Eton America Beamer PN2, Beamer II PN2B, Beamer Matrix PN2C, beamer R2-50 Service Manual

www.Get2itParts.com

www.Get2itParts.com

ETON America

Beamer Service Manual

Covers:

Beamer PN2

Beamer II PN2B

Beamer Matrix PN2C

www.Get2itParts.com

www.Get2itParts.com

Table of Contents

1. INFORMATION..................................................................................................................................... 4

1.1 SAFETY ........................................................................................................................................... 4

1.2 NOTES.............................................................................................................................................. 4

1.3 Specifications.................................................................................................................................... 5

1.4 SERIAL NUMBER .......................................................................................................................... 6

1.5 Standard Torque Values.................................................................................................................... 7

2. MAINTENANCE................................................................................................................................... 8

2.1 MAINTENANCE DATA................................................................................................................. 8

2.2 MAINTENANCE SCHEDULE ....................................................................................................... 9

2.3 FUEL TUBE..................................................................................................................................... 9

2.4 THROTTLE OPERATION.............................................................................................................. 9

2.5 THROTTLE CABLE ADJUSTMENT .......................................................................................... 10

2.6 AIR CLEANER.............................................................................................................................. 10

2.7 SPARK PLUG................................................................................................................................ 10

2.8 IDLE SPEED.................................................................................................................................. 11

2.9 BRAKE SYSTEM.......................................................................................................................... 11

2.10 WHEELS AND TIRES................................................................................................................. 12

2.11 GEAR OIL.................................................................................................................................... 12

2.12 ENGINE STOP SWITCH............................................................................................................. 12

2.13 HIGH-LOW BEAM CONTROLLER.......................................................................................... 13

3. ENGINE REMOVAL AND INSTALLATION................................................................................... 14

3.1 ENGINE REMOVAL..................................................................................................................... 14

3.2 ENGINE INSTALLATION............................................................................................................ 16

4. ENGINE FUEL SYSTEM.................................................................................................................... 17

4.1 TROUBLESHOOTING.................................................................................................................. 17

4.2 CARBURETOR.............................................................................................................................. 18

5. ENGINE LUBRICATION AND COOLING SYSTEM...................................................................... 21

5.1 TROUBLESHOOTING.................................................................................................................. 21

5.2 ENGINE LUBRICATION SYSTEM............................................................................................. 21

5.3 CAUTION: Fuel/Oil Ratio ............................................................................................................. 21

5.4 OIL PUMP...................................................................................................................................... 22

5.5 COOLING SYSTEM...................................................................................................................... 23

6. ENGINE COMBUSTION SYSTEM ................................................................................................... 24

6.1 TROUBLESHOOTING.................................................................................................................. 24

6.2 CYLINDER AND PISTON REMOVAL....................................................................................... 25

6.3 CYLINDER AND PISTON INSPECTION ................................................................................... 25

6.4 INSTALLATION ........................................................................................................................... 27

7. TRANSMISSION SYSTEM................................................................................................................ 29

7.1 TROUBLESHOOTING.................................................................................................................. 29

7.2 THE PARTS DRAWING OF TRANSMISSION SYSTEM.......................................................... 29

7.3 TRANSMISSION POWER PATH ................................................................................................ 30

7.4 AUTOMATIC CONTINUOUS VARIABLE TRANSMISSION.................................................. 31

7.5 CONTINUOUS VARIABLE TRANSMISSION........................................................................... 31

7.6 TRANSMISSION BOX ................................................................................................................. 32

Beamer Rev-2.0.2 Page 2 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

7.6 TRANSMISSION BOX ................................................................................................................. 32

7.7 ELECTRIC STARTER MOTOR................................................................................................... 33

7.8 KICK STARTER............................................................................................................................ 33

8. FRONT WHEEL, BRAKE AND STEERING SYSTEM.................................................................... 35

8.1 TROUBLESHOOTING.................................................................................................................. 35

8.2 MAINTANENCE DATA............................................................................................................... 35

8.3 SPEEDOMETER CABLE REMOVAL......................................................................................... 36

8.4 HANDLEBAR REPLACEMENT.................................................................................................. 36

8.5 FRONT WHEEL ............................................................................................................................ 37

8.6 FRONT BRAKE............................................................................................................................. 38

