Page 1

1

Page 2

2

Page 3

3

INDEX

1.1 Presentation

4

1.2 Warranty

5

1.2.1 Exclusions from warranty

5

1.3 Machine identification

5

1.4

Equipment 7

1.5 Machine description and use limitation

7

1.5.1 Description

7

1.5.2 Use limitation

7

1.6 Noise 7

1.7 Technical

features

8

SECTION

2:

Safety

and

prevention

2.1 Safety 8

2.1.1 General safety

regulations

9

2.2 Safety signs (Symbols)

10

2.3 Safe use and maintenance 11

SECTION

3:

Transport

and

installation

3.1 Packaging

12

3.2 Shipping 12

3.3 Unpackaging

12

3.4 Positioning

1 2

3.5 Storing 12

SECTION

4: Use

4.1 Connection to the electric

circuit

13

4.2 Preparing the

electrolyte

13

4.3 Tank

filling

14

4.4 Booster

filling

14

4.5 Preparing deoxidizer liquid

14

4.6 Hazardous operations

14

4.

7

Starting the machine

15

4.8 Stopping the machine

15

4.9 Backfire

16

4.1O

Safety devices

17

4.11 Refilling deoxidizer liquid

18

4.12 Refilling distilled or demineralized water

18

SECTION 5: Maintenance

5.1 Generalities

17

5.2 Every six months

17

5.3 Once year

18

5.4 Every four year

18

5.5 Putting the machine out of service

18

5.6 Scrapping

18

5.7 Disposing of the

electrolyte 18

5.8 Disposing of the liquid

deoxidizer 18

5.9 Trouble shooting

19

5.1O Interventions

21

5.10.1 What to do in order to see if the tank is short-circuited

21

5.10.2 Controlling pressure, adjustment valve

21

5.10.3 Checking valve tightness 22

5.10.4 Replacing the valve

22

5.10.5 Replacing the

electrolyte

23

SECTION

6:

Spare

parts

6.1 Spare parts

23

FIGURELIST

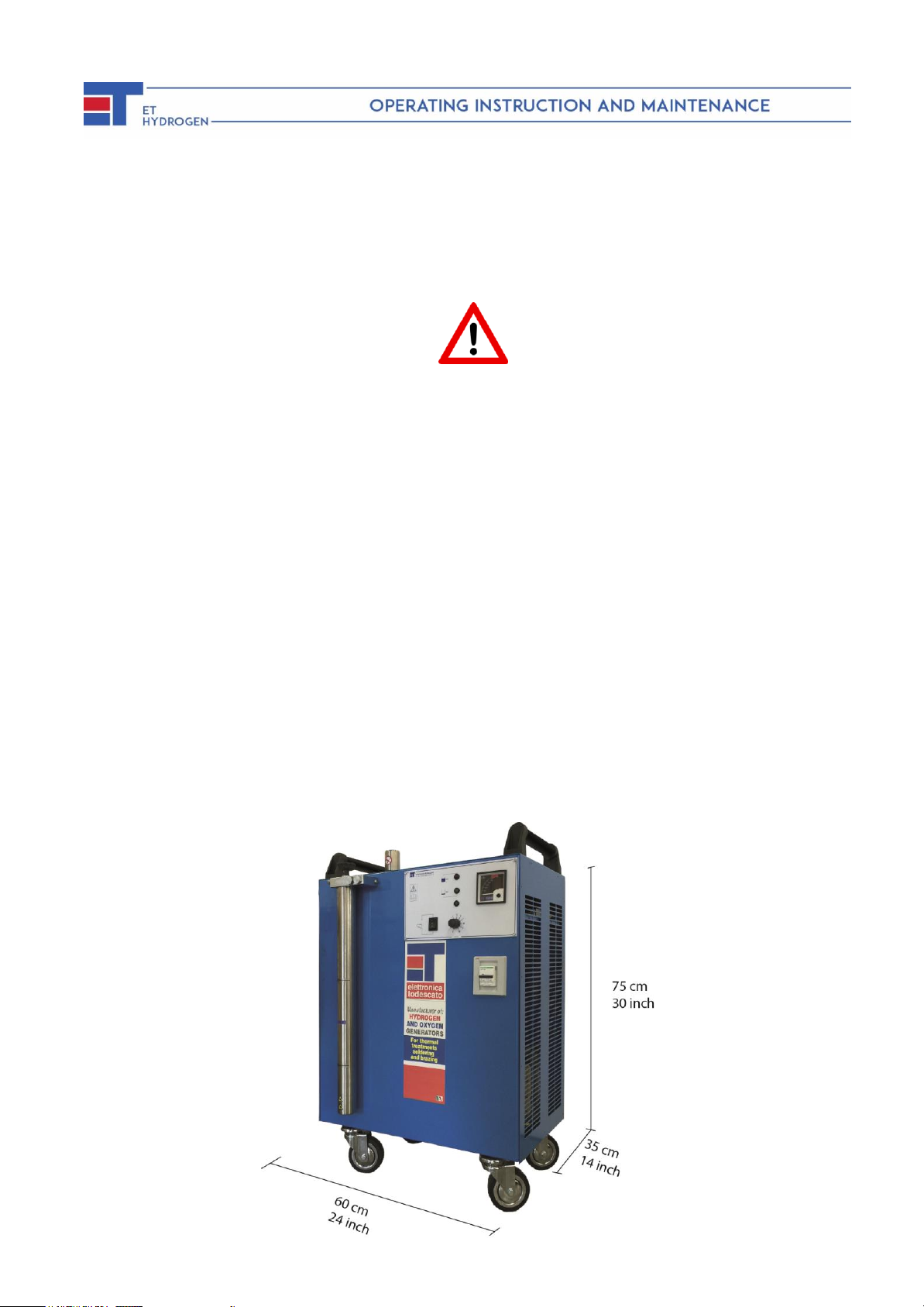

Fig. 1 Welding and components

6

Fig.2

Machine Layout

8

Fig. 3 Safety signs

10

Fig.4 Valve replacement

22

Fig.5 Spare parts

24

Fig. 6 Wiring diagram 27

Tab.6 Special torch 30

Page 4

4

SECTION 1

Description and main features of the welder

1.1 PRESENTATION

This manual gives information regarded as necessary to know, use correctly and carry out normal

