EX32008 series www.etherwan.com

Quick Start Guide

This quick start guide describes how to install and use the

Industrial Ethernet Switch. Capable of operating at

temperature extremes of -10°C to +60°C, this is the switch of

choice for harsh environments constrained by space.

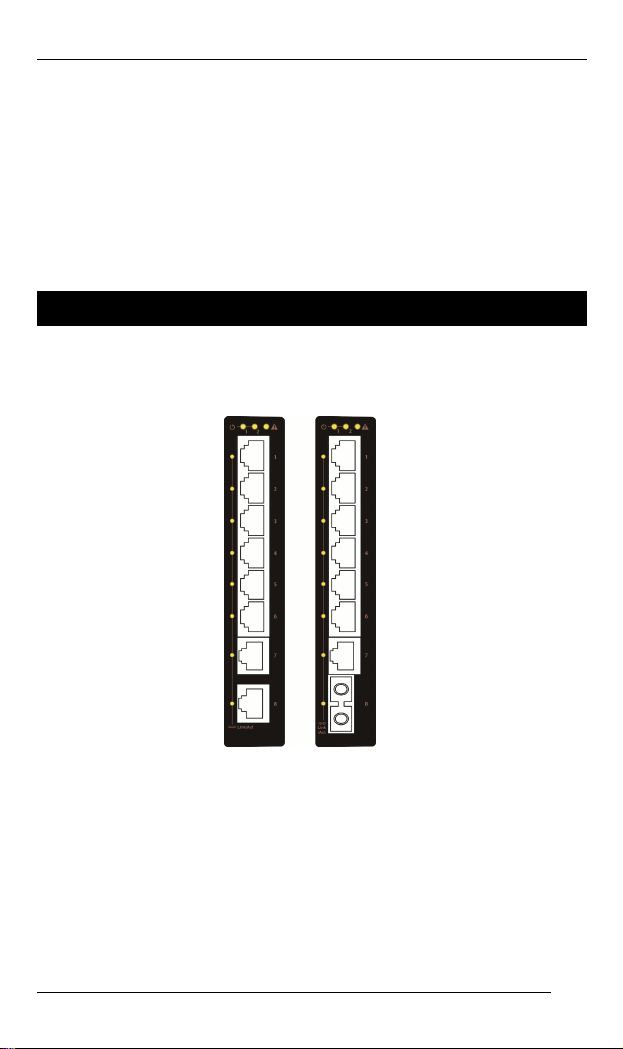

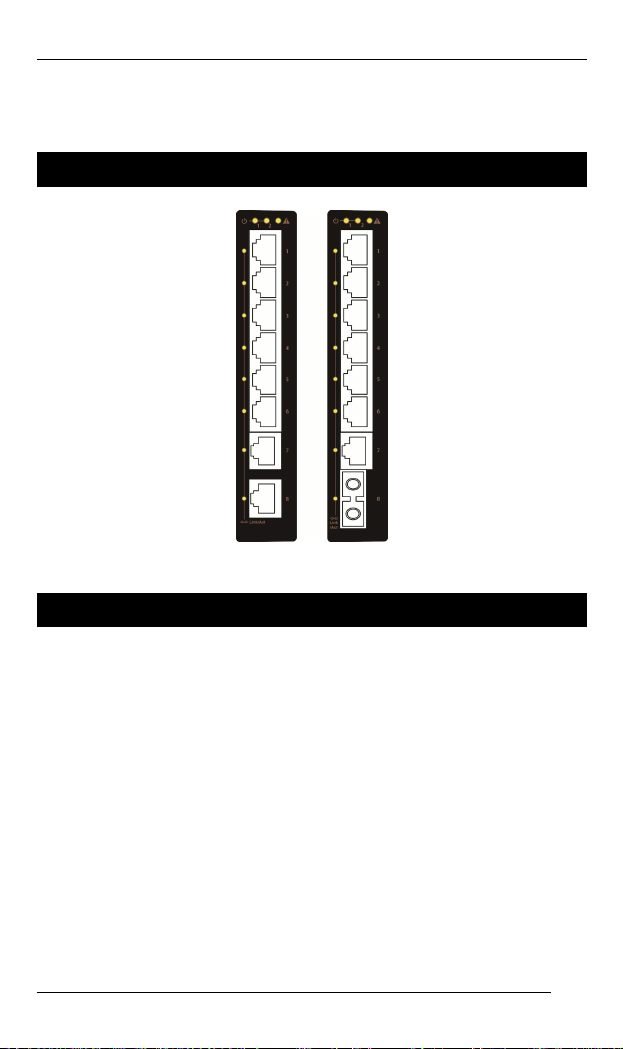

Physical Description

The Port Status LEDs

1

EX32008 series www.etherwan.com

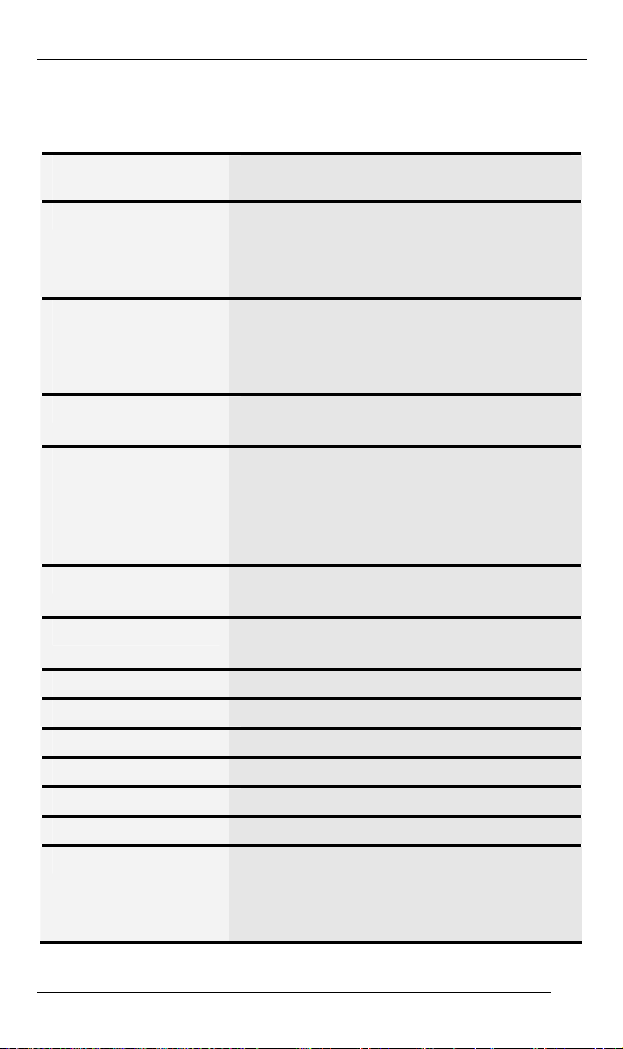

LED State Indication

Power 1, 2

(Green)

Fault (Red)

10/100TX or 100FX/BX Ports

Link/Act

(Green)

Steady Power on.

Off Power off.

Steady Relay Starts alarm.

Off Relay non-alarm.

Steady A valid network connection established.

Blinking

Off No link.

Transmitting or receiving data.

Act stands for Activity.

The Terminal Block and Power Inputs

Power Input Assignment

+

Power 1

Power 2

Relay Output Rating 1A @ 250VAC

12~48VDC

-

Power Ground

+

12~48VDC

-

Power Ground

Earth Ground

Terminal Block

DC Terminal Block Power Input: The DC Terminal Block

2

EX32008 series www.etherwan.com

power input can be used to power up this Switch.

