ETME SD series, SW series, SDA series Operating Instructions Manual

OPERATING INSTRUCTIONS

SECTIONAL DOOR OPERATOR

3

1. CONTENTS

1. Contents .................................................... 3

2. General instructions .................................. 3

3. Safety-related regulations ......................... 4

4. Safety instructions ..................................... 4

5. Mounting .................................................... 5

6. Initial operation .......................................... 6

7. Technical data ......................................... 11

8. Drawings .................................................. 12

9. Maintenance ............................................ 13

10. Transport, Storage, Disposal................... 13

11. Service, Spare parts, Accessories .......... 13

12. Declaration of conformity ......................... 14

13. Annex ...................................................... 15

2. GENERAL INSTRUCTIONS

2.1 Original operating instructions

This manual is the original manual.

Copyright protection: any reproduction is permitted

only with approval of the manufacturer.

Subject to alterations in the interest of technical pro-

gress.

All dimensions given in mm. The diagrams in this

manual are not to scale.

2.2 Intended use

The operator series SD, SW and SDA are intended for

driving loads that do not need to be secured against

falling, such as: weight counterbalanced sectional

doors.

For other applications of the operators, the manufacturer must be consulted.

2.3 Warranty

The function and safety of the equipment is only gua-

ranteed if the warning and safety instructions included

in these operating instructions are adhered to.

The manufacturer is not liable for injury to persons or

damage to property if these occur as a result of the

warnings and safety advice being disregarded.

The CE declaration and the warranty will void if components are changed.

Only original spare parts and by the manufacturer approved accessories shall be used. These parts are

used to maintain the quality and safety of the machine.

Changes are only permitted after consultation with the

manufacturer.

2.4 Target group

Only qualified and trained specialists are permitted to

mount the operator and perform mechanical maintenance.

Only qualified and trained electricians may connect

the operator and carry out the electrical maintenance.

Qualified and trained people have knowledge of general and specific safety and accident prevention regulations, the relevant regulations and standards, training

in the use and maintenance of adequate safety

equipment, as well as the ability to recognize hazards

associated with their work.

2.5 Key to symbols

DANGER !

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

WARNING !

Indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

CAUTION !

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

NOTICE !

Indicates an imminent danger of damage or destruction.

INFORMATION !

Reference to separate documents which must be complied with.

4

3. SAFETY-RELATED REGULATIONS

For connecting, programming and servicing, the following regulations must be observed (the list is not exhaustive)!

Construction product standards:

EN 13241-1

EN 12445

EN 12453

EN 12635

EN 12978

Electromagnetic compatibility (EMC):

EN 55014-1

EN 61000-3-2

EN 61000-3-3

EN 61000-6-2

EN 61000-6-3

Machinery Directive:

EN 60204-1

EN 12100-1

Local protective regulations must be complied with.

4 SAFETY INSTRUCTIONS

DANGER !

Failure to observe the instructions in this document can

result in mortal danger!

DANGER !

Risk of death by electric shock!

When installing the operator, when opening housings

and work on electrical equipment, the operator has to

be disconnected from the power.

Observe the local safety regulations.

NOTICE !

To avoid damage to the operator and at the door, the

drive must be mounted only if :

the drive is undamaged,

the ambient temperature is -20 ° C to +60 ° C,

the installation site altitude does not exceed 1,000 m

above sea level.

The use of the operator, as well as the standard

cable is only allowed indoors.

For outdoor installation must be consulted with the

manufacturer.

WARNING !

Make sure that children can not access the door

control or the hand-held transmitter.

Ensure, before moving the door, that no persons or

objects within range of the door.

Test all existing emergency command devices.

Pay attention to possible crushing and shearing

points on the door system.

Never reach into a running gate, into the guide rail or

moving parts.

INFORMATION !

For drives with fixed connection a main switch with

appropriate building main fuse must be provided.

WARNING !

Before installation, ensure that:

the operator is installed with the intended covers or

guards,

all seals are correctly and

all glands and screws are tightened correctly.

5

5. MOUNTING

5.1 Preparation

Check that the delivery is complete.

Check if all accessories for your installation situati-

on are present (e.g. console).

Check if the system has a suitable mains connec-

tion and a mains switch.

Remove all unnecessary components from the door

Remove all devices, which are not required after

installation of the drive system.

Before installation, ensure that the operator is not

blocked,

Before installation, ensure that the operator has

been newly prepared after a lengthy storage period,

Before installation, ensure that no other sources of

danger are present,

Before installation, ensure that the installation site

has been cordoned off over a wide area.