maintenance operations on this welder « L/45 » (hereinafter referred to as machine) fabricated by

«Elettronica Todescato S.r.l.» di Arcugnano (Vicenza) Italy (hereinafter referred to as Manufacturer).

The material in this manual is not intended to be a complete description of the parts nor a detailed

explanation of their option. The user, however, will find the kind of information normally required to

operate the machine correctly and safely and also to keep in good working condition.

Compliance with and observance of what is described in the manual is an essential condition for the

trouble-free operation, long life and cost effective performance of the machine.

ATTENTION

Failure to observe the instructions in this manual, negligence, incorrect or improper use of the

machine can be cause of machine warranty coverage cancellation by manufacturer.

Manufacturer therefore declines any and all liability for injury to people or damage to property

caused by failure to follow the instructions given in this manual.

Service work or overhauls involving complex operations must be entrusted to an authorized Technical

Service Center which has the necessary specialized personnel, or directly to the Manufacturer who is at

your complete disposal to ensure fast and complete technical assistance and anything else that can

promote improved operation and optimal performance by the machine.

DANGER

This manual must be kept in a safe place at the disposal of the operator and service engineer,

for consultation at any time during the machine’s entire working life. It should be delivered with

the machine if the latter is sold.

The manual must be kept in a safe place that is familiar to the assigned personnel. It is the

responsibility of the personnel to keep the manual complete to allow for a consultation for the

entire life of the machine. If the manual is damaged or lost, a copy must be immediately

requested to the Manufacturer.

Page 5

5

1.2 WARRANTY

Elettronica Todescato Srl ensures that the machine referred to in this manual has been tested in its own

premises. The machine is guaranteed for 1 year (12 months) from the date of purchase. Should the machine

be tampered with or improperly used, particularly concerning the safety devices, the warranty will be voided

and the manufacturer will be discharged from any liability whatsoever. Upon delivery, make sure that the

machine has not suffered damage during transportation and that it is complete with all standard accessories

and any optional equipment specifically ordered. Complaints must be written and submitted to your reseller

within and not later than 8 (eight) days.

1.2.1 EXCLUSIONS FROM WARRANTY

This warranty shall be null and void (apart from the causes given in the Purchase Contract):

- If the machine is used with incorrect voltage.

- If the damage is due to insufficient maintenance or lack of proper service.

- If, following repairs carried out by the owner without manufacturers consent due to installation of nonoriginal spare parts, the machine has been changed and the damage was caused by these changes.

- If the instructions given in this manual were not followed correctly.

- Exceptional events.

Damage caused by negligence, lack of care, improper and bad use of the machine or incorrect maneuvering

by the operator shall also cause this warranty coverage to be null and void.

ATTENTION

Removal of safety devices installed on the machine will automatically make this warranty null and

void of the Manufacturer.

1.3 MACHINE IDENTIFICATION

Each machine is equipped of identification plate (fig.1 # 21), giving the following information:

- Name and address of Manufacturer;

- «CE» mark;

- A) Machine type;

- B) Year of fabrication;

- C) Serial number;

- D) Voltage;

- E) Ampere;

- F) Watt;

- G) Frequency;

- H) Pressure.

The data given on the identification plate should be written in the spaces provided on the back cover

of this manual and should always be specified when ordering spare parts or requesting Technical

Assistance.

Page 6

6

...

-

.

FIG.

1 -

WELDING AND

COMPONENTS

LEGEND

Fig.1

1.

Three-position

switch

2. Safety cap

3.

Circuit

breaker

4.

Power control

knob

5.

Minimum level indicator light

(yellow)

6.

Maximum level indicator light

(red)

7. Booster

8. Hand le knob

9. holder

10. On

indicator l

ight

11.

Shut-off

valve-

12.

Gas supply indicator

1/hour

13. Flame arrester cap

14.

Check valve

cap

15.

Special torch (brass nozzle

type)

16.

Standard torch (needle

type)

17. Wheel

42. Torch hose fitting & shut- off valve

43. Burner

tip

51. Power

cord

230

V.50

Hz.

56. Torch hose

66. Torch hose fitting

68. Identification plate & her position

Page 7

7

1.4 EQUIPMENT

Standard Eq

uipment:

−

Burner tip

− Spare fuse.

− power cord

− fire proof rubber hose

− plastic funnel

−

User Manual

Optionals:

− Can containing liquid deoxidizer.

− Can containing

−

Torch

holder

−

2.5 Bar pressure gauge.

− One Year Maintenance Kit

− MACHINE DESCRIPTION AND USE LIMITATION

The

«ET- hydroge

n L/350 Welder

is a

machine marked

with «CE» symbol in compliance

with European Union

regulations

pursuant to

EEC Directive

2014/35/UE and 2014/30/CE

as

detailed in the UE

Declaration

of

Conformity annexed to

each

machine.

