ETME RDA series Operating Instructions Manual

OPERATING INSTRUCTIONS

ROLLING DOOR OPERATORS

3

1. CONTENTS

1. Contents .................................................... 3

2. General instructions .................................. 3

3. Safety-related regulations ......................... 4

4. Safety instructions ..................................... 4

5. Mounting .................................................... 5

6. Anti-Drop Safeguard .................................. 6

7. Initial operation .......................................... 6

8. Technical data ......................................... 12

9. Dimensions .............................................. 12

10. Drawings .................................................. 13

11. Maintenance ............................................ 14

12. Transport, Storage, Disposal................... 14

13. Service, Spare parts, Accessories .......... 14

14. Declaration of conformity ......................... 15

15. Annex ...................................................... 16

2. GENERAL INSTRUCTIONS

2.1 Original operating instructions

This manual is the original manual.

Copyright protection: any reproduction is permitted

only with approval of the manufacturer.

Subject to alterations in the interest of technical pro-

gress.

All dimensions given in mm. The diagrams in this

manual are not to scale.

2.2 Intended use

The operator series RDA are designed exclusively for

opening and closing doors (such as rolling doors or

rolling grilles) which have to be secured against falling.

For other applications of the operators, the manufacturer must be consulted.

2.3 Warranty

The function and safety of the equipment is only guaranteed if the warning and safety instructions included

in these operating instructions are adhered to.

The manufacturer is not liable for injury to persons or

damage to property if these occur as a result of the

warnings and safety advice being disregarded.

The CE declaration and the warranty will void if components are changed.

Only original spare parts and by the manufacturer approved accessories shall be used. These parts are

used to maintain the quality and safety of the machine. Changes are only permitted after consultation with

the manufacturer.

2.4 Target group

Only qualified and trained specialists are permitted to

mount the operator and perform mechanical maintenance.

Only qualified and trained electricians may connect

the operator and carry out the electrical maintenance.

Qualified and trained people have knowledge of general and specific safety and accident prevention regulations, the relevant regulations and standards, training

in the use and maintenance of adequate safety

equipment, as well as the ability to recognize hazards

associated with their work.

2.5 Key to symbols

DANGER !

Indicates a hazard with a high level of risk which, if not

avoided, will result in death or serious injury.

WARNING !

Indicates a hazard with a medium level of risk which, if

not avoided, could result in death or serious injury.

CAUTION !

Indicates a hazard with a low level of risk which, if not

avoided, could result in minor or moderate injury.

NOTICE !

Indicates an imminent danger of damage or destruction.

INFORMATION !

Reference to separate documents which must be complied with.

4

3. SAFETY-RELATED REGULATIONS

For connecting, programming and servicing, the following regulations must be observed (the list is not exhaustive)!

Construction product standards:

EN 13241-1

EN 12445

EN 12453

EN 12635

EN 12978

Electromagnetic compatibility (EMC):

EN 55014-1

EN 61000-3-2

EN 61000-3-3

EN 61000-6-2

EN 61000-6-3

Machinery Directive

EN 60204-1

EN 12100-1

Local protective regulations must be complied with.

4. SAFETY INSTRUCTIONS

DANGER !

Failure to observe the instructions in this document can

result in mortal danger!

DANGER !

Risk of death by electric shock!

When installing the operator, when opening housings

and work on electrical equipment, the operator has to

be disconnected from the power.

Observe the local safety regulations.

NOTICE !

To avoid damage to the operator and at the door, the

drive must be mounted only if:

the drive is undamaged,

the ambient temperature is -20 ° C to +60 ° C,

the installation site altitude does not exceed 1,000 m

above sea level.

The use of the operator, as well as the standard

cable is only allowed indoors.

For outdoor installation must be consulted with the

manufacturer.

WARNING !

Make sure that children can not access the door

control or the hand-held transmitter.

Ensure, before moving the door, that no persons or

objects within range of the door.

Test all existing emergency command devices.

Pay attention to possible crushing and shearing

points on the door system.