DIP Switch Settings

DIP No. On Off

1 Port 1 Alarm Enable. Port 1 Alarm Disable.

2 Port 2 Alarm Enable. Port 2 Alarm Disable.

3 Port 3 Alarm Enable. Port 3 Alarm Disable.

4 Port 4 Alarm Enable. Port 4 Alarm Disable.

5 Port 5 Alarm Enable. Port 5 Alarm Disable.

6 Port 6 Alarm Enable. Port 6 Alarm Disable.

7 Port 7 Alarm Enable. Port 7 Alarm Disable.

8 Port 8 Alarm Enable. Port 8 Alarm Disable.

The Ethernet Connectors

The 10/100Base-TX Connections

The following lists the pinouts of 10/100Base-TX ports.

3

EX32008 series www.etherwan.com

Pin Regular Ports Uplink port

1 Output Transmit Data + Input Receive Data +

2 Output Transmit Data - Input Receive Data -

3 Input Receive Data + Output Transmit Data +

4 NC NC

5 NC NC

6 Input Receive Data - Output Transmit Data -

7 NC NC

8 NC NC

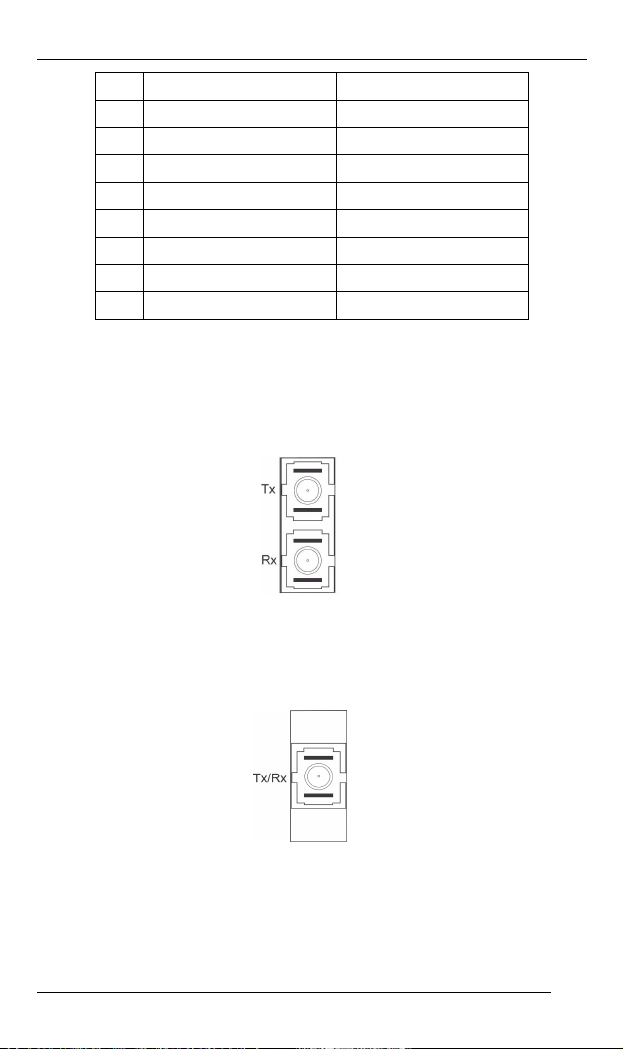

The 100Base-FX Connections

The fiber port pinouts: The Tx (transmit) port of device I is

connected to the Rx (receive) port of device II, and the Rx

(receive) port of device I to the Tx (transmit) port of device II.

The WDM 100Base-BX Connections

The fiber port pinouts: Only one optical fiber is required to

transmit and receive data.

4

EX32008 series www.etherwan.com

Functional Description

Complies with EN61000-6-2 & EN61000-6-4 EMC Generic

standard immunity for industrial environment.

Supports IEEE802.3az 10Base-Te only. 10Base-T is not

supported. 10Base-Te is fully interoperable with 10Base-T

over 100m of class D (Category 5) or better cabling as

specified in ISO/IEC 11801:1995.

Supports 802.3az/802.3u/802.3x. Auto-negotiation:

10/100Mbps, Full/Half-duplex. Auto MDI/MDIX.