DESCRIPTION

The «ET Hydrogen Welder L/350» can be used in craftwork or industrial workshop with a

minimum volume of 30 m³ and provided with natural ventilation by means of suitable openings to

the outside in compliance with the regulations in force in the user’s country. This machine is mainly

used for soft and hard brazing applications in the fields of jewellery, goldsmith, costume jewellery,

dental mechanics, micromechanics, and for welding materials such as platinum, beryl, nickel,

thermocouples, enamel copper, glass, quartz and for welding metal to metal and applicable for

welding in industry, within the limitations of the machine.

USE LIMITATIONS

The hydrogen and oxygen mixture produced by this welder must be solely used to produce one

flame for braze welding or thermal treatments of metal parts in general, or for working quartz glass.

DANGER

Any use different from those quoted here within and not included or not directly inferred

from this instructions’ manual, will be regarded as «NOT ALLOWED».

Page 8

8

It is not permitted to operate the machine when the flame is out. This would result in an

accumulation of explosive mixture in the surrounding environment and pollution caused by

the methyl alcohol.

The machine has been designed for professional use. The operator must be of proven

ability and capable of reading and understanding the instructions given in this manual.

The operator must also use the machine in accordance with the ruling accident prevention

standards, operating conditions and characteristics of the machine.

DANGER

THE USE OF THE MACHINE FOR ANY OTHER PURPOSE THAN THAT DESCRIBED IN THIS

MANUAL RELIEVES THE MANUFACTURER OF ANY RESPOSIBILITY FOR DAMAGES TO

PERSONS, ANIMALS OR THINGS RESULTING FROM INAPPROPRIATE USE.

1.6 NOISE

The noise level (acoustic pressure) was determined with the machine running under no load

conditions with the readings of the 70 dB(A) inferior.

1.7 TECHNICAL FEATURES

/

Page 9

9

FIG. - MACHINE LAYOUT

H2/O2 Gas production

It/h

350

Water consumption

gr/h

175

Alcohol consumption

gr/h

57

Booster tank capacity

Lt

0,68

Maximum power

Watt

1500

Electrolyte

Lt

6,6

Weight

Kg

95

TABLE 1

SECTION 2

Safety and Prevention

2.1 SAFETY

The owner of the machine must instruct personnel about the risk of industrial accident, the safety

device installed for operator safety and on general industrial accident prevention regulations applied

by law in the country where the machine is to be operated.

Operator safety is a matter of considerable importance for machine design and fabrication. When

designing a new machine, every effort is made to foresee every possible dangerous situation and,

naturally, adopt suitable safety devices to counter them. Therefore, a careful reading of this manual

and special care and attention whenever any intrinsically operations have to be carried out are

obligatory.

DANGER

Manufacturer declines any and all liability for injury to people or damage to things caused by failure

to follow this safety regulation and accident prevention recommendations detailed here.

Pay further attention when you see this symbol in the manual.

2.1.1 GENERAL SAFETY REGULATIONS

Page 10

10

ATTENTION

Failing to comply with the information described in «Section 2 – Safety and Prevention» and

the mishandling of the safety devices relieves the Manufacturer from any responsibility in

the event of accidents, damage or machine malfunctions.

General rules:

- The user undertakes to entrust the machine to qualified and trained personnel only.

- The user is bound to take all the necessary measures for preventing unauthorized

personnel from accessing the machine.

- The user undertakes to provide its personnel with adequate information regarding the

application and observance of the safety regulations. To this end, the user undertakes to

ensure that all the personnel understand the machine operating instructions and the safety

regulations relative to their particular responsibility.

- The user must inform the Manufacturer of any defects or malfunctions in the accident

prevention system and any situations of potential danger.

- The personnel must use the personal protection items provided for by law and respect

instructions given in this manual.

- The personnel must respect the danger and caution symbols on the machine.

- The personnel must not perform operations or interventions under their own initiative that lie

outside their competence.

- The personnel is obliged to notify superiors of any problem or dangerous situation that may

arise.

- The machine has been commissioned and tested with all the parts included within the

standard equipment. The installation of parts or other makes or modifications to the machine

may vary its characteristics and compromise its operating safety.

- The machine must only be used for the purpose for which it was constructed.

2.2 SAFETY SIGNS (Symbols)

During the construction of machine, all the possible solutions for the safety the operator have been

adopted. The machine may nevertheless present ulterior risks which have not been possible to

eliminate completely under certain operating conditions. These risks have been highlighted on the

machine with adhesive warning symbols that indicate the various situations of reduced safety or

danger.

ATTENTION

Keep the safety stickers clean and replace them immediately if they are peeling away or are

damaged.

Page 11

11

The following warnings refer to Figure 3. Read them carefully and learn their meaning.

1) Excessive voltage. Before interventions, disconnect power.

2) Toxic substance, if swallowed. Do not inhale the vapors.

3) Easily flammable.

4) Corrosive liquid when in touch with body members.

5) Attention, electrostatic discharge sensitive device.

6) Flammable. Do not approach free flames.

7) Use protection glass.

8) Use protection mask for respiratory tract.

9) Use protection gloves.

10) Before using the machine, read the operating instructions carefully.

11) Attention, do not turn the handle knob while the flames are lit.

Page 12

12

FIG. 3 ·S· AFETY SIGNS

2.3 SAFE USE AND MAINTENACE

ATTENTION

- The use of the machine is prohibited to:

o Operators who have not read and understood the instructions given in this manual;

o Inexperienced persons;

o Operators not in good physical/mental health.

