OPERATING INSTRUCTIONS

G

G

M

M

V

V

2

2

-

-

K

K

Microprocessor-Based Power Supply

Subject to change without prior notice

and Analyzing Unit

for Torque Transducers

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

3

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

Content

1 GENERAL INFORMATION ........................................................................................................................................ 6

1.1 COMPANY ADDRESS................................................................................................................................................... 6

1.2 DESCRIPTION ............................................................................................................................................................. 6

1.3 FEATURES .................................................................................................................................................................. 6

2 STARTUP ........................................................................................................................................................................ 6

2.1 IMPORTANT NOTES .................................................................................................................................................... 6

2.2 FRONT PANEL OF UNIT ............................................................................................................................................... 7

2.3 CONNECTIONS OVERVIEW.......................................................................................................................................... 8

2.4 CONNECTING THE TORQUE TRANSDUCER .................................................................................................................. 9

2.5 SWITCHING ON ........................................................................................................................................................... 9

2.6 SWITCHING OFF ......................................................................................................................................................... 9

3 WHAT'S NEW IN SOFTWARE VERSION V5.1 (AF TER V4.1) ........................................................................... 10

3.1 DYNAMIC REPEAT RATE FOR KEYS........................................................................................................................... 10

3.2 AUTOMATIC CONVERSION OF THE TRANSDUCER FULL SCALE VALUE TO OTHER UNITS ............................................ 10

3.3 SUPPORTING TRANSDUCERS WITH TWO MEASURING RANGES .................................................................................. 10

3.4 IMPROVED SUPPORT FOR A NUMBER OF INPUTS ....................................................................................................... 10

3.5 UNIVERSAL INPUT RANGE FOR THE ACTIVE AND PASSIVE INPUT .............................................................................. 10

3.6 ADJUSTABLE OVERLOAD RANGE.............................................................................................................................. 11

3.7 AUTOMATICALLY TRACKING ZERO-POINT DRIFT ..................................................................................................... 11

3.8 PULSE-TYPE SCREWDRIVER MODE ........................................................................................................................... 11

3.9 STREAMLINING PARAMETER SET ENTRY .................................................................................................................. 11

3.9.1 Defaults ........................................................................................................................................................... 11

3.9.2 Hiding unused functions ................................................................................................................................. 11

3.9.3 Correction factor ............................................................................................................................................ 12

3.9.4 Filter for peak measuring ............................................................................................................................... 12

3.10 DELETING MEASURED VALUES ................................................................................................................................ 12

3.11 DETECTING NEW TRANSDUCERS AND NEW MEASURING RANGES ............................................................................. 12

3.12 POWER-SAVING FUNCTION (STANDBY) .................................................................................................................... 12

3.13 CANCEL SERIAL TRANSMISSION ............................................................................................................................... 12

3.14 CONTINUOUS OUTPUT WITH A MINIMUM 0.5 SECOND INTERVAL PERIOD ................................................................. 12

3.15 ANALOG OUTPUT ..................................................................................................................................................... 12

3.16 BATTERY PROTECTION ............................................................................................................................................ 13

4 MENU STRUCTURE................................................................................................................................................... 13

4.1 INTRODUCTION ........................................................................................................................................................ 13

4.2 DIRECT FUNCTION KEYS .......................................................................................................................................... 13

4.3 MEASURE MENU ...................................................................................................................................................... 14

4.4 MENU: DELETE MEASURED VALUE .......................................................................................................................... 14

4.5 MENU: OUTPUT ....................................................................................................................................................... 14

4.6 PARAMETER MENU .................................................................................................................................................. 14

4.6.1 Transducer ...................................................................................................................................................... 14

4.6.2 Limits .............................................................................................................................................................. 15

4.6.3 Settings ............................................................................................................................................................ 16

4.6.4 Parameter set .................................................................................................................................................. 16

5 SETTINGS .................................................................................................................................................................... 16

5.1 FUNCTIONS .............................................................................................................................................................. 16

5.2 PASSWORD .............................................................................................................................................................. 16

5.3 INITIAL SETTINGS..................................................................................................................................................... 16

5.4 DEFAULTS ............................................................................................................................................................... 16

6 INITIAL SETTINGS .................................................................................................................................................... 17

6.1 LANGUAGE .............................................................................................................................................................. 17

6.2 TIME OF DAY AND DATE .......................................................................................................................................... 17

6.3 PRINTER (SERIAL INTERFACE) ................................................................................................................................. 17

6.4 USB2.0-INTERFACE ................................................................................................................................................ 17

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

4

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

6.5 STANDBY (POWER-SAVING FUNCTION) .................................................................................................................... 17

6.6 DISPLAY ILLUMINATION .......................................................................................................................................... 18

6.7 CONTRAST OF DISPLAY ........................................................................................................................................... 18

7 MEASURING MODES ............................................................................................................................................... 18

7.1 TRACKING MEASUREMENTS .................................................................................................................................... 18

7.2 FILTER ..................................................................................................................................................................... 18

7.3 OUTPUTTING MEASURED VALUES CONTINUOUSLY .................................................................................................. 18

7.4 SPEED MEASUREMENTS ........................................................................................................................................... 19

7.5 POWER MEASUREMENT ........................................................................................................................................... 19

7.6 PEAK MEASURING ................................................................................................................................................... 19

7.7 TORQUE WRENCH MEASUREMENTS ......................................................................................................................... 19

8 THE ENTRY EDITOR ................................................................................................................................................ 20

8.1 INTRODUCTION........................................................................................................................................................ 20

8.2 SELECT SETTINGS .................................................................................................................................................... 20

8.3 ENTERING NUMBERS ............................................................................................................................................... 20

8.4 TRANSDUCER FULL SCALE VALUE ........................................................................................................................... 20

8.5 ALPHANUMERIC TEXTS ........................................................................................................................................... 21

9 THE PARAMET ER SET ............................................................................................................................................ 21

9.1 INTRODUCTION........................................................................................................................................................ 21

9.2 DESCRIPTION TEXT FOR PARAMETER SETS .............................................................................................................. 21

9.3 PARAMETER SET "0" ................................................................................................................................................ 21

9.4 PARAMETER SET DISPLAY ....................................................................................................................................... 22

9.5 PRINTOUT OF THE PARAMETER SET ........................................................................................................................ 22

9.6 SELECTION .............................................................................................................................................................. 23

9.7 CREATE NEW ........................................................................................................................................................... 23

9.8 EDITING .................................................................................................................................................................. 23

9.9 ERASE ..................................................................................................................................................................... 26

10 SCREWING TECHNOLOGY ................................................................................................................................ 27

10.1 TIME-BASED SEQUENCE DIAGRAM ......................................................................................................................... 27

10.2 TIMING .................................................................................................................................................................... 27

10.3 ANGLE .................................................................................................................................................................... 28

11 STORING MEASURED VALUES ......................................................................................................................... 28

11.1 THE MEASURED-VALUE STORAGE ........................................................................................................................... 28

11.2 THE DATA RECORD .................................................................................................................................................. 28

11.3 MEMORY SETTINGS................................................................................................................................................. 28

