ETI SNOW SWITCH LCD-8 Quick Manual

MODEL LCD–8

AUTOMATIC SNOW/ICE MELTING SYSTEM CONTROL PANEL

SAFETY

Make all electrical connections in compliance with the National Electrical

Code (NFPA 70) and local electrical code. If you have questions

concerning the installation or application, contact Customer Service.

Abnormal Odor or Smoke

In the event of smoke or a burning or abnormal odor, immediately

interrupt power to the unit by unplugging the unit or by turning off the

circuit breaker protecting the unit.

Electrical Shock / Fire Hazard

Even when the snow melting elements are disconnected, as long as the

circuit breaker is on and power is running to the unit, voltage is still

being applied to the system’s yellow leads. Therefore, never touch the

ends of the yellow leads or let the two leads touch each other. Do not let

the two yellow leads contact any component inside the unit.

Any installation involving electric heater wiring must be grounded to

earth to protect against shock and re hazard. Suitable ground fault

detection and interrupting systems must be in use at all times to reduce

shock and re hazard and to protect equipment.

Electric wiring to heating elements must be installed in accordance

with National Electrical Code (NEC) or Canadian Electrical Code (CEC)

requirements and all other local and applicable electrical codes and

any third party standards. Follow the installation instructions contained

herein and those provided by the heater manufacturer.

Use a GFEP (Ground Fault Equipment Protection) circuit breaker on

each branch circuit connected to the ice melting system. Clearly label

each circuit breaker with its function. This is vitally important when there

is more than a single point of disconnect.

Size the circuit breaker in accordance with the size of the expected load.

The maximum current load for the LCD-8 is 16 Amp resistive. This product

is intended for use in residential or light commercial applications.

South Bend, Indiana USA | networketi.com

SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 24782 REV C

Make certain that the heater shield is properly grounded.

Failure to do so may result in damage to the equipment

or re.

Following installation and prior to beginning system

operation, refer to and perform the Post-Installation Tests

(page 12) described in this manual.

ADDITIONAL INFORMATION

More information is made available regularly through

our website, www.networketi.com. Please visit us online

for Data Sheets, Manuals, White Papers, technical articles,

and more. The most current and up to date version of this

and every other manual for our products can be found in

Acrobat (PDF) format to view online or to print. This is to

assist you in installing and using our products to the best

effect possible. If you have any comments about this or

any other product from ETI, please contact us.

PRODUCT OVERVIEW

The Snow Switch® Model LCD–8 (Figure 1) is a

congurable aerial snow melting system controller which

makes automatic snow melting a cost-effective alternative

in even the smallest applications. Heaters operate at

temperatures below the LCD-8’s congurable set point,

pre-programmed to 38°F (3.3°C), only when required.

The adjustable hold-on period, pre-programmed to 3

hours, continues heater operation after snow stops to

ensure complete melting. The LCD–8 controller includes

an internal magnetic reed switch used for manual heater

cycling and conguring the controller’s operational

temperature set point and hold-on time.

The LCD–8 controller is available as a model which

operates from either an automatic selecting 100VAC –

240VAC or as a model which operates from 24VAC. These

two voltage options combine with the congurable hold-

on time and temperature set point to meet the need of a

wide number of applications using just two part numbers.