- Periodically check that the machine and its protection devices are in perfect working order.

- Before maintenance operations or repairs on the machine, disconnect power.

- Maintenance operations and repairs must only be carried out by personnel trained to

perform these special functions.

- At the end of the maintenance operations and repairs, before restarting the machine, the

technical foreman must check that the work has been finished, the safety device

reactivated and the protections reassembled.

- The spare parts must correspond with those stipulated by the Manufacturer. Only use

original spare parts.

Page 13

13

- During maintenance operations and repairs, protective clothing must be worn, i.e.

protective eyewear, gloves for preventing cuts and mask for respiratory tract protection.

- Do not use water jets to clean the machine.

SECTION 3

Transport and Installation

3.1 PACKAGING

The welder is wrapped up in a polythene film and subsequently packed in a three-layer waterproof

cardboard box sealed with adhesive tape and secured by a double strap.

3.2 SHIPPING

Whatever transportation method is used, (either by plane, sea or land) continental or

intercontinental, the machine tanks will be empty.

If REQUESTED or where PERMITTED:

The packaged electrolyte salts and/or bottled demineralized water, will be shipped according to

the rules, law and regulations of the machine’s destination (country).

3.3 UNPACKAGING

Make sure that:

- The welder has not suffered damage during transportation and, if necessary, report to the

manufacturer or authorized reseller.

3.4 POSITIONING

Set the welder on a solid and stable surface, away from heat sources. Allow at least 50 cm of free

space for the cooling louvres on the machine sides, for proper air circulation.

3.5 STORING

When the welder is in storage, the tank must be filled with electrolyte (Fig.5 # 46) and the machine

must be started for a few minutes at least once a month.

Avoid storing in humid places.

Page 14

14

SECTION 4

Use

4.1 CONNECTION TO THE ELECTRIC CIRCUIT

Check that the main voltage corresponds to the voltage indicated on the plate at the rear of the

welder (Fig. 1 # 21). Test the electrical circuit grounding to make sure that is it efficient.

- Slide the switch (Fig.1 # 1) to the “O” position.

- Insert power cable plug (Fig.5 # 31) into the current outlet.

4.2 PREPARING THE ELECTROLYTE

Pour 180 grams of KOH (Potassium Hydroxide) into a clean stainless-steel vessel and/or hard

plastic container that has been previously filled with 0,445 liters (0.118 US gal) of distilled or

demineralized water. If the vessel needs to be cleaned, wash it with tap water a few times, until it

becomes clean and after that, dry it with a rag. Stir immediately but gently, using a clean stainlesssteel implement, until the product is fully dissolved, producing a reaction that generates heat. Wait

until the solution has cooled down. DO NOT USE DETERGENTS OR LIQUID SOAPS.

DO NOT PREPARE the electrolyte solution inside the machine tank. It must be prepared into an

external vessel BEFORE being introduced inside the machine tank.

DANGER

AVOID SPILLS. ALLOW COOLING TIME.

THE ELECTROLYTE IS HIGHLY CAUSTIC AND CAN CAUSE SERIOUS SCALDS TO THE

SKIN AND HUMAN BODY. WHEN HANDLING THIS PRODUCT, ALWAYS MAKE SURE THAT

A CONTAINER FULL OF WATER AND VINEGAR IS WHITHIN REACH, IN ORDER TO BE

ABLE TO WASH IMMEDIATELY ANY PART THAT COMES INTO CONTACT WITH THE

PRODUCT AND SUBSEQUENTLY RINSE CAREFULLY WITH RUNNING WATER.

THE USE OF PROTECTIVE CLOTHES, GLOVES, GLASSES, MASK FOR RESPIRATORY

TRACT, IS OBLIGATORY.

IF THE PRODUCT COMES INTO CONTACT WITH THE EYES, WASH AND RINSE THEM

REPEATEDLY AND IMMEDIATELY, THEN TAKE THE AFFECTED PERSON TO A FIRST AID

STATION.

4.3 TANK FILLING

1) Slide the switch (Fig.1 # 1) to the “=” position; the green indicator light (Fig.1 # 12) and the

“MIN” yellow indicator light (Fig.1 # 5) on the control panel will be illuminated.

Page 15

15

2) BEFORE ANY RE-FILL OPERATION, REMOVE THE BOOSTER TANK (FLUX)

ALWAYS FIRST, (Fig 1 # 7).

3) Remove the safety cap (Fig.1 # 2).

4) Through the use of a funnel, slowly pour the electrolyte previously prepared thought the

filling neck (Fig.1 # 3) and into the tank (Fig.5 # 46). The “MAX” yellow light (Fig.1 # 5) will

go out. If the “MAX” red light (Fig.1 # 6) does not shine after all the electrolyte has been

poured into the tank, add distilled or demineralized water until the light is illuminated.

DANGER

IT IS RECOMMENDED THAT NO WATER IS POURED WHEN THE RED LIGHT IS ON.

5) Put the safety cap back into place (Fig.1 # 2) and tighten it. Do not over tighten.

6) Slide the switch (Fig.1 # 1) to the “O” off position.

IMPORTANT NOTE:

For the first startup of our ET systems, or for the yearly maintenance (once every year), the

machine must be filled or refilled with electrolyte solution.

For the daily refill it is mandatory to pour only demineralized (or distilled) water inside the

electrolyte tank

Pouring electrolyte solution daily will cause a crystallization inside the tank and

consequent obstructions of machines’ hoses, potentially causing a general malfunction.