11.4 DISPLAYING THE STORED MEASURED VALUES ........................................................................................................ 29

11.5 DELETE MEASURED VALUES .................................................................................................................................... 29

12 PRINTING OUT THE STORED MEASURED VA LUES ................................................................................... 30

13 OPTIONAL FUNCTIONS ...................................................................................................................................... 31

13.1 BATTERY OPERATION .............................................................................................................................................. 31

13.2 PASSIVE INPUT ........................................................................................................................................................ 31

13.3 DIGITAL INPUT ........................................................................................................................................................ 31

13.4 MEASURED-VALUE TRANSMISSION GMV2-K PC ............................................................................................... 31

13.4.1 FUNCTION ........................................................................................................................................................... 31

13.4.2 MENU BAR .......................................................................................................................................................... 31

13.4.3 DATA TRANSM ISSION .......................................................................................................................................... 31

13.4.4 MEASURED-VALUE TABLE .................................................................................................................................. 32

13.4.5 STATISTIC AL ANALYSIS ....................................................................................................................................... 32

13.4.6 MEASURED-VALUE DIAGRAM .............................................................................................................................. 32

13.4.7 TORQUE WRENCH DOCUMENT ............................................................................................................................. 32

13.4.8 GENERAL INFORMATION ..................................................................................................................................... 33

13.5 INPUTS / OUTPUTS ................................................................................................................................................... 33

13.6 SHUTDOWN FOR ELECTRIC SCREWDRIVERS ............................................................................................................. 33

13.7 SHUTDOWN OF HYDRAULIC UNIT ............................................................................................................................ 33

13.8 OK OUTPUT ............................................................................................................................................................. 33

13.9 NOK OUTPUT .......................................................................................................................................................... 33

13.10 ANALOG OUTPUT ................................................................................................................................................ 33

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

5

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

13.11 EXTERNAL CONTROL ........................................................................................................................................... 34

13.11.1 Zeroadjust ................................................................................................................................................... 34

13.11.2 Storing / Printing / Erasing ......................................................................................................................... 34

13.12 MEASURED-VALUE PRINTOUT TO THE DIGIMATIC DP-1 HS ................................................................................ 34

13.12.1 Introduction ................................................................................................................................................ 34

13.12.2 Connection and preparation ....................................................................................................................... 34

13.12.3 Transmission of limits ................................................................................................................................. 35

13.12.4 Printing out the measured values ................................................................................................................ 35

14 ERROR MESSAGES ............................................................................................................................................... 35

14.1 GENERAL ................................................................................................................................................................. 35

14.2 FAULTS AND THEIR CAUSES ..................................................................................................................................... 36

15 PIN ASSIGNMENTS ............................................................................................................................................... 37

11 DISPOSAL CONSIDERATIONS ........................................................................................................................... 38

12 OVERVIEW OF THE GMV2-K V5.1 MENU STRUCTURE ............................................................................. 39

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

6

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

1 General information

1.1 Company address

ETH Messtechnik GmbH, Hagstr. 10, 74417 Gschwend, Germany

1.2 Description

GMV2-K is a microprocessor-based measuring, control and analyzing unit for the most common screwing and laboratory

applications. Due to its compact design and optional battery operation, the unit is very suited for portable use. Measured

values can be stored and printed out with date and time of day. The power-operated screwdriver can be automatically

switched off with separate power circuitry.

1.3 Features

• Menu-assisted operation and setting

• Recording torque, angle of rotation, speed and power

• For torque transducers from 1 Ncm to 100 kNm full scale value

• Shut off according to torque and/or angle of rotation (optional)

• 1000 measured-value storage

• 50 parameter set storage

• Mains operation (100V – 240V) or optional integrated charger, 8-hour battery operation.

• RS-232 port for printer

• Measured-data transmission to PC

• EMC sealed housing

2 Startup

2.1 Important notes

If the unit is opened or dismounted within the warranty period the warranty will be rendered null and void.

The unit should only be opened by qualified staff.

Only cables designed for use with the unit may be connected to it. Damage caused by connecting incorrect cables are not

covered by the warranty.

In battery operation, operation of the electric screwdriver is not possible!

The unit is not grounded during battery operation. Should current-carrying equipment be connected to the unit they must be

grounded according to technical regulations.

The full scale value displayed on the screen must always correspond with the actual transducer being used.

Where there is a risk of injury to persons and damage to equipment, the user must take appropriate safety measures (for

example, use covers, overload protection devices) (relevant accident prevention regulations should be observed!).

Due to the use of surge arresters (Varistors) an Insulation measurement according VDE 701/702 is not possible.

Please use the substitute leakage current measurement method according VDE 701/702.

The unit is not approved for service in hazardous areas.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

7

E1 < CW peak A SR : 995

↓ 8,10

P: 1 ST : 5 DR : 1 10 Nm

Zeroadj

Test

Menu

NIO ↓ 12 Grad

Error:

Charg

90%

Op no:

<Engine block-K> ID no 1234-03

ON/

OFF

Return

The four

menu keys

Key without

function

Transducer full

Torque

Angle of rotation or speed

Parameter set

number

Field for

error messages

Data

Memory number

Mode

direct function

direct function

Transducer Test

Menu tree selection

Remaining store

(number of free memory

Assessment of angle

Assessment of torque

Overall assessment

Peak status

Password level

Correction factor or filter

time

Parameter set

text

Operator no.