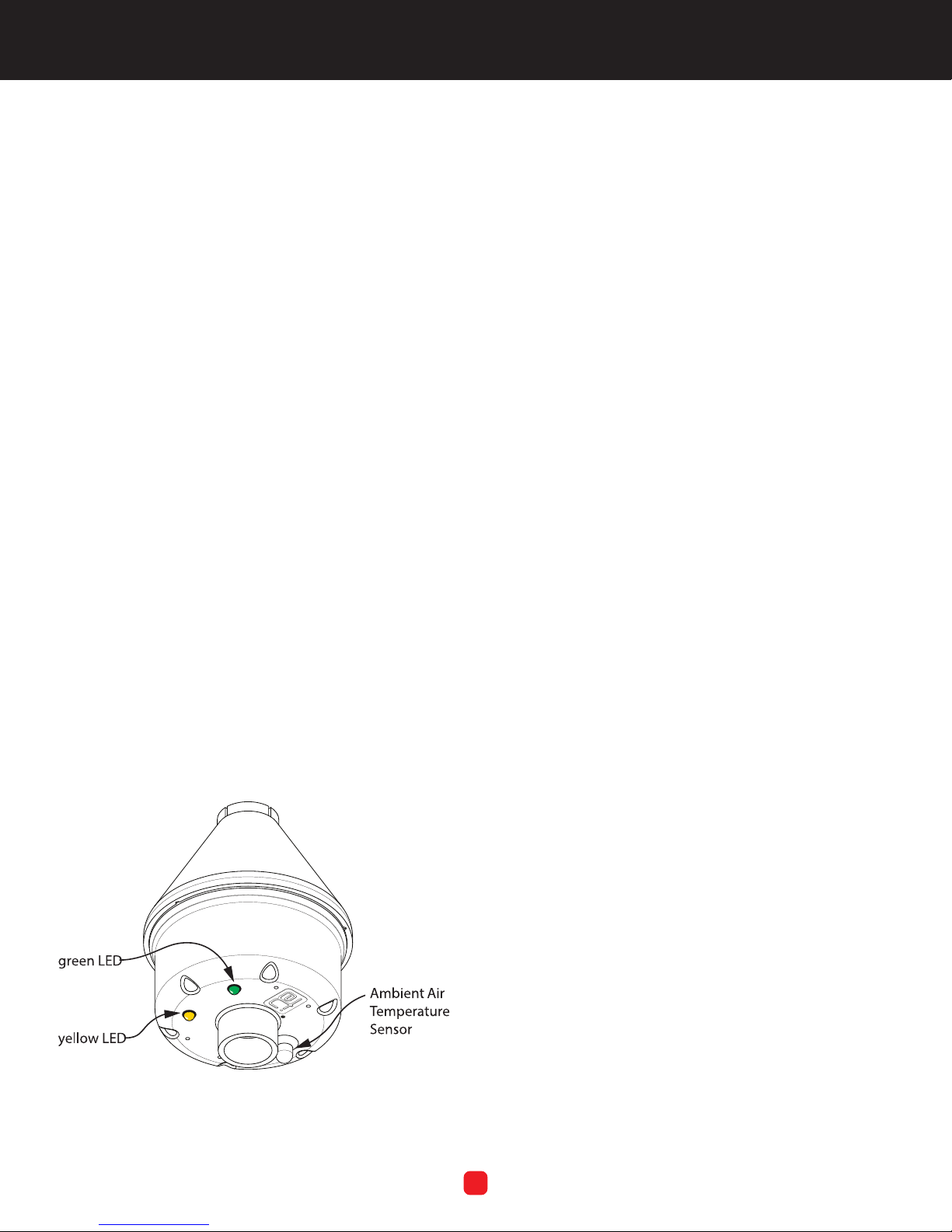

FIGURE 1. LCD-8

inductive. The operating temperature range extends from

–40°F to 140°F (–40°C to 60°C). The redesigned, patent

pending, rugged polycarbonate enclosure provides

excellent protection at temperature extremes, while

allowing snow to shed to prevent iglooing over the

moisture sensor.

The internal magnetic reed switch allows for both

conguration and manual heater operation without the

need for external switches—which are susceptible to

damage—or the need to open the enclosure.

Verifying system functionality after installation or when

troubleshooting used to require spray circuit cooler

or ice for controller activation. The Sno-Test™ feature

eliminates this need by performing a self-test after power

application and operating heaters in a unique pattern for

a few seconds. Reading the test results takes only an AC

voltmeter or clamp-on ammeter.

It controls heater loads up to 16 amps resistive or 3 amps

South Bend, Indiana USA | networketi.com

A congurable snow sensor with two light-emitting diode

2

SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 24782 REV C

(LED) indicator lamps (Figure 2), the LCD-8 features a

hold-on timer which allows its system to operate to a drier

surface after melting snow.

• The hold-on timer can be congured for off, 1 hour, 3

hours or 5 hours. The operating temperature can be

congured for none (precipitation sensor), 36°F, 38°F

or 40°F.

• The low-temperature lockout (17°F/-8.3°C), which

disengages unit operation, can be enabled or not.

• Pre-programmed conguration: 38°F (3.3°C) operating

temperature; 3 hour hold-on; no lockout.

• The LCD-8 uses an internal magnetic switch. The user

swipes a magnet externally across this switch to start a

hold-on cycle or to terminate a running hold-on cycle.

This switch may also be used to recongure the unit, or

to view the current conguration.

• The green LED, ordinarily on steady, blinks to indicate a

concern with the unit. This LED is also used in the LCD8’s conguration process.

Immediately upon receipt, inspect the container and

packing material for any noticeable damage. Unpack the

unit, taking care not to damage the packing materials.

Conrm all components noted in “Packing List” above

are included. Save the shipping container and related

materials until normal operation has been established.

If the unit must be returned, take care to ensure that it is

repackaged as it was received.

As soon as the unit arrives at your facility, inspect it for

mechanical damage. If any of the following problems is

found, contact ETI, Customer Service immediately:

• contents incomplete or incorrect;

• internal or external mechanical damage; or

• defective operation.

ETI Customer Service is available between 8:00 a.m. and

5:00 p.m. Eastern Time. In the event of shipping damage,

keep the packing materials for inspection by the carrier.

• The yellow LED indicator is lit whenever the output

relay is powered (“on”).

• There is an initialization period where the heaters are

tested.

UNPACKING THE LCD-8

RETURNS AND REPLACEMENT PART PURCHASES

Equipment cannot be returned for credit once it has

been installed. ETI will repair or replace faulty equipment

under warranty. Prior to removal of equipment for

warranty return, please contact ETI Technical Support for

troubleshooting assistance.

Before returning a unit to ETI, obtain a Return Merchandise

Authorization from our Customer Service Department,

available between 8:00 a.m. and 5:00 p.m. Eastern Time. If

possible, use the original container and packing materials

when packing the unit for shipment. It is important to

mark the Return Merchandise Authorization clearly

on the outside of the shipping container so that it may

be correctly processed upon receipt at Environmental

Technology.