4.4 BOOSTER TANK FILLING

1) Loosen the handle knob (Fig.1 # 8) and remove the Booster Tank (Fig.1 # 7).

2) Pour the deoxidizer liquid (see sec. 4.5) into the Booster Tank until it reaches the “MAX”

marked on the outside. Do not pour liquid beyond this level.

3) The eventual electrostatic charge of your body may cause a spark and flame up the

liquid deoxidizer, this is to be avoided. Therefore take a moment to discharge your

electrostatic charge on another metal object before approaching the Booster Tank.

before approaching the Booster Tank while on its seat, you touch, for a moment with the

other hand, the Booster holder (Fig.1 # 9). Repeat this operation each time you perform the

Booster filling deoxidizer.

4) Place the Booster Tank back into place (Fig.1 # 7) and tighten the handle knob (Fig.1 # 8),

just enough. Do not overtighten in order to preserve the gaskets’ integrity.

4.5 PREPARING FLUX (DEOXIDIZER) LIQUID.

Page 16

16

DANGER

METHYL ALCOHOL IS BOTH FLAMMABLE AND TOXIC. HANDLING MUST TAKE PLACE

AWAY FROM FLAMES, SPARKES AND HEAT SOURCES. IN GENERAL AVOID CONTACT

WITH THE MOUTH AND AVOID INHALING ITS VAPORS.

By dissolving boric acid with methyl alcohol (as explained hereunder) you will obtain a green flame

with high deoxidizing power, that is indispensable for braze welding operations, since it ensures

optimal flow and penetration of the solder. In the thermic treatments, methyl alcohol is normally

used in its pure state.

1) Pour the desired quantity of methyl alcohol into a plastic container provided with hermetic

seal cap.

2) Add the boric acid in the form of flakes in a proportion of 15- 20 grams. (as a maximum)

per each liter of methyl alcohol.

3) Close the container, shake it up and wait until the product is fully dissolved, before using.

4.6 HAZARDOUS OPERATIONS

DANGER

When the flames are burning:

- Do not unscrew the handle knob screw (Fig.1 # 8).

- Do not unscrew the Safety Cap (Fig.1 # 2).

- Do not bring flames or sparkles near the filling neck, the safety car and booster

tank/booster holder (Fig.1 # 2, 3, 7, 9).

- Do not introduce metal objects inside the tank (Fig.5 # 46).

4.7 STARTING THE MACHINE

1) Connect the welder to a current outlet.

2) Mount the burner tip onto the torch cone by screwing it and pushing it into place, until it is

tight enough (Fig.1 # 11).

3) Set the power control knob (Fig.1 # 4) according to the indications shown in Table 2.

4) Slide the switch (Fig.1 # 1) to the “-“ position. The green indicator (Fig.1 # 12) and red

indicator (Fig.1 # 6) will be illuminated.

Page 17

17

5) Wait for approximately two minutes, until you hear/feel the emission of gas from the burner

tip (Fig.1 # 11).

6) Light the torch with a standard lighter or an electronic igniter.

Clean the orifice (Fig. 1 # 11) with a thin steal wire or other similar safe object, in order to not

cause personal harm or damage the burner tip. You may also put the burner tip in luke warm

water for the cleaning of the orifice.

DANGER

Yo

u can adjust the flames

by manually operating

on the power

control

knob

(Fig. 1 # 4)

provided

that you

keep

within

the

liter/hour limit

values in the

indicator

, (T

able 2*A / 2*B ). Setting

the

power

level below

the

minimum

value allowed, will cause a pressure drop

that

would

melt the

burner tip, resulting in backfire

in

the

booster.

WARNING : With a full tank the welder will operate 6-8 Hours.

4.8

STOPPING THE

MACHINE

To turn off the welder, you must perform the following operations:

1) Put out the flame by turning rapidly the shut-off valve

(Fig. 1 # 42) and turn power knob to the zero position.

DANGER

If

this

operation

is

performed

slowly, it

can

result

in

backfire.

2) Slide the switch (Fig.1 # 1) to the

"O" p

osition.

ATTENTION

After

turning

off the

machine

and

throughout the necessary cooling

time

(approx. 5 hours)

do

not

unscrew the safety cap this should happen, tighten

it

back and start the

machine

for 30

seconds, with

the

power control

knob (

Fig.

1 # 4) set

on the

maximum value.

ATTENTION

Clean the

orifice

of the burner

tips (Fig.1 # 43) with a

thin steel wire daily, before

starting

the

welder.

4.9 BACKFIRE

Backfire can occur for the following reasons:

-when putting the flame out and the movement has

been

performed too

slowly;

(on the contrary, this operation

should be done

rapidly,

as described above).

- The burner tip diameter is greater than the diameter

recommended in Table 2*A or 2*B.

-The gas delivery is insufficient, due to wrong power setting.

-

- Failure in the welder electric circuit.

- Lack of voltage in the supply channels.

- Obstruction or gas leakages.

- Lack of deoxidizer.

Page 18

18

- Backfiring causes a detonation in the booster and

if there is no deoxidizer the flame

will

reach the flame

arrester.

In about

20

seconds the

power supply indicator will

be

cut off

and the gas

supply indicator

( Fig. 1 # 12)

will

move

back to

zero . To

restart the welder,

you must perform the following

operations:

1)

Turn off the

welder.

2)

Unscrew

the safety cap (Fig. 1 # 2).

3)

Remove

the

flame arrester

cap (

Fig.

4 #18)

and replace the flame arrester (Fig.

4 # 51) and gaskets

(

Fig.