ID text

for data records

Automatic tracking of zero-point drift

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

2.2 Front panel of unit

record

Nm

Zeroadj /Clear

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

8

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

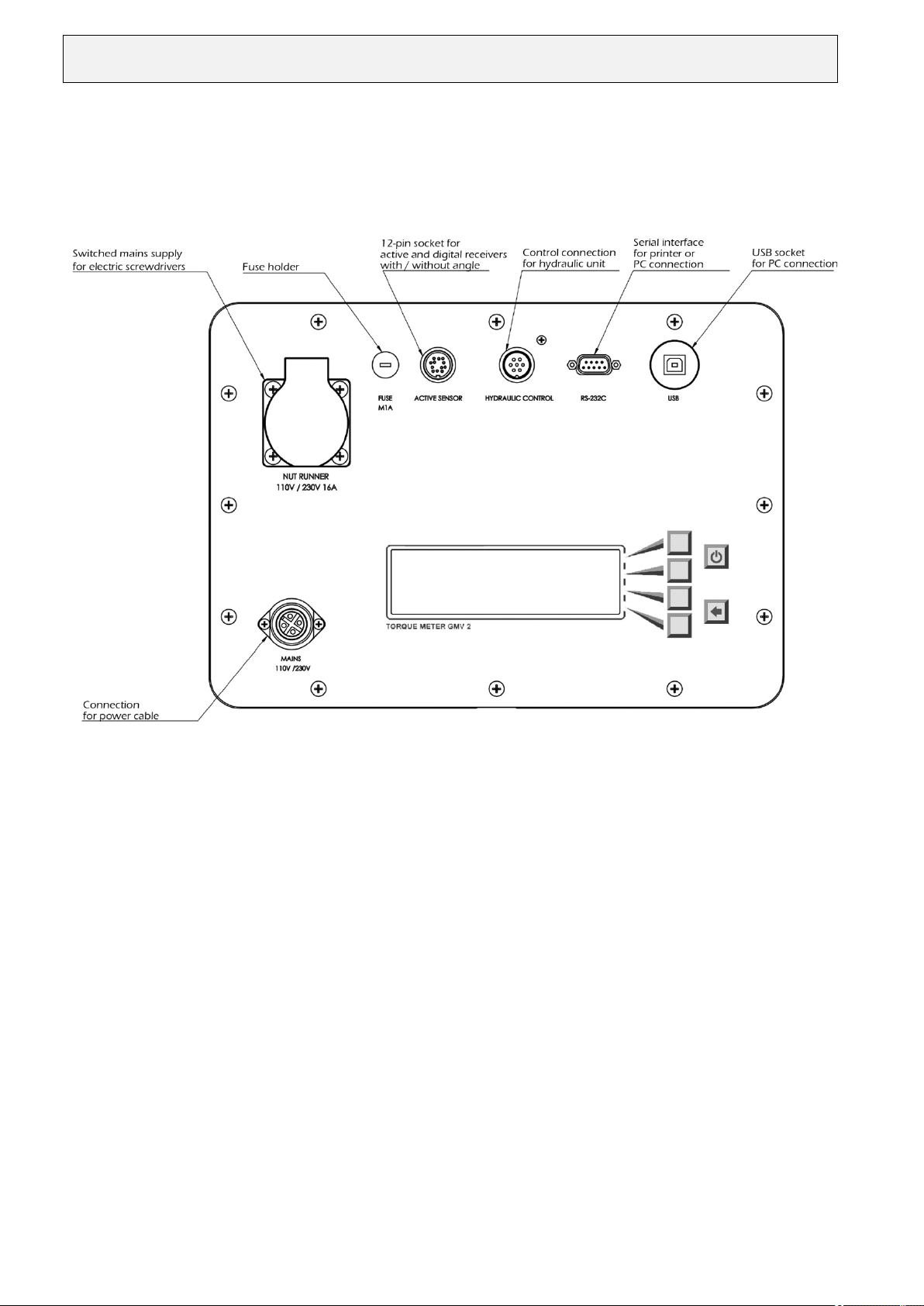

2.3 Connections overview

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

9

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

2.4 Connecting the torque transducer

Suitable connection cables are available for different types of torque transducers!

This standard GMV2-K unit has been designed for use with active transducers with a ± 1.25V to ± 10V signal. A

±0.5mV/V to ±4mV/V passive input and a digital input are available as an option. Please use the appropriate cable only

which can be obtained from ETH.

2.5 Switching on

You can switch the unit on with the button when you have checked that the cable has been correctly connected.

After a short self-test all settings valid before the unit was switched off are reloaded. The transducer is now zeroed. The

unit is then ready. If the error message "Charge!" appears now, please connect the power cable. You can now power the

unit from the mains or switch it off and let it charge for approximately five hours.

If you keep the key pressed while switching on the device, time of day, software version and the optional functions will be

displayed. The following abbreviations appear:

• V x.xx Software version

“-”

• ax Active input with adjustable input range

• px Passive input with adjustable input range

• d Digital input

“-”

• W Angle measurement

• T PC transfer

• E I/Os

• D Output for Digimatic printer

Notes:

− When the unit is being switched on the outputs are operated for a short period. The manual switch for the power-

operated screwdriver should therefore be switched off during power-up.

− Check before the first measurement that the initial settings for the unit (see Sec. 6) meet your requirements.

− If the battery is not charged fifteen minutes after the first charge message, the unit switches itself off.

When the calibration period for the GMV2-K has elapsed, the error message

“Error: Calibration date” appears when the device is switched on. In this case, please send the device to ETH.

2.6 Switching off

You can switch off the device with the button. If the power-saving function (standby) is enabled, the device switches

itself off if it unused for a set period. If, due to a fault, you cannot operate or switch off the unit, you can remove the fuse

from the rear (data may however be lost in this case).

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

10

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

3 What's new in software version V 5. 1 (after V4.1)

3.1 Dynamic repeat rate for keys

The keys (+, -, choose, etc.) now have a repeat function when pressed for longer periods.

The repeat rate increases continually.

3.2 Automatic conversion of the transducer full scale value to other units

When a transducer with integral chip is connected to the device, a unit that is different to the transducer unit may be

selected in the parameter set. The transducer full scale value is automatically converted to the selected unit. Only the

available units can now be used!

Example:

• Transducer with 10 Nm, selected unit “InLb” displayed full scale value: 88.51 Inlb

• Transducer wit 10 Nm, selected unit “Ncm” displayed full scale value: 1000 Ncm

Note:

• If, when programming a parameter set, a particular unit is not available, disconnect the transducer and then choose the

wanted unit.

3.3 Supporting transducers with two measuring ranges (option on request)

Transducers with two measuring ranges can now be connected to the active socket.

The small measuring range appears in the menu as “akt2rng, standard_range”.

The large measuring range appears in the menu as “akt2rng, high_range”.

Note:

• This is an optional function and is not available in all devices

• Select the “Standard_range” option for transducers with only one measuring range!

3.4 Improved support for a number of inputs

When the GMV2-K supports inputs for a number of transducer models, each of the available inputs can be selected as

required. The GMV2-K socket designation, the transducer model and, if applicable, the measuring range (stndrt / large)

will be displayed.

In addition, this information is also output when the parameter set is displayed or printed out.

Note:

• This is an optional function and is not available in all devices

3.5 Universal input range for the active and passive input

Menu path:

• “Menu -> Param -> ParSet -> Change -> Edit”

• “Menu -> Param -> Transducer -> “Model” or “Sig./Ua”

The inputs can be adjusted easily now to the output signal from most sensors. They can be programmed separately for each

parameter set. If a default value is available, it will be used without the system asking for confirmation. The correct value

can be entered for every parameter set with the setting “Enter” for Ua. This is how the calibration value is entered for

passive transducers.

Input range:

Active input: ±1.25V to ±10V in steps of 1mV, or 5V / 10V

Passive input: ±0.5mV/V to ±4mV/V in steps of 1µV/V, or 1mV/V / 2mV/V / 4mV/V

Note:

This is an optional feature and therefore not available in all devices

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

11

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

3.6 Adjustable overload range

Menu path:

• “Menu -> Param -> Param set -> Change -> Edit”

• “Menu -> Measure -> Overload

The measuring range can now be much larger than the nominal signal of the transducer. The overload range can be

programmed separately for each parameter set from 0% to 100% of the transducer end value – however, the resolution of

the displayed measurement is reduced in proportion to the selected overload range. Different values can be programmed by

selecting “Enter” in the defaults under overload range.

(Menu path: “Menu -> Param -> Setting -> Defaults -> Overload”).

Caution

• If the mechanical overload capability of the torque transducer is exceeded for even a short period, this will

immediately destroy the transducer!