8.7 FRONT FORK ................................................................................................................................ 40

9. REAR WHEELAND BRAKE SYSTEM......................................................................................... 41

9.1 TROUBLESHOOTING.................................................................................................................. 41

9.2 MAINTENANCE DATA............................................................................................................... 41

9.3 REAR WHEEL REMOVAL.......................................................................................................... 41

9.4 REAR WHEEL INSPECTION....................................................................................................... 42

9.5 REAR BRAKE ............................................................................................................................... 42

9.6 REAR SHOCK ABSORBER PARTS DRAWING ....................................................................... 43

10. PLASTIC BODY PARTS............................................................................................................... 44

10.1 FRONT FENDER......................................................................................................................... 44

10.2 BODY COVER............................................................................................................................. 44

11. ELECTRICAL SYSTEM ............................................................................................................... 48

11.1 TROUBLESHOOTING................................................................................................................ 48

11.2 IGNITION COIL.......................................................................................................................... 49

11.3 IGNITION TIMING..................................................................................................................... 49

11.4 BATTERY INSPECTION AND MAINTENANCE.................................................................... 50

11.5 STARTER MOTOR ..................................................................................................................... 52

11.6 WIRING DIAGRAMS ................................................................................................................. 53

Beamer Rev-2.0.2 Page 3 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

1. INFORMATION

1.1 SAFETY

Gasoline is extremely flammable and is explosive under certain conditions.

Do not smoke or allow sparks or flames in your work area.

Never run the engine in a closed area. The exhaust contains poisonous carbon monoxide gas that may

cause loss of consciousness and lead to death.

The battery electrolyte contains sulfuric acid. Protect your eyes, skin and clothing. If you spill the

electrolyte on your skin or in your eyes, flush thoroughly with water. Call a doctor if electrolyte gets in

your eyes.

1.2 NOTES

All information, illustrations, directions and specifications included in this publication are based on the

latest product information available at the time of approval for printing.

E-TON Dynamic Technology Industry Co., Ltd. reserves the right to make changes at any time without

notice and without incurring any obligation whatever.

No part of this publication may be reproduced without written permission.

