mark on the

steering shaft side. Install the tie-rod with the

“R” mark on the wh eel s ide. Installation is the

reverse order of removal.

8-10

www.Get2itParts.com

www.Get2itParts.com

REAR WHEEL SYSTEM

9. REAR

9.1 Parts drawing

9.2 Troubleshooting

9.3 Rear Wheel and Rear Brake Removal

9.4 Drive Mechanism

9.5 Rear Brake and Wheel Installation

9.6 Shock Absorber

9.7 Swing arm

9.1 Parts Drawings

WHEEL SYSTEM

Rear Wheel Assembly

www.Get2itParts.com

www.Get2itParts.com

9.2 Trouble Shooting

Bad Brake Performance:

-Brake shoes are worn

-Bad brake adjustment

-Brake lining oily, greasy or dirty

-Brake drums are worn

-Brake arm setting is improperly engage

Vibration or Wobble

-Axle is not tightened well

-Bent rim

-Axle bearings are worn

-Faulty tires

-Rear axle bearing holder is faulty

Brake Drag

-Incorrect brake adjustment

-Sticking brake cam

-Sticking brake cable

Hard Suspension

-Bent damper rod

-Faulty swing arm pivot bushing

Soft Suspension

-Weak shock absorber damper

-Weak shock absorber spring

REAR WHEEL SYSTEM

9.3 REAR WHEEL & REAR BRAKE REMOVAL

Loosen the cotter pin and wheel nuts. Raise the rear

wheel off the ground by placing a support under the

frame.

Remove the wheel and wheel hub.

Remove the brake drum cover.

9-2

www.Get2itParts.com

www.Get2itParts.com

9.3 REAR WHEEL & REAR BRAKE

REMOVAL

Remove the axle collar and brake drum.

Check the brake lining thickness.

Minimum limit: 2.0 mm / 0.08”

CAUTION:

Do not get grease or oil the brake lining surface

and brake drum. Otherwise, braking power will

be reduced.

(continued)

REAR WHEEL SYSTEM

Check the brake drum for damage. Replace if

necessary.

Check the brake drum inner diameter.

Maximum limit: 131 mm / 5.16”

9.4 DRIVE MECHANISM

Remove the rear wheel and the rear brake.

Remove the skid plate under the swing arm.

Remove the drive chain cover.

9-3

9.4 DRIVE MECHANISM REAR WHEEL SYSTEM

www.Get2itParts.com

www.Get2itParts.com

(continued)

Disassemble the chain retaining clips and master link.

Remove the chain.

For chain tensioner installation and disassembly, see

section 9.6 at the end of this chapter.

Disassemble the driven sprocket, axle, and sprocket

collar.

Check the driven sprocket for damage or wear. Replace if

necessary.

Place the rear axle on V-blocks and check the run out.

The run out limit is 0.5 mm. / 0.02”

Check the turning of inner race of bearing with fingers.

The bearings should turn smoothly and quietly. Replace if

necessary.

Also check that the bearing outer race fits tightly in the

axle holder. Replace if necessary.

NOTE: Replace the bearings in pairs.

9-4

9.4 DRIVE MECHANISM REAR WHEEL SYSTEM

www.Get2itParts.com

www.Get2itParts.com

(continued)

Installation

Add grease to the dust seal lips and install dust seals.

Assemble the rear axle and the driven sprocket.

Assembly the drive chains on the driven sprocket.

Assemble the master link and retaining clip.

Note the retaining clip direction.

Install the drive chain cover.

Assemble the chain under the cover.

Install the skid plate.

Install the drive chain cover.

9.5 REAR DRUM BRAKE & WHEEL

INSTALLATION

Install the wear indicator plate aligning the tab on the axle

holder with the slit on the cam. Install the brake arm

spring and felt seal.

Note: for CXL-150 and RXL-150R hydraulic disc

brake, see section 9.7 at the end of this chapter.