3.7 Automatically tracking zero-point drift

The zero voltage on torque sensors varies slightly as a function of temperature: the zero-point drifts when the device is

switched on until the sensor reaches its operating temperature. In the zero-load condition, the system detects and tracks this

drift and compensates for it accordingly. The device continues to take correct measurements. When the tracking function

for zero-point drift is active, an “A” (Automatic) appears at the bottom of the screen.

3.8 Pulse-type screwdriver mode

This function is very similar to the peak measuring function: additionally, a correction factor is available in this mode, but

angle measurements cannot be taken.

3.9 Streamlining parameter set entry

3.9.1 Defaults

Menu path: “Menu -> Param -> Setting -> Defaults”

In “Defaults” either a fixed numerical value or “Enter” may be selected.

The desired value may be entered when programming a parameter set and when “Enter” is set.

When a fixed numerica l value is the default setting, it is automatically loaded without confirmation from the user

when a parameter set is programmed. This saves multiple data entries.

A default setting is available for each of the following:

- input sensitivity of the active and passive input

- overload range

- automatic tracking of zero-point drift

Examples:

• If you always use thread adapter transducers (DRFS..., DRFN...), select active - 5V

• If you always use laboratory transducers (DRL), select active - 10V

• Select passive, Enter for passive transducers

Note:

• Changes to the default setting do not immediately impact the current parameter set!

The default setting is not loaded until a parameter set is processed or programmed.

• Parameter sets that have already been programmed are not changed when defaults are changed.

3.9.2 Hiding unused funct ion s

Menu path: “Menu -> Param -> Setting -> Function”

Functions that are seldom used can be hidden, so that they are disabled (without user confirmation) when a parameter set is

programmed. The process of entering the parameter set is thus shortened.

The functions are always available in the direct parameter entry menu.: “Menu -> Measure ... / Parameter..”.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

12

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

Example:

• The “Parameter set text, data record ID and operator number” menu can be hidden for all operating modes (“More”).

• Angle, speed and power measurement are disabled during tracking measurements.

Note:

• Changing the functions does not immediately impact the currently available parameter sets!

3.9.3 Correction factor

A correction factor may only be entered in the (new) operating mode “impulse wrench”

3.9.4 Filter for peak measuring

This function is no longer available in version V5.2!

3.10 Deleting measured values

Menu path: Menu -> MVclear...

The operator can now choose whether he wants to delete all measured values, the measured values in a parameter set, or

only single data records (see sec. 11.5, page 29).

3.11 Detecting new transducers and new measuring ranges

When ETH transducers that are equipped with a memory chip are used, the GMV2-K detects the removal and insertion of

the transducer, and when the measuring range is changed. The device is subsequently zeroed and the system checks that the

settings in the parameter set match the transducer settings.

3.12 Power-saving function (standby)

Menu path: Menu -> Param -> Setting -> Initial setting -> Standby

To save power, the LCD illumination and the GMV2-K power themselves off after set time periods, which can be adjusted.

This function may also be disabled.

Adjustable delay times for switching off the LCD illumination are: 1 min – 1 h. Adjustable delay times for switching off

the device are: 1 min – 3 h.

Note:

• These delay times are reset when measured values are saved or output.

• The standby function is disabled when the output is continuous.

3.13 Cancel serial transmi ssio n

Serial transmission can be canceled with the OFF key.

3.14 Continuous output with a minimum 0.5 second interval peri od

The minimum cycle time has been increased to 0.5 seconds due to the enhanced functionality of the GMV2-K.

3.15 Analog output

The optional analog output is now zeroed with the Zeroadjust key. Additionally, the automatic tracking of zero-point drift

is enabled.

Note:

• The output signal is scaled to ±5V independently of the input signal (passive, active & digital).

• The overload range must be set to 7% (standard).

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

13

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

3.16 Battery protection

To prevent the battery from totally discharging and thus protect it from damage, the device powers itself off when the

battery is low.

4 Menu structure

4.1 Introduction

The GMV2-K offers extensive measuring, control and adjusting features.

A hierarchical menu system is available to allow simple, self-explanatory operation.

A menu offers a list of selection options similar to a menu in a restaurant.

Each selection in turn offers further selections (and so on). A structure is generated that is similar to the branching of a tree.

The menu structure is shown in page 39. The actual functions are situated at the end of the "branches".

When the unit is first switched on it is in normal operating mode, that is, in level 0 in the menu structure. The GMV2-K is

only ready here. In addition to status information, torque, and if necessary angle and OK /NOK assessment (arrows) are

displayed in the first and last lines (see Sec. 2.2, page 7) on the screen.

Use the "Menu" key to enter the menu tree. You may navigate to the right in the tree, that is, to a higher level with the four

menu keys on the right beside the screen.

Use the return key to move back again to the left or to the next lower level.

The menu path is described as "X-> Y-> Z", which means:

When you press menu key ("X"), you reach the next menu. When you press the "Y" key here you reach a menu, where you

can select "Z".

4.2 Direct function keys

In normal operation (level 0) there are three keys with which a function is immediately executed when pressed. Some direct

function keys are assigned multiple functions. The assigned function depends on the settings selected. When no function is

assigned to the key there is no inscription and the key is disabled.

Note: The password for the first level also blocks the direct function keys.

• Store - Output / Start - Stop:

1.) Store: The value displayed on the screen is stored in the measured-value memory every time the key is pressed

(manual save).

2.) Output: The value displayed on the screen is printed out through the RS 232 serial port every time the key is

pressed (one-off manual printout).

3.) Start - Stop: Continuous measured-value output can be started (“contin” appears in the bottom line) or stopped.

• Clear / Zeroadjust:

1.) Clear the measured peak value. Torque and angle of rotation are reset to "0", Counters are reset and restarted. The

unit starts the measuring process from the beginning. The measurement is not stored! Press the Store key beforehand

for manual saving!

2.) Zeroadjust transducer and display. The offset voltage for the transducer is compensated so that, with no loading, the

value "0" appears on the screen. Zeroadjust should be repeated often as every transducer drifts with temperature. The

transducer must be completely unloaded during Zeroadjust!

Notes:

− If the offset voltage is greater than the adjusting range of the unit, an error message is output to the screen, and the

procedure must be repeated. Otherwise, accurate measurements cannot be taken!

This fault may be caused by loading the transducer during Zeroadjust, or it indicates that the transducer (overloading) or

the connection cable are defective.

− The transducer is automatically zeroed when the unit is switched on and when you return from the menu level.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

14

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

• Test:

"Test" serves to test the transducer. It outputs its maximum signal, the full scale value for the transducer is displayed on

the screen. However, this test cannot

“On/Off” button is also available.

The "Return" key serves to return to the previous a level in the menu. Typically, to return to normal operation this key

must be pressed a number of times. If you are in normal operation when you press the "Return" key, you will return to

password level 0.

be performed in the peak measuring mode with counter-clockwise rotation! The

4.3 Measure menu

For direct and fast changeover of the peak, track, torque wrench or speed measurement modes without having to program a

parameter set. Parameter set "0" is selected automatically! Parameter set "0" contains the settings for the current parameter

set.

Notes:

− This menu is only suited for determining screwing parameters. Measured values and parameters cannot be saved!