Beamer Rev-2.0.2 Page 4 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

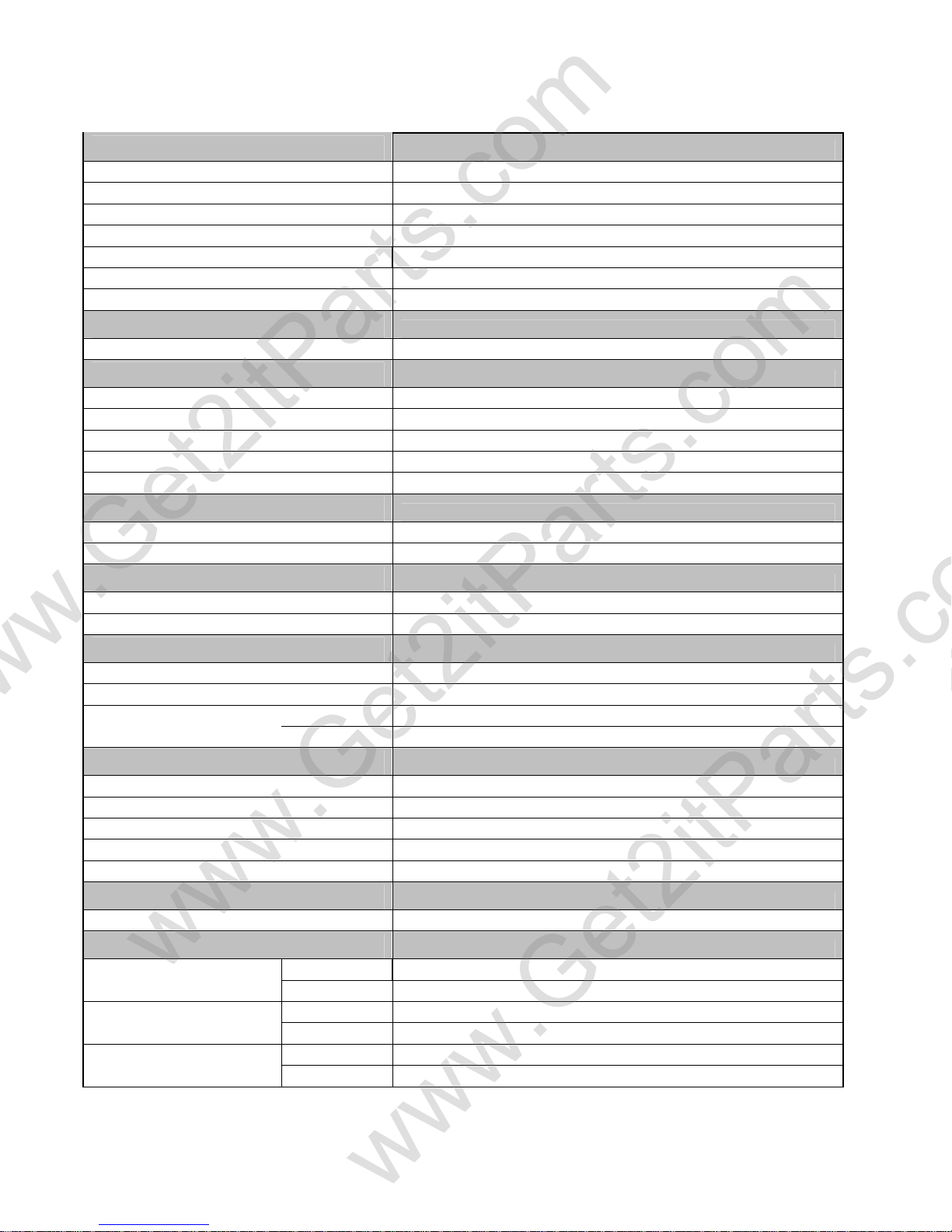

1.3 Specifications

Engine

Type Two cycle air cooled oil injected

Displacement 49.3cc

Bore / Stroke φ40.0 * 39.2mm

Compression - Ratio / Pressure 6.8 : 1 / 90-120psi

Torque / BHP 5.2N m @ 7000rpm / 1.5BHP

Estimated MPG 65mpg/795mpg

Starting Electrical with Kick starter back up

Transmission

Type Automatic (C.V.T. V-Belt)

Chassis

Overall Length 1830mm / 72.0"

Overall Width 650mm / 25.6"

Overall High 1100mm / 43.3"

Wheel Base 1260mm / 49.6"

Dry Weight 82kg / 180.7lb

Suspension

Front Telescopic Fork

Rear Unit Swing Arm / Single Shock

Brakes

Front Hydraulic Disc

Rear Mechanical Drum

Tires

Front 120/90-10

Rear 130/90-10

Tire Pressure

Front Front 18psi / 1.25kg/cm2 (Cold)

Rear

Carburetor

Make/Size

Main Jet

Pilot Jet

Air Mixture Adjustment

Idle Speed

Battery

Jell Acid (Maintenance Free)

Fluids

Fuel

2 Cycle Oil

Transmission

Type Unleaded Gasoline 89 octane

Volume 5.5liters / 1.5gal

Type

Volume 1.1 liters / 1.2qts

Type SAE 80/90 weight

Volume 100cc / 3.4oz

Rear 25psi / 1.75kg/cm2 (Cold)

Mikuni 18mm (Manual Coke)

85mm

20mm

Back out ¾ - 1¼ turns

Idle 1700 - 1900rpm

12V-4AH/5AH - GTX5L-BS

High grade synthetic 2 cycle injector oil

Beamer Rev-2.0.2 Page 5 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

Spark Plug

NGK (recommended)

Nipendenso

Champion

Electrode Gap 0.6-0.7mm / 0.023"

GVWR

GAWR (Front)

GAWR (Rear)

Available Colors

*Subject to availability

BPR7HS

W22FRP-U

QL82YC

240kg. / 530lbs.

76kg. / 167lbs.

165kg. / 164lbs.

Red

Blue

Yellow

Black

1.4 SERIAL NUMBER

The frame serial number is stamped on the front of the frame, at the front of the footrest plate.

The engine serial number is stamped on the left side of the engine crankcase.