4 # 52

and 54

).

4)

Pour liquid deoxidizer into the

Booster until it reaches

the required level; reassemble and start the

welder.

4.1O

SAFETY DEVICES

- Safety cap

releases overpressure

in

excess

of

Bar

.

- Pressure switch:

cuts off gas production when

pres

sure exceeds

1.7bar.

- Flame arrester:

stops

the

flame propagation

in the

tank and cuts off the gas

supply.

4.11

REFILLING DE-OXIDIZER LIQUID

This

operation

must be

performed

after 6-8 working

hours,

o r

when you see that the flame is fading

and

getting

shorter, refill the with additional flux.

1)

Put out the

flame.

2)

Turn

off the welder.

3)

Unscrew the handle knob ( Fig.

1 # 8) .

4)

Pour liquid deoxidizer into

the Booster until it reaches

the maximum

level

by using the marked plastic

sticker. (

Fig.1 # 7)

5)

Reassemble

the Booster cap and

tighten.

Do not over tighten.

4.12 REFILLING DISTILLED

OR

DEMINERALIZED WATER

ATTENTION

The water used up by the machine must be refilled.

The operation must be performed when the yellow indication light is on (Fig.1 # 5).

1)

Slide the switch

(

Fig.

1 # 1)

to

the "="

position.

2) With a clean funnel, pour slowly distilled or

demineralized water through the filling neck (Fig. 5 # 28) until

the

"MAX"

red light indicator (Fig.1 # 6) is

illuminated. (Do not add more water than necessary). The

generator

autonomy of

operation

is 6-8 hours.

3)

Tighten the safety cap (Fig:1 # 2) Start the· welder

tor at l

east

2-3

minutes

or

for all the time necessary.

Page 19

19

SECTION 5

MAINTENANCE

5.1 GENERALITIES

ATTENTION

Any maintenance operation inside the welder must be performed solely by adequate

technicians who have been officially trained.

DANGER

INSIDE THE MACHINE, THERE ARE LIVE COMPONENTS (230 OR 115 VOLT AC),

CONTACT WITH THESE PARTS CAN CAUSE ELECTRIC SHOCK.

5.2 EVERY SIX MONTHS

Disconnect the plug from the intake.

Remove the Booster Tank, the handle knob and the gaskets. Remove encrustations from the

hole and the round groove underneath the Booster Holder.

We recommend to replace the booster gasket and the handle knob O. ring every six

months. (Fig. 5 # 22, 24).

To clean eventual encrustations on the bottom of the Booster Tank and inside the torch proceed

as follows:

1) Remove the liquid deoxidizer from the Booster Tank, soak it horizontally together with the

torch in a container filled with about 6 cm of water.

2) Provide boiling for at least 30 minutes time necessary to complete dissolution of

encrustations.

5.3 ONCE A YEAR

For optimal performance and safety measures it is necessary to replace the following parts:

- Check valve

- Electrolyte solution

- Torch fireproof rubber hose

- Gasket set

Page 20

20

5.4 EVERY FOUR YEARS

Every four years the machine must undergo a complete technical and operational review. Such

operation must be performed by the manufacturing firm or by skilled technical personnel.

ATTENTION

The manufacturing firm is not liable for any damage caused by the machine due to lack of

review.

NOTE: The tank O.ring MUST be replaced every five (5) years according to the

manufacture’s specifications.

5.5 PUTTING THE MACHINE OUT OF SERVICE

1) Empty the electrolyte and rinse the tank.

2) Empty the liquid deoxidizer from the Booster Tank.

3) Disassemble the machine components and store them separately, according to the

material they are made of.

5.6 SCRAPPING

Hand the materials that can be salvaged to companies specialized in recycling raw materials.

5.7 DISPOSING OF THE ELECTROLYTE

Neutralize it to PH7 by adding hydrochloric acid (and small part of albite in powder) and give

disposition to an authorized company that handles toxic waste material.

5.8 DISPOSING DEOXIDIZER LIQUID

It can be regenerated by distillation. Alternatively, it must be handed over to a company

specialized in the disposal of toxic products.

5.9 TROUBLE SHOOTING

We list hereunder the most frequent, operational complications, failures, relevant causes, and

provide a brief description on how to repair or adjust the equipment in order to guarantee an

adequate condition of the equipment in use that respects the manufacturer’s parameters.

Ensuring proper safety standards are abided by, maintaining functional performance, while

keeping the integrity of the warranty guarantee established by the manufacturer.

Page 21

21

MALFUNCTION

CAUSE

REMEDY

1) The pointer of the gas

supply

indicator (Fig.1 # 20)

returns back to zero.

- The burner tip diameter

is insufficient.

- Obstructions due to

scale formation.

- Change the burner tip –

see Table 2.

- Clean the apparatus

See sec. 5.2

2) The flame is faint and

elongated, its contours

blurred. The flame

heating power is

insufficient.

- The electrolyte has

been contaminated by

foreign matter, such as

methyl alcohol, oil,

grease, etc…

- Replace the electrolyte

(sec. 5.10.5).

- Check the tightness of

the valve (sec.5.10.3).

- Replace the valve, if

necessary (sec. 5.10.4).

3) The flame cannot be

lighted or is very short.

Obstructions due to scales or

there is a gas leakage in the

pneumatic channels

(see par. 5.2).

Gas leakage: Do not

depressurize the machine and

remove the power cable.

Start with a brush, spread soapy

water all over the fitting and

Booster Tank, below the Booster

holder (Fig.5 # 7, 9, 17), on the

torch hose fittings and torch

cones (Fig.1 # 10, 15, 16). If you

see bubbles coming up, it means

that there is a gas leakage.