Finally, you should create a new parameter set with these settings. See sec. 9.7, page 23

− A power-operated screwdriver cannot be switched off during tracking measurements!

− For torque wrench measurements the yielding moment should be at least 2% of the transducer full scale value.

4.4 Menu: Delete measured value

Menu path: Menu-> MVclear ...

See also sec. 11.5, page 29

4.5 Menu: Output

Measured values and parameter sets can be either displayed on the screen (see secs 11.4 and 9.4) or printed out through the

serial interface (see secs 12 and 9.5). Alternatively they can be uploaded to a computer .

In “Menu -> Output-> Display-> Light” the LCD display illumination can be switched on/off and in “Menu -> Output->

Display-> Contrast” the display contrast can be set manually.

4.6 Parameter menu

4.6.1 Transducer

Menu path: Menu-> Param-> Transducer

This menu allows the values for the torque transducer to be set directly in the test phase (parameter set no. 0). It subdivides

into "Full scale value", "Angle" and "Type" or “Sig./Ua” and “Zeroadjust”.

• The full scale value is set with the Entry editor (see Sec. 8.4).

• The "Angle" menu can be used to define whether the transducer used allows an angle measurement.

Angle decoders with 360 pulses per revolution are supported in this version.

The limits must be entered to display the angle on the screen! (Menu-> Parameter-> Limit -> Angle)

Note:

Angle measurement is only available in the software version with suffix "W".

• Different inputs for different transducer types can be selected in the "Type" / “Sig./Ua” menu depending on the

configuration level of the unit. GMV2-K is equipped with an active input as standard. A passive input and a digital

input are available as an option. If the type is selected, the transducer output signal can be entered in volts or mV/V.

• Automatic tracking of zero-point drift can be enabled/disabled in the “zero” menu..

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

15

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

4.6.2 Limits

Menu path: Menu-> Param-> Limits

Limits can be set directly in this menu in the test phase (parameter set no. 0). It subdivides into "Torque", "Angle" and

"Timing".

Torque limits:

• All limits are also entered as unsigned numbers for counter-clockwise rotation.

• The limit evaluation display (arrow) uses the angle value (unsigned).

• "Limit max" and "Limit min" define the maximum and minimum allowed torque (OK window).

• "Shut off" determines the torque at which the power-operated screwdriver is switched off. However the "Inputs/outputs"

option and external power circuitry are required for this function and it is only enabled for peak measuring.

"Trigger" defines the torque at which angle counting begins. This is normally the joining torque.

Operation:

The torque limits are not

entered here with the entry editor!

The current value appears on the screen. You can increment or decrement this value with the "+" and "-" keys. A brief

keystroke changes the last digit by a minimum amount. The longer you hold the key pressed, the quicker the display runs.

You should therefore release the key briefly before the desired number to allow you to make the fine adjustment more

slowly.

The "no" key disables the limit value.

Confirm the entry with "OK", because the return key aborts the changes!

Notes:

− All limits are also entered for counter-clockwise rotation as unsigned numbers.

− Torques are entered here without a plausibility check. This means that the minimum value can be set greater than the

peak. The user is responsible for the correctness of the entries here.

− All torques must exceed 5% of the full scale value so as to be detected! If you enter "0" as a trigger, the torque must

exceed 5% of the full scale value for peak measuring, so that angle counting can begin.

Angle limits:

In contrast to the torque limits, angle limits are entered with the Entry editor (see Sec. 8.3). This means that the angle entry

can only be terminated with "OK". The previous menu level is then automatically selected. If the return key is pressed

during entry the previous value is reloaded. There is also no plausibility check here. However if a transducer without angle

is selected, the angle menu is disabled and an error message is output.

You can activate the angle functions with "Menu-> Parameter-> Transducer-> Angle-> on".

• All limits are also entered for counter-clockwise rotation as unsigned numbers.

• The limit evaluation display (arrow) uses the angle value (unsigned).

• "Limit max" and "Limit min" define the allowed maximum and minimum angle of rotation (OK window). Counting

begins when the trigger torque is exceeded. You can define this with the torque limits.

• "Shut off" defines the angle of rotation at which the power-operated screwdriver is switched off. However the

"Inputs/outputs" option and external power circuitry are required for this purpose.

Note:

The "Angle limits" menu is only available in the variant with suffix "W".

Timing:

The times are also entered with the Entry editor (see Sec. 8.3)

Undesirable torque peaks that can occur at the beginning of screwing are suppressed during the "Suppression phase". This

occurs when the power-operated screwdriver is being mounted, and especially with self-tapping screws.

The value "0" disables the timing.

The "After Time" defines how long the peak measuring and angle counting remain active after the power-operated

screwdriver has been switched off. The value “0” disables the time period so that the GMV2-K is always ready. It should

not be too small. Otherwise, the power-operated screwdriver with its centrifugal mass runs on when the measurement has

been stopped. In which case too small a value would be displayed. This time period depends on the screwing application

and must be determined for each individual case. If possible, therefore, you should use the default setting “0” !

If it has to be changed, select a long period!

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

16

Measurement

Level 1

Level 2

Level 3

Password

for

level 1

Password

for

level 3

Password

for

level 2

Passwords set for level 1 to 3

(Level 0)

Measurement

Level 1

Level 2

Level 3

Password set for level 3 only

(Level 0)

Measurement

Level 1

Level 2

Level 3

Password set for level 1 only

(level 0)

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

4.6.3 Settings

The GMV2-K settings are described in detail in secs 5 and 6.

4.6.4 Parameter set

This is the most important menu. A parameter set must be created (programmed) before measurements can be taken or

screws can be screwed. This topic is so comprehensive that it is dealt with in a separate section. See sec. 9.

5 Settings

5.1 Functions

Menu path: “Menu -> Param -> Setting -> Function”

You can enable/disable different functions.

5.2 Password

Menu path: “Menu -> Param -> Setting -> Password”

If the password is programmed in the first level, all keys, except the On/Off key and the password prompt are disabled. To

return to level 0, press the “Return” key again in measuring mode!

You can jump from level zero to level 3 by entering the password for level 3 (see diagram).

Note:

• You should assign a password, at least, to the third level to prevent unauthorized persons from setting

• Should you forget your passwords, we can provide you with instructions on how to delete all passwords.

5.3 Initial settings

See sec. 6

5.4 Defaults

See sec.3.9.1, page 11.

You can program a password (maximum 4-digit number) for each of the three levels as a

protection for the device settings against unauthorized change. First, you need to enable

level 3. You can then select the level, for which you want to change the password. The

system prompts you to enter the password. As soon as you enter a number greater than

zero, password protection is enabled and you will be prompted to note down this number.

The password protection in the level is disabled if you enter a zero as password. The

system will then also display the message ”Protection disabled”. The sections in the levels

of the menu structure (sec. 12, page 39) are highlighted in color. The enabled level is

shown on the bottom left of the screen.

Additionally only a certain level may be protected with one

password, which means that different levels of password

protection can be assigned to different user groups.