Beamer Rev-2.0.2 Page 6 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

1.5 Standard Torque Values

ENGINE

¾ Cylinder head nut 28-30 N-m (20.7-22.1 lb./ft)

¾ Spark plug 12-19 N-m (8.9-14.0 lb./ft)

¾ Cylinder head bolt 20-30 N-m (14.8-22.1 lb./ft)

¾ Alternator bolt 8-12 N-m (5.9- 8.9 lb./ft)

FRAME

¾ Handlebar upper holder bolt 24-30 N-m (17.7-22.1 lb./ft)

¾ Steering shaft nut 50-60 N-m (36.9-44.3 lb./ft)

¾ Steering shaft bushing holder nut 24-30 N-m (17.7-22.1 lb./ft)

¾ Wheel rim bolt 18-25 N-m (13.3-18.4 lb./ft)

¾ Tie rod lock nut 35-43 N-m (25.8-31.7 lb./ft)

¾ King pin nut 30-40 N-m (22.1-29.5 lb./ft)

¾ Handlebar lower holder nut 40-48 N-m (29.5-35.4 lb./ft)

¾ Front wheel bolt 24-30 N-m (17.7-22.1 lb./ft)

¾ Front axle nut 55-65 N-m (40.6-47.9 lb./ft)

¾ Front brake arm nut 4-7 N-m (3.0- 5.2 lb./ft)

¾ Rear brake arm nut 7-12 N-m (5.2- 8.9 lb./ft)

¾ Rear axle nut 60-80 N-m (44.3-59.0 lb./ft)

¾ Rear wheel bolt 24-30 N-m (17.7-22.1 lb./ft)

¾ Exhaust muffler mounting bolt 30-35 N-m (22.1-25.8 lb./ft)

¾ Engine hanger bolt 24-30 N-m (17.7-22.1 lb./ft)

Beamer Rev-2.0.2 Page 7 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

2. MAINTENANCE

2.1 MAINTENANCE DATA

2.2 MAINTENANCE SCHEDULE

2.3 FUEL TUBE

2.4 THROTTLE OPERATION

2.5 THROTTLE CABLE ADJUSTMENT

2.6 AIR CLEANER

2.7 SPARK PLUG

2.8 IDLE SPEED

2.9 BRAKE SYSTEM

2.10 WHEELS AND TIRES

2.11 STEERING SYSTEM

2.12 GEAR OIL

2.1 MAINTENANCE DATA

SPECIFICATION

SPARK PLUG:

SPARK PLUG GAP: 0.6-0.7 mm

RECOMMENDED SPARK PLUGS: NGK BPR7HS

THROTTLE LEVER FREE PLAY: 5-10 mm

IDLE SPEED: 1600±100 rpm

BRAKE LEVER FREE PLAY: 15-25 mm

TIRES:

FRONT TIRE SIZE 120/90-10

REAR TIRE SIZE 130-90-10

FRONT/REAR TIRE PRESSURE 2.5± 0.3 kgf/cm2

TORQUE VALUES

SPARK PLUG 12-19 N-m

TIE-ROD LOCK NUT 35-43 N-m

LUBRICATION:

ENGINE OIL JASO FC Grade or same degree oil

GEAR LUBRICATION OIL SAE 40

Beamer Rev-2.0.2 Page 8 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

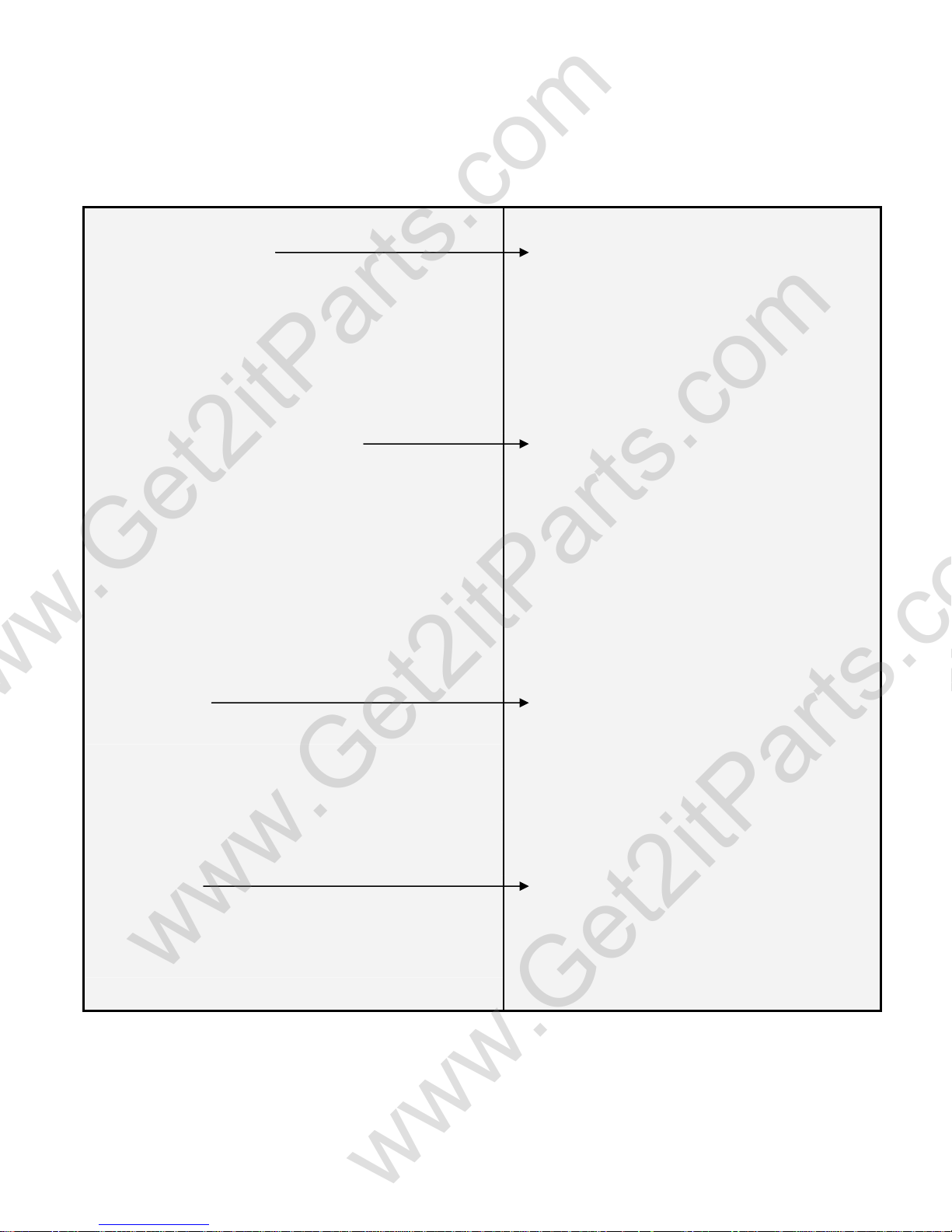

2.2 MAINTENANCE SCHEDULE

The maintenance intervals in the follow table are based upon average riding conditions. Riding in

unusually dusty areas may require more frequent servicing. E-TON recommends that all maintenance

and inspections be performed ONLY by a qualified and fully trained technician.

Fuel Line I

Throttle Operation I I I

Air Filter system &

Element

Spark Plug I R

Carburetor Idle Speed I I I

Brake Shoe Wear I I I

Brake System I I

Nut, Bolt, Fastener I I

Wheels & Wheel Nuts I I

Steering System

Suspension System I I

C.V.T. Air Filter C R

Air Induction Reed Valve I C/R

Transmission Gear Oil I R

Note –

I: Inspect and Clean, Adjust, Lubricate, or Replace (if necessary)

C: Clean

L: Lubricate

R: Replace

INITIAL

SERVICE

(First week) (Every 30 operating

I C R

REGULAR SERVICE

days)

I

EVERY

YEAR

I

I

I

I

2.3 FUEL TUBE

Inspect the fuel lines for deterioration, damage, or

leaks, and replace if necessary.

2.4 THROTTLE OPERATION

Inspect for smooth throttle lever full opening and

automatic full closing in all steering positions.

Inspect for deterioration, damage, or kinking

in the throttle cable. Replace if necessary.

Check the throttle lever. Free play is 5-10 mm at the tip

of the throttle lever.

Disconnect the throttle cable at the upper end.

Lubricate the cable with commercially available lubricant to prevent premature wear.