100Base-FX: Multi/Single mode SC or ST type.

100Base-BX: WDM Single mode SC type.

Supports 1024 MAC addresses, 448K bits buffer

memory.

Supports IEEE802.3az Energy Efficient Ethernet (EEE).

IEEE802.1Q VLAN Tag Based Priority, Class of

Service.

Output Queue Schedule Mode: Weighted Round Robin

(WRR) with 2 priority queues.

Power Supply: Redundant 12~48VDC Terminal Block

power inputs.

Power consumption: 2.47W Max.

Provides reverse polarity protection.

Supports normal close and normal open.

Operating temperature ranges from -10°C to 60°C

(14°F to 140°F).

Slim design with DIN-Rail mount installation.

5

EX32008 series www.etherwan.com

Assembly, Startup, and Dismantling

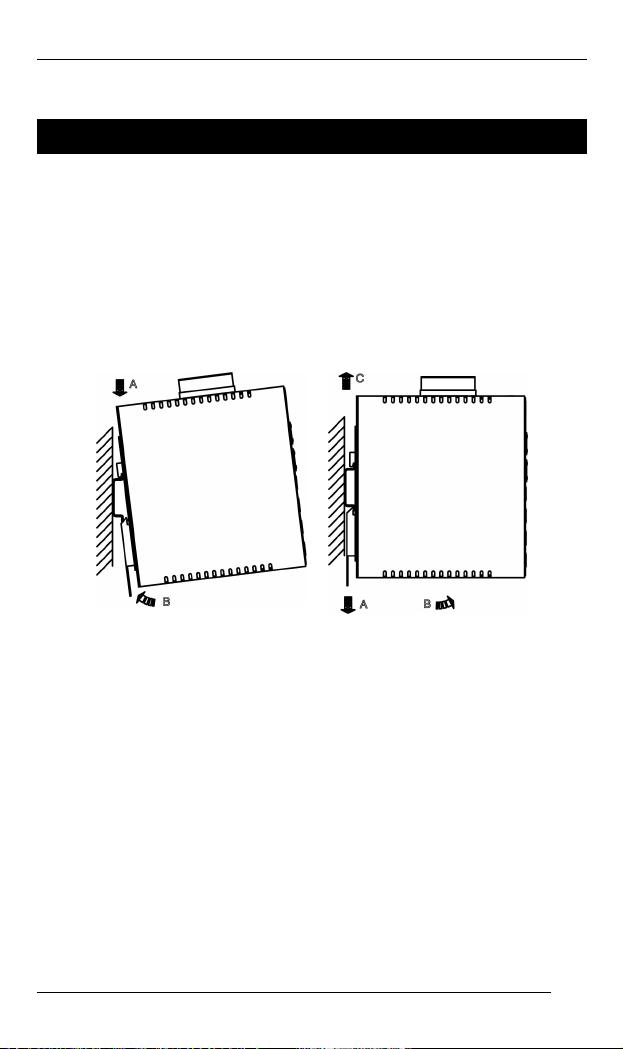

Assembly: Place the device on the DIN rail from above

using the slot. Push the front of the device toward the

mounting surface until it audibly snaps into place.

Startup: Connect the supply voltage to start up the

device via the terminal block.

Dismantling: Pull out the lower edge and then remove

the device from the DIN rail.

6

EX32008 series www.etherwan.com

Preface

A member of the growing family of rugged switches, this

switch addresses a need for a smaller switch. This switch

provides an affordable solution for rugged and outdoor

environment, transportation road-side cabinet, industrial floor

shop, multitenant dwellings or Fiber To The Home (FTTH)

applications. Capable of operating at temperature extremes of

-10°C to +60°C, this is the switch of choice for harsh

environments constrained by space.

Plug-and-Play Solution:

The switch is a plug-and-play Industrial Ethernet Switch in

compact size. It doesn't have any complicated software to set

up.

This manual describes how to install and use the Industrial

Ethernet Switch. This switch integrates full wire speed

switching technology. This switch brings the answer to

complicated hardened networking environments.