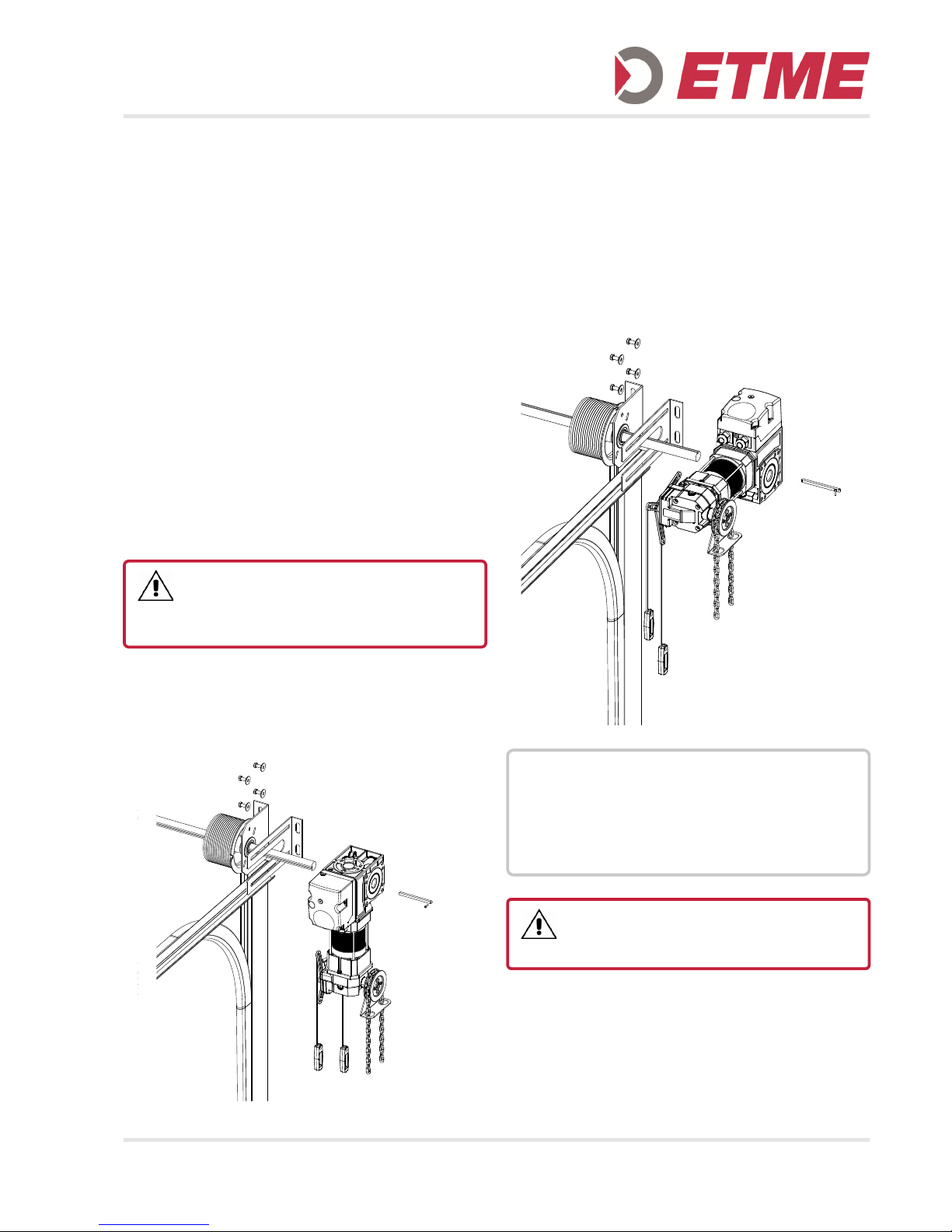

5.2 Mounting of the Operator

Install the torque bracket

Insert the feather key into the shaft

The shaft end is greased before fitting the drive

When using collars, slide the collar onto the shaft

Secure the feather key against sliding

Mounting operator in inverted position:

DANGER !

All components must be designed in relation to the

construction and the ground for the loads during tripping

of the safety catch device.

NOTICE !

To avoid damage to the operator and to the door, the

operator must be mounted with torque support bracket so that it is vibration dampened.

When mounting the operator do not carry or pull at

the cable.

DANGER !

With a continuous shaft groove the feather key has to

be secured against moving.

Loading...

Loading...