9-5

www.Get2itParts.com

www.Get2itParts.com

9.5 REAR DRUM BRAKE & WHEEL

INSTALLATION

(continued)

Install the brake arm. Tighten the brake arm bolt and nut

with 10 N-m (7.4 ft-lbs) torque. Install the adjusters.

NOTE: Make sure the rear brake lever and pedal have

the proper amount of free play.

Add grease to the brake cam and anchor pin.

Install the brake shoes and springs to their original positions.

REAR WHEEL SYSTEM

Install the brake drum and brake drum cover.

Assemble the wheel.

Torque the rear axle nut to 60-80 N-m / 44-59 ft-lbs.

Install a new cotter pin.

Adjust rear brake level free play.

Adjust drive chain slack.

9-6

www.Get2itParts.com

www.Get2itParts.com

9.6 CHAIN TENSIONER (IF EQUIPPED)

To remove the chain tensioner, relax the drive chain.

Remove the chain tensioner bolt and retaining spring.

Installation is the reverse order of removal.

9-7

REAR WHEEL SYSTEM

www.Get2itParts.com

www.Get2itParts.com

9.7 HYDRAULIC DISC BRAKE SYSTEM

(CXL-150 & RXL-150R ONLY)

Raise the rear wheel off the ground by placing a block or

stand under the frame. Remove the cotter pin, axle nut,

and washer. Slide the wheel and hub off the axle.

To remove the rear caliper, remove the two bolts that

hold the brake caliper to the holder as shown in picture.

Also, remove the rear brake hydraulic line and place

into a container for proper draining.

9-8

www.Get2itParts.com

www.Get2itParts.com

9.7 HYDRAULIC DISC BRAKE SYSTEM

(cont’d)

Remove the rear wheel axle nuts and then remove the

mounting seat of the disc.

Unscrew the bolts and remove the brake rotor.

Check the thickness of the disc in several places and

replace if less than 3mm / 0.12”.

Check the disc for cracks or large worn grooves. Replace

the disc if badly worn or cracked.

Check whether the disc is bent or warped, and replace if

necessary.

Clean the disc of any dirt or oil and grease contamination.

Ensure the cooling holes are free of dirt and the friction

surface is smooth and even across the entire disc. Replace

if necessary.

Remove the brake line from the caliper.

Remove the brake pads from the brake caliper by pressing

the caliper piston inward fully and removing the static pad

from the retaining clips. Then, lift the piston pad from the

piston to remove it from the caliper.

Check the thickness of the brake pads and replace if the

thickness is less than 1mm / 0.04”. Also, replace the pads

if they show signs of uneven wear or are cracked or

otherwise damaged, or have been contaminated with oil,

grease, or brake fluid.

Inspect the caliper piston for signs of brake fluid leaks and

replace if necessary.

9-9

BLEEDER SCREW

BRAKE LINE

www.Get2itParts.com

www.Get2itParts.com

9.7 HYDRAULIC DISC BRAKE SYSTEM

(cont’d)

Rear Brake Installation

NOTE: Take great care as to not contaminate the

brake pads or rotor with oil, grease, or brake fluid

during installation

To reinstall the brakes, first replace the brake rotor on

the mounting seat. Reinstall the mounting seat over

the axle and secure with the two large axle nuts.

Apply Red Lock-Tite and torque to 60-80 N-m / 44-59

ft-lbs.

Press the caliper piston inward fully and place the

piston pad over the retaining pins and piston. Replace

the static pad in the retaining clip and ensure that it is

fully engaged and in the proper location.

Slide the caliper back into position over the rotor and

replace the two caliper retaining bolts. Torque to 30-40

N-m / 22-30 ft-lbs.

The brake line will require bleeding of air at this point.

Remove the reservoir cap on the handle bars by

removing the two cap bolts as shown in picture.

To bleed the brake line of air, first build pressure by

pumping the master cylinder lever. Then, while

applying the lever, loosen the bleeder screw to release

air from the lines. With the lever still applied, tighten

the bleeder screw and pump to build pressure again.