To get the most out of this manual, you should have an

understanding of Ethernet networking concepts.

In this manual, you will find:

Features on the switch

Illustrative LED functions

Installation instructions

Specifications

7

EX32008 series www.etherwan.com

Table of Contents

QUICK START GUIDE 1

PHYSICAL DESCRIPTION 1

The Port Status LEDs 1

The Terminal Block and Power Inputs 2

DIP Switch Settings 3

The Ethernet Connectors 3

FUNCTIONAL DESCRIPTION 5

ASSEMBLY, STARTUP, AND DISMANTLING 6

REFACE 7

P

T

ABLE OF CONTENTS 8

RODUCT OVERVIEW 9

P

INDUSTRIAL ETHERNET SWITCH 9

PACKAGE CONTENTS 9

PRODUCT HIGHLIGHTS 10

Basic Features 10

FRONT PANEL DISPLAY 11

PHYSICAL PORTS 12

INSTALLATION 13

SELECTING A SITE FOR THE SWITCH 13

DIN RAIL MOUNTING 14

CONNECTING TO POWER 15

DC Terminal Block Power Inputs 15

CONNECTING TO YOUR NETWORK 17

Cable Type & Length 17

Cabling 18

SPECIFICATIONS 19

8

EX32008 series www.etherwan.com

Product Overview

Industrial Ethernet Switch

Package Contents

When you unpack the product package, you shall find the

items listed below. Please inspect the contents, and report

any apparent damage or missing items immediately to your

authorized reseller.

This Switch

User’s Manual

9

EX32008 series www.etherwan.com

Product Highlights

Basic Features

Complies with EN61000-6-2 & EN61000-6-4 EMC Generic

standard immunity for industrial environment.

Supports IEEE802.3az 10Base-Te only. 10Base-T is not

supported. 10Base-Te is fully interoperable with 10Base-T

over 100m of class D (Category 5) or better cabling as

specified in ISO/IEC 11801:1995.

Supports 802.3az/802.3u/802.3x. Auto-negotiation:

10/100Mbps, Full/Half-duplex. Auto MDI/MDIX.

100Base-FX: Multi/Single mode SC or ST type.

100Base-BX: WDM Single mode SC type.

Supports 1024 MAC addresses, 448K bits buffer

memory.

Supports IEEE802.3az Energy Efficient Ethernet (EEE).

IEEE802.1Q VLAN Tag Based Priority, Class of

Service.

Output Queue Schedule Mode: Weighted Round Robin

(WRR) with 2 priority queues.

Power Supply: Redundant 12~48VDC Terminal Block

power inputs.

Power consumption: 2.47W Max.

Provides reverse polarity protection.

Supports normal close and normal open.

Operating temperature ranges from -10°C to 60°C

(14°F to 140°F).

Slim design with DIN-Rail mount installation.

10

EX32008 series www.etherwan.com

Front Panel Display

Power Status (Power)

This LED comes on when the switch is properly connected to power and turned on.

Port Status LEDs

The LEDs display status for each respective port.