Replace the safety cap if

necessary.

ATTENTION: the same

operation can be performed on

the fittings and hoses inside

the welder. In this case unplug

the welder, for there are live

components (230 or 115 Volt

AC) inside.

4) The flame is shortened

even when the power

control is set at

maximum value.

- The electrolyte has been

completed or is contaminated

with substances.(Section 5.10.5).

- The power circuit board is

faulty.

- One of the two rectifier diodes

(Fig. 5 # 27) is not conducting.

- Change the electrolyte

solution.

- Substitute the power

circuit board (Fig.5 # 19).

How to spot the faulty diode:

1. Remove the cover (Fig.5

# 32) from the frame.

2. Start the welder and let it

work for 5-6 minutes with

Page 22

22

the flame off and the

power control set at the

maximum value.

3. Unplug the welder and

touch immediately the

body of the two rectifier

diodes.

4. The temperature of the

faulty diode is lower than

that of the other diode.

How to replace the faulty

diode:

Spread silicone grease all over

the contacts surface of the new

diode, mount it and tighten the

stop nut underneath using

dynamometric wrench set from

0,25 to 0,32 Kgm.

5) When starting the

machine the fuse blows

out (Fig. 5 # 49).

- Faulty Power circuit

board.

- One of the rectifier diode

is short- circuited.

- Short- circuit inside the

tank (Fig. 5 # 46), due to

accidental introduction of

a metal object.

- Short- circuit of the tank

cover (Fig. 5 # 43) with

the tank, due to over

compression of the cover

“OR” (Fig. 5 # 45).

Substitute the power circuit bard

How to spot the short- circuit

diode:

1. Disconnect the terminals

of the two diodes (Fig. 5

# 27) from the cooper flat

conductors.

2. Using an OHM meter (at

OHM 1) measure the

resistance between the

body and the diode,

nominal value of 6002000 OHM. The

defective diode, gives a

very low value even if

you invert the OHM

Meter points.

3. Replace the faulty diode.

- The power transformer

(Fig. 5 # 39) is shortcircuit.

- The fan motor (Fig. 5 #

29) is short- circuited.

- There is a leakage in

the electric circuit.

1. Empty the tank (Fig. 5 #

46) and dry

accordingly, verify that

the anode in (Fig. 5 #

43) and that it is

isolated from the

cathode (Fig. 5 # 46).

2. Dismount the anode

(Fig. 5, and remove the

metallic object causing

the short- circuit.

3. Verify that the O Ring

in (Fig. 5 # 45) is

mounted correctly and

that the isolators (Fig. 5

# 38) are inserted in

such a way that the

Page 23

23

anode is not in contact

with the cathode.

4. If the transformer is

short- circuit,

substitute the item.

5. Change the ventilator if

needed.

6. Verify that the internal

cables are isolated or

that there is no shortcircuit caused by the

liquid consumed

internally, if so, clean

with demineralized

water conductors or

components damaged.

7. Substitute the diode

making sure that

special care is taken to

put silicone on the

surface of the new

diode, tighten the diode

with parameters of 0,25

– 0,32 Kgm.

6) No gas comes out of

the burner tip.

- Check valve blocked.

- Torch/ burner tip

obstructed.

- Booster tank

obstructed.

- Gas leakage in

pneumatic channels.

- Replace the check

valve.

- Clean the apparatus

See sec. 5.2.

In case of gas leakage,

repeat steps REMEDY 3

above.

7) Burner Tip (burns) and

Back Flame occurs.

- Flame is lit before the

pressure arrives at the

burner tip.

- Burner tip excessively

big whilst the the

power regulator too

low.

- Turning machine off

while leaving the flame

mistakenly on.

- Unscrew safety cap or

booster tank while

flame is lit.

- Gas leakage in

pneumatic channels.

- Before opening flame,

wait approx. 2 minutes

to verify that the gas

comes out of the

burner tip.

- Consult Table 2.

- Always turn flame off

before turning machine

off.

- Turn flame off, before

removing booster tank

or safety cap.

- In case of gas leakage,

repeat steps REMEDY 3

above.

Page 24

24

8) The flame appears Red

or fluctuates.

- Flux / deoxidizer is

consumed.

- Liquid levels are above

max limits.

- Humidity Accumulation

in the torch channel.

- Soapy substance

internally formed,

caused by

contamination.

- Substitute with new deoxidizer.

- Remove excessive

liquids until reaching

the proper indication.

- Remove accumulated

humidity, dismounting

the torch and tubes,

drying them.

- Empty tank, repeat

periodically with water

then substitute the

electrolyte solution.

Page 25

25

5.10 INTERVENTIONS

5.10.1 WHAT TO DO IN ORDER TO SEE IF THE TANK IS SHORT- CIRCUITED

1) Disconnect the plug from the correct outlet.

2) Remove the screws and remove the two copper conductors (Fig.5 # 50) from the tank cover

(Fig. 5 # 43).

3) Turn on the machine.

If the fuse blows out: see Trouble shooting sec. 5.9

If, on the contrary, the fuse does not blow out, perform the following operations:

1) Empty the electrolyte.

2) Disassemble the tank cover in the following order: First remove the hose from fitting

(Fig. 5 # 40), then the connectors of the two level sensors (Fig. 5 # 42, 44), paying special

attention to the order of the connections, and the four nuts (Fig. 5 # 36).

3) Remove any metal object from the tank.

4) Replace the tank cover “O.ring” (Fig. 5 # 45), replace the cover insulators (Fig. 5 # 38) if faulty,

center the tank cover and make sure that the “O.ring” is positioned properly in its seat.

5) Tighten the four nuts first manually and then by using a wrench.

6) Connect the hose to the fitting, connect the level sensors and the two copper conductors.

7) Refill the tank with electrolyte.

5.10.2 CONTROLLING PRESSURE, ADJUSTING THE VALVE

1) Turn off the machine and remove the safety cap (Fig. 5 # 2).

2) Fit the pressure gauge on the filler neck (Fig. 1 # 3).

3) Unscrew the check valve cap (Fig. 1 # 13).

4) Turn the power control knob (Fig. 1 # 4), to the maximum power level.

5) Start the welder and wait until the pressure reading on the pressure gauge is stable. Pressure

should be 1.1 Bar.

5.10.3 CHECKING VALVE TIGHTNESS

When the welder is on, the working pressure must be approximately, (1.0- 1.2 Bar). Then, after turning

off the welder, check that the pressure reading on the pressure gauge drops to the approx. 0.5 Bar,

over 5-6 minutes. If the pressure drop is greater than 0.5 Bar, replace the valve (see. 5.10.4).

ATTENTION

Page 26

26

If is very important that the valve is tight, since this enables the machine to maintain a

minimum pressure of approx. 0.3 Bar inside the tank, even after several hours. Keep in mind

that when the machine is not working, the tank cools down causing a pressure drop. If for

some reason there is a total lack of pressure, the methyl alcohol contained in the Booster Tank

would be sucked in, thus contaminating the electrolyte.

5.10.4 REPLACING THE VALVE

1) Turn off the welder and remove the pressure gauge or safety cap (Fig.5 # 2).

2) Unscrew the check valve cap (Fig. 4 ; A # 13).

3) Unscrew the threaded disk (Fig. 4; B # 21).

4) Remove the valve and relevant “O.ring” from the seat.

5) Install the new valve and relevant “O.ring” (Fig. 4; C # 23, 53).

6) Tighten the threaded disk 21, the check valve cap 13, and safety cap (Fig.1 # 2).

7) Check pressure (sec. 5.10.3).

A B C D

FIG. 4

Page 27

27

5.10.5 REPLACING THE ELECTROLYTE

1) Empty the exhausted electrolyte.

2) Pour 0,445 Lt (0,118 US gal) of demineralized water into the tank, shake well and empty.

3) Repeat this operation until the water that comes out is clean.

4) Pour the new electrolyte into the tank (sec. 4.2).

SECTION 6

SPARE PARTS

6.1 SPARE PARTS

Orders for spare parts should be sent to the Manufacturer or Authorized Distributor specifying the

following information:

- Machine Model.

- Serial Number.

- Year of Fabrication.

- Ordering Code Number for the part required, description of the part and the number

required.

- Shipping Instructions. If this is not specified by Manufacturer, even though doing its utmost

to offer this service as efficiently as possible, cannot and it will not be liable for any shipping

delays caused by force majeure events. Transportation costs are always to costumer

account. Goods travel at buyer peril and risk even if sold carriage forward.

Lastly,the Manufacturer is at your complete disposal for any technical assistance or spare

parts needed.

Page 28

28

FIG. 5 SPARE PARTS

Page 29

29

Page 30

30

Page 31

31

Page 32

32

SPECIAL TORCH WITH FLAME ARRESTER

Before lighting the special torch you must adjust power control knob ( Fig. l # 4) so that the gas supply indicator (

Fig. l # 12) indicates liter per hour corresponding to the burner tip used as showed Tab.2* A

(See above)

WARNING: In case more torches are used, the liter of gas supply indicator must correspond to the sum of the

liters of each burner tip used

To extinguish the flame: Close by a quick movement the shut off valve (Tab.6 # 16). Subsequently reopen back

the shut off valve.

Back fire: The back fire causes the permanent shut off of the flame arrester (Tab.6 # 16) and interrupts the gas

output from the torch. The power supply will be cut off and the gas supply indicator (Fig. l # 12) will move back

to zero.

The flame arrester must be replaced

Replacement of flame arrester: Turn off the welder, unscrew the safety cap (Fig. l # 2) close the shut off valve,

unscrew the hexagon and replace the flame arrester 54 and O-ring 52 (Fig. A)

Adjust the

Power

Control Knob

and simultaneously check

the Gas Supply Indicator,

according to Min and Max

L/h (see Table 2*A)

Page 33

33

Welder L/350 Table 2*B

Standard torch

HOW TO ADJUST THE POWER ACCORDING TO NEEDLE TIP SIZE:

Table 2*B

Adjust the

Power

Control Knob

and simultaneously

check the Gas

Supply Indicator,

according to Min

and Max L/h (see

Table 2*B)

Gas supply Indicator

Page 34

34

Fig. 8 Special torch for welder mod. L/350

Page 35

35

Fig. 9 - Booster holder, handle knob and booster tank layout.

9

59

13

14

8

60

7

7 Booster tank

8 Handle knob

9 Booster holder

13 Flame arrester cap

14 Check valve cap

59 Handle knob O-ring

60 Booster rubber gasket

Page 36

36

ELETTRONICA TODESCATO Srl

36057 Arcugnano (Vicenza) Italia- Via A Volta, 9/A-C

Tel. +39- 444 289227- Fax +39- 444 289229

www.

elettronicatodescato.com e.mail: info@elettronicatodescato.com

Loading...

Loading...