Example:

If only the password for the third level is programmed (left

diagram), everyone has access to the functions on levels 1 and

2 without a password. Since there is no password available for

the first and second levels, they merge with the measuring

mode. A password is needed for the third level.

passwords!

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

17

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

6 Initial settings

6.1 Language

Menu path:

Menu-> Parameter-> Program-> Initial setting-> Language

The unit is fully multilingual. If the language is changed, screen texts, key labels and date format are adapted accordingly.

The setting becomes effective when the language key is pressed (Caution!)

German, English, French and Italian have been realized for this software version.

Note:

Other languages can be realized at customer request.

6.2 Time of day and Date

Menu path:

Menu-> Parameter-> Setting-> Initial Setting -> Clock

The actual time of day is displayed at the bottom of the screen. A flashing underline (cursor) indicates what can be

changed. You can change the compete numbers only with the “+” und “-” keys, i.e. you cannot change the units and tens

separately. The longer you keep the keys pressed, the quicker numbers will change (dynamic).

Use the “<==” key to move between minute, hour, day, month and year. Don't forget to press the OK key to save the time

of day! Press the return key to cancel the setting.

Notes:

− Date and time of day are briefly flashed on the screen w he n the unit is switched on – which allows you to che c k

them.

6.3 Printer (Serial interf a ce)

Menu path:

Menu-> Parameter-> Setting -> Initial setting -> Printer

Procedure:

First select the desired printer. For "Standard" and “==> PC” the system prompts you for the baud rate. No baud rate setting

is required for DP-1 HS.

1.) Selecting the printer:

• "Standard" key for standard printer, (PC transmission with the program “Hyperterminal”)

• “===> PC“ key for measured-value transmission in an EXCEL

The keystroke makes the selection immediately effective and item 2. is selected).

2.) Setting the baud rate:

Default values 1200 baud to 19200 can be selected in succession with "+" and "-" keys.

The OK key accepts the selected setting.

The return key cancels the change and jumps to the "Initial setting" menu.

Notes:

Other formats are available at customer request.

®

file (optional)

• Factory default: baud rate 4800 Bd (suitable for printers supplied by us!), sta ndard printer.

• Transmission format: 8 data bits, no parity, 1 stop bit, XON-XOFF, text transmission

• See Sec. 15. for pin assignment

6.4 USB2.0-Interface

To use the USB2.0 interface, first install the supplied driver software! Only then may the USB port be used.

6.5 Standby (power-saving function)

See sec. 3.12., page 12.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

18

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

6.6 Display illumination

Menu path:

Menu-> Output-> Display-> Light

LCD lighting is turned on and off by pressing the "Light" key.

Note:

• In standby mode, display illumination is switched off after a set period if no keys are pressed (see Sec. 3.13). Press a

key (Test, Return, ...) to switch illumination back on again.

6.7 Contrast of display

Menu path:

Menu-> Output-> Display-> Contrast

Use the“+” and “-” keys to set the contrast. If the contrast is too high, the background will be dark; if the contrast is too

low, the figures will be pale.

Note:

• The contrast should only be changed for extreme ambient temperatures

7 Measuring modes

7.1 Tracking measurements

Appropriate for continuous display of static or very slowly changing torques and angles.

To read the values, the tracking measurements must be slow. The display follows fast changes in torque with a delay,

which depends on the filter setting, see the next section.

Notes:

• Speed measurement and power measurement can be activated here if angle measurement has been de-activated.

• The switch-off function is not available here!

• An adjustable filter can also be programmed (0.1 to 10 s).

• If switched on, the optional angle counting function is permanently enabled. It is reset when the transducer is

zeroadjusted.

7.2 Filter

Menu path: “Menu -> Param -> Param set -> New -> Program”

In the laboratory, very often the torque and the speed do not remain constant during a revolution – this makes it difficult to

read the display. This filter is based on the moving average and it can filter out these fluctuations. The range of the time

period over which the measured values are averaged can be set between 0.1 s and 10 s. This time period applies to the

torque, the speed and thus to the power measurement. Filtering is optimized by selecting the filter time according to the

following formula and by making it as big as possible:

Filter time[s] = n * 60 / speed[min

Example:

For a speed of 30 rev/min, select a time between 2.0 s and 10.0 s.

Note:

Please keep in mind that double the filter time must elapse before the final value appears on the display.

-1

]; n = 1, 2, ....

7.3 Outputting measured values continuously

Menu path: “Menu -> Param -> Param set -> New -> Program”

Tracking measurements can be continuously printed out or saved. The allowed interval time ranges from 0.5 s to 900 s

(15 min). Typically, the maximum output rate is determined by the printer speed.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

19

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

7.4 Speed measurements

This measuring mode is a variation of the tracking measurement and is not a separate operating mode!

It is only a function in its own right in "Menu-> Measure-> Track-> Speed" (parameter set no. 0). During parameter set

programming, speed measurement is activated by selecting tracking measurement without angle measurement and finally

starting speed measurement with "yes". You can select between 60 and 360 pulses per revolution: this allows you to record

the speed for torque transducers with angle measurement.

Notes:

• The speed is determined for the duration of a second.

• Maximum speed: 30, 000

• Accuracy: ±1 digit;

-1

7.5 Power measurement

This mode is an extra function under tracking measurements and is not an operating mode in its own right!

It is only a separate function under “Menu-> Measure-> Track-> Power” (parameter set 0).

Power measurement can be started when programming the parameter set after speed measurement has been enabled.

Selecting the format determines the maximum power that can be displayed. If the scale range is exceeded, “-----” is

displayed.

Note:

• The accuracy of the power measurement function is a function of the accuracy and resolution of the torque and speed

measurements.

• Since the speed per second is measured, additional measurements errors may occur from the time shift during periods

of rapid speed changes. A sufficiently large filter should be used as a remedial measure here.

7.6 Peak measuring

This measuring mode is mainly used in screwing technology. Not only does it allow the largest occurring torque to be

detected, but also offers numerous functions for assembly automation: time-based measuring, screwdriver control,

OK/NOK assessment with setpoint values and automatic storing and erasing of measured values. The status of the

measurement is shown to the left on the bottom of the screen. See Sec. 2.2, page 7.

Explanation of symbols:

* new measurement, before start-up suppression

t start-up suppression is running, no measurement

1 ready for measurement, peak storage

< angle trigger exceeded, angle counting operative

0 shutoff activated

X Measurements stopped (“after time” terminated) / bend detected on torque wrench

! error condition, device not ready for measurements

- device not ready (zeroadjust, etc.)

The adjustable parameters are explained in sec. 9.8 "Parameter set". The time-based sequence is shown in sec. 10.1.

7.7 Torque wrench measurements

This operating mode has been specially designed to check the torque values of torque wrenches. Only clockwise

measurements can be made. The peak torque until the yielding point is reached is displayed. Any further increase in

torque after this point has no effect on the measurement results. Due to the mechanical properties of the wrench, the

yielding torque can only be determined precisely by slowly and smoothly operating the torque wrench. Status “1” –

indicating that the device is ready “–“ is displayed before the measuring process starts. If a bend is detected, “X” is output

as status. The transducer should be selected, so that the minimum wrench torque to be measured is at least 2% of the

transducer full scale value. If a parameter set is programmed, all memory settings such as erasure time can be made.