Beamer Rev-2.0.2 Page 9 of 55 9/21/2006

www.Get2itParts.com

www.Get2itParts.com

2.5 THROTTLE CABLE

ADJUSTMENT

Slide the rubber adjuster cap off the throttle

housing, loosen the locking nut, and adjust the

free play of the throttle lever by turning the

adjuster on the throttle housing. Inspect the free

play of the throttle lever.

This free play should be 5-10mm.

2.6 AIR CLEANER

Unscrew the air cleaner cover screws.

Pull out the air filter element from the air cleaner

case. Wash the element in non-flammable solvent.

Squeeze out the solvent thoroughly.

Let it dry. Soak the filter element in gear oil and

then squeeze out the excess oil.

Install the element into the air cleaner carefully.

2.7 SPARK PLUG

The spark plug is located at the front of the

engine. Disconnect the spark plug cap and remove

the spark plug. Check the spark plug electrodes

for wear. Change the spark plug if the electrodes

and insulator tip appear unusually fouled or

burned.

Discard the spark plug if there is apparent wear or

if the insulator is cracked or chipped.

The spark plug gap should be set to 0.6-0.7mm.

With the sealing washer attached, thread the spark

plug in by hand to prevent cross threading.

Torque the spark plug to 12-19 N-m.

Beamer Rev-2.0.2 Page 10 of 55 11/21/2005

j

www.Get2itParts.com

www.Get2itParts.com

2.8 IDLE SPEED

Connect a tachometer.

Warm up the engine for at least 10 minutes.

Turn the idle-speed adjust screw on the carburetor

to obtain the idle speed. "Turn in" (clockwise)

to get higher speed. "Turn out" (counter clockwise)

to get lower speed.

IDLE SPEED: 1600±100 rpm

2.9 BRAKE SYSTEM

Inspect the front brake lever and cable for

excessive play or other damage.

Replace or repair if necessary.

Measure the free play of the brake lever at the end

of the brake lever.

The standard of free play is 15-25 mm.

Inspect the rear brake lever and cable for

excessive play or other damage.

Replace or repair if necessary.

Measure the free play of the rear brake lever at

the end of the lever. The standard is 15-25 mm.

Adjust the free play of the rear brake lever by

turning the adjuster on the rear axle.

Air Mixture

ustment Screw

Ad

Idle Adjustment Screw

Beamer Rev-2.0.2 Page 11 of 55 11/21/2005

t

www.Get2itParts.com

www.Get2itParts.com

2.10 WHEELS AND TIRES

Inspect the tire surfaces for cuts, nails, or other sharp

objects. Check the tire pressure at cold tire condition.

The standard tire pressure is 2.5±0.3 kgf/cm2

2.11 GEAR OIL

Transmission gear oil needs to be changed every year

or after every 3000 miles of service.

The drain bolt is located at the rear of engine.

Remove the drain bolt and loosen the fill bolt to drain

the transmission gear box.

Inspect the drained oil for foreign materials. If the oil

contains a high concentration of metal shavings or

powder, disassemble the transmission for further

inspection.

Reinstall the drain bolt and refill the gear box with

100cc

/ 3.4oz of SAE 80-90 Gear Oil

Note: for best results, drain the transmission while

the engine is warm.

Fill Plug

Drain Bol

2.12 ENGINE STOP SWITCH

The engine stop switch is located beside the left handle bar.

In an emergency, pushing this switch will stop the engine.

The stop switch must be place in the on position, the top of the

switch pressed down, for the engine to start.

If your engine fails to start, check the switch.

Beamer Rev-2.0.2 Page 12 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

2.13 HIGH-LOW BEAM CONTROLLER

This controller is located beside right handle bar and

controls the headlight intensity setting.

When the switch is placed in the full right position, the

headlights are set to illuminate at 100% intensity. In the

center position the headlight will illuminate at 60%

intensity. Placed in the far left position, the headlights

will be off.

NOTE: It is recommended that you have the headlight

on at all times when operating the vehicle to improve

your visibility to other traffic.

Beamer Rev-2.0.2 Page 13 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

3. ENGINE REMOVAL AND INSTALLATION

3.1 ENGINE REMOVAL

Remove the seat, helmet box, and body cover.

(See chapter 10 for complete instructions)

Disconnect oil tube, fuel tube, and vacuum line tube.