Never reach into a running gate, into the guide rail or

moving parts.

INFORMATION !

For drives with fixed connection a main switch with

appropriate building main fuse must be provided.

WARNING !

Before installation, ensure that:

the operator is installed with the intended covers or

guards,

all seals are correctly and

all glands and screws are tightened correctly.

5

5. MOUNTING

5.1 Preparation

Check that the delivery is complete.

Check if all accessories for your installation situati-

on are present (e.g. bracket).

Check if the system has a suitable mains connec-

tion and a mains switch.

Remove all unnecessary components from the door

Remove all devices, which are not required after

installation of the drive system.

Before installation, ensure that the operator is not

blocked,

Before installation, ensure that the operator has

been newly prepared after a lengthy storage period,

Before installation, ensure that no other sources of

danger are present,

Before installation, ensure that the installation site

has been cordoned off over a wide area.

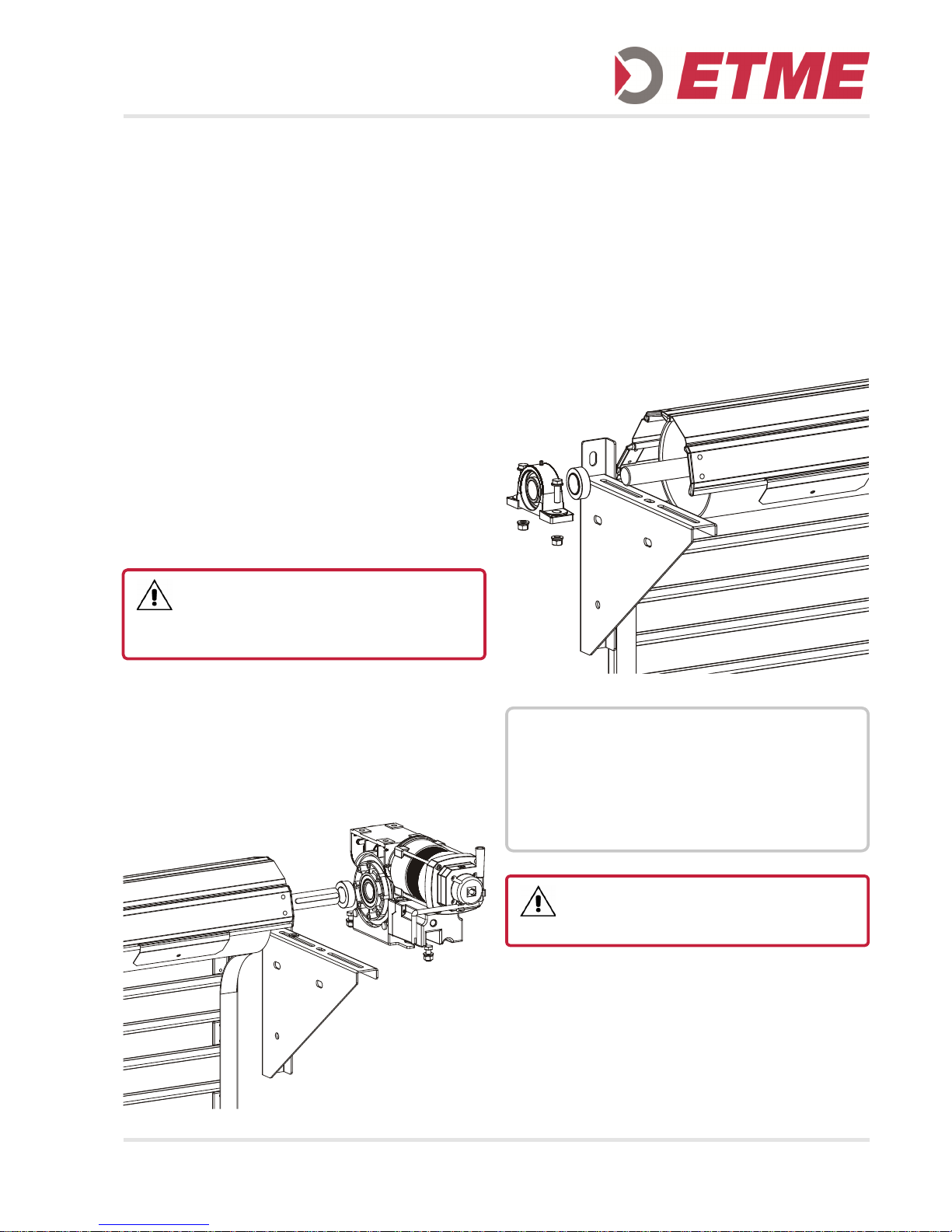

5.2 Mounting the Operator

Install the torque bracket

Insert the feather key into the shaft

The shaft end is greased before fitting the drive

When using collars, slide the collar onto the shaft

Secure the feather key against sliding

Connect the drive to the shaft

Attach the drive to the bracket

Slide the counter bearing onto the shaft

Attach the counter bearing to the bracket

The brackets must be mounted so that the shaft is

in the horizontal

The fixation against axial displacement of the shaft

is made on the opposite side at counter bearing, by

means of a screw or with collars on both sides

DANGER !

All components must be designed in relation to the

construction and the ground for the loads during tripping

of the safety catch device.

NOTICE !

To avoid damage to the operator and to the door, the

operator must be mounted on a bracket with a pendulum foot or a torque support bracket so that it is

vibration dampened.

When mounting the operator do not carry or pull at

the cable.

DANGER !

With a continuous shaft groove the feather key has to

be secured against moving.

6

6. ANTI-DROP SAFEGUARD

In accordance with the EN 12604 all RDA-operators

are equipped with an integrated locking device, which

works in both directions.

The locking device is entrained load-free and wearfree. If the drive unit fails, the locking device is automatically triggered. The load moved by the operator is

then smoothly brought to a standstill in the position

concerned.

The power transmission between the motor and the

door shaft is interrupted after the drive unit fails. The

operator must be replaced.

The anti-drop safeguard device is distinguished by the

following features:

Protection against worm shaft and worm gear failu-

re

Independent of the rotational speed

Independent of the direction of rotation

Can be mounted in any position

Unsusceptible to vibrations

Maintenance-free

Self-controlling

Excellent damping properties when device is trigge-

red

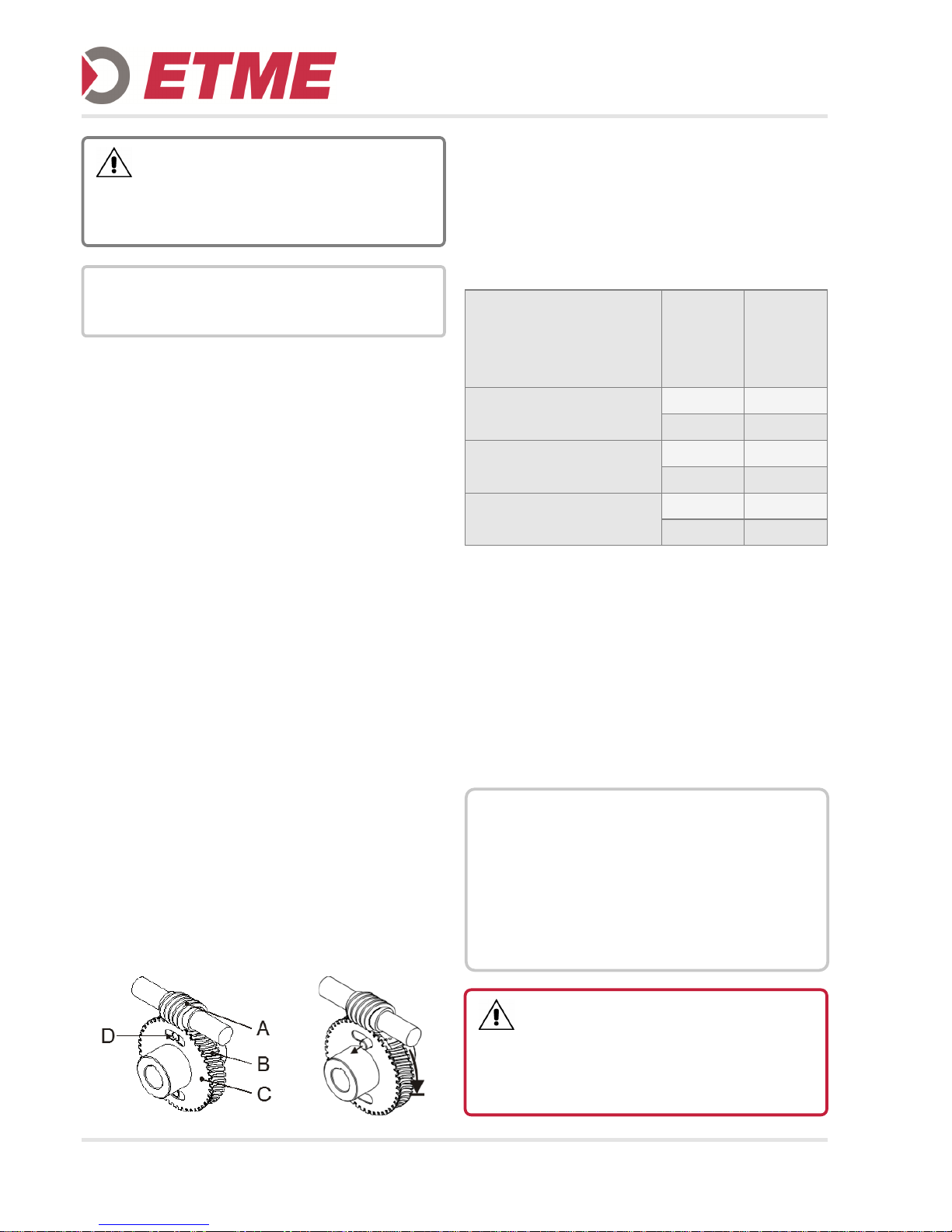

6.1 Function

In case of exceeding wear the teeth of the brass worm

wheel (B) may collapse and allow the wheel to turn

underneath the steel worm shaft (A). The pilot wheel

(C) remains unaffected, due to the relative rotation of

the two wheels a set of hardened lock-bolts (D) are

released and will immediately and permanently block

the gearbox.

7. INITIAL OPERATION

Power-operated doors shall be audited at least annually by a trained person, before first use and as required (with written proof).

The operator of the door system shall be trained after

initial operation.

Before installation, ensure that the direction of rotation

of the gear motor is correct, and all protective devices

are active.

CAUTION !

For operators with weights greater than 20 kg additional

aids shall be used, such as hooks or ropes for securing

and lifting. On the drives corresponding eyes are provided.

INFORMATION !

The relevant instructions for the door must be observed

when fitting the operator to the door.

Nebenstehende Maximalwerte dürfen auch

bei frequenzgeregeltem Betrieb nicht

überschritten werden

The values in this table may not be ex-

ceeded even in frequency controlled

operation

max. Betriebs-

drehzahl

max. Operating

Speed

max. zul.

Drehmoment

max. Torque

TOR-FV 5/083

100 min-1 200 Nm

200 min-1 100 Nm

TOR-FV 7/119

95 min-1 750 Nm

210 min-1 300 Nm

TOR-FV 6/111

30 min-1 1.554 Nm

120 min-1 1.118 Nm

NOTICE !

To avoid damage to the drive, the following points must

be observed:

The types of cable and their diameters must be sel-

ected according to current regulations.

The nominal currents and the type of connection

must correspond to those on the motor type plate.

The drive details must agree with the connected

loads.

DANGER !

Danger of fatal electric shock!

Before commencing cabling works, you MUST disconnect the drive system from the main supply. Ensure

that the electricity supply remains disconnected throughout the cabling works.

Loading...

Loading...