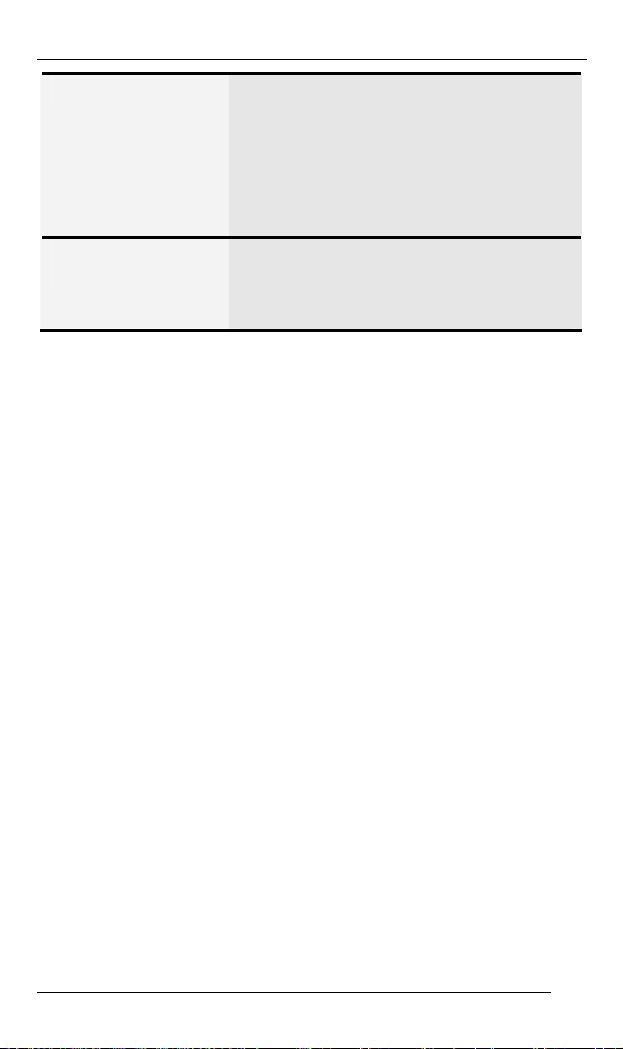

LED State Indication

Power 1, 2

(Green)

Fault (Red)

10/100TX or 100FX/BX Ports

Link/Act

(Green)

Steady Power on.

Off Power off.

Steady Relay Starts alarm.

Off Relay non-alarm.

Steady A valid network connection established.

Blinking

Off No link.

Transmitting or receiving data.

Act stands for Activity.

11

EX32008 series www.etherwan.com

Physical Ports

This switch provides:

Eight 10/100Base-TX ports

Seven 10/100Base-TX ports + one 100Base-FX/BX port

Connectivity

RJ-45 connectors

SC or ST connector on 100Base-FX fiber port

SC connector on 100Base-BX fiber port

12

EX32008 series www.etherwan.com

Installation

This chapter gives step-by-step instructions about how to

install the switch:

Selecting a Site for the Switch

As with any electric device, you should place the switch

where it will not be subjected to extreme temperatures,

humidity, or electromagnetic interference. Specifically, the site

you select should meet the following requirements:

The ambient temperature should be between -10 to 60

degrees Celsius.

The relative humidity should be less than 95 percent,

non-condensing.

Surrounding electrical devices should not exceed the

electromagnetic field (RFC) standards.

Make sure that the switch receives adequate ventilation.

Do not block the ventilation holes on each side of the

switch.

The power outlet should be within 1.8 meters of the

switch.

13

EX32008 series www.etherwan.com

DIN Rail Mounting

Installation: Place the switch on the DIN rail from above using

the slot. Push the front of the switch toward the mounting

surface until it audibly snaps into place.

Removal: Pull out the lower edge and then remove the switch

from the DIN rail.

14

EX32008 series www.etherwan.com

Connecting to Power

DC Terminal Block Power Inputs

Connect the DC power cord to the plug-able terminal

block on the switch, and then plug it into a standard DC

outlet.

Disconnect the power cord if you want to shut down the

switch.

Power Input Assignment

+

Power 1

Power 2

Relay Output Rating 1A @ 250VAC

12~48VDC

-

Power Ground

+

12~48VDC

-

Power Ground

Earth Ground

Terminal Block

CAUTION: This equipment is designed to permit the

connection of the earthed conductor of the DC supply circuit

to the earthing conductor at the equipment.

15

EX32008 series www.etherwan.com

If this connection is made, all of the following conditions must

be met:

This equipment shall be connected to directly to the DC

supply system earthing electrode conductor or to a

bonding jumper from an earthing terminal bar or bus to

which the DC supply system earthing electrode conductor

is connected.

This equipment shall be located in the same immediate

area (such as, adjacent cabinets) as any other equipment

that has a connection between the earthed conductor of

the same DC supply circuit and the earthing conductor,

and also the point of earthing of the DC system. The DC

system shall not be earthed elsewhere.