Note:

• Peak measuring has to be used for torque wrenches not having any torque drop

• The angle measurement is always de-activated here.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

20

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

8 The Entry Editor

8.1 Introduction

The entry editor is used to enter torques, angles, times or to make a selection. Operation is thus standardized.

The editor has three important functions:

• it accepts your entries and allows you to change existing values with the four menu keys

• it allows you to choose between different settings

• it checks your entries.

Value entry and selection are different, the entry of the transducer full scale value is a combination of both. Operating the

editor is fully explained in the following sections.

8.2 Select settings

To program a parameter set you must select from a series of possible settings. You move to the next selection with the

"choose" menu key. The list is always repeated from the beginning. Should you press the key too many times, continue to

press the key until the desired setting appears again between the angle brackets (> <) or is displayed with a flashing

underline (cursor). The entry must be confirmed and terminated with the OK key! The return key reinstates the old

selection and returns to the entry. A short bleep is output as a warning.

8.3 Entering numbers

Torque values, angles, time periods and numbers are entered in a very similar manner. However, the transducer full scale

value is entered somewhat differently.

The heading explains what is being set. The current value is displayed with the predefined unit. The number of decimal

points is fixed and cannot be changed. The entry is made from right to left! That is, first the units, then the tens, then the

hundreds and so forth

The cursor is an important part of the entry. It appears as a flashing bold underline under a number, which indicates that

this position can now be changed.

Every time the "+" key is pressed the complete number is increased by the value of this position (reduced with "-").

If the position number is reduced during this operation, the cursor automatically moves to a lower position!

The "<==" key serves two purposes. It shifts the cursor to the left by one position (from the fifth position back to the first

position). If the first positions are 0, a one is carried. This means that when the initial value is 0 the number 100 can be

entered by pressing "<==" twice.

The entry must be confirmed with "OK" and then terminated.

The return key aborts the changes, restores the old value and moves the cursor to the lowest position..

Tips:

• By pressing the Return key (you can press it twice), the old value is restored and you can restart the entry

• To change the previous position again, you can reset the higher position to 0 with "-". The cursor will then be moved

to a lower non-zero position.

• Should you wish to set the maximum possible value, keep pressing "<==" until a five-digit number, for example

"10000", appears. A plausibility check is started with the OK key. An error message is output and the system

corrects the setting to the maximum possible value. Press OK again to terminate the entry.

• In a similar manner you will obtain the minimum possible value, when you set zero and press OK

• You can enter small numbers conveniently with the “+” and “-” keys, as they respond dynamically

8.4 Transducer full scale value

The data entry editor is active here as well. You may also set the unit and the number of decimal places here.

The transducer full scale value is entered by selecting unit, decimal places and by entering the numerical value. These steps

are described in the previous sections.

The following units can be chosen in this version: Ncm, Nm, kNm, inlb, ftlb, Bar, N and kN.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

21

Blanks A B C ... Y Z 0 1 2 3 4 5 6 7 8 9

+

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

8.5 Alphanumeric texts

The maximum length of the ID text and the description text is 12 characters.

The texts can be input via the keyboard or with a barcode scanner (see below).

Keyboard:

Use the “+” und “-“ keys to select blank, the letters A – Z and numbers 0 – 9:

The “+” and “-“ keys react dynamically, i.e. a brief keystroke changes the number slowly. The number changes quicker

when you hold the keys pressed longer. By hitting the “==> key” you move the cursor ( _ ) – as well as the data entry

position – to the right. After the 12th character the cursor is repositioned at the beginning of the text. You can delete

existing text with the Return key and terminate the text input with the OK key.

Barcode scanner (optional):

You can input these texts more conveniently and quicker with a barcode scanner. You can order a barcode scanner as an

accessory from ETH. Please read the user manual for the scanner before using it. The scanner allows you to use the

characters minus, period and slash (standard). The extended Code 39 allows you to use the entire ASCII character set.

When the text has been scanned, you can still edit it from the keyboard. It has to be acknowledged with the OK key. For

connection to the GMV2-K see page 8.

9 The parameter set

9.1 Introduction

GMV2-K allows complex measurements in screwing technology and offers numerous monitoring and control functions.

The torque can be evaluated in very different ways. All values and settings that influence the procedure and type of

measurement and processing are called parameters.

Typically, the parameters are precisely adapted for the screwing task at hand. It makes sense to assemble all individual

parameters for a screwing sequence in one parameter set. GMV2-K can save 49 such parameter sets. A wide range of

screwing operations can thus be carried out conveniently and in quick succession. When the system is switched on, the last

actual set is selected.

A parameter set must therefore be programmed before measurements can be taken.

9.2 Description text for parameter sets

Menu -> Param -> Param set -> New -> Program (for newly created parameter sets)

Menu -> Param -> Param set -> Change -> Edit (to edit existing parameter sets)

We recommend you write a small text describing the parameter set in order to make it easier to choose a particular set and

to avoid operator errors. This text is displayed at the bottom of the screen. The maximum 12 character long alphanumerical

text is entered at the end of the parameter set programming.

Note: “More settings” must be enabled in the function settings (Menu-> Param-> Setting -> Function)!

9.3 Parameter set "0"

Menu -> Measure

Even when you enter limits directly, you use a parameter set. Please note that set number "0" has different features with

respect to other sets. Since parameter set "0" contains the current settings, it is always overwritten when another set is

selected. It can however be copied to another number. See Sec. 9. 7.

The evaluation of the measurement is based on the values in the parameter set, however changes can be made to set number

"0" at any time. The measured values cannot therefore be stored for parameter set number "0"! It only serves to determine

the individual parameters experimentally.

This set cannot be selected directly: it is therefore disabled. Parameter set "0" is automatically selected when individual

values are changed in a stored parameter set. This can be seen on the parameter set display on the top left of the screen.

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

22

Output Param

-------------------------

Data record length: 6

Input: Socket designation, Input type

DatRec length: Data record length

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

9.4 Parameter set display

Menu paths:

1.) Menu-> Parameter-> ParSet-> Display

2.) Menu-> Output-> Display-> Param

The function for displaying individual parameters in a set can be called up in two different ways.

A parameter set is output to the LCD display in a maximum of six pages:

You can page through a parameter set with “Page+” or “Page-”. As soon as the last page is displayed, the first page is

displayed again. Empty pages are automatically skipped. A word in [...] means that this word is only displayed when the

function is enabled.

1. Setting 1:

2. [Setting 2:] [Displays the settings for filter time, speed, power and continuous output]

3. [Setting 3:] [Parameter set text, settings for data record ID and operator number]

4. Torque: All torque values are displayed here

5. [Angle:] [Displays all angle limits values (optional: only available with Version AW)]

6. Times: Displays all times (only available for peak measurements)

The display begins with the first page of the current set. Another parameter set can be displayed now with "Param +" or

"Param -". The page selection is not affected. Parameters from different sets can thus be compared with each other.