Disconnect the wires of the A/C generator and the

starter motor.

Beamer Rev-2.0.2 Page 14 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

Disconnect the wires of the carburetor and the

throttle cable.

Remove the cap from the spark plug.

Remove the bolt at the low end of the rear shock.

Beamer Rev-2.0.2 Page 15 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

Remove the engine hanger nut.

Remove the rear brake cable adjusting nut.

Pull the engine out from the frame.

3.2 ENGINE INSTALLATION

Install engine in reverse order of disassembly.

Torque value:

M8 nut 15 - 22 lbf-ft

M10 nut 22 - 29 lbf-ft

M12 nut 36 – 43 lbf-ft

After installing the engine, check the parts below:

o All connections (A/C generator,

starter motor, etc)

o Carburetor throttle cable

o Rear brake cable

o Oil tubes and fuel tubes

Beamer Rev-2.0.2 Page 16 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

4. ENGINE FUEL SYSTEM

4.1 TROUBLESHOOTING

ENGINE WILL NOT START

ENGINE IDLES UNSTEADILY, STALLS,

OR RUNS POORLY

LEAN MIXTURE

¾ NO FUEL IN TANK

¾ NO FUEL IN CYLINDER

¾ TOO MUCH FUEL INTO CYLINDER

¾ NO SPARK AT PLUG

¾ AIR CLEANER CLOGGED

¾ IMPROPER ADJUSTMENT OF THE

IDLE SPEED SCREW AT CARBURETOR

¾ IGNITION MALFUNCTION

¾ FUEL/AIR MIXTURE RATIO TOO LEAN OR

TOO RICH

¾ AIR CLEANER DIRTY

¾ INSULATOR LEAKS

¾ FUEL TANK CAP BREATHING HOLE

CLOGGED

¾ CARBURETOR FUEL JET CLOGGED

¾ FUEL TANK CAP BREATHING HOLE

CLOGGED

¾ FUEL FILTER CLOGGED

¾ FUEL FLOWS IN THE TUBE IRREGULARLY

¾ FLOAT LEVEL IN CARBURETOR TOO LOW

RICH MIXTURE

Beamer Rev-2.0.2 Page 17 of 55 11/21/2005

¾ FLOAT NEEDLE VALVE IN CARBURETOR

FAULTY

¾ FLOAT LEVEL TOO HIGH

¾ AIR DUCT IN CARBURETOR IS CLOGGED

¾ AIR CLEANER DIRTY

r

r

www.Get2itParts.com

www.Get2itParts.com

4.2 CARBURETOR

REMOVAL

Remove the air cleaner.

Disconnect the fuel line and auto-choke electric wire.

Unscrew the intake pipe mounting bolts at the

carburetor, and then remove the carburetor.

Note: Before removing carburetor, you must shut the

fuel flow off.

Remove the carburetor cap.

Remove the throttle cable from the throttle valve

while depressing the throttle valve spring.

Remove the needle clip retainer, the jet needle, and

needle clip. Inspect the throttle valve and jet needle

surface for wear, scratches, or dirt.

Carbureto

Air Cleane

Beamer Rev-2.0.2 Page 18 of 55 11/21/2005

t

t

www.Get2itParts.com

www.Get2itParts.com

DISASSEMBLY

Unscrew the float chamber screws and remove the

float chamber.

Disassemble the float arm pin, float and float needle

valve.

Inspect the seat of the float needle valve for wear or

damage.

Disassemble the idle jet, main jet, idle speed

adjustment screw, and idle mixture adjustment screw.

Inspect all jets and screws for wear or damage.

Clean the passages and jets with compressed air.

ASSEMBLY

Clean all parts in solvent and blow it dry with

compressed air. Assembly is the reverse order of

disassembly.

Main Je

Pilot Je

Beamer Rev-2.0.2 Page 19 of 55 11/21/2005

www.Get2itParts.com

www.Get2itParts.com

THROTTLE VALVE ASSEMBLY

Install the needle clip on the jet needle.

Install the jet needle into the throttle valve.

Assemble the throttle cable, spring, and throttle

valve. Align the throttle valve groove with the idle

speed adjust screw and install the carburetor cap to

the carburetor.

Beamer Rev-2.0.2 Page 20 of 55 11/21/2005

Loading...

Loading...