The DC supply source is to be located within the same

premises as the equipment.

Switching or disconnecting devices shall not be in the

earthed circuit conductor between the DC source and the

point of connection of the earthing electrode conductor.

16

EX32008 series www.etherwan.com

Connecting to Your Network

Cable Type & Length

It is necessary to follow the cable specifications below when

connecting the switch to your network. Use appropriate

cables that meet your speed and cabling requirements.

Cable Specifications

Speed Connector Port

Speed

Half/Full

Duplex

10Base-Te RJ-45 10/20 Mbps 2-pair

100Base-TX RJ-45 100/200

Mbps

100Base-FX SC, ST 2000 Mbps MMF (50 or

100Base-FX SC, ST 200 Mbps SMF (9 or

100Base-BX SC 200 Mbps SMF (9 or

Cable Max.

Distance

UTP/STP

Cat. 3, 4, 5

2-pair

UTP/STP

Cat. 5

62.5μm)

10μm)

10μm)

100 m

100 m

2 km

20 km

20 km

17

EX32008 series www.etherwan.com

Cabling

Step 1: First, ensure the power of the switch and end devices are turned off.

<Note> Always ensure that the power is off before any installation.

Step 2: Prepare cable with corresponding connectors for each type of port

<Note> To connect two regular RJ-45 ports between switches or hubs, you need a

Step 3: Consult the previous section for cabling requirements based on

Step 4: Connect one end of the cable to the switch and the other end to a

Step 5: Once the connections between two end devices are made

in use.

straight or cross-over cable.

connectors and speed.

desired device.

successfully, turn on the power and the switch is operational.

18

EX32008 series www.etherwan.com

Specifications

Industrial Compact

Switch

Applicable Standards IEEE 802.3az 10Base-Te

Forwarding Rate

10Base-Te:

100Base-TX:

100Base-FX/BX:

Performance 148,80pps for 10Mbps

Cable

10Base-Te:

100Base-TX:

100Base-FX/BX:

LED Indicators Per unit – Power 1, 2 (Green), Fault (Red)

Dimensions 35mm (W) × 86mm (D) × 149mm (H)

Net Weight 0.3Kg (0.66lb.)

Power Terminal Block: 12-48VDC

Power Consumption 2.47W Max.

Operating Temperature -10°C to 60°C (14°F to 140°F)

Storage Temperature -25°C to 85°C (-13°F to 185°F)

Humidity 5%-95% non-condensing

EMI FCC Part 15B, Class A

10/100Base-TX auto-negotiating ports with

RJ-45 connectors, 100Base-FX/BX fiber port

IEEE 802.3u 100Base-TX/FX

IEEE 802.1x Full-duplex Flow Control

IEEE 802.1az Energy Efficient Ethernet

10 / 20Mbps Half / Full-duplex

100 / 200Mbps Half / Full-duplex

200Mbps Full-duplex

148,810pps for 100Mbps

2-pair UTP/STP Cat. 5

2-pair UTP/STP Cat. 5

Up to 100m (328ft)

MMF (50 or 62.5μm), SMF (9 or10μm)

Per port – Link/Act (Green)

(1.4” (W) × 3.44” (D) × 5.96” (H))

VCCI Class A

EN61000-6-4:

EN55022, EN61000-3-2, EN61000-3-3

19

EX32008 series www.etherwan.com

EMS EN61000-6-2:

EN61000-4-2 (ESD Standard)

EN61000-4-3 (Radiated RFI Standards)

EN61000-4-4 (Burst Standards)

EN61000-4-5 (Surge Standards)

EN61000-4-6 (Induced RFI Standards)

EN61000-4-8 (Magnetic Field Standards)

Environmental Test

Compliance

IEC60068-2-6 Fc (Vibration Resistance)

IEC60068-2-27 Ea (Shock)

FED STD 101C Method 5007.1 (Free Fall with

package)

20

Loading...

Loading...