Repeat this process until all air is expelled from the

line and tension is felt on the master cylinder lever.

PISTONS

RESERVOIR CAP

BLEEDER SCREW

Ensure the volume of brake fluid is at the maximum line of

the master cylinder reservoir at all times during the

bleeding process.

9-10

www.Get2itParts.com

www.Get2itParts.com

FENDERS AND EXHAUST PIPE

10. FENDERS AND EXHAUST PIPE

10.1 Parts Drawings

10.2 REAR FENDER REMOVAL

Pull the seat release latch to remove the seat. The seat release

latch is under the center of the rear grab bar.

Fender Removal:

Remove the rear rack.

Unscrew the two bolts which connect the front fender and rear

fender.

Unscrew the two bolts which connect the rear fender and frame.

These two bolts are just below the seat.

10-1

www.Get2itParts.com

www.Get2itParts.com

FENDERS AND EXHAUST PIPE

10.2 REAR FENDER REMOVAL

(continued)

Unscrew the six screws which connect with the footrest plate.

Pull the rear fender backward so the rear fender can be

removed.

10.3 FRONT-TRIM REMOVAL

Unscrew the two screws just below the headlights of the

central-front-trim. Unscrew the two screws between the

central-front-trim and central-rear-trim. Then remove them and

the headlight together.

10.4 CENTRAL-REAR-TRIM

(YXL/CXL ONLY)

Remove the fuel tank cap.

Remove the central-rear-trim two mounting bolts

from the fuel tank.

Pull the central-rear-trim upward.

REMOVAL

10-2

www.Get2itParts.com

www.Get2itParts.com

FENDERS AND EXHAUST PIPE

10.5 FRONT FENDER REMOVAL

After removing the rear fender, central-front-trim, and

central-rear-trim, remove the two front fender mounting bolts from the front frame.

Remove the mounting bolts and nuts from the front

fender and footrest plate.

10.6 EXHAUST PIPE REMOVAL

Do not service the exhaust pipe while hot. Wait at

least 15 minutes after turning off the engine to

remove the exhaust pipe. Remove the seat, rear

fender, and footrest plate before removing the

exhaust pipe. Unscrew the two exhaust pipe bolts

fixed to the engine.

.

10-3

www.Get2itParts.com

www.Get2itParts.com

10.6 EXHAUST PIPE REMOVAL

(continued)

Remove the exhaust pipe bolts mounted on the

frame below the seat.

Remove the exhaust pipe carefully.

FENDERS AND EXHAUST PIPE

10.7 EXHAUST PIPE INSTALLATION

Installation is the reverse order of removal. Be

sure to install a new exhaust gasket as well.

Exhaust muffler bolts torque: 30 N-m (22 ft-lbs)

NOTE: After installation, check the entire system

to make sure that there are no exhaust leaks.

Spark Arrestor Removal & Installation

Later model CXLs and the RXL 150R models are

equipped with a spark arrestor. To remove, remove

the 4mm hex head bolt and pull the spark arrestor

from the end of the pipe. Spark arrestor should be

cleaned after every ten hours of riding.

10-4

ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

11. ELECTRICAL SYSTEM

11.1 Troubleshooting

11.2 Ignition coil

11.3 Ignition timing

11.4 Alternator exciter coil

11.5 Battery Caution

11.6 Battery voltage

11.7 Charging

11.8 Electric starter

11.9 Light bulbs replacement

11.10 Wiring diagrams

11.1 Troubleshooting

Engine starts but stops:

-Improper ignition timing

-Faulty spark plug

No spark at plug:

-Engine stop switch at "off " position

-Gearshift bar is not at neutral position

-Faulty ignition coil

-Faulty generator

-Faulty CDI unit

-Poor connection:

Between CDI and ignition coil

Between alternator and CDI unit

Between CDI and engine stop switch

Between ignition coil and spark plug

Between generator and CDI unit

Engine starts but runs poorly:

IGNITION PRIMARY CIRCUIT:

-Faulty generator

-Faulty CDI unit

-Faulty alternator exciter coil

-Loose contact terminals

-Faulty ignition coil

IGNITION SECONDARY CIRCUIT:

-Faulty plug

-Loose spark plug wire

IMPROPER IGNITION TIMING:

-Faulty generator

-Faulty CDI unit

Charging system failure:

-Loose, broken, or shorted wire

-Faulty alternator faulty ignition switch

11-1

ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

11.1 Troubleshooting (continued)

Intermittent engine power:

-Loose battery connection

-Loose charging system connection

Starter motor will not turn:

-Dead battery

-Faulty ignition switch

-Loose or disconnected wire

Starter motor and engine turn, but engine does not start:

-Faulty ignition system

-Faulty engine stop switch

Headlight malfunction:

-Switch not in ON position

-The light bulb is burned out

11.2 IGNITION COIL

Remove the spark plug cap from the spark plug.

Disconnect the ignition coil primary wire.

Measure the primary coil resistance. (See Ref. 1)

STANDARD: 0.1 - 0.3Ω

Measure the secondary coil resistance with the

spark plug cap in place. (See Ref. 2)

STANDARD: 7.4 - 11 kΩ

1

11.3 IGNITION TIMING

The ignition advance is 15°± 3°/4000rpm

The Capacitive Discharge Ignition (CDI) system is factory pre-set and does not require adjustment.

11.4 ALTERNATOR EXCITER COIL

Remove the seat / rear fender and front fender. (See chapter 10) Disconnect the exciter coil wire.

Measure the resistance between the white/red or blue/yellow wire and ground.

STANDARD: 115-135

Ω

2

11-2

ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

11.5 BATTERY CAUTION

The battery gives off explosive gases; keep sparks, flames, and

cigarettes away. Provide adequate ventilation when charging or

using the battery in an open area. The battery contains sulfuric

acid (electrolyte). Contact with skin or eyes may cause severe

burns. Wear protective clothing and a face shield. Electrolyte is

poisonous. If swallowed drink large quantities of water or milk

and call a physician.

11.6 BATTERY VOLTAGE INSPECTION

The battery is under the seat; you can see this battery

after removing the seat.

Measure the battery voltage using a voltmeter.

VOLTAGE : Fully charged : 13.1 V

Undercharged : Below 12.0 V

BATTERY REMOVAL

Remove the seat. Disconnect the negative cable and

then the position cable and remove the battery.

BATTERY INSTALLATION

Install the battery in the reverse order of removal. After

installing the battery, coat the terminals with clean

grease.

11.7 CHARGING

Connect the charge positive cable to the battery positive

terminal. Connect the charge negative cable to the

battery negative terminal. Use 0.9A charging current

about 5 hours (normal charging) or using 4A

charging current about 1 hour (quick charging).

Keep flames and sparks away from a battery being

charged. Quick charging should be limited to an

emergency; Normal charging is preferred.

11-3

ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

11.8 ELECTRIC STARTER

A weak battery may be unable to run the starter motor

correctly.

If the battery voltage is sufficient but the engine is not

cranking, the starter motor may be damaged.

Troubleshooting

Starter Motor Turns Slowly:

-Weak battery.

-Poorly connected starter motor cable.

-Faulty starter motor.

-Poorly connected battery ground cable.

Starter Motor Will Not Turn:

-Engine stop switch at "off "position.

-Gearshift bar is not at neutral position.

-Check for a blown fuse near battery.

Make sure that the battery is fully charged and in

good condition.

11.9 LIGHT BULB REPLACEMENT

Remove the handle bar cover.

Remove the central-front cover and headlight together.

RXL 150R

11-4

CXL/YXL

ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

11.9 LIGHT BULB REPLACEMENT

Remove the bulb socket by turning it counterclockwise.

Replace the bulb with a new one. Install the bulb socket

by turning clockwise until secured.

INDICATOR

Remove the handle bar cover.

Remove the indicator lamp unit by turning it counter

clockwise. Replace with a new one.

(continued)

TAIL LIGHT

Remove the taillight lens by removing the 2 screws that

secure it. Remove the taillight bulb by turning counter

clockwise. Insert a replacement bulb and turn clockwise

until secure. Replace the taillight lens and secure with

the 2 screws

11-5

11.10 WIRING DIAGRAMS ELECTRICAL SYSTEMS

www.Get2itParts.com

www.Get2itParts.com

YXL Wiring Diagram

11-6

www.Get2itParts.com

www.Get2itParts.com

CXL Wiring Diagram

11-7

www.Get2itParts.com

www.Get2itParts.com

RXL-150R

Wiring Diagram

11-8

www.Get2itParts.com

www.Get2itParts.com

12. TROUBLESHOOTING

12.1 – Flowchart – Engine Will Not Start

12.2 – Flowchart – Engine Dies After Shifting (150cc)

12.1 Engine Will Not Start

www.Get2itParts.com

www.Get2itParts.com

(Start motor turns)

Engine Does Not

Start

Legend:

Flow

"Yes"

"No"

Is Ignition

switch on?

Engine stop

switch on?

Is brake

lever applied?

Turn on ignition

switch

Turn on engine

stop switch

Fully apply brake

lever

Engine

starts?

Engine

starts?

Engine

starts?

Test the brake switch. The brake switch is a

normal open switch. Disconnect the two leads

on the switch and test continuity with a

multi-meter. With brake lever applied, there

should be continuity and with brake lever

released there should be no continuity.

Did switch test

correctly?

Problem Solved.

Repair or replace

brake switch

Continue to

12.1.2

Engine

starts?

12.1.2 Engine Will Not Start, continued

www.Get2itParts.com

www.Get2itParts.com

Engine Does Not

Start

Legend:

Flow

"Yes"

"No"

Tether switch

active?

Fuel in tank?

Fuel petcock in

'ON' position ?

Repair/replace

tether switch

Fill tank (50:1

fuel/oil mix for

Turn fuel petcock

to ON position

40cc)

Engine

starts?

Engine

starts?

Engine

starts?

Fuel line

clogged?

Fuel filter

clogged?

Continue to

12.1.3

Clear fuel lines

Clean/replace

fuel filter

Problem Solved.

Engine

starts?

Engine

starts?

12.1.3 Engine Will Not Start, continued

www.Get2itParts.com

www.Get2itParts.com

Engine Does Not

Start

Legend:

Flow

"Yes"

"No"

Carburetor main

jet stuck/clogged?

Spark plug

fouled?

Plug gap set

to 0.036'?

Clean carburetor

Clean or replace

spark plug

Set gap to 0.036'

Engine

starts?

Engine

starts?

Engine

starts?

Test for spark at the spark

plug. Remove the plug and

place it in the ignition cap,

and ground against the

motor. Press the starter

button and check for spark.

Spark at

plug?

Problem Solved.

Continue to

12.1.5

Continue to

12.1.4

12.1.4 Engine Will Not Start, continued

www.Get2itParts.com

www.Get2itParts.com

Engine Does Not

Start

Legend:

Flow

"Yes"

"No"

Turn the ignition

switch to the OFF

position to be

tested.

Turn the ignition

switch to the ON

position to be

tested.

Depress the left

hand brake. Check

the rear lights.

Probe across the red

and brown leads with

a multi meter.

Probe across the red

and brown leads with

a multi meter.

No current at

ground?

Current

detected?

Problem unsolved.

Rear lights do not

light when brake

depressed, or stay

on when released?

Check all wire connections at

the CDI box and A/C generator

assembly. If problem persists,

contact ETON Technical Service at:

(864)-278-9585 EXT 114

Replace ignition

switch

Replace rear

brake safety

switch

Engine

starts?

Problem Solved.

Loading...

Loading...