For more information about replacement parts or for a

replacement Manual, please visit www.networketi.com.

FIGURE 2. LCD-8 LEDs

South Bend, Indiana USA | networketi.com

3

SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 24782 REV C

INSTALLATION

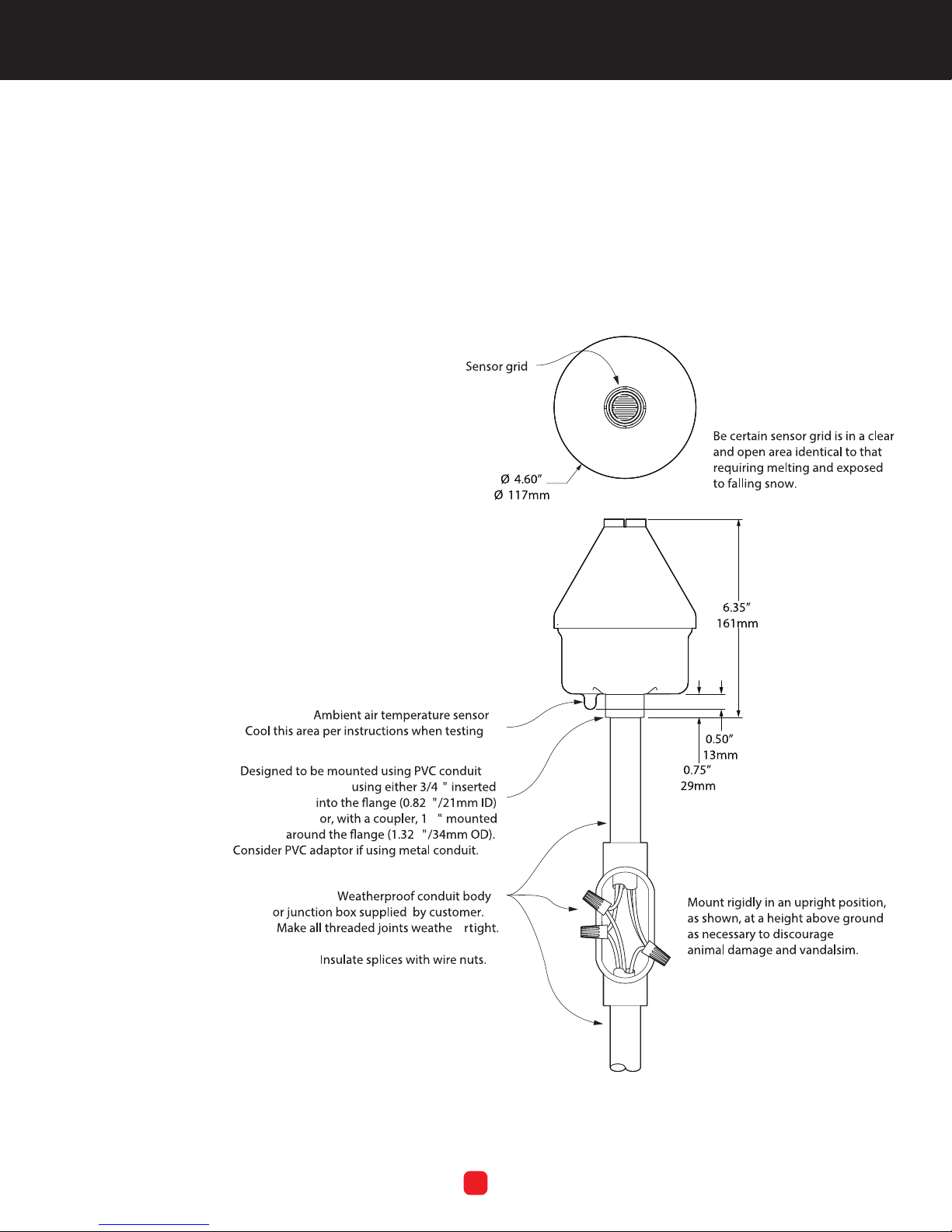

With user-supplied hardware, mount the LCD-8 securely

in an upright position (sensor grid at top; see Figure 3)

in a clear and open area typical of the area to be melted,

either above the roof line or removed from the building

and exposed to, rather than protected from, falling snow.

AVOID: OVERHEAD TREES, SHRUBS, WIRES, EAVES, ETC.,

AND FALLING OR BLOWING DEBRIS.

AVOID: VEHICLE AND FOOT TRAFFIC. DO NOT CREATE A

SAFETY HAZARD.

AVOID: EXPOSURE TO ARTIFICIAL HEAT SOURCES AND

EXCESSIVE SHOCK AND VIBRATION.

The LCD-8 also should be positioned at a height above

ground that reduces, eliminates or discourages damage

caused by animals or vandals.

South Bend, Indiana USA | networketi.com

FIGURE 3. LCD-8 installation

4

SNOW/ICE CONTROL INSTALLATION MANUAL | PART NO. 24782 REV C

Loading...

Loading...