Transducer: Transducer full scale value, [measuring range]

Input signal, overload range [,automatic zeroing]

Mode: [Direction,] measuring mode [,correction factor]

Memory setting: Memory setting

9.5 Printout of the Parameter Set

Menu path:

Menu-> Output-> RS232-> Param

All parameter sets are printed out in succession by pressing the "all" key. You may also select an individual set with

"Param +" and "Param -". Hit the OK key to print out this set.

Parameter sets cannot be printed out on the DP-1 HS (optional)!

------------------------ Component 0815-01

PAR: 3

Transd: 200 Nm

Input

Type: 5V Cur2Ran

large_range

Zeroadjust: automatic

Overload: 25 %

Op. mode: Peak

Rot Dir: CW

Torque

- Lim max: 150.0 Nm

- Lim min: 100.0 Nm

- Shutoff: 120.0 Nm

Angle: none

Timing

- Suppr.: - -

- After: undef.

ErasrTm: - Store setting: none

Data record length: undef.

Sample printout of parameter sets:

Wheel rim-III

PAR: 5

Input: 3.320V active

Zeroadjust: automatic

Overload: 50 %

Transducer: 1000 Nm

Mode: Pulse screwdr

Rot Dir: CCW

Co. fact: 86 %

Torque

- Lim max: -800 Nm

- Lim min: -300 Nm

- Shutoff: - -

- Trigger: -200 Nm

Angle: none

Timing

- Suppr.: - -

- After: 1000 ms

- ErasrTm: 1 s

Op. no.: yes

DR ID: yes

Store setting: CanTime

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

23

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

9.6 Selection

Menu path:

Menu-> Parameter -> ParSet-> choose

A parameter set becomes the current set when selected and confirmed with "OK". The measurements will be made with

these settings. The number of the selected set is displayed on the top left of the screen to the left. The "return" key aborts

the selection!

Notes:

• The parameters are copied internally to set number "0" with this function. Direct entries are thus overwritten.

• When working with switchable transducers with numerous measuring ranges and measuring-range detection per chip,

the desired parameter set must be programmed and e.g. selected in GMV2-K before the measuring range can be

changed over. Then, the error message is removed and the measuring level is reached by pressing the Return key.

• When you are working with transducers with two measuring ranges the transducer is switched automatically to the

desired measuring range by entering the required measuring channel in the parameter set.

• If the DP-1 HS (optional) is selected as printer and the parameter set contains torque limits, the system prompts you to

transmit the limits to the printer.

9.7 Create new

Menu path:

Menu-> Parameter -> ParSet-> new

To quickly set all necessary parameters for the analyzing unit, a parameter set should be created for this purpose. GMV2-K

can store 49 different sets. The sets are not lost when the unit is switched off.

A new parameter set is automatically assigned the number of the first free memory area. Gaps arising when individual sets

are erased can thus be re-assigned. You may now start programming ("program" menu) or use an existing parameter set as

a template ("Copy" menu). A set, including set number "0", can be selected for copying with "Param - " and "Param +".

After confirmation with "OK" you should start programming. All settings are displayed and the values are checked. A

parameter set is programmed in the same way as with editing. A more detailed description is given in the following section.

Notes:

• When a parameter set is first created, it is automatically selected and becomes the current set.

• If the DP-1 HS (optional) is selected as printer and the parameter set contains torque limits, the system prompts you to

transmit the limits to the printer. The printer has to be connected in this case.

9.8 Editing

Menu path:

Menu-> Parameter -> ParSet-> change-> edit

Settings in existing parameter sets may be altered in this menu. However, if measured values have already been stored with

this set it is protected against changes and an error message will be output. Before a stored parameter set can be used,

measured values stored in this parameter set in the device have to be deleted.

To ensure that all parameters are entered, the user is forced to enter the parameters in succession and to confirm with "OK".

This entry loop cannot be aborted prematurely! However, you can always confirm with "OK" and thus quickly reach the

end of the loop. In which case you must also confirm the last prompt "All entries correct? "" with with "yes". Otherwise the

loop will run through again.

Only the necessary parameters are prompted depending on the selected measuring mode and can be set with the Entry

editor (Sec. 8). The order has been arranged so that a plausibility check of interdependent values is made. If entries are

incorrect, an error message is displayed after confirmation, an acoustic alarm is output and the value is automatically

corrected so that it is within the permissible range!

Some queries can be skipped by having fixed values in the defaults and by hiding functions (see secs 3.10.1 and 3.10.2,

page 11).

Subject to change without prior notice

ETH-messtechnik gmbh D-74415 Gschwend P.O. 16

24

Nr.: 162e Operating Instructions GMV2-K revised: 09.05.2019 Rev.: 0

All available parameters are detailed below:

• Transducer (type):

The input changeover is not available with all software versions!

Changeover between "active", "Cur2Ran", "passive"" and and "digital". Different sockets can be selected as well.

• active-/passive- Sign./Ua:

Adjusting the measurement input to the transducer nominal signal (Ua).

- active: ±1.250V to ±10V or selection of standard values (±5V, ±10V)

- passive: ±0.5mV/V to ±4mV/V or selection of standard values (±1mV/V, ±2mV/V, ±4mV/V)

• Overload:

This is the percentage by which the measuring range of the GMV2-K is greater than the nominal transducer signal.

This allows torques that are greater then the full scale value of the transducer to be measured. It can be used with

pulse-type screwdrivers with the correction factor. The standard value is 7%. The adjustable range is 0% to 100%

Caution

- If the mechanical overload capability of the torque transducer is exceeded for even a short period (see data

sheet), this will immediately destroy the transducer!

- The specified accuracy of transducer is not guaranteed at more than 50% overload

- The GMV2-K resolution worsens accordingly

• Transducer full scale value:

Nominal transducer torque.

Setting range: 1.000 Ncm to 200 kNm; 1.000 inlb to 1999 inlb / ftlb.

• Operating mode:

- Track:

- Peak:

- Torque wrench:

See also sec. 7.7 page 19

- Pulse-type

factor).

Continuous display of current torque, angle of rotation or speed and power.

The highest value is stored. See Sec. 10. for screwings.

For clockwise rotation only. The peak value before yielding point is reached is stored.

screwdriver: Specially designed for pulse-type and impact screwdrivers (peak measuring with correction

• Filter:

Tracking measurements: “Average value for n s”.

0 s: Filter disabled, otherwise average value over a period of n seconds.

Setting range: 0.1 s to 10.0 s.

• Correction factor:

Only available in “Pulse-type screwdriver” mode. It is the ratio of the indicated value to the measured value in

percent. Setting range: 50% to 150%. The default value 100% disables the correction factor.

The measured torque for pulse-type screwdrivers deviates significantly from the torque applied to the screw. The

indicated value can be adapted with the correction factor. It is calculated as follows:

Correction factor = 100% * (measured torque in the screw / uncorrected measured value)

• Direction:

- Peak measuring only: clockwise or counter-clockwise rotation.

• Torque (processing): choose between

- "Display": display only,

- "Monitoring": with limits (OK/NOK assessment), without shut off,

- "Shut off": same as monitoring, with shut off of power-operated screwdriver by external power circuitry, however

only available